SalvisLab VC20, VC50 Instruction Manual

Vacucenter VC20 / VC50

ew

User Manual

Copyright © SalvisLab / Edition 191107 Copyright © SalvisLab / Edition 191107

swiss made

User Manual Vacucenter VC20, VC50

CE DECLARATON OF CONFIRMITY...............................................................................................................4

IMPORTANT INFORMATION............................................................................................................................5

QUICK INFORMATION FOR SERVICE ....................................................................................................................5

TECHNICAL DATA’S ........................................................................................................................................6

TECHNICAL DATA’S VACUUM DRYING OVEN........................................................................................................6

INTRODUCTION ................................................................................................................................................7

OVERVIEW ........................................................................................................................................................7

APPLICATIONS...................................................................................................................................................7

CONSTRUCTION ................................................................................................................................................7

VACUUM AND AIR SYSTEMS ...............................................................................................................................7

CONTROLLER ....................................................................................................................................................8

SAFETY ............................................................................................................................................................8

GETTING STARTED..........................................................................................................................................9

PARTS DELIVERED.............................................................................................................................................9

INSTALL REQUIREMENTS ....................................................................................................................................9

INSTALLING .......................................................................................................................................................9

CLEANING .........................................................................................................................................................9

SYSTEM COMPONENTS................................................................................................................................10

CONTROLLER.................................................................................................................................................11

KEYPAD & DISPLAY .........................................................................................................................................11

OPERATING ....................................................................................................................................................12

HOW TO INTERPRET DISPLAYS DESCRIBED IN THIS MANUAL................................................................................12

MAIN MENU - OVERVIEW .................................................................................................................................13

1 MAIN MENU - TEMP & OPTIONS ....................................................................................................................14

2 MAIN MENU - PROGRAM ...............................................................................................................................16

2.1 MENU PROGRAM - START ..........................................................................................................................17

2.2 MENU PROGRAM - NEW.............................................................................................................................18

2.3 MENU PROGRAM- EDIT..............................................................................................................................20

2.4 MENU PROGRAM - DELETE ........................................................................................................................23

2.5 MENU PROGRAM - PRINT...........................................................................................................................23

3 MAIN MENU - CONFIGURATION......................................................................................................................24

4 MENU SERVICE MODE ..................................................................................................................................26

STATUS DISPLAYS ........................................................................................................................................27

GENERAL........................................................................................................................................................27

5 STATUS DISPLAY: MANUAL MODE – DEFINED START-DATE............................................................................27

6 STATUS DISPLAY: MANUAL MODE – PROCESS RUNNING................................................................................27

7 STATUS DISPLAY: PROGRAM MODE - DEFINED PROGRAM START DATE...........................................................28

8 STATUS DISPLAY: PROGRAM MODE - PROGRAM RUNNING..............................................................................28

9 CANCEL A RUNNING PROCESS BY ESC KEY...................................................................................................29

10 MESSAGES AND ERRORS ............................................................................................................................29

PRINTER OPERATION ...................................................................................................................................30

CONNECTING A PRINTER .................................................................................................................................30

EXAMPLES OF DIFFERENT PRINTER OUTPUTS ....................................................................................................30

APPENDIX A....................................................................................................................................................31

HYSTERESIS VALUE FOR THE VACUUM-CONTROL .............................................................................................31

GRAPHS OF TEMPERATURE LIMITS AND GRADIENT AND PROGRAM-RUN..............................................................31

RANGE OF GRADIENT .......................................................................................................................................31

GRAPHICAL PRESENTATION OF A PROGRAM-RUN...............................................................................................32

- 2 - Copyright © SalvisLab / Edition 191107

APPENDIX B ................................................................................................................................................... 33

MENU STRUCTURE & INPUT FIELDS................................................................................................................. 33

APPENDIX C ................................................................................................................................................... 34

WIRING DIAGRAM VC 20................................................................................................................................. 34

APPENDIX D ................................................................................................................................................... 35

WIRING DIAGRAM VC 20 WITH VALVE CONTROL .............................................................................................. 35

APPENDIX E ................................................................................................................................................... 36

WIRING DIAGRAM VC 20 WITH VALVE- / PUMP CONTROL ................................................................................. 36

APPENDIX F ................................................................................................................................................... 37

WIRING DIAGRAM VC 50................................................................................................................................. 37

