SaltDogg 1400550SS User Manual

Installation Manual

Stainless Steel

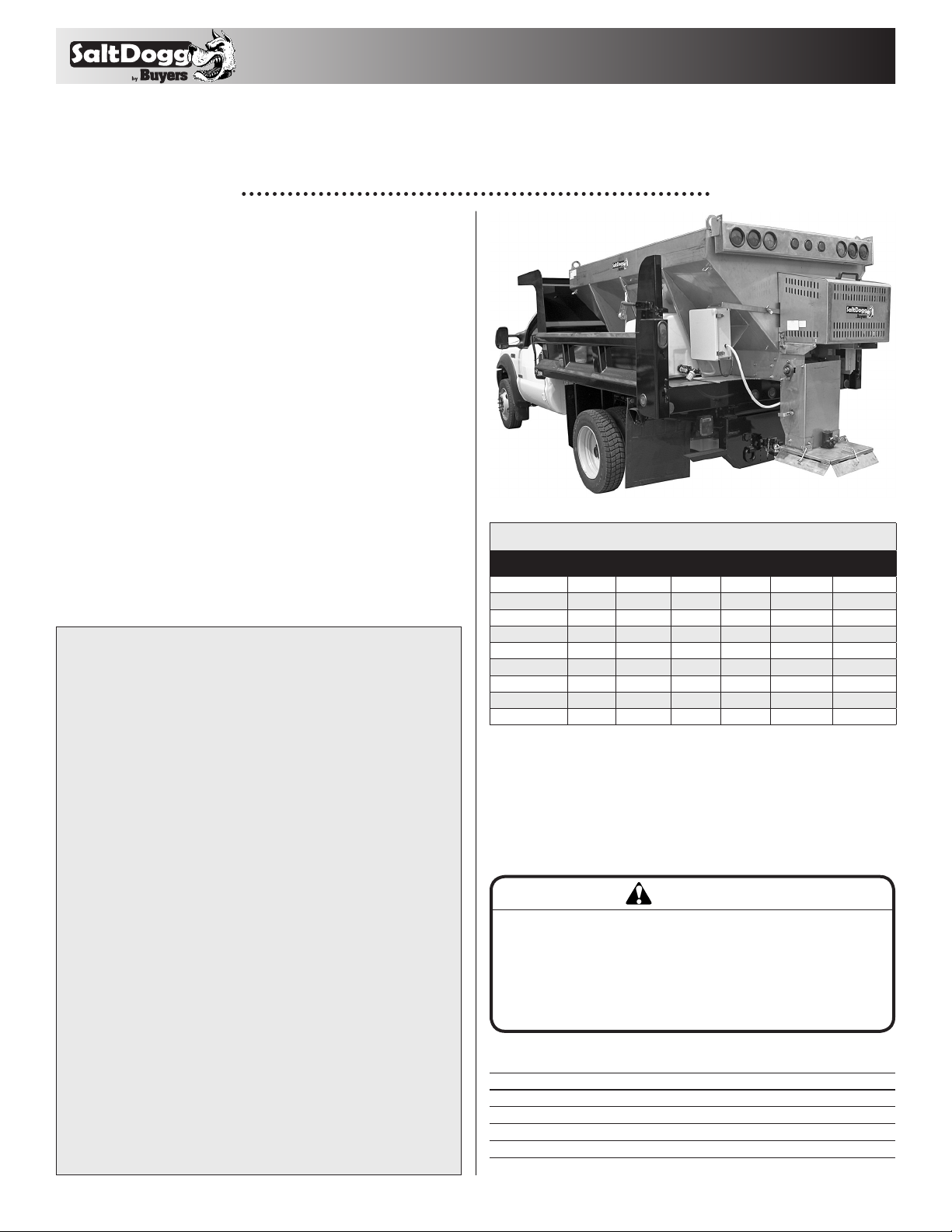

Self-Contained Hopper Spreaders

Table of Contents

Warranty Information .................................................. 1

General Information ................................................. 1-2

Safety Precautions ..................................................... 2

General Installation .................................................. 2-3

Installation Instructions - Gas Models ..................... 3-4

- Hydraulic Models ............... 6

Chute Installation ........................................................ 5

Spreader Operation - Gas Models ..........................4-5

- Hydraulic Models ................. 6-7

Chute Operation ......................................................5-6

Spreader Maintenance ............................................ 7-9

Optional Equipment .................................................... 9

Repair Parts & Drawings ......................................10 -16

SPREADER WARRANTY INFORMATION

This warranty replaces all previous warranties and no employee of this

company is authorized to extend additional warranties, or agreements, or

implications not explicitly covered herein.

