SaltDogg 1471456SSH User Manual

TM

Instruction Manual

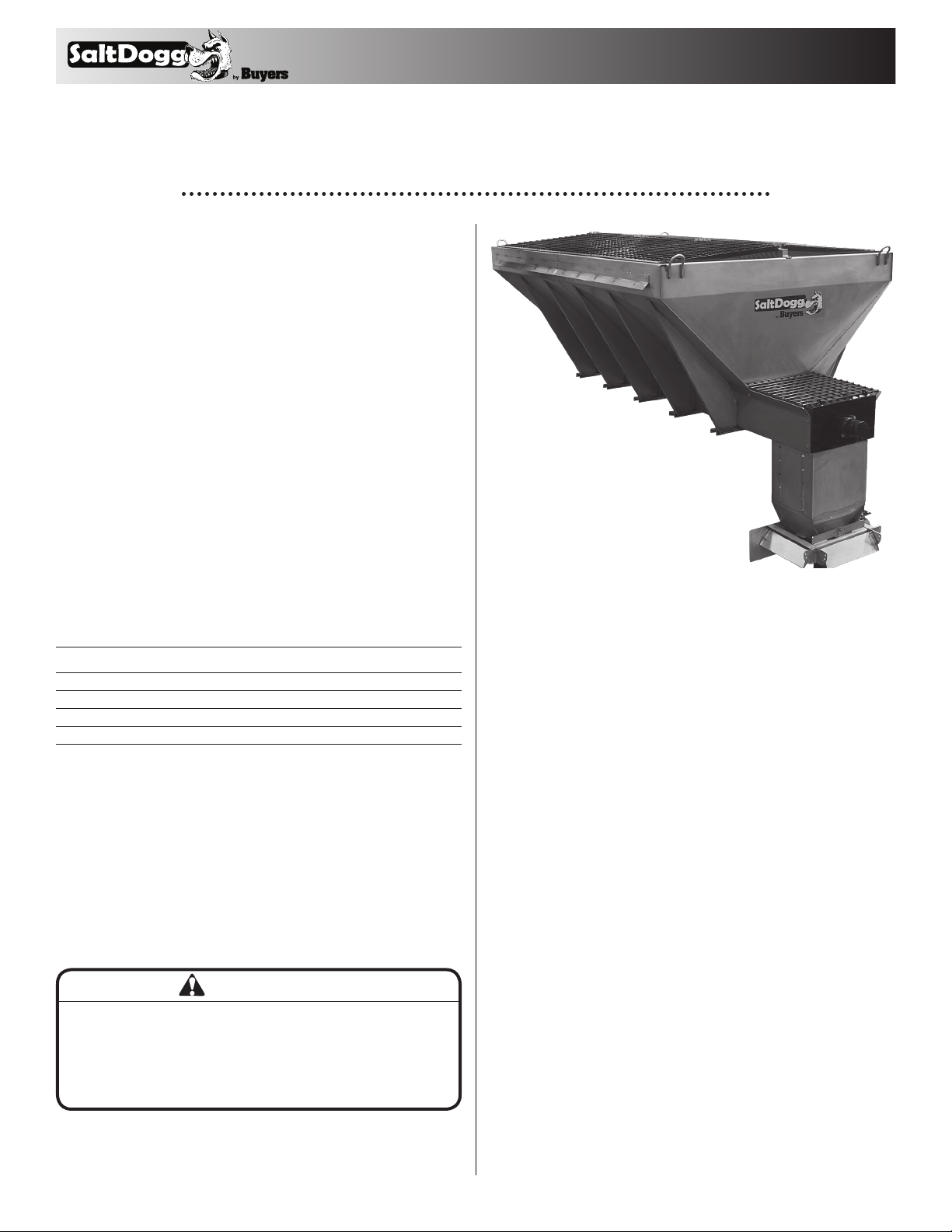

Municipal-Sized Hydraulic

Powered Stainless Steel Hopper

Spreaders

Table of Contents

General Information .................................................1

Safety Precautions ................................................1-2

Installation Instruction .........................................2-8

Spreader Operation ...............................................2-8

Spreader Maintenance ..........................................2-8

Optional Equipment .................................................5

Repair Parts .......................................................... 6-8

Warranty Information ..............................................8

9049 Tyler Blvd. • Mentor, Ohio 44060

Phone (440) 974-8888 • Fax (440) 974-0165

Toll-Free Fax 800-841-8003 • saltdogg.com

General Information

MODEL NO.

1471056SSH

1471156SSH

1471256SSH

1471456SSH

OVERA LL

LENGTH WIDTH HEIGH T

162" 84" 60" 2655 lbs. 7.0

168" 84" 60" 2855 lbs. 8.0

180" 84" 60" 3055 lbs. 9.0

204" 84" 60" 3561 lbs. 10.0

EMPTY

WEIGHT

CAPAC ITY

CU. YDS.

