SaMASZ Sp. z o.o.

Poland, 15-161 Białystok, ul. Trawiasta 15

Rok założenia – 1984

NIP 966-159-29-76

tel. (+48) (85) 664-70-31

fax (+48) (85) 664-70-41

e-mail: samasz@samasz.pl

www.samasz.pl

OPERATOR’S MANUAL

REAR DRUM MOWER

Z 010 – 1.65 m

Z 010/1 – 1.85 m

Z 010/2 – 2.10 m

Z 010/4 – 2.10 m

Serial No:

The original instruction

IN005EN010

2012.06.13

EDITION NO 10

ADJUSTING THE MOWER FOR MOWING

DANGER

TURNING THE DRIVE ON,

IF THE MOWER IS NOT

IN WORKING POSITION

DANGER

LIFTING THE MOWER BEFORE

THE MOWING DISCS COME

TO COMPLETE STANDSTILL

DANGER

OPERATING WHEN ANY

PERSON REMAINS IN THE

DANGER AREA OF 50 m

Translated by: Łukasz Łapiński

Operator’s manual

Z 010; Z 010/1; Z 010/2; Z 010/4

Contents Page

Rear drum mower

1. IDENTIFYING THE MACHINE ................................................................................................ 2

2. INTRODUCTION ......................................................................................................................... 2

3. TECHNICAL DATA ..................................................................................................................... 3

3.1. Specifications ........................................................................................................................... 3

3.2. Design and working principle .................................................................................................. 4

3.3. Standard equipment and spare parts ......................................................................................... 5

4. SAFETY ADVICE ......................................................................................................................... 6

4.1. General rules ............................................................................................................................. 6

4.2. Transport................................................................................................................................... 8

4.2.1. Placing the mower onto a transport vehicle ..................................................................................... 8

4.3. Operating elements ................................................................................................................... 9

4.4. The articulated telescoping shaft .............................................................................................. 9

4.5. Residual risk ............................................................................................................................. 9

4.6. Warning decals ....................................................................................................................... 10

4.7. Design and operation of safety breakaway device ................................................................. 13

5. OPERATION OF THE MOWER.............................................................................................. 14

5.1. Attaching the mower to the tractor ......................................................................................... 14

5.2. Preparing the mower for transport .......................................................................................... 15

5.2.1. Standard design ............................................................................................................................. 15

5.2.2. Desing with hydraulic lifting (optional equipment) ...................................................................... 15

5.2.3. Mechanical lock of hydraulic lifting ............................................................................................. 16

5.3. Preparing the mower for transport on public roads ................................................................ 16

5.4. Connecting the articulated telescopic shaft ............................................................................ 17

5.5. Adjustment of conditioner shaft’s position ............................................................................ 18

5.6. Replacement of flails in conditioner’s shaft ........................................................................... 18

5.7. Operation ................................................................................................................................ 19

5.7.1. Standard design ............................................................................................................................. 19

5.7.2. Design with hydraulic lifting (optional equipment) ...................................................................... 19

6. MOUNTING AND ADJUSTMENT .......................................................................................... 20

6.1. Mounting and timing of the knives ........................................................................................ 20

6.2. Replacing the knives............................................................................................................... 20

6.3. Adjusting the cutting unit ....................................................................................................... 21

6.4. Adjusting the cutting height ................................................................................................... 21

6.5. 3-point linkage support chain ................................................................................................. 21

6.6. Maintenance and service ........................................................................................................ 22

6.6.1. Checking the knives and knife holders .......................................................................................... 22

6.6.2. Checking the V-belts tension ......................................................................................................... 22

6.6.3. Daily maintenance ......................................................................................................................... 23

6.6.4. After-season maintenance .............................................................................................................. 23

7. LUBRICATION INSTRUCTION ............................................................................................. 24

8. DEFECTS AND THEIR REPAIRS ........................................................................................... 25

9. DISASSEMBLY AND WITHDRAWAL FROM WORK ....................................................... 26

9.1. Disassembly ............................................................................................................................ 26

9.2. Scrapping ................................................................................................................................ 26

10. WARRANTY CARD ................................................................................................................ 26

11. WARRANTY TERMS.............................................................................................................. 27

11.1. Warranty claims procedures .............................................................................................. 27

11.2. Warranty repairs record ..................................................................................................... 28

- 1 -

Operator’s manual

Z 010; Z 010/1; Z 010/2; Z 010/4

1. IDENTIFYING THE MACHINE

Rear drum mower

Data plate is mounted to the mower’s main frame in the place shown below (Fig. 1).

Data plate includes:

- name of the manufacturer,

- mower’s serial number,

- mower’s type,

- manufacturing date,

- version number,

CAUTION:

For more detailed information concerning the mower ask your dealer or

manufacturer.

Fig. 1. Data plate place

- weight,

- quality management sign,

- CE sign,

- MADE IN POLAND sign,

- barcode.

2. INTRODUCTION

This operator’s manual should be considered as the basic mower’s equipment. If the mower is

handed over to another operator, it should be in working condition and given away along with

operator’s manual and it’s other basic equipment.

Operator’s manual is attached to every machine in order that the operator can familiarize

himself with design, working principles, service and adjustment of the mower. The user of

the mower should be familiar with common safety rules and procedures.

The mower is manufactured according to international safety rules.

Compliance with the warnings in this operator’s manual will ensure safe operation.

Please contact your dealer if you have any queries relating to the operation and service of

the mower.

Operator’s manual remains part of mower’s equipment.

GENERAL WARNING

When operating the mower please comply with the warnings and safety

regulations shown throughout this manual by this safety alert symbol.

CAUTION:

Operation of the mower before reading the operator’s manual carefully as

well as operating by the unauthorised staff, especially by children, is strictly

forbidden.

- 2 -

Operator’s manual

pA

Amax

Cpeak

Z 010; Z 010/1; Z 010/2; Z 010/4

3. TECHNICAL DATA

Rear drum mower

Rotary suspended rear drum mower is designed for mowing the following: common grass,

medick, etc on meadows and on stone free fields as well as forming swath out of these. Meadow

being mowed should be even, previously prepared by rolling and other processing. In lifted rotary

mower with swath conditioners, as a result of difference in speed of moving consequent layers of

grass under influence of flails, process of attrition of plant wax layer occurs. It makes grass drying

process simpler and faster by approx. 30 – 40 %.

