Quality since 1946

Instructions Manual

Direct Drive

Under Tailgate Spreader

NOTE: This manual applies to spreaders starting

with serial No. 1465

Table of Contents

Warranty Information ............................................... 1

Spreader Installation Instructions ........................ 1,2

Spreader Installation Drawing ................................. 2

Spinner Assembly Instructions ..............................3,4

Spinner Assembly Drawing ...................................3,4

Hydraulics Installation ............................................. 5

Operating Instructions .......................................... 5,6

Recommended Maintenance .................................... 6

Parts list: Spreader Assembly .................................. 7

Spreader Parts Drawing ........................................... 7

Parts List: Hardware Box ......................................... 8

Spinner Components Drawing ................................. 8

Auger Replacement Kit ............................................. 8

UNDER TAILGATE SPREADER WARRANTY

This warranty replaces all previous warranties and no employee

of this company is authorized to extend any additional warranties, or agreements, or implications not explicitly covered herein.

Buyers Products Company warrants all parts of the product to

be free from defects in material and workmanship for a period of

(1) one year from the date of original installation. Parts must be

properly installed and used under normal conditions. Normal wear

is excluded.

9049 Tyler Blvd. • Mentor, Ohio 44060

Phone (440) 974-8888 • Fax (440) 974-0165

Toll-Free Fax 800-841-8003 • buyersproducts.com

Installation Instructions

NOTE: The left and right end plates may, on

occasion, get bent through improper handling

during shipment or storage. If this should happen, square and true the left and right end plates

before installation.

1. Aligning the spreader:

A. Position the spreader with the truck such that

the auger drive is located on the right side of the

truck (passenger side).

Any par t which has been altered, including modification, misuse,

accident, or lack of maintenance will not be considered under this

warranty. Hydraulic units are not to be disassembled without

the express written permission from Buyers Products Company.

The sole responsibility of Buyers Products Company under this

warranty is limited to repairing or replacing any part(s) which

are returned, prepaid, 30 days after such defect is discovered,

and returned part(s) are found to be defective by Buyers Products

Company.

Authorization from Buyers Products Company must be obtained

before returning any part. The following information must accompany defective parts returned to Buyers Products Company: RM A#,

spreader model, serial number, date installed, and distributor from

whom it was purchased. Buyers Products Company shall not be

liable for damage arising out of failure of any unit to operate properly, or failure, or delay in work, or for any consequential damages.

No charges for transportation or labor performed on any part will

be allowed under this warranty.

B. Lift the spreader up and under the dump body

tailgate, positioning the spreader forward as close

as possible to the dump body. The tailgate of the

dump body should lay down horizontally over the

spreader.

C. Support the spreader solidly and securely when

positioning for mounting.

