SALVIS Combi‐Steamer

623 611 1011 T

611 621 1011 1021 QT

2011 2021 QT

CUCINAr Easy

r

CUCINA

Pro

Installation instructions

Table of contents page

1. User information 3.............................................................

1.1 Information about the instructions for the appliance 3..........................

1.2 Symbols in front of the text 3...............................................

1.3 Warning signs, danger symbols and information symbols 3.....................

1.4 Documenting the type plate data 4..........................................

2. Safety instructions 4...........................................................

3. Transport, Setup 5.............................................................

3.1 Inspection for transport damages 5..........................................

3.2 Transport 5..............................................................

3.3 Setup 5..................................................................

3.3.1 Observe the setup regulations 5.............................................

3.3.2 Choosing the setup location 6...............................................

3.3.3 Maintain clearances 6......................................................

3.3.4 Setup on tables and support structures 7.....................................

3.3.6 Setup of the upright appliances, e.g. Type 2011 8..............................

3.3.7 Installing the compensation frame for Type 2011/2021 (option) 8.................

3.3.8 Apply the safety sticker ”Max. shelf level for liquid cooking products” 9............

4. Water connection 9............................................................

4.1 Information for water connection 9...........................................

4.2 Choice of water softening device / water filter / water treatment 10................

4.2.1 Water treatment systems 10.................................................

4.2.2 Do not use these systems. 10................................................

4.2.3 Water hardness conversion table by country 10.................................

4.2.4 Requirements on the soft‐ and cold‐water connection 11.........................

4.3 Connection of soft‐ and cold water 12.........................................

5. Connecting water drainage – connection examples 13............................

6. Electrical connection 14........................................................

6.1 Connection to an energy optimisation unit (option) 15...........................

6.2 Connection to a load shedding unit 15........................................

7. Initial commissioning 15........................................................

8. Dimensions, connections, technical data 16......................................

8.1 Dimensions and connections 623T, 611T, 1011T 16..........................

2 / 24

8.2 Dimensions and connections 611/621QT, 1011/1021QT 17....................

8.3 Dimensions and connections 2011/2021QT 18................................

8.4 Technical data: 623T, 611T, 1011T 19......................................

8.5 Technical data: 611/621QT, 1011/1021QT 19................................

8.6 Technical data: 2011/2021QT 20............................................

8.7 Technical specifications condensation cover (optional) 20.......................

Translation of the original installation instructions

1. User information

1.1 Information about the instructions for the appliance

These installation instructions contain technical data, information on transport, setup, installation and ad

justment of the appliance. Hand the installation instructions to the installing assemblers. Make sure that

during the installation of the appliance the installation instructions are followed meticulously. This will pro

tect you and prevent damages to your appliance.

Refer to the operating instructions for information about operating the appliance.

Read the operating‐ and installation instructions carefully before starting to use the appliance.

The owner of the appliance must ensure that the instructions are accessible to the staff employed to oper

ate the appliance.

Always keep the documents accompanying the appliance close to hand and pass these on with the appli

ance to any new owner.

Installation instructions

1.2 Symbols in front of the text

. You are requested to carry out an action.

− Enumeration and listing

D Notes, operational sequences

Text without symbols: Descriptions or explanations after a heading.

Text in italics – refers to another chapter

1.3 Warning signs, danger symbols and information symbols

DANGER! High voltage! Risk of electric shock that may result in serious injury or death!

WARNING! Risk of injury, risk of damage! Warning of possible injury, a health risk or dam

age to property! Wear protective clothing, protective gloves and safety goggles! Exercise

appropriate caution!

Information! Notes containing particularly useful information and tips.

3 / 24

Installation instructions

1.4 Documenting the type plate data

623T, 611T, 1011T

Type plate in the

appliance on the bottom

of the unit

Type plate on the side

panel and front

611QT, 1011QT, 2011QT

Type plate

behind the

control panel

Type plate on the

side panel and front

. Enter the type plate data below before setting up

the appliance.

. Please quote these data when you require

after‐sales service for the appliance. This will

speed up the response to your questions.

Model:

Year of manufacture:

Serial‐number (S.No.):

2. Safety instructions

D Note the safety information in the operating‐ and installation instructions.

D Caution! Before opening the appliance, switch it off at the mains and safeguard it against being

switched back on.

D Wrong electrical‐ installation can lead to serious injuries or death. Electrical connections may be made

only by an electrical‐specialist!

D Incorrect setup, settings, modifications or neglected service work on the appliance may cause damage

to the unit or personal injuries.

D The water supply‐ and drain connections may be made only be skilled persons or the authorised cus

tomer service!

D The appliance may not be operated without water connection! Otherwise overheating and cut‐out

through the control system.

D Damages caused by ignoring installation instructions are exempt from the warranty.

D Damaged devices must not be connected or used any more!

D The appliance may no longer be operated when the glazing in the door, on the cooking chamber light

ing or on the control panel is damaged!

D Repair‐ and service tasks may be performed only by authorised and trained service personnel.

4 / 24

3. Transport, Setup

3.1 Inspection for transport damages

. Check the packaging and appliance for transport damages.

. If transport damages are suspected, notify your freight carrier or the factory without delay!

3.2 Transport

D If the appliance must be transported outdoors at freezing temperatures, the water‐carrying systems in

the appliance must first be drained by authorised customer service. Otherwise the water in the com

ponents will freeze and damage the appliance.

