SaltDogg 1400600SS User Manual

9049 Tyler Blvd. • Mentor, Ohio 44060

TM

Phone (440) 974-8888 • Fax (440) 974-0165

Toll-Free Fax 800-841-8003 • saltdogg.com

Installation Manual

1400600SS Self-Contained Stainless Steel Hopper Spreaders

Table of Contents

Warranty Information ................................................................ 1

General Information .................................................................. 1

Safety Precautions .....................................................................2

Installation Instructions ...........................................................3

Spreader Operation ....................................................................4

Spreader Maintenance .............................................................. 6

Repair Parts & Drawings .......................................................... 8

SPREADER WARRANTY INFORMATION

This warranty replaces all previous warranties and no employee

of this company is authorized to extend additional warranties, or

agreements, or implications not explicitly covered herein.

Buyers Products Company warrants all parts of the product to be

free from defects in material and workmanship for a period of one (1)

year, from the date of installation. Parts must be properly installed

and used under normal conditions. Normal wear is excluded.

Any part which has been altered, including modifications, misuse,

accident, or lack of maintenance will not be considered under this

warranty.

The sole responsibility of Buyers Products Company under this

warranty is limited to repairing or replacing any part(s) which

are returned, prepaid, 30 days after such defect is discovered,

and returned part(s) are found to be defec tive by Buyers Products

Company.

General Information

1. Recommended Vehicle Requirements:

• 3/4 or 1 ton Pick-up Truck Above 8500# GVWR

2. Average Material Weights:

MAtERI Al WEIGH t (POUNDS PER CUb IC YARD)

#1 Rock Salt 950

#2 Rock Salt 1,215

Coarse Sand - Dry 2,565

Coarse Sand - Wet 3,240

Note: To calculate the total spreader weight (including ice

control material); add the empty spreader weight plus the

ice control material and spreader accessories.

Authorization from Buyers Products Company must be obtained

before returning any part. The following information must accom-

pany defective parts returned to Buyers Products Company: RMA#,

spreader model, serial number, date installed, and distributor from

whom purchased.

Buyers Products Company shall not be liable for damage arising out

of failure of any unit to operate properly, or failure, or delay in work,

or for any consequential damages. No charges for transportation or

labor performed on any part will be allowed under this warranty.

CAUTION

Do not overload vehicle beyond the vehicle’s Gross

Vehicle Weight Rating (GVWR) or Gross Axel

Weight Ratings (GAWR). Check the vehicle’s load

rating certification sticker for maximum vehicle

capacity.

