SaMASZ Sp. z o.o.

Established

– 1984

Poland, 16-060 Zabłudów, ul. Trawiasta 1

NIP PL-966-159-29-76

tel. (+48) (85) 664 70 31

fax (+48) (85) 664 70 41

e-mail: samasz@samasz.pl

www.samasz.pl

OPERATOR’S MANUAL

REAR DISC MOWER

KDT 180 - 5' 11"

KDT 220 - 7' 3"

KDT 220 W - 7' 3"

KDT 220 S - 7' 3"

KDT 260 - 8' 6"

KDT 260 W - 8' 6"

KDT 260 S - 8' 6"

KDT 260 SL - 9' 10"

KDT 340 - 11' 2"

KDT 341 - 11' 2"

Serial No:

The original instruction

IN221USA010

17.03.2017

EDITION № 10

Optimum inclination towards the ground is 0 ÷ 5°

to the mowing direction

It is allowed to work in horizontal position.

Different inclination may damage the mower.

DO NOT

TURN THE DRIVE ON

IF THE MOWER IS NOT IN

WORKING POSITION

DO NOT

LIFT THE MOWER

BEFORE THE MOWING

DISCS HAVE COME TO

COMPLETE STANDSTILL

DO NOT

OPERATE WHEN ANY

PERSON REMAINS IN THE

DANGER AREA OF 170′.

Well-proven design with thousands of machines in regular use in many countries and quality

CAUTION:

Keep this manual for future use.

materials ensure high durability and reliability of SaMASZ mowers.

- 1 -

Operator’s manual

1. IDENTIFYING THE MACHINE ........................................................................................................................... 2

2. INTRODUCTION .................................................................................................................................................... 2

3. PROPER AND INTENDED USE ........................................................................................................................... 3

3.1. Technical data ....................................................................................................................................................... 4

3.2. Design and working principle ............................................................................................................................... 5

3.3. Standard equipment and spare parts ..................................................................................................................... 6

4. SAFETY PRECATIONS ......................................................................................................................................... 8

4.1. General safety rules and regulations ..................................................................................................................... 8

4.2. Conditions of mounting mower on tractor .......................................................................................................... 10

4.3. Transport ............................................................................................................................................................. 10

4.3.1. Putting the mower onto another vehicle for transport ................................................................................... 11

4.4. Working parts ..................................................................................................................................................... 12

4.5. PTO shaft ............................................................................................................................................................ 12

4.6. Hydraulic assembly ............................................................................................................................................ 12

4.7. Residual risk ....................................................................................................................................................... 13

4.7.1. Danger of machine entanglement .................................................................................................................. 13

4.7.2. Danger of cutting injury ................................................................................................................................ 13

4.7.3. Danger of injury from liquid ejection out of hydraulic system ..................................................................... 13

4.7.4. Forbidden actions .......................................................................................................................................... 13

4.7.5. Residual risk assessment ............................................................................................................................... 14

4.8. Safety labels and their meaning .......................................................................................................................... 14

5. OPERATION .......................................................................................................................................................... 17

5.1. Attaching the mower to the tractor ..................................................................................................................... 17

5.2. Preparing the mower for transport ...................................................................................................................... 18

5.3. Preparing the mower for transport on public roads ............................................................................................. 19

5.4. Mounting PTO shaft ........................................................................................................................................... 19

5.5. Moving from transport to working position ........................................................................................................ 20

5.5.1. Operating positions of the mower ................................................................................................................. 21

5.6. Preparing the mower for work ............................................................................................................................ 22

5.7. Operation (mowing) ............................................................................................................................................ 22

5.7.1. Essential information concerning mowing .................................................................................................... 23

5.7.2. Design and and operation of safety breakaway device .................................................................................. 24

5.7.3. Mower clogging ............................................................................................................................................ 25

5.7.4. Taking turns over swaths ............................................................................................................................... 25

5.8. Storing ................................................................................................................................................................ 25

5.9. Dismounting mower from tractor ....................................................................................................................... 25

6. MOUNTING AND ADJUSTMENTS ................................................................................................................... 26

6.1. Mounting and timing of the knives ..................................................................................................................... 26

6.2. Replacing the knives ........................................................................................................................................... 26

6.3. Adjusting the cutterbar........................................................................................................................................ 27

6.4. Adjusting the cutting height ................................................................................................................................ 29

6.5. 3-point linkage support chain ............................................................................................................................. 30

6.6. Adjusting the space between tine conditioner’s mask and its shaft .................................................................... 30

6.7. Replacing the conditioner’s tines ........................................................................................................................ 31

6.8. Adjusting force of the prssure of roller conditioner ............................................................................................ 32

6.9. Maintenance and service ..................................................................................................................................... 32

6.9.1. Checking the knives and knife holders .......................................................................................................... 32

6.9.2. Checking the tension of the V-belts .............................................................................................................. 33

6.9.3. Inspection of tension of toothed belt for gears of rollers and conditioner ..................................................... 33

6.9.4. Daily maintenance ......................................................................................................................................... 34

6.9.5. After-season maintenance and storing of machine ........................................................................................ 34

7. LUBRICATION ..................................................................................................................................................... 35

7.1. Cutterbar ............................................................................................................................................................. 35

7.2. Intersecting axis gear .......................................................................................................................................... 36

7.3. Roller conditioner’s gearbox .............................................................................................................................. 36

7.4. Bearings and joints ............................................................................................................................................. 37

8. MALFUNCTION AND THEIR REPAIRS .......................................................................................................... 38

9. DISASSEMBLY AND WITHDRAWAL FROM USE ........................................................................................ 39

9.1. Scrapping ............................................................................................................................................................ 39

10. WARRANTY CARD .............................................................................................................................................. 39

11. WARRANTY TERMS ........................................................................................................................................... 39

11.1. Warranty claims procedures ............................................................................................................................... 39

11.2. Warranty repairs record ...................................................................................................................................... 40

APPENDIX CALCULATING AXIS LOAD ................................................................................................................ 41

Rear disc mowers

KDT

- 2 -

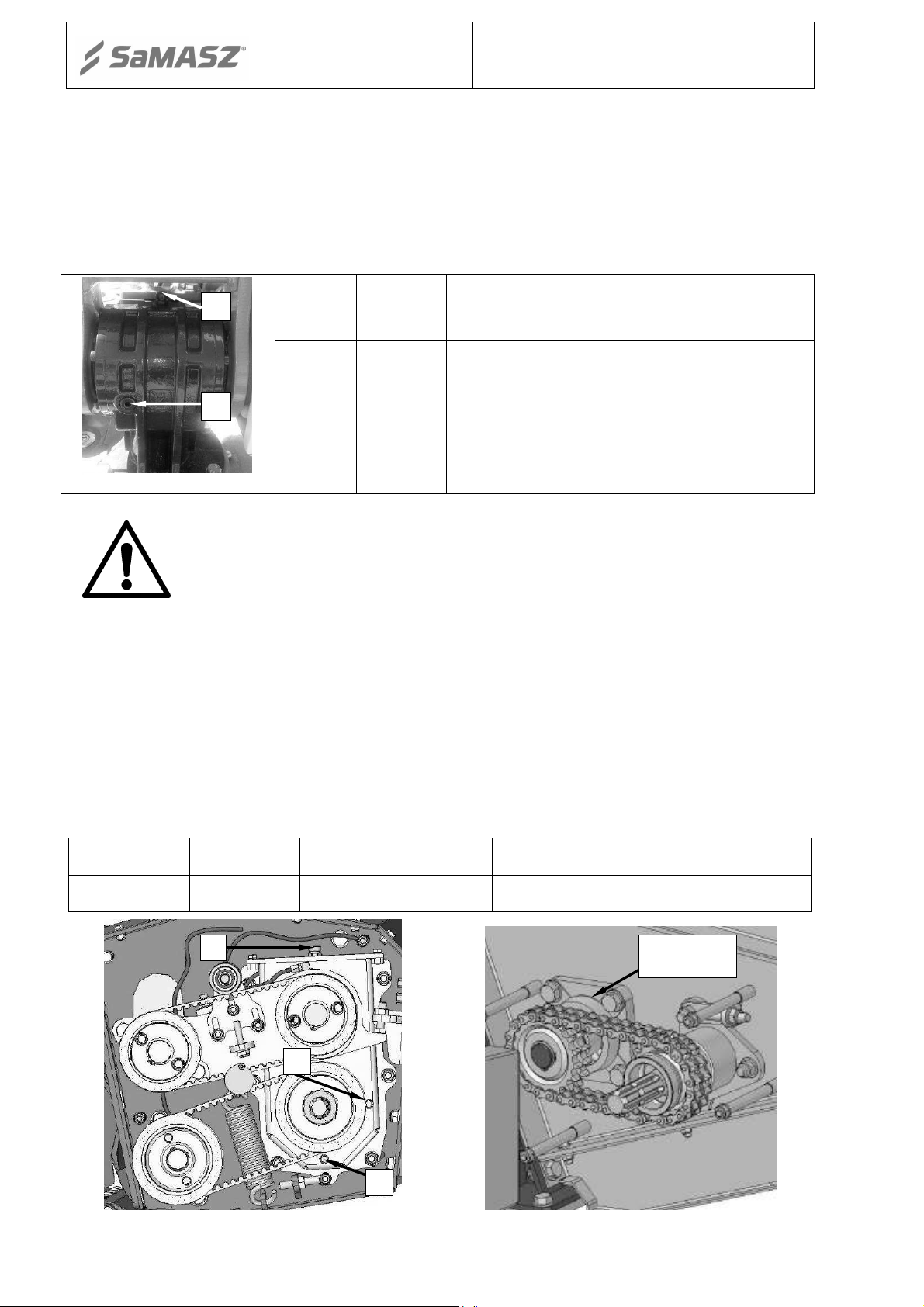

Data plate location

Data plate

Data p

late includes:

- name and adress of the manufacturer,

-

model year,

- CE marking means, that the produce

-

version number,

conforms to 2006/42/EC Directive and

-

machine weight,

harmonized standards,

-

id number,

- machine symbol,

-

barcode.

- date

of manufacture,

Operator’s manual

1. IDENTIFYING THE MACHINE

Rear disc mowers

KDT

Data plate is mounted to the mower’s main frame in the place shown below (Fig. 1).

Fig. 1.

Fig. 2.

NOTE:

For more detailed information concerning the mower ask your dealer or manufacturer.

2. INTRODUCTION

This operator’s manual is essential for safe and proper use of this mower and should be read

before anyone operates this mower. It should be kept near the mower for future use. If the

mower is used by other operator, it should be in working condition and include this

operator’s manual and all other basic equipment.