WARNING:

It is forbidden to use the mower for purposes other than those listed in this

instruction. Using the mower for other purposes will be classified as use not

according with the intended use and could exclude the manufacturer from

responsibility from any resulting damages. The mower should be used,

serviced and repaired only by persons familiar with its characteristics and

with safety regulations. Unauthorized modification of the mower may release

the manufacturer from responsibility for any resulting malfunctions or

damages.

The Z 010 mower should be used with class 0.9 tractors with 40 HP of power.

The Z 010/1 mower should be used with class 0.9 tractors with 60 HP of power.

The Z 010/2 mower should be used with class 0.9 tractors with 70 HP of power.

The Z 010/4 mower should be used with class 0.9 tractors with 75 HP of power.

3.1. Specifications

Tab. 1. Specifications

Model Z 010 Z 010/1 Z 010/2 Z 010/4

Working width 1.65 m 1.85 m 2.10 m 2.10 m

Number of knives [pcs] 6 (2 x 3) 6 (2 x 3) 8 (2x4) 8 (2x4)

Tractor PTO rpm 540 obr/min 540 obr/min 540 obr/min 540 obr/min

Tractor power required 40 KM 60 KM 70 KM od 75 KM

Working capacity ~ 1.5 ha/h ~ 2.0 ha/h ~ 2.5 ha/h ~ 2.5 ha/h

Transport length 2500 mm 3050 mm 3610 mm 3610 mm

Transport width 1560 mm 1580 mm 1730 mm 1820 mm

Operation width 3160 mm 3330 mm 3920 mm 3920 mm

Conditioner’s working width - - - 700 mm

Weight 400 kg 455 kg 555 kg 690 kg

Nosie level L

PTO shaft requirement 400 Nm 400 Nm 540 Nm* 540 Nm *

Conditioner’s PTO

No. of flails [pcs] - - - 36

Conditioner’s shaft rears

Cutting speed of the knife 90 m/s 88.3 m/s 90.2 m/s 90.2 m/s

Drum rpm 2046 obr/min 1813 obr/min 1610 obr/min 1610 obr/min

Tractor class 0.9 0.9 1.4 1.4

*with overrunning clutch

LpA – noise level related to 8 hour working time. Averaged in time acoustic pressure level corrected by

frequency characteristic A.

L

– maximum value corrected by frequency characteristic A of acoustic pressure level.

Amax

L

– peak level of acoustic pressure corrected by frequency characteristic C.

