TM

Instruction Manual

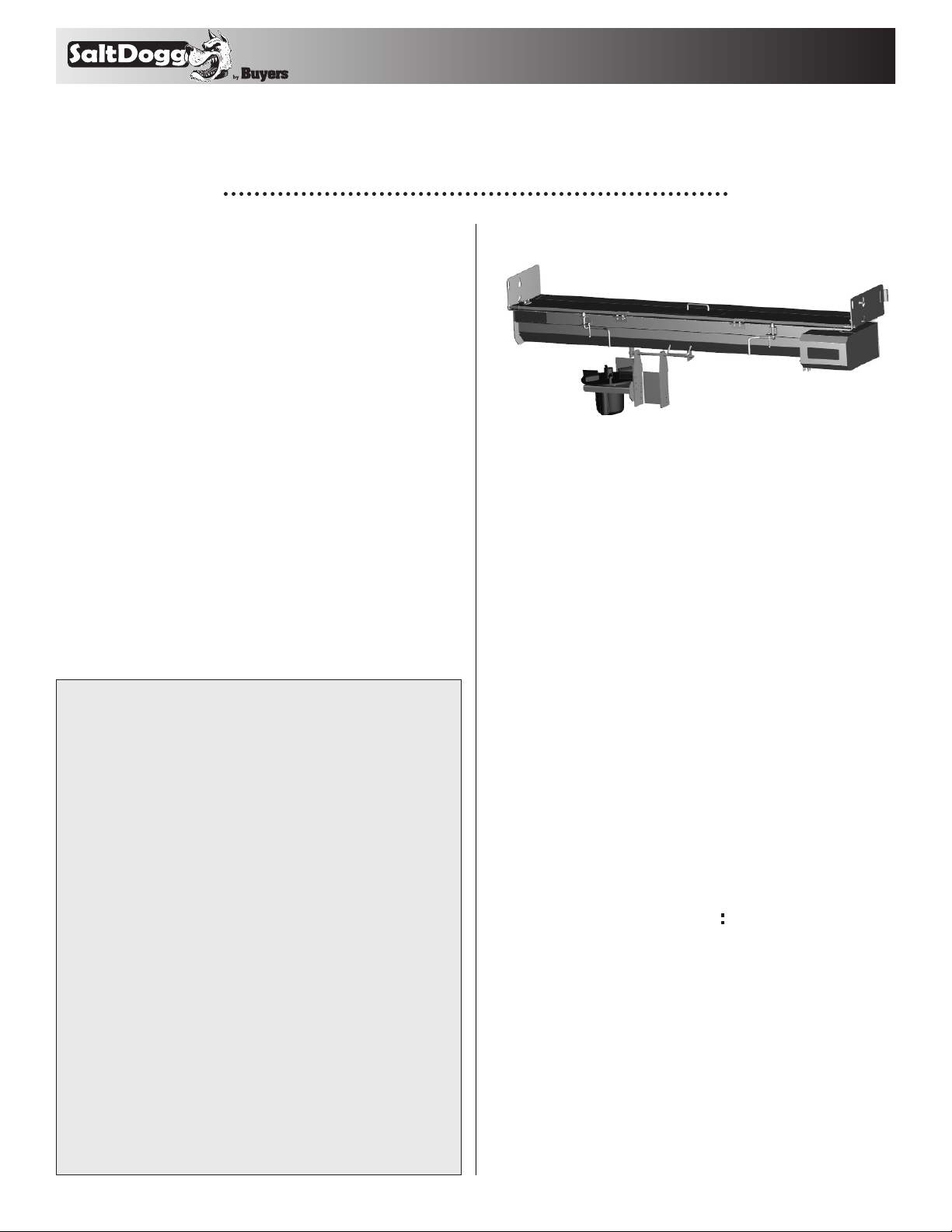

Under Tailgate Spreaders

Electric 12 VDC

92440SSA

Table of Contents

Warranty Information ............................................... 1

Spreader Installation Instructions ........................ 1,2

Spreader Installation Drawing ................................. 2

Spinner Assembly Instructions ..............................3,4

Spinner Assembly Drawing ...................................3,4

Operating Instructions ...........................................5,6

Recommended Maintenance .................................... 6

Parts list .................................................................... 7

Parts List: Hardware Box ......................................... 8

Spinner Components Drawing ................................. 8

UNDER TAILGATE SPREADER WARRANTY

This warranty replaces all previous warranties and no employee

of this company is authorized to extend any additional warranties,

or agreements, or implications not explicitly covered herein.