D Accessories are secured inside the cooking chamber by the factory for transport. If these transport

braces are removed, you should transport the appliance only while emptied and cleared.

Installation instructions

. Note the weight of the appliance when transporting it by hand. Use the appropriate number of persons

and suitable aids, such as carrying devices and protective gloves. For dimensions and weight informa

tion, see from page 16, Chapter 8.

. Transport on lift truck only on a pallet. Do not raise the lift truck against the appliance since this may

damage components.

. Secure the appliance against tipping over during transport!

. Remove all protective foils from the appliance before the final setup. Remove residual adhesive with

cleaner's naphtha.

3.3 Setup

D Setup and orientation of the appliances must be performed by authorised customer service!

D To improve accessibility for service work, we recommend carrying out the water‐ and electrical connec

tions in a flexible manner.

D The safety temperature limiter cuts off at freezing temperatures. Once the safety temperature limiter

has been sufficiently warmed again from the room temperature, it activates itself automatically.

D No casters or wheels may be installed on the appliance!

D Special precautions must be taken when setting up the unit on mobile tables or racks! See page 7

Chapter 3.3.4!

. All cartons, packaging material, documents and accessories need to be removed from the cooking

chamber.

3.3.1 Observe the setup regulations

D Please observe the local kitchen regulations.

D Installation work must be carried out in accordance with the manufacturer's installation instructions and

in accordance with accepted technical regulations.

D Observe the work‐safety information supplied by the employers' liability insurance association.

5 / 24

Installation instructions

3.3.2 Choosing the setup location

D Set up the appliance safe against frost. The ambient temperature at the installation site may not fall

below freezing. Otherwise the water in the components will freeze and damage the appliance.

D No heat‐ or steam sources may be located underneath or next to the appliance.

D The device must not be able to directly intake cold supply air from outside the building. If the tempera

ture of the air supply is too low, error messages and malfunctions can occur.

D The environment at the location of installation must always be ventilated and heated in such a manner

that humidity or steam cannot condense in the device. Damages caused by this are not subject to the

manufacturer's warranty obligation.

D Do not set up the appliance next to deep fryers! Water from the pull‐out shower must not enter the

deep fryer (observe the safety regulations)!

D Setup under exhaust hoods according to VDI 2052 guidelines (room air systems for kitchens).

D Set up the appliance so that the cooking chamber door cannot hit against any objects when opening it,

such as wall or devices (risk of breakage of glazing).

3.3.3 Maintain clearances

5 cm /

2 inches

D The clearance of the appliance to the wall at the

left, right and rear must be at least

5 cm / 2 inches.

D Only with types QT: Because the main service

duties take place at the left side of the appliance,

we recommend maintaining a larger distance at

this side, e. g. greater than 80 cm / 32 inches.

D Provide distances to heat‐ or steam sources or

install shields to prevent any steam as well as

warm or moist air to enter the appliance. If the

Clearances for type:

T = 5 cm / 2 inches

QT = 5 - 80 cm / 2 - 32 inches

D Allow sufficient manoeuvring space for the operating personnel (hazard from accidentally bumping into

persons)!

D Do not block the supply and exhaust‐air openings on the appliance.

D The environment on the vent pipe for the cooking chamber must be resistant to steam and hot air!

D Hot air or steam exists from the exhaust openings. For this reason, do not store any objects, e.g. on

wall shelves, above the appliance.

D No base or pedestal blinds may be installed on the appliance

623T, 611T, 1011T, 611QT, 1011QT, 2011QT

Supply air/exhaust air for cooking chamber

5‐10 cm /

2‐4 inches

ambient temperature above, below or to the left of

the appliance is too high, this may trip the safety

cut‐out of the appliance.

Supply air/exhaust air for cooking chamber

6 / 24

Supply air - control

system

Exhaust air - control system

Supply air -

control system

Exhaust air - control

system

3.3.4 Setup on tables and support structures

e

D Use only support frames approved by the appliance manufacturer.

D When setting up the appliance on countertops and work tables sufficient stability and load capacity

must be observed. Note the weight of the appliance, including the contents. For weight information, see

from page 16, Chapter 8.

D Secure support frames and setup surfaces against tipping.

Safety notes and instructions for use for units on mobile table or rack

. Setting up the unit of mobile tables or racks should be avoided for safety reasons! However, if the cu

stomer requests a mobile design, the following instructions on setup and use must be observed!

D To protect power cables, secure the mobile table or rack with a safety chain! The safety chain must be

shorter than the power cable! Fasten the safety chain accordingly short.

D The table or rack must be secured against rolling off during operation! Lock the parking brake at the

wheels! The appliance must not be moved during operation!

D Move mobile tables or racks carrying units only on level surfaces! Do not drive over inclines or steps!

D Before moving the unit remove vessels/food items from the unit, switch off the room's main switch, pull

the power plug, close the water shut-off tap, remove the water drain pipe and water supply hose, wind

up all supply lines and secure against falling down, disengage the parking brake on the wheels; caution

- danger of tipping: Move the table or rack carrying the unit carefully!

Installation instructions

D Check before each reconnection whether the electrical supply cables and hose connections are not

damaged! The unit must not be started if the supply lines are damaged!

3.3.5 Adjust screw bases, secure the appliance against movement, type 623, 611, 1011

D Set up the appliance level. Compensate minor unevenness with the adjustable bases. Attention, note

maximum extension dimension!

D Secure the appliance against movement.