Cpeak

L

L

80 ± 1 dB

82 ± 1 dB

114 ± 1 dB

- - - 250 Nm

- - - 630 obr/min

- 3 -

Operator’s manual

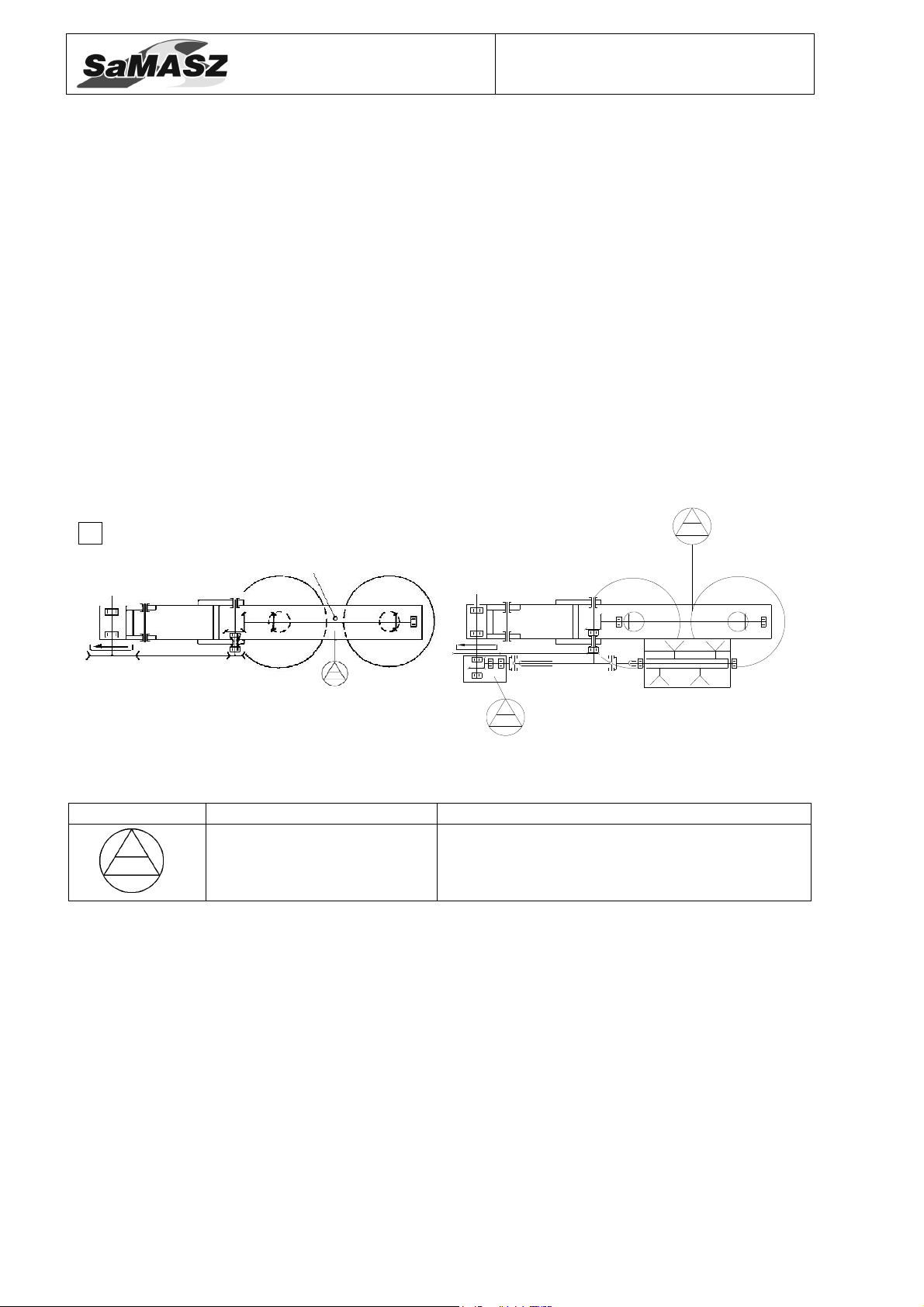

3.2. Design and working principle

W

1

1 – 3-point-linkage frame,

2 – middle bar,

3 – hydraulic cylinder – extra equipment,

4 – main frame and gearbox,

S

7

Fig. 2. Parts of SaMASZ rear drum mower – flat cover

6

4

5

Fig. 3. Parts of SaMASZ rear drum mower – slanted cover

Rear drum mower

Z 010; Z 010/1; Z 010/2; Z 010/4

3

8

3

2

5 – cutting unit,

6 – cover guard,

7 – drive unit,

8 – mechanical lock.

4

6

5

1

Mower with swath conditioner comprises the following assemblies (Fig. 4):

6

1

5

1 – conditioner’s shaft,

2 – conditioner’s gearbox,

3 – belt gear guard,

2

4

3

Fig. 4. Mower with swath conditioner

4 – conditioner’s drive guard,

5 – working drums guard,

6 – conditioner’s upper guard.

Comprehensively tested construction and proper choice of materials ensure high reliability and

durability of our products.

- 4 -

Operator’s manual

Shaft end with unidirectional right

–

Z 010; Z 010/1; Z 010/2; Z 010/4

3.3. Standard equipment and spare parts

The mowers are sold with the following standard equipment:

warranty card,

operator’s manual with spare parts list,

cutting knives: 1 set,

repair paint – 150 ml,

PTO shaft (Tab. 2),

spare set of flails for conditioner (mower Z 010/4),

spray paint (150 ml).

Optional extra equipment:

warning plates with combined lights and reflectors,

warning triangle.

Rear drum mower

Tab. 2. PTO shafts for SaMASZ rear drum mowers

Mower Power Length Moment

HP mm Nm

Z 010;

Z 010/1

Z 010/2

Z 010/4

Shaft end without clutch –

Connect to tractor.

35 660-900 460 7G3N066CE007007MA

35 660-900 460 7G3N066CE007096MA

35 660-900 620 7G5N066CE007096LA

Fig. 5a. Shaft lubricating instructions and connecting directions Z 010 and Z 010/1

Shaft end without clutch –

Connect to tractor.

Fig. 5b. Shaft lubricating instructions and connecting directions Z 010/2

50h

50h

Symbol

50h

50h

50h

50h

Clutch Manufacturer Notes

Bondioli & Pavesi

Overrunning

right

Overrunning

right

Bondioli & Pavesi

Bondioli & Pavesi

Shaft end without clutch

Connect to the mower.

clutch – Connect to the mower.

- 5 -

Operator’s manual

ft end with unidirectional right

Z 010; Z 010/1; Z 010/2; Z 010/4

Rear drum mower

Shaft end without clutch –

Connect to tractor.

50h

Sha

clutch – Connect to the mower.

50h

Fig. 5c. Shaft lubricating instructions and connecting directions Z 010/4

50h

WARNING:

The frequency of lubrication of the articulated telescoping shaft should be

carefully adhered to. Points shown on Fig. 4 should be lubricated every

8 hours. The articulated telescoping shaft should also be lubricated before

and after longer periods of disuse.

It is possible to use shafts with similar technical parameters from different manufacturers after

consulting SaMASZ.

WARNING:

Before commencing operation, operator’s manual on the mower PTO shaft

should be read thoroughly. In the event of the PTO shaft damage due to its use

for any other purpose than specified in the manual, the SaMASZ company

shall not bear any responsibility for the shaft manufacturer not accepting the

warranty claim. Clutch long-lasting operation with overload of max

10 second period is forbidden.

WARNING:

Additional equipment must be purchased separately.

The manufacturer will equip the mower with connecting elements (brackets and supports) used to

install required lamps and signs. Integrated lamps and reflectors are mounted on the warning board.

4. SAFETY ADVICE

4.1. General rules

The front axle of the driving tractor should be adequately loaded to maintain balance. If

necessary use front wheel weights.

All manipulation of the hydraulic hoist control lever should be made only from the driving seat,

operating the hoist while outside the tractor is forbidden.

In tractors with electro-hydraulic control system (EHR) the hoist is operated with a button

outside the cabin of the tractor. During operation please remain especially cautious.

When changing the mower position from operating to transporting the PTO shaft should be

removed completely or at least on the end connected to the PTO of the tractor.

Operating the mower without covers or the apron is forbidden. The mower should also not be

operated with a damaged or raised apron (there is a danger of the mower throwing hard

objects).

- 6 -

Operator’s manual

Mowing can only be started after the power take-off reaches a nominal speed of 540 rpm.

The power take-off cannot exceed speeds of 600 rpm.

There should be a safe distance between the mower and people, a minimum of 50 m. Utmost

care should be maintained while working in the vicinity of roads and streets.

Any servicing or adjusting of the mower must be done only after the engine and cutting discs

have stopped.

The condition of blade holders must be periodically checked. Any damaged or worn holders

must be replaced.

During transport on public roads all traffic laws regarding lighting and additional equipment for

the mower must be observed. During transport the mower should be equipped with

the removable light board and the triangular safety sign.

WARNING:

Any maintenance or repair of the mower should be done with the tractor

engine off, the cutting bar resting on the ground and all rotating parts must be

During any repair being performed while the mower is lifted on the TPH, the mower should be

secured with a support or a chain so that it does not fall.

The condition of bolts and other connectors should be periodically checked. Operation of

the mower with damaged connectors is unnaceptable.

The regulator line changing the position of the mower should have enough slack and be

properly installed in the cabin of the tractor.

During operation of the mower the Regulation of the Farm Ministry and Food Economy

(Rozporządzenie Ministra Rolnictwa i Gospodarki Żywnościowej) from 12.01.1998 dealing

with safety and hygiene during the operation of tractors, machinery, tools and equipment used

for farming (Dz. U. nr 12/98 poz. 51), should be observed.