APPENDIX G................................................................................................................................................... 38

WIRING DIAGRAM VC 50 WITH VALVE CONTROL .............................................................................................. 38

APPENDIX H ................................................................................................................................................... 39

WIRING DIAGRAM VC 50 WITH VALVE- / PUMP CONTROL ................................................................................. 39

APPENDIX I..................................................................................................................................................... 40

DRAWING VC 20 ............................................................................................................................................ 40

APPENDIX J.................................................................................................................................................... 41

DRAWING VC 50 ............................................................................................................................................ 41

APPENDIX K ................................................................................................................................................... 42

DRAWING SPARE PARTS PANEL ...................................................................................................................... 42

APPENDIX L ................................................................................................................................................... 43

DRAWING SPARE PARTS DOOR....................................................................................................................... 43

APPENDIX M................................................................................................................................................... 44

DRAWING SPARE PARTS CHAMBER ................................................................................................................. 44

APPENDIX N ................................................................................................................................................... 45

DRAWING SPARE PARTS VALVE / POWER SUPPLY ........................................................................................... 45

APPENDIX O................................................................................................................................................... 46

SPARE PART NUMBERS .................................................................................................................................. 46

SPARE PART NUMBERS .................................................................................................................................. 47

Copyright© SalvisLab / Edition 191107 - 3 -

CE DECLARATON OF CONFIRMITY

Declaration of Confirmity

Wir

We

Nous

(Name des Anbieters) (supplier's name) (nom du fournisseur)

erklären in alleiniger Verantwortung, dass das Produkt

declare under our sole responsibility that the product

déclarons sous notre seule responsabilité que le produit

Vacuum Drying Oven VC – 20 / 50

Year of Construction 2002

(Bezeichnung Typ oder Modell, Los-, Chargen- oder Seriennummer, möglichst Herkunft und Stückzahl)

(name, type or model, lot, batch or serial number, possibly sources and numbers of items)

(nom, type ou modèle, no de lot, d'échantillon ou de série, éventuellement sources et nombre d’exemplaires)

auf das sich diese Erklärung bezieht, mit der/den folgenden Norm(en) oder normativen Dokument(en)

übereinstimmt

to which this declaration relates is in conformity with the following standard(s) or other normative

document(s)

auquel se réfère cette déclaration est conforme à la (aux) norme(s) ou autre(s) document(s) normatif(s)

(Titel und/oder Nummer sowie Ausgabedatum der Norm(en) oder der anderen normativen (Dokumente)

(title and/or number and date of issue of the standard(s) or other normative document(s)

(titre et/ou no et date de publication de la (des) norme(s) ou autre(s) document(s) normatif(s)

Gemäss den Bestimmungen der Richtlinie(n): following the provisions of Directive(s); conformément

aux dispositions de(s) Directive(s)

(falls zutreffend) (if applicable) (le cas échéant)

73/23/EWG 89/336/EWG

EN 60335-1 1988 EN 55014

(Ort und Datum der Ausstellung) (Name/Unterschrift oder Kennzeichnung des Befugten)

(Place and date of issue) (name and signature or equivalent marking of authorised person)

(Lieu et date) (nom et signature du signataire autorisé)

Rotkreuz, 12.02.2002 Marcel Käppeli

Technical Manager

Renggli AG / Salvis-Lab

Birkenstrasse 31, CH-6343 Rotkreuz

(Anschrift) (address) (adresse)

- 4 - Copyright © SalvisLab / Edition 191107

Important Information

Quick Information for Service

Please fill out all necessary information for your Vacucenter.

It helps you when you contact your Dealer or Service Department.

SERIAL NUMBER:

TYPE

VACUUM OPTION

PHONE NUMBER SERVICE

PURCHASE DATE

SOFTWARE VERSION

(See Display on Power ON)