Types 623T, 611T, 1011T Types 611 QT, 1011 QT

Optional

Support

base article

no. 881166

120 to max.

180 mm

Extend max. 5 mm.

Corner profile article

no. 878391

At least two items

required. Affix, for

example, diagonally

across to the table top.

Standard

The setup face of the base

is perforated in the centre.

Punch out the perforation

to place on the locking

disk.

100 to max.

130 mm

Locking disk compl. article no. 880654

At least two items required. E.g. affix to th

table top for the front bases.

7 / 24

Installation instructions

3.3.6 Setup of the upright appliances, e.g. Type 2011

. Align the appliance horizontally to ensure that

. Check after aligning the unit whether the door

Door catch

Door closing

mechanism

Base clamp

D Risk of damage If not set correctly, the door

. Install washers on the wheel attachments of the

D The rack trolley must not brush against the seals

D The seal area of the rack trolley must lie flush

. Secure the appliance against movement.

water is optimally drained from the cooking cham

ber.

closing mechanism properly engages with the

door catch.

closing mechanism may hit the tip of the door

catch and damage it.

rack trolley to align the trolley flush with the coo

king chamber.

of the cooking chamber, and must have a uniform

distance on all sides.

against the lower door seal to ensure closure.

Extend screw base max.

55 mm.

. Secure the front screw bases with the foot

clamps against turning.

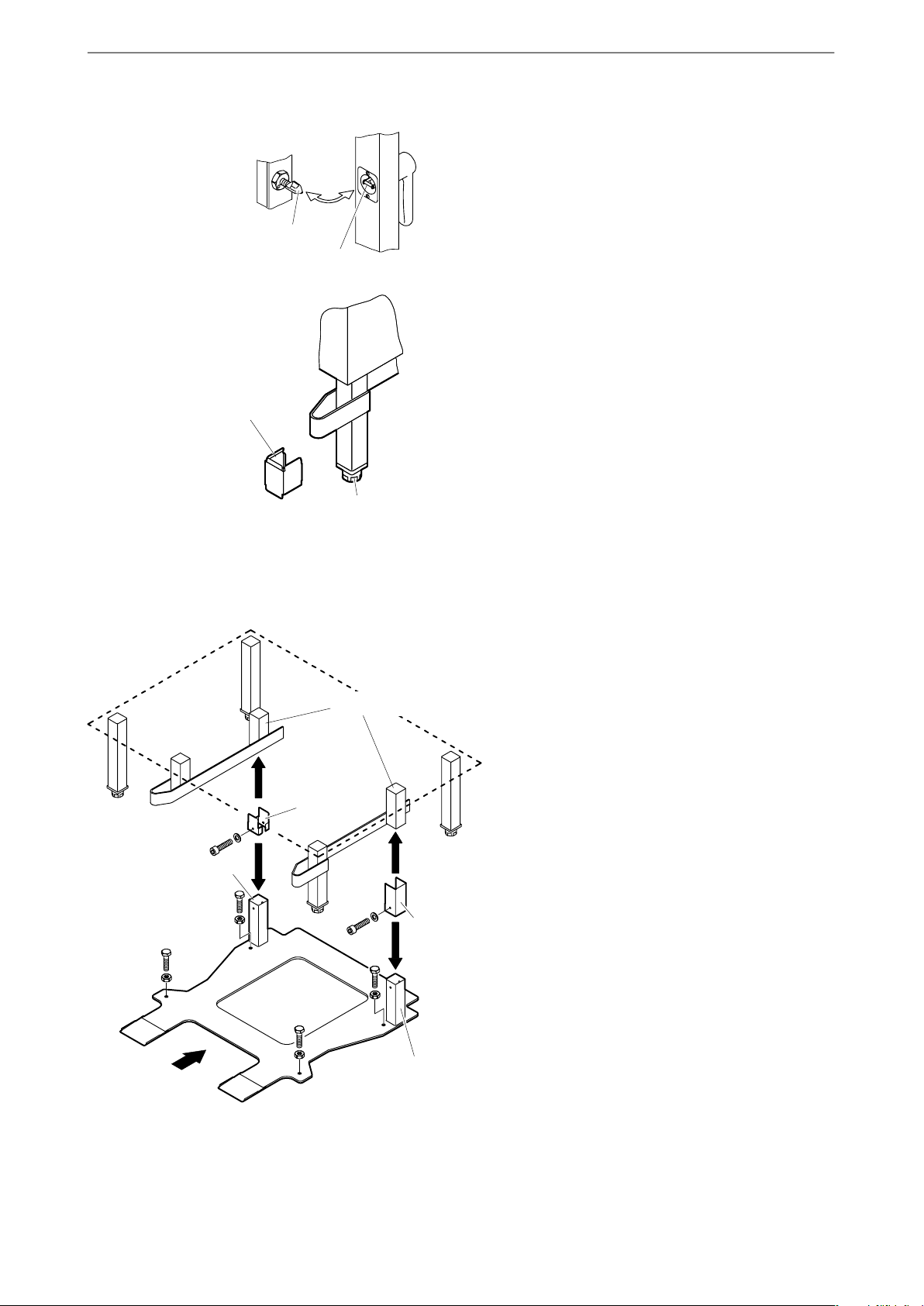

3.3.7 Installing the compensation frame for Type 2011/2021 (option)

The compensation frame is required in order to com

pensate for the unevenness of the ground and to

ensure parallel entry into the cooking chamber.