Operator’s manual is delivered with every machine so that the operator can familiarize

himself with the design, working principle, servicing and adjustment of the mower. The

operator should be familiar with common safety rules and procedures.

The mower is manufactured according to international safety rules.

Compliance with the safety precautions in this operator’s manual will enable safe operation.

Please contact your dealer if you have any queries relating to the operation and service of

the mower.

Operator’s manual remains part of mower’s equipment.

- 3 -

No tilt

3° tilt

5° tilt

"

"

"

.8

"

.4

"

"

"

"

Operator’s manual

3. PROPER AND INTENDED USE

Rear disc mowers

KDT

Mower KDT is equipped with the Perfect Cut cutterbar. The mowing height differences,

depending on the inclination angle of the cutterbar are shown below Tab. 1.

Tab. 1. Mowing height depending on cutterbar's inclination angle

„Perfect Cut” cutting bar

Standard mowing height

Optional heights when using high mowing topping

Optional heights when using high mowing double topping

"

• The front mounted disc mower is intended for mowing green fodder such as grass and alfalfa

on permanent grassland (pastures), on crop fields without rocks, and forming loose rows of cut

fodder. The pasture or field being mown should be even and best if prepared by rolling. In

the event there is a majority of tall grass, the first and second mowing should be done at a

height of 2.4" - 2.8", while with a majority of short grass, at a height of 2". The last mowing

should be done a little higher - at 2.8" - 3.1" from the ground.

• The front mounted disc mower with tine/roller conditioner is intended for mowing green fodder

such as grass and alfalfa on permanent grassland (pastures), on crop fields without rocks, and

forming loose rows of cut forage. As a result of the passing of the layers of the green fodder

through the flails or rollers, the grass stems are broken and a layer of wax is removed. This

facilitates and speeds up the drying process of the fodder by approximately 30 to 40%. The use

of rollers is especially recommended when mowing legumes such as alfalfa Rollers are

particularly recommended for mowing grass legume such as alfalfa. The pasture or field being

mown should be even, best if prepared by rolling. This is especially true of mowers with rollers

as they tolerate rocks with a diameter of a few inches. If a larger stone is picked up stop and

remove it as it could cause damage of the discs. With a majority of tall grasses the first and

second mowing should be done at a height of 2.4" - 2.8", while with a majority of short grass it

should be cut at a height of 2". The last cut should be done a little higher - at 2.8" - 3.1"from

the ground.

Note: Grass, which has not grown much should be mowed with zero angle inclination

- 4 -

Model:

Working width

5' 11"

7' 3"

8' 6"

9' 10"

11' 2"

11' 2"

Number of knives [pcs.]

8 (2 x 4)

10 (2 x 5)

12 (2 x 6)

14 (2 x 7)

16 (2 x 8)

16 (2 x 8)

Tractor PTO rpm

540 rpm

(30 HP)

(50 HP)

(70 HP)

(80 HP)

(90 HP)

(9

0 HP)

3-point linkage category

II

Working capacity

~ 2.0 ha/h

~ 2.5 ha/h

~ 3.0 ha/h

~ 3.5 ha/h

~ 4.0 ha/h

~ 4.0 ha/h

Transport length

3' 11"

Transport width

6' 1"

7' 1"

7' 1"

7' 1"

7' 3" 7' 3"

Working width

11' 6"

13' 9"

15' 1"

16' 9"

18' 1" 18' 1"

W

eight

1213

lbs.

1477 lbs.

1599

lbs.

1730

lbs.

1818

lbs.

1818

lbs.

Cutting speed of the knife

91 m/s

Disc rpm

3250 rpm

Noise level

LpA

101 ± 1 dB

L

Amax

113 ± 1 dB

L

Cpeak

116 ± 1 dB

Model:

Working width

7' 3"

8' 6"

8' 6"

7' 3"

8' 6"

Number of knives [pcs.]

10 (2 x 5)

12 (2 x 6)

12 (2 x 6)

10 (2 x 5)

12 (2 x 6)

Tractor PTO rpm

540 rpm

(60 HP)

(90 HP)

(90 HP)

(60 HP)

(90 HP)

3-point linkage category

II

Working capacity

~ 2,0 ha/h

~ 2,8 ha/h

~ 2,8 ha/h

~ 2,0 ha/h

~ 2,8 ha/h

Transport length

5' 3"

4' 4' 4' 11"

4' 9"

Transport width

7' 7' 7' 7' 7' 3"

Working width

13' 9"

15' 4"

15' 4"

13' 9" 15' 5"

Weight

2073

lbs.

2194

lbs.

2194

lbs.

2095

lbs.

2215

lbs.

Cutting speed of the knives

91 m/s

Disc rpm

3250 rpm

L

Amax

109 ±

1 dB

109 ±

1 dB

L

Cpeak

112 ±

1 dB

112 ±

1 dB

Operator’s manual

WARNING

Use of the mower for purposes other than described above is forbidden. Improper

use can be dangerous and may lead to voiding the warranty. Mower should be

operated and repaired only by persons familiar with its detailed specifications and

with all applicable safety rules and regulations as well as the relative dangers.

Unauthorized modifications to the mower will lead to voiding the warranty.

3.1. Technical data

Tab. 2. Specification of the mower KDT

:

KDT 180 KDT220 KDT260 KDT300 KDT340 KDT 341

Rear disc mowers

KDT

Tractor power required

Tractor power required

22 kW

30 kW

50 kW

60 kW

70 kW

70 kW

KDT 220 S KDT 260 S KDT 260 SL KDT 220 W KDT 260 W

44 kW

66 kW

66 kW

44 kW

66 kW

Noise level L

S – Mowers with tine conditioner W – Mower with roller conditioner

LpA – noise level related to 8 hour working time. Averaged in time acoustic pressure level corrected by

frequency characteristic A.

L

– maximum value corrected by frequency characteristic A of acoustic pressure level.

Amax

L

– peak level of acoustic pressure corrected by frequency characteristic C.