VC20

VC50

None

Vacuum Display

Vacuum Control Valve

Vacuum Control Pump

Copyright© SalvisLab / Edition 191107 - 5 -

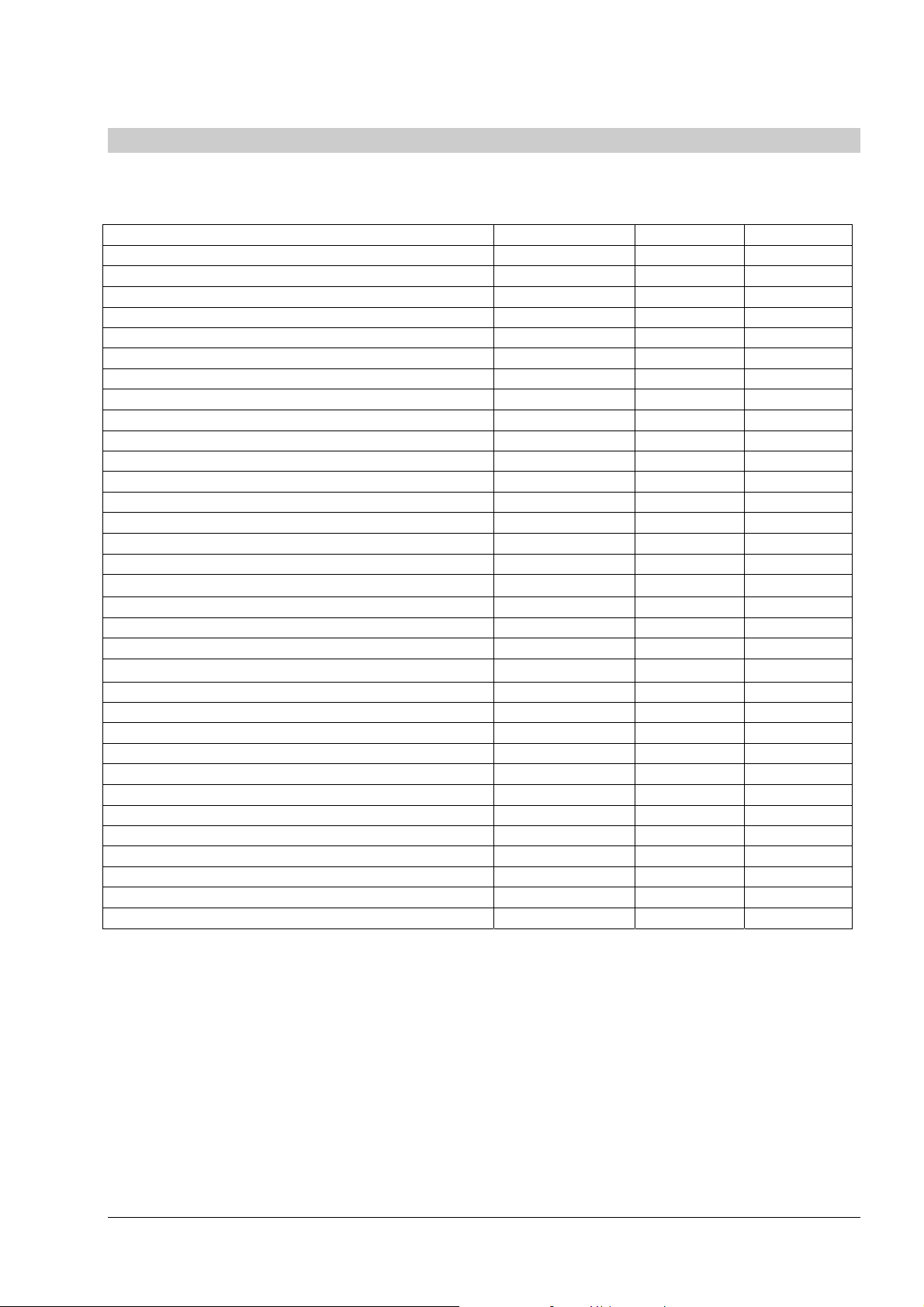

Technical Data’s

A

Technical Data’s Vacuum Drying Oven

Outer Dimension

VC 20 VC 50

Width mm 545 645

Height mm 375 475

Depth mm 425 525

Installation: Wall distance from the back mm 50 50

Installation: Wail distance from the side mm 50 50

Inner Dimension

Width mm 250 350

Height mm 250 350

Depth mm 320 420

Internal volume l 20 50

Shelves standard/max 1/3 1/5

Load per shelve kg 20 20

Weight (empty) kg 48 62

Temperature range approx. 5 °C over RT to °C 200 200

Temperature deviation

Temperature deviation

Temperature deviation

Temperature fluctuation

Heating up

3)