Buyers Products Company warrants all parts of the product to be free from

defects in material and workmanship for a period of one (1) year, excluding

the gasoline engine, from the date of installation. Parts must be properly

installed and used under normal conditions. Normal wear is excluded.

Any part which has been altered, including modifications, misuse, accident,

or lack of maintenance will not be considered under this warranty.

The sole responsibility of Buyers Products Company under this warranty is

limited to repairing or replacing any part(s) which are returned, prepaid, 30

days after such defect is discovered, and returned part(s) are found to be

defective by Buyers Products Company.

Authorization from Buyers Products Company must be obtained before

returning any part. The following information must accompany defective

parts returned to Buyers Products Company: RMA#, spreader model, serial

number, date installed, and distributor from whom purchased.

Buyers Products Company shall not be liable for damage arising out of

failure of any unit to operate properly, or failure, or delay in work, or for any

consequential damages. No charges for transportation or labor performed

on any part will be allowed under this warranty.

The gasoline engine is solely warranted through engine’s manufacturer. All

engine related warranty claims are to be processed through the engine’s

manufacturer. This information is explained in the engine owner’s manual.

9049 Tyler Blvd. • Mentor, Ohio 44060

Phone (440) 974-8888 • Fax (440) 974-0165

Toll-Free Fax 800-841-8003 • saltdogg.com

Spreader Models and Specifications

MODEL # POWER

1400455SS

1400460SS

1400465SS

1400475SS

1400475SSH

1400500SS

1400500SSH

1400550SS

1400550SSH

Gas 96" 115.9" 58" 1,395 lb s. 2.5 yds.

Gas 108" 12 7. 9 " 58" 1,46 0 lbs. 2.75 yds.

Gas 120 " 138 .9" 58" 1,526 lbs. 3.0 yds.

Gas 96" 116" 70" 1, 470 lbs . 3.0 yds.

Hydraulic 96" 116" 70" 1,4 0 5 l bs . 3.0 yds.

Gas 108" 128" 70" 1,500 lbs. 4.0 yds.

Hydraulic 108" 128" 70" 1,435 lbs. 4.0 yds.

Gas 120 " 140" 70" 1,560 lbs. 4.5 yds.

Hydraulic 120 " 140" 70" 1,500 lbs. 4.5 yds.

HOPPER

LENGTH

OVERALL

LENGTH

OVERALL

WIDTH

EMPTY

WEIGHT CAPAC ITY

General Information

1. Recommended Vehicle Requirements:

This spreader is to be used on trucks with dump

bodies or flat bed trucks with a Gross Vehicle Weight

Rated chassis of 15,000 lbs. or greater.

CAUTION

Do not overload vehicle beyond the vehicle’s Gross

Vehicle Weight Rating (GVWR) or Gross Axle Weight

Ratings (GAWR). Check the vehicle’s load rating certification sticker for maximum vehicle capacity.

2. Average Material Weights:

MATERI AL WEIGH T (PO UNDS PER CUBI C YARD)

#1 Rock Salt 950

#2 Rock Salt 1,215

Coarse Sand - Dry 2,565

Coarse Sand - Wet 3,240

1

Note: To calculate the total spreader weight

(including ice control material); add the empty

spreader weight plus the ice control material and

spreader accessories.

3. Recommended Fastener Torques:

Maintain all fastener torques as shown in the following

table. Failure to do so may cause injury to persons.

SAE GRADE 2 SAE GRADE 5

FT-L BS FT- LBS

1/4-20 6 9

5/16 -18 11 18

3/8-18 19 31

3/8-24 24 46

7/16-14 30 50

1/2-13 45 75

9/16-12 66 110

5/8-11 93 150

4. Engine Oil (gas models) and Gearbox Oil

(all models):

The engine crankcase of gasoline powered spreaders is filled with 1 quart of SAE 5W-30 motor oil at the

factory. The gearbox of any spreader is filled with SAE

90 gear lubricant at the factory.