Cpeak

pA

98 ± 1 dB 97 ± 1 dB

- 5 -

2 3

5 6

2

8 9 10

4 –

Cutterbar

11 –

Support legs

Operator’s manual

Rear disc mowers

KDT

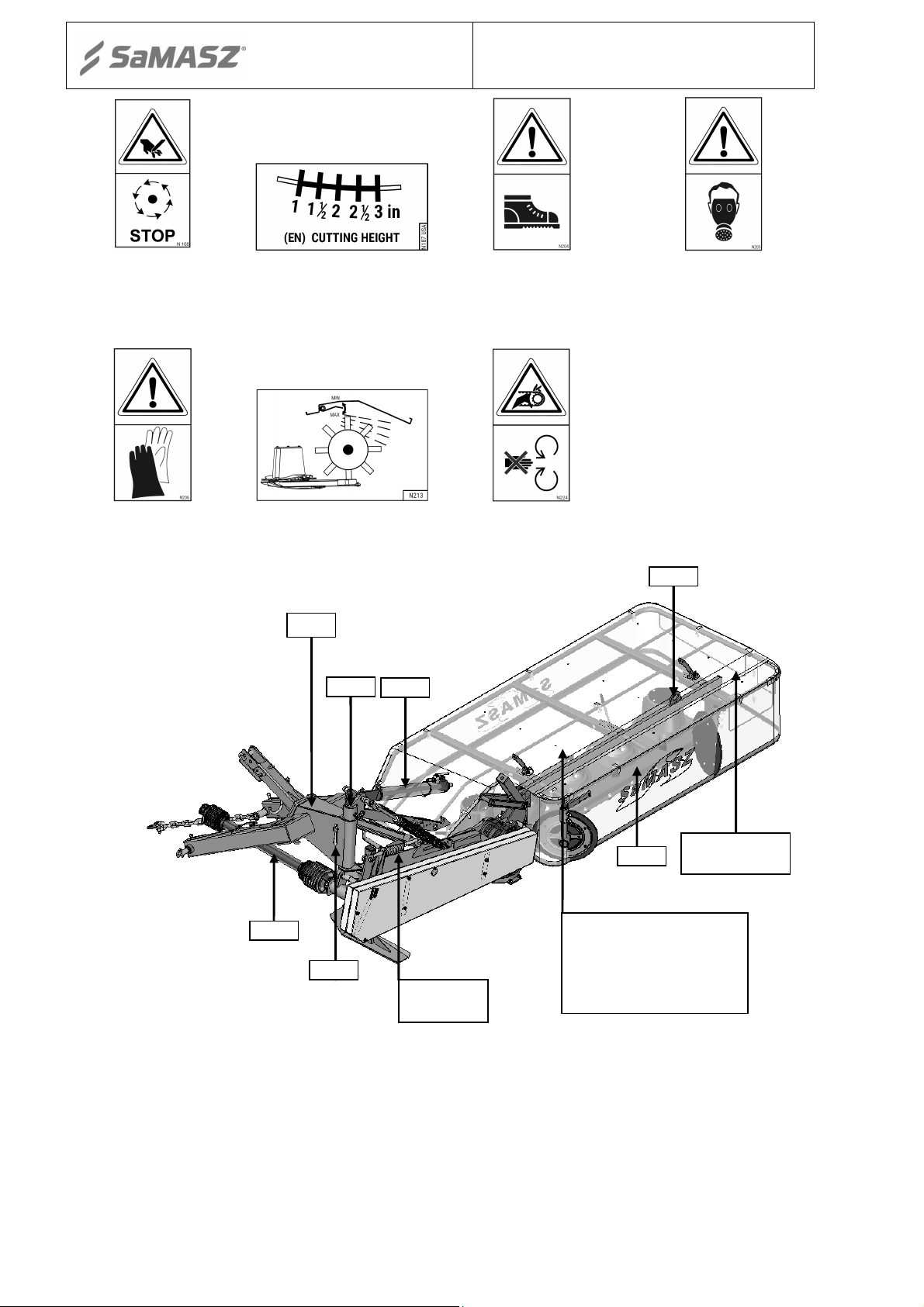

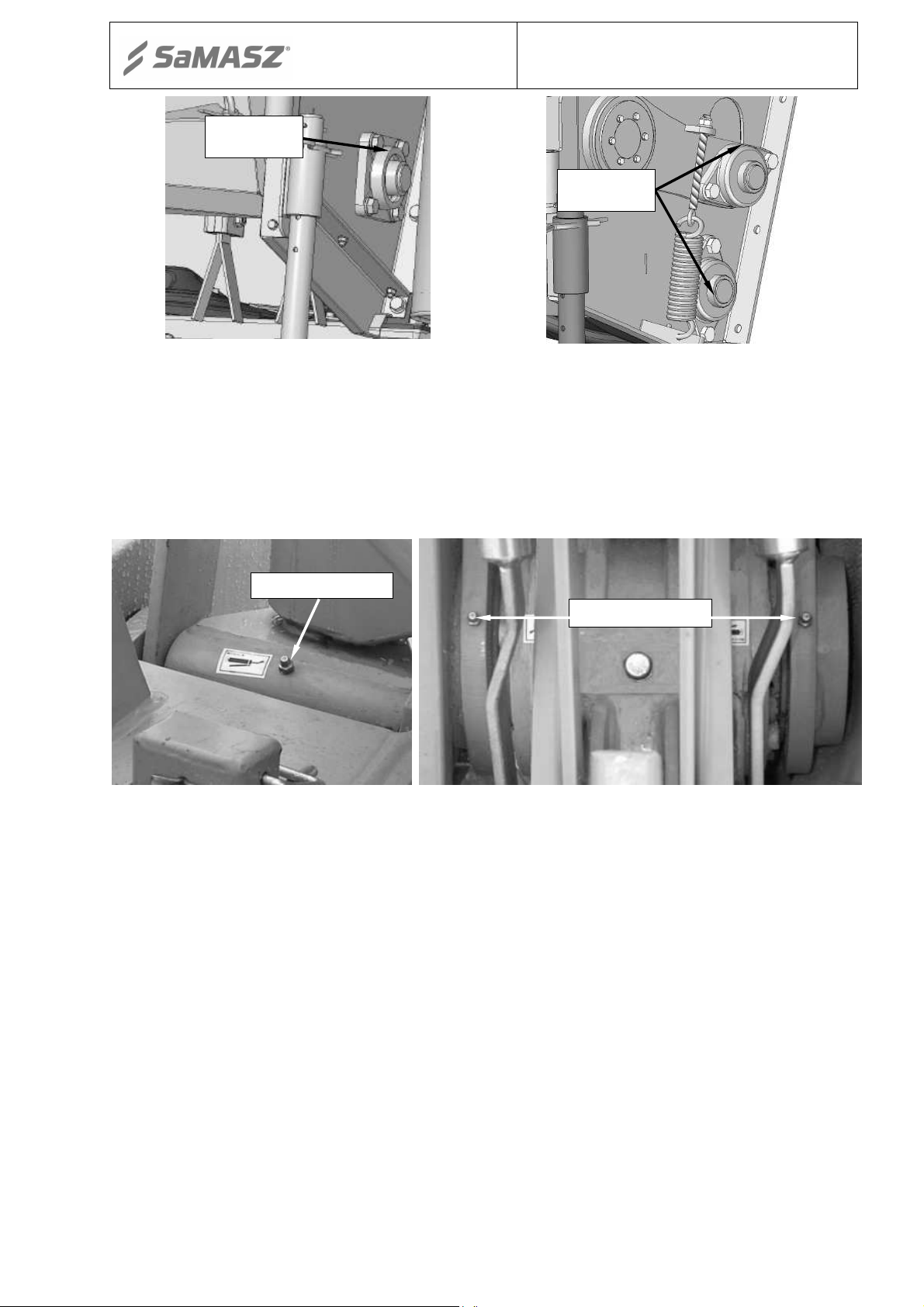

3.2. Design and working principle

3-point linkage frame (1) enables attachment of the mower to tractor’s 3-point linkage. Drive

from tractor’s rpm is transmitted through drive unit (3) on the cutterbar (4). Hydraulic cylinder (2)

is used to adjust the mower to working position. It is supplied from outer hydraulics of the tractor.

Main frame, on which the cutterbar (4) is situated, is supported by the springs (7). Swath discs (5)

are mounted on the main frame.

1

7

4

1 – 3-point linkage frame

2 – Hydraulic cylinder with

3 – Drive unit

Fig. 3a. Parts of SaMASZ rear disc mower

5 – Swath discs

6 – Safety curtain

7 – Support springs

3-point linkage frame (1) enables attachment of the mower to tractor’s 3-point linkage. Drive

from tractor’s rpm is transmitted through

intersecting axis gear

(3) on the cutterbar (4). On the

cutterbar, there are discs with two knives each. Apart from that, drive from tractor’s rpm through

chain gear

(9) and PTO shaft (10) is transmitted to tine conditioner (8). Hydraulic cylinder (2) is

used to adjust the mower to working position. It is supplied from outer hydraulics of the tractor.

Main frame, on which the cutterbar (4) is situated, is supported by the springs (7). Swath guides (5)

are mounted on the main frame.

1

7

4

1 – 3-point linkage frame

2 – Hydraulic cylinder with

3 – Intersecting axis gear

4 – Cutterbar

5 – Swath discs

3

Fig. 3b. Parts of SaMASZ rear disc mower with tine conditioner

11

5

6 – Safety curtain

7 – Support springs

8 – Tine conditioner

9 – Chain gear

10 – PTO shaft

11

6

- 6 -

2 3 4 5 6 7 8 9 10

11 –

Support legs

KM ft. in Nm

KDT 180

21 3'-3

' 12'' 270 7G2N086CE007096MA

KDT 260 S/SL/W

Operator’s manual

Rear disc mowers

KDT

3-point linkage frame (1) enables attachment of the mower to tractor’s 3-point linkage. Drive

from tractor’s rpm is transmitted through

intersecting axis gear

(3) on the cutterbar (4). On the

cutterbar, there are disco with two knives each. Apart from that, drive from tractor’s rpm through

Intersecting axis gear

(3) and PTO shaft (10) is transmitted to roller conditioner (8). Hydraulic

cylinder (2) is used to adjust the mower to working position. It is supplied from outer hydraulics of

the tractor. Main frame, on which the cutterbar is situated, is supported by the springs (7). Swath

guides (5) are mounted on the main frame.

1

Fig. 3c. Parts of SaMASZ rear disc mower with tine conditioner

1 – 3-point linakge frame

2 – Hydraulic cylinder with support springs

3 – Intersecting axis gear

4 – Cutterbar

5 – Swath guides

11

6 – Safety guard

7 – Springs

8 – Roller conditioner

9 – Chain gear

10 – PTO shaft

11

3.3. Standard equipment and spare parts

The mowers are sold with the following standard equipment:

warranty card,

operator’s manual with spare parts list,

cutting knives: additional set,

PTO shaft with overrunning clutch,

spray paint (150 ml).

Optional extra equipment:

warning plate with combined lights and reflectors,

warning triangle.

Tab. 3. PTO shaft for rear disc mower

Model Power Lenght Torque Symbol Clutch Producent

KDT 220 ; KDT 260

KDT 300 ; KDT 340

KDT 341

KDT 220 S/SL/W

35 2'12-4'22'' 460 7G4N091CE007096MA

Overrunning

right

BONDIOLI

& PAVESSI

- 7 -

To

nd with overrunning

To be mounted

Operator’s manual

PTO shaft’s end without clutch –

be mounted on the tractor’s side.

Rear disc mowers

KDT

PTO shaft’s e

clutch –

on mower’s side

NOTE:

Lubricate the PTO shaft with high quality multi-purpose grease every 50 shaft

operating hours. If access holes are available, lubricate fittings through access holes.

PTO shafts of other brands with equivalent parameters could be used afer first obtaining SaMASZ

permission.

The mower is equipped with such elements as holders and brackets used to mount warning lights

and plates. Combined lights and reflectors are mounted on the warning plates.

NOTE:

Optional extra equipment should be ordered separately.

Fig. 4. PTO shaft lubrication points. Mounting directions

- 8 -

Operator’s manual

Rear disc mowers

KDT

4. SAFETY PRECATIONS

The following precautions are for your safety. They must be read carefully and

followed by every person who operates or maintains the machine. Failure to follow these safety

precautions could result in serious injury or death to the operator, maintenance person or bystanders

and property damage to the machine and surrounding property.

Safety Signal Words

This manual and the safety labels attached to this equipment utilize signal words that signify safety

hazards with different levels of severity. Below are the words used and the definitions for these

words:

• DANGER indicates a hazardous situation which, if not avoided, will result in death

or serious injury

• WARNING indicates a hazardous situation which, if not avoided, could result in

death or serious injury

• CAUTION indicates a hazardous situation which, if not avoided, could result in

minor or moderate injury

• NOTICE is used to address practices not related to physical injury

4.1. General safety rules and regulations

The following descriptions are for your safety: They must therefore be read

carefully and applied every time you use the machine.

The machine has been designed for use by one single operator.

When using, servicing, repairing, moving or storing the machine, the operator must wear safety

shoes, safety gloves plus ear protection and dust mask if necessary.

During use, the machine may give rise to dust, especially if the soil is dry. You are advised to

use a tractor with a cab fitted with filters in the ventilation system. Failing this, wear a dust

mask with filter to protect your respiratory tract.

Front axis of the tractor should be weighted to keep the balance. If need be, use front wheel

weights.

In order to keep steering conditions, impact on front axis should be at least 20% of the complete

tractor.

Be extremely careful whenever using hydraulic lift lever or buttons. Any operation with

hydraulic lift lever should be done from operator’s seat; DO NOT move the lever from outside

of a tractor.

In case of tractors equipped with EHR, operating with hydraulic lift is done by the buttons

mounted outside the tractor’s cabin. When operating be extremely careful.

When switching from mowing to transport position, remove the entire PTO shaft or at least one

end of the shaft from the tractor’s PTO so it cannot turn.

When attaching the mower to a tractor, the operator should wear protective gloves.

DO NOT operate the mower unless all safety guards are in place and operational. In addition,

any damaged protective aprons should be replaced with a new one

DO NOT exceed 600 PTO rpm.

- 9 -

Operator’s manual

No person (except operator) should stand within danger area which is a minimum of 170’

Rear disc mowers

KDT

from any operating part, especially when operating near roads and in areas with stones and

other debris.

machine

Be certain that children and animals are at a safe distance away from the

.

IMPORTANT: Maintenance and adjustment should ONLY be done after the following has

occurred:

tractor’s engine has been stopped

all rotating parts have come to complete standstill (NOTE: cutting knives will

and ignition key has been taken out,

rotate for several minutes after engine is turned off),

the cutterbar is on the ground, and

Never tamper with or remove safety devices on the machine or make them inoperable.

Before starting work and periodically thereafter, replace any damaged, missing and/or worn

knives and knife holders.

When driving on public roads always comply with local traffic regulations, especially those

concerning warning lights.

When the mower is lifted for repair on 3-point linkage, it should be secured against falling by

mechanical support or by chain.

The bolts and other fasteners have to be periodically checked and, if necessary, tightened or

replaced. DO NOT work with damaged or worn fasteners.

Never lift the mower on tractor linkage when the drive is operating and the cutting discs are

rotating.

