SALICRU SLC ADAPT Users guide

USER'S MANUAL

UNINTERRUPTIBLE POWER SUPPLY (UPS)

SLC serie ADAPT

180, 300 y 500 kVA

General index

1. INTRODUCTION.

1.1. THANK YOU LETTER.

2. SAFETY INFORMATION.

2.1. USING THIS MANUAL.

2.1.1. Conventions and symbols used.

3. QUALITY ASSURANCE AND STANDARDS.

3.1. STATEMENT BY THE MANAGEMENT.

3.2. STANDARDS.

3.2.1. First and second environment.

3.2.1.1. First environment.

3.2.1.2. Second environment.

3.3. ENVIRONMENT.

4. PRESENTATION.

4.1. VIEWS.

4.1.1. Views of the device.

4.1.2. Device configurations.

4.2. DEFINITION OF THE PRODUCT.

4.2.1. Nomenclature.

4.3. GENERAL DESCRIPTION.

4.3.1. Introduction.

4.3.2. Conceptual diagram of the system.

4.3.2.1. Power modules (PM).

4.3.2.2. Static bypass.

4.3.2.3. Extra charger modules for 180 and 300kVA devices.

4.3.3. UPS operating modes.

4.3.3.1. Normal mode.

4.3.3.2. Battery mode.

4.3.3.3. Bypass mode.

4.3.3.4. Manual Bypass mode (maintenance bypass).

4.3.3.5. Parallel-Redundant mode.

4.3.3.6. ECO mode.

4.3.3.7. Frequency converter mode.

5. INSTALLATION.

5.1. RECEPTION OF THE DEVICE.

5.1.1. Reception, unpacking and contents.

5.1.2. Storage.

5.1.3. Unpacking and transportation to the site.

5.1.3.1. Unpacking the power module.

5.1.4. Siting, immobilising and considerations.

5.1.5. Room for the batteries.

5.2. CABINET POSITIONING.

5.2.1. 180 to 300kVA devices.

5.2.2. 500kVA devices.

5.2.3. Batteries.

5.2.4. Installation of seismic kits (optional).

5.2.5. Installation of power modules.

5.2.6. Installation of extra charger modules.

5.3. CONNECTIONS.

5.3.1. Cable entry for 180 and 300kVA devices.

5.3.2. Cable entry for 500kVA devices.

5.3.3. Connection to the entry.

5.3.3.1. Specifications.

5.3.3.2. Specifications for power cable terminals.

5.3.3.3. Disconnectors.

5.3.3.4. Connection of the power cables.

5.3.4. Control and communication cables.

5.3.4.1. Relay interface.

5.3.4.2. Communications interface.

6. OPERATION.

6.1. STARTUP PROCEDURE.

6.1.1. Startup in Normal mode.

6.1.2. Startup from Battery mode (COLD START function).

6.2. SHUTTING DOWN THE UPS.

6.3. PROCEDURE TO TRANSFER BET WEEN OPERATING MODES.

6.3.1. Transfer from Normal mode to Battery mode.

6.3.2. Transfer from Normal mode to Bypass mode.

6.3.3. Transfer from Bypass mode to Normal mode.

6.3.4. Transfer from Normal mode to maintenance Bypass mode.

6.3.5. Transfer from maintenance Bypass mode to Normal mode.

6.4. BATTERY MAINTENANCE.

6.5. EPO.

2 SALICRU

6.6. INSTALLATION OF THE PARALLEL SYSTEM.

8.6. WARRANTY CONDITIONS.

6.6.1. Location of parallel cards.

6.6.2. Jumper settings for parallel operation.

6.6.2.1. Case of 2 UPSs in parallel.

6.6.2.2. Case of 3 UPSs in parallel.

6.6.3. Setting the parameters on the display screen.

6.6.4. Connection of parallel cables.

6.6.5. Verification of the parallel system.

6.6.6. Parallel system switching.

7. CONTROL PANEL OF THE MODULES AND

THE UPS.

7.1. CONTROL PANEL OF THE MODULES.

7.1.1. Status LE D.

7.1.2. Operation and control buttons.

7.1. 3 . L CD.

7.2. UPS CONTROL PANEL.

7.2.1. LED indicators.

7.2.2. Control and operation buttons.

8.6.1. Terms of the warranty.

8.6.2. Exclusions.

8.7. TECHNICAL SERVICES NETWORK.

9. ANNEXES.

9.1. GENERAL TECHNICAL SPECIFICATIONS.

9.2. GLOSSARY.

7.2.3. LCD touch screen.

7.3. MAIN MENU.

7.3.1. C abinet .

7.3.2. Power module.

7.3.3. Settings.

7.3.3.1. Date & Time setting.

7.3.3.2. Language setting.

7.3.3.3. Communications protocol setting.

7.3.3.4. User settings.

7.3.3.5. Battery settings.

7.3.4. L o g.

7.3.5. Operate menu.

7.3.6. Charts.

8. MAINTENANCE, WARRANTY AND SERVICE.

8.1. PRECAUTIONS.

8.2. POWER MODULE MAINTENANCE INSTRUCTIONS.

8.3. MAINTENANCE INSTRUCTIONS.

8.3.1. CONTROL AND BYPASS UNIT MAINTENANCE

INSTRUCTIONS.

8.4. BATTERY MAINTENANCE.

8.4.1. Notes for the installation and replacement of the battery.

8.5. REPLACE DUST FILTER (OPTIONAL).

SLC ADAPT UNINTERRUPTIBLE POWER SUPPLY (UPS)USER'S MANUAL

3

1. INTRODUCTION.

1.1. THANK YOU LETTER.

We thank you in advance for the trust placed in us in the purchasing of this product. Read this instruction manual carefully

in order to familiarise yourself with its content, since the more

you know and understand the device the greater your satisfaction, level of safety and optimisation of its functionalities will

be.

We remain at your disposal for any additional information or

queries that you may wish to make.

Yours sincerely

SALICRU

• The device described here is capable of causing sig-

nificant physical injury if improperly handled. For this

reason, its installation, maintenance and/or repair must be

carried out exclusively by our staff or qualified personnel.

• Although no effort has been spared to ensure that the in-

formation in this user manual is complete and accurate,

we accept no liability for any errors or omissions that may

exist.

The images included in this document are for illustrative

purposes and may not exactly represent the parts of the

device shown; therefore they are not contractual. However,

any divergence that may arise will be remedied or solved

with the correct labelling on the unit.

• Following our policy of constant evolution, we reserve

the right to modify the characteristics, operations

or actions described in this document without prior

notice.

• Reproduction, copying, assignment to third parties,

modification or total or partial translation of this

manual or document, in any form or by any means, without

previous written permission by us is prohibited, with

the company reserving full and exclusive property rights

over it.

4 SALICRU

2. SAFETY INFORMATION.

2.1. USING THIS MANUAL.

The documentation for any standard device is available to the

customer for download on our website (www.salicru.com).

• For devices ‘powered by socket,’ this is the website for

obtaining the user manual and ‘Safety Instructions’

EK266*08.

• For devices with ‘permanent connection’ via terminals, a

CD-ROM or pen drive containing all necessary information

for connection and startup, including ‘Safety Instructions’

EK266*08, may be supplied with it.

Before carrying out any action on the device relating to its installation or startup, change of location, configuration or handling of any kind, carefully read the safety instructions.

The purpose of the user manual is to provide information regarding safety and explanations of the procedures for installation and operation of the equipment. Read them carefully and

follow the steps indicated in the order established.

Compliance with the ‘Safety Instructions’ is man-

datory and the user is legally responsible for com-

pliance and enforcement.

2.1.1. Conventions and symbols used.

Some symbols may be used and appear on the device, batteries

and/or in the context of the user manual.

For more information, see Section 1.1.1 of the ‘Safety Instruc-

tions’ document EK266*08.

The device is delivered properly labelled for correct identification

of each of its parts, which, together with the instructions

described in this user manual, allows installation and startup

operations to be performed in a simple and organised manner

without any doubts whatsoever.

Finally, once the equipment is installed and operating, it is

recommended to save the documentation downloaded from the

website, CD-ROM or pen drive in a safe and easy-to-access

place, for any future queries or doubts that may arise.

The following terms are used interchangeably in the document

to refer to:

• ‘SLC ADAPT,’ ‘device,’ ‘unit’ or ‘UPS’ - Uninterruptible

power supply.

Depending on the context of the phrase, it can refer either

to the actual UPS itself or to the UPS and the batteries,

regardless of whether or not it is all assembled in the same

metal enclosure.

• ‘Batteries’ or ‘accumulators’ - Bank or set of elements

that stores the flow of electrons by electrochemical means.

• ‘T.S.S.’ - Technical Service and Support.

• ‘Customer,’ ‘installer,’ ‘operator’ or ‘user’ - These are

used interchangeably and by extension to refer to the in-

staller and/or operator who will carry out the corresponding

actions, and the same person may be responsible for car-

rying out the respective actions when acting on behalf, or

in representation, of the above.

SLC ADAPT UNINTERRUPTIBLE POWER SUPPLY (UPS)USER'S MANUAL

5

3. QUALITY ASSURANCE AND STANDARDS.

3.1. STATEMENT BY THE MANAGEMENT.

Our goal is customer satisfaction, therefore this Management

has decided to establish a Quality and Environment Policy,

through the implementation of a Quality and Environmental

Management System that will enable us to comply with the

requirements demanded in the ISO9001 and ISO14001 and

also by our Customers and Stakeholders.

Likewise, the management of the company is committed to

the development and improvement of the Quality and Environmental Management System, through:

• Communication to the entire company of the importance

of satisfying both the customer's requirements as well as

legal and regulatory requirements.

• The dissemination of the Quality and Environment Policy

and the setting of the Quality and Environment objectives.

• Conducting reviews by the Management.

• Providing the necessary resources.