9

TM

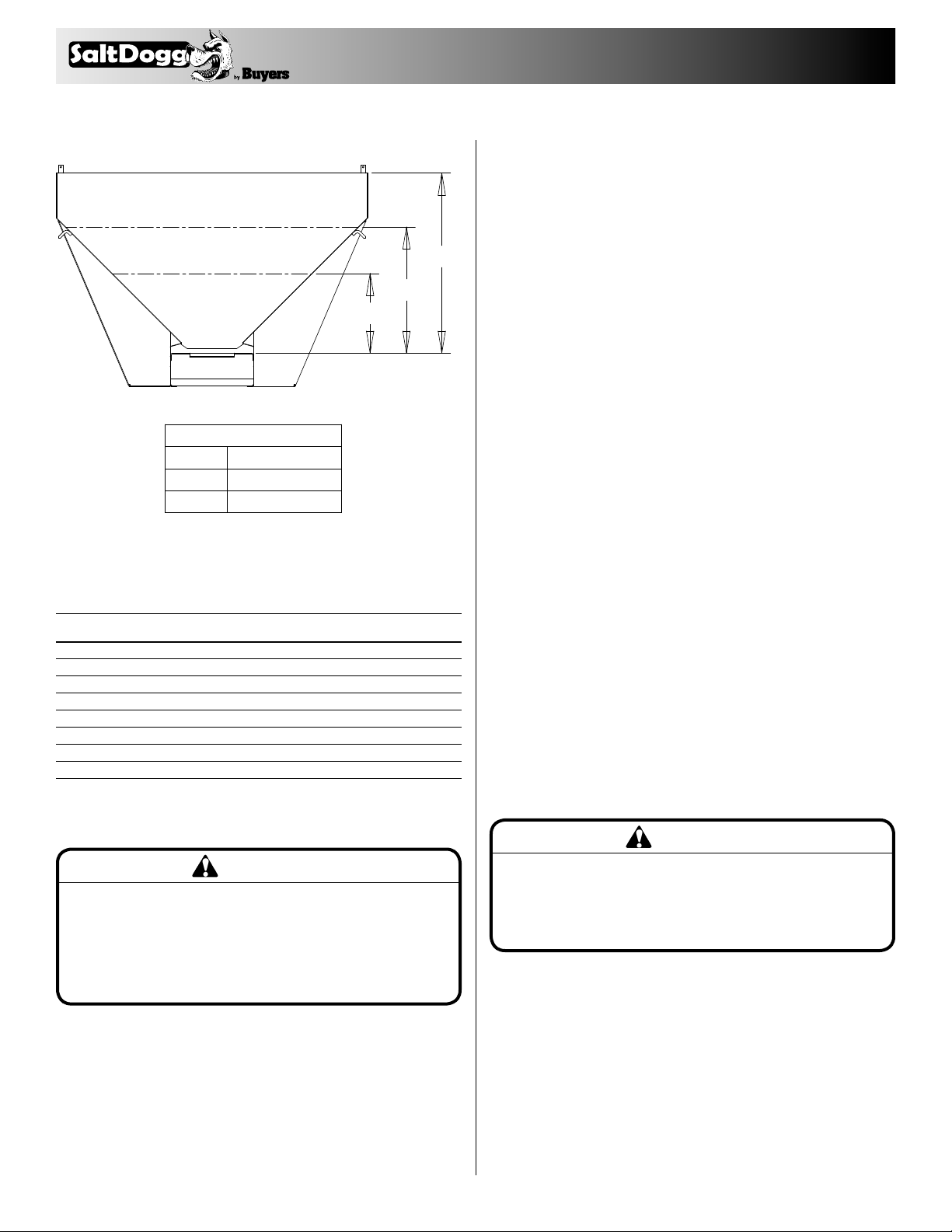

3. Hopper Storage Capacity

4. Make sure the motor cover is securely fastened to the

spreader before operating the spreader.

5. Verify that all personnel are clear of the spreader spray

area before starting or operating this spreader.

"27

6. Keep all loose clothing, hair, jewelry and limbs clear of the

"19

"12

spreader before starting or operating this spreader.

7. Do not over-load your vehicle beyond payload limits. If

there are any questions, contact the vehicle manufacturer.

8. Do not adjust, clean, oil or unclog material jams without

first turning off the spreader.

HOPPER CAPACITIES

12" .50 CU-YD

19" 1.0 CU-YD

27" 1.80 CU-YD

4. Recommended Fastener Torques:

Maintain all fastener torques as shown in the following

table. Failure to do so may cause injury to persons.

SAE GRADE 2 SAE GRADE 5

ft-lbS ft-lbS

1/4-20 6 9

5/16-18 11 18

3/8-18 19 31

3/8-24 24 46

7/16-14 30 50

1/2-13 45 75

9/16-12 66 110

5/8-11 93 150

Safety Precautions

WARNING

Observe the following Safety Precautions before,

during and after operating this spreader. By following these precautions and common sense, possible

injury to persons and potential damage to this

machine may be avoided.

1. Read this entire Owner’s Manual before operating this

spreader.

9. Do not climb on or in the spreader during operation. Do

not ride on the spreader while the vehicle is in motion.

10. Make sure the spreader is securely fastened to the vehicle in accordance with this manual.

11. Do not operate a spreader that is in need of maintenance

or repairs.

12. Always disconnect the wire harness before removing or

replacing any electrical components.

Installation Instructions

1. Mounting the Spreader onto the Vehicle:

A. Remove the tailgate from the vehicle.

B. Lift the spreader by lifting loops on side of hopper.

WARNING

The lifting device must be adequately rated to lift

a payload equal to or greater than the spreader

weight. See page 1 for spreader weights. Empty

spreader before lifting.

C. Elevate the spreader off the vehicle with lumber. Place

lumber under the side gussets of the spreader. This will help

with removal of excess material that accumulates under the

spreader.

2. Read all safety decals on the spreader before operating the

spreader.

3. Check to make sure all safety guards are securely

mounted into place before operating this spreader.

D. Center the spreader on the vehicle with the end of the

gear mount 14" to the rear of the nearest vertical obstruction

(bumper, trailer hitch, etc). Attach chute to spreader, check

for interference between the vehicle and the Spinner/Chute

Assembly.

22

TM

E. Bolt the spreader to the vehicle frame through the lengths

of lumber using the holes located in each of the four (4) side

gussets. Use 1/2" SAE Grade 5 hardware as required by

vehicle application.

F. In addition secure the spreader to the vehicle by attaching the four (4) tie-down eyes located at each corner of the

spreader to the vehicle’s factory installed anchor points using suitable tie-down devices.

• The spreader must be securely fastened to the

frame of the vehicle.

• Verify with the vehicle’s manufacturer that the

factory installed anchor points are designed for

tie-down of such load.

• Periodically check that the spreader mounting

hardware is securely tightened, retighten if necessary.