1)

at 50°C ± °C 1.0 1.0

1)

at 100°C ± °C 1.7 1.9

1)

at 150°C ± °C 2.4 2.6

2)

at 150°C ± °C 0.2 0.2

to 70°C Min 39 42

to 150°C Min 58 106

Power supply (±10%) 50/60 Hz V 230/115 230/115

Nominal wattage W 900 1200

Heat radiation at 100°C W 185 205

at 150°C W 243 286

Equipment

Microprocessor -Temperature Controller with LCD Yes Yes

Timer Hours / Min 0-999h 59m 0-999h 59m

Printer – Communication Interface RS 232 Yes Yes

djustable Print Interval Yes Yes

Programming Program / Step 50 / 15 50 / 15

Ramp function adjustable in steps of °C 0.1 0.1

1) Measured with 3 temperature probes on horizontal level / divided in 1/3 of the chamber size

2) maximum temperature deviation in time for one temperature probe

3) to 98% of set temperature

All technical specification are specified for units with standard equipment at an ambient temperature of 25 °C (77 °F) and a

Voltage fluctuation of ±10 %. The temperature data are determinated in accordance to following DIN 12880, part 2 respecting

the recommended wall clearances of 10 % of the height, width and depth of the inner chamber. All indications are average

values, typical for units produced in series. We reserve the right to alter technical specifications at all times without prior notice.

- 6 - Copyright © SalvisLab / Edition 191107

Introduction

Overview

The Vacucenter VC20 / VC50 is a vacuum oven with a Microprocessor-controller with enhanced Fuzzy-Logic

- Allows precise ramping of temperature as well as an excellent reproduction of temperature distribution in

the chamber.

Special Insulation - Less heat loss. Saves energy and costs. Ambient temperature of housing surface

Robust Swiss quality design – Made even for scientific applications

Work Chambers are of stainless steel and are provided with fully adjustable aluminium shelve

The chambers have well radiused corners for easy cleaning.

Exterior is of textured powder coated mild steel.

Applications

The Vacucenter Line is designed for all purposes of vacuum drying in a variety of laboratory fields.

All Systems have a controller with alphanumeric display and programming capabilities. Temperature ranges

up to 200°C.

Construction

Extremely compact construction. Saves valuable space in the lab.

Inner chamber of electro-polished stainless steel Resistant to chemicals and highly durable.

Much more shelf area than other vacuum ovens (for the same inner volume): max. 5 shelves in the VC 50,

max. 3 shelves in the VC 20.

Shelves made of 5 mm thick aluminium conduct heat efficiently.

Aluminium shelves are anodised to resist chemicals.

Door seal can easily be removed for cleaning or replacing. The door seal of other vacuum ovens is

either glued-in place or screwed-in.

VC 2O only: The shelf supports can easily be removed for ease of cleaning.

All corners are rounded.

The big size glass-window allows a full view of the inner chamber.

The window is made of double glazed safety glass. This is a safety feature: should one pane break, there is

still a second one. Tile double-glazing is also an excellent thermal insulator.

All corners are rounded. The door handle is integrated in the door. No hot surfaces. There is no risk of injury

or burn.

The door latch is spring loaded. Should there be an over-pressure caused by accidental oxidation inside the

chamber, the door will open slightly and allow its release.

Vacuum and Air Systems

Electromagnetic valve controls the vacuum connection at rear. In ease of power failure, this valves shuts

automatically, the oven is tight and thus remains under vacuum. When the power comes back, the vacuum

valve opens automatically and normal operation resumes. The timer continues where it left off.

The inlet of fresh air or inert gas is controlled by a needle valve which allows gentle metering of the incoming

air (or gas) and thus prevents turbulence inside the chamber.

A deflector plate at the inlet of the chamber prevents the incoming air from blowing down directly at a powder

sample.

Copyright© SalvisLab / Edition 191107 - 7 -

Controller

Fuzzy-Logic microprocessor controller with digital alphanumeric LCD-Display, real time clock, variable fan

speed and temperature ramp.

Intelligent Fan-Speed control IntelliFan - Wide range of temperature ramping functions. More user

application. In combination with Fuzzy-logic gives you an excellent stability of temperature distribution and

accuracy of programmed ramp.

Brilliant LCD Display for user-dialog and easy to operate keypad for fast programming and operating.

User dialog with controller is displaying your local language. Up to five languages can be selected.