Up to approx. 25 mm unevenness of the ground can

be compensated.

Kit compensating frame Item No. 881895: Suitable

for 881718 plate rack trolley, 880625 GN rack trolley,

879482 BN rack trolley.

Installing compensating frame

. Use the screw feet and align the appliance hori

zontally

1. Remove the Allen screws from the clamps.

2. Push the clamps downwards over the retaining

tube.

1./5.

Square tube

5.

4.

2.

Retaining tube

Clamp, left

1./5.

4.

Clamp,

right

2.

8 / 24

3. Compensation frame not placed beneath the

5.

Square tube

3.

appliance.

4. Push the clamps upwards over the retaining tube.

5. Use an Allen screw to fully tighten the clamps.

6. Horizontally align the compensation frame with

hexagon-headed bolts and lock using hexagon

nuts.

. Check to make sure that the rack trolley can be

moved in parallel to the edge of the cooking

chamber.

Installation instructions

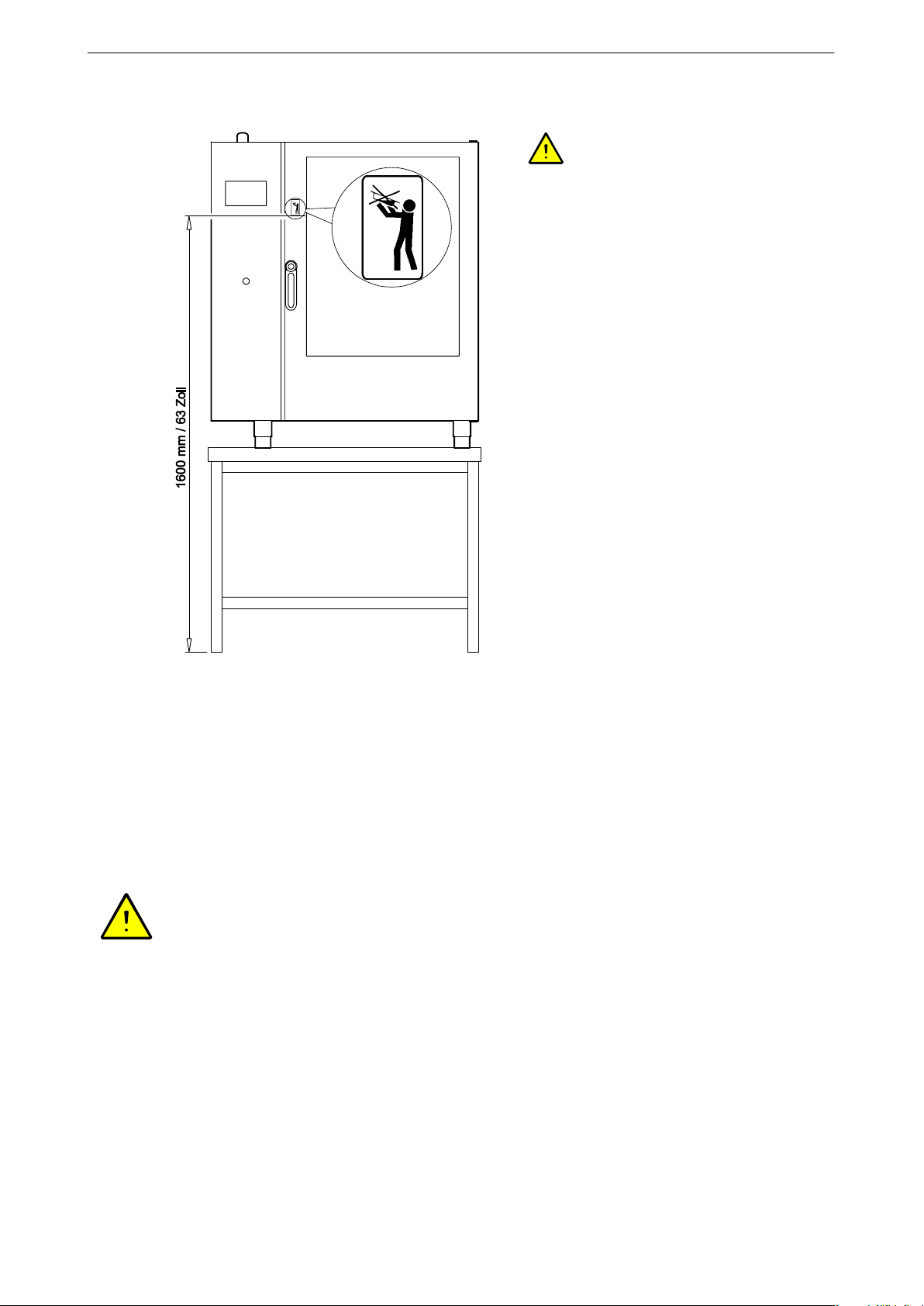

3.3.8 Apply the safety sticker ”Max. shelf level for liquid cooking products”

D WARNING! Scald hazard! Containers

with liquids or products to be boiled, becoming

liquid during the cooking process, may only be

pushed into the slot that can be easily viewed by

the operating personnel.

D Slopping may cause scalding when removing li

quid cooked products!

D For appliance where the top slot for containers is

placed higher than 1.60 m / 63 inches, the sticker

”Max. shelf level for containers with liquid” must

be affixed.

. Affix the sticker at a level of 1.60 m / 63 inches.

