TM

Instruction Manual

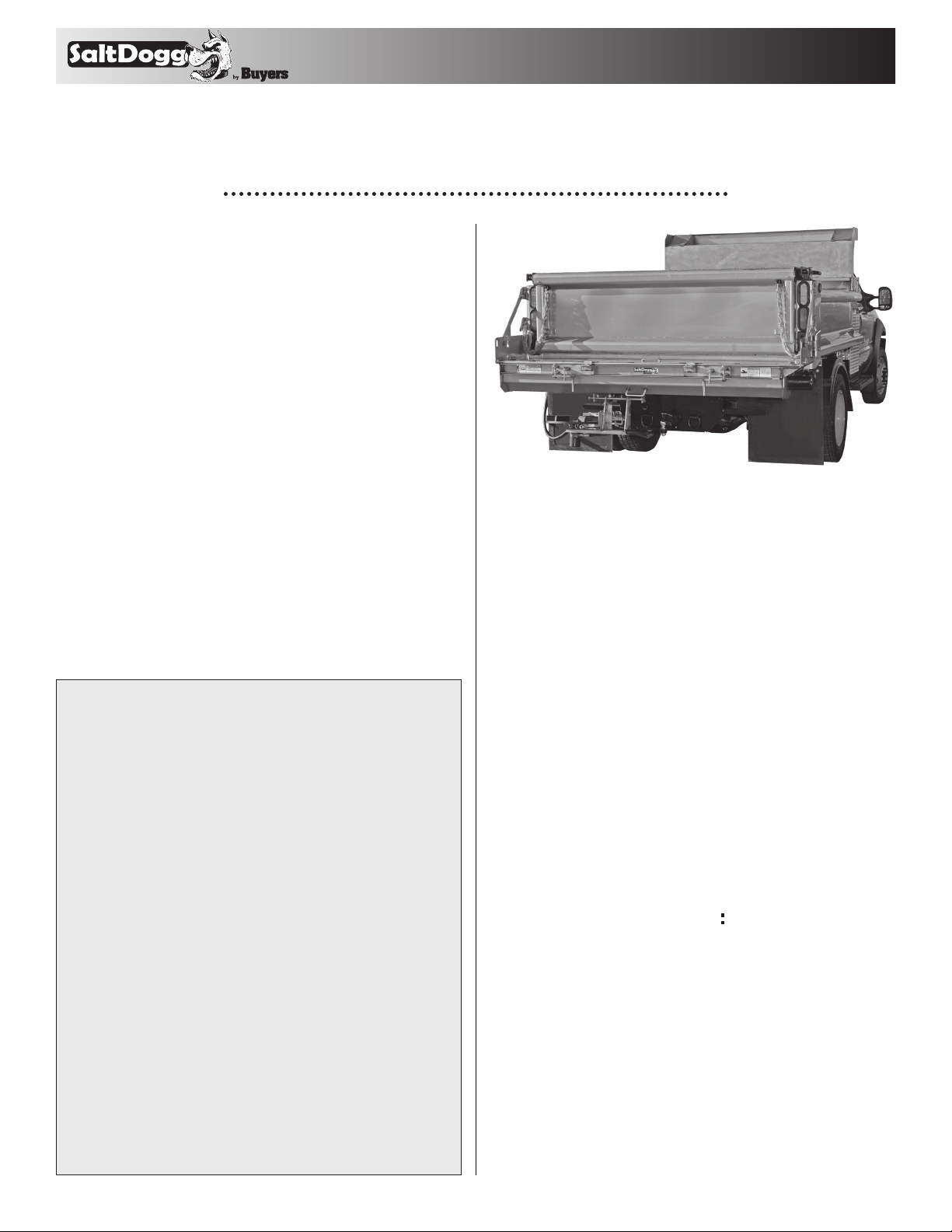

Direct Drive & 5:1 Gear Reduction

Under Tailgate Spreaders

NOTE: This manual applies to spreaders with a

top screen.