Buyers Products Company warrants all par ts of the product to

be free from defects in material and workmanship for a period of

(1) one year from the date of original installation. Parts must be

properly installed and used under normal conditions. Normal wear

is excluded.

Any part which has been altered, including modification, misuse,

accident, or lack of maintenance will not be considered under this

warranty. The sole responsibility of Buyers Products Company

under this warranty is limited to repairing or replacing any

part(s) which are returned, prepaid, 30 days after such defect is

discovered, and returned par t(s) are found to be defective by Buyers

Products Company.

Authorization from Buyers Products Company must be

obtained before returning any part. The following information

must accompany defective parts returned to Buyers Products

Company: RMA#, spreader model, serial number, date installed,

and distributor from whom it was purchased. Buyers Products

Company shall not be liable for damage arising out of failure of

any unit to operate properly, or failure, or delay in work, or for any

consequential damages. No charges for transportation or labor

performed on any part will be allowed under this warranty.

9049 Tyler Blvd. • Mentor, Ohio 44060

Phone (440) 974-8888 • Fax (440) 974-0165

Toll-Free Fax 800-841-8003 • saltdogg.com

Installation Instructions

NOTE: The left and right end plates may, on

occasion, get bent through improper handling

during shipment or storage. If this should happen, square and true the left and right end plates

before installation.

1. Aligning the spreader:

A. Position the spreader with the truck such that

the auger gear motor is located on the right side of

the truck (passenger side).

B. Lift the spreader up and under the dump body

tailgate, positioning the spreader forward as close

as possible to the dump body. The tailgate of the

dump body should lay down horizontally over the

spreader.

C. Support the spreader solidly and securely when

positioning for mounting.

