SaltDogg TGS05B User Manual

Qualit y since 194 6

Installation Instructions

TGS05B

SAFETY PRECAUTIONS

WARNING

Observe the following Safety Precautions before,

during and after operating this spreader. By following these precautions and common sense, possible injury to persons and potential damage to

this machine may be avoided.

1. Read this entire Owners Manual before operating this spreader.

2. Read all safety decals on the spreader before

operating.

3. Verify that all personnel are clear of the

spreader spray area before starting or operating

this spreader.

4. Do not adjust, clean, lubricate or unclog material

jambs without first turning off the spreader.

5. Make sure the spreader is securely fastened to

the vehicle in accordance with this manual.

6. Do not operate a spreader that is in need of

maintenance or repairs.

7. Always disconnect the battery before removing

or replacing electrical components.

SPREADER ASSEMBLY

Check contents of box against parts list to make

sure all components are included. When ordering

replacement or spare parts refer to parts list for

part numbers.

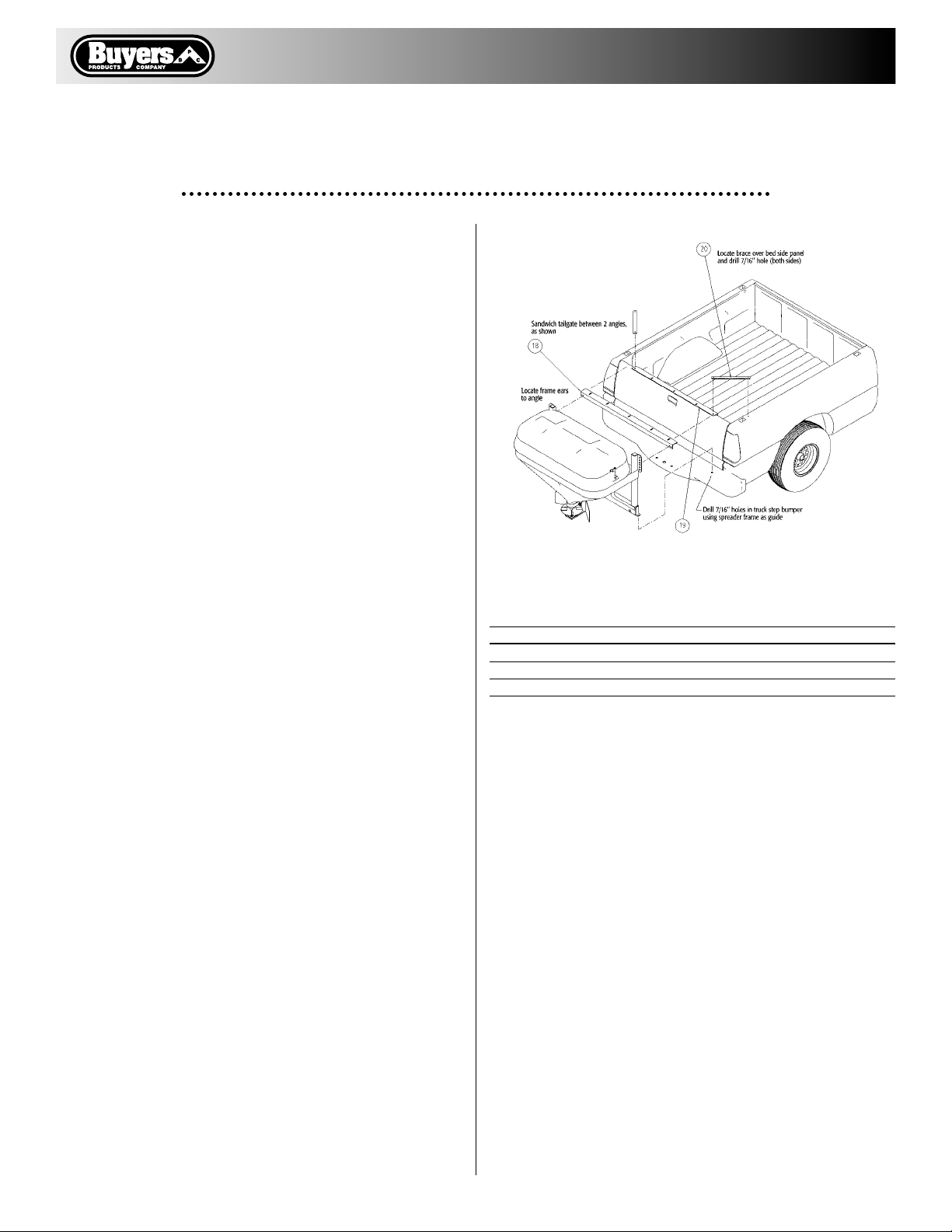

INSTALLATION

1. Locate and mark center of tailgate.

2. Assemble Angles (18, 19) and Braces (20) as

shown in Fig.1 Use 3/8" carriage bolts, flat washers

and nuts. Do not tighten fasteners at this moment.