The tractor used with the mower should be equipped with a driver's cabin.

The mower cannot be used if the tractor has not been properly balanced.

Never start the mower if it is in the up position.

Never start the mower if people or animals are in the proximity of the mower.

Never lift the tarpaulin apron before the rotating parts of the mower come to a complete stop.

The tractor engine must be turned off.

Observe all safety signs, warnings or warning signs placed on the mower.

Before turning on the tractor make sure that all drives are disengaged and the hydraulic control

lever is in neutral.

Do not leave a running tractor without supervision. Before leaving the tractor turn off

the engine and remove the key from ignition.

It is forbidden to operate the mower in reverse.

Never climb on top of the mower.

Lifting the mower on the hitch of the tractor while the drive is engaged and the discs are

spinning is forbidden.

Acceptable ground incline while operating or transporting the mower is 8°.

Do not get between the tractor and the mower before the equipment has been secured through

the engagement of the parking brake of the tractor.

All inspections of the condition of the mower and any adjustments should be done while

the mower is opened and lowered to the ground.

In case of repairs or adjustments which must be done under the mower it must be secured from

falling using a proper support.

When parts need replacing only original spare parts form the spare parts catalogue should be

used.

Special attention should be paid to the cover-guards of the drive shafts. Never work with

damaged shaft guards.

at rest.

Z 010; Z 010/1; Z 010/2; Z 010/4

Rear drum mower

- 7 -

Operator’s manual

Hydraulic hoses should be periodically checked and in the event of damage or age should be

replaced. Hydraulic hoses should not be used for a period longer than 5 years.

Never repair damaged hydraulic hoses with tape.

While connecting hydraulic hoses to the hydraulic connectors on the tractor make sure

the hydraulic system of the tractor and the mower is not under pressure,

When working with hydraulic systems wear safety glasses and work gloves. Hydraulic oil

under pressure (16 MPa) can penetrate the skin and cause an infection. In the event of such

injury immediately get medical care.

The mower should be stored under cover and in a manner preventing any injury to people and

animals.

Z 010; Z 010/1; Z 010/2; Z 010/4

4.2. Transport

Any changes in the position of the mower can only be done after making sure that there are no

people in the vicinity of the mower (be careful of children).

During time of transport install on the mower the portable light board and the triangular safety

sign identifying a slow moving vehicle.

When transporting the mower it should always be placed in the transporting position. See

point 5.2.

Before the mower which is mounted on the tractor can be placed in the transporting position

please make sure that the power take-off is turned off and all rotating elements have come to

a complete stop.

Driving speed should always be appropriate to road conditions.

Maximum speed of 25 km/h must not be exceeded.

4.2.1. Placing the mower onto a transport vehicle

The carrier and the driver are responsible for safety during the transport of a mower. All

equipment and parts must be secured during transport. The following rules should be observed

when placing a mower onto a transport vehicle:

the mower can be lifted only in places designated for this purpose and labeled with a hook sign.

(Fig. 6),

equipment having a higher lifting capacity than the weight of the mower, shown on

the identification plate, should be used to hoist the mower. This also concerns lines and chains

used to lift the mower,

all folding elements should be secured in the transport position,

Rear drum mower

Transport

Uchwyty transportowe

opening

Fig. 6. Places designated for lifting the mower

the mower should be immobilized on the loading platform of the transporting vehicle so that it

cannot move.

WARNING:

The person operating the hoist is responsible for maintaining a safe

environment during lifting of the mower.

- 8 -

Operator’s manual

Z 010; Z 010/1; Z 010/2; Z 010/4

4.3. Operating elements

Rear drum mower

Before operating the mower check the condition of the blades and blade holders.

Worn or damaged blades or holders should be immediately replaced.

4.4. The articulated telescoping shaft

Use only articulated telescopic shafts recommended by the manufacturer of the mower.

4.5. Residual risk

Despite the fact that the manufacturer of the mower SaMASZ Sp. z o.o. Bialystok, in order to

eliminate danger, assumes responsibility for the design and construction of its mowers, some

elements of risk are unavoidable during mower operation.

Major source of risk follows performance of these operations:

operation of mower by minors as well as not being familiarized with operator's manual,

operation of mower by persons under influence of alcohol or other abusive substances,

not keeping caution while transportation and shifting of mower during operation,

transport of persons remaining on the machine,

presence of persons and animals within the mower operation range,

performing operations related to servicing and adjustment with engine on.

1. The danger of getting caught or pulled in

This danger occurs during changing the positioning of the mower, or working on the mower

while the rotating elements are in operation and with the guards removed.

During operation, maintenance or adjustments to the mower always use protective gloves,

covered footwear, protective clothing without any loose elements, such as belts etc. Always observe

the warnings on the mower.

2. The danger of injury

This can occur during the replacement of working elements with sharp edges. During all

repairs and maintenance always wear protective gloves.

3. The dangers of spurting hydraulic oil

During hydraulic hose connection and disconnection to and from the tractor make certain that

the hydraulic system of the tractor and the mower are not pressurized.

When dealing with a hydraulic system wear safety glasses and protective gloves. Regularly

check the hoses of the hydraulic system.

ATTENTION:

4. Prohibitions

The following activities are prohibited during mower operation:

do not clear, adjust or repair the mower while it is in motion,

never change the order of procedures described in this operating manual,

never operate the mower if it is not in good working condition or has damaged safety aprons,

never place feet or hands near moving parts of the mower,

during repairs or maintenance of the mower use the instructions in this manual, and always

with the drive shaft disconnected from the tractor,

before performing any task concentrate on the task being performed,

never operate the mower under the influence of alcohol, drugs or strong medications,

clothing should neither be too loose or too tight. Any loose elements of clothing can be pulled

into the machine by its moving parts,

the mower must not be operated by children or handicapped people.

Residual risk is the result of inappropriate behavior of the operator.

- 9 -

Operator’s manual

While assessing residual risk the mower is treated as a machine which to the moment of its

manufacture was designed and constructed according to the level of technology used at the time of

its manufacture.

Z 010; Z 010/1; Z 010/2; Z 010/4

Rear drum mower

WARNING:

If the instructions and prohibitions are not adhered to there remains residual

risk.