When operating the mower, the tractor should always be equipped with operator protection that

is required by laws and regulations.

Never start the mower when the mower blades are off the ground.

Before you start the tractor make sure that all drives are turned off and the levers that turn the

hydraulics are in neutral position.

Never leave tractor’s engine running without supervision. Before you leave the tractor, turn off

the engine and remove the key from tractor’s ignition.

DO NOT operate the mower when driving the tractor backwards.

Permissible inclination of the mower on a slope when working and during transport is 8°.

Exceeding this incline can result in mower tipover.

Never stand between tractor and mower unless tractor and mower are secured against moving

by the tractor’s brake.

If any maintenance must be done under an elevated mower, it must be blocked or otherwise

secured against falling.

When the parts of the mower need replacement, use only original spare parts as described in the

spare parts list. Pay particular attention to PTO shaft’s guards and mower’s and tractor’s spline

shaft guards.

Hydraulic hoses are potentially very dangerous. Do the following to minimize any hazards:

Hydraulic hoses should be periodically checked and if any damage to the hoses have

occurred or if they have been used more than 5 years, replace with new ones.

Never use scotch tape to repair hydraulic hoses.

When connecting hydraulic hoses to tractor’s hydraulic connectors, make sure that

the tractor’s or mower’s hydraulic system is not under pressure.

The mower should be stored under a roof and in a way as to not be hazardous bot people or

animals.

In the event of an accident involving this mower in a field or on a road, follow all applicable

first aid procedures and contact SaMASZ technical service.

Mower should be kept clean, so as to avoid danger of fire.

- 10 -

Operator’s manual

Rear disc mowers

KDT

4.2. Conditions of mounting mower on tractor

Prior to the mounting operation, be sure that the tractor and mower hitches are compatible and

that the tractor's hitch load is adequate for the machine which is to be mounted or attached.

Prior to mounting the machine, examine the technical condition of the mower's hitch assembly

and tractor's 3-point linkage.

Use only genuine cotter pins to mount the mower on a tractor.

4.3. Transport

The lifting, handling and transporting operations can be very dangerous unless they are carried out

with the utmost caution. Have all persons not involved in the actual work move away from the area

and limit the zone where the operations are to be carried out. Also make sure that the area in which

the operations take place is clear and that there is a sufficient escape route, i.e. a free, safe zone to

which the operators can quickly move if the load should fall.

The safety hooks and ropes used to lift the machine must be of an adequate carrying capacity.

To minimize the risk of serious injury or death, do the following:

When the machine is converted from the transport position to the work position and vice versa,

you could be pinched or crushed by some of its parts. Take extra care when carrying out these

maneuvers and have all persons keep well clear of the danger zone.

Do not change position of the mower until there are no people or animals around (pay particular

attention to children).

While transporting the mower, put a warning plate with combined lights and reflectors and

warning triangle on the mower.

During transport, always put the mower in its proper and safe transport position. See section 5.3.

Before putting the mower in transport position, make sure that the tractor’s PTO is turned off

and all rotating parts have come to a complete stop.

Do not drive over 25 km/h (15 mph). Drive slower if road conditions are poor, especially on

irregular surfaces or steep slopes.

The behavior of the tractor on the road, such as its turning and braking capacities, are affected

by the implements mounted.

When driving on the road after work, check to make sure that the tires and soil working tools

are clean to prevent the road surface from becoming dirty.

Make sure that the machine is not damaged during transport.

- 11 -

Operator’s manual

Rear disc mowers

KDT

4.3.1. Putting the mower onto another vehicle for transport

The driver and the carrier are responsible for the mower’s transport safety. Equipment and

parts must be secured during transport. To put the mower onto another vehicle in a safe way, please

obey the following rules:

Transport should be done by qualified and specifically trained personnel,

Grab the mower by any lifting devices only in places indicated by hook sign (Fig. 5),

Fig. 5. Transport holders

For mower lifting, use only lifting devices with hoisting capacity larger than mower’s

weight shown in data plate. This also applies to ropes and chains used for lifting,

Do not lift if transport belts, belt suspensions, ropes are damaged. Whenever damage to

these parts occurs, replace with new ones,

When mounting slings, chains, handles etc., always set the machine's center of gravity

properly,

To safely support the machine, use ropes of adequate length so that the angle between them

is no greater than 120°, and the angle between the strand and the vertical is no greater than

60°,

Lift the machine with the utmost caution and move it slowly,

No one should be within the range of action of the lifting equipment when any transporting

operations are being carried out,

Collapsible parts should be blocked in transport position,

When the mower is on the vehicle’s trailer, the machine should be secured against moving.

- 12 -

Operator’s manual

Rear disc mowers

KDT

Fig. 6. Location of centre of gravity on mowers KDT

Tab. 4. Location of centre of gravity

Dimension

[ft in]

KDT 180 KDT 220 KDT 260 KDT 300 KDT 340 KDT 341

Model

A 2′ 5″ 2′ 4″ 2′ 8″ 2′ 4″ 2′ 4″ 2′ 4″

B 5′ 1′ 6″ 1′ 1′ 7″ 1′ 7″

C 2′ 9″ 3′ 2″ 3′ 4″ 3′ 5″ 3′7″ 3′7″

Dimension

[ft in]

KDT 220 S KDT 220 W KDT 260 S KDT 260 SL KDT 260 W

Model

A 2′ 9″ 2′ 9″ 2′ 8″ 2′ 8″ 2′ 9″

B 4′ 5.5″ 8″ 8″ 9″

C 3′ 4″ 3′ 6″ 3′ 5″ 3′ 4″ 3′ 7″

4.4. Working parts

Before operating the mower check knife’s and knife holder’s condition.

Worn or damaged knives or knife holders should be immediately replaced with new one.

4.5. PTO shaft

Before operating, read bar manufacturer's manual placed on the bar. Follow all safety

precautions in that manual.

Use only PTO shafts recommended by mower’s manufacturer with guards in good condition.

In order to operate safely, use only undamaged PTO shafts and shields. Damaged PTO shafts

and shields must be repaired or replaced with new ones before use.

4.6. Hydraulic assembly

Hydraulic assembly is under high pressure. Hydraulic oil under pressure may penetrate skin

and cause serious injury or death. Skin and eyes should be protected when working around this

assembly.

In case of injury caused by a liquid under pressure, call a doctor immediately.

Hydraulic hoses can be connected to the tractor's hydraulics provided that both the tractor’s and

the mower's hydraulic assemblies are not under pressure. To remove the pressure from the

hoses, start the tractor's hydraulic valves several times with the tractor off.

- 13 -

Operator’s manual

When looking for oil leaks, do so safely. Use a cardboard card. Do not touch any potential

Rear disc mowers

KDT

leaks until the entire hydraulic assembly has been relieved of pressure.

Use only hydraulic oil featuring oil purity class 9 - 10 in accordance with NAS 1638.

When using hydraulic hoses:

Avoid stretching the hoses when operating.

Do not allow hydraulic hoses to get deflected.

Do not expose hydraulic hoses to contact with any sharp edges.

If damaged or worn, replace the hoses with new ones.

Useful life for hydraulic hoses is 5 years from their production date.

4.7. Residual risk

Despite the fact that SaMASZ, the manufacturer of the mower, has taken great care in the

design and manufacturing of the mower, certain risks during mower operation and maintenance are

unavoidable. A major source of risk that could result in serious injury or death can occur during the

performance of these operations.

Major source of risk follows performance of these operations:

operation of mower by minors,

operation by individuals who have not read the operator's manual and safety labels,

operation of mower by persons under influence of alcohol or other substances,

not being cautious during transportation and moving mower during operation,

transport of persons who are on the machine,

presence of persons and animals within the mower operation range,

performing servicing and machine adjustments with the engine on.

4.7.1. Danger of machine entanglement

This risk occurs when (1) changing position of a mower, (2) operating near rotating parts, and

(3) working without safety guards. During operation, maintenance and adjustment, always wear

protective gloves, shoes and clothes without loose parts, belts and so on. Always comply with

safety labels placed on the mower.

4.7.2. Danger of cutting injury

This risk occurs during replacement of working parts with sharp edges. During any

maintenance work, always use safety gloves.

4.7.3. Danger of injury from liquid ejection out of hydraulic system

During connection of hydraulic hoses to hydraulic connectors, be sure that tractor’s or

mower’s hydraulic system is not under pressure. Regularly check hydraulic hoses for leaks.

4.7.4. Forbidden actions

During mower’s operation, do not do the following:

never unblock the mower, make any regulations or repairs of the mower while it is in

motion,

never change order of operation and maintenance activities described in operator’s manual,

never operate the mower when it is not in working order or has damaged safety guards,

never get your hands and legs close to rotating parts of the mower,

during repair and maintenance of the mower, always comply with descriptions included in

operator’s manual. Always do these activities when the tractor’s drive is off,

never operate the mower under influence of alcohol, drugs, or strong medicine that impair

your attention,

do not wear clothes or jewelry that are too loose or too tight. Too loose clothing or jewelry

may be pulled in by the rotating parts of the mower,

the mower should not be operated by children or by handicapped people,

When describing residual risk, the mower complies with the state of the art in technology on the

date it was manufactured.

- 14 -

correctness of its usage, if the noise level in work place reach

es or exceeds 85 dB

.

Operator’s manual

Rear disc mowers

KDT

4.7.5. Residual risk assessment

Residual risk occurs from not complying with the instructions and safety precautions. Such risk can

be minimized by doing the following:

thorough familiarizing yourself with operator’s manual,

allow no persons on the machine when operating,

allow no persons within the mower operation range,

adjust, maintain and lubricate the machine with the engine off,

only skilled persons should perform repairs of the machine,

children and strangers must keep away when the machine is operating,

When the risk of exposure to noise cannot be avoided or eliminated by any

protective means or organization of work, the employer (farmer) must:

1) provide the operator with individual means of noise protection if the noise level

in work place exceeds 80 dB.