Clean the area where the sticker will be affixed

before applying t.

4. Water connection

4.1 Information for water connection

D Obtain information from your local water utility company on the water quality, water pressure and water

hardness.

D Observe the regional regulations and the ”Technical Rules for Drinking Water‐Installations EN 1717”!

D The appliance may only be connected to tap water that corresponds to the potable water regulations.

D There must be no connecting pipes made from galvanized iron or similar material between the water

softening device and the appliance (otherwise risk of rust forming)!

D Observe the installation‐ and user manuals for the water softener.

9 / 24

Installation instructions

4.2 Choice of water softening device / water filter / water treatment

4.2.1 Water treatment systems

D The manufacturers of water softening devices offer systems provided specifically for hot circulating‐air

steamers/combi‐steamers. They may also be combined with particle‐/fine‐ and active carbon filters. We

recommend, for example, the water softener from Brita Co.

D Do not connect the water softener to previously softened water.

D Reverse‐ or osmosis‐systems may generally constitute an economic alternative to full and/or partial

desalination via filtering systems. Osmosis systems remove nearly all hardness‐forming ingredients

and non‐hardened minerals from the water. These systems are also required to remove high chloride‐

and silicate concentrations.

D Particle‐/fine filters with filter grades 5‐15 µm filter, for example, contaminations such as deposits from

water pipes, sand, iron particles or suspended matter. Choose sufficient flow capacity of the fine filter to

prevent any pressure loss and to ensure an adequate flow rate.

D Active carbon filters remove excessive chlorine contents.

4.2.2 Do not use these systems.

D Sodium ion exchangers (as customary with dish washers) are not permitted for these appliances.

Glazing may become dull and irreparable damage may occur in the cooking chamber.

D Systems with phosphate‐ and silicate dosing may not be used. They may cause malfunctions in appli

ance parts and deposits in the cooking chamber.

D Systems based on electromagnetic fields do not provide protection against scale formation with this

type of appliance.

4.2.3 Water hardness conversion table by country

Conversion for the units of water hardness

°dH °e °fH ppm mval/l mmol/l

German degrees 1 °dH = 1 1,253 1,78 17,8 0,357 0,1783

British degrees 1 °e = 0,798 1 1,43 14,3 0,285 0,142

10 / 24

French degrees 1 °fH = 0,560 0,702 1 10 0,2 0,1

ppm CaCO3 (U.S.) 1 ppm = 0,056 0,07 0,1 1 0,02 0,01

mval/l earthy‐base ions 1 mval/l = 2,8 3,51 5 50 1 0,50

mval/l earthy‐base ions 1 mmol/l = 5,6 7,02 10,00 100,0 2,00 1

4.2.4 Requirements on the soft‐ and cold‐water connection

D The steam generation in the appliances is carried out as fresh steam, that means, the water is directly

introduced into the cooking chamber.

D The water must conform to the Drinking Water Regulations.

D In order to prevent damage to the appliance, the following requirements must be observed.

Soft water Cold water

Installation instructions

Application For steam generation and automatic

cleaning.

A backflow preventer is installed in

the water supply line.

Water temperature Max. 50°C Cold water (max. 20°C)

Min. water

pressure

Max. water

pressure

Water hardness

°dH

Carbonate

hardness

°dH

A booster pump must be installed if the water pressure is too low. Check the dy

namic water pressure, e.g. with the pull‐out shower opened.

A pressure reducer must be installed if the water pressure is too high.

Total hardness maximal 5°dH

(0.89 mmol/l)

Max. 2°dH

200 kPa = 2 bar (dynamic / flow pressure)

600 kPa = 6 bar (static)

For the steam relief and pull‐out

shower

A backflow preventer is installed in

the water supply line.

Do not connect to hot water due to

excessive water consumption or poor

function of the steam relief (steam

condensation)!

Total hardness maximal 10°dH

(1.783 mmol/l)

Sulphate

SO

4

Chlorine /Chlorine

dioxide content

Chloride Max. 50 mg/l (50 ppm)

Iron Max. 0.1 mg

pH value 6.5 - 7.5

Conductivity

value

Contaminations Install a water filter grade 5‐15 µm to remove, e.g. water pipe deposits, sand, iron

Install a reverse osmosis system

above 10 mg/l; otherwise there is a

risk of damage from glazing corro

sion.

At a chlorine content above 0.1 mg/l (corresponds to 0.1 ppm) an active carbon

filter needs to be installed.

Above 50 mg/l (50 ppm) a reverse osmosis system needs to be installed;

otherwise strongly increased risk of corrosion.

Max. conductivity value 200 µS/cm (micro Siemens)

particles or suspended matter.

11 / 24

Installation instructions

4.3 Connection of soft‐ and cold water

Risk of damage The appliance may not be operated without water connection! A water connection is re

quired even if the appliance is only used for baking!

623T, 611T, 1011T

Cold water

connection

611QT, 1011QT, 2011QT

Cold water

connection

Soft water

connection

Soft water

connection

D The connection requires using a pressure‐resist

ant flexible DVGW‐tested hose with a diameter of

at least 1/2 inch and union of 3/4 inch. Provide a

hose of adequate length to allow the appliance to

be moved during service tasks.

D The appliance are factory‐equipped with a soft‐

and cold water connection. Use the connecting

piece only if you cannot provide separate water

supplies and the specifications for the cold and

soft‐water connections are ensured.