1. Recommended Vehicle Requirements

Buyers Municipal-Sized Hopper Spreaders are

intended for spreading abrasives and/or chemicals, primarily for ice and snow control. They are

intended for installation on truck chassis or dump

bodies with GVWR 26,000 lbs. Spreaders are

intended to be mounted on trucks with Cab To

Axle/Tandem Dimension minimum of 84 inches.

IMPORTANT

The Cab to Axle/Tandem dimensions are only guidelines.

Consult federal, state and local weight laws and chassis

manufacturer’s ratings to ensure neither government weight

restrictions, nor GVWR and GAWRs are exceeded.

2. Average Material Weights

MATERIAL WEIGHT (POUNDS PER CUBIC YARD)

#1 Rock Salt - 950

#2 Rock Salt - 1,215

Coarse Sand - Dry 2,565

Coarse Sand - Wet 3,240

3. Recommended Fastener Torques

Maintain all fastener torques as shown in the fol

lowing table. Failure to do so may cause injury to

persons.

SAE GRADE 2 SAE GRADE 5

ft-lbs ft-lbs

5/16-18 11 18

3/8-18 19 31

3/8-24 24 46

7/16-14 30 50

1/2-13 45 75

9/16-12 66 110

5/8-11 93 150

1

—continued inside

TM

General Safety Precautions

WARNING

Observe the following Safety Precautions before,

during and after operating this spreader. By following these precautions and common sense, possible

injury to persons and potential damage to this

machine may be avoided.

1. Read this entire Owner’s Manual before operat

-

ing this spreader.

2. Read all safety decals on the spreader before

operating the spreader.

3. Check to make sure all safety guards are securely

mounted into place before operating your spreader.

4. Verify that all personnel are clear of the spreader

spray area before starting or operating this

spreader.

5. Keep all loose clothing, hair, jewelry and limbs

clear of the spreader before starting or operating

this spreader.

6. Do not over-load your vehicle beyond payload

limits.

7. Do not perform any service operation on the

spreader while it is running.

8. Do not climb on or into the spreader during

operation.

9. Do not ride on the spreader while the vehicle is

in motion.

10. Make sure the spreader is securely fastened to

the vehicle.

11. Do not operate a spreader that is in need of

maintenance or repair.

Center the spreader in the vehicle. Spreader sills

3.

must overhang 20” beyond the back end of the vehicle.

4. If the dump body is not flat, it is suggested that

the spreader be placed on two 1" x 6" hardwood

boards. This will evenly distribute the weight of

the loaded spreader on the entire cross channels.

5. The spreader may be secured to the vehicle by

using Tie-Down Kit Buyers part #3010548 (sold

separately).

6. Periodically check that the spreader mounting

hardware is securely tightened.

Chassis Mounting

1. Hardwood wear strips usually 1" x 3" (not furnished) must be fitted to the truck chassis.

2. The spreader should be positioned on the

wooden wear strips so hopper sills must overhang

20” beyond the back end of the vehicle.

3. In addition a distance of approximately 4"-6"

must be left between the truck cab and the front of

the hopper. This will help facilitate any future servicing of the conveyor chain.

4.

Qualified installer must fabricate suitable angles to

attach hopper cross members to track’s frame.

DO NOT weld mounting angles to the truck frame.

Doing so can cause fatigue cracking of the truck frame.

CUT 5"

FROM

BOTTOM

General Installation Instructions

Dump Body Mounting

1. Remove the tailgate from the vehicle if

applicable.

2. Lift the spreader using the (4) lifting loops in the

corners of the hopper.

WARNING

The lifting device must be adequately rated to lift

a payload equal to or greater than the spreader

weight. See page 1 for spreader weights. Empty the

spreader before lifting.