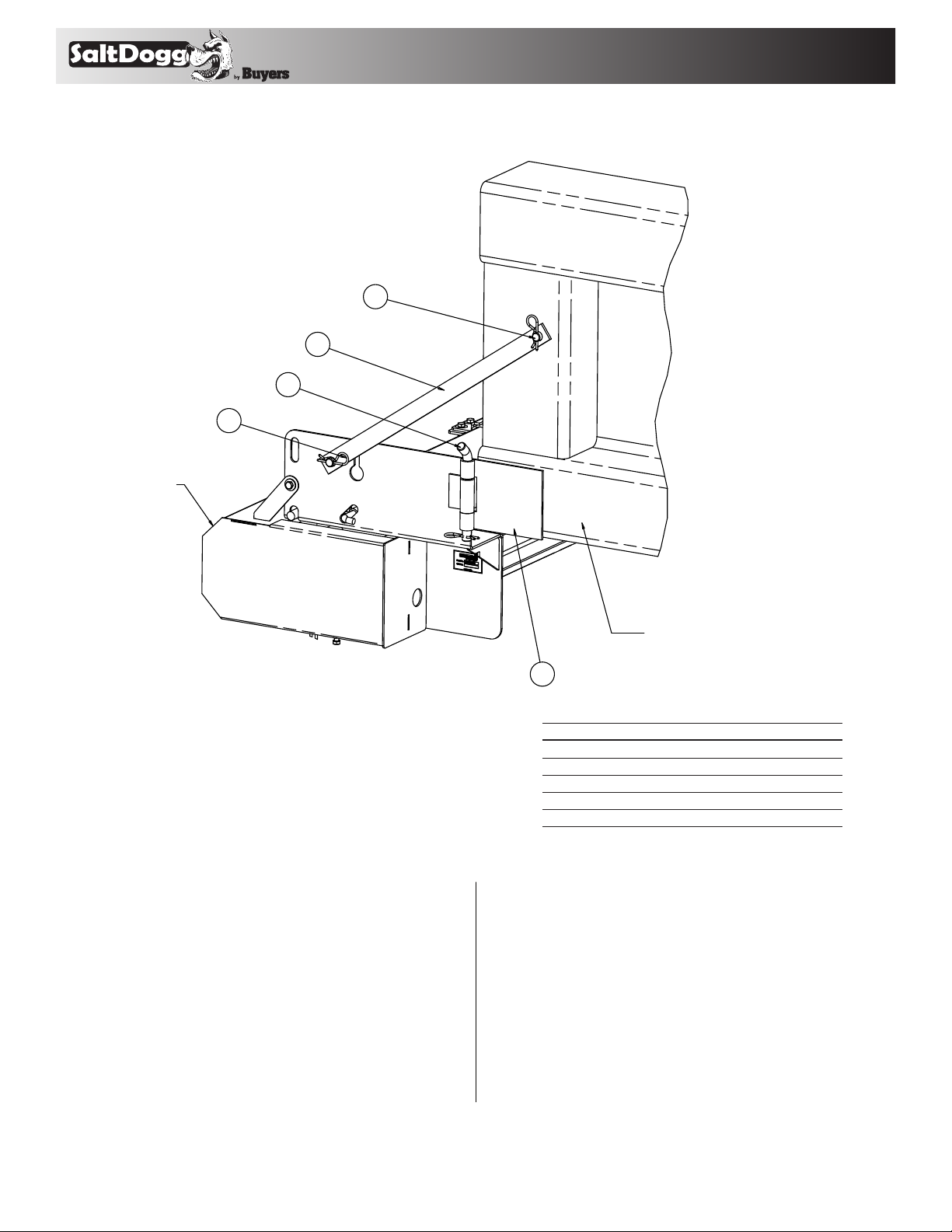

2. Attach mounting brackets (See Fig. 1.)

A. Attach a quick detach plate, (1) to both sides of

the spreader frame using hinge pins (2) and a hairpin cotter pins (5).

B. Position the (2) quick detach plates over the

dump body rub rails and flush with rear edge of

dump body.

C. Weld the quick detach plates to the dump body

rub rails. Weld the plates continuously around 3

sides of each plate. Do not weld along the edge of

the plates next to the attachment pin.

1

—c ontinued inside

SPREADER

TM

Mounting Hardware Installation Drawing

Figure 1

4

3

2

5

D. Align the pin brace (4) on the dump body using

the iron brace (3) for exact positioning. For proper

fit, hanger iron brace may require some minor

bending.

E. Weld the pin braces (4) to the dump body sides,

all around.

F. Attach the iron braces (3) to the pin braces on

the sides of the dump body and the sides of the

spreader using two hairpin cotter pins (Item 5).

DUMP BODY

1

Bill of Materials

item qty. description

1 2 Quick Detach Plate 3009526

2 2 Hinge Pin 3011139

3 2 Hanger Iron Brace 3011137

4 2 Pin Brace 3000210

5 6 Hair Pin Cotter 5/32" –

G. If there is a gap between the spreader and the

dump body, weld or bolt a steel strip to the forward

edge of the spreader to cover the gap.

H. If you have purchased the tailgate side shields

(purchased separately as P/N 924F0106), bolt or

weld them to the inside of the tailgate to prevent

material spillage at the ends of the spreader.