Table of Contents

Warranty Information ............................................... 1

Spreader Installation Instructions ........................ 1,2

Spreader Installation Drawing ................................. 2

Spinner Assembly Instructions ................................ 3

Spinner Assembly Drawing ...................................3,4

Hydraulics Installation ............................................. 4

Operating Instructions ...........................................5,6

Recommended Maintenance .................................... 6

Parts list: Spreader Assembly .................................. 7

Spreader Parts Drawing ........................................... 7

Parts List: Hardware Box ......................................... 8

Spinner Components Drawing ................................. 8

Auger Replacement Kits ........................................... 8

UNDER TAILGATE SPREADER WARRANTY

This warranty replaces all previous warranties and no employee

of this company is authorized to extend any additional warranties, or agreements, or implications not explicitly covered herein.

Buyers Products Company warrants all par ts of the product to

be free from defects in material and workmanship for a period of

(1) one year from the date of original installation. Parts must be

properly installed and used under normal conditions. Normal wear

is excluded.

Any part which has been altered, including modification, misuse,

accident, or lack of maintenance will not be considered under this

warranty. Hydraulic units are not to be disassembled without

the express written permission from Buyers Products Company.

The sole responsibility of Buyers Products Company under this

warranty is limited to repairing or replacing any part(s) which

are returned, prepaid, 30 days after such defect is discovered,

and returned part(s) are found to be defective by Buyers Products

Company.

Authorization from Buyers Products Company must be obtained

before returning any part. The following information must accompany defective parts returned to Buyers Products Company: RMA#,

spreader model, serial number, date installed, and distributor from

whom it was purchased. Buyers Products Company shall not be

liable for damage arising out of failure of any unit to operate properly, or failure, or delay in work, or for any consequential damages.

No charges for transpor tation or labor performed on any part will

be allowed under this warranty.

9049 Tyler Blvd. • Mentor, Ohio 44060

Phone (440) 974-8888 • Fax (440) 974-0165

Toll-Free Fax 800-841-8003 • saltdogg.com

Installation Instructions

NOTE: The left and right end plates may, on

occasion, get bent through improper handling

during shipment or storage. If this should happen, square and true the left and right end plates

before installation.

1. Aligning the spreader:

A. Position the spreader with the truck such that

the auger drive is located on the right side of the

truck (passenger side).

B. Lift the spreader up and under the dump body

tailgate, positioning the spreader forward as close

as possible to the dump body. The tailgate of the

dump body should lay down horizontally over the

spreader.

C. Support the spreader solidly and securely when

positioning for mounting.