2) provide the operator with individual means of noise protection and supervise the

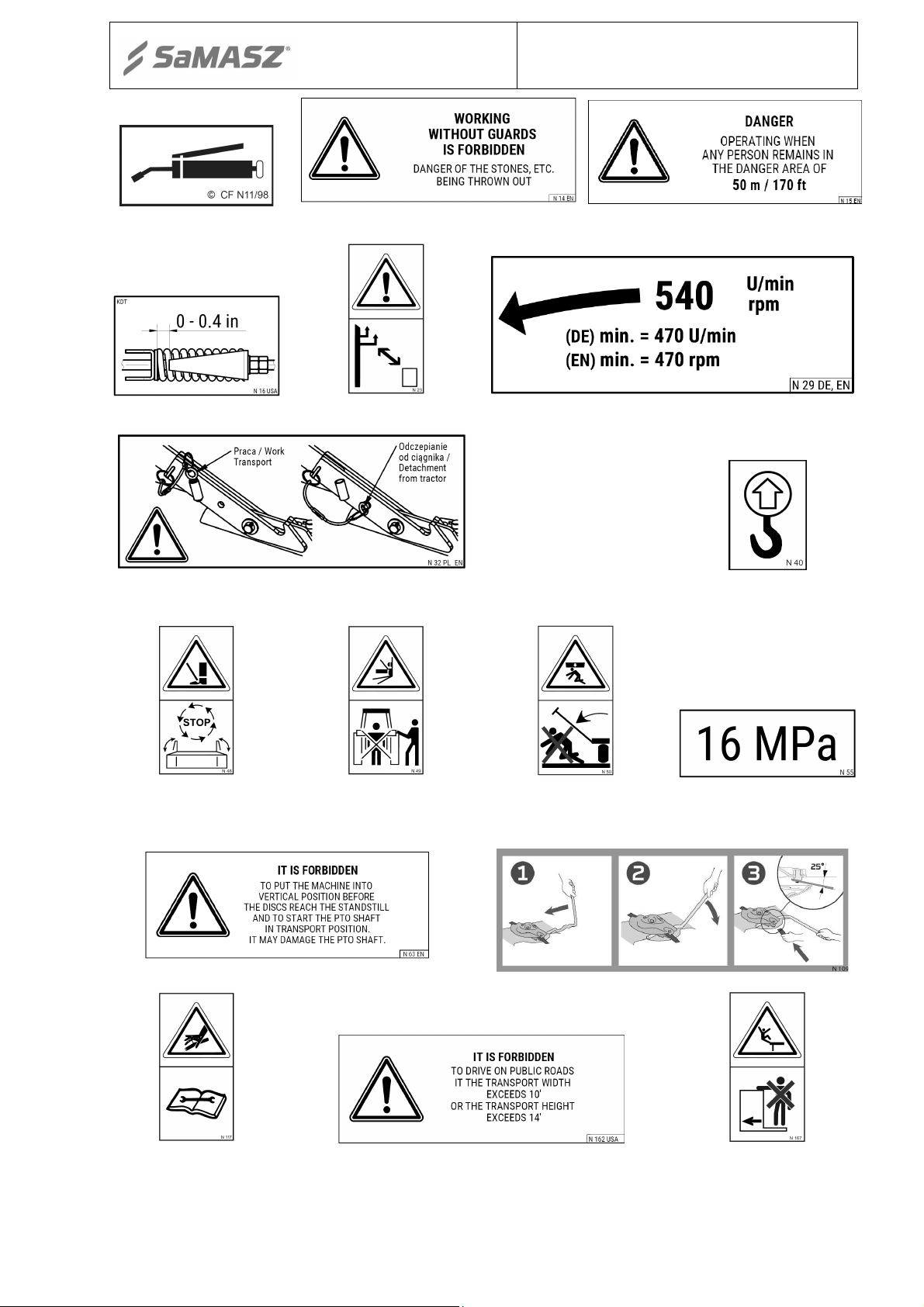

4.8. Safety labels and their meaning

Safety labels are critical to safe use of this mower. They must be read, understood and followed.

Also, be sure that:

All warning decals are clean and legible

All lost or damaged decals are replaced by ordering new decals from your dealer or supplier

All persons using this mower have read the section of this manual explaining the meanings of

these labels

All spare part used for repair of the mower should have all safety labels provided by the

manufacturer.

N-01

Be extremely careful when

PTO shaft is rotating

N-05

CAUTION: belt

transmission, be extremely

careful

N-02

CAUTION: cutting knives.

Approach during operation

is forbidden

N-06

CAUTION: pulling-in

parts

N-03

Read the operator’s manual

before putting the mower

into operation

N-07

Operating is forbidden

when any person is within

the danger area of 170'

N-04

While making repairs the

machine must be stopped

N-09

CAUTION: rotor

- 15 -

Lubrication point

Watch out: power lines

the mower

steering tractor’s lift

Operator’s manual

Rear disc mowers

KDT

N-11

N-16 N-23

N-32 N-40

N-14 N-15

N-29

Transport hook for lifting of

N-48

Stay a way from mower’s

inclination area

N-63 N-109

N-117

Under pressure. Consult

technical manual for

service procedures

N-49

Never stand near tractor’s

3-point linkage while

N-50

Do not stay in the swinging

area of mower’s parts

N-162 N-167

Do not remain on the

machine while driving

N-55

- 16 -

04

48

N-40

N-40

N-187

N-149

N-55

N-109

Operator’s manual

Rear disc mowers

KDT

N-168

Do not touch the machine

before the rotating parts

have not come to a

complete standstill

N-206

Use the required Personal

Protective

Fig. 7a. Placement points of warning signs on mower without conditioner

N-187

Cutterbar "Perfect Cut"

N-213

(for KDT S/SL)

N-29

N-05; N-16

N-204

Use the required Personal

Protective

N-224

Do not open and remove

safety guards with motor

operating

N-32

N-205

Use the required Personal

Protective

N-14; N-15

N-63; N-162

N-01 ; N-02 ; N-03 ; NN-06 ; N-07 ; N-23 ; N-

N-49 ; N-50 ; N-117

N-167 ; N-168 ; N-204

N-205 ; N-206 ; N-224

- 17 -

N-149

N-187

04

48

N-205 ; N

-

206 ; N-224

N-109

N-40

N-201

N-40

Operator’s manual

Fig. 7b. Placement points of warning signs on the mower with tine/roller conditioner

N-29

N-05

N-16

N-32

N-14; N-15

N-63 ; N-162

N-09

N-213

Rear disc mowers

KDT

N-01 ; N-02 ; N-03 ; NN-06 ; N-07 ; N-23 ; N-

N-49 ; N-50 ; N-117

N-167 ; N-168 ; N-204

CAUTION:

Any spare part used for repair of the mower should have all warning decals

provided by the manufacturer.

5. OPERATION

WARNING:

Before beginning to use this machine, do the following:

- Read manual, especially safety precautions in section 4.

- Make sure you are familiar with all controls and functions.

- Make sure all safety devices are in place and working. Fix or replace if not

working or damaged.

- Replace protective cover if damaged.

5.1. Attaching the mower to the tractor

WARNING:

-

Only hitch and unhitch machine on a flat surface with compact dirt.

- Keep everyone away from area between mower and tractor.

- Be careful near link road zone of tractor's rear power lift. Contains sharp parts.

Mower’s frame is adjusted to be attached to the tractors with 3-point-linkage (Fig. 8). The mower

has been attached, adjust (on the flat ground) the mower’s position by means of top S and lower W

links (Fig. 8). The cutterbar should lean towards the driving direction. Lower links W should be

connected to 3-point linkage frame pins A. Support chain L holds up mower’s linkage frame. Insert

and tighten the safety pins into the pin holes and make sure that they are well locked. Connect

hydraulic hose to tractor’s hydraulic connector.

- 18 -

Z

A

W

Operator’s manual

Rear disc mowers

KDT

After the mower has been attached to tractor, check the balance and steerability of tractor-mower

set. To do this, calculate to formulas given in the appendix or weigh the set, and then drive on the

scales only with front axis of the tractor (the mower must be in transport position – lifted upwards).

If the pressure on the front axis is at least 20 % of the whole set’s pressure, it means the set is

stable. If not, the front axis should be balanced.

S

L

Fig. 8. Connecting the mower to the tractor

1

2

a)

3

b)

Fig. 9. a) 1 - pin, 2 - bush, 3 – hole in the bar b) Z - lock

WARNING:

Before disconnecting the mower put the pin 1 into the hole 3 in the bar (Fig.

9a) to secure the linkage against falling. When the mower is connected the

pin should be in the bush 2 on the middle bar.

5.2. Preparing the mower for transport

To prepare the mower for transport and to meet safety precautions, please do the following:

lift the mower with tractor hydraulic lift until the lower lift pins of the mower 3-point linkage

frame raise about 1' 8'' above the ground (Fig. 11),

lift support leg up and secure it with split cotter,

remove the pin 1 and put it into the bush 2 (Fig. 9a),

lift the cutterbar by hydraulic cylinder vertically until the pawl Z locks in (Fig. 9b),

secure the cutterbar against falling by the shut-off valve (Fig. 10b) placed on the mower’s

hydraulic cylinder.

WARNING:

During transport the shut-off valve of mower hydraulic lift should always be

closed – the valve lever in Z position (

Fig. 10

). It protects the mower against

incidental falling in case of hydraulic failure.

- 19 -

b)

Operator’s manual

O

Rear disc mowers

KDT

Z

a)

Fig. 10. Shut-off valve position: a) open(work), b) closed(transport)

'2''

'8''

Fig. 11. Rear disc mower in its transport position

5.3. Preparing the mower for transport on public roads

WARNING:

Legal requirements for transport on public roads may differ from state to

state. Check your location’s requirements and comply.

To comply with safety precautions concerning transport on the public roads the mower should be

equipped with the following devices:

portable warning-light plates, to be mounted on both sides of mower top guard in their

holders. The panel consists of warning plate with combined lamp mounted (parking, stop

lights and driving direction) and with red reflectors facing the rear and white light on the

front.

WARNING:

Do not drive on public roads if the machine’s transport height is more than

13' 2'' (when transported, transport height should be lowered on the tractor

links).

5.4. Mounting PTO shaft

PTO shaft’s end with overrunning clutch should be mounted on mower’s side.

When connecting PTO shaft between tractor and mower make sure that external guard tube of the

shaft is on the tractor’s side. The PTO shaft plastic guards have to be secured by fastening their

small chains to immovable parts of tractor and mower. The PTO shaft must operate at the lowest

possible angle. This will ensure that both shaft and the machine last as long as possible.

CAUTION:

If need be, shorten the PTO shaft according to its operator’s manual given by

the shaft’s manufacturer (

Fig. 12

).

- 20 -

Operator’s manual

Fig. 12. Instruction of PTO shaft shortening

CAUTION:

Handle all parts with utmost care. Never place your hands or fingers between

one part and the other. Wear safety clothes such as gloves, protective

footwear and goggles. The operation of shortening must be carried out with

the utmost care as the PTO shaft will have to be replaced if the telescopic

shafts are shortened to an excessive extent.

CAUTION:

The PTO shaft should be mounted only during operation time and

disconnected from tractor PTO for transport and service.

NOTICE:

The manufacturer declines all liability for damage caused by an incorrectly

fitted or used PTO shaft.

