TM

Installation Instructions

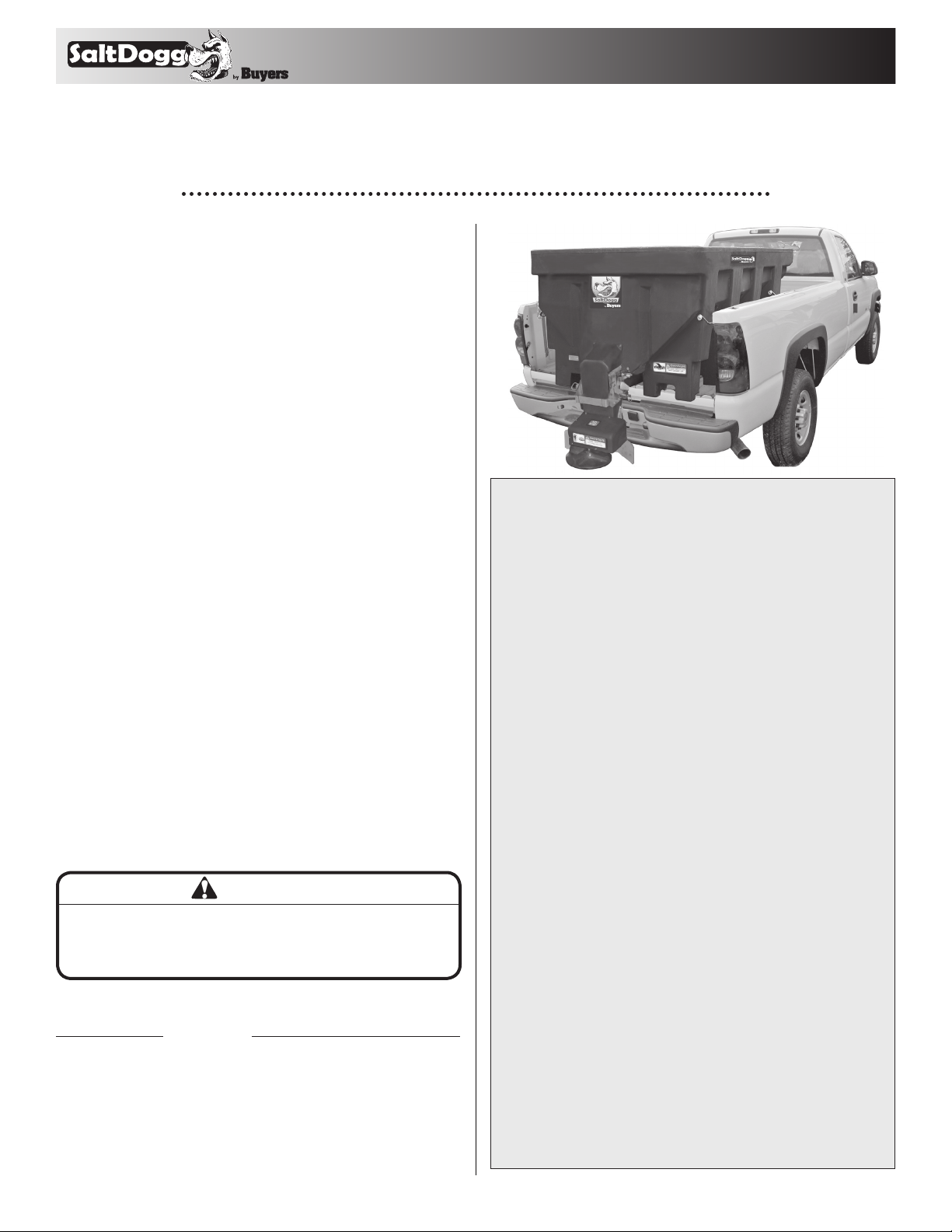

Salt Dogg

Spreader Hopper Poly Electrical

1.5 cubic yards

Protected by U.S. patent D520 524; other patents pending

Table of Contents

General Information .................................................. ..................1

Safety Precautions ..................................................... ..................1

Warranty Information ............................................... ..................2

Installation Instructions ........................................... .................. 2

Spreader Operation ......................................................................5

Spreader Maintenance ............................................. ...................5

Repair Parts & Drawings ........................................................ 6-9

Note: This manual applies to spreaders with serial numbers

2700 and above.

General Information

Spreader model no.s:

• SHPE1500 - spreader with standard chute

• SHPE1500X - spreader with extended chute

Overall Length: 92-1/8"

Overall Width: 50 -1 /2"

Overall Height (installed): 37-1/2"

Empty Weight: 410 lbs.

Capacity Struck: 1.5 cu. yd.

Vehicle Requirements

• 3/4 or 1 ton Pickup Truck above 8500# GVWR.