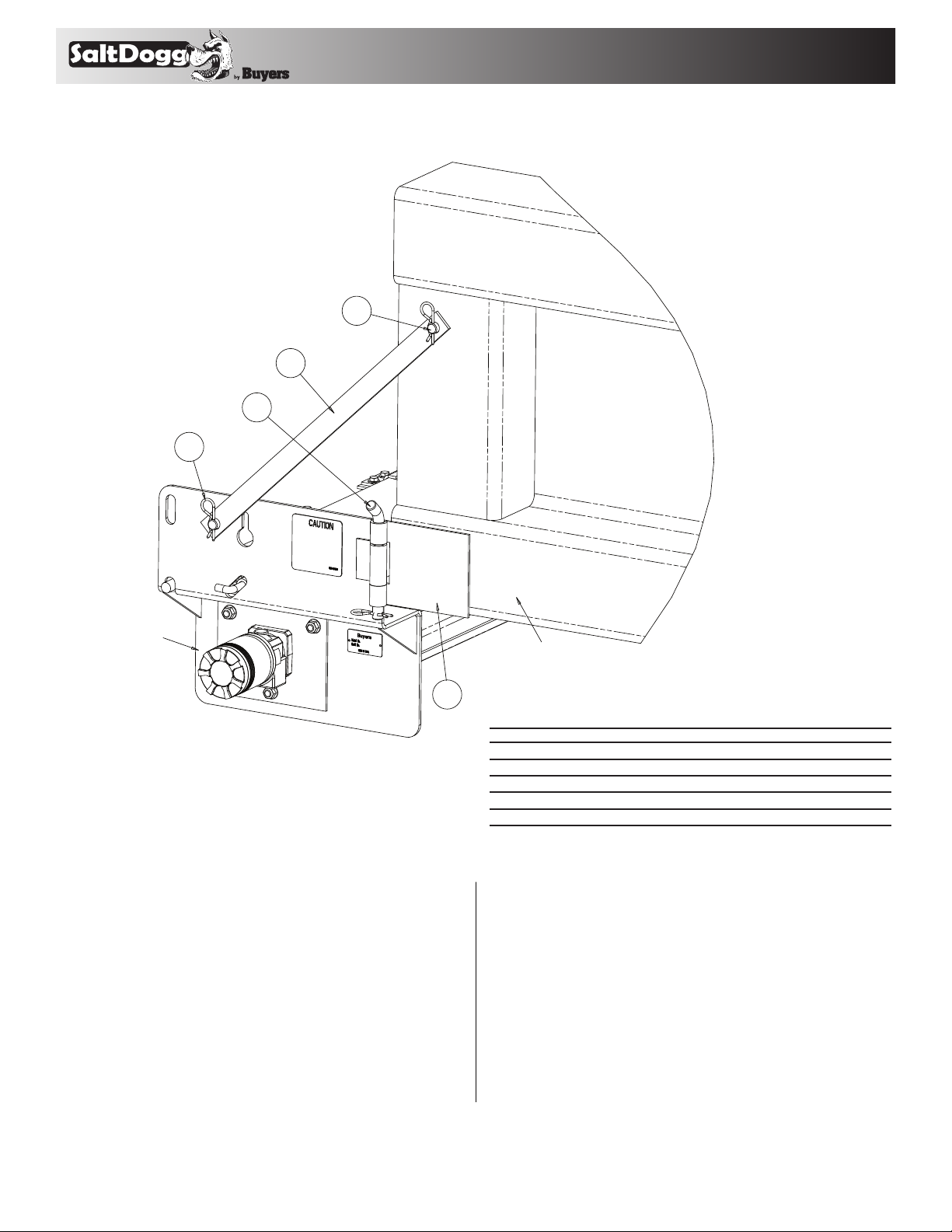

2. Attach mounting brackets (See hardware

installation drawing on page 2.)

A. Attach a quick detach plate, (Item 1) to both

sides of the spreader frame using hinge pins (Item

2) and a hairpin cotter pins (Item 5).

B. Position the (2) quick detach plates over the

dump body rub rails and flush with rear edge of

dump body.

C. Weld the (2) quick detach plates to the dump

body rub rails. Weld the plates continuously around

(3) sides of each plate. Do not weld along the edge

of the plates next to the attachment pin.

1

—continued inside

5

TM

Mounting Hardware Installation Drawing

4

3

2

SPREADER

FRAME

1

NOTE: Lockout hardware

is not shown

D. Align the pin brace (Item 4) on the dump body

using the iron brace (Item 3) for exact positioning.

For proper fit, hanger iron brace may require some

minor bending.

E. Weld the (2) pin braces (Item 4) to the dump

body sides, all around.

F. Attach the iron braces (Item 3) to the pin braces

on the sides of the dump body and the sides of the

spreader using (2) hairpin cotter pins (Item 5).

DUMP BODY

Bill of Materials

ITEM QT Y. DESCRIPTION CARBON STAINLESS

1 2 Quick Detach Plate

2 2 Hinge Pin

3 2 Hanger Iron Brace

4 2 Pin Brace

5 6 Hair Pin Cotter 5/32"

924F0102 3009526

924F0103 3011139

924 F0101 3011137

9240021B 3000210

— —

G. If there is a gap between the spreader and the

dump body, weld or bolt a steel strip to the forward

edge of the spreader to cover the gap.

