9049 Tyler Blvd. • Mentor, Ohio 44060

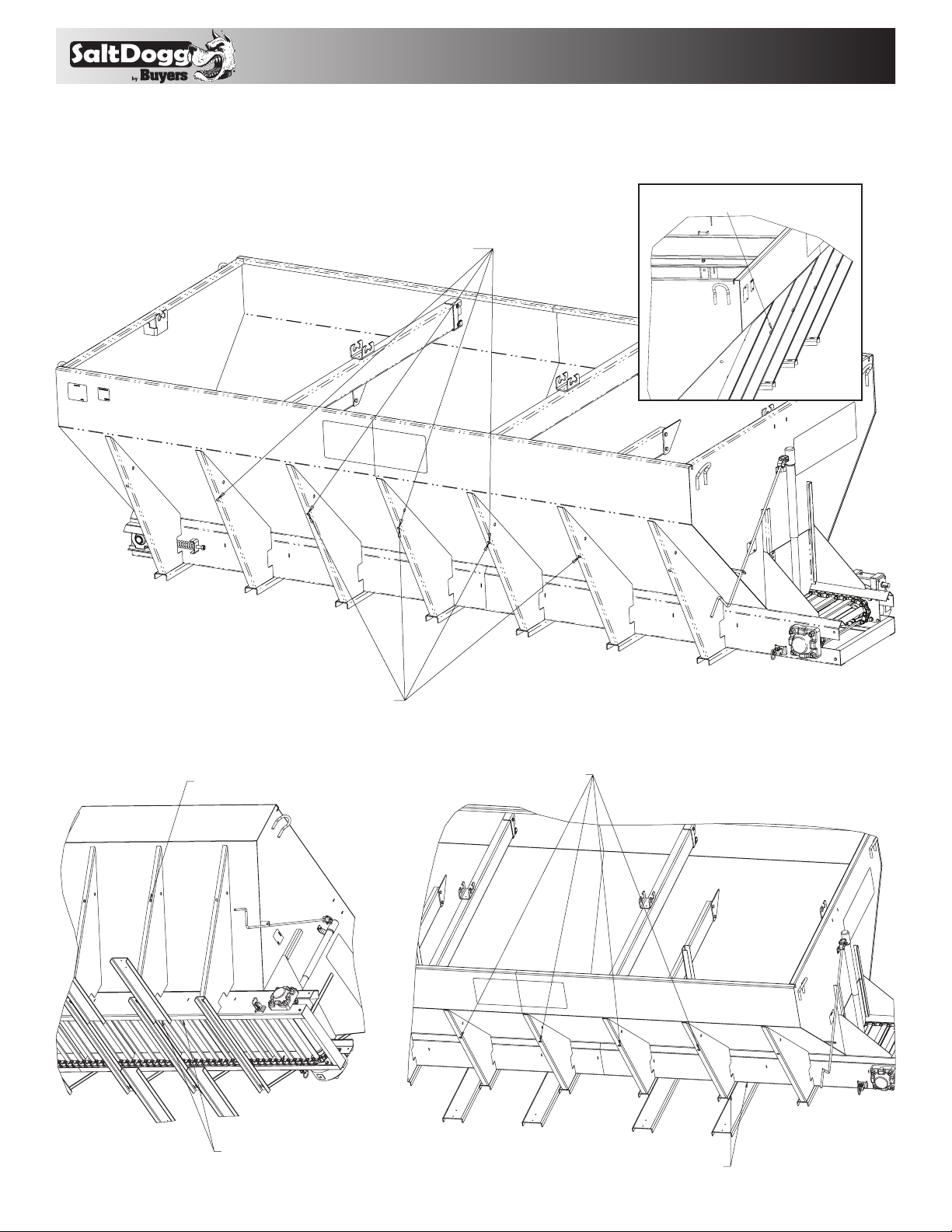

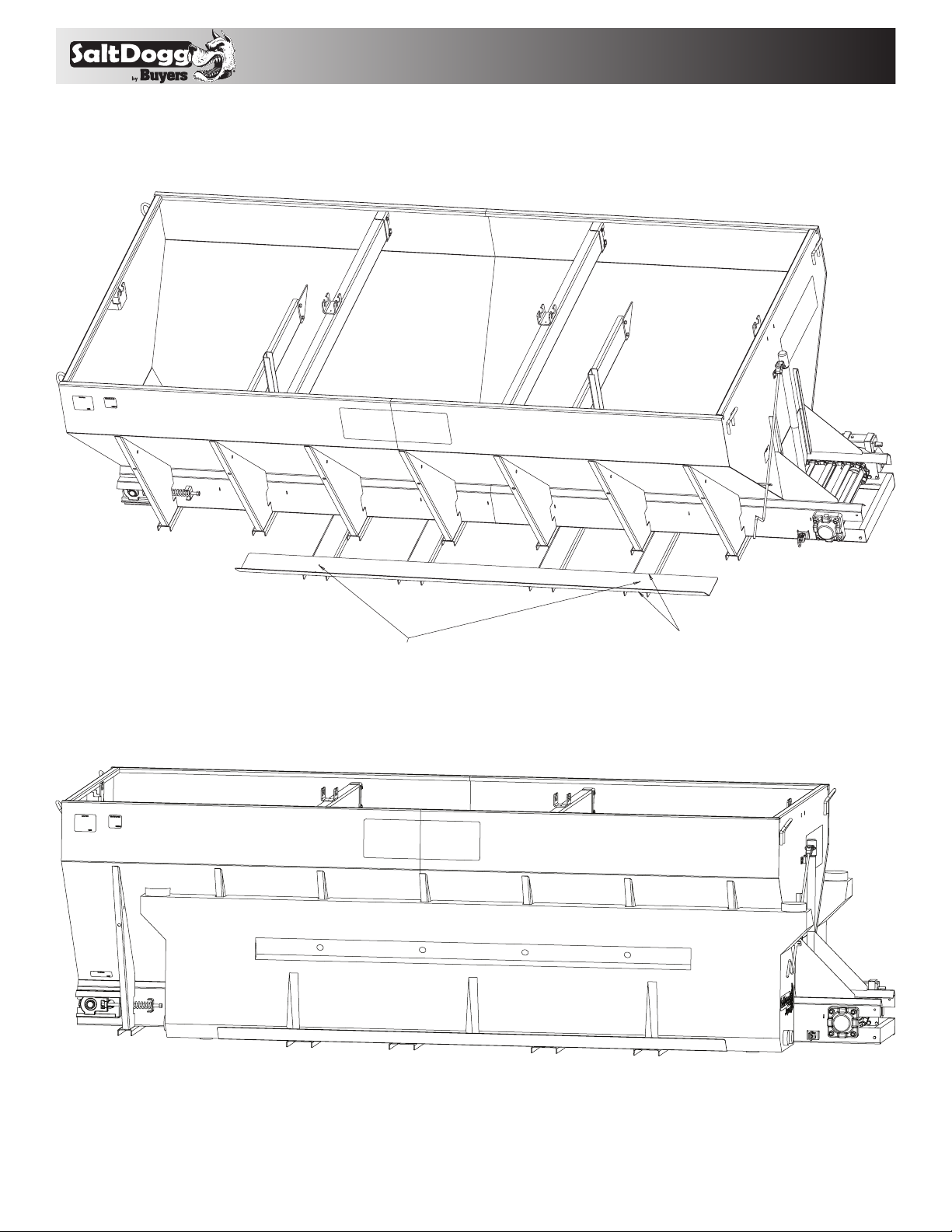

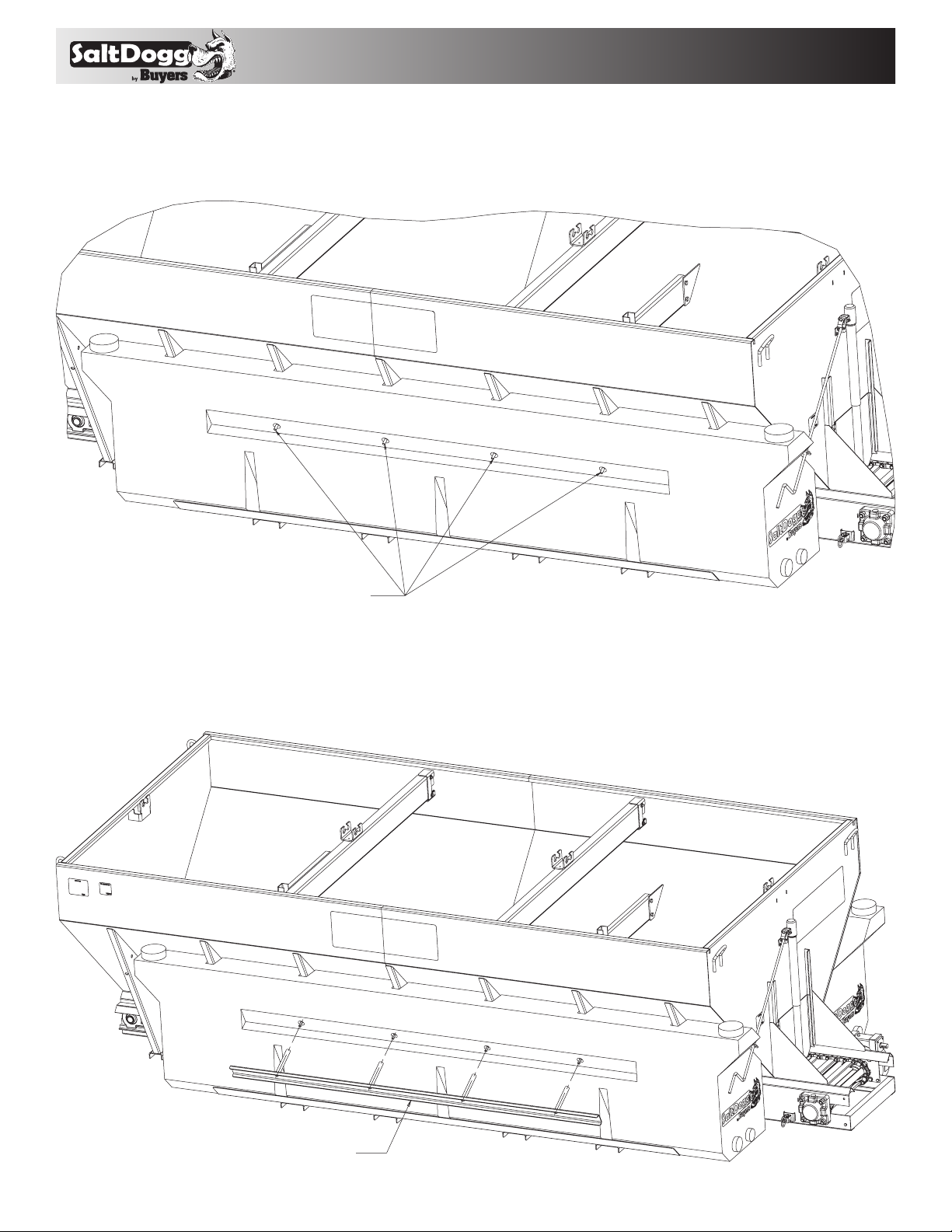

INSTALLATION A - 400 gal. reservoirs positioned towards front of spreader

INSTALLATION B - 400 gal. reservoirs positioned towards rear of spreader

9049 Tyler Blvd. • Mentor, Ohio 44060

Phone (440) 974-8888 • Fax (800) 841-8003

Phone (440) 974-8888 • Fax (800) 841-8003

www.saltdogg.com

www.saltdogg.com

Installation Instructions

LS10 Liquid Spay System 2 x 400 gallon tanks

LS10 is designed for 14 and 15 ft long municipal type spreaders. Installation is possible in two styles

(see installation A and installation B pictures).

1

Fig. 1

—continued inside

9049 Tyler Blvd. • Mentor, Ohio 44060

FOR INSTALLATION B

WELD PROJECTION WELD NUTS IN THESE LOCATIONS

IN SHOWN LOCATIONS

WELDED NUTS

Phone (440) 974-8888 • Fax (800) 841-8003

www.saltdogg.com

1. Position 1/2-13 projection weld nuts on inside gusset surface and weld them as shown in FIG 1

and FIG 2. Follow welding order for Installation A or Installation B.

ALIGN NUT IN THE HOLE. WELD AROUND NUT.

PROTECT THREAD FROM WELDING.

Fig. 1

FOR INSTALLATION A

Fig. 2

WELD PROJECTION WELD NUTS IN THESE LOCATIOS

2. Align channels #3026808 to hopper sill bottom edge and clamp to hopper cross channels. See

FIG 3 for channels positions and welding recommendations.