WARNING

Verify that the above oil viscosity meets your operating temperature requirements. If not, empty and

refill with the proper viscosity oil. Before starting

spreader, check that the engine crankcase and gearbox are filled to the proper level with lubricant.

General Safety Precautions

WARNING

Observe the following Safety Precautions before,

during and after operating this spreader. By following these precautions and common sense, possible

injury to persons and potential damage to this

machine may be avoided.

• Verify that all personnel are clear of the spreader

spray area before starting or operating this

sprea der.

• Keep all loose clothing, hair, jewelry and limbs

clear of the spreader before starting or operating this

sprea der.

• Do not over-load your vehicle beyond payload limits.

• Do not perform any service operation on the

spreader while it is running.

• Do not climb on or into the spreader during

operation.

• Do not ride on the spreader while the vehicle is in

motion.

• Make sure the spreader is securely fastened to the

vehicle.

• Do not operate a spreader that is in need of maintenance or repair.

Safety Precautions – Gas Powered Models

• On gas powered models, make sure the engine

cover is securely fastened to the spreader before operating the spreader.

• On gas powered spreader versions, never lay tools

or equipment on top of the 12V DC battery as this

could accidentally ground the positive (+) battery terminal. Grounding the battery could result in electrical

shock, burns or damage to the vehicle or equipment.

• Always disconnect the battery before removing or

replacing any electrical component.

• A charging battery gives off gases that can explode

if touched by a spark or flame. Cover the top of the

battery with electrically non-conductive material to

keep sparks away from battery gases.

• If the spreader must be operated with the spreader

battery disconnected, insulate the positive (red) battery cable and red wire from the engine alternator with

electrical tape.

• Read this entire Owner’s Manual before operating this spreader; this includes the engine Operator’s

Manuals for gas powered versions as well.

• Read all safety decals on the spreader before operating the spreader.

• Check to make sure all safety guards are securely

mounted into place before operating your spreader.

2

General Installation Instructions –

All Models

1. Mounting the Spreader onto the Vehicle:

• Remove the tailgate from the vehicle if applicable.

• Lift the spreader using the (4) lifting loops in the

corners of the hopper.