CAUTION:

Use the machines with PTO shafts designed to drive them. Before the work

begins, check the safety guards (in tractor, mower and PTO shaft), if they are

placed correctly and are not damaged. Damaged or lost parts must be replaced

with genuine ones. Make sure the PTO shaft is properly mounted. It is forbidden

to approach the rotating parts, because it may lead to serious injuries or even

death. All service and repair operations must be done only after the tractor

engine has been stopped and ignition key off, all rotating parts have come to

the complete standstill and the cutterbar is on the ground. Before the operation

begins, read operator’s manuals of both the machine and PTO shaft.

5.5. Moving from transport to working position

Rear disc mowers

KDT

WARNING:

Moving the mower to and from operating position from the transport position

should only take place on even and stable ground. Prior to making the moves

make sure whether there are no unauthorized persons exposed to any

The safely move to the operating position, do the following:

open the shut-off valve on the hydraulic cylinder (Fig. 10a),

lower the mower until the cutterbar is at least 1′ 4″ above the ground,

make sure there is nobody around in the place where you are going to lower the mower,

hazardous moving parts.

- 21 -

max. 30º

Operator’s manual

tighten the cord until the lock Z is released (Fig. 10a) and by means of hydraulic cylinder put

Rear disc mowers

KDT

the mower into horizontal position,

with tractor’s lever lower the cutterbar to reach the horizontal position in a possibly slow way,

lower the mower until the support chain tightens. If the 3-point linkage frame is more than

1′ 4″ above the ground, adjust the chain.

By means of link S (Fig. 8) adjust the cutting height. Extending the link S increases the cutting

height and shortening the link reduces it.

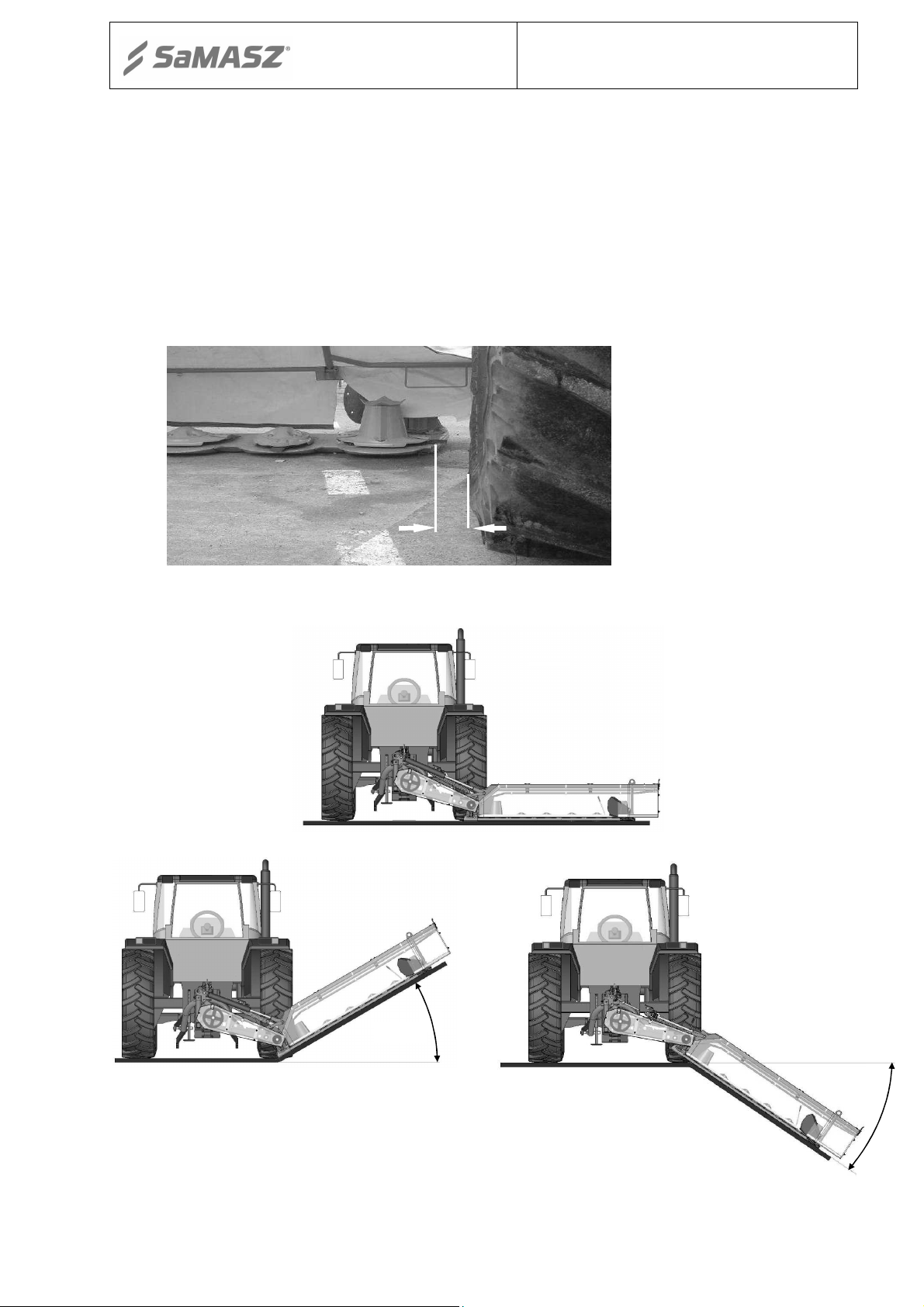

The proper distance between the end of cutterbar and tractor’s tyre Y should be about 0 to 4″ for

KDT 180, KDT 220, KDT 260. For KDT 300 Y should be between 11.8″ and 1′ 4. For KDT 340,

KDT 341 between 1′ 8″ and 1′ 12″.

For KDT 180; KDT 220;

KDT 260

Y = from 0 to 4″

For KDT 300

Y = from 11.8″ to 1′ 4″

For KDT 340;

KDT 341

Y = from 1′ 8″ to 1′ 12″

Y

Fig. 13. Proper distance between the cutterbar and tyre

5.5.1. Operating positions of the mower

max. 30º

Fig. 14. Operating positions of the mower

- 22 -

Operator’s manual

Rear disc mowers

KDT

5.6. Preparing the mower for work

NOTICE:

Before sale SaMASZ protects the cylinders with special grease against

weather which may cause premature wear. Before operating the mower,

remove the exceess grease from the cylinders.

Put the mower into motion when the cutterbar is on the ground so that oil can fill the whole

cutterbar. When the mower is in working position, please do the following:

be sure cutterbar to the ground,

connect PTO shaft between tractor and mower,

by means of upper regulating bar of the mower, adjust the cutterbar’s height and inclination

towards the ground. Proper inclination of the cutterbar is between 0° and 5°. It is regulated by

extending or shortening the bar,

slowly engage the PTO clutch and wait until the cutting unit reaches its rated speed. Tractor’s

engine rpm should be considerably lower, so that the fuel consumption could be reduced,

engage tractor gear and drive slowly into the grass-field. Flat meadows can be mowed with any

speed. If the meadow in uneven, reduce speed.

WARNING:

Do not operate the conveyor when it is in vertical position.

NOTICE:

DO NOT pull the cutterbar towards the tractor, because it will lead to

cutterbar’s premature wear or even its damage.

WARNING:

Improperly relieved cutting unit of the mower will cause increase of cutterbar

pressure on the ground which will lead to faster wear of sliding skids, overload

of cutterbar, higher fuel consumption, damage to the stubble and

5.7. Operation (mowing)

contamination of the fodder.

WARNING:

The operator must be seated in the tractor’s driver’s seat when the machine is

operating since only from that position is he able safely and properly operate

the mower. Before he leaves the driver’s seat, the operator must stop the

engine, apply the parking brake and turn off the tractor engine.

Always use appropriate protective equipment (safety footwear, gloves, ear protection and dust

mask)

Before using the machine, make sure that all the safety devices are in their correct positions and in a

good condition. These safety devices must be immediately replaced if they are faulty or damaged.

In particular, the protective cover must be checked regularly. It must be immediately replaced if it is

missing or damaged in any way.

IMPORTANT: If a disc mower is your first experience (you have mowed with 2-drum mower),

you need a piece of essential information:

1. Main advantage of disc mowers is their small power demand – 20% less tractor power, small

moment of inertia and possibility to manufacture mowers with large working width.

- 23 -

Operator’s manual

Rear disc mowers

KDT

2. There is however a certain disadvantage - creased stubble, especially when it comes to lying

grass. Straight grass may be mowed with horizontal adjustment of the mower and then the

stubble will be even, but it will not look as attractive as with 2-drum or 4-drum mowers,

because the knives work horizontally to the ground and inclined grass bends because of wind

blasts. After the grass is mowed, it stands up, which makes an impression of inaccurate mowing.

Every mower may leave stripes of uncut grass when it comes to the knives which cut the grass

towards the grass direction.

It is a normal phenomenon. Practically, it is not possible to achieve such attractive stubble as in

2-drum mowers, because the knives work horizontally or at an angle of up to 8° to the ground,

and when it comes to 2-drum and 4-drum mowers, slantwise through the ground (even 23°).

Despite these ‘disadvantages’, disc mowers are ‘winning farmers’ trust’ and modern

technologies give an opportunity to manufacture very durable mowers.

3. The most even stubble with very low grasses is obtained with disc mowers when half of

the discs rotate to the right and half to the left. A disadvantage of this system is a narrow and

thick windrow which needs to be spread out.

5.7.1. Essential information concerning mowing

Optimum work parameters

1. Inclination towards the front 0-5 degrees which equates to 1.8" - 2.8" of mowing height.

2. Operation speed around 6 mph or more, if the conditions allow.

3. PTO rpm = 470-520 rpm. PTO rpm less than 540 may cause stripes of uncut grass between the

disc.

High and inclined grass

1. Heighten the cutterbar’s inclination to H = about 1.8".

2. If there is no inclination the grass will be wedged on the forming drums.

3. Speed can be more than 8 mph (the faster – the better).

4. Do not turn in the mowed grass.

Optimum inclination of the cutterbar towards the ground is between 0° to 5°. If the inclination

exceeds 5°, there might be a slight unevenness of mowed grass. It impairs slightly the quality of

mowing and has an influence on the mower’s operation. When the cutterbar is pulled in the other

direction, it significantly impairs the quality of mowing and in some cases the mower stops

mowing. Besides, it may lead to premature wear or even damage of the slides and cutterbar.

When high grass prevails, first and second cut should be mowed at height level 2.4" - 2.8", but

when the grass grows low it should be mowed at 2". The last cut should be mowed a little bit

higher, 2.8" - 3" above the ground.