REAR MOST NUT

ALIGN CHANNEL EDGE WITH

SILL EDGE. CLAMP CHANNELS

IN THIS POSITION

Fig. 3

WELD CHANNEL TO HOPPER

2

9049 Tyler Blvd. • Mentor, Ohio 44060

GRIND OFF EXCESSIVE WELDS, IF NECESSARY

INSTALL TANKS AS SHOWN

Phone (440) 974-8888 • Fax (800) 841-8003

www.saltdogg.com

3. Align holes in retainer #3026545 with holes in channels #3026808 and weld retainers to channels

as shown in FIG 4.

Fig. 4

ALIGN HOLES IN CHANNELS AND RETAINERS

WELD RETAINERS TO EVERY CHANNEL.

4. Install tanks #3026538 on retainers aligning 4 holes in tanks with nuts wedded to gussets FIG 5.

Fig. 5

3

9049 Tyler Blvd. • Mentor, Ohio 44060

LEAVING ABOUT 1 INCH EXPOSED.

PASS THREADED RODS THRU TUBES.

Phone (440) 974-8888 • Fax (800) 841-8003

www.saltdogg.com

5. Apply thread locker on threaded rods #3026587. Pass rods thru tank holes and screw them into

welded nuts. Leave rods sticking out about 1 inch from tank surface FIG 6.

Fig. 6

APPLY THREAD LOCKER ON THREADED ROD.

ASSEMBLY THREADED RODS INTO WELDED NUTS,

6. Insert retainer #3026545 into tank holes. Pass threaded rods thru tubes FIG 7.

Fig. 7

INSERT RETAINERUPPER INTO TANK OPENINGS AS SHOWN.

4

Phone (440) 974-8888 • Fax (800) 841-8003

SECURE RETAINER USING 1/2 INCH WASHERS AND NUTS.

7. Secure retainer using 1/2 inch flat washers and nylon insert nuts FIG 8.

Fig. 8

9049 Tyler Blvd. • Mentor, Ohio 44060

www.saltdogg.com

8. Weld enclosure bracket #3028485 in desired location based on Installation A or B style. If space is

limited custom bracket fabrication is necessary.

9. If jack handle is rubbing against tank or other obstacle, it can be relocated using supplied handle

guide #3026823. To relocate handle it must be disassembled from jack, pass thru handle guide and

reassembled to jack FIG 9. After these operations, handle guide can be positioned and welded in

new location. Make sure that jack is operating freely after handle reposition!

JACK HANDLE CAN BE

REPOSITIONED USING SUPPLIED

ATTACH ENCLOSURE TO

BRACKET

ATTACH ENCLOSURE BRACKET.

DIFFERENT LOCATIONS CAN BE USED.

5

9049 Tyler Blvd. • Mentor, Ohio 44060

Phone (440) 974-8888 • Fax (800) 841-8003

www.saltdogg.com

10. Assembly enclosure assembly LS102 to bracket, making sure that enough space left to open

enclosure door.

11. Plumb: Reservoir, ball valve, filter, pump enclosure, and spray nozzles according to plumbing

schematic using supplied fittings, hose, and hose clamps. Do not use Teflon tape on threads. Use

liquid thread sealant.

12. In order to install liquid spray nozzles, 2 holes 11/16" diameter must be drilled in chute. Or

nozzles can be installed above spreader conveyor chain ( some custom bracket fabrication is

required).

Cab Controller Installation Instructions FIGs 10-12

1. Install cab controller (#WSE1) in cab for convenient driver operation. Mounting bracket and fasteners included.

WSE25

25' Cable Connector

Fig. 10 WSE1 Cab Controller, front view Fig. 10 WSE1 Cab Controller, rear view

8' Cable Connector

WSE24

2. Route 8' wire harness (#WSE24) under dash from controller (#WSE1) to truck’s fuse panel.

3. Ground “black” wire from controller to truck frame or truck’s battery (not dash).

4. Attach “green” wire in 8' wire harness (#WSE24) to a fused and keyed 15 Amp hot wire circuit.

5. Connect main power “white” wire in 8' wire harness (#WSE24) to fuse box that is “hot” full time or

to battery “positive”.

6. Route the 25' wire harness (#WSE25) from the rear of the spreader to the cab. Plug connector on

controller (#WSE1) to the connector on pump harness (#WSE25).