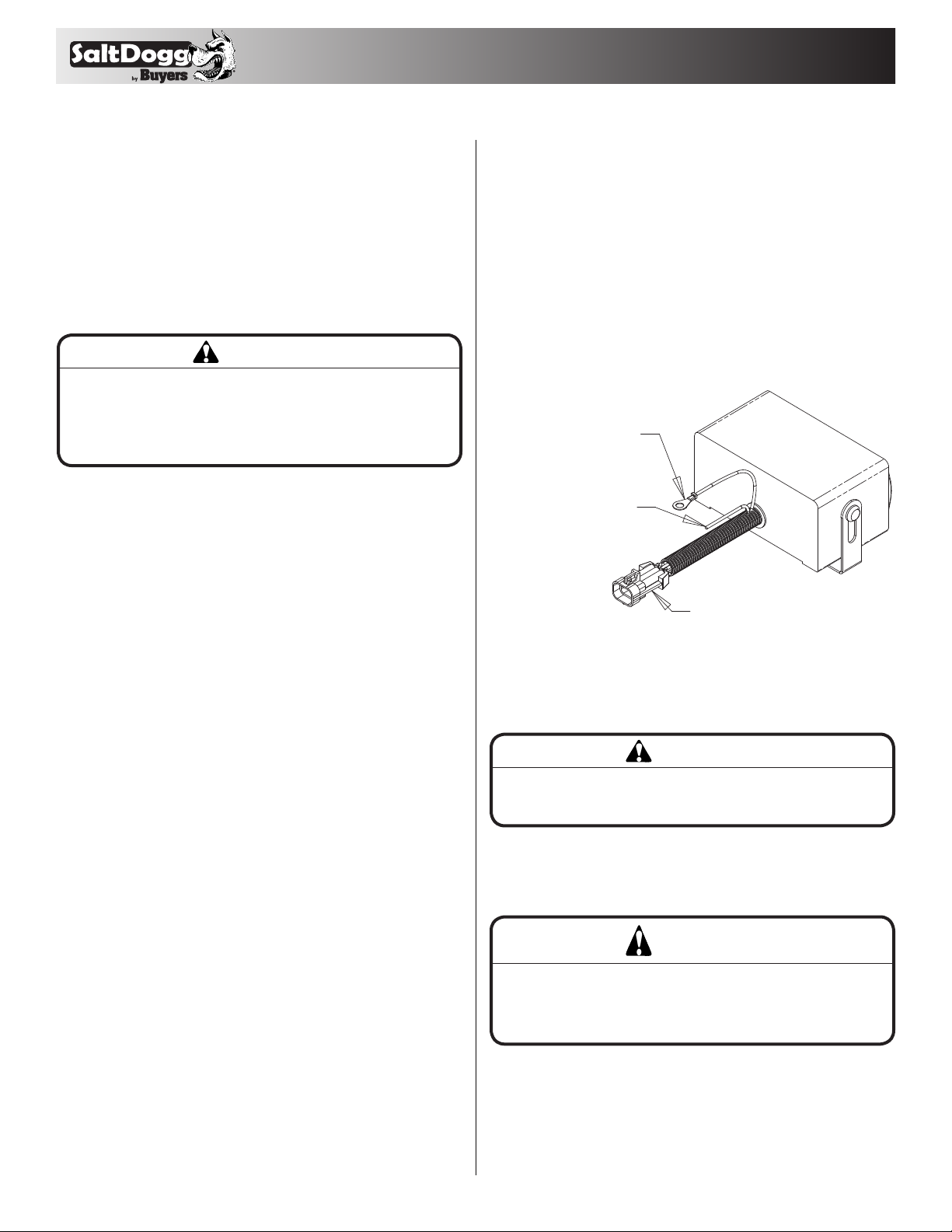

Control Box & Vehicle Wiring Harness Installation

- Gas Powered Models.

Note: The following instructions show how to

install the spreader so that the engine will draw

power to start the engine from a dedicated battery

located on the spreader.

1. Vehicle Wiring Installation

WARNING

The lifting device must be adequately rated to lift a

payload equal to or greater than the spreader weight.

See page 1 for spreader weights. Empty spreader

before lifting.

• Keeping the spreader elevated off the vehicle with

lumber helps with removal of material that accumulates under the spreader during operation. Place

lumber under the side gussets and central rails of the

sprea der.

• Center the spreader in the vehicle with the end of

the spreader about 14" beyond the back end of the

vehicle.

• Bolt the spreader through the lumber and into the

vehicle frame using the holes located in each of the

side gussets. Use 1/2" SAE grade 5 hardware.

• The spreader may be further secured to the vehicle

by using appropriate tie-down straps from the spreader to the vehicle’s factory installed anchor points.

• Verify with the vehicle’s manufacturer that the factory installed anchor points are designed for tie-down

of such load.

• Periodically check that the spreader mounting hardware is securely tightened.

Cab Control Box

AT TACH TO

VEHICLE GROUND

AT TACH TO 12V DC POWER

SOURCE CONTROLLED

BY VEHICLE IGNITION

TO SPREADER HARNESS

• Determine a wiring path for the vehicle wiring harness.

WARNING

Do not drill holes into fuel tanks, fuel lines, through

electrical wiring, etc that may be damaged by drilling.

• Mount the control box in a convenient location in the

truck cab.

WARNING

Do not install control box in the vehicle’s airbag

deployment area. Refer to the vehicle’s manual for

airbag deployment area.

• Connect the green wire from the vehicle wiring

harness to a known good vehicle ground.

• Connect the stripped end of the red wire to an

accessory wire terminal that is controlled by the

vehicle’s ignition switch.

3

2. Spreader Wiring Installation

• Attach the terminal end of the black (negative) battery cable to the negative terminal (marked "-") on the

battery.

• Connect the terminal end of the red (positive) battery cable to the positive terminal (marked "+") on the

battery.

• Verify that the Ignition Switch in Control Box is in the

"OFF" position prior to completing next step.

• Connect the spreader and vehicle wiring harnesses

to each other.

Spreader Operation - Gas Powered Models

Note: Before starting the gas spreader engine

follow all safety precautions.