2

TM

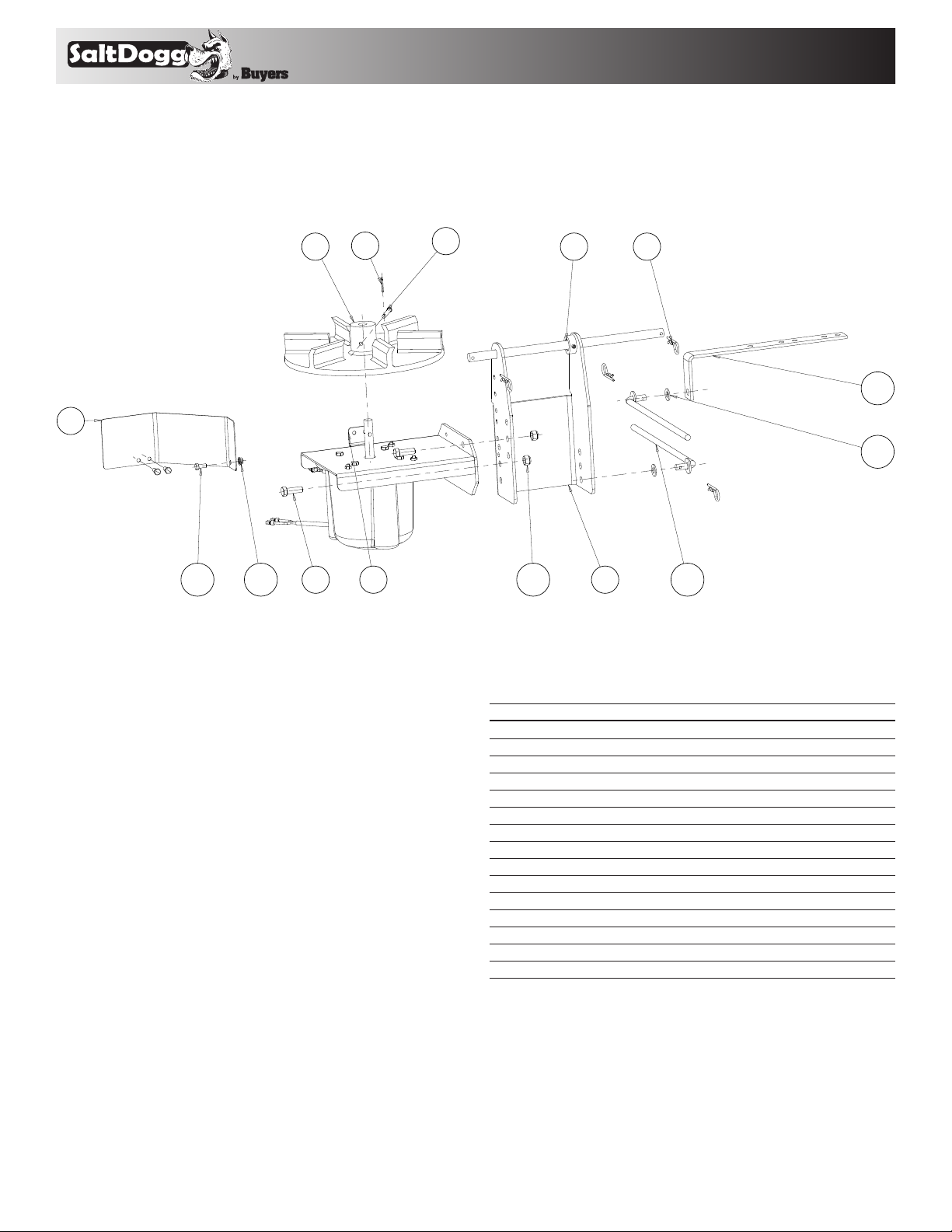

2. Spinner assembly installation:

Figure 2

4

7

9 10 11 12 13

6

3

5

2

8

15

14

1

A. Attach heights adjustment bracket (1) to

spreader lower tray using rod hinge (2) and hair

pins.

B. Attach spinner motor assembly (3) to heights

adjustment bracket (1) using ½-13 screws and nuts.

C. If extra clearance required, use upper holes in

heights adjustment bracket.

D. Attach spinner shield (7) to heights adjustment

bracket (1) using 5/16-18 screws and nuts.

E. Attach spinner disk (4) to motor shaft using

clevis pin and cotter pin.

Bill of Materials

item qty. description

1 1 Bracket Heights Adj. Weldment 3017175

2 1 Rod, Hinge 3006646

3 1 Bracket Spinner Motor Assembly 3017176

4 1 Spinner, 14" Poly CCW 3016394

5 1 Pin, Clevis, 5/16 x 2-1/2, .141 Hole ZN –

6 1 Cotter Pin, 1/8 x 1, Zinc –

7 1 Shield Spinner Disk 301717 2

8 4 Pin, Hair Cotter 5/32" ZN 3.25 OAL –

9 2 Screw, HHC 1/2-13x1.50 SST –

10 2 Nut, Nylock 1/2-13 Zinc –

11 3 Screw, Hex HD, 5/16-18 x 3/4 GR5 SS –

12 3 Nut, Hex Flange - 5/16-18 SS –

13 2 Weldment, Parallel Linkage 924F 0 012

14 2 Washer, Flat 1/2 ID SST –

15 1 Angle, Spinner Lug 3006645

3

TM

PARALLEL

LINKAGE HOLE

D

D1

L

L1

D

D1

L

L1

PARALLEL

LINKAGE HOLE

Figure 3

J. Keeping the spinner assembly level, secure the

spinner frame in place using the set screw or 5/1618 hex screw.

3. Control Box and Vehicle Wiring Harness Installation

MAKE SURE YOU HAVE CONNECTED THE PROPER WIRE COLOR.

THIS IS WIRE GROUND ELECTRICAL SYSTEM! NO

CONNECTIONS TO TRUCK’S FRAME OR BODY ALLOWED!

WARNING

WARNING! Do not drill holes into fuel tanks, fuel lines,

through electrical wiring, etc that may be damaged by

drilling. To insure good performance of your spreader,

check the condition of truck’s electrical system. Using

digital voltmeter, check alternator and battery voltage.

