SalvisLab IC40, IC80, IC160, IC 240, IC 400 Instruction Manual

User Manual Incucenter IC40, 80, 160, 240, 400

IMPORTANT INFORMATION ....................................................................................................... 2

QUICK INFORMATION FOR SERVICE ................................................................................................. 2

INTRODUCTION ........................................................................................................................ 3

OVERVIEW............................................................................................................................... 3

APPLICATIONS ..........................................................................................................................3

CONTROLLER ............................................................................................................................ 3

SAFETY .................................................................................................................................. 3

GETTING STARTED ................................................................................................................... 4

PARTS DELIVERED ...................................................................................................................... 4

INSTALL REQUIREMENTS............................................................................................................... 4

INSTALLING SYSTEM................................................................................................................... 4

CLEANING SYSTEM .................................................................................................................... 4

SYSTEM COMPONENTS ............................................................................................................ 5

CONTROLLER ...........................................................................................................................6

KEYPAD & DISPLAY ................................................................................................................... 6

OPERATING .............................................................................................................................. 7

HOW TO INTERPRET DISPLAYS DESCRIBED IN THIS MANUAL... ................................................................. 7

MAIN MENU OVERVIEW............................................................................................................... 8

1 MAIN MENU TEMP & OPTIONS ................................................................................................... 9

2 MAIN MENU PROGRAM........................................................................................................... 11

2.1 MENU PROGRAM START ...................................................................................................... 12

2.2 MENU PROGRAM NEW......................................................................................................... 13

2.3 MENU PROGRAM EDIT ......................................................................................................... 16

2.4 MENU PROGRAM DELETE ..................................................................................................... 18

2.5 MENU PROGRAM PRINT ....................................................................................................... 18

3 MAIN MENU CONFIGURATION................................................................................................... 19

4 MENU SERVICE MODE ............................................................................................................ 20

OPERATING DISPLAYS ............................................................................................................ 21

GENERAL............................................................................................................................... 21

5 OPERATING DISPLAY: MANUAL MODE DELAYED START................................................................... 21

6 STATUS DISPLAY: NORMAL MODE RUNNING ................................................................................ 21

7 STATUS DISPLAY: PROGRAM MODE DELAYED PROGRAM START......................................................... 22

8 STATUS DISPLAY: PROGRAM MODE PROGRAM RUNNING .................................................................. 22

9 CANCEL A RUNNING PROCESS BY ESC KEY .................................................................................. 22

10 MESSAGES AND ERRORS ....................................................................................................... 23

PRINTER OPERATION .............................................................................................................. 24

CONNECTING A PRINTER ............................................................................................................ 24

APPENDIX A ........................................................................................................................... 25

MENU STRUCTURE & INPUT FIELDS .............................................................................................. 25

Important Information Quick Information for Service

Important Information

Quick Information for Service

Please fill out all necessary information for your Incucenter.

It helps you when you contact your Dealer or Service department.

SERIAL NUMBER:

PHONE NUMBER SERVICE

PURCHASE DATE

SOFTWARE VERSION

(See Display on Power ON)

Notes:

- 2 - Copyright © SalvisLab

Overview Introduction

Introduction

Overview

The INCUCENTER is an Incubator with forced air and an intelligent control of fan-speed in a range

between 0-100%. The control of ramping functions allows fast and accurate heating up procedure and

therefore more applications available to users

Microprocessor-controller with enhanced Fuzzy-Logic - Allows precise ramping of temperature as well

as an excellent reproduction of temperature distribution in the chamber.

Special Insulation - Less heat loss. Saves energy and costs. Ambient temperature of housing surface

Robust Swiss quality design – Made even for scientific applications

Work Chambers are of stainless steel and are provided with fully adjustable chromium plated rod

shelves.

The chambers have well radiused corners for easy cleaning.

Exterior is of textured powder coated mild steel.

Applications

The INCUCENTER is an extremely versatile incubator. It can be used Research & Development, Quality

Control as well industrial applications. Some examples: Drying and sterilization applications in scientific

as well as industrial usage suit well for this oven. A must when precise temperature distribution and a

high accuracy are needed

Note: The Incucenter incubators are not built to use substances which are explosible or let free

explosible gases during the incubation process.

Controller

Fuzzy-Logic microprocessor controller with digital alphanumeric LCD-Display, real time clock, variable

fan speed and temperature ramp.

Intelligent Fan-Speed control IntelliFan - Wide range of temperature ramping functions. More user

application. In combination with Fuzzy-logic gives you an excellent stability of temperature distribution

and accuracy of programmed ramp.

Brilliant LCD Display for user-dialog and easy to operate keypad for fast programming and operating.

User dialog with controller is displaying your local language. Up to five languages can be selected.

