Heavy Duty Plastic Lockers – 40000 Series

Locker Installation Instructions

Thank you for selecting 40000 Series Heavy Duty Plastic Lockers. We are confident that the quality and construction of the lockers will prove to be a

good investment. These instructions are intended to assist you in the assembly, placement, and anchoring of your lockers. Individual job conditions

will dictate whether the lockers must be anchored to the wall, the floor, or both.

Separate parts from packaging and make sure all parts are accounted for before discarding any packaging

material. If any parts are missing, do not begin installation until you obtain the missing parts.

Lockers should be installed in a climate-controlled environment and shielded from direct sunlight. All lockers

must be either secured against a wall or installed back-to-back (for island configuration).

Make sure all floors and walls are clean and smooth. Remove loose impediments, such as protruding nails, and

other debris which could affect installation. The lockers must be square and level and floor supported or they will

not operate properly. A locker that is square may not be level, so be sure to check both.

Review your locker layout drawings and verify the number of lockers and components before beginning

installation.

Carefully lift lockers at the base when moving and positioning. Do not drag the lockers.

LOCKER BASES MUST BE SQUARE AND LEVEL, AND ANCHORED TO THE FLOOR BEFORE THE LOCKERS ARE

INSTALLED. THE LOCKERS WILL NOT OPERATE PROPERLY IF THE BASE IS NOT SQUARE AND LEVEL AND

NOT FLOOR-SUPPORTED. A LOCKER BASE THAT IS SQUARE MAY NOT BE LEVEL, SO BE SURE TO CHECK

BOTH.

FAILURE TO COMPLY WITH THESE INSTRUCTIONS MAY RESULT IN PERSONAL INJURY AND/OR PROPERTY

DAMAGE AND WILL VOID THE LOCKER WARRANTY.

Tools required: Tape measure - - - 9/32” drill bit - - - hammer drill for drilling into concrete - - - 6’ level and shims - - - power drill - - - Phillips driver

bit - - - clamps - - - 3/16” masonry drill bit (6” long minimum) - - - circular saw - - - right-angle power drill - - - chalk and string.

The following tips may be helpful: A string line along the top and bottom of the lockers may be used to help in alignment. If shims are required

after locker installation is complete, remove obstructive screws, apply the shims, then replace the screws. Avoid twisting the locker frames when

applying shims.

SALSBURY INDUSTRIES

1010 East 62nd Street, Los Angeles, CA 90001-1598

Phone: 1-800-562-5377 Int’l Phone: 323-846-6700

Fax: 1-800-562-5399 Int’l Fax: 323-846-6800

www.lockers.com engineering

Installation instructions are provided as general guidelines. It is advised that a professional installer be consulted. Salsbury Industries assumes no product assembly or installation liability.

Copyright © 2010 Salsbury Industries. All rights reserved. (Rev. 05, 1/13/2010) Page 1 of 6