Easy to operate and programming with EasyMenu

It allows the storage of 50 programs and 15 program steps (a step = a ramp, a temperature, a fan-speed and

a dwell time=Hold Time). The programs remain stored in memory even without external power (battery

buffered).

Holding Time (dwell time) 0 - 999h 59m

The real time clock allows a process to be started at any time – i.e.: on January 6, 2002 at 5 30 in the

morning.

RS-232 interface. All data can be protocol led with a printer or computer. Remote controlling and

programming, Door-Switch - switch-off heater/fan by opening door

Safety

DIN 12880 class 3.1 In case of over-temperature, a built in safety controller as a back-up circuit takes over

the control of the heating and will shutdown the oven.

There is also an additional mechanical over-temperature device which shuts down the oven

High quality accurate PT 100 temperature sensors.

Superior “Swiss Made” manufacturing quality according ISO9001

Door-Switch - switch-off heater/fan by opening door

Optional threshold pressure Switch (no heating until 300 mbar reached)

- 8 - Copyright © SalvisLab / Edition 191107

Getting Started

Parts delivered

Your System will be delivered with following Parts:

1 System Unit

1 Shelf

1 Power Cord

1 User Manual

Install requirements

Ensure that following conditions are met before you install the system.

Electric power connection as per type plate on inside of door must meet your power connector.

The ambient temperature is min. +5° C ... max. 35° C (+40° F ... 95° F)

Installing

Place shelf in appropriate position.

Plug cord

Close door.

Switch power on

Display shows current Firmware Version see Power On Sequence

To start oven or program it see Chapter Operating Menus

Cleaning

To clean the System use mild detergents. No Acid or similar detergents should be used.

Copyright© SalvisLab / Edition 191107 - 9 -

System Components

1 Controller

2 Pressure Gauge

3 Inert Gas / Air Inlet

4 Precision Valve

5 Vacuum Switch

6 Door Handle

7 Shelf

8 Shelf Glider

9 Double Paned Security Glass

10 Spring loaded door lock

11 Spring loaded door hinge

12 Pass through NW 25

13 Serial Interface RS232

14 Power connection

15 Vacuum connection

16 Serial number plate

17 Power connection for vauum pump (only by option

vacuum control of internal valve/vacuum pump)