2

TM

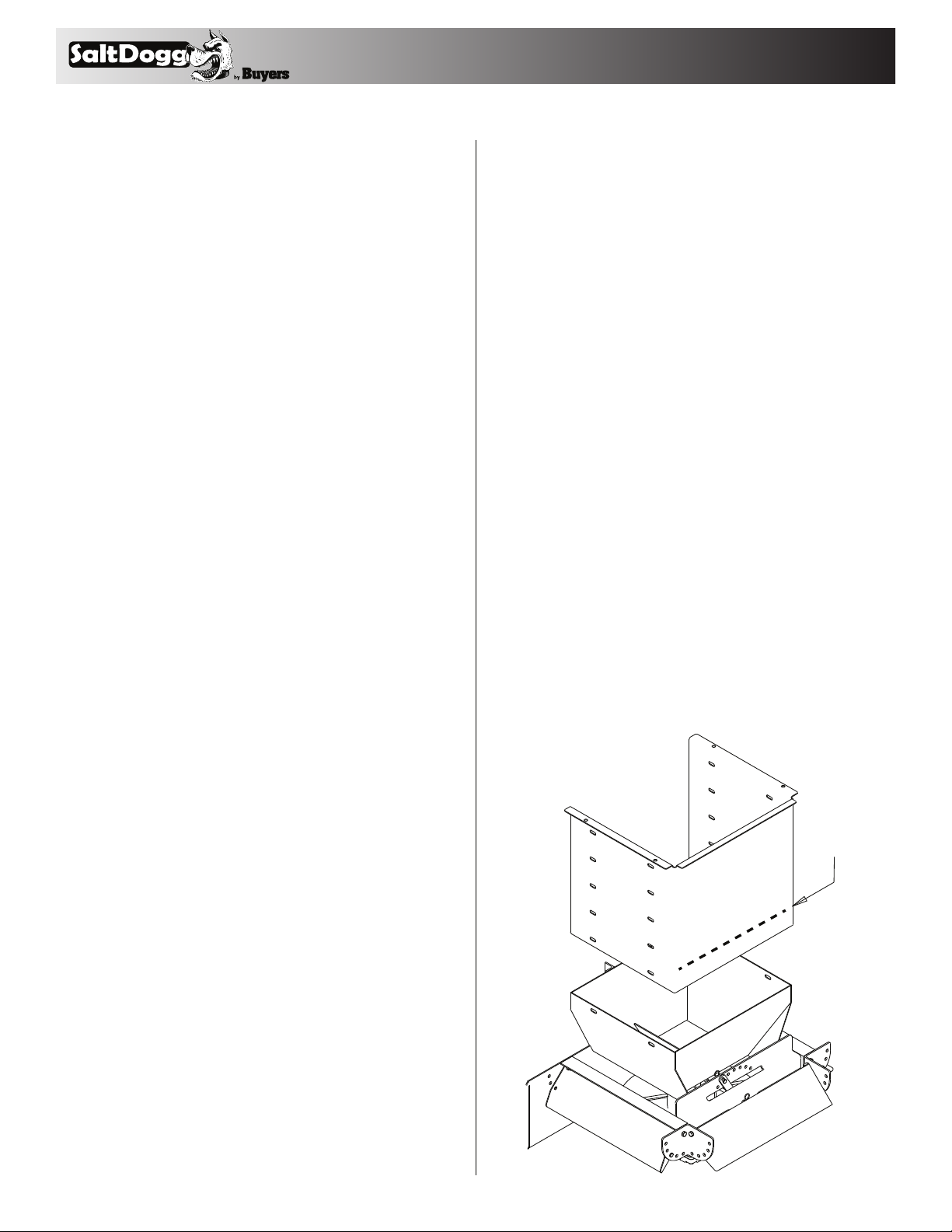

Chute Installation

1. Bolt chute to Hopper using provided hardware.

2. Chute heights can be adjusted by sliding lower

chute assembly up or down inside of upper chute

assembly. Adjustment slots are spaced by 3".

Secure lower chute assembly using all 4 carriage

bolts provided. Make sure all four bolts are used

for installation. To increase ground clearance

cut upper chute as shown and use lower slots in

bottom chute.