Easy to operate and programming with EasyMenu

It allows the storage of 50 programs and 15 program steps (a step = a ramp, a temperature, a fanspeed and a dwell time=Hold Time). The programs remain stored in memory even without external

power (battery buffered).

Holding Time (dwell time) 0 - 999h 59m

The real time clock allows a process to be started at any time – i.e.: on January 6, 2002 at 5 30 in the

morning.

RS-232 interface. All data can be protocolled with a printer or computer. Remote controlling and

programming, Door-Switch - switch-off heater/fan by opening door

Safety

DIN 12880 class 3.1 In case of over-temperature, a built in safety controller as a back-up circuit takes

over the control of the heating and will shutdown the oven.

There is also an additional mechanical over-temperature device which shuts down the oven

High quality accurate PT 100 temperature sensors.

Superior “Swiss Made” manufacturing quality according ISO9001

Copyright© SalvisLab - 3 -

Getting Started Parts delivered

Getting Started

Parts delivered

Your System will be delivered with following Parts:

1 Incucenter Unit

2 Shelves

1 Power Cord

1 User Manual

Install requirements

Ensure that following conditions are met before you install the system.

Electric power connection as per type plate on inside of the door must meet your power connector.

For 230 V, 50/60 Hz min

For 115 V, 50/60 Hz min

The ambient temperature is min. +5° C ... max. 35° C (+40° F ... 95° F)

Leave at least 10cm space between system and walls or benches.

Installing System

The System comes with two shelves. Place shelf in appropriate position.

Plug cord

Close door.

Switch power on

Display shows current Firmware Version see Power On Sequence

To start oven or program it see Chapter Operating Menus

Cleaning System

To clean the system use mild detergents. No Acid or similar detergents should be used.

- 4 - Copyright © SalvisLab

Cleaning System System Components

System Components

1 Controller

2 Door Handle

3 RS232 Connector (rear)

4 Fan

5 Door Lock

6 Shelf

1

2

3

4

5 6

Copyright© SalvisLab - 5 -

Controller Keypad & Display

Controller

Keypad & Display

Buttons

S

T

Up You can scroll through the menu structure

Down You can scroll through the menu structure

Enter Confirm a menu selection, Confirm a value input or an answer choice

ESC Escape Cancel actual operation, Go back in Menu Structure, Quit actual state ….

-

Plus

Minus

+

To control the system the controller has few “easy to use” buttons on a foil

keypad. Simply press desired button.

All information is displayed on a Liquid Crystal Display (LCD) with backlit.

LED Indicators for status of Power, Heat and Program are used to indicate

the main process status.

Buzzer (not visible) is indicating audible Status or Alarm

Increase a value in flashing input fields , Select multiple Choices;

Input Value must flash to make + button operable

Decrease a flashing value, Select multiple Choices;

Input Value must flash to make + button operable

ON/OFF Switch ON or OFF your System. When on LED is lit

LED Indicators

When lit: Heat Power is on

When lit: You are running a program

When flashing: A delayed start for program operation was entered.