@lockers.com

Heavy Duty Plastic Lockers – 40000 Series

Locker Base Installation Instructions

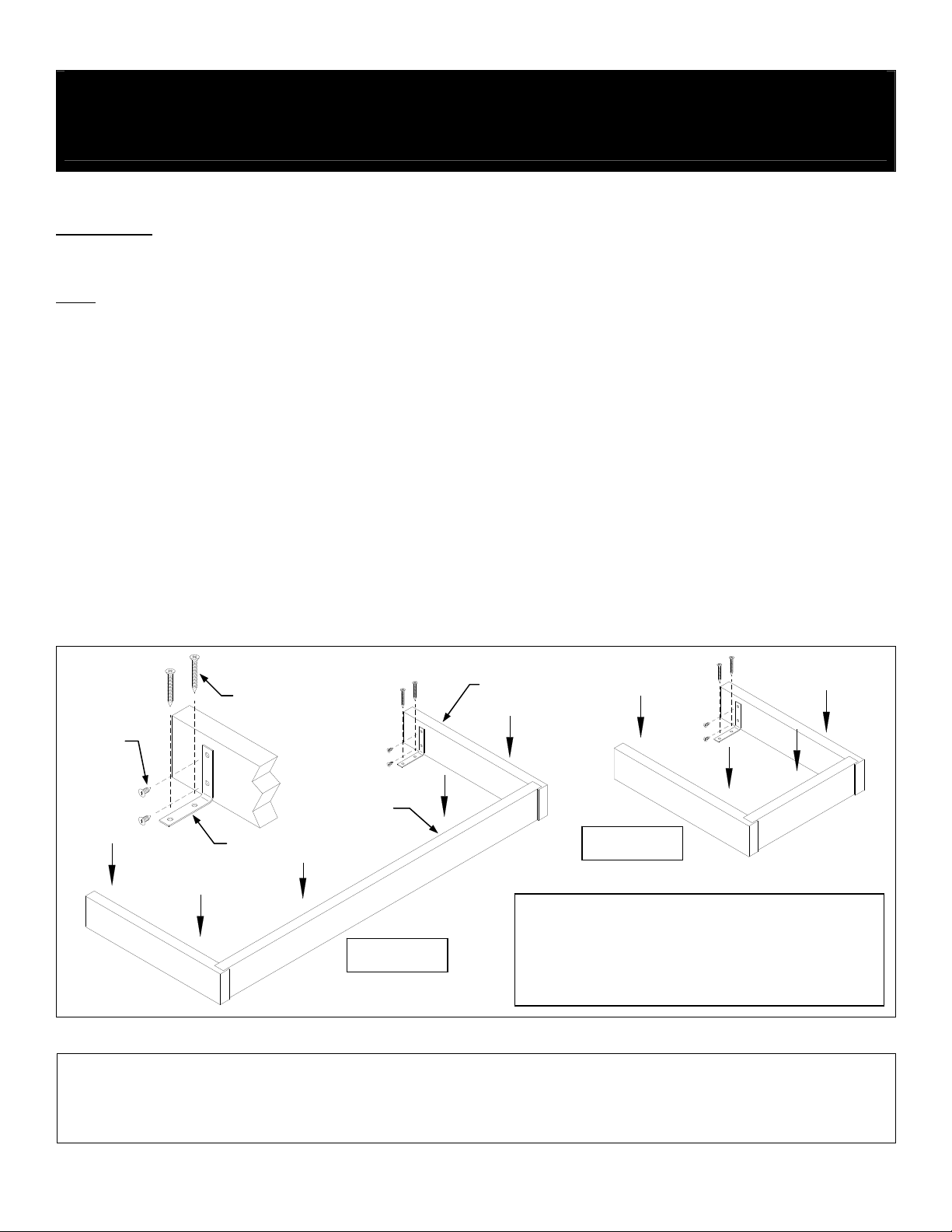

IMPORTANT: Make sure the base is square and level before anchoring to the floor. The base may be square but

not level, so be sure to check both. Shim under the base if necessary. This will ensure proper locker operation.

NOTE: The base front pieces are precut to length for 1-wide (12”) or 3-wide (36”) lockers, and come with slotted base side pieces. The length of the

base front pieces may be trimmed during installation by cutting to the desired length. DO NOT cut the base side pieces. The side pieces are the

correct length for 18” deep lockers.

Each set of base pieces includes a package of angle brackets to attach the base pieces to the floor, ¼” x 1-3/4” Tapcon screws to fasten the angle

bracket to the floor, and #10 x ½” sheet metal screws to attach the brackets to the base front and side pieces.

1. Plan the locker layout. Measure and mark placement lines on the floor for the locker bases. One or two lockers will require one or two 1-wide

bases. Three or more lockers in a row will require 3-wide bases and perhaps one or two 1-wide bases. As supplied, the bases are 1” wider than the

basic 12” wide locker to accommodate two (2) 1/2” thick side panels. As additional lockers and bases are arranged in a row with a side panel at one

end or both ends, some of the base front piece(s) must be trimmed by 1” or 1/2” to maintain a flush surface alignment between the end panel and the

base side piece. If side panels are not being used, further trimming of the front base pieces may be necessary

2. Position the base side and front pieces per the floor layout. The ends of the base front pieces fit into the slots in the base side pieces. See the

illustration below. Square and level the base front pieces and side pieces using shims as required. If shims are used, place them under the

mounting brackets perpendicular to the bracket.