5. Residual risk assessment

When keeping such recommendations as:

thorough familiarizing with operator’s manual,

no persons remaining on the machine when operating and during drives,

no persons remaining within the mower operation range,

adjustment, maintenance and lubrication of the machine with engine off,

performing repairs of the machine only by skilled persons,

operation of the machine by persons, which are familiarized with operator’s manual,

in the event of the machine protection against children and unauthorized personnel residual risk

when operating the mower may be limited to necessary minimum.

4.6. Warning decals

In the event when avoiding or eliminating professional risk resulting from

exposure to noise is not possible through use of mass safety device or work

organization, the employer (farmer):

1)

makes available personal hearing safety devices if the levels of noise in

working environment exceed 80 dB.

2)

makes available personal hearing safety devices and ensures they are properly

used if the levels of noise in the working environment reach or exceed 85 dB.

CAUTION:

a) all warning decals should be clean and legible,

b) lost or damaged decals must be replaced,

c) please order new decals from your dealer or supplier.

1. N-1

Be extremely careful when PTO

shaft is rotating!

Caution – cutting knives. Approach

during operation is forbidden!

2. N-2

3. N-3

Caution – read the operator’s

manual before putting the mower

into operation!

- 10 -

Operator’s manual

Z 010; Z 010/1; Z 010/2; Z 010/4

Rear drum mower

4. N-4

Caution – while making repairs

the machine must be stopped!

7. N-7

Operating is forbidden when any

person is within the danger area

of 50 m!

5. N-5

Caution – belt transmission, be

extremely careful!

8. N-9

Caution: rotor

6. N-6

Caution – rotating parts

9. N-11

10. N-13 11. N-29 12. N-33

13. N-40

Transport hook for lifting of the

mower

Do not get too close to the hoist of

the tractor during operation of the

14. N-49

15. N-50

Do not get under the mower

hoist

16. N-51

Do not get under the mower

17. N-52

18. N-55

Use protective gloves

- 11 -

Operator’s manual

Z 010; Z 010/1; Z 010/2; Z 010/4

Rear drum mower

19. N-107 20. N-120

21. P-2 22. A-6

Fig. 7a.

Fig. 7b. Points of placing warning signs on mower with swath conditioner Z 010/4 a.o.

Locations

of warning signs (Z 010, Z 010/1, Z 010/2)

- 12 -

Operator’s manual

R

Z 010

R

Z 010/1, Z 010/2

R

Z 010/4

Z 010; Z 010/1; Z 010/2; Z 010/4

4.7. Design and operation of safety breakaway device

Fig. 8. Safety device

Rear drum mower

Safety device (Fig. 8) spring is adjustable, therefore changing the force needed to make safety

device work. In the event of hitting an immovable obstacle one of the safety device flat bars slides

out and disconnects the safety device. After that the mower folds back about 20 degrees (Fig. 9).

The operator has time to shut off the tractor and protect the mower.

Tab. 3. Recommended length of safety device spring

Z 010/4 – 2.10 m with soil breaker,

If the safety device breaks away too easily, tighten up the spring approximately 1 - 2 mm.

DO NOT tighten up too much, because you may prevent the safety device from working and

damage the mower.

Fig. 9. The mower breaks back when the safety device operates

Model Dimension „R” of safety device spring [mm]

Z 010 – 1.65 m 140

Z 010/1 – 1.85 m 135

Z 010/2 – 2.10 m 135

model with polyurethane spring

103

CAUTION:

Do not switch the mower safety breakaway device from transport to

operating position and from operating to transport position with the mower

cutterbar up, connected engine or the tractor engaged neutral.

- 13 -

Operator’s manual

a) In order to switch the mower safety breakaway device from transport to operating position,

the following steps should be taken:

lower the mower cutterbar onto the ground,

unlock the transport clip (!!!!!),

turn the tractor front wheels left most (Fig. 11) and drive backwards until the mower catch

bumper contacts the middle beam,

disconnect the tractor engine and engage neutral or engage hand-brake, so the tractor is

protected from moving,

put the mower safety breakaway device onto pin on the catch and protect with a safety pin

(Fig. 9).

b) In order to switch the mower safety breakaway device from operating to transport position,

the following steps should be taken:

lower the mower cutterbar onto the ground,

disconnect the tractor engine and engage neutral or engage hand-brake, so the tractor is

protected from moving,

remove the safety pin and take the safety breakaway device off from the pin (Fig. 8),

connect the tractor engine, turn the wheels left most and drive the tractor forward until

the transport position clip is locked.

Z 010; Z 010/1; Z 010/2; Z 010/4

Rear drum mower

5. OPERATION OF THE MOWER

5.1. Attaching the mower to the tractor

The mower is connected to the tractor’s 3-point-linkage.

Once the mower is suspended the setting shall be adjusted on even ground with use of

adjustment screw S (Fig. 10) and hangers W of the tractor lower links. The mower discs should be

parallel to the ground; hence this is a condition for sustainable stubble management. Hangers W of

the tractor lower links should be placed on pins A of the mower 3-point linkage frame.

Connect the mower hydraulic hose (optional) to the tractor one-section hydraulic connector.

In order to achieve this entire unit must be weighed first, then drive onto the scale only with

the front axle of the tractor (the mower must be in the transport position, lifted up). If the weight of

the front axle of the tractor is at least 20% of the entire weight of the unit then steering ability has

been preserved. If this is not the case the front axle should be additionally weighed down.

S

W

A

Fig. 10. The mower connected to the tractor

- 14 -

Operator’s manual

b)

Fig. 12

a

Fig. 12

b.