Fig. 7

6

Fig. 11 Plumbing Diagram

9049 Tyler Blvd. • Mentor, Ohio 44060

Phone (440) 974-8888 • Fax (800) 841-8003

www.saltdogg.com

Reservoir

#3010816

Ball Valve #WSE10

Filter #WSE11

Pump Enclosure #WSE22

Reservoir

#3010816

Ball Valve #WSE10

Filter #WSE11

25' Harness

#WSE25

Pump #WSE3

Pressure Switch #WSE4

Spray Nozzles

Controller

#WSE1

8' Harness

#WSE24

7

Phone (440) 974-8888 • Fax (800) 841-8003

Fig. 12 Nozzle Assembly

WSE9 WSE9 WSE9

WSE34 WSE13

9049 Tyler Blvd. • Mentor, Ohio 44060

www.saltdogg.com

WSE 6168 WSE6065

WSE33 WSE33WSE33

3000269

WSE7

WSE15

WS E14

3000269

WSE7

WSE15

WS E14

from

3010 816

WSE2

WSE10

Fig. 13 Filter/Valve Assembly

WSE2 WSE30

WS E 11

8

WSE9

WSE 6168

to

WSE22

9049 Tyler Blvd. • Mentor, Ohio 44060

Phone (440) 974-8888 • Fax (800) 841-8003

www.saltdogg.com

Liquid Spray System Operating Instructions

1. Read all instructions before operating. Always

wear hand, eye, and skin protection when

working with de-icing chemicals. Make sure

everyone is standing clear of liquid spray system

before operating.

2. Inspect all plumbing for leaks.

3. Open ball valve (#WSE10) at the reservoir.

4. Make sure reservoir has adequate supply

of clean de-icing liquid. Do not operate pump

without liquid.

5. Before turning the cab controller on, turn the

black speed control knob counter clockwise until

it stops to set the pump at the slowest speed.

6. To energize system, turn red power button to

illuminate LCD screen “on” position.

7. Increase pump speed to desired liquid spray

application rate by turning black knob clockwise.

8. If the red low pressure warning light/alarm

comes on, the reservoir is empty or the pump is

off. Do not operate pump without liquid. Note:

Low pressure light and alarm will sound each

time system is started. This is normal and

occurs until sufficient pressure is achieved to

open pressure switch (turning off light/buzzer).

9. Close ball valve (#WSE10) at the reservoir

when not in use.

Liquid Spray System Trouble Shooting Guide

Motor & Pump Operate Erratically: 1,2,3,4,5 (Possible Problem)

Motor runs – Pump does not: 1,2,3,4,5,6,7 (Possible Problem)

Motor & Pump fail to operate: 8,9,10,11,12 (Possible Problem)

POSSIBLE PROBLEM: REPAIR:

1. Little or no de-icer in tank/s Fill

2. Clogged filter Clean

3. Clogged Nozzles Clean

4. Damaged suction hose Replace

5. Ruptured pump diaphragm Replace

6. Ball valve is closed at tank/s Open valve

7. Frozen parts Thaw out

8. Bad electrical connection Inspect

9. Motor failure- burned/seized Replace

10. Cab controller on-off switch not turned on Turn on

11. Bad cab controller on-off switch Replace

12. Blown fuse in cab controller or fuse panel Inspect/replace

CAUTION

Always wear hand, eye, and skin protection when working with

de-icing chemicals. Use extreme care!

Liquid Spray System Routine Maintenance

RESERVOIR:

-Inspect fittings for leaks from cracks or

looseness

-Inspect filler/breather for cracks. Depress

breather to check for adequate spring pressure

or binding

PLUMBING:

-Inspect hoses/fittings/ball valve for leaks,

cracks, looseness, chafing, binding etc.

FILT ER:

-Remove and clean filter element every 8 to 10

hours or as needed depending on how clean

de-icing liquid is

PUMP-PRESSURE SWITCH & ENCLOSURE:

-Inspect wiring for wear and loose or corroded

connections

-Inspect door and gasket to prevent corrosion

NOZZLES:

-Inspect operation for even spray pattern.

Remove and clean as needed

CAB CONTROLLER:

-Inspect lights, switch, and flow control knob

-Inspect wire harness and connections for wear

and loose or corroded connections

CLEANING:

-Wash with hot water and soap after each use

STORAGE:

-Store inside to prevent freezing

-Drain liquid de-icer from tank/s and hoses

when not in use for more than two days or

during extremely low temperatures

-RV anti-freeze or windshield washer fluid should

be run through the system for several minutes

to flush de-icer from the system to prevent

component freezing especially for end of season

storage

CAUTION

Always wear hand, eye, and skin protection when working with

de-icing chemicals. Use extreme care!