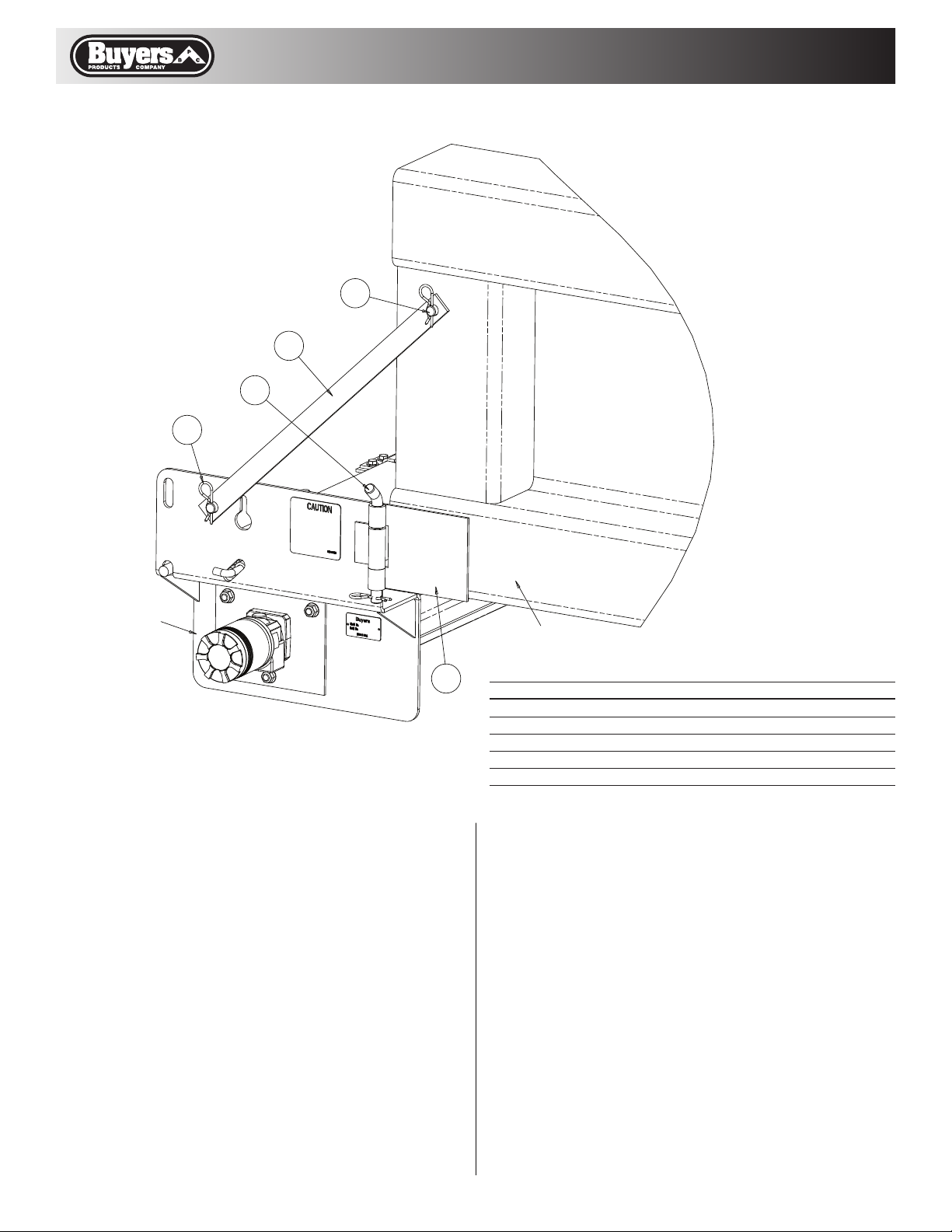

2. Attach mounting brackets (See hardware in-

stallation drawing on page 2.)

A. Attach a quick detach plate, (Item 1) to both

sides of the spreader frame using hinge pins (Item

2) and a hairpin cotter pins (Item 5).

9

Quality since 1946

1

2

3

4

5

DUMP BODY

SPREADER

FRAME

Mounting Hardware Installation Drawing

9049 Tyler Blvd. • Mentor, Ohio 44060

Phone (440) 974-8888 • Fax (440) 974-0165

Toll-Free Fax 800-841-8003 • buyersproducts.com

B. Position the (2) quick detach plates over the

dump body rub rails and flush with rear edge of

dump body.

C. Weld the (2) quick detach plates to the dump

body rub rails. Weld the plates continuously around

(3) sides of each plate. Do not weld along the edge

of the plates next to the attachment pin.

D. Align the pin brace (Item 4) on the dump body

using the iron brace (Item 3) for exact positioning.

For proper fit, hanger iron brace may require some

minor bending.

E. Weld the (2) pin braces (Item 4) to the dump

body sides, all around.

Bill of Materials

item pa rt no. qty. descri ptio n

1 924F0102 2 Quick Detach Plate

2 924F0103 2 Hinge Pin

3 924F0101 2 Hanger Iron Brace

4 9240021B 2 Pin Brace

5 HP12 6 Hair Pin Cotter 5/32"

F. Attach the iron braces (Item 3) to the pin braces

on the sides of the dump body and the sides of the

spreader using (2) hairpin cotter pins (Item 5).

G. If there is a gap between the spreader and the

dump body, weld or bolt a steel strip to the forward

edge of the spreader to cover the gap.

H. If you have purchased the tailgate side shields

(purchased separately as P/N 924F0106), bolt or

weld them to the inside of the tailgate to prevent

material spillage at the ends of the spreader.