Z 010; Z 010/1; Z 010/2; Z 010/4

5.2. Preparing the mower for transport

Rear drum mower

5.2.1. Standard design

To put the mower into the transport position, please do the following:

mount the 3-point linkage frame onto the tractor links,

position the 3-point linkage frame with beam along the tractor axis (Fig. 11a),

adjust the mower with top link S (Fig. 10), if needed,

disconnect the PTO shaft.

a)

Fig. 11. Mower positions: a) transport position; b) working position

5.2.2. Desing with hydraulic lifting (optional equipment)

To put the mower into the transport position, please do the following:

connect the hydraulic hose for lifting the mower to tractor hydraulic service,

lift the mower with tractor hydraulic lift until the lower lift pins of the mower linkage frame

raise about 500 mm above the ground,

with tractor hydraulic lever pressurise the hydraulic cylinder on the mower and lift the cutting

unit of the machine to the vertical position,

. Side transport position

Rear transport position

CAUTION:

During transport the shut-off valve of mower hydraulic lift should

always be closed – the valve lever in Z position (Fig. 14). It protects

the mower against incidental falling in case of hydraulic failure.

to prevent the mower from falling down close the shut-off valve (Fig. 14) on the hydraulic

cylinder (Fig. 13),

- 15 -

Operator’s manual

O

in the side transport position (Fig. 12a) you can leave PTO shaft connected. In the rear transport

position (Fig. 12b) you have to disconnect PTO shaft.

min. 500 mm

Fig. 13. Mower raised for transport position Fig. 14. Shut-off valve positions

To prepare the mower for transport and to meet safety precautions please:

check carefully the area around the tractor and machine when lifting or lowering the mower,

before lifting the machine into transport position set the machine with the tractor linkage

parallel to the ground.

5.2.3. Mechanical lock of hydraulic lifting

Mechanical lock is placed on hydraulic lifting cylinder to prevent incidental mower’s falling

in its transport position. It is a locking pawl witch is automatically locking in transport position.

Before lowering the mower open the lock by pulling a string connected (Fig. 15).

Fig. 15. Mechanical lock of hydraulic lifting

Z 010; Z 010/1; Z 010/2; Z 010/4

– open

Z – closed

Z

O

Rear drum mower

5.3. Preparing the mower for transport on public roads

To meet safety precautions concerning transport on the public roads in Poland the mower

should be equipped with following devices:

portable warning-light plates, to be mounted on both sides of mower top guard in their holders,

- 16 -

Operator’s manual

Z 010; Z 010/1; Z 010/2; Z 010/4

Fig. 16. SaMASZ mower in the transport position with warning plates

CAUTION:

The warning devices can be ordered from the mower manufacturer.

warning triangle which can be put into holder on top mower guard.

5.4. Connecting the articulated telescopic shaft

When connecting PTO shaft between tractor and mower make sure, that external guard tube

of the shaft is on the tractor’s side.

The PTO shaft plastic guards have to be secured by fastening their small chains to immovable

parts of tractor and mower.

CAUTION:

The PTO shaft should be mounted only during operation time and

disconnected from tractor PTO for transport and service.

CAUTION:

If need be, shorten the PTO shaft according to its operator’s manual given by

the shaft’s manufacturer (Fig. 17).

Fig. 17 Instruktion of PTO shaft ahortening

Rear drum mower

- 17 -

Operator’s manual

CAUTION:

Operate machinery only with the articulated telescoping shafts designated for

use with that machinery. Before strating work chceck if all the covers

(tractor, machinery and shaft) are in place and functioning. Gamage or lost

elements must be replaced with original spares. Check weather

the articulated telescoping ahaft is properly installed. Never get close to

rotating part sit could result in injury or death. During servicing of the shaft

or the machine the engine and the power take-off the tractor must be turned

off. Before operating any machinery carefully read the operating manuals of

the shaft and the machine.

CAUTION:

For Z 010/2 mower use shaft with right overrunning clutch only. See Tab. 2

and Fig. 4b. Use of shaft with no clutch may cause serious damage to

the mower and therefore warranty to be invalid.

Z 010; Z 010/1; Z 010/2; Z 010/4

Rear drum mower

5.5. Adjustment of conditioner shaft’s position

Correct position of conditioner’s shaft in relation to cutting plates enables proper distribution

of grass swath for further treatment. In order to achieve this pay particular attention to placement of

lift, so constant distance of ∼2 cm is kept between ends of flails and surface of cutting plate. In the

event of dense and abundant grass, the tolerance should be increased up to ∼3 cm, so soil breaker is

prevented from clogging. Adjustment of this distance is performed with use of spacers installed

between mower’s frame and conditioner’s lift (Fig. 18).

Adjustment

washers

Fig. 18. Adjustment of conditioner shaft’s position

5.6. Replacement of flails in conditioner’s shaft

If flails worn on normal basis, they must be replaced. Prior to commencing any operation,

on each occasion check condition of bolts, on which flails are set as well as condition of flails

themselves.

CAUTION:

By replacement of crimper’s ram always use a new bolt M12x50, zinc.

cl. 8.8 and a new self-locking nut M12, zinc. cl. 8, tightening

torque 55 Nm.

- 18 -

Operator’s manual

Disassembly of flail encompasses unscrewing nut (M12 oc. kl. 8) with open wrench (19),

taking bolt M12x50 kl. 8.8. out and taking flail out as well. Assembly of new flail is performed in

the opposite way (Fig. 19).

1. Bolt M12x50 kl. 8.8

2. Flat washer ∅12

3. Self-locking nut M12 zinc. cl. 8

4. Ram

5. Flail’s rubber insert

Z 010; Z 010/1; Z 010/2; Z 010/4

Fig. 19. Replacing the crimper’s rams

5.7. Operation

Rear drum mower

5.7.1. Standard design

lower the mower until the sliding saucers come into contact with the ground,

open the locking pawl “Z” (Fig. 20) to allow pin “T” to move in the slot in lifting bar “N”.

It allows the mower to follow the ground contours,

connect PTO shaft between tractor and mower,

slowly engage the PTO clutch and wait until the cutting unit reaches its rated speed,

engage tractor gear and drive slowly into the grass - field.