3.2. STANDARDS.

The product standards mentioned above incorporate

relevant clauses that comply with IEC and EN standards

for safety (IEC/EN/AS60950), electromagnetic emission

and immunity (IEC/EN/AS61000 series) and construction

(IEC/EN/AS60146 series and 60950).

The manufacturer is not liable in the event of modification or intervention on the device by the user.

WARNING!:

The SLC ADAPT is a modular double-conversion on-line

30 to 1500 kVA C3 category UPS.

The product’s CE declaration of conformity is available

to the customer upon express request to our head office.

3.2.1. First and second environment.

3.2.1.1. First environment.

Environment including residential, commercial and light industry installations, directly connected, without intermediate

transformers, to a low voltage public power grid.

The SLC ADAPT is designed, manufactured and sold in accordance with Quality Management Standard ENISO9001. The

marking indicates conformity with EC Directives through the application of the following standards:

• 2014/35/EU. - Low voltage safety.

• 2014/30/EU. - Electromagnetic Compatibility (EMC).

• 2011/65/EU. - Restriction of the use of hazardous sub-

stances in electrical and electronic equipment (RoHS).

In accordance with the specifications of the harmonised

standards. Reference standards:

• EN-IEC 62040-1. Uninterruptible power supplies (UPS).

Part 1-1: General and safety requirements for UPS used in

user access areas.

• EN-IEC 60950-1. Information technology equipment.

Safety. Part 1: General requirements.

• EN-IEC 62040-2. Uninterruptible power supplies (UPS).

Part 2: EMC requirements.

The UPS has been designed in accordance with the following

European and international standards:

Element Standard reference

General safety requirements for

UPSs used in areas accessible to

operators

EN50091-1-1

IEC62040-1-1

AS62040-1-1

3.2.1.2. Second environment.

An environment that includes all commercial, light industrial

and industrial establishments that are not directly connected

to a low voltage power grid supplying buildings used for residential purposes.

3.3. ENVIRONMENT.

This product has been designed to respect the environment and

manufactured in accordance with ISO14001.

Recycling of the device at the end of its useful life:

Our company undertakes to use the services of authorised and

regulatory companies to treat the set of products recovered at

the end of their useful life (contact your distributor).

Packaging:

For the recycling of the packaging there must be compliance

with the legal requirements in force, in accordance with the

specific regulations of the country where the device is installed.

Batteries:

Batteries pose a serious danger to health and the environment.

The disposal of them shall be carried out in accordance with

the laws in force.

Electromagnetic compatibility

(EMC) requirements for UPSs

EN50091-2

IEC62040-2

AS62040-2(C3)

Method for specifying the

performance and testing

requirements of UPSs

EN50091-3

IEC62040-3

AS62040-3(VFI SS 111)