• 135 amp or higher alternator is recommended.

CAUTION

Do not overload vehicle beyond the vehicle’s GVWR or GAWR.

Check vehicle's load rating certification sticker for maximum

vehicle capacity.

Average Material Weights

Materials to use Weight (pounds per cubic yard)

Fine Salt-Dry 2,250

Coarse Salt-Dry 1,431

Sand/Salt up to 50/50 Mix-Dry 2,700

Note: To calculate the total spreader weight (including ice

control material), add the empty spreader weight plus the ice

control material and spreader accessories.

9049 Tyler Blvd. • Mentor, Ohio 44060

Phone (440) 974-8888 • Fax (440) 974-0165

Toll-Free Fax 800-841-8003 • saltdogg.com

SHPE1500 SALT DOGG SPREADER WARRANTY

INFORMATION

This warranty replaces all previous warranties and

no employee of this company is authorized to extend

additional warranties, or agreements, or implications

not explicitly covered herein.

Buyers Products Company warrants all parts of the

product to be free from defects in material and workmanship for a period of one (1) year. Parts must be

properly installed and used under normal conditions.

Normal wear is excluded.

Any part, which has been altered, including modifications, misuse, accident, or lack of maintenance will

not be considered under this warranty.

The sole responsibility of Buyers Products Company

under this warranty is limited to repairing or replacing any part(s), which are returned, prepaid, 30

days after such defect is discovered, and returned

part(s) are found to be defective by Buyers Products

Company.

Authorization from Buyers Products Company must

be obtained before returning any part. The following

information must accompany defective parts returned

to Buyers Products Company: RMA #, spreader model,

serial number, date installed, and distributor from

whom purchased.

Buyers Products Company shall not be liable for

damage arising out of failure of any unit to operate

properly, or failure, or delay in work, or for any consequential damages. No charges for transportation

or labor performed on any part will be allowed under

this warranty.

—continued inside

9

TM

13.5

8

2" x 4"

2" x 6"