Z

N

N

Z

T

T

a)

Fig. 20. Positions of locking pawl “Z”: a) transport, b) working

5.7.2. Design with hydraulic lifting (optional equipment)

open the shut-off valve on the hydraulic cylinder (Fig. 14),

move the cutting unit into the working position,

lower the mower until the sliding saucers come into contact with the ground,

connect PTO shaft between tractor and mower,

slowly engage PTO clutch and wait until the cutting unit reaches its rated speed,

engage tractor gear and drive slowly into the grass - field.

b)

- 19 -

Operator’s manual

about 40 cm

Fig. 21. Working position of SaMASZ rear drum mower

Z 010; Z 010/1; Z 010/2; Z 010/4

Rear drum mower

6. MOUNTING AND ADJUSTMENT

6.1. Mounting and timing of the knives

Fig. 22. Timing of the knives on the mowing saucers

6.2. Replacing the knives

Mounting lever

Mounting lever

Mowing saucer

Mowing saucer

Knife

Knife

Knife holder Sliding saucer

Knife holder

Fig. 23. Mounting and replacing the knives

Z010,

Z010/1

Z010/2

Sliding saucer

- 20 -

Operator’s manual

CAUTION:

The cutting edges of the new knives should be directed towards ground.

6.3. Adjusting the cutting unit

ADJUSTING THE MOWER FOR MOWING

Fig. 24. Adjust the drums level with the ground

Rear drum mower

Z 010; Z 010/1; Z 010/2; Z 010/4

6.4. Adjusting the cutting height

The mower has a factory-set cutting height of 58 - 60 mm. The cutting height can be adjusted

by removing a distance ring (spacer), as shown in (Fig. 25). After removing a new cutting height of

50 - 52 mm is achieved. By putting one additional spacer over the support saucer a cutting height of

66 - 68 mm is obtained. Additional spacers are available (optional extras).

CAUTION:

When mounting additional distance rings longer bolts - M10x35 must be

Sliding saucer

Support saucer

used and tightened to a torque of 55 Nm.

Distance ring

50-52 mm

Fastening bolts

Fig. 25. Adjusting the cutting height by fitting or removing the distance ring

66-68 mm

6.5. 3-point linkage support chain

(Model Z 010/2)

Support chain (Fig. 25) is used to ensure 3-point linkage frame of the mower is always at

the same height, to set the mowing unit parallel to the ground and to relieve the hydraulic lift of

the tractor. If the cutting unit is not set parallel to the ground, the bearings of sliding saucers will be

subject to premature wear.

When connecting mower to the tractor, the hanger plate “A” of support chain should be

disconnected from chain and put on the pin “B” of top link. Then the mower has to be lifted with

hydraulic lift about 40 cm high (Fig. 20). The support chain is then connected to the hanger plate

“A” so that is tensioned when the mower is in the working position.

- 21 -

Operator’s manual

A

Z 010; Z 010/1; Z 010/2; Z 010/4

B

Rear drum mower

Fig. 26. 3-point linkage support chain

6.6. Maintenance and service

6.6.1. Checking the knives and knife holders

All knives should have the same lengths and weights. Always check mower before starting

work for damaged, missing and/or worn blades (knives). Replace blades, if necessary, only in sets.

Make sure all knives in a set are of the same length and weight. The knife holders must not be

damaged or deformed and the knife holder pin, on which the knife is pivoting, shouldn’t be worn

down by more than 50% of its cross-section (Fig. 27). If the knife holder pin is worn too much

and/or the knife holder is worn or deformed on the outside edges, please replace the knife holder

immediately. The riveting of the pin in the knife holder must be checked for safety and quality too.

If the riveting is loose, replace the knife holder.

6.6.2. Checking the V-belts tension

Check the V-belt tension. Their deflection under finger pressure must not exceed 30 mm.

V-belts are tensioned with spring tensioner (Fig. 28) equipped with checking plate (1). Distance

“A” between plate tip and holder should be 0 – 3.0 mm. If the gap is wider the V-belts will be

looser.

When any of the belts are damaged, the complete set must be replaced.

Knife holder pin

Fig. 27. Permissible wear of knife holders

- 22 -

Operator’s manual

1

Z 010; Z 010/1; Z 010/2; Z 010/4

A

Fig. 28. Spring V-belts tensioner, 1 – checking plate. Check dimension “A” should be 0 – 3.0 mm

6.6.3. Daily maintenance

Everyday after work please carry out the following maintenance:

wash the mower with water under pressure after every use, especially between the cutting bard

and discs, because dried mud with grass can cause premature wearing out of the bearings in the

disc assembly or block proper rotation of the assembly,

remove grass and mud,

check all visible units and parts and their connections; tighten all loose bolts and nuts and

replace all damaged and/or worn parts with new genuine ones,

grease PTO shaft tubes with STP grease,

if necessary, lubricate the parts and units according to lubrication instruction.

Rear drum mower

6.6.4. After-season maintenance

At the end of the season the mower should be cleaned, washed and dried. Carefully grease

unpainted surfaces and 3-point linkage pins.

After that the following work should be carried out:

remove any traces of rust and paint the area affected,

loosen v-belts,

check lubrication of gear trough – Fig. 29,

if leaks occur and the plastic cap of air-escape valve (table 1, pos. 14) is damaged, replacement

of the sealing under gear trough cover and of the valve cup are recommended. If water is

discovered in the oil, it must be changed, otherwise the gears, bearings and shafts could be

damaged. Put the replacement sealing carefully into place and tighten cover screws uniformly.

periodically inspect the mower and lubricate moving parts in order to protect them from

corrosion which effects proper operation of the mower,

check hydraulic hoses regularly. Replace any damaged or old hoses. The period of hydraulic

hose utilization should not exceed 5 years from the date of their manufacture printed on

the hose.

- 23 -

Operator’s manual

b)

air-

escape valve with plastic cap

Z 010; Z 010/1; Z 010/2; Z 010/4

7. LUBRICATION INSTRUCTION

Gear trough (gearbox)

The oil level is to be checked periodically through the venting opening on the gear trough.

The oil level should be 15 ÷ 20 mm above the bottom of the trough, when the frame is level. Oil

capacities in the gear box are:

Z 010 – 2.5 litre,

Z 010/1 – 3.5 litre,

Z 010/2 – 4.5 litre.

If the checked oil level is low, please check and eliminate any leaks and fill up to the oil level

required.

Mower’s gearbox and conditioner’s intersecting axis gear

The oil level has to be checked periodically through the venting opening on the gear box.

The oil level should be 15 ÷ 30 mm above the bottom. Oil capacities in the gear boxes are for

mower Z 010/4 – 4,5 litre.