- 6 - Copyright © SalvisLab

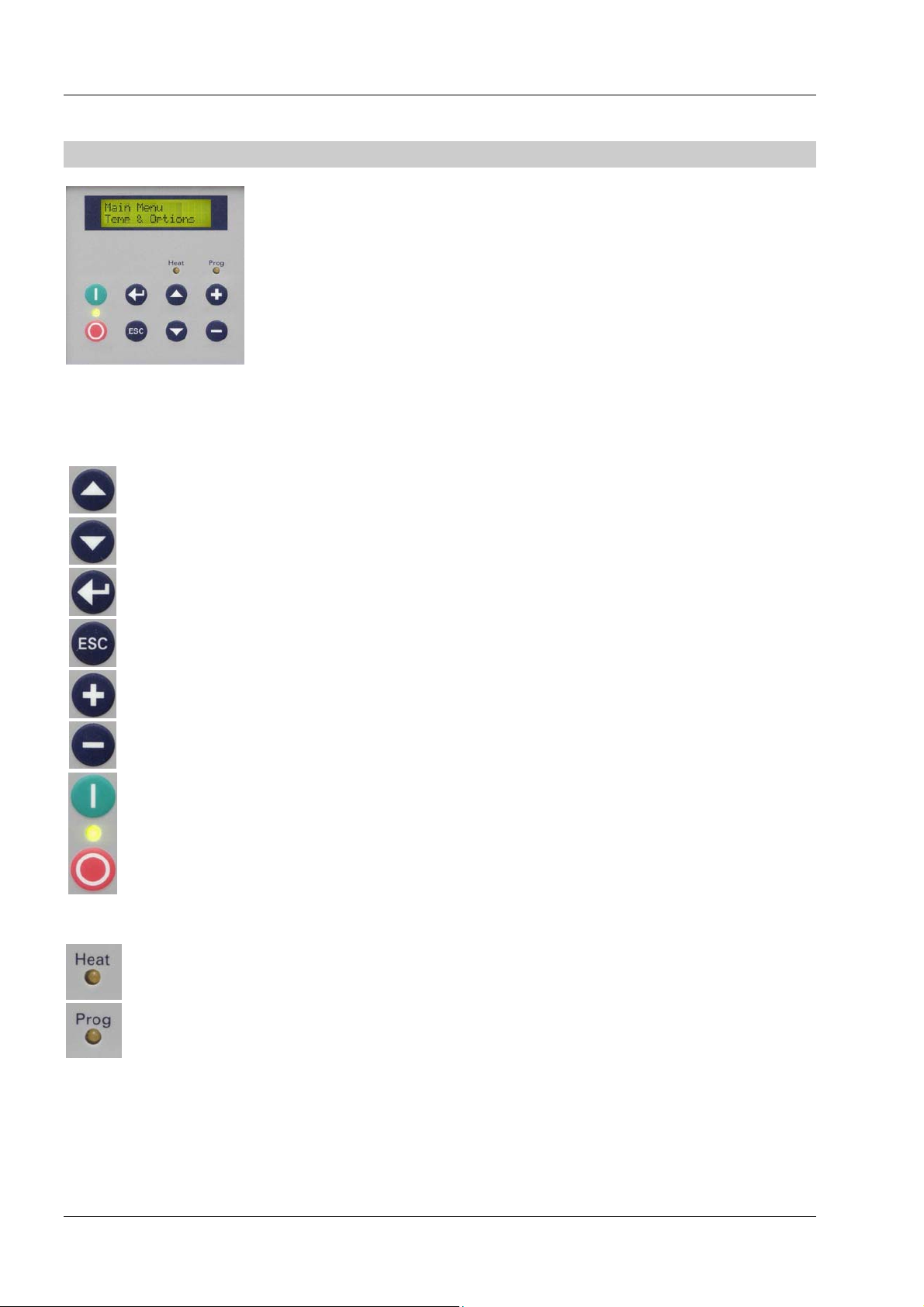

How to interpret displays described in this manual... Operating

Operating

How to interpret displays described in this manual...

Power ON Sequence

By pressing the power-on button, the display will show the

Salvis Lab

Revision XX.XX

Input Field

software version. All standard, pre-setted or saved information

will be loaded during this process. After a while display will

show first Main Menu Point

Set Temperature

180.0°C

Multiple Input Fields

Set_Start-Date__

DDMMYY__17.08.08

Multiple Choice Fields

Display_Interval

Off___On_______

A input value which is underlayed with yellow(grey)

background means this value is flashing on the real display.

If you reach a multiple input display first time, the first part (…

of 3 in this example) of the input field is flashing to indicate

input here.. Flashing input fields are changed with +/- keys

In a multiple choice field the last actual setted (pre-set) option

will flash. Change option with + or – and confirm with

Definitions of terms

What is a Set Temperature?

A Set Temperature is the target temperature you want operate the system with.

What is a Gradient?

A Gradient is the slope of the heating up process to the specific set temperature.

It is indicated as ºC / Minute. Negative Gradients are not allowed. The maximal value of a gradient is

system depending and has a range and is pre-defined by factory. A system specific curve of gradient

corridors see

What is a Fan Speed?

The Fan-Speed is a percentage of a range of rounds per minute. The minimal or maximal RPM Value is

system depending. The % Value is based on this min/max range.

What is a Holding Time?

A timer is used to specify how long a set temperature has to be hold. The timer starts counting back

when the set temperature is reached. The maximal time you can set is: 999 hours and 59 minutes.

This equals a max time of 41 days 15 hours and 59 minutes

What is a Start Date/Time

If you are using a start date or time you will be able to set a future date/time to start the system with

pre-setted parameters i.e. temperature, Gradient, Fan Speed, Timer

Copyright© SalvisLab - 7 -

Operating Main Menu Overview

Main Menu Overview

General operation buttons

In general you can scroll through the menu points with the T or S button.

Select the desired menu point with

1 Temperature & Options

Manual operation with a set temperature. You can select

Main Menu

Temp & Options

2 Program

Main Menu

Program

3 Configuration

options like gradient, hold-time (dwell-time), fan speed, presetted start date/time.

Press to select Ä 1.1

ESC returns to Ä 1

The menu Program is divided in menus for creating, editing,

deleting and printing programs.

Press to select Ä 2.1

ESC returns to Ä 1

Main Menu

Configuration

4 Service Mode

Main Menu

Service Mode

This menu point allows you to configure the system

Press to select Ä 3.1

ESC returns to Ä 1

This menu point is protected by an access-code and is

available only for trained Service-Technicians.

Press to select Ä 4.1

ESC returns to Ä 1

- 8 - Copyright © SalvisLab

Loading...

Loading...