9

LS10

8

9049 Tyler Blvd. • Mentor, Ohio 44060

Phone (440) 974-8888 • Fax (800) 841-8003

www.saltdogg.com

7

15

9

Bill of Materials

ITEM PART NO. QTY. DESCRIPTION

1 LS102 1 ENCLOSURE ASSY, WETTING SYST

2 3012164 1 PLUG, SQUARE HEAD, 3/4 NPT

3 3000269 12 WASHER, FLAT 1/2 USS, SST

4 WSE15 2 RUBBER, NOZZLE

5 FWL050088013SS 3 WASHER, LOCK - 1/2 SPLIT SST

6 FNH050013041HSS 3 NUT, 1/2-13 HEAVY HEX, SST

7 3026538 2 TANK 400 GAL POLY

8 3026808 8 CHANNEL

9 3026807 2 RETAINER

10 3026587 8 TREADED ROD 1/2-13 SST

11 3026545 2 RETAINER, UPPER

12 3014454 8 NUT, 1/2-13 PROJECTION WELD SST

13 FNE050013053SS 8 NUT, NYLOCK 1/2-13 SS

14 3026823 1 GUIDE, HANDLE JACK

15 3028485 1 BRACKET, ENCLOSURE

WSE2 4 NIPPLE, HEX 3/4 X 1/2 POLY

2

3

4

5

6

10 11

14

ITEM PART NO. QTY. DESCRIPTION

WSE10 2 VALVE BALL, 1/2 NPT, POLYPROPYLENE

WSE11 2 FILTER, 3/4 NPT, 6 GPM, 300 MICRON,POLY

WSE13 2 ELBOW, BRASS 1/4 NPTF X 1/4 NPTF

WSE14 2 NOZZLE CAP

WSE24 1 HARNESS, WIRE W/ CONNECTOR 8 FT

WSE30 2 BARB,HOSE 3/4 MNPT X 1/2 HB

WSE696 1 HOSE POLY 1/2 X 96 IN

3000165 1 LABEL, 1" X 3" ADHESIVE

3009750 1 DECAL, LIQUID SYSTEM

WSE33 6 BARB,HOSE 1/4 MNPT X 1/2 HB, BRASS

WSE34 2 TEE,1/4 FNPT X 1/4 FNPT X 1/4 FNPT,BR ASS

WSE6168 1 HOSE POLY 1/2 X 168 IN

1

WSE7 2 NOZZLE BODY, BRASS

WSE9 10 CLAMP, HOSE

WSE1 1 CONTROLLER, WET SPRAY SYSTEM

12

13

10

9049 Tyler Blvd. • Mentor, Ohio 44060

Phone (440) 974-8888 • Fax (800) 841-8003

www.saltdogg.com

SAFETY ALERT SYMBOL

This Symbol Means

Please Read & Understand Completely

Before Operating!

EQUIPMENT INSTALLERS & OPERATORS:

TURN OFF ALL POWER BEFORE PERFOM ING

ANY SERVICE OPERATIONS.

• Follow Recommended Operating Procedure.

• Keep Equipment In Safe Operating Condition

At All Times.

• Recognize & Avoid Hazards While Operating,

Servicing and Maintaining Equipment.

ATTENTION!

CAUTION

RESERVOIR & COMPONENTS

MAY CONTAIN HAZARDOUS

MATERIAL.

HANDLE WITH CARE.

WARRANTY

Buyers Products Co. warrants all truck /trailer hardware manufactured or distributed by it, to be free from defects in material and

workmanship for a period of one year from date of shipment. Parts

must be properly installed and used under normal conditions.

Any product which has been altered, including modification, misuse, accident or lack of maintenance will not be considered under

warranty. Normal wear is excluded. The sole responsibility of Buyers

Products Co. under this warranty is limited to repairing or replacing any

part or parts which are returned, prepaid, and are found to be defective

by Buyers Products Co. Authorization from Buyers Products Co. must

be obtained before returning any part. No charges for transportation

or labor performed on Buyers’ products will be allowed under this

warrant y.

11

3027062 Rev. C

Loading...

Loading...