FIT TO BOX

FIT TO BOX

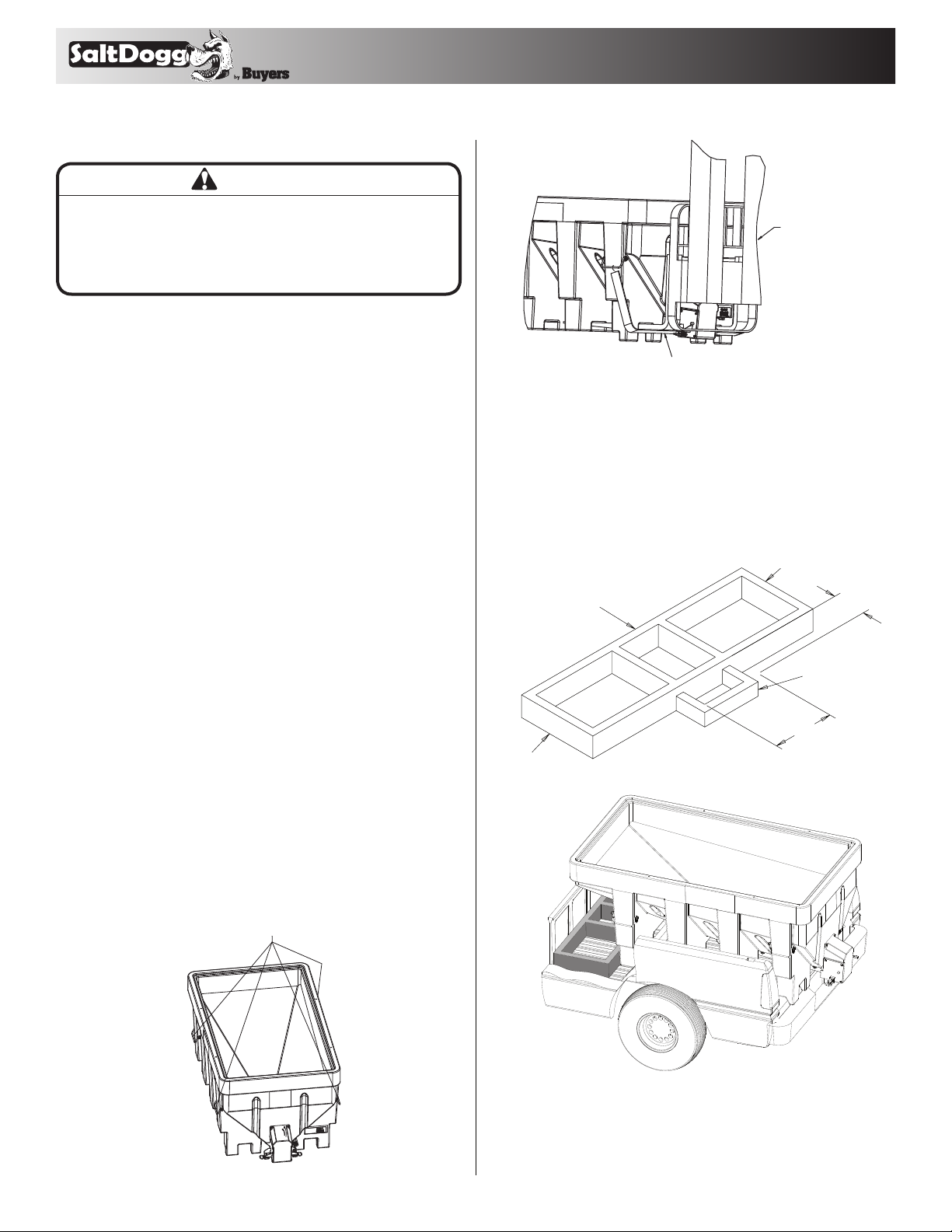

Fork Lift

Pass strap under forks. Attach

strap to tie down on opposite

side of spreader. Tighten strap.

Safety Precautions

Use Tie Downs

WARNING

Observe the following Safety Precautions before, during and

after operating this spreader. By following these precautions

and common sense, possible injury to persons and potential

damage to this machine may be avoided.

1. Read this entire Owners Manual before operating this

spreader.

2. Read all safety decals on the spreader before

operating.

3. Check to make sure all safety guards are securely

mounted into place before operating this spreader.

4. Verify that all personnel are clear of the spreader spray

area before starting or operating this spreader.

5. Do not over-load your vehicle beyond payload limits. If

there are any questions, contact the vehicle manufacturer.

6. Do not adjust, clean, lubricate or unclog material jambs

without first turning off the spreader.

7. Do not climb on or in the spreader during operation. Do not

ride on the spreader while the vehicle is

in motion.

8. Make sure the spreader is securely fastened to the vehicle

in accordance with this manual.

9. Do not operate a spreader that is in need of maintenance

or repairs.

10. Always disconnect the battery before removing or

replacing electrical components.

Fig. 2

D. Slide spreader forward until step on spreader’s most rear

leg makes contact with truck’s bed.

E. Center the spreader from side to side on the vehicle.

F. Measure the distance from the front of the truck bed

to front of the hopper’s front legs. Fabricate spacer to fit

between front of the spreader and front of the bed per Fig. 3

and Fig. 4

Fig. 3

Installation Instructions

1. Mounting the Spreader onto the Vehicle:

A. Remove the tailgate from the vehicle.

B. Check truck’s bed for all kinds of sharp debris or foreign

objects. They can cut and seriously damage poly hopper.

C. Lift spreader- See appropriate instructions below. Lift

spreader by tie downs - Fig. 1. Lift spreader using fork liftInsert fork into fork slots molded in spreader legs - Fig. 2.

Use fork extensions or strap spreader to fork lift as shown.

Fig. 1

Fig. 4

Reinstall screen after removing chute and hardware box

from the hopper.

Always use screen during spreader operation!