6 SALICRU

4. PRESENTATION.

4.1. VIEWS.

4.1.1. Views of the device.

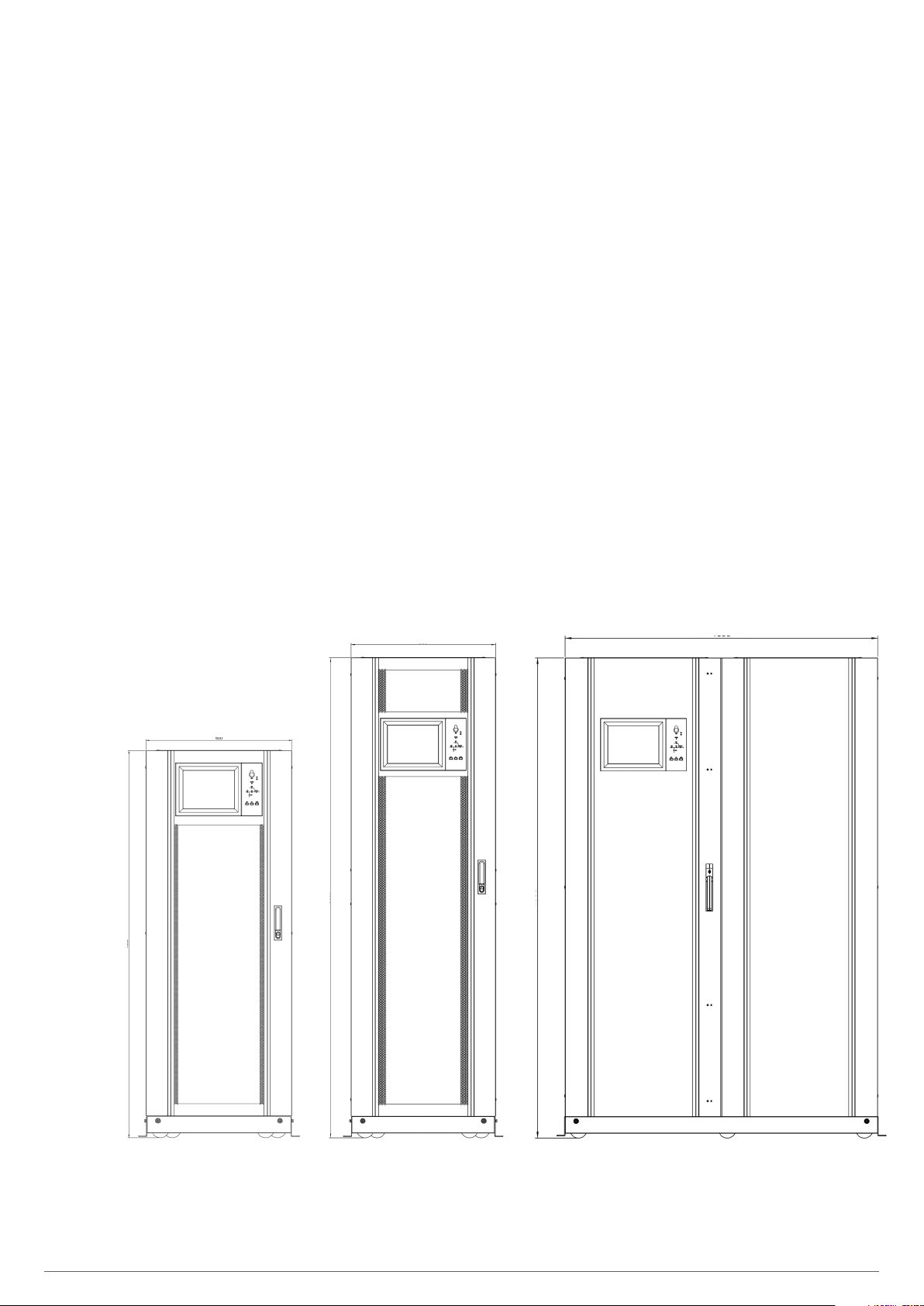

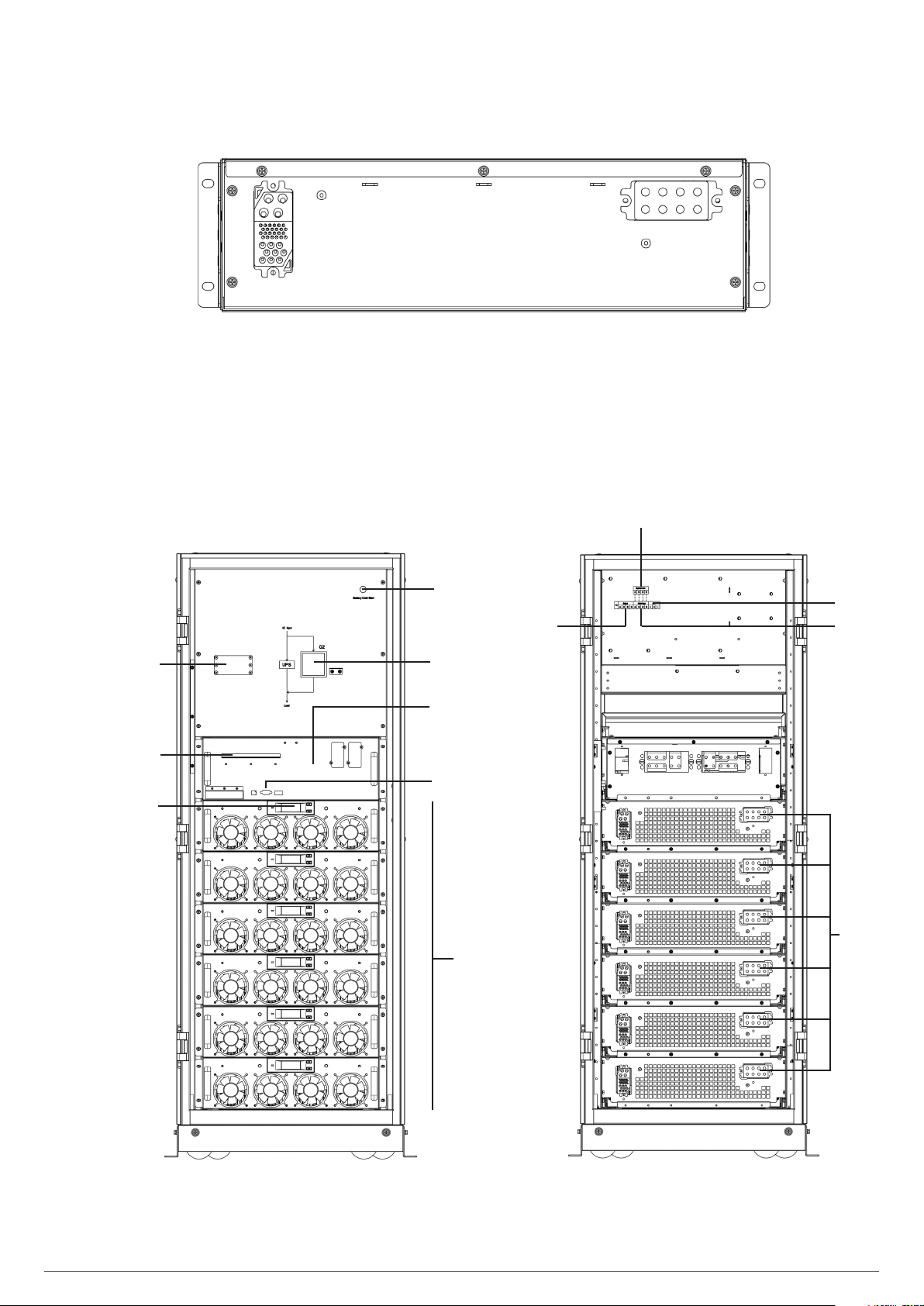

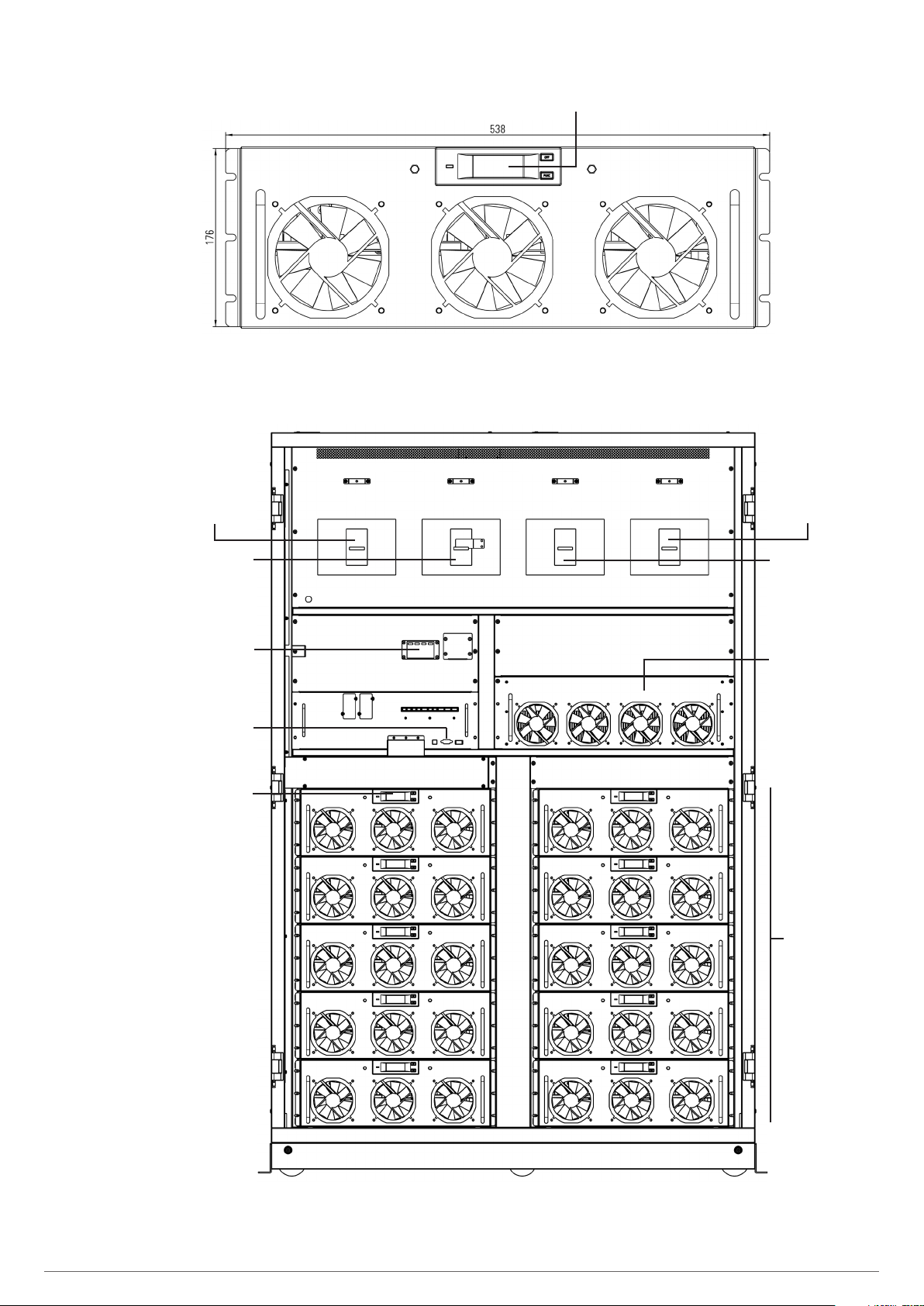

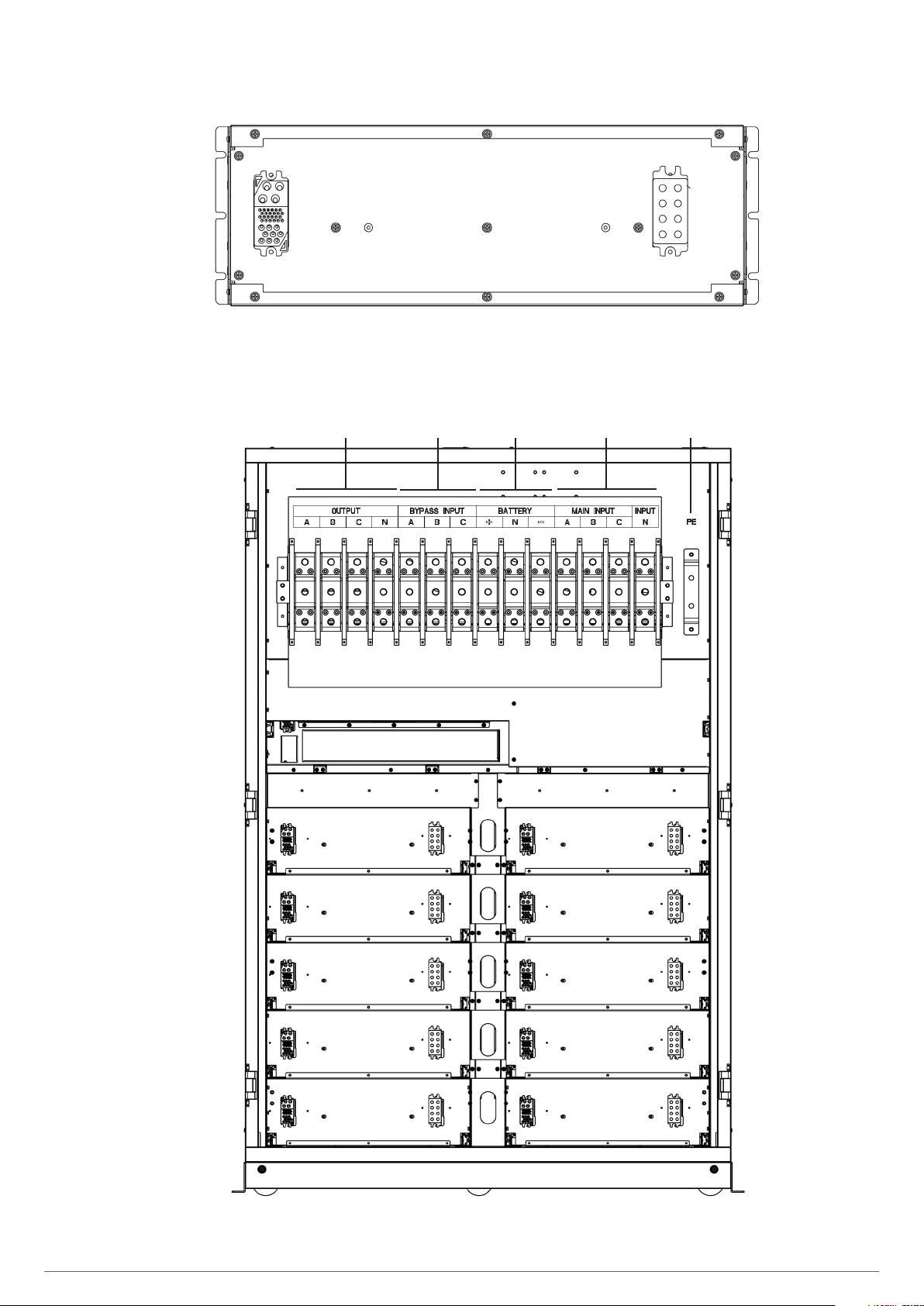

Fig. 1 to Fig. 13 show the views and dimensions (in mm) of

6-slot (180 kVA) and 10-slot (300 kVA and 500 kVA) devices.

Because the product is constantly evolving, however, slight

discrepancies or contradictions may arise. If in any doubt, the

labelling on the device itself will always prevail.

1600

600

2000

600

1300

2000

Fig. 1. General view of 6- and 10-slot cabinets.