. Rinse through the water pipes in the building sys

tem and supply hoses before connecting.

. Connect the appliance to an easily accessible

water stopcock.

Connection

G3/4 inches

Dirt screen

item‐No. 249688

Water connection

G3/4 inches

Dirt screen

item‐No. 249688

Sealing ring

(included in

connecting piece)

Connecting piece

Item No.: 878801

(cannot be used for

Type T)

D The supply hose may not be kinked or deformed!

. Check that all connections are watertight.

Connection with connecting piece

The connecting piece may be used only if the water

corresponds to the requirements for soft water.

For requirements on the cold‐ and soft water connec

tion, see page 11 Chapter 4.2.4

12 / 24

Installation instructions

5. Connecting water drainage – connection examples

1. Siphon with drain funnel

Device

rear

Siphon with

overflow

At least 2 cm / 1 inch

Open drain funnel

≥ 50 mm

On-site siphon

2. Floor drain with siphon

Recommended for models 2011, 2021 and doubl

rack designs QT

Device

rear

Siphon with

overflow

D It is preferable to use the first or second connec

tion examples!

D The waste water system must be designed ac

cording to DIN 1986‐100 and DIN EN 12056‐1.

D Use steam temperature‐resistant and flame‐retar

dant drain pipe (HT pipe).

D Do not reduce the pipe diameter.

D The diameter of the on‐site drainage pipe must

be at least 50 mm.

D Do not place open drain funnel and water drain in

substructures or under the unit! Condensate may

form from escaping steam! Escaping steam must

be able to move away unhindered and must not

be able to enter electric appliances!

D The manufacturer does not assume any liability

for consequential damages due to incorrect

connection!

D The slope from the appliance to the waste water

connection must be at least 10%!

. To prevent water pouches from forming in waste

water pipes routed freely of extended distances,

the waste water pipe should be fastened at

shorter distances.

. Fill the siphon with water.

3. Wall connection with on-site siphon and vent pipe

We recommend installing a vent pipe when fitting with an

automatic cleaning system and direct connection.

Vent pipe protruding

above top of device

Device

rear

Siphon with overflow

At least

25 cm / 10 inch

On-site siphon

≥ 50 mm

4. Wall mounting (not for Switzerland)

Get authorized Customer Service to install

an odour trap in the appliance: Locate and

attach the hose from the drip plate to the

appliance siphon so that it creates an

odour trap.

Siphon with overflow

Device

rear

≥ 50 mm

13 / 24

Installation instructions

6. Electrical connection

DANGER! Electrical voltage! Risk of electric shock that may result in serious injury or death! Installation,

service and repair tasks may only be carried out by authorised Customer Service.

D If the appliance was transported in a cold environment, it must be stored at least for two hours in a

warm and dry room before making the electrical connection. This prevents condensation of moisture on

the electrical components and their subsequent damage.

D Electrical connection must be carried out by a qualified electrician‐

− according to the applicable VDE 0100 regulations and

− the regulations of the power supply company concerned.

D An electrical main switch must be installed upstream with easy access. The switch must effectively

disconnect the appliance at all poles from the mains. The contact opening must be at least 3 mm.

D Instruct the owner and the operating personnel where the main switch provided in the kitchen for the

appliance is located so that the appliance may be switched off without danger in the event of hazards

to the user.

D Install ground fault circuit interrupter for safety reasons.

623T, 611T, 1011T

Electrical

supply

cable

611QT, 1011QT, 2011QT

Equipotential bonding

Equipotential

bonding

D Comply with the circuit diagram included with the

appliance!

D Table units are supplied with a power cable as

series equipment. If the connecting cables must

be replaced, for example, due to the building

structure, a mains cable of the type H07RNF

according to VDEstandard must be used.

D Observe the data on the type plate when making

the electrical connection.

The appliance must be connected to the equi

potential bonding system (earth connection). Its effi

ciency must be checked in accordance with

VDE0190.

Electrical‐supply cable

14 / 24

6.1 Connection to an energy optimisation unit (option)

Installation instructions

Circuit diagram example

PCB control assembly

6.2 Connection to a load shedding unit

− Load shedding units switch off the consumers in the event of power peaks.

− In the event of switching off by the load shedding unit, the cooking chamber heating is switched off.

− Thereby, heating-up and cooking processes currently being carried out are not taken into considera

tion.

Connection

D A load shedding unit must only be connected by an electrical technician or the authorised customer

service.

D When purchasing the "Connection energy optim

isation" option, the appliance is equipped by the

factory with the necessary interface (ABCD inter

face).

− A = Appliance switched on

− B = Appliance is heating

− C = Requirement (energy optimisation unit)

− D = Neutral conductor (N)

D An energy optimisation unit may be connected

only by an electrical technician or the authorised

customer service.

D Connection, see circuit diagram!

Important:

− For example, if the phases L2 and L3 are switched off by the load shedding unit, the fused power path

(fuse F4) must be reconnected to L1.

− Observe the circuit diagram!

D If connection to L1 is not correct, operation is not possible. An error message is emitted.

7. Initial commissioning

. Remove cartons, foils, accessories, grilles and containers from the cooking chamber.

. Clean outside of the appliance.

. Clean the cooking chamber.

D If a heating process is not possible after transport in cold environments: The safety temperature limiter

cuts off at freezing temperatures. Once the safety temperature limiter has been sufficiently warmed

again from the room temperature, it activates itself automatically.