The oil capacity in conditioner's gear should be ~ 0.3 l. Intersecting axis gear of conditioner’s

drive should be filled with gear oil through filler, located in the gear's cover.

a)

Rear drum mower

Tab. 4. Lubrication table

Symbol Oil type Lubrication frequency

Gear oil

80W/90

Fig. 29. Lubrication points a) mowers

Z 010; Z 010/1; Z 010/2, b) mower Z 010/4

Once every 3 seasons

(if working intensively)

- 24 -

Operator’s manual

8. DEFECTS AND THEIR REPAIRS

Defect Reason Repair

Some missing blades Install or replaced blades

Worn blades Replace worn blades

Improperly installed blades

(left – right)

Space between the knife and knife

holder is filled with mud, grass,

The mower mows partially –

leaves furrows between discs

Damaged tractor PTO, does not

Stones between moving parts Stop and remove

Sliding V-belts

power the mower

etc.

Rear drum mower

Z 010; Z 010/1; Z 010/2; Z 010/4

Install blades according to

operating manual

Remove dirt (wash with water

under pressure)

Too low spring tension –

Regulate the spring acc. to

instructions

Worn V-belts – Replace V-belts

Repair PTO

Laid grass Low mowing on each occasion

A mower with roller or scarifier may not mow properly with very

Safety device is working

often without clear reason

Insufficient spring tension

Worn elements of safety device Replace the safety device

Damaged or dirty hydraulic

The mower will not fold up

connections

Damaged tractor hydraulic system

Leaking cylinder

Excesive vibration during

work

Dirty oil in hydraulic unit of the

Damaged PTO shaft

Oil leak in gear Not tight assembly

tractor

low grass or during rain

Adjust spring tension according

to operator’s manual

Replace or clean hydraulic

connections

Check the functioning of

the tractor hydraulic system

Replace oil in hydraulic unit of

the tractor (recommended class

of cleanliness of oil according

to NAS 1638 is minimum

9-10). Purchase repair kit of the

cylinder and replace damaged

sealings

Check the condition of PTO

shaft and if need be replace

Examine tightness and check

oil level.

- 25 -

Operator’s manual

Z 010; Z 010/1; Z 010/2; Z 010/4

9. DISASSEMBLY AND WITHDRAWAL FROM WORK

Rear drum mower

CAUTION:

Before disassembly the mower should be disconnected from the tractor.

9.1. Disassembly

Before starting any repair or service the mower should be cleaned and any grass or dirt

removed. Carefully check nuts and bolts for correct tension and the pins for wear. Replace as

necessary.

9.2. Scrapping

If the mower cannot be repaired anymore, it should be withdrawn from use.

For this purpose oil from gear trough should be drained and delivered to a proper waste

treatment company. Clean the mower parts, dismantle and dispose properly of all plastic parts.

After that, the mower could be sold to breaker’s yard.

10. WARRANTY CARD

REAR DRUM MOWERS

The product quality has been checked and meets the required standards and regulations and is

permitted for use.

CAUTION:

A warranty card without the required information or with corrected or

illegible information – is invalid.

Serial number

Date of manufacture

Manufacturer’s stamp

QC signature

Date of purchase

Dealer’s stamp

Dealer’s signature

- 26 -

Operator’s manual

Z 010; Z 010/1; Z 010/2; Z 010/4

11. WARRANTY TERMS

11.1. Warranty claims procedures

1. The manufacturer guarantees its products against faults in materials or production.

2. Faults or malfunctions of the mower which become apparent within a 24 month period of

the date of purchase will be corrected free of chargé at the buyer’s residence.

3. Any faults or malfunctions should be reported in person, by letter or phone. Repairs will be

performed within 14 days. Warranty repairs are done by the manufacturer or at authorized

service points.

4. Claims for product replacement or returns are accepted and processed by the manufacturer

within 14 days.

5. The following cases are not covered by warranty:

a) operating the mower not according to the operating manual or its intended use,

b) random events or others for which the guarantor is not responsible. transport

damage,

c) natural wear of parts such as: natural wear of parts such as: cutting plates, sliding

skids, intersecting axis gears and parts inside the gearboxes, bushings and sliding

elements, joints, knife holder, cutting knives, V-belts, bearings, lower hubs, safety

curtains, connective elements, etc.,

d) use of non – original parts.

Rear drum mower

6. The Purchaser bears the costs of technical estimation – when the manufacturer finds that

7. The manufacturer has the right to cancel a warranty in following cases:

8. Manufacturer can break the service agreement with immediate effect when the user do not pay

9. Manufacturer does not take compensation responsibility for the loss caused by breakdown of

Such repairs can be performed at the cost of the buyer.

a claimed product is free of defects and a technical report will confirm that.

1. interference of the interior of the mower, changes of its mechanical design or

intentional damages,

2. extensive damage to the mower caused by random event, running into an obstacle or

other for which the guarantor is not responsible,

3. missing required signatures or an attempt to forge them on the warranty card,

4. operating the mower not according with its intended use or operating manual.

receivables according to that agreement in a timely manner and the delay in payment is longer

than 30 days from maturity date. Breaking the service agreement caused by the user makes

simultaneous breaching of the warranty.

the machine during work.

CAUTION:

During your purchase please make sure that the seller carefully fills out

the warranty card including the place and date of purchase and the seal and

signature of the seller. Missing information can cause loss of warranty.

CAUTION:

Please ask your dealer to complete and return the warranty card, otherwise

you may loose your warranty rights.

CAUTION:

After the warranty period repairs can be performed for payment by

authorized service providers designated by the distributor. Providing this

information is the responsibility of the distributor.

- 27 -

Operator’s manual

CAUTION:

The manufacturer reserves the right to alter technical design and

specification without prior notice and without liability.

CAUTION:

The SaMASZ Company is continually working on improvement and

development of all types and models of mowers. For this reason the form,

accessories and technology of delivered products can change. No claims can

be made based on the data, illustrations or descriptions contained in this

manual or the spare parts catalogue.

The SaMASZ is not responsible for printing errors.

11.2. Warranty repairs record

Repair description and changed spare parts:

Date, stamp and signature of repair shop.

Date, stamp and signature of repair shop.

Date, stamp and signature of repair shop.

Rear drum mower

Z 010; Z 010/1; Z 010/2; Z 010/4

- 28 -

Loading...

Loading...