SLC ADAPT UNINTERRUPTIBLE POWER SUPPLY (UPS)USER'S MANUAL

7

4.98

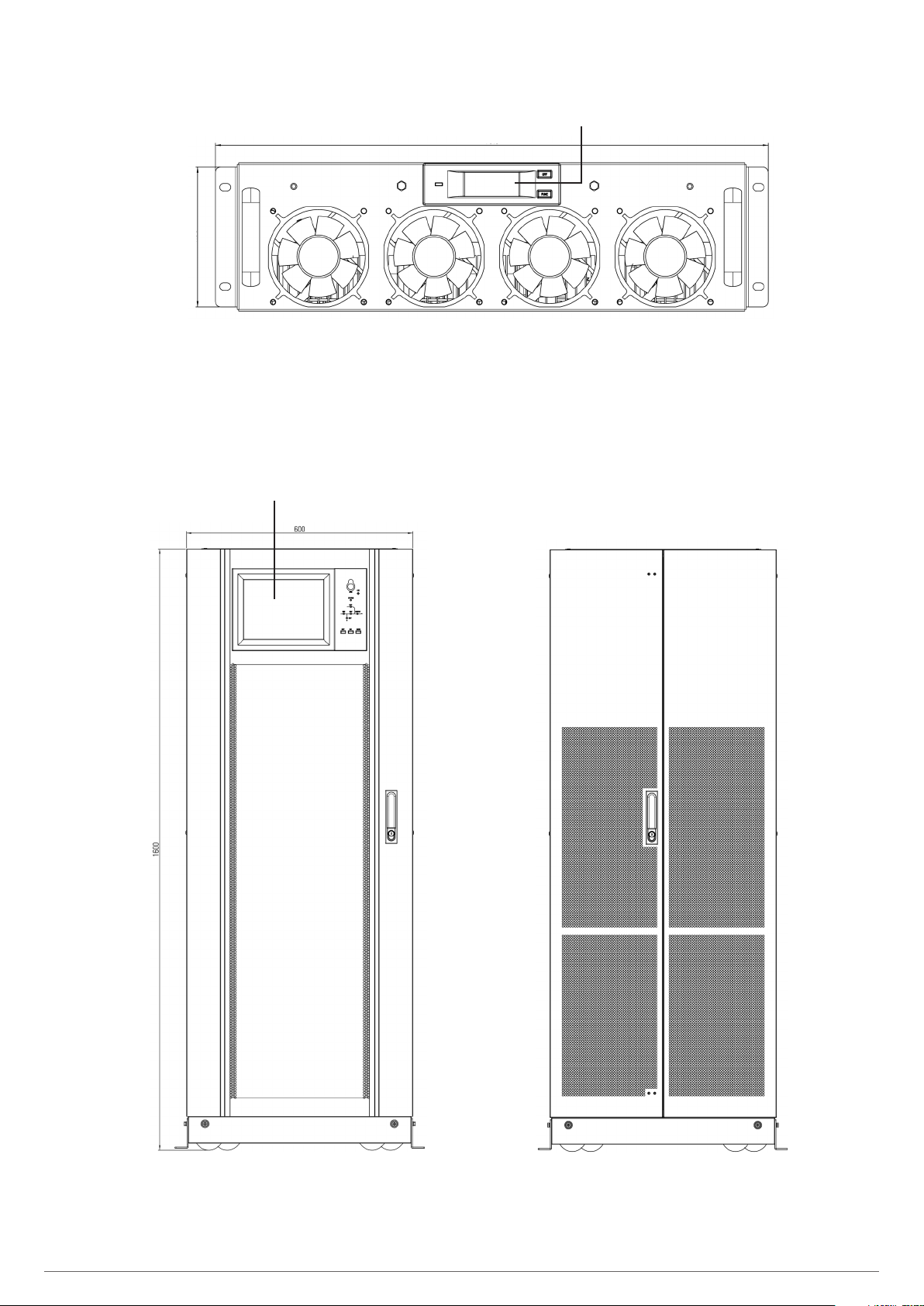

Fig. 2. Front view of 30 kVA module

(20 kVA for 3x208 V AC voltages).

Touch display

LCD

19.8

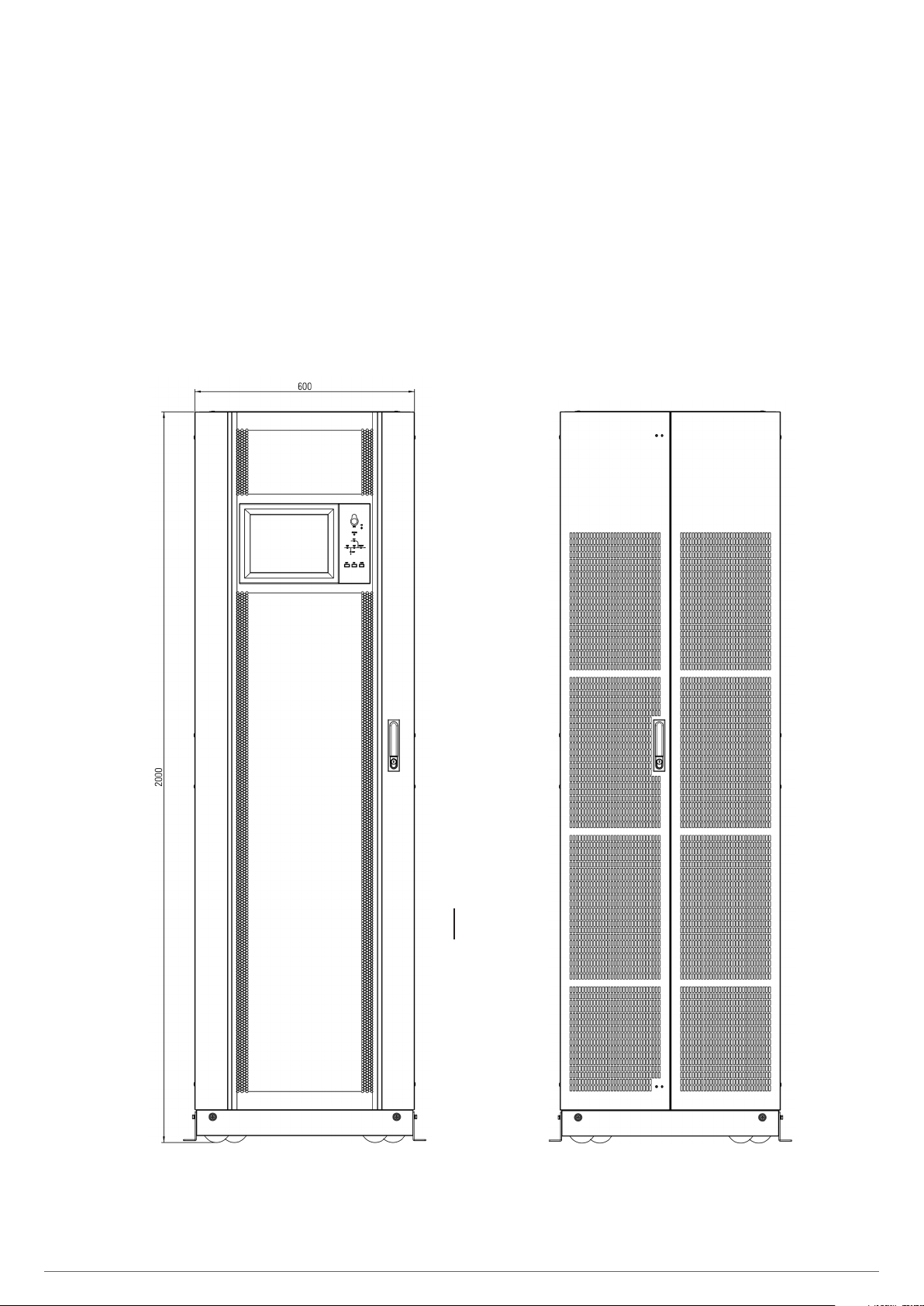

Fig. 3. Front and rear view of 6-slot cabinet - 180 kVA

(120 kVA at 3x208 V) with closed doors.

8 SALICRU

Fig. 4. Rear view of 30 kVA module

(20 kVA for 3x208 V AC voltages).

Bypass input

A B C N

SPD

(option)

Relay

interface

Module

display

Cold Start

Manual bypass

marking

Free slot for

Bypass module

Communications

interface

30kVA power

modules

Output

A B C N

Batteries

+ N –

Input

A B C N

Power

module

connector

Fig. 5. Front and rear view of 6-slot cabinet - 180 kVA

(120 kVA at 3x208 V) with open doors.

SLC ADAPT UNINTERRUPTIBLE POWER SUPPLY (UPS)USER'S MANUAL

9

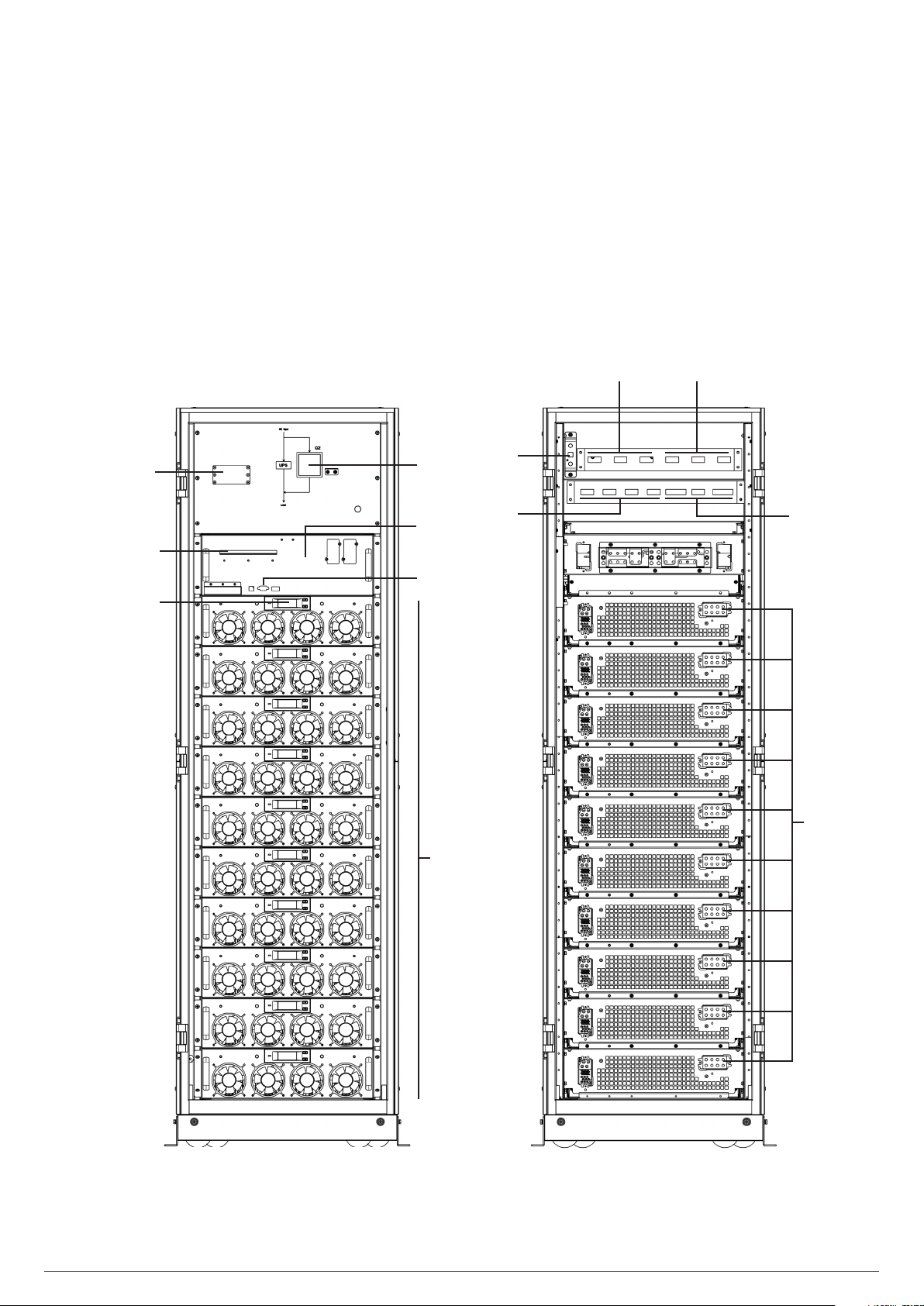

Fig. 6. Front and rear view of 10-slot cabinet - 300 kVA

(200 kVA at 3x208 V) with closed doors.