2

TM

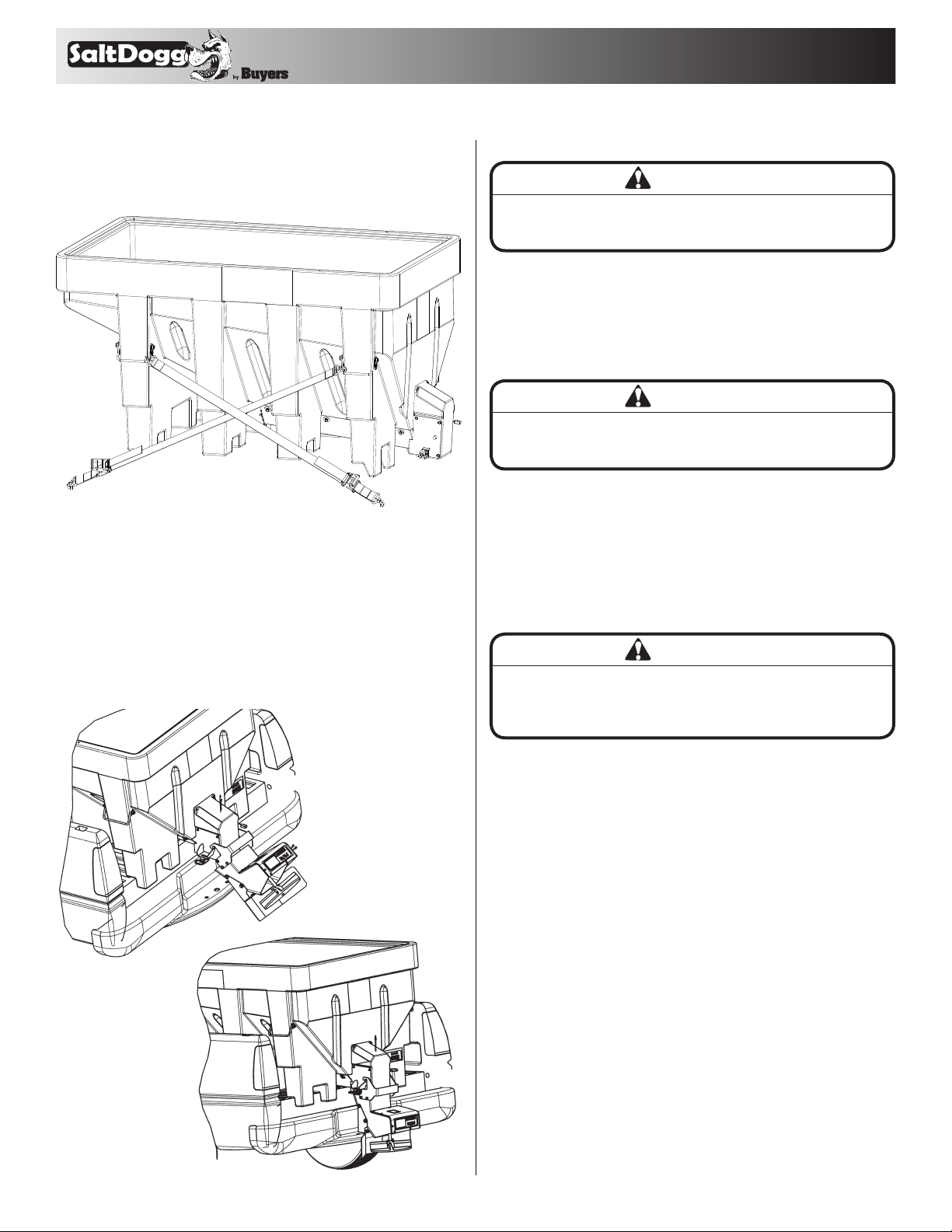

G. Secure spreader using four ratchet straps as shown in Fig.

5. Tighten straps evenly to secure spreader in the middle of

the truck box.

Fig. 5

Verify with the vehicle’s manufacturer that the factory

installed anchor points are designed for tie-down such

load. Inspect straps and hardware after each time spreader

is loaded. Tighten straps and hardware if necessary.

2. Mounting the Spinner/Chute Assembly

A. Attach the Chute Assembly to the spreader. First, hook

the Chute to the spreader by openings in the Chute’s handle.

Then rotate the Chute into operating position and lock using

two spring latches.

3. Control Box and Vehicle Wiring Harness Installation

WARNING

Do not drill holes into fuel tanks, fuel lines, through electrical

wiring, etc that may be damaged by drilling.

To insure good performance of your spreader, check the

condition of truck’s electrical system. Using digital voltmeter,

check alternator and battery voltage. With engine running

and head lights and heater fan on good voltage reading

should fall between 13.0 and 15.3 volts. If voltage reading

falls out of this range, check and adjust your electric system.

WARNING

Use extreme caution when working around an operating

vehicle engine.

A. Lay out a wiring path for the Vehicle Wiring Harness.

Connect the Wire Harness smaller terminal to the Chute’s

harness, large terminal to the Hopper’s harness. Drill all

necessary holes or use existing ones to pass the round

terminal into the trucks cab. Attach harness to truck’s frame.

B. Mount the Controller in a convenient location in the truck

cab. It is recommended not to mount Controller directly in

front of the heat vents.

WARNING

Do not install controller in the deployment path of an air

bag.Refer to vehicle manufacturer’s manual for air bag

deployment area(s).

C. Connect the Wire Harness round terminal to the

Controller round terminal.

D. Lay out path for the Power Cable in the truck’s engine

compartment. Drill hole in the firewall or use an existing one

to pass wire harness. It is recommended to pass the Power

Cable from inside of the cab to the battery due to the large

high amperage connector. Do not route close to exhaust

system!

E. Connect Power Cable terminal to Controller.

F. Connect the Power Cable ring terminals to the truck’s

battery, white-positive, and black-negative.

G. Make sure that the Controller is OFF. Connect blue wire’s

small female terminal to Controller’s Ignition wire. Connect

the blue wire from the Controller to an accessory wire/

terminal that is controlled by the vehicle’s ignition switch

(See Fig. 7).

Spreader Operation

1. SHPE1500 spreader is equipped with a dual independent

speed Controller with warning lights and a Vibrator switch.

To start the spreader, press the ON-OFF switch. Switch will

illuminate. The auger will accelerate to full speed for 2 sec.,

3

Loading...

Loading...