3. Center assembly on top of tailgate. Lower angle

must be flush with top and inside surfaces of

tailgate.

9049 Tyler Blvd. • Mentor, Ohio 44060

Phone (440) 974-8888 • Fax (440) 974-0165

Toll-Free Fax 800-841-8003 • buyersproducts.com

Fig. 1 Mounting

Chart A Torque

BOLT NUT SIZE TORQUE (FT-LBS)

1/4-20 6.0

5/16-18 11.0

3/8-16 20.0

4. Position braces (20) on top of side rails. Using

holes in braces as guides mark and drill holes for

3/8" screws.

5. Attach braces to side rails using 3/8" screws,

flat washers and nuts.

6. Center spreader assembly on top of rear

bumper and align with holes in Angle (18).

7. Using holes in spreader frame as guides, mark

and drill holes for 3/8" screws in rear bumper.

8. Assemble spreader to Angle (18) and rear

bumper. Adjust position of Angles (18, 19) to bring

spreader into vertical position. Tighten all screws

at this moment.

5

—continued inside

Qualit y since 194 6

ELECTRICAL INSTALLATION

WARNING!

Do not drill holes into fuel tanks, fuel lines,

through electrical wiring, etc that may be

damaged by drilling.

To insure good performance of your spreader,

check the condition of truck’s electrical system.

Using digital voltmeter, check alternator and

battery voltage. With engine running and head

lights and heater fan ON good voltage reading

should fall between 13.0 and 15.3 volts. If voltage

reading falls out of this range, check and adjust

your electric system.

1. Lay out path for the Red Wire (0203800) in the

truck’s engine compartment. This wire will be connected to positive terminal on truck’s battery. Drill

hole in the firewall or use an existing one to pass

wire into cab.

Do not route close to exhaust system!

2. Lay out a wiring path for the Wire Assembly

222" long (0203600) toward rear bumper. Drill all

necessary holes or use existing ones to pass the

flat blade connector into the trucks cab. Attach

harness to truck’s frame.

Do not route close to exhaust system!

3. Install Socket Assembly (0203200) near rear

bumper. Remove paint/ primer and attach black

wire of this assembly to truck frame. Doing this

will insure good connection.

4. Connect Wire Assembly (0203600) to Socket

Assembly (0203200).

5. Mount the Controller (3006587) in a convenient

location in the truck cab. Connect Black ground

wire to truck’s frame or battery negative post

(additional wire is required). Connection to battery

negative post is recommended for newer trucks

(2000 and up). It is recommended not to mount

Controller directly in front of the heat vents.

6. Make sure that the Controller is OFF. Connect

blue wire’s small female terminal to Controller’s

connector on controller’s rear wall. Connect the

blue wire from to an accessory wire/terminal

that is controlled by the vehicle’s ignition switch.

Connect battery wire and 222" wire assembly to

Controller.

7. Connect the Red Wire (0203800) ring terminals

to the battery positive post.

8. Attach Adapter (3009863) to Socket Assembly

(0203200).

9. Connect Red motor wire to Black adapter wire

and Black motor wire to Red adapter wire.

10. Make sure Controller is OFF, start the truck.

11. Turn Controller ON. Adjust speed to desired

setting.

Do not change speed abruptly!

It may stall motor.

12. Observe spinner direction of rotation. The

correct direction is counter clock wise when

looking inside hopper from the top. If direction

is clock wise reverse wires between Motor and

Adapter.

IMPORTANT!

Make sure all wires are securely attached to

vehicle or spreader’s frame. Use wire ties and/or

wire clamps to attach wires. All excess wires

must be rolled into bundles and attached to

vehicle or spreader.

SPREADER MAINTENANCE

1. This spreader is designed to use lose free

floating materials such as #1 dry Rock Salt. Using

different grades and/or wet material will affect

spreader performance. Wet material can “bridge”

and stop floating onto spinner disk.

2. Make sure lid is installed and latches are

secured when spreader is in use.

3. Do not leave material in hopper between uses.

4. Do not drive with material in hopper.

5. Always clean/ wash hopper at the end of

the day.

6. Spray lubricant around motor shaft to prevent

water from penetrating into the motor.

7. Apply dielectric grease to all electrical connectors between uses and for long term storage.

CAUTION!

DO NOT ATTEMPT TO INSTALL OR REMOVE

SPREADER WITH MATERIAL IN IT.

2

Loading...

Loading...