10 SALICRU

Bypass input

A B C N

Input

A B C N

SPD

(option)

Relay

interface

Module

display

Cold Start

Manual bypass

marking

Free slot

for Bypass

module

Communications

30 kVA power

A B C N

interface

modules

Output

PE

Batteries

+ N –

Power

module

connector

Fig. 7. Front and rear view of 10-slot cabinet - 300 kVA

(200 kVA at 3x208 V) with open doors.

SLC ADAPT UNINTERRUPTIBLE POWER SUPPLY (UPS)USER'S MANUAL

11

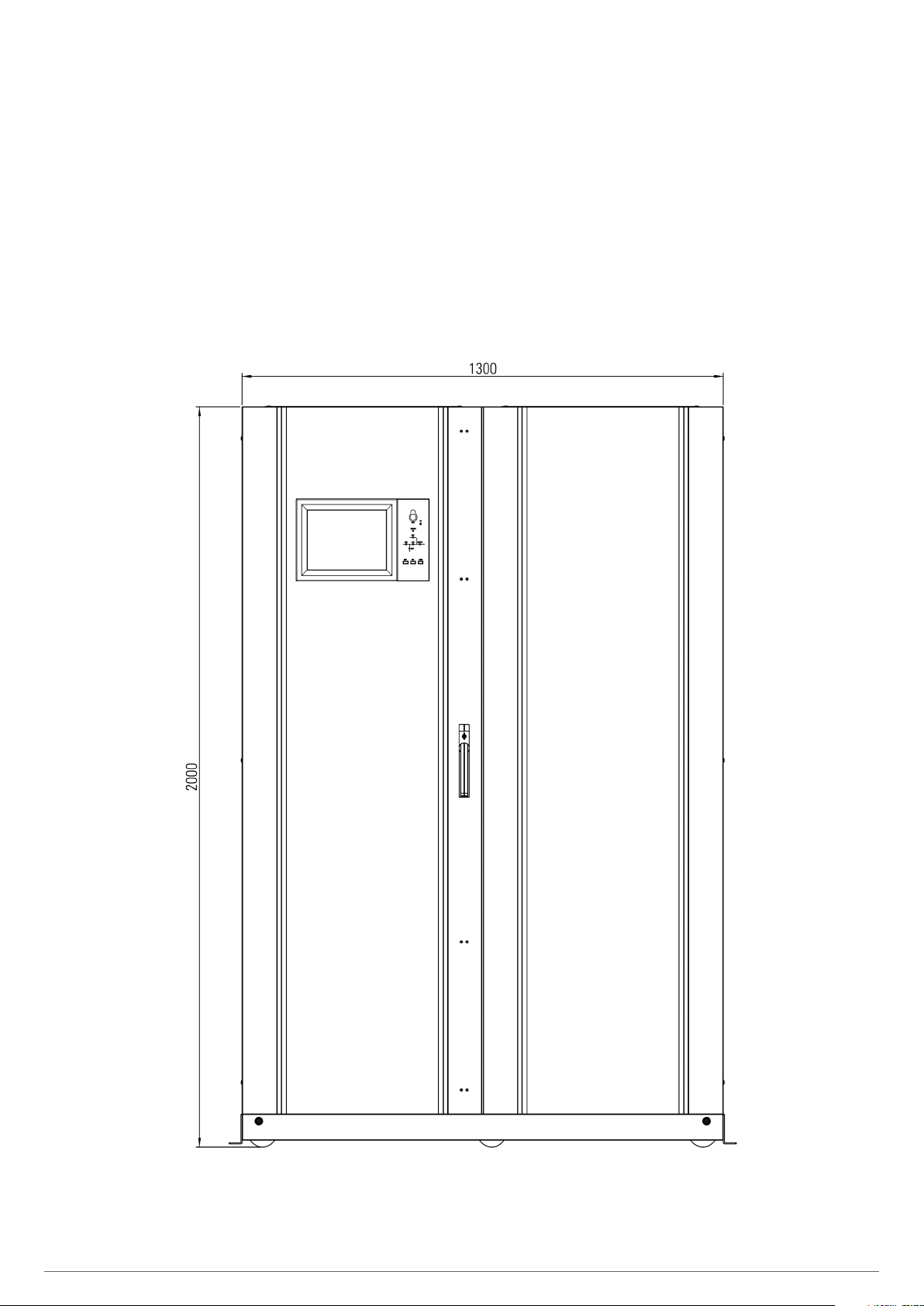

Fig. 8. Front view of 10-slot cabinet - 500 kVA

(300 kVA at 3x208 V) with closed doors.

12 SALICRU

Fig. 9. Rear view of 10-slot cabinet - 500 kVA

(300 kVA at 3x208 V) with closed doors.

SLC ADAPT UNINTERRUPTIBLE POWER SUPPLY (UPS)USER'S MANUAL

13

Fig. 10. Front view of 50kVA module

(30 kVA for 3x208 V AC voltages).

LCD

UPS input

disconnector

Manual Bypass

disconnector

SPD (Surge Protection Device)

(Optional)

Communications

interface

Module

display

UPS input

Cold Start

Q1

Manual bypass

Bypass input UPS output

Q2 Q4 Q3

UPS output

disconnector

Bypass input

disconnector

Bypass

module

50 kVA power

modules

Fig. 11. Front view of 10-slot cabinet - 500 kVA

with open doors.

14 SALICRU

Fig. 12. Rear view of 50 kVA module

(30 kVA for 3x208 V AC voltages)

Output

A B C N

Bypass input

A B C

Batteries

+ N –

Input

A B C N

PE

Fig. 13. Rear view of 10-slot cabinet - 500 kVA

with open doors.

SLC ADAPT UNINTERRUPTIBLE POWER SUPPLY (UPS)USER'S MANUAL

15

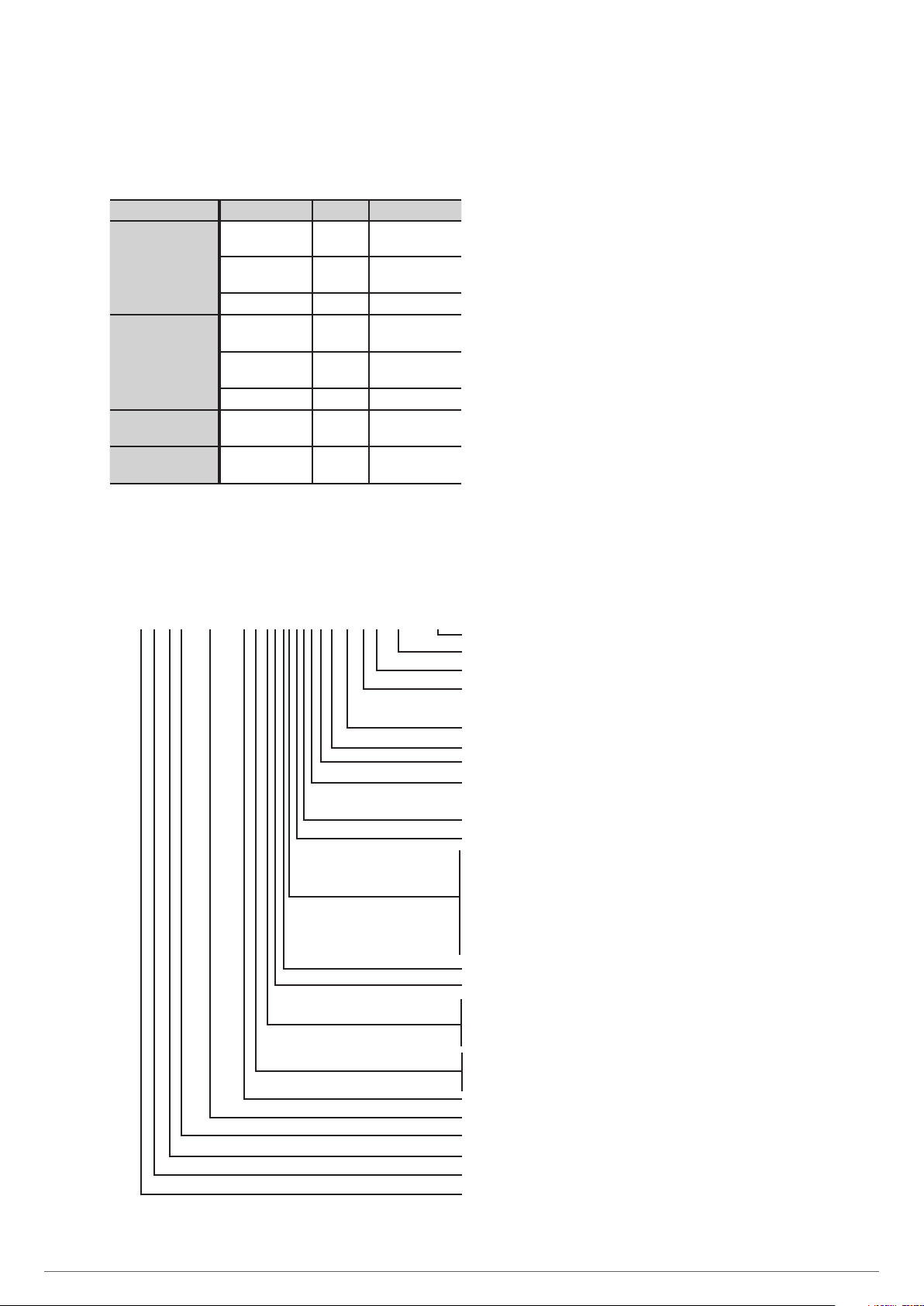

4.1.2. Device configurations.

The following table provides information about the configuration of the UPS:

Item Components Quantity Note

Requirement,

installed in factory

Requirement,

installed in factory

Requirement,

installed in factory

Requirement,

installed in factory

Requirement,

installed on site

Requirement,

installed on site

6-slot cabinet

10-slot cabinet

30 kVA power

module

50 kVA power

module

Manual bypass 1

Bypass and

monitoring module

Dust filter 1 Optional

Manual bypass 1

Bypass and

monitoring module

Dust filter 1 Optional

Power module 1-10

Power module 1-10

1

1

4.2. DEFINITION OF THE PRODUCT.

4.2.1. Nomenclature.

SLC-6+1/10A-ADAPT 100X R P2LBDCS B1 0/36AB165 EE116502

EE Special device EE

165 Last three digits of the battery code

AB Letters of the battery family

36 Number of batteries in a single branch. For banks of common

batteries, all batteries in the system will be indicated

0/ Devices prepared for standard backups

B1 Subrack/cabinet with external batteries

S Ambient temperature sensor

C Subrack mounted on box-type BATT MOD (batteries supplied

factory mounted)

D Transient protection filter

B Independent bypass line

L Single-phase input/single-phase output device

N Three-phase input/single-phase output devices (independent

bypass line must be included)

M Single-phase input/three-phase output device (independent

bypass line must be included)

Three-phase input/three-phase output device

2 Number of subracks/cabinets in parallel

P Material needed to parallel subrack/cabinets

R ADAPT X series device in subrack format (subrack not inte-

grated into a cabinet)

Y IP20 protection rating with open door and keyless lock

X Indication for modules with 2U height. Disregard for ≥3U

modules

100 Total power of subrack/cabinet

ADAPT UPS series

A,B,C Cabinet type

10 Total number of slots in subrack/cabinet

1 Number of redundant modules (disregard if none)

6 Number of modules installed in subrack/cabinet without

taking into account redundancy

16 SALICRU

4.3. GENERAL DESCRIPTION.

4.3.1. Introduction.

The SLC ADAPT series is classified as an on-line doubleconversion uninterruptible power supply with DSP control and

three-level IGBT inverter technology, modular topology and

great flexibility.

Reliability: The DSP control associated with three-level PWM

technology increases the performance of the system and, together

with the redundancy of the modules, manages to increase the

availability of power to the critical loads, a parameter that

contributes to achieving a good TIER classification for the entire

system.

Availability: Its hot-swap modules can be added or replaced

during operation, thereby improving mean time to repair

(MTTR) and reducing maintenance costs. Moreover, both the

control display and the bypass module can be replaced without

affecting the operation of the device. In addition, the system’s remote management, which can be integrated into any

platform, also makes operation easier. The extensive backup

options available, along with smart battery charging, ensure

continuous operation of the protected critical loads.

Modularity: This allows simple configurable solutions from

30 to 1500 kVA by installing 30 or 50 kVA modules in the 6-slot

(30 kVA modules) or 10-slot cabinets. As composite solutions,

a maximum of 30modules can be paralleled to obtain higher

power systems or N+n structures. Either way, it is only possible

to install identical modules in the same cabinet and/or parallel

cabinets with modules of equal power. This enables gradual

growth and scaling for future expansion depending on the

need for pay-as-you-grow protection, improving the total cost

of ownership (TCO) and providing a high level of flexibility. At

operational level, a cabinet consisting of ‘N’ modules connected

in parallel is considered a single UPS.

Any expansion or structural change to the number of modules

is possible even during normal operation and without needing

to shut down the hot-swappable system, all with the simple

use of a screwdriver to remove or screw the fixing screws of

the module(s). Although all of the UPS’s modules incorporate a

battery charger that can allocate up to 20% of its rated power

to maintaining them at an optimum charge level depending on

the type and number of elements, 50 A battery charger modules

are available to be installed solely with the 30 kVA SLC ADAPT

modules. As many charging modules as considered appropriate

can be installed, but this will be to the detriment of the total

number of UPS modules and, consequently, the total power of

the system, which will be reduced.

Backup: The capacity of the batteries determines the backup

time of the system when replacing the usual source of energy

during mains failures. The accumulator bank is always common

to any system mounted in the same cabinet. Batteries owned by

the customer or supplied with the UPS, depending on different

factors in addition to the power and/or backup requested, can

be installed in a back or one or more cabinets, always external

to the UPS itself.

SLC ADAPT series UPSs basically consist of:

• 6- or 10-slot cabinet to install the power modules.

• Power modules consisting of the following blocks:

AC/DC PFC rectifier.

Battery charger.

DC/AC inverter.

Digital control and UPS management.

• Centralised bypass module: control of UPS and parallel pa-

rameters.

• Maintenance bypass.

• Control panel with touch screen (see section X for more

information).

• Batteries (number, type and location depending on the

backup time).

• Self-supporting 36 and 46U cabinets for the placement of

the different modules.

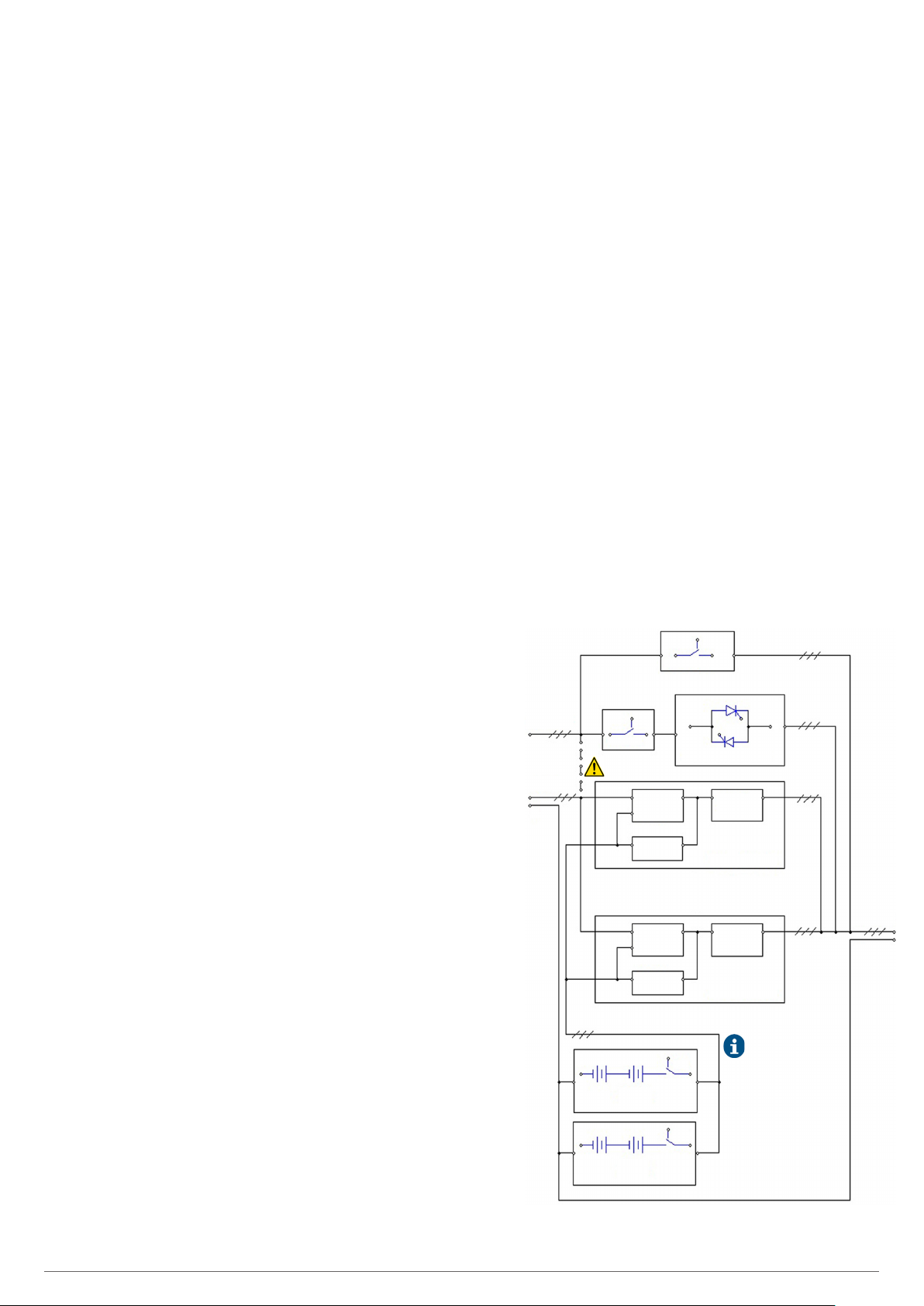

4.3.2. Conceptual diagram of the system.

The modular UPSs of the SLC ADAPT series consist of power

modules, a bypass and monitoring module, and a cabinet with

a range of disconnectors for Input, Bypass Output and Manual

Bypass. The 180 and 300 kVA UPSs only have a manual bypass

switch. One or more battery branches should be installed to

provide backup power in the event of a power failure. The

structure of the UPS is shown in Fig. 14.