7

1

2

8

6

11

3

4

12 17 16 15 14 13

5

9

10

- 10 - Copyright © SalvisLab / Edition 191107

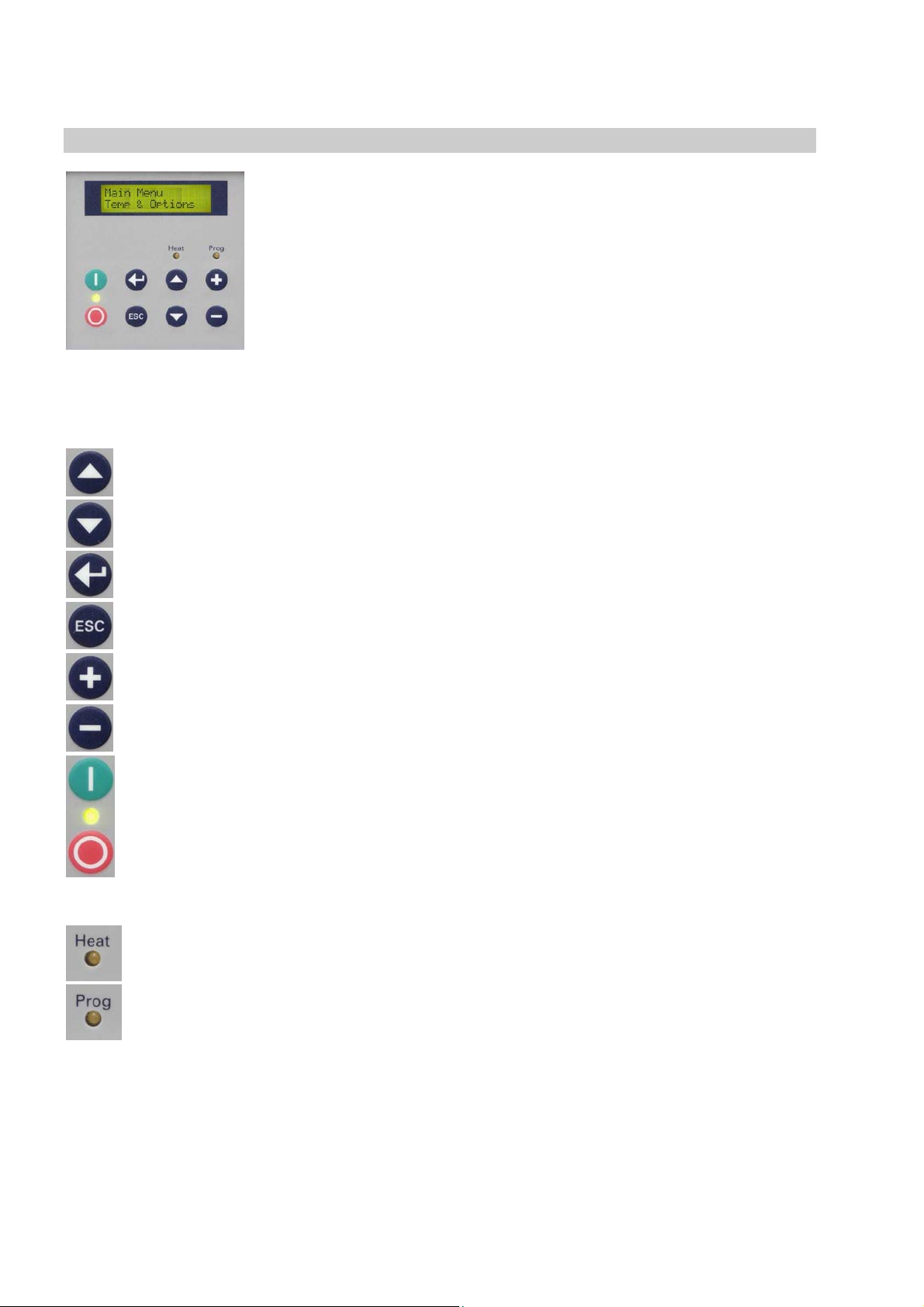

Controller

Keypad & Display

Buttons

S

T

Up You can scroll through the menu structure

Down You can scroll through the menu structure

Enter Confirm a menu selection, Confirm a value input or an answer choice

ESC

+

-

Escape Cancel actual operation, Go back in Menu Structure, Quit actual state ….

Plus

Minus

To control the system the controller has few “easy to use” buttons on a foil

keypad. Simply press desired button.

All information is displayed on a Liquid Crystal Display (LCD) with backlit.

LED Indicators for status of Power, Heating and Program are used to indicate

the main process status.

Buzzer (not visible) is indicating audible Status or Alarm

Increase a value in flashing input fields , Select multiple Choices;

Input Value must flash to make + button operable

Decrease a flashing value, Select multiple Choices;

Input Value must flash to make + button operable

ON/OFF Switch ON or OFF your System. When on LED is lit

LED Indicators

When lit: Heat Power is on

When lit: You are running a program

When flashing: A delayed start for program operation was entered.

Copyright© SalvisLab / Edition 191107 - 11 -

Operating

How to interpret displays described in this manual...

Power ON Sequence

By pressing the power-on button, the display will show the

Salvis Lab

Revision XX.XX

Input Field

software version. All standard, pre-setted or saved information will

be loaded during this process. After a while display will show first

Main Menu Point

Set Temperature

100.1°C

Multiple Input Fields

Set_Start-Date

DDMMYY__17.08.07

Multiple Choice Fields

Display_Interval

Yes___ No

A input value which is underlayed with yellow(grey) background

means this value is flashing on the real display.

If you reach a multiple input display first time, the first part (… of 3

in this example) of the input field is flashing to indicate input here..

Flashing input fields are changed with +/- keys

In a multiple choice field the last actual setted (pre-set) option will

flash. Change option with + or – and confirm with

Definitions of terms

What is a Set Temperature?

A Set Temperature is the target temperature you want operate the system with.

What is a Gradient?

A Gradient is the slope of the heating up process to the specific set temperature.

It is indicated as ºC / Minute. Negative Gradients are not allowed. The maximal value of a gradient is system

depending and has a range and is pre-defined by factory. A system specific curve of gradient corridors see

What is a Set Vacuum / Hysteresis Vacuum (only with Vacuum Controller Option)?