Too high a PTO rpm whirls the air, which may cause inclination of the grass in front of discs,

which impairs the quality of mowing.

Too low a PTO rpm impairs the quality of mowing and in some cases the mower stops mowing

(too low linear velocity of the knife).

In contrast with 2-drum mowers, straight mounting of the mower and full speed are not always

possible. Adjust inclination of the mower, PTO rpm, speed and correctness of knife-mounting to

get the best results.

In case of mowing soft meadows, the pressure of the cutterbar on the ground should be reduced

by adjusting support springs.

Always check to make sure that the ground speed suits the conditions or work and that it does

not create a potential source of danger

Do not take sharp turns anytime and do not operate in reverse.

- 24 -

device operates

R

Operator’s manual

Fig. 15. Shape of the stubble with cutterbar’s inclination 0°, 3° and 5°

5.7.2. Design and and operation of safety breakaway device

Rear disc mowers

KDT

In the event of hitting an immovable obstacle one of the safety device flat bars slides out and

disconnects the safety device. After that the mower folds back about 34 degrees (Fig. 17).

The operator has time to shut off the tractor and protect the mower. Safety device spring is

adjustable (Fig. 16), therefore changing the force needed to make safety device work.

Fig. 16. Safety device

Fig. 17. The mower breaks back when the safety

- 25 -

take turns

to take turns

Operator’s manual

Rear disc mowers

KDT

Recommended length of safety device spring R (Fig. 16) should be 5.6". If the safety device breaks

away too easily, tighten up the spring approximately .04"-.08". DO NOT tighten up too much,

because you may prevent the safety device from working and damage the mower.

5.7.3. Mower clogging

When operating the mower, pay attention to variable conditions on the field, which may cause the

mower to clog, such as: terrain unevenness, height and density of grass as well as other objects in

the grass. In order to avoid clogging, mowing speed should be adjusted to the conditions. In order to

take care of machine clogging, lower the cutterbar onto the ground, disconnect the drive and

remove the ignition key. When eliminating the mower's clogging wear all appropriate protective

gear.

5.7.4. Taking turns over swaths

Lift the mower with hydraulic cylinder and take the turn. The mower does not need to be

additionaly lifted by tractor’s 3-point linkage.

Fig. 18a. KDF & KDT mower set prepared to

Fig. 18b. KDF & KDT mower set prepared

5.8. Storing

Mower should be stored in paved, dry places, protected against precipitation. In order to

minimize the space necessary for storage the mower may be stored in a vertical position but always

on paved surface. Storing the mower on an unpaved surface may cause the mower to lose stability

and turnover.

NOTICE:

When stored for long time (e.g. in winter season), the machine should be in an

upright position on paved surface (with closed cylinders). Storing the mowe in a

horizontal position may cause faster wearing (rusting) of the cylinder from the inside

(through vent valve) by being penetrated by moisture from the air.

5.9. Dismounting mower from tractor

WARNING:

When dismounting, make sure there is no person in between the mower and

the tractor.

To dismount the mower from the tractor:

turn cutterbar's drive off,

place the mower on even, paved ground, lower and protect support legs, check, if the mower is

properly protected against falling,

turn the tractor's engine off and take ignition key off,

dismount tractor's rpm and place it on a PTO shaft holder, that is standard-delivered with the

mower,

disconnect hydraulic hose,

detach tractor's upper link and lower strands from mower's linkage.

- 26 -

Operator’s manual

Rear disc mowers

KDT

6. MOUNTING AND ADJUSTMENTS

6.1. Mounting and timing of the knives

The knives should be mounted as shown in

manufacturer recommended knives are measured 105x49x4 and conform to standard PN-EN

795:2002. Mount the knives so that cutting edges are directed towards ground, so that a knife lifts

the grass after cutting.

Fig. 19. Mounting of the knives on mowing discs

WARNING:

- Use only knives recommended by manufacturer.

- Check condition of knives and holders before each operation. Worn or

damaged knives should be replaced immediately.

6.2. Replacing the knives

Replace knives, if necessary, only in sets. Make sure all knives in a set are of the same length

and weight. The knife holders (Fig. 30) must not be damaged or deformed. If the knife holder pin is

worn too much, please replace it immediately.

NOTICE:

During work, if mower begins to shake, it means that the disc (discs) are

operating only with one knife. In that case, using the mower in this

condition for a long time could cause serious damage to the cutterbar.

WARNING:

When replacing knives, the engine must be stopped and the cutterbar must

lie on the ground. PTO shaft must be disconnected. Discs should be

perpendicular to cutterbar.

Fig. 20. Quick replacing of the knives with mounting lever

Fig.

19 and Fig. 20. The knives recommended by the

- 27 -

Operator’s manual

6.3. Adjusting the cutterbar

Rear disc mowers

KDT

Swath width is adjusted with swath guides mounted on the 3-point linkage frame of

the cutterbar (Fig. 21).

In order to adjust the guide, the following should be performed (for: KDT 180, KDT 220,

KDT 260, KDT 300, KDT 340):

loosen locknuts (2) and screws (3),

shift the guide arm (6),

tighten screws (3) and locknuts (2),

loosen locknuts (4) and screws (5),

then adjust height and shield angle (7),

tighten screws (5) and locknuts (4).

1

3 2

6

5

4

7

Fig. 21. Adjustment of swath guides: 1 - swath guide, 2 - locknuts, 3- arm adjustment screws, 4 - locknuts, 5-

shield adjustment screws, 6- guide arm, 7- shield

In order to set swath width, adjustment of swath guides (1) should be performed (Fig. 22)

(for: KDT 220 S, KDT 260 S, KDT 260 SL):

loosen eye screw (2) of the swath guide,

set the swath guide (1) as needed,

tighten screw (2),

even spreading of swath might be adjusted with wheels (3) the same as it is preformed with

guides.

- 28 -

Operator’s manual

Rear disc mowers

KDT

1

2

1

Fig. 22. Adjustment of swath guides: 1- swath guide, 2 - adjustment screw, 3 - swath wheel

In order to set swath width, adjustment of swath guides (1) should be performed (Fig. 23)

(for: KDT 220 W, KDT 260 W):

loosen eye screw (2) of the swath guide,

set the swath guide (1) as needed,

tighten screw (2).

1

2

1

Fig. 23. Adjustment of swath guides: 1- swath guide, 2 - adjustment screw

NOTICE:

Before you change the knife check disc turns (Fig. 24).

CAUTION:

Different mounting of the knives will block the mower. When mounting pay

particular attention to loose rotation of the knife on the knife holder pin.

- 29 -

Operator’s manual

Rear disc mowers

KDT

NOTICE:

Due to high discs rpm speed, change knife holders in sets of the same weight

– each holder has weight marked. Improperly changed knife holders will

damage disc bearings.

KDT 180 KDT 220

KDT 260 KDT 300

KDT 340

KDT 341

Fig. 24. Rotation directions of disks

6.4. Adjusting the cutting height

By means of upper link S (Fig. 8) adjust the cutting height.

Extending the link S increases the cutting height and shortening the link

reduces it. Cutting height is shown by the scale placed on the 3-point

linkage frame (Fig. 25), recommended height is 1.8"÷2.8".

Fig. 25. Cutting height scale

Disc with the

forming drum

Disc without

the forming drum

- 30 -

~1'4"

Operator’s manual

6.5. 3-point linkage support chain

a)

Support chain is used to ensure 3-point linkage frame of the mower is always at the same

height, to set the mowing unit parallel to the ground and to relieve the hydraulic lift of the tractor.

When connecting mower to the tractor, the hanger plate A of support chain should be disconnected

from chain and put on the pin B of upper link (Fig. 26a). Then the mower has to be lifted with

hydraulic lift about 1'4" high (Fig. 26b). The support chain is then connected to the hanger plate A,

so that is tensioned when the mower is in its working position. If the 3-point linkage frame is more

than 1'4" above the ground, adjust the chain.

6.6. Adjusting the space between tine conditioner’s mask and its shaft

(Models: KDT 220 S and KDT 260 S(SL))

Depending on size and thickness of the mowing grass, there may be a necessity to adjust

the mask of the conditioner. The higher and thicker grass, the bigger the space between

conditioner’s mask and its shaft should be. Proper adjustment should be based on the experience, in

order not to block the conditioner and not to activate the friction clutch of PTO shaft. The way how

the mask is regulated is shown in Fig. 27.

Fig. 27. Adjusting tine conditioner’s mask

B

A

b)

Fig. 26. Support chain

+

Rear disc mowers

KDT

-

- 31 -

Operator’s manual

Rear disc mowers

KDT

6.7. Replacing the conditioner’s tines

(Models: KDT 220 S and KDT 260 S(SL))

Prior to commencing any operation, check condition of bolts on which flails are set, as well as

condition of fails themselves. If flails or bolts are worn or damaed, it is necessary to replace them.

Bear in mind, that flails should be replaced in pairs (opposite) featuring the same weight

in order to keep shaft well balanced. Not keeping the shaft well balanced may lead to premature

wearing of bearings as well as the shaft itself.

Replacement of flails 3 consists in unscrewing of nuts 2, removing bolts 4 and mounting

brand new flails 3 (Fig. 28).

NOTICE:

In order to tighten screw connection use special purpose bolt M16×60 z.

Property Class 10.9 and self-protected nut M16 z. Property Class 8.8; torque

down until tight.

1. Scarfier shaft

2. Self-locking nut M16 z. Property Class 8.8

3. Flail

4. Bolt M16x60 kl. 10.9

1. Scarfier shaft

2. Self-locking nut M16 z. Property Class 8.8

3. Washer

4. Plastic flail

5. Bolt M16x60 kl. 10.9

6. Plastic flail insert

Fig. 28b. Replacement of flails in light-weight conditioner roller

Fig. 28a. Parts of tine conditioner

1

2

3

6

5

4

- 32 -

Operator’s manual

Rear disc mowers

KDT

Tab. 5. Torque values for bolts

In the absence of specific torque values, the following chart can be used as a guide to the

maximum safe torque for a particular size and grade of fastener. There is no torque difference for

fine or coarse threads. Torque values are based on clean, dry threads. Reduce value by 10% if

threads are oiled before assembly.