3. Using the applicable mounting hardware supplied, anchor the base pieces to the floor. Use a 3/16” masonry drill bit for the 1/4” x 1-3/4” Tapcon

screws. Use at least two (2) angle brackets for each front piece or side piece.

Base Installation

Tapcon Screw

Side Piece

Sheet

Metal

Screws

Front Piece

Angle Bracket

1-Wide Base

Use 1/4” x 1-3/4” Tapcon concrete screws (blue) to attach

angle brackets to floor. Drill pilot hole with 3/16” masonry bit.

3-Wide Base

Use #10 x ½” sheetmetal screws to attach angle brackets to

plastic base members.

SALSBURY INDUSTRIES

1010 East 62nd Street, Los Angeles, CA 90001-1598

Phone: 1-800-562-5377 Int’l Phone: 323-846-6700

Fax: 1-800-562-5399 Int’l Fax: 323-846-6800

www.lockers.com engineering

Installation instructions are provided as general guidelines. It is advised that a professional installer be consulted. Salsbury Industries assumes no product assembly or installation liability.

Copyright © 2010 Salsbury Industries. All rights reserved. (Rev. 05, 1/13/2010) Page 2 of 6

@lockers.com

Heavy Duty Plastic Lockers – 40000 Series

Locker Installation Instructions

Note: Refer to your layouts for proper locker position. The first locker is usually installed at a corner or at the end of a run.

IMPORTANT NOTE: Make sure each locker is square and level before securing into place. The lockers may be square, but not level, so be

sure to check both. Use shims as needed.

1. Position the first locker according to your layouts. Square and level the locker using shims as required. Secure the locker to the wall in two

places with the two ¼” x 1-3/4” Tapcon screws. With the screws centered across the width of the locker, place one near the top and one near the

bottom as shown in the illustration below.

2. Postion the second locker next to the first locker. Square and level the lockers using shims as required to align the tops and fronts.

IMPORTANT: Lockers must be installed flush with adjacent lockers.

3. Temporarily clamp the lockers together at the top and bottom. Drill four (4) 9/32” clearance holes through one locker as shown in the illustration

below. The holes should be located 1-1/2” from the front of the locker and evenly spaced, top to bottom. Fasten the lockers to each other using the

#10 x ¾” security torx screws provided.

4. Position additional lockers according to your layouts. Square and level each locker using shims as required. Fasten lockers to each other using

the #10 x 3/4” security torx screws provided.

5. Secure each locker to the wall in two places with the appropriate wall installation hardware provided. Use two 1/4” x 1-3/4” Tapcon screws,

placing one near the top and one near the bottom of the locker as shown below.

CENTERLINE

DRILL 3/16” DIA. PILOT HOLE

IN CONCRETE OR BLOCK

WALL

OF LOCKER

BACK

DRILL 9/32” DIA. CLEARANCE HOLE

THROUGH BACK OF LOCKER

1/4” x 1-3/4” TAPCON SCREW

#10 x 3/4” SECURITY TORX SCREWS

SALSBURY INDUSTRIES

1010 East 62nd Street, Los Angeles, CA 90001-1598

Phone: 1-800-562-5377 Int’l Phone: 323-846-6700

Fax: 1-800-562-5399 Int’l Fax: 323-846-6800

www.lockers.com engineering

Installation instructions are provided as general guidelines. It is advised that a professional installer be consulted. Salsbury Industries assumes no product assembly or installation liability.

Copyright © 2010 Salsbury Industries. All rights reserved. (Rev. 05, 1/13/2010) Page 3 of 6

@lockers.com

Heavy Duty Plastic Lockers – 40000 Series

Sloping Hood Installation Instructions

The Slope Tops are shipped in two (2) standard lengths of 1-wide (12”) and 3-wide (36”) to fit the lockers without any cutting or trimming. Wall strips

will be either 12” or 36” in length. The color of the wall strips may vary, but they are not visible after installation.