With engine running and head lights and heater fan ON

good voltage reading should fall between 13.0 and 15.3

volts. If voltage reading falls out of this range, check and

adjust your electric system.

Figure 4

F. The leveling mechanism may now be mounted.

Park truck on flat, level surface. With spinner

assembly in level position, carefully measure “L”

and “D” distances. Use any of 3 available holes in

heights adjustment bracket. Locate angle (15) such

that ½” hole will position with D1=D and L1=L.

Modify angle if necessary.

G. Secure angle (15) to the truck frame.

H. Attach parallel linkage rods (13) to heights

adjustment bracket and angle. Secure them using

½” washers and hair pins.

I. Clamp parallel linkage rods together. To verify

leveling action, slowly raise the dump. Be sure that

spinner motor assembly and linkages do not have

any interference with truck body and it does not

have contact with the road. After checking weld

parallel linkage bars together.

NOTE: Always disconnect battery before attempting to

install electrical components on your vehicle.

A. Mount the controller in a convenient location in the truck

cab. It is recommended not to mount the controller directly in

front of heat vents. Allow ample air space around controller.

CAUTION

DO NOT MOUNT CONTROLLER IN THE WAY OF AIR

BAG DEPLOYMENT!

B. Route both wire harnesses into truck cab through firewall

(it maybe necessary to drill holes). Insulate hole to avoid

water leaks.

C. Insure no wires are nicked or damaged during

installation.

D. Connect the 4-pin connector on the wire harness to the

control box 4-pin connector.

E. Connect the 2-pin connector on the power cable to the

control box mating connector.

F. Connect wire harness single connectors to control box

connectors.

G. Connect fuse connector to the fuse terminal or ignition

switch (5 AMP max).

H. Lay out a path for the power cable to the battery, use

quick ties to secure power cable.

DO NOT CONNECT TO BATTERY AT THIS TIME!

I. Lay out path for wire harness to the rear of the vehicle. It

is recommended to stay clear of the exhaust system. Excess

heat can damage the wire harnesses. Use quick ties to

secure harness to underbody.

J. Connect the wire harness to the motor. Make sure wire

colors on wire harness match colors on the motor.

4

TM

CONNECT TO BATTERY

TERMINALS ONLY

CONNECT TO FUSE OR WIRE

IN FUSE PANEL CONTROLLED

BY IGNITION SWITCH

5 AMP MAX

CONNECT TO CHAIN/ AUGER

CONNECT TO

CHUTE MOTOR

#0203700

GEAR MOTOR

#3016943

CONNECT TO VIBRATOR

OPTIONAL

CONNECT

#3016944

CONNECT

CONNECT

#3016934

CONTROLLER

Thoroughly clean battery terminals. Make sure battery

terminals have no tarnish or corrosion. DO NOT CONNECT

WIRE HARNESS TO DAMAGED OR CORRODED

TERMINALS!

IT MAY RESULT IN OVERHEATING, LOST POWER AND

POTENTIAL CONTROLLER DAMAGE!

K. Connect the power cable directly to the battery.

L. Insure all functions of the controller are

working properly.

M. Observe auger moving in proper direction. If direction is

wrong reverse wires between Motor and Wire Harness.

N. Optional spot light (5 AMP max) can be installed on

spreader. Remove cap from single white wire. Connect light

to this wire and trucks frame.

IM PO RTA N T

CONNECT

CONNECT

IMPORTANT Make sure all wires securely attached to

vehicle or spreader. Use wire ties and/or wire clamps

to attach wires. All excess wires must be rolled into

bungles and attached to vehicle or spreader.

ATTACH WIRE HARNESS TO LOWER

DOOR USING CLAMP HK1113 AND

WING NUT 3005723. LEAVE ENOUGH

WIRE SLACK TO PLUG CONNECTORS

5

TO GEAR MOTOR.

Figure 5

TM

Spreader Assembly Parts List

22

29 30 31 32 33 34

23

26

1

7

6

17

24 25

12

13

10

8

20

19

18

11

14

44

9

28

27

3

5

2

4

36

Bill of Materials

item qt y. descr ipti on pArt no.