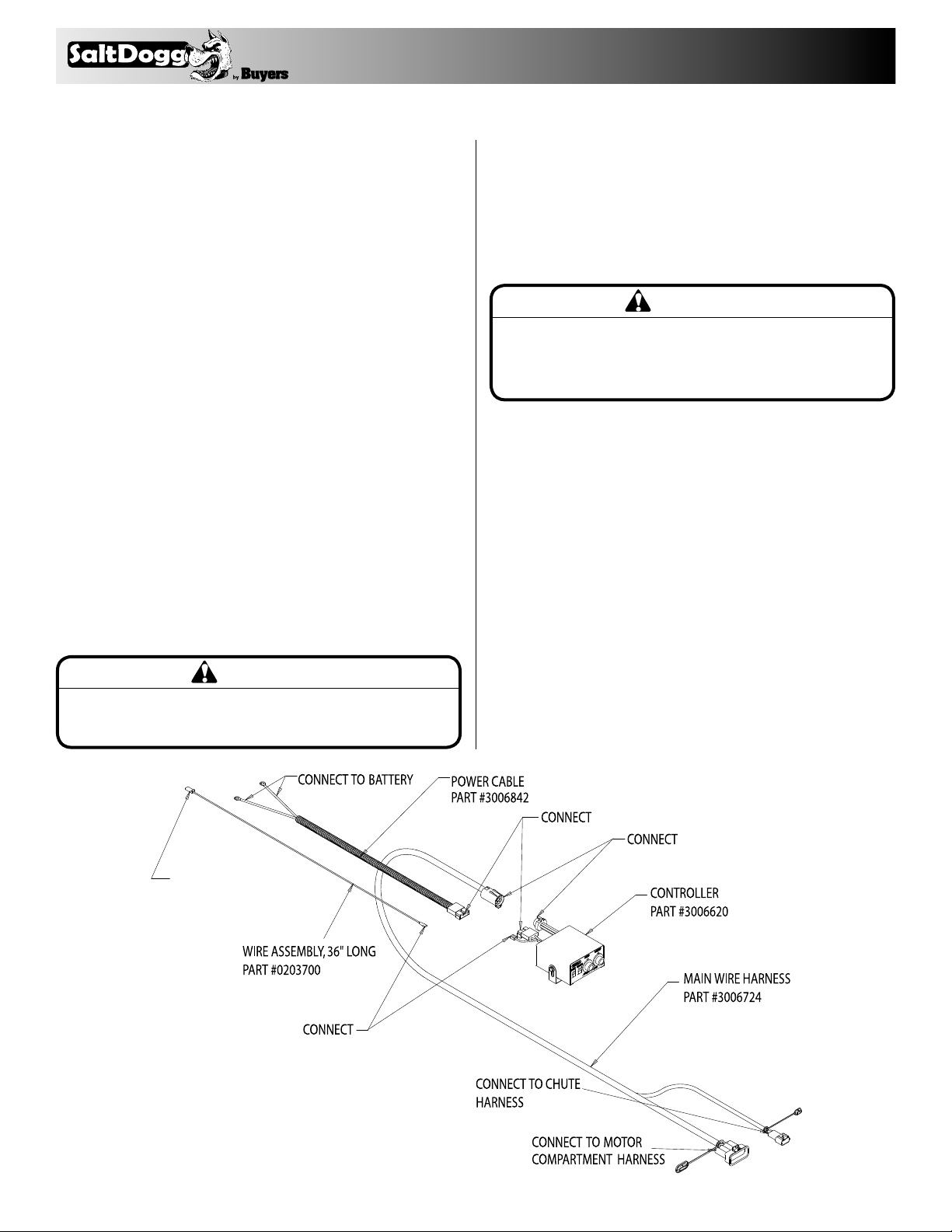

2. Control Box and Vehicle Wiring Harness Installation

To insure good performance of your spreader, check the

condition of truck’s electrical system. Using digital voltmeter,

check alternator and battery voltage. With engine running

and head lights and heater fan on good voltage reading

should fall between 13.0 and 15.3 volts. If voltage reading

falls out of this range, check and adjust your electric system.

A. Lay out a wiring path for the Vehicle Wiring Harness.

Connect the Wire Harness smaller connector to the Chute’s

harness, large connector to the Hopper’s harness. Drill

all necessary holes or use existing ones to pass the round

connector into the trucks cab. Attach harness to truck’s frame.

B. Mount the Controller in a convenient location in the truck

cab. It is recommended not to mount Controller directly in

front of the heat vents.

WARNING

Do not install controller in the deployment path of an air

bag. Refer to vehicle manufacturer’s manual for air bag

deployment area(s).

C. Connect the Wire Harness round connector to the

Controller round connector.

Lay out path for the Power Cable in the truck’s engine

D.

compartment. Drill hole in the firewall or use an existing one

to pass wire harness. It is recommended to pass the Power

Cable from inside of the cab to the battery due to the large high

amperage connector. Do not route close to exhaust system!

E. Connect Power Cable terminal to Controller.

F. Connect the Power Cable ring terminals to the truck’s

battery, white-positive, and black-negative.

WARNING

Use extreme caution when working around an operating

vehicle engine.

CONNECT TO

FUSE OR WIRE IN

FUSE PANNEL

INSIDE TRUCK CAB

G.

Make sure that the Controller is OFF. Connect blue wire’s

small female terminal to Controller’s Ignition wire. Connect the

blue wire to an accessory wire/terminal that is controlled by

the vehicle’s ignition switch.

33

Loading...

Loading...