Set Vacuum is the target vacuum value. Hysteresis Vacuum is the vacuum-value range to the set value.

Within this range the valve or pump is not active. This is a P-control behaviour.

What is a Holding Time?

A timer is used to specify how long a set temperature has to be hold. The timer starts counting back when

the set temperature is reached. The maximal time you can set is: 999 hours and 59 minutes. This equals a

max time of 41 days 15 hours and 59 minutes

What is a Start Date/Time

If you are using a start date or time you will be able to set a future date/time to start a process or a program.

- 12 - Copyright © SalvisLab / Edition 191107

Main Menu - Overview

General operation buttons

In general you can scroll through the menu points with the T or S button.

Select the desired menu point with

1 Temperature & Options

Main Menu

Temp & Options

2 Program

Main Menu

Program

3 Configuration

Manual Operation: Define a set temperature and options like

gradient, Vacuum values, Hold-time (dwell-time), programmed

start date/time.

Press to select Ä 1.1

ESC returns to Ä 1

Programmed Operation: The menu Program is divided in

menus for creating, editing, deleting , starting and printing

programs.

Press to select Ä 2.1

ESC returns to Ä 1

Main Menu

Configuration

4 Service Mode

Main Menu

Service Mode

This menu point allows you to configure the system

Press to select Ä 3.1

ESC returns to Ä 1

This menu point is protected by an access-code and is available

only for trained Service-Technicians.

Press to select Ä 4.1

ESC returns to Ä 1

Copyright© SalvisLab / Edition 191107 - 13 -

1 Main Menu - Temp & Options

Manual Operation: Define a set temperature and options like

Main Menu

Temp & Options

1.1 Set Temperature

gradient, Vacuum values, Hold-time (dwell-time), programmed

start date/time.

Press to select Ä 1.1

ESC returns to Ä 1

Set_Temperature_

_________100.1°C

1.2 Set Vacuum

Set Vacuum

_____ 120.6mbar

1.3 Set Hysteresis of vacuum (P-type control behaviour)

Hyster. Vacuum

_____ 2.5mbar

1.4 Select Quick Start or Start with Options

Start_?

Now__ Options

1.5 Set Gradient

Gradient

2.0°C/Min

+/- change desired value.

confirms and saves value Ä 1.2

ESC restores the old value or returns to Ä 1

Option “Vacuum Control” (Valve or Pump) only !

+/- Change value

confirms and saves value Ä 1.3

ESC restores the old value or returns to Ä 1

Option “Vacuum Control” (Valve or Pump) only !

+/- Change value

confirms and saves value Ä 1.4

ESC restores the old value or returns to 1

+/- Select desired answer

confirms and saves value

If Now selected: System will start immediately Ä 6

If Option

ESC cancels and returns to Ä 1

+/- Change value

confirms and saves the value Ä 1.6

ESC restores the old value or returns to Ä 1

Note: A value of 0,0 means maximal possible gradient value!

selected Ä 1.5

- 14 - Copyright © SalvisLab / Edition 191107

1.6 Set Holding Time (dwell time)

Hold Time

HHH:MM____ 15:00

1.7 Set Start-Date

Start Date

DDMMYY__15.05.07

1.8 Set Start Time

Start Time

HH:MM______13:10

+/- Change value

confirm value and skips to the next input field (HH Ä MM) or

stores the time and go to Ä 1.7

ESC restores the old value and skips back one input field

(MMÄHH) or goes back to Ä 1

Note: A value of 0:00 means endless holding time

+/- Change desired value

confirm value and skips to the next input field (DD Ä MM,

MMÄYY) or stores the date and go to Ä 1.8

ESC restores the old value and skips back one input field

(YYÄMM, MMÄ DD) or goes back to Ä 1

Note: The pre-set date is the actual date from the real-time clock.

+/- Change desired value

confirm value and skips to the next input field (HH Ä MM) or

stores the time and go to :

If the Start Date and/or Start Time is in the past, the display will

return back to Ä 1

If your Start Date and/or Start Time is in the future you will see

the operating display Ä 5

ESC restores the old value and skips back one input field

(MMÄHH) or goes back to Ä 2.1

Note: The pre-set time is the actual time from the real-time clock.

Copyright© SalvisLab / Edition 191107 - 15 -

Loading...

Loading...