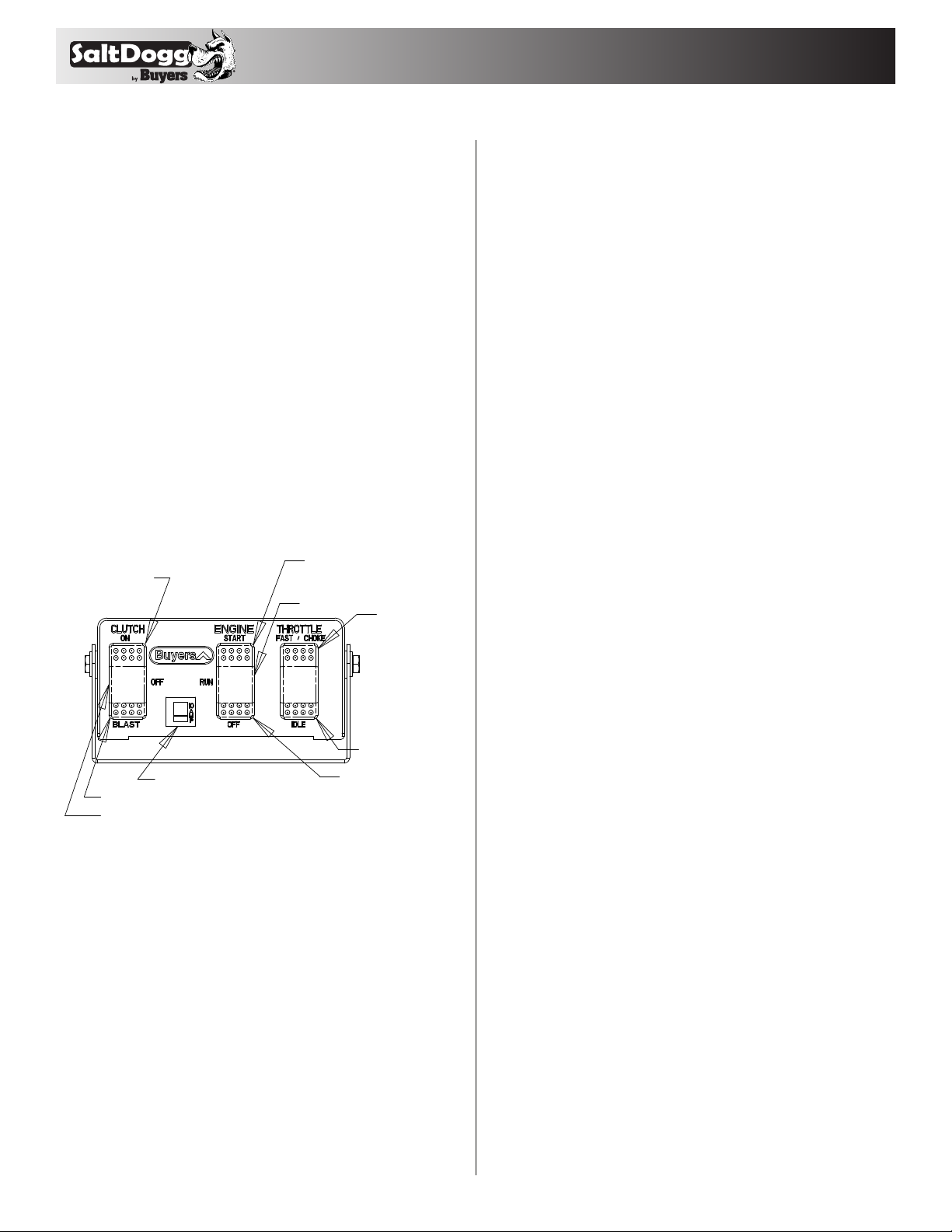

Cab Control Box Functions:

HOLD TO CRANK ENGINE

ENGAGE CLUTCH

(SPREAD)

CIRCUIT BREAKER

ENGAGE CLUTCH (BLAST )

DISENGAGE CLUTCH (CENTER)

1. Clutch Switch: The clutch switch is a three position switch with the following functions:

• "OFF" position: While in this position, with the engine running, the spreader feed chain and the spinner

disk will not rotate and therefore the spreader will not

spread ice control material.