Q2

MANUAL BYPASS

STATIC BYPASS

LINE INPUT -R, S, T-

INLET LINE OF UPS

-R, S, T-

N

Q1

BYPASS

Connection strips

between phases for mains.

REC / PFC

BAT / DC

DC / DC

INVERTER

REC / PFC

BAT / DC

DC / DC

INVERTER

BATTERY MODULE

STATIC BYPASS MODULE

DC / AC

INVERTER

POWER MODULE # 1

•

•

•

DC / AC

INVERTER

POWER MODULE #N

BCB

BCB

The batteries are represented in

the structural diagram as they are

an essential part of all UPSs,

although they will never be

included in the cabinet itself. The

batteries can be supplied in a

separate cabinet, in a bank or not

supplied if the customer already

has them.

OUTPUT

U, V, W

N

BATTERY MODULE

Fig. 14. Conceptual diagram of the SLC ADAPT series

modular UPS.

SLC ADAPT UNINTERRUPTIBLE POWER SUPPLY (UPS)USER'S MANUAL

17

Fig. 14 shows, byway of example, a single-line diagram of the

device with three-phase input and output.

All modules in the cabinet are structured according to the same

criteria, terminals for the power supply of the PFC rectifier and

independent static bypass, and input, output, static bypass

and manual bypass disconnectors. However, unless otherwise

requested, for separate networks originally from the factory,

the terminals of the phases of both blocks are connected by

means of strips to provide a single common input.

When separate power supplies are required, it is

obligatory to remove the strips between the phases of

both blocks before connecting the power cables, leaving the

connection strip of the neutral terminals.

4.3.2.1. Power modules (PM).

Power modules are the basic core of the entire SLC ADAPT

system. Apart from the static bypass block and LCD touch

screen, each power module contains all of the converters and

functionalities of a traditional UPS. Since this device consists

of a number of variable modules depending on the cabinet

used, a multi-parallel system is obtained with the behaviour

equivalent to that of a single mono-bloc UPS and the advantages of a modular UPS.

The system supplies power to the critical load (such as communication and data processing equipment) with uninterrupted

high quality AC power. The power supplied by the unit is stable,

without voltage and/or frequency variations and free from

other disturbances such as cuts or micro-cuts, sine wave alterations, electrical noise, anomalies commonly present in the

commercial AC network.

This is achieved through the double-conversion high frequency

Pulse Width Modulation (PWM), in combination with a digital

control based on a Digital Signal Processor (DSP), which provides high reliability and availability.

As can be seen in Fig. 14, the AC power supplied to the UPS

input is converted into DC voltage. This voltage supplies a converter that transforms the voltage type from DC to AC, clean of

disturbances and variations of the AC input mains. If this fails,

the PFC rectifier changes the input source of the AC mains to

that of the batteries, powering in the same way through the

output of the UPS to the load for a limited time, that of the

backup determined by the battery pack.

4.3.2.1.1. Available power ratings.

The SLC ADAPT series has two different power modules, 30

and 50 kVA, as can be seen in Fig. 2, Fig. 4, Fig. 10 and Fig. 12.

4.3.2.2. Static bypass.

Static transfer switch.

In the event of inverter failure, overload or overtemperature,

the voltage connected to the static bypass line can supply

power to the load connected to the UPS output.

The static bypass module identified in Fig. 14 contains the

power management and control circuits that allow the most

optimum decision in each scenario to be made, in order to select the most favourable power to the critical load connected

to the output of the UPS, either from the inverter or from the

static bypass itself.

During normal system operation, the load is connected to the

inverter and in case of overload or failure, it will automatically

transfer to the static bypass line. In order to provide a clean

transfer (without interruption) between the inverter output and

the bypass line, they must be fully synchronized during normal

operation. This is achieved through real-time digital control of

the inverter, so that the frequency of the inverter follows the

frequency of the bypass line if the bypass is within the range of

acceptable frequencies.

In addition, a Manual Bypass, which is very useful during periods

of maintenance or failure, is included and allows continuous

powering of the critical load while the UPS is out of service.

When the UPS is operating in bypass mode (over static

bypass), connected devices are not protected against

power cuts or micro-cuts, overvoltages, voltage and/or frequency variations as they are powered directly from the AC

mains.

4.3.2.3. Extra charger modules for 180 and 300 kVA devices.

The smart charging module is designed to supply the necessary

charging current for long backup applications. The module is hot

swappable and has the same size and appearance of any power

module, supplying an adjustable current of between 0 and 50 A.

On the front, they have a high resolution LCD where the user

can monitor the different load parameters in real time.

The modules are designed to be inserted in 6- and 10-slot

cabinets with only 30 kVA modules - 180 and 300 kVA devices

- and can be inserted in the necessary number to meet battery

charging needs.

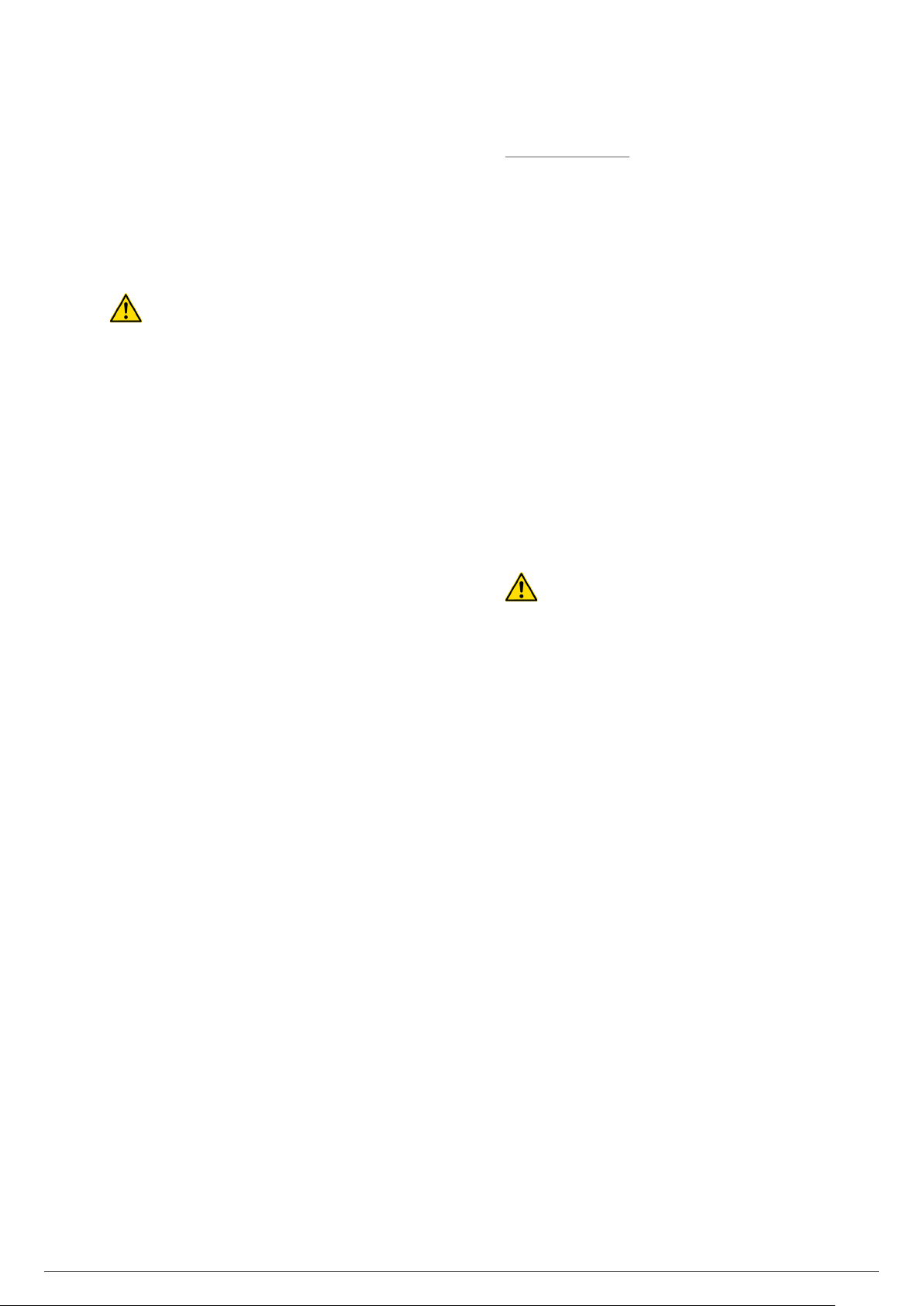

4.3.2.3.1. Wiring diagram.

As can be seen in the diagram in Fig. 15, the charger modules

are connected in parallel to the power modules. The total current of the system is the sum of the current supplied by the

power modules and the charger modules.

18 SALICRU

4.3.3.1. Normal mode.

Power module 1

Input

terminal

Battery

terminal

Power module n

Power modules

Charger module 1

Charger module m

Extra charger modules

Output

terminal

Fig. 15. Conceptual diagram of the extra charger modules.

4.3.3. UPS operating modes.

The modular double-conversion on-line UPS has the following

operating modes:

• Normal mode

• Battery mode

• Bypass mode

• Maintenance mode (manual bypass)

• ECO mode

• Frequency converter mode

During the description of the operating modes the operation

is described referring to the PFC-rectifier and inverter parts as

functional parts of a module, although there will be as many of

them as there are modules connected in parallel.

The inverter of each power module is responsible for powering

the critical loads at all times. The rectifier/charger of the AC

input powers the inverter with DC voltage while simultaneously

charging the associated backup battery, either at float or quick

voltage.