H. If you have purchased the tailgate side shields

(purchased separately as P/N 924F0106PR or

924F0106SSPR, Stainless), bolt or weld them to the

inside of the tailgate to prevent material spillage at

the ends of the spreader.

2

TM

Linkage

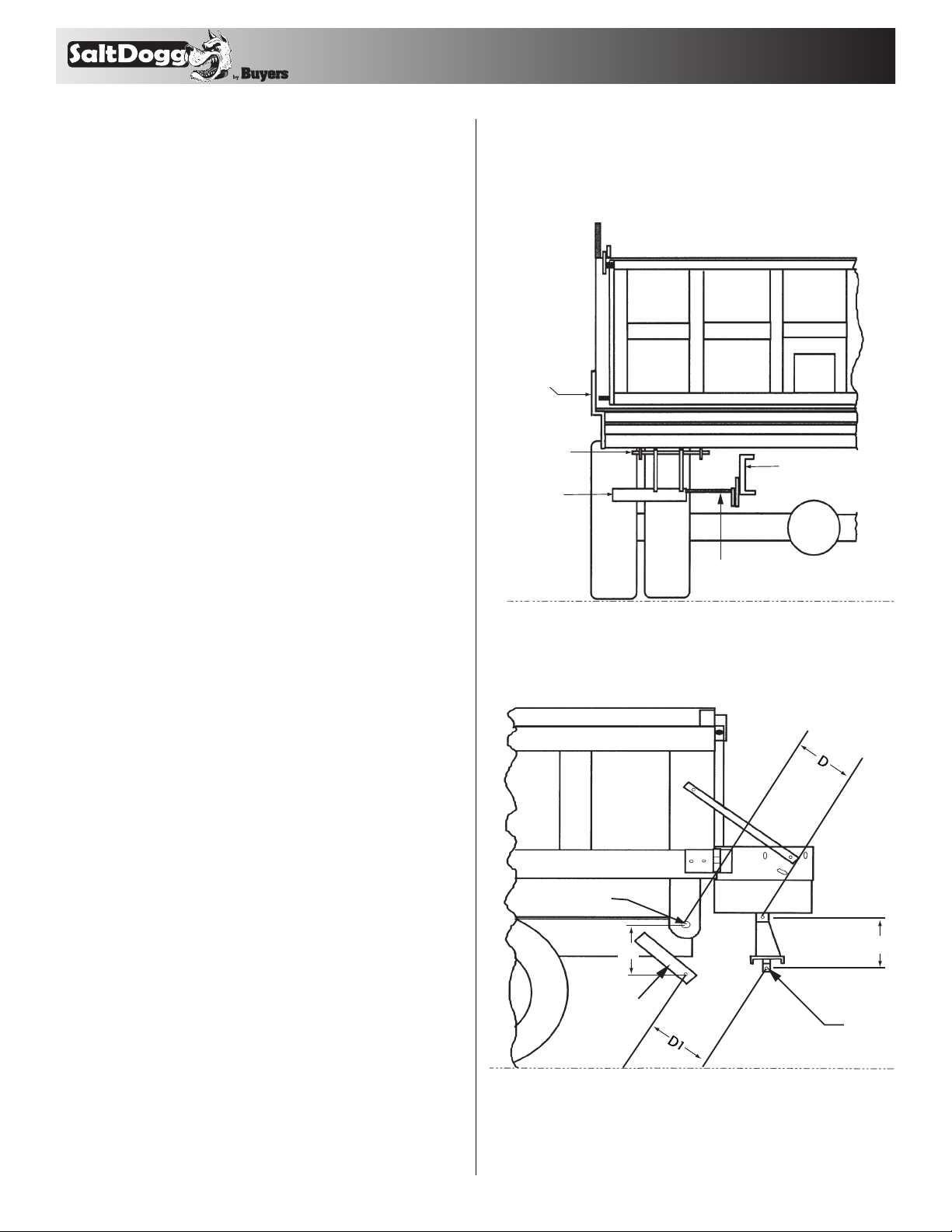

3. Spinner assembly installation: (See installation

drawings on pages 3 and 4.)