• "ON" position: While in this position, the spreader

feed chain and the spinner disk will rotate and material will be dispensed when the engine is running.

• "BLAST" position: While in this position with the

engine running, the spreader feed chain and the spinner disk will spin. The switch must be held

"BLAST" position to activate this function.

RUN

THROTTLE UP

CHOKE

THROTTLE DOWN

ENGINE OFF

down in the

2. Ignition Switch: The ignition switch is a three

position switch with the following functions:

• "OFF" position: While in this position, 12V DC power

is shut off to the spreader. To turn off the spreader,

turn the switch to this position.

• "ON" position: While in this position, 12V DC power

is turned on to the spreader.

• "START" position: While holding in this position, the

spreader’s engine starter is activated.

3. Throttle Switch: The throttle switch is a two

position switch with the following functions:

• "CHOKE/FAST" position: While in this position, the

engine speed will gradually increase until the engine

linkage reaches its choke position.

• "IDLE" position: While in this position, the engine

speed will gradually decrease.

4. Starting the Gas Engine

• Verify that the clutch switch and ignition switch on

the cab control box are in the "OFF" position.

• Turn the vehicle’s ignition to the "ON" position.

• Turn the spreader’s ignition switch to the "ON" position.

• Press the throttle switch on the cab control box to

the "Idle" position and hold for approximately two

seconds.

• Hold the ignition switch in the "START" position.

• While the engine is cranking, press and hold the

throttle switch to the "CHOKE/FAST" position.

• Release the ignition and throttle switches when the

engine starts.

• After the engine starts, press and hold the throttle

switch to the "IDLE" position to release the choke

(hold switch for 1/2-1 seconds).

5. Stopping the Engine

• Reduce engine RPM by holding throttle switch to the

"IDLE" position for 2-3 sec.

• To stop the engine, press the ignition switch to the

"OFF" position.

Clutch Operation - Gas Powered Models

• Start the engine & adjust the speed to slightly above

idle.

• Push the clutch switch into the "ON" position.

• Increase the engine RPM by pressing the throttle

switch to the "CHOKE/FAST" position.

• It is recommended that the clutch only be engaged

4

at the lowest possible speed without stopping the

engine. This practice will prevent premature spinner

chain failure and chain tension loss.

• Do not repeatedly use the "Blast" function. Using

this function often, will prematurely wear the clutch

and flex coupler and promote component failure.