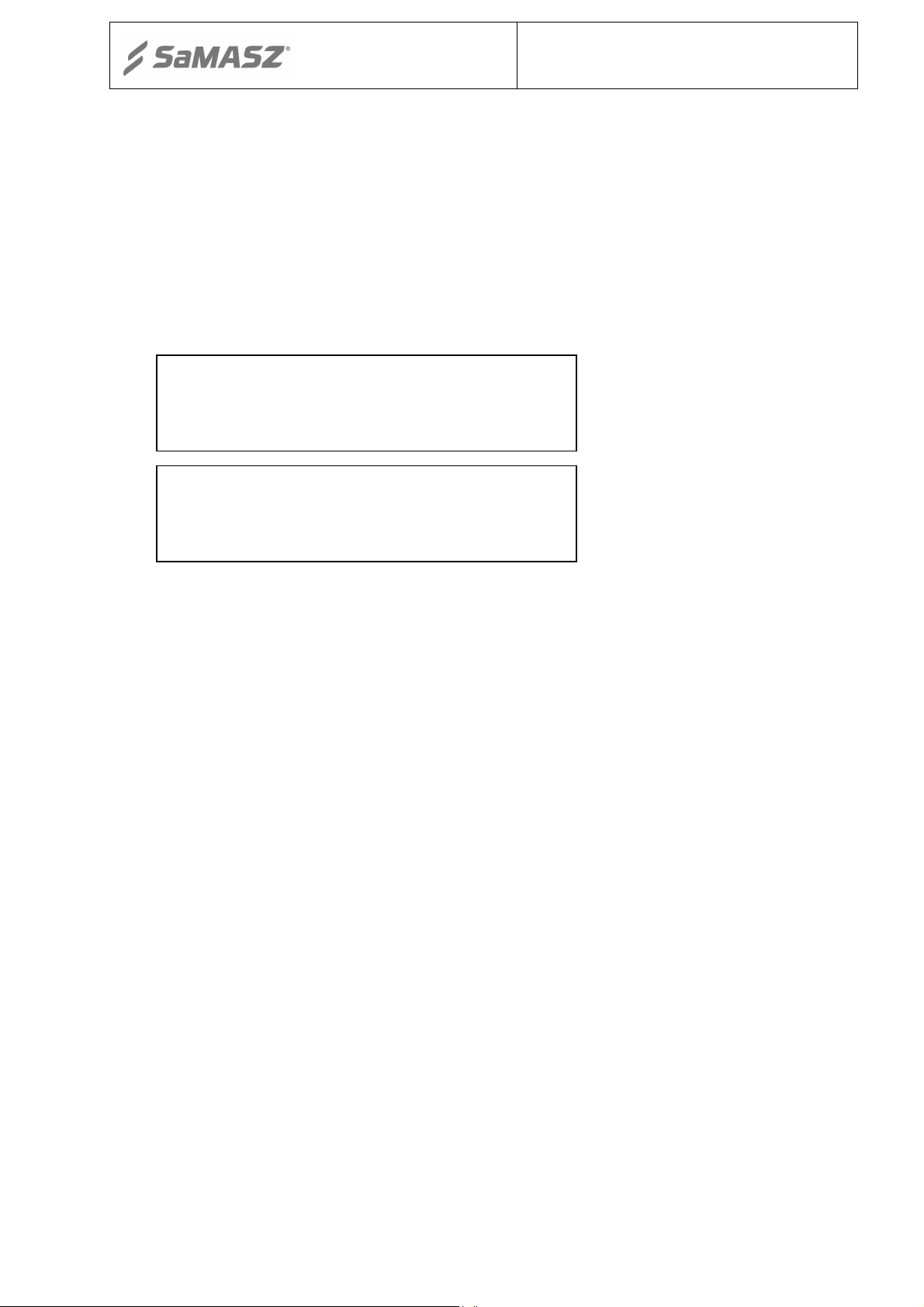

6.8. Adjusting force of the prssure of roller conditioner

(Models: KDT 220 W and KDT 260 W)

If need be, the force of the roller conditioner’s pressure can be regulated by changing

the tension of springs S (Fig. 29) by means of the nut N. Adjustment should be done on both sides

of the conditioner

N

S

Fig. 29. Adjusting the force of the pressure of roller conditioner

6.9. Maintenance and service

6.9.1. Checking the knives and knife holders

All knives should have the same lengths and weights. Always check mower before starting

work for damaged, missing and/or worn knives. Replace them, if necessary, only in sets.

If the knife holder pin is worn too much and/or the knife holder is worn or deformed, please

replace it immediately (Fig. 30).

- 33 -

b)

Operator’s manual

Rear disc mowers

KDT

a)

10min.

Fig. 30. Permissible wear of knife holder pin on disk a) knife base M12 b) knife base M12 with claw

NOTICE:

If the knife is missing or disc cover plate is damaged the vibrations may

occur, which leads to cutterbar’s damage. In that case warranty claim will be

revoked. If the disc or disc cover plate is damaged, the whole set must be

immediately replaced (2 knives) with new genuine ones.

6.9.2. Checking the tension of the V-belts

Check the V-belt tension. V-belts are tensioned with spring tensioner (Fig. 31) equipped with

checking plate. Distance S between plate tip and holder should be 0.4". If the gap is wider the

V-belts will be looser. Tensioning is done by nuts N. When any of the belts are damaged,

the complete set must be replaced.

S

Fig. 31. Spring V-belts tensioner

6.9.3. Inspection of tension of toothed belt for gears of rollers and conditioner

Drive from cog gear shaft is transmitted on rollers/conditioner roller axles through toothed

belts. Constant belt tension is provided by tensioner adjustable with tensioning nut N (Fig. 32b)

Belt tightening can be checked through eye O (Fig. 32a and c). In order to tension the belt

remove safety guard (Fig. 32a and c) having unscrewed four nuts S. Then, tension the toothed belt

using tensioning screw and nut N (Fig. 32b and d). Properly tensioned belt, when pressed with

thumb in the middle should deflect by approx.. 0.2".

N

- 34 -

O

Operator’s manual

Fig. 32a. Rollers transmission guard

Fig. 32c. Conditioner roller transmission

6.9.4. Daily maintenance

S

guard

Rear disc mowers

KDT

N

Fig. 32b. Adjusting tension of transmission

toothed belt

Fig. 32d. Adjusting tension of toothed belt for

conditioner roller transmission

When you finish each day of operation carry out the following maintenance:

check all visible parts and components and their connections; tighten all loose bolts and nuts

and replace all damaged and/or worn parts with new genuine ones,

clean the mower, especially between discs and cutterbar, because grass with mud may damage

bearings in disc module,

remove grass and mud,

check the cutterbar,

grease PTO shaft tubes with STP grease,

if necessary, lubricate the parts and components according to lubrication instructions (chapter7).

Parts which may cause risk to operator’s health and safety are as follows: damaged discs, missing or

damaged safety covers, worn or damaged hydraulic hoses, PTO shaft guides, worn knives and knife

holder pins.

6.9.5. After-season maintenance and storing of machine

At the end of mowing season the following shall be performed:

lower the mower’s cutterbar onto the ground,

take the PTO shaft extension out of the tractor rpm or dismount the complete PTO shaft and

install it into corresponding holder at the 3-point linkage frame,

unmount hydraulic and electrical hoses from the tractor and hang them onto corresponding

holders on the 3-point linkage frame,

- 35 -

Operator’s manual

unmount the mower from the tractor (reverse procedure as in case of attaching the mower to

Rear disc mowers

KDT

the tractor item 5.1), and then drive the tractor away.

Mower should be stored in standstill position, so it is supported onto supporting leg and the

cutterbar. It is recommended to store the set on paved ground, preferably in roofed places,

inaccessible to unauthorized personnel or animals.

If the machine is stored for a long period of time before first operation, its technical condition

should be examined and special attention should be paid to the hydraulics and the drive. Paint the

area where the paint is missing, hydraulic hoses checked and lubricated.

Additionally:

remove any traces of rust and paint the area,

check the oil level in the angle drives and the cutterbar (Section 7). If leaks are discovered, they

should be repaired immediately and lost oil replaced. If water in oil is discovered, immediately

change the oil as it could cause corrosion of internal mechanisms such as gear wheels, bearings,

or shafts, and cause breakdowns,

periodically inspect the mower and lubricate moving parts in order to protect them from

corrosion which adversely affects the proper operation of the mower,

check hydraulic hoses regularly. Replace any damaged or old hoses. In any case, you should

replace hoses that have been in use more than 5 years from the date of their manufacture printed

on the hose.

7. LUBRICATION

7.1. Cutterbar

Refilling the oil of the cutterbar is done through the inlet A (Fig. 33). Proper oil level is 0.2" -

0.3" from the cutterbar bottom. Oil capacities are given in table below.

Tab. 6. Oil capacities

Model Oil capacity [l] Oil type Lubrication frequency

KDT 180 – 5' 11" 3.5

KDT 220 S/W – 7' 3" 4.5

KDT 260 S,SL/W – 8' 6" 5.0

KDT 300 – 9' 10" 6.0

KDT 340 – 11' 2"

KDT 341 – 11' 2"

6.5

80W90

(if working intensively more frequently)

Once every 3 seasons

A

Fig. 33. Point of oil inspection a) and manner of oil replacement in cutterbar b)

b)

In order to drain oil out of the cutterbar, firstly lift the mower up onto tractor's links and then

dismount the cutterbar closure as shown on Fig. 33b and tilt the cutterbar so, as to enable the old oil

to drain. Oil drained out of the cutterbar should be disposed in a proper manner.

- 36 -

[

US gal lqd

]

(if working intensively)

C

A

B

Operator’s manual

Rear disc mowers

KDT

7.2. Intersecting axis gear

Everyday before starting work please check the oil level and, if needed, please refill after

having removed the vent A on the top of the gear (Fig. 34). The oil level can be checked through

the check opening B on the side of the gear. Please refill the oil until it is visible in the check

opening B. The oil capacity: about 0.26 US gal lqd.

Tab. 7. Oil capacities

Oil

Model

Capacity

[US gal lqd]

Oil type Lubrication frequency

All types

0.26

Transol 680 ÷ 1000

(acc. to ISO 3448 oil

viscosity grade :

VG-680 – 1000 )

Once every 3 seasons

(if working intensively

more frequently)

Fig. 34

IMPORTANT:

The above instructions should be strictly followed. If the discs in

the cutterbar rotate loosely, do not worry about the high intersecting axis

gear temperature; after long working time it may reach even 100oC.

7.3. Roller conditioner’s gearbox

Before you check the lubrication of the gearbox, please remove the safety guard. Everyday

before starting work please check the oil level and, if needed, please refill after having removed

the vent A on the top of the gearbox (Fig. 35) The oil level can be checked through the check

opening B on the side of the gear. Please refill the oil until it is visible in the check opening B.

The oil level: about 0.13 US gal lqd. Check oil level when the cutterbar is on the ground. Removing

the worked oil from the gearbox is done through the outlet C.

Tab. 8. Oil capacities

Model

Oil capacity