A. Attach the spinner shield (Item 2) to the spinner

frame (Item 1) using (2) 5/16-18 x 1-1/4 cap screws,

5/16 flat washers and (2) 5/16-18 hex flange nuts.

B. Attach the spinner disk sub assembly to the

hydraulic motor on the spinner frame and tighten

the set screw in the disk collar.

Note: Be sure to lubricate the hydraulic motor

shaft generously with Never Seez lubricant before

assembling.

C. Attach the spinner frame assembly to the lower

tray of the spreader with the hinge rod and attach

(2) hairpin cotter pins.

D. The leveling mechanism may now be mounted.

Park truck on flat, level surface. With spinner

assembly in level position, carefully measure “L”

and “D” distances. Use any of 3 available holes in

height adjustment bracket. Locate bar or spinner

lug such that ½” hole will position with D1=D and

L1=L. Modify angle if necessary.

Parallel Linkage, Spinner Frame & Bar

Installation Drawings

Spreader

Hinge Rod

Truck Frame

Spinner

Frame

Spinner Lug or Bar

E. Secure bar or spinner lug to the truck frame.

F. Attach parallel linkage rods to heights

adjustment bracket and angle. Secure them using

½” washers and hair pins.

G. Clamp parallel linkage rods together. To verify

leveling action, slowly raise the dump. Be sure that

spinner motor assembly and linkages do not have

any interference with truck body and it does not

have contact with the road. After checking weld

parallel linkage bars together.

H. Keeping the spinner assembly level, remove

the set screw from the clamp collar and secure

the spinner frame in place using the spinner

assembly lock.

Dump Body

Hinge

L1

Bar

L

Parallel

Hole

3

TM

3/4" (1) Wire Hos e

Parallel Linkage, Spinner Frame & Bar Installation Drawings (cont.)

Bill of Materials

ITEM QT Y. DESCRIPTION CARBON STAINLESS

1 1 Spinner Frame Assy.

2 1 Spinner Shield

3 1 Spinner Disk Assy.

4 2 Linkage Rods, Welded

30 2018 4 3018 416

92 4F0 015 3006659

30 0 14 7 2A 3 0 014 72 A

92 4F 0 012 92 4F 0 012

3

ITEM QT Y. DESCRIPTION CARBON STAINLESS

5 1 Hinge Rod

6 1 Spinner Lug

7 1 Bar

8 1 Height Adjustment Bracket

92 4F 0 018 300664 6

92 4F 0 013 300 6645

92 4 F 0014 9 2 4 F 0 014

30 2018 5 3017 175

2

1

Hydraulic Installation Instructions

A. During assembly take precautions to keep all

hydraulic components as clean as possible.

B. Allow enough hose length to prevent kinking

and stretching of the hoses and to permit raising

the dump body. Support long hoses with wire ties

or clamps.

C. Protect hoses from wear caused by sliding and/

or vibration.

D. For proper rotation of auger and spinner motors,

hoses may be reversed.

Note: Use of a pipe joint sealant compatible with

hydraulic oil is recommended for all screw fittings.

E. Use swivel type hose ends to connect hoses to

flow valve. Damage to valve body may occur if the

fittings in flow valve are over tightened

F. To achieve an additional positive shutoff of the

auger motor, the inlet flow must pass through

the bulkhead fitting (preinstalled on the bottom

tray), through latch bracket, through the quick

disconnect fitting assembly (preinstalled on the

side plate) then to the motor.

G. Buyers Products recommends a minimum flow

rate of 9 GPM @ 1000 rpm to operate our spreaders.