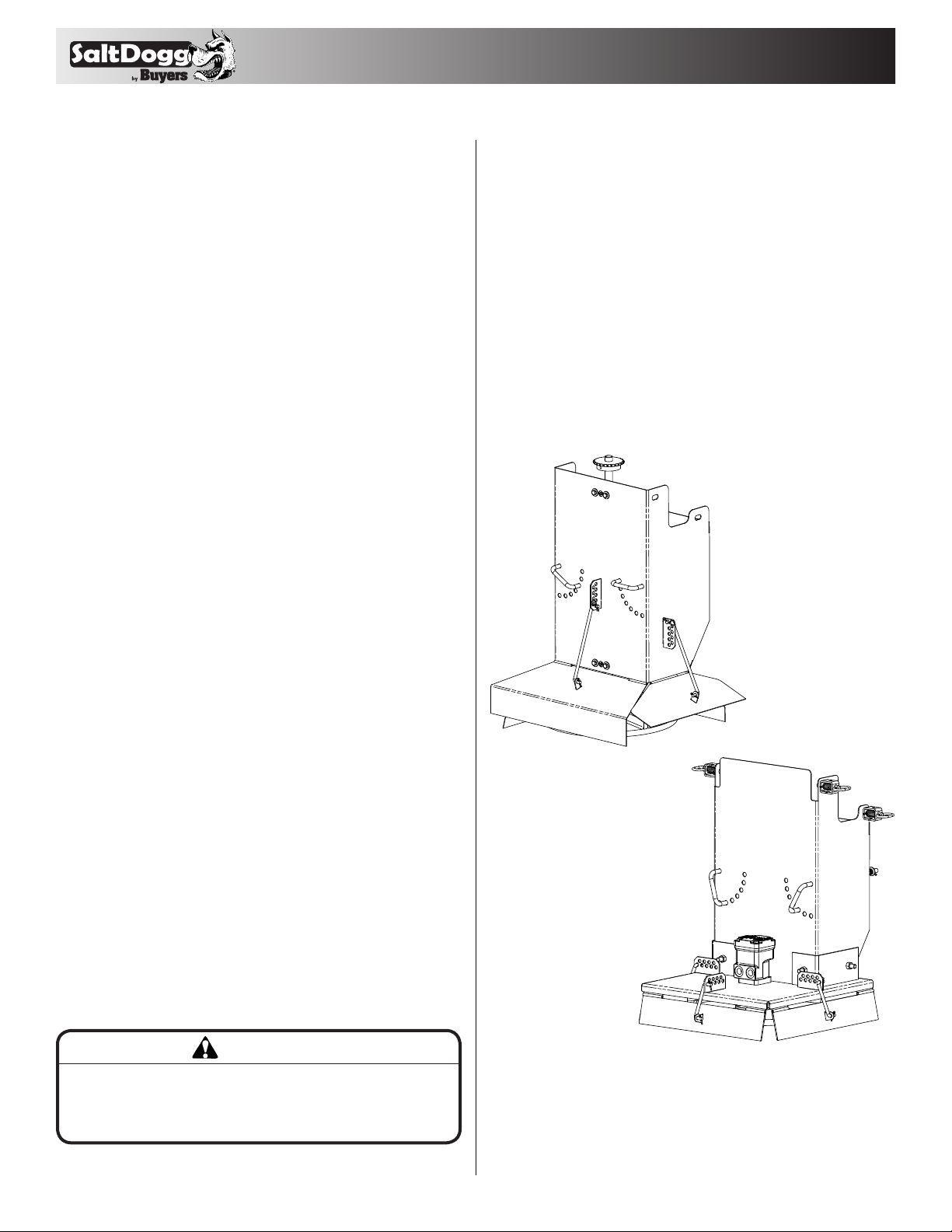

Spinner Chute Installation Instructions -

Gas Powered Models

1. Mounting the Gas Spinner Chute Assembly

• Remove the chain guard by first removing the four

(4) 1/4-20 X 3/4" hex head bolts, lock washers, and

nuts.

• Attach the Spinner Chute Assembly to the gas powered spreader using the four (4) 1/2-13 x 1.25 hex head

screws, flat washers, lock washers, and nuts. The

flat washers are to be placed over the slots in the sill

extensions. Push the chute assembly forward towards

the cab of the vehicle and loosely attach the hardware. Do not tighten the fasteners at this time.

• Install the roller chain between the spinner chute

sprocket and the gearbox sprocket. Make sure both

sprockets are horizontally in line with one another. If

the sprockets are out of alignment, adjust the height

of the gearbox sprocket to correct the alignment.

Install the roller chain master link.

• To adjust the roller chain tension, pull the spinner

chute assembly away from the rear of the vehicle

to take up slack in chain then tighten chute fasteners. The correct chain tension should allow a 5/16"

deflection midway between both chain sprockets. If

additional adjustment is needed, loosen the spinner

shaft bearing bolts and slide the shaft away from the

gearbox sprocket. Be sure to maintain the vertical

alignment of the spinner shaft and bearings before

tightening the hardware.

• Replace the chain guard using the four (4) 1/4-20 X

3/4" hex head bolts, lock washers, and nuts.

• Tighten all hardware to the recommended torque

specifications as shown in this manual.

Spinner Chute Installation Instructions -

Hydraulic Models

1.

Mounting the Hydraulic Spinner Chute Assembly

• Install the hydraulic spinner chute assembly by simply engaging the (4) spring loaded plungers into the

corresponding holes in the spreader frame.

Spinner Chute Assembly Operation – All Models

• The spread pattern and the amount of material dispensed will depend on the following factors:

• Engine RPM.

Gasoline Chute

CAUTION

Do not over-tension either roller chain. Overtensioning can cause damage to bearings, roller

chain, sprockets, or the engine.

Hydraulic Chute

• Feed gate door position.

• Baffle settings.

• Keep the following rules in mind:

• Increasing the engine RPM will increase

the speed of the conveyor and therefore

5

Loading...

Loading...