. Before initial commissioning or after extended operating breaks, fill approx. 5 litres of water into the

cooking compartment drain (overheating protection/(odour trap).

Only for appliances with automatic cleaning system, not for Types 2011:

. Before initial commissioning or after extended operating breaks, fill approx. 5 litres of water into the

cooking chamber drain (overheating protection/odour trap).

D If no water is filled (fault number 4003), this results in destruction of the pumps in the drain system!

Description of cleaning process, see chapter in the operating instructions:

− Connection of the cleaning‐ and rinse‐aid canisters for automatic cleaning (optional)

− Cleaning the appliance and the cooking chamber

15 / 24

Installation instructions

8. Dimensions, connections, technical data

8.1 Dimensions and connections 623T, 611T, 1011T

Width:

623T

611T = 809 mm

1011T = 809 mm

Cooking chamber supply air

38 mm

Cooking chamber

exhaust air

38 mm

Length:

Height:

623T = 764 mm

611T = 764 mm

1011T = 1,004 mm

Electrical connection

Rinse‐aid (blue)

Cleaner (red)

Equipotential bonding

Network connection (LAN)

Cold water 3/4 inches

Soft water 3/4

inches

Drain pipe

dia. 40 mm

623T = 435 mm

611T = 615 mm

1011T = 615 mm

16 / 24

We reserve the right to make technical changes

Installation instructions

8.2 Dimensions and connections 611/621QT, 1011/1021QT

Width:

Length:

795 mm

980 mm

Cooking chamber exhaust air

35 mm

Cooking chamber supply air

Height with bases

611QT = 840 mm

1011QT = 1,120 mm

Cold water 3/4 inches

55

145

75

Soft water 3/4 inches

Equipotential bonding

Rinse‐aid

(blue)

Network

connection (LAN)

63 mm

710

Cleaner

(red)

Electrical

connection

Drain pipe diameter 40 mm

Rear of

appliance

We reserve the right to make technical changes

17 / 24

Installation instructions

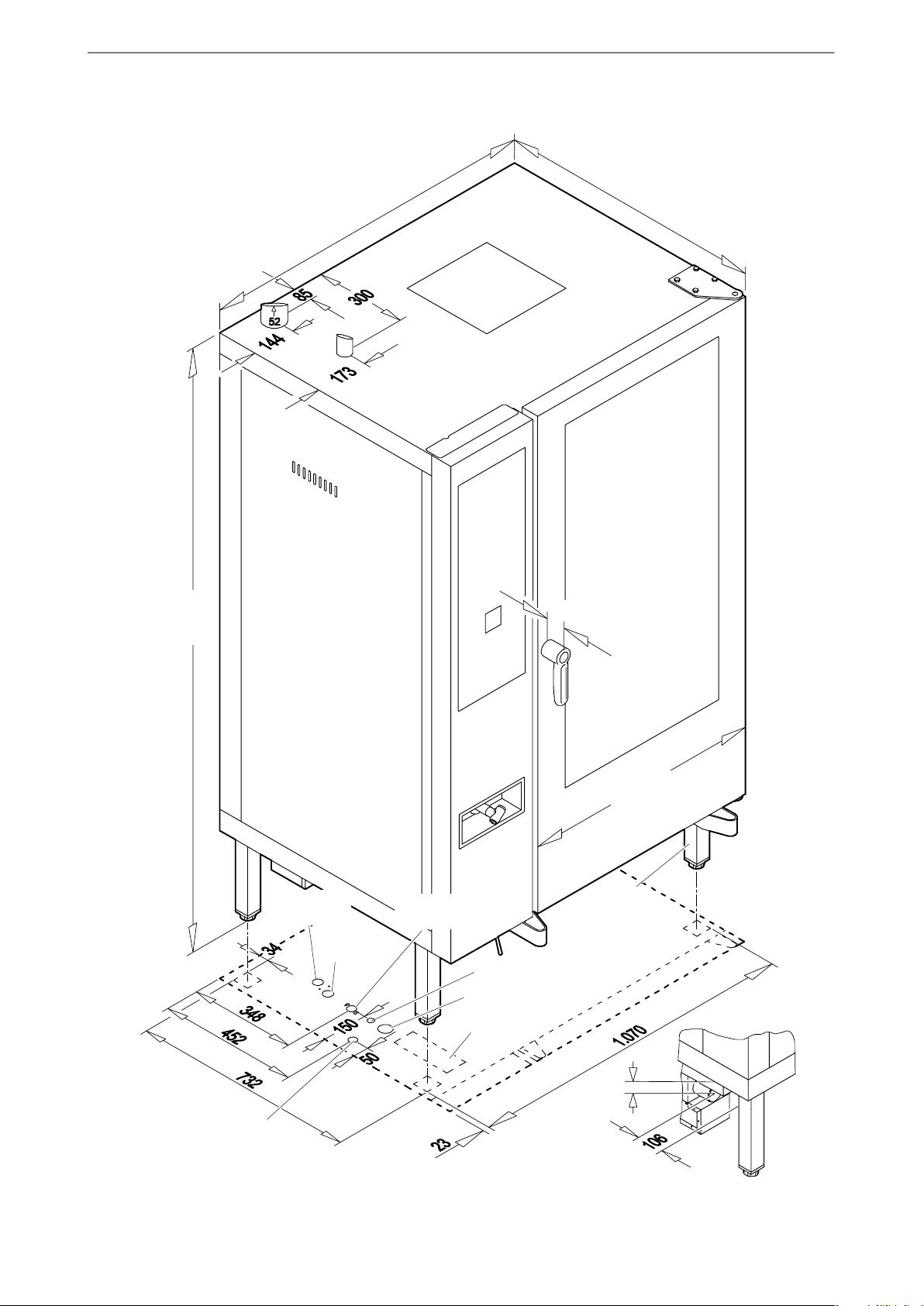

8.3 Dimensions and connections 2011/2021QT

Cooking chamber

exhaust air

Height with

bases

1930 mm

Length:

1115 mm

Width:

880 mm

Cooking

chamber

supply air

63 mm

Cleaner

(red)

Rinse‐aid

(blue)

Soft water 3/4 inches

We reserve the right to make technical changes

Cold water

3/4 inches

Air filter

Width:

785 mm

Base

52x52 mm

Potential equalisation

Electrical

connection

Rear of device

92

Drain pipe diameter 50 mm

18 / 24

8.4 Technical data: 623T, 611T, 1011T

Installation instructions

Technical specifica

tions

623 T 611 T 1011 T

Cooking chamber size 6 x GN 2/3 6 x GN 1/1 10 x GN 1/1

Voltage

Connected load

Fuse

Thermal output, sensi

tive

Thermal output, latent

Steam output

Degree of protection

against water

Appliance noise level

400V 3N 50/60Hz

*)

230V 1N 50/60Hz /

*)

3.8 kW / 6.3 KW 8.6 kW 11.0 kW

3 x 16A

*)

1x16A

0.76 kW

*)

0.46 kW

1.134 kW

*)

0.684 kW

1.67 kg/h

*)

1.01 kg/h

400V 3N 50/60Hz 400V 3N 50/60Hz

3 x 16 A 3 x 16 A

1.03 kW 1.32 kW

1.548 kW 1.98 kW

2.28 kg/h 2.92 kg/h

IPX4 IPX4 IPX4

x70 dB (A) x70 dB (A) x70 dB (A)

Empty weight Approx. 84 kg Approx. 93 kg Approx. 107 kg

8.5 Technical data: 611/621QT, 1011/1021QT

Technical specifica

tions

Cooking chamber size 6 x GN 1/1 10 x GN 1/1 7 x GN 2/1 11 x GN 2/1

Voltage 400V 3N

Connected load 11,0 KW 16.4 kW 18,6 KW 25,5 / 30,7 / 33,5

Fuse 3 x 16A 3 x 25 A 3 x 32 A

Thermal output, sensi

tive

Thermal output, latent 1.98 kW 2.96 kW 3,35 kW 6,03 kW

Steam output 2.92 kg/h 4.35 kg/h 4,93 kg/h 8,87 kg/h

Degree of protection

against water

611 QT 1011 QT 621 QT 1021 QT

400V 3N

50/60Hz

50/60Hz

1.32 kW 1.97 kW 2,23 kW 4,02 kW

IPX5 IPX5 IPX5 IPX5

400V 3N

50/60Hz

*)

230V 3

50/60Hz

*)

3 x 50 A

400V 3 / 3N

50/60Hz

440V 3 50/60Hz

kW

3 x 40 A

3 x 50 A

Appliance noise level

x70 dB (A) x70 dB (A) x70 dB (A) x70 dB (A)

Empty weight Approx. 142 kg Approx. 166 kg Approx. 142 kg Approx. 166 kg

19 / 24

Installation instructions

8.6 Technical data: 2011/2021QT

Technical data 2011 QT 2021 QT

Cooking chamber size 20 x GN 1/1 20 x GN 2/1

Voltage 400V 3N 50/60Hz 400V 3 / 400V 3N

Connected load 34,6 kW / 44,0 kW 51,5 kW / 67,1 kW

Fuse 3 x 63 A 3 x 80 A

Thermal output, sensitive 4,15 kW / 5,28 kW 6,18 kW / 8,05 kW

Thermal output, latent 6.228 kW / 7.92 kW 9,27 kW / 12,08 kW

Steam output 9.169 kg/h / 11.66 kg/h 13,65 kg/h / 17,78 kg/h

50/60Hz

3 x 100 A

Degree of protection against

water

Appliance noise level

Empty weight Approx. 385 kg Approx. 385 kg

IPX4 IPX4

x70 dB (A) x70 dB (A)

8.7 Technical specifications condensation cover (optional)

Technical specifications 623/611/1011 T 611/1011/621/1021 QT

Height of the condensation

cover

Fan speeds 4 4

Fan output 600 m3³/h 1200 m3³/h

Voltage

Connected load 0.06 kW 0.18 kW

Fuse Via device connection Via device connection

Connected inside the Hot air

steamer/ Combi-steamer

150 mm 170 mm

230V 1N 50/60 Hz

230V 1N 50/60 Hz

Connected inside the Hot air

steamer/ Combi-steamer

20 / 24

Appliance noise level

Weight Approx. 22 kg Approx. 40 kg

x70 dB (A) x70 dB (A)

21 / 24

22 / 24

23 / 24

Translation of the original installation instructions

878976 / 7.11 / 12.15

SALVIS AG

Nordstrasse 15

CH‐4665 Oftringen

Tel. +41 (0)62 788 18 18

Fax. +41 (0)62 788 18 98

Internet: www.salvis.ch

E‐Mail: info@salvis.ch

Loading...

Loading...