5

8

Hydraulic Flow Diagram

Tank

3/4" (1)

Wire Hose

1

T

3

Pump

3/4" (2) Wir e Hose

A

P

S

Valve

1-1/4" S piral

SuctionHose

3/4" (2) Wir e Hose

1/2" (1) Wire Hose

1/2" Quick Disconnects

Recommended Parts (not included)

ITEM PART NO. QTY DESCRIPTION

1

HV715

2

HVC1

3

SM R15

1 Dual Flow Regulator Valve

1 Dual Flow Regulator Console

1 15 Gallon Reservoir

6

7

4

3/4" Quick

Disconnects

1/2" (1) Wire Hose

Side Plate Mounted

1/2" Quick Disconnects

1/2" (1) Wire Hose

1/2" (1) Wire Hose

Auger Motor

CW Rotation

Spinner Motor

CCW Rotation

4

TM

Operating Instructions

Auger Quick Disconnect Installation

Attach Inlet

Flow Here

Flow to

Motor

Hose must pass

through bracket

CAUTION

A. Be sure everyone is standing clear.

B. Be alert for anything that may require shutting

down the system.

C. Before working in or around spreader equipment, be sure all hydraulic controls are moved to

off position.

1. Pre-start up.

A. Use high grade non foaming hydraulic oil to fill

reservoir about 3/4 full.

B. Position valve on/off lever to off.

C. Move auger and spinner knobs on the valve to

the open position.

D. Engage PTO and circulate hydraulic oil for several minutes to warm up.

E. Move valve on/off lever to on.

F. Inspect hydraulic system for leaks.

G. Check auger and spinner to see if they are work-

ing properly.

H. Refill reservoir to 3/4 full.

I. Hydraulic system should now be ready for use.

2. Initial use of spreader

A. Shut off spinner and auger knobs and position

the on/off lever to on. Engage the PTO and allow

the hydraulic system to warm up.

B. Open the cover plate and secure vertically with

locking brackets.

C. Open dump body tailgate as wide as possible

from bottom without bearing against cover plate.

Set stop chains.

D. Position spinner assembly to the far left (drivers

side), tighten clamp. Determine placement of material at various spinner and auger speeds by spreading a small amount of material (Far left position

used to spread (3) three or (4) four lane highway

from right lane).

E. Position spinner assembly to the far right (passenger side), tighten clamp. Determine placement

of material at various spinner and auger speeds

by spreading a small amount of material (Far right

position used to spread (4) four lane highway from

left lane).

F. Changing auger and spinner speeds on the valve

and placing spinner at various positions from left to

right will produce various spread patterns.

5

TM

3. Using the Auger Lock-out System

A. Shut off spinner and auger then position the

main hydraulics on/off lever to off. Turn off truck.

B. Verify hydraulic system is shut off then disconnect the quick disconnect fitting on the side plate

of the spreader.

C. The lower tray may now be opened for servicing.

D. After servicing, close and lock the tray in op-

erating position then reroute the hydraulic hose

through the latch bracket and reconnect the quick

disconnect coupler.

E. Verify that all hydraulic components are still

in operational condition, turn the main hydraulics back on and test the function of the unit. If

any issues are noticed turn off spreader and main

hydraulics then inspect and/or service the entire

spreader and/or hydraulic system.

DANGER

Before working in or around the auger area, all power

to the spreader must be turned off. Disengage the PTO,

shut off the engine and follow the lock out instructions.

After servicing is complete, reverse the process to

restore the spreader function. NEVER PUT ANY PART OF

YOUR BODY INSIDE THE AUGER AREA OF SPREADER.

4. Miscellaneous

A. Valve setting changes may be made with truck

in motion.

B. By moving on/off lever to the off position, spinner and auger may be stopped at the same time

without changing their valve settings.

C. Close cover plate flat over spreader trough and

lock in place for normal use of dump truck. Tailgate

may be opened from top or bottom.

D. When truck is used for extensive hauling the

spinner assembly should be removed.

E. If auger clogs, shut off spinner, open auger knob

valve and increase the engine speed. With the

engine at a higher speed, move the valve lever

from the on to the off positions rapidly; repeat as

needed. This action may unclog the auger. If this

action fails to free the auger, manual unclogging

will be required.