1. Drill two (2) 3/16” diameter clearance holes through the top of

each of the installed lockers as shown in the illustration below,

making sure that the holes are located 1-1/4” from the front edge of

the locker. This dimension is critical to ensure proper installation.

HOLE LOCATIONS

2. Position the wall strip (or strips) on top of the lockers flush against

the wall as shown in the illustration to the right.

drill 1/4” mounting holes into the wall strip as follows:

CONCRETE or BLOCK WALLS: Put two (2) holes 1” in from each

end of each 12” wall strip. Do the same for each 36” wall strip and

put a third (3

1-1/4” from the bottom edge of the wall strip. Use a 3/16” diameter

masonry drill bit and 1/4” x 2-1/4” long Tapcon screws to fasten the

wall strip to the wall.

STUD WALLS: Drill the mounting holes at every stud location

covered by the wall strip. The holes must be located at least 1-1/4”

from the bottom edge of the wall strip. Anchor the wall strip to the

wall with 1/4” x 1-3/4” long pan head screws.

NOTE: The 12” wide wall strips are too short to span two (2)

studs in a conventionally framed wall.

rd

) hole in the center. The holes must be located at least

Measure, scribe and

LOCATION OF WALL STRIPS

SALSBURY INDUSTRIES

1010 East 62nd Street, Los Angeles, CA 90001-1598

Phone: 1-800-562-5377 Int’l Phone: 323-846-6700

Fax: 1-800-562-5399 Int’l Fax: 323-846-6800

www.lockers.com engineering

Installation instructions are provided as general guidelines. It is advised that a professional installer be consulted. Salsbury Industries assumes no product assembly or installation liability.

Copyright © 2010 Salsbury Industries. All rights reserved. (Rev. 05, 1/13/2010) Page 4 of 6

@lockers.com

Heavy Duty Plastic Lockers – 40000 Series

Sloping Hood Installation Instructions

LOCATION OF HOLES IN WALL STRIPS

1. Fit the groove of the first slope top over the front edge of the locker. Rest the back edge of the slope top onto the wall strip. The 12” wide and the

36” wide slope tops are the same except for width and are installed in the same manner.

2. Fit the groove of the next slope top section over the front edge of the locker and rest its back edge onto the wall strip.

3. Secure the slope tops to the lockers with the #8 x 1-1/4” long screws provided. Do not overtighten screws.

4. Install the remaining slope tops.

NOTE: If desired, caulk the gap in the back edge of the slope top where it meets the wall strip.

SALSBURY INDUSTRIES

1010 East 62nd Street, Los Angeles, CA 90001-1598

Phone: 1-800-562-5377 Int’l Phone: 323-846-6700

Fax: 1-800-562-5399 Int’l Fax: 323-846-6800

www.lockers.com engineering

Installation instructions are provided as general guidelines. It is advised that a professional installer be consulted. Salsbury Industries assumes no product assembly or installation liability.

Copyright © 2010 Salsbury Industries. All rights reserved. (Rev. 05, 1/13/2010) Page 5 of 6

@lockers.com

Heavy Duty Plastic Lockers – 40000 Series

End Panel Installation Instructions

1. Drill five (5) 3/16” diameter holes through each of the exposed locker sides where the end panel is to be attached at the locations

shown in the illustration below.

2. Fasten each end panel to its corresponding locker side using the # 6 x 5/8” screws provided. The screws must be inserted through the inside of

the locker and screwed into the end panel. The screws should not protrude through the end panel.

INSTALLATION OF END PANELS

Do not drill holes into the end panel.

SALSBURY INDUSTRIES

1010 East 62nd Street, Los Angeles, CA 90001-1598

Phone: 1-800-562-5377 Int’l Phone: 323-846-6700

Fax: 1-800-562-5399 Int’l Fax: 323-846-6800

www.lockers.com engineering

Installation instructions are provided as general guidelines. It is advised that a professional installer be consulted. Salsbury Industries assumes no product assembly or installation liability.

Copyright © 2010 Salsbury Industries. All rights reserved. (Rev. 05, 1/13/2010) Page 6 of 6

@lockers.com

Loading...

Loading...