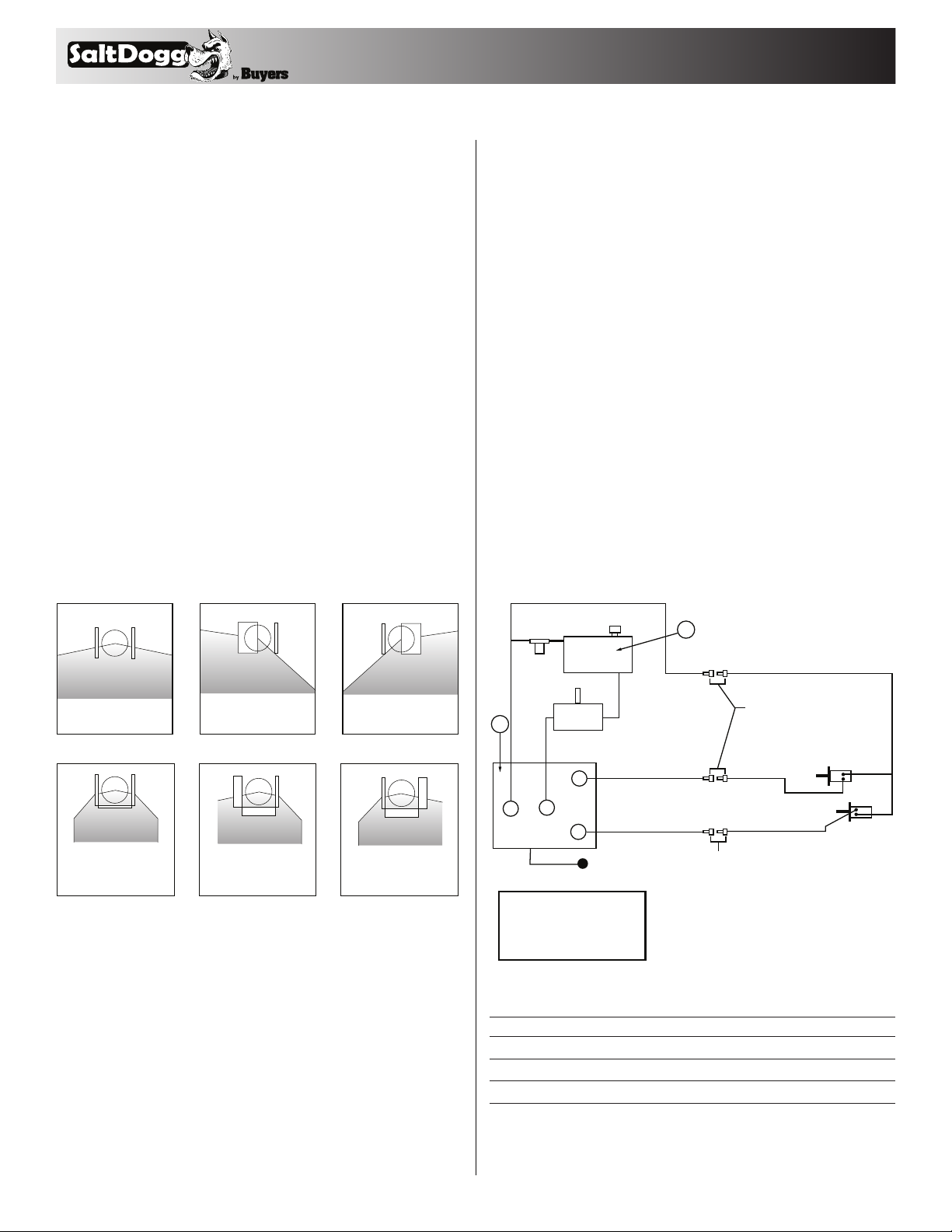

3. The spread pattern and the amount of material

dispensed will depend on the following factors:

• Auger speed.

• Spinner RPM.

• Baffle settings.

Below are illustrations that show the baffles effect

on the spread pattern as viewed from the top of the

spinner disk.

Internal Baffle Adjustment

Installation Instructions – Hydraulic System

1. During assembly take precautions to keep all

hydraulic components as clean as possible.

2. Allow enough hose length to prevent kinking

and stretching of the hoses and to permit raising

the dump body. Support long hoses with wire ties

or clamps.

3. Protect hoses from wear caused by sliding and/

or vibration.

4. For proper rotation of conveyor chain and

spinner motors, hoses may be reversed.

5. Note: Use of a pipe joint sealant compatible with

hydraulic oil is recommended for all screw fittings.

6. Use swivel type hose ends to connect hoses to

flow valve. Damage to valve body may occur if the

fittings in flow valve are over tightened.

7. A 10 micron return line filter is recommended

to protect the pump, valve, and motors from wear

causing contamination.

3/4" (1) Wire Ho se

Both internal

baffles out

Right baffle out

External Baffle Adjustment

All baffles adjusted

down for a confined

spread pattern

Right baffle deflects

material down;

heavy on right side

Left baffle in,

Right baffle in,

Left baffle out

Left baffle deflects

material down;

heavy on left side

10 Mi rco n

Filter

3/4" (1)

Wire Hose

1

T

Valve

ON/OFF Lever

Valve Key

T= Tank/Reservoir

P= Pump/Pressure In

A= Auger (Conveyer Chain)

S= Spinner

Tank

Pump

3/4" (2) Wi re Hose

A

P

S

1/2" (1) Wire Hos e

1-1/4" Spiral

Suction Hose

3/4" (2) Wi re Hose

2

1/2" (1) Wire Hos e

3/4" Quic k

Disconnects

1/2" (1) Wire Hos e

1/2" (1) Wire Hos e

1/2" Quick Disconnects

(1) Single braid wire hose

(2) Double braid wire hose

Main Components

ITEM PART N O. QT Y. DESCRIPTION

1 HV 715 1 Dual Flow Regulator Valve

2 SM R15S 1 15-Gallon reservoir

N/S H VC1 1 Dual Flow Regulator Console

Conve yer

Chain Motor

Spinner Motor

3

Loading...

Loading...