CAUTION

Position the valve on/off control lever in the off position when the spreader is not in use or is removed. In

the event the valve on/off control lever is left in the on

position, a heat problem may occur as the pump continues to pump oil to the hydraulic valve. This could cause

a hose to burst spraying hot oil.

HYDRAULICS SHOWN CONNECTED

(AUGER POWER ON) TRAY AND LID

MUST REMAIN IN OPERATIONAL

POSITIONS

HYDRAULICS SHOWN DISCONNECTED

(AUGER POWER OFF) MAIN POWER

MUST ALSO BE SWITCHED OFF

BEFORE TRAY AND LID MAY BE

OPENED FOR SERVICE

Recommended Maintenance

A. Warm up hydraulic system before using.

B. Keep the reservoir 3/4 full with high grade non-

foaming hydraulic oil.

C. Use precautions to keep contaminants from getting in reservoir when filling.

D. Quick connects are a prime source of contamination.

1. Clean quick connects before connecting or

disconnecting them.

2. Protect quick connects from contaminates.

E. Lubricate all bearings with suitable type grease

on a regular basis. More frequent lubrication is

recommended during periods of heavy use.

F. Lubricate the spinner hinge rod periodically.

G. Maintain the proper lubrication level in all gear-

boxes with SAE 90 gear lubricant.

H. When not in use, keep the spreader tray empty

to prevent freezing of material around auger in

extremely cold weather.

I. To extend the life of your spreader:

1. Hose down and clean after each use.

2. Repaint and/or oil after each season.

6

TM

6

Spreader Assembly Parts List

7

8

4

11b

10b

9b

12

10

9

20

21

22

23

1

1b

11

FRAME SHOWN FOR REFERENCE ONLY

ACTUAL FRAME MAY BE DIFFERENT

25

26

4

6

24

6

4

3

5

22

USED ON

92421SSA & 92426SSA

2

13

31

39

19

6

7

8

LEFT SIDE DISCHARGE MODELS

4

13

14

15

USED ON DIRECT DRIVE MODELS ONLY

16

17

18

19

24

LEFT SIDE DISCHARGE MODELS

31

32

33

GEARBOX PARTS (92430SSA ONLY)

34

28

29

30

31

37

38

30

23

4

36

35

33

32

Bill of Materials

ITEM QT Y.

1 1 Bottom Tray - Standard Discharge

1b 1 Bottom Tray - Driver Side Discharge

2 1 Top Cover

3 1 Bracket, Cover Mount

4 9/10 Screw, Hex Head Cap, 3/8-16 X 1

5 3 Washer, Flat, 3/8in

6 10 Nut, Nylon Locking, 3/8-16 X 7/16

7 2 Bracket, Cover Latch

8 2 Latch Handle

9 1 Auger - Standard Discharge

9b 1 Auger - Driver Side Discharge

10 1 Screen - Standard Discharge

10b 1 Screen - Driver Side Discharge

11 1 Plate, Anti-Spill - Standard Discharge

11b 1 Plate, Anti-Spill - Driver Side Discharge

12 4 Hairpin Cotter

13 1 Sleeve, Auger

14 1 Motor Adapter

15 1 Screw, Hex Head Cap, 1/2-13 X 3

16 1 Nut, Locking, 1/2-13

17 1 Elbow, 90 Deg Male NPT to Male NPT

18 1 Coupler, Hydraulic Quick, 1/2in NPT

DESCRIPTION CARBON STAINLESS

(Direct Drive/Gearbox)

- Male Half of B40004

- Female Half of B40004

3008429 3008443

- 3024304

3013931 3025122

3008430 3008447

FCS038016100 FCS038016100SS

FWF038100007 FWF038100007SS

FNE038016044 FNE038016044SS

3006965 3006968

9240063 3000268

924F0082 924F0081

- 3017487

3024306 3024306

-

3026623

-

3023297

3022531

3023298

1420 016 1420016

9240083 9240083

924F0084 924F0084

FCS050013300

3001250

92401213 3001253

H3529X8 H3529X8

B40004 B40004

B400041 B400041

B400042 B400042

ITEM QT Y.