1 1 Frame, Welded, 96 UTS SS 3015 029

2 1 Tray, Lower Weldment, SS 96 UTS 3015 033

3 2 Latch, Cover HNG MTG BRKT 300 8447

4 1 Rod, Latch, UTS Tray SST PS 3019 033

5 1 Rod, Latch, UTS Tray SST DS 3019 032

6 1 Gasket, Felt Bearing 9240087

7 1 Bearing, 1-1/4 Flange 2 Hole 9240086

8 1 Adapter, Gear Motor, Weldment 3014455

9 1 Bearing, Flanged 1-1/8" 141020 0

10 2 Screw, HCAP 7/16-14 x 1.25 SST –

11 2 Nut HEX NYLOCK 7/16-14 SST –

12 3 Washer, Flat 1/2 USS, SST –

13 3 Screw, HHC- 1/2-13 X 1 SST –

14 1 Gear Motor Conveyor 12 VDC 3013821

15 12 Washer, Flat 3/8 USS SST –

16 15 Screw, HHC 3/8-16 x 1 304 SST –

17 1 Weldment, 96 UTS Auger 924F0081

18 1 Sleeve, Auger Adapter 3 014 858

19 1 Screw, HHC - 1/2-13 x 3 SST –

20 1 Nut, Nylock 1/2-13 Zinc –

21 11 Nut, Nylock 3/8-16 SST –

22 6 Nut, Hex FLNG 3/8-16 SST –

38 39 40 41

item qt y. descr ipti on pArt no.

23 1 Plate, Spinner Cover 3000270

24 2 Nut NYLOCK 5/8-11 SST –

25 2 Screw, HHC - 3/8-16 X 3.5 SST –

26 5 Pin, Hair Cotter, Clear Zinc .091 x 2 –

27 1 Decal, #1, Danger Stay Clear 9240131

28 2 Screw, HHC - 3/8-16 X 1.25 SST –

29 1 Plate, Auger Cover 3014897

30 4 Pin, Clevis 3/8 x 1.125 SST –

31 1 Weldment, Cover, 96IN UTS SST 3012956

32 2 Bracket, SST Cover Latch w. Holes 3006968

33 2 Handle, Stainless Steel Locking 3000268

34 1 Decal, Salt Dogg, BLK/WHT on CLR 3011132

35 1 Cover, Gear Motor Weldment 3017187

36 2 Screw, HHC - 5/16-18 X 5/8 SST –

37 1 Cover Side Gear Motor 301718 6

38 2 Bracket, Receptacle SZ8 Deutsch

39 2 Screw, HHC - 3/8-16 X 1.25 SST –

40 1 Plug 1.00' Dome Heyco 1702 3017483

41 2 Bushing Strain Relief Heyco 2047 3017482

42 3 Screw #12-14x. 74 SS 3015 873

43 1 Decal #2, Danger Before Svce

44 1 Motor Replacement for 3013821

21

43

35

42

37

16

15

3017121

9240132

3014778

6

TM

Hardware Box Parts List

15

10

2

1

11

5

4

14

8

6

7

9

12

13

Bill of Materials

item qt y. descr ipti on pArt no.

1 1 Bracket Spinner Motor Assy. 3017176

2 1 Spinner Shield Disk 3 017172

3 1 Spinner, 14" Poly CW 3016394

4 2 Weldment, Parallel Linkage 92 4F0 012

5 1 Rod, Hinge 3006646

6 1 Angle, Spinner Lug 3006645

7 2 Bracket, Hanger, UTS SST 3011137

8 2 Plate, Detach, Mount SST 3009526

9 2 Pin, Hinge, SST 3011139

10 1 Hardware Bag, UTS Electro 3015181

11 1 Controller Speed 12 VDC, 60 AMP 3016934

12 1 Wire Harness, Main 301694 4

13 1 Power Cord 3016943

14 1 Wire Assembly, 36 Long 0203700

15 1 Bracket Heights Adj. Weldment 3017175

1 Instruction Manual, UTS Electro 3017501

3

7

9049 Tyler Blvd. • Mentor, Ohio 44060

TM

Phone (440) 974-8888 • Fax (440) 974-0165

Toll-Free Fax 800-841-8003 • saltdogg.com

Spreader Motor Assembly

3

1

2

6

4

5

Bill of Materials

item qt y. descr ipti on pArt no.

1 1 Bracket Weldment, Spinner Motor 3017171

2 1 Motor 12 VDC, .5 HP Spinner 3016309

3 4 Screw, HHC 3/8-16 x 1 304 SST –

4 1 Cover, Motor, Drilled 3017174

5 3 Screw, Cap 1/4-20 x 3/4 SST –

6 1 Wire Harness, Chute 3006753

8

30175 01 Rev. C

Loading...

Loading...