2

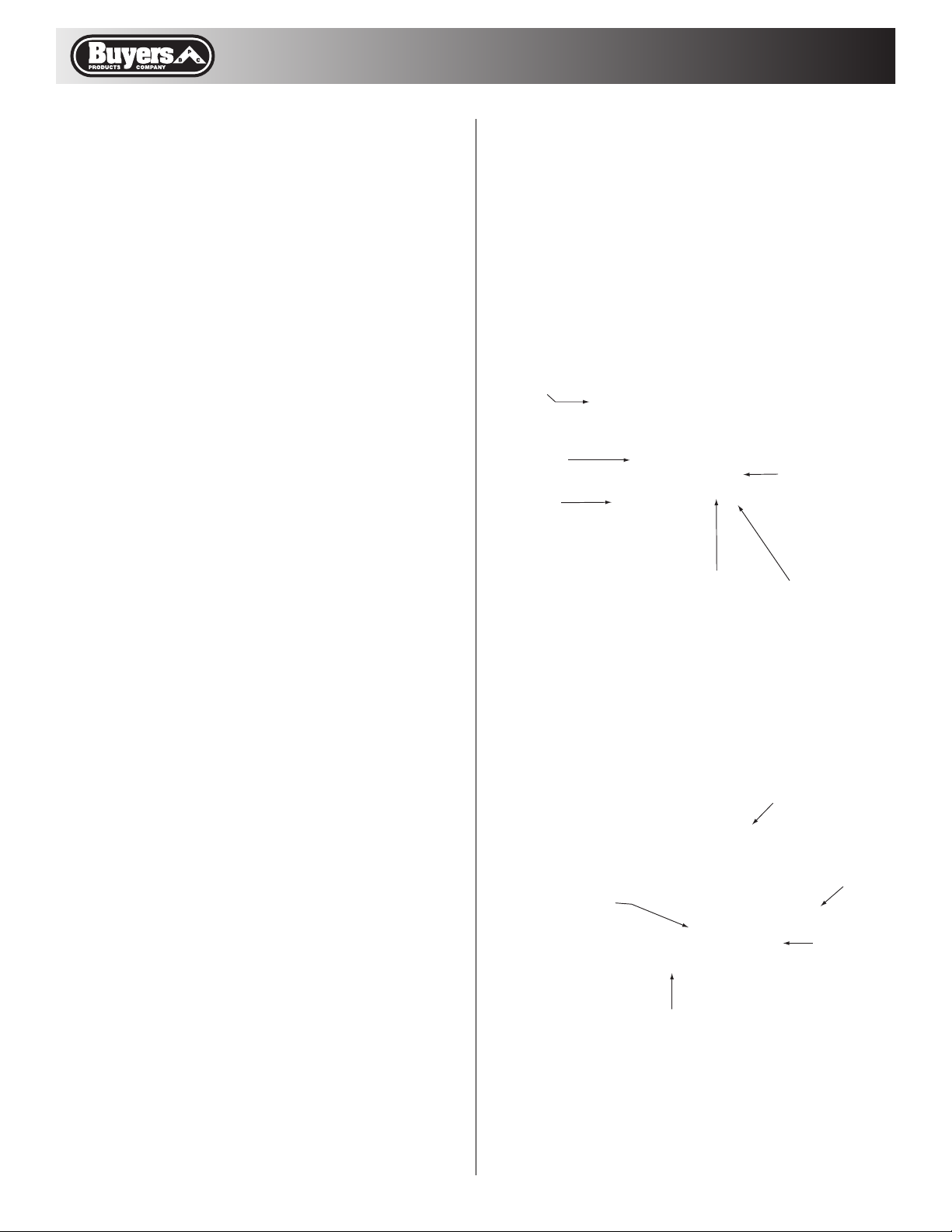

Quality since 1946

Truck Frame

Hinge Rod

Spinner

Frame

Spinner

Lug

Bar

Spreader

Dump Body

Hinge

Bar

Spinner

Frame

Spreader

Hanger Iron

Brace

9049 Tyler Blvd. • Mentor, Ohio 44060

Phone (440) 974-8888 • Fax (440) 974-0165

Toll-Free Fax 800-841-8003 • buyersproducts.com

3. Spinner assembly installation: (See installation

drawings on pages 3 and 4.)

A. Attach the spinner shield (Item 2) to the spinner

frame (Item 1) using (3) 5/16-18 x 3/4 cap screws

and (3) 5/16-18 hex flange nuts.

B. Attach the spinner disk sub assembly (Item 3)

to the hydraulic motor on the spinner frame and

tighten the set screw in the disk collar.

Note: Be sure to lubricate the hydraulic motor shaft

generously with Never Seez lubricant before assembling.

C. Attach the spinner frame assembly (Item 1) to

the lower tray of the spreader with the hinge rod

(Item 5) and attach (2) hairpin cotter pins.

D. Weld bar (Item 7) on the outside of the truck’s

(driver’s side) main frame rail. Locate the center of

the hole in the bar (Item 7) 11-1/2" vertically below

the dump body hinge pin center.

Parallel Linkage, Spinner Frame & Bar

Installation Drawings

E. Bolt the spinner lug (Item 6) and hose clamp to

the spinner frame using (1) 5/16-18 x 3/4 hex head

cap screw and (1) 5/16-18 x 1-1/2 hex head cap

screw with (2) 5/16 -18 hex nuts.

F. Attach one parallel linkage rod (Item 4) to the

spinner lug (Item 6) using (1) 1/2" flat washer and

(1) hairpin cotter pin. Attach the other parallel

linkage rod (Item 4) to the frame bar (Item 7) using

another 1/2" flat washer and another (1) hairpin

cotter pin.

G. Keeping the spinner assembly level, remove

the set screw from the clamp collar and secure the

spinner frame in place using the spinner assembly

lock.

H. Weld the (2) parallel linkage rods (Item 4) solidly

together.

3

Loading...

Loading...