DESCRIPTION CARBON STAINLESS

19 1 Fitting,Bulkhead,1/2in MNPT X 1/2in

MJIC W/ Lock Nut

20 1 Bearing

21 1 Felt Gasket

22 4/5 Nut, Serrated Flange, 3/8-16

(Direct Drive/Gearbox)

23 2 Screw, Hex Head Cap, 3/8in-16 X 1-1/4

24 2/1 Cam Handle - CW

24b 0/1 Cam Handle - CCW

25 2 Nut, Nylon Locking, 5/8-11

26 2 Screw, Hex Head Cap, 3/8-16 X 3

27 3 Bracket, Screen Mount

28 1 Plate, Motor Mount

29 1 Hydraulic Motor - Direct Drive Only

30 3/2 Nut, Serrated Flange, 1/2-13

(Direct Drive/Gearbox)

31 3/2 Bolt, Carriage, 1/2-13 X 1

(Direct Drive/Gearbox)

32 4 Screw, Hex Head Cap, 3/8-16 X 3/4

33 4 Washer, Split Lock, 3/8in

34 1 Plate, Gearbox Mount

35 1 Gearbox

36 1

Hydraulic Motor - Gearbox Model Only

37 4 Screw, Hex Head Cap, 1/2in-13 X 1

38 4 Washer, Split Lock, 1/2in

39 1

Bracket, Fitting Mount

7

H2706LNX8X8 H2706LNX8X8

9240086 9240086

9240087 9240087

92401211 3001255

FCS038016125 FCS038016125SS

3014762 3019032

3014763 3019033

FNE063011069

FCS038016300

3001247

3007068

3026624 3022533

3000458 3001367

CM074P CM074P

92401212 3001523

FCB050013100

9240125

3001522

FCS038016075SS

FWL038069009 FWL038069009SS

3000457

9240089

CM034P

3001366

9240089

CM034P

FCS050013100 FCS050013100SS

FWL050088013 FWL050088013SS

3026625 3023290

TM

Hardware Box Contents

9049 Tyler Blvd. • Mentor, Ohio 44060

Phone (440) 974-8888 • Fax (440) 974-0165

Toll-Free Fax 800-841-8003 • saltdogg.com

12

11

1

Bill of Materials

ITEM Q TY. DESCRIPTION CARBON STAINLESS

1 1 Spinner Frame Assy.

2 1 Spinner Shield

3 1 Spinner Disk Assy.

4 2 Linkage Rods, Welded

5 1 Hinge Rod

6 1 Spinner Lug

30 2018 4 3 018 416

92 4F0 015 3006659

30 0 14 7 2A 3 0 0147 2 A

92 4F 0 012 924 F 00 12

92 4F 0 018 3006646

92 4F 0 013 3006645

7

2

4

5

6

8

10

9

3

ITEM QTY DESCRIP TION CARBON STAINLESS

7 1 Bar

8 2 Bar, Hanger Brace

9 2 Detatch Mounting Plate

10 2 Hinge Pin

11 1 Hardware Bag

12 1 Height Adjustment Bracket

92 4 F 0014 924 F 0 014

924 F0101 3 0 11137

92 4F 010 2 3009526

92 4F 0103 30 111 3 9

3015630 3 017 834

30 2018 5 3 017 175

Auger Replacement Kit

Standard Discharge (924F0081AK)

Left Side Discharge (3026661)

1

6

3

7

2

8

5

4

Bill of Materials

ITEM PART N O. QTY DESCRIPTION

924 F0 081

1

30 174 87

2

9240083

3

924F0084

4

9240086

5

9240087

6

7

8

9

—

—

—

—

8

1 Auger Standard Discharge

1 Auger Lef t Side Discharge

1 Adaptor Sleeve

1 Adaptor Shaft

1 Bearing

1 Felt Gasket

1 Capscrew

1 Locknut, Reversible Hex

2 Capscrew

2 Nut, Serratted Flange

9

3026614 Rev. A

Loading...

Loading...