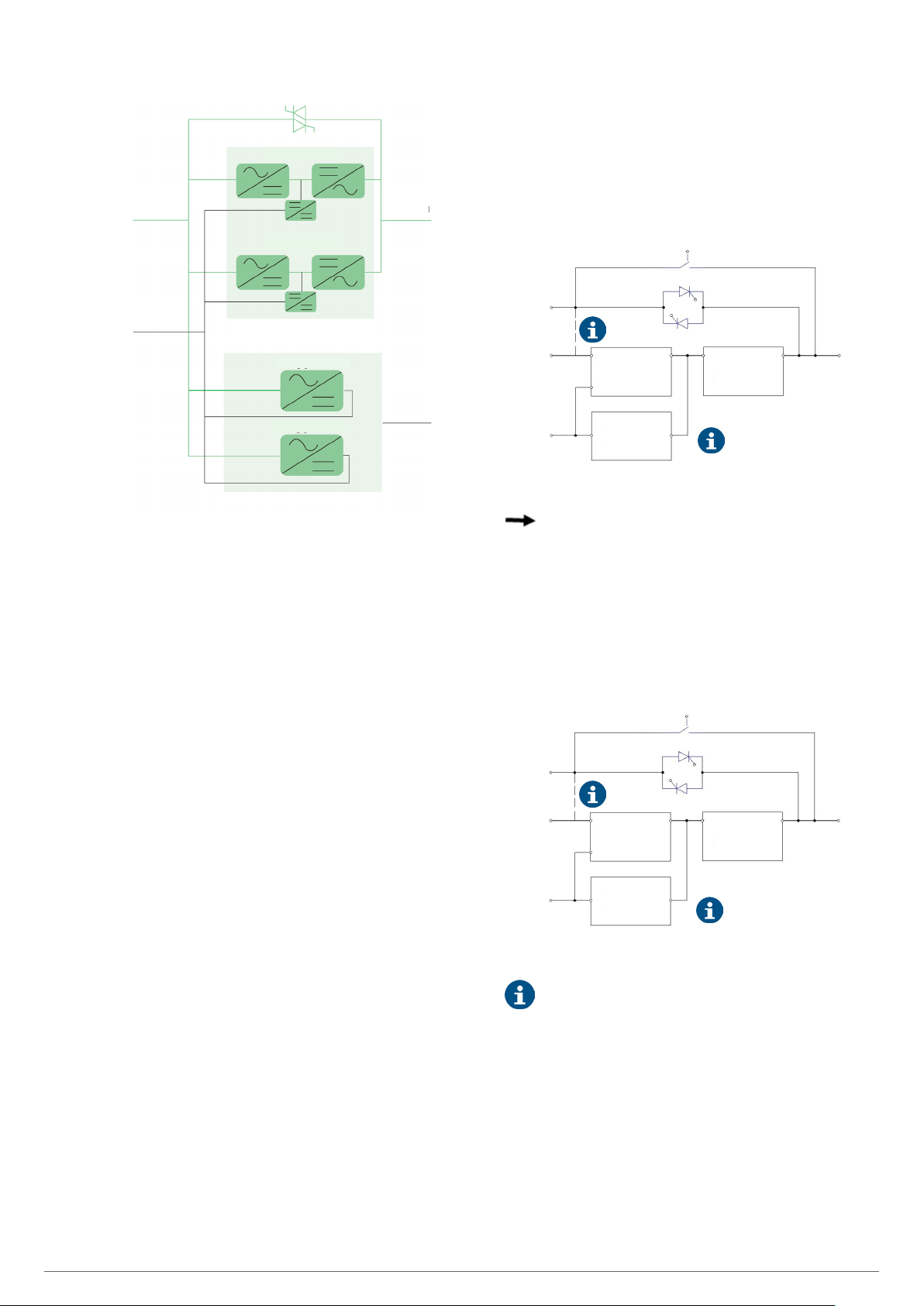

AC / DC

BAT / DC

Charger

Manual bypass

Inverter

DC / AC

Connection strips between

phases for mains.

AC output

AC input

Bypass

AC input

Rectifier

Batteries

Static bypass

PFC rectifier

DC / DC Battery

Fig. 16. Conceptual diagram of the UPS in Normal mode.

Indicates the direction of the energy flow.

4.3.3.2. Battery mode.

In the event of failure of the AC input power mains, the inverter,

by means of the power it obtains from the battery, supplies the

critical loads of the output in AC. By doing so, the power supply

is not interrupted in the event of failure. Once the AC power

input is restored, the ‘Normal mode’ function will be restored

automatically without the user needing to intervene.

AC / DC

BAT / DC

Manual bypass

Inverter

DC / AC

AC output

AC input

Bypass

AC input

Rectifier

Static bypass

PFC rectifier

DC / DC Battery

Batteries

Charger

Connection strips between

phases for mains.

Fig. 17. Conceptual diagram of the UPS in Battery mode.

With the Battery Cold Start function, the UPS can be

started without mains power. See details in section

6.1.2.

SLC ADAPT UNINTERRUPTIBLE POWER SUPPLY (UPS)USER'S MANUAL

19

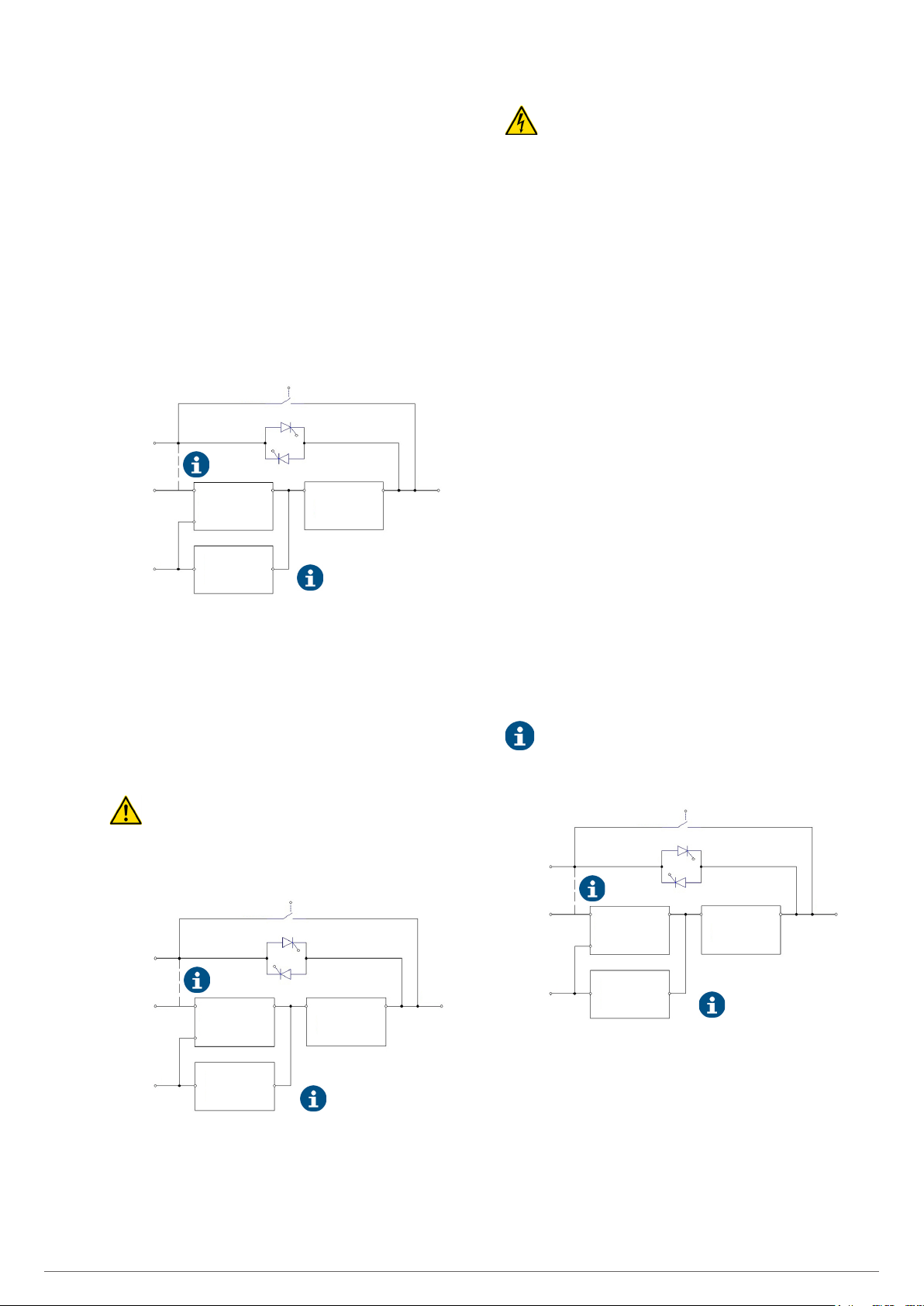

4.3.3.3. Bypass mode.

If the inverter’s overload capacity is exceeded in Normal

mode, or if the inverter cannot supply power to the loads for

any reason, the static switch will transfer the inverter’s load

to bypass, without interrupting the power to the critical loads.

If the inverter is not synchronised with the bypass, the static

switch will transfer the load from the inverter to the bypass,

interrupting the load. This is done to prevent short circuits due

to the paralleling of non-synchronised AC inputs. The time of

this interruption is programmable, the typical value being less

than 3/4 of a cycle, e.g. less than 15 ms (50Hz) and 12.5 ms

(60Hz). The transfer or retransfer action can be performed via

commands through the control panel.

AC / DC

BAT / DC

Charger

Manual bypass

Inverter

DC / AC

Connection strips between

phases for mains.

AC output

AC input

Bypass

AC input

Rectifier

Batteries

Static bypass

PFC rectifier

DC / DC Battery

DANGER: During manual bypass mode, the input,

output and bypass terminals (version B) are live even if

all modules are switched off.

It is recommended in this operating mode:

– Remove the fastening screws of all power, control

and bypass modules.

– Slightly pull the handles on each one until they are

protruding by about 4-5 cm from their housing in

order to enable them to be unplugged from their

connector located on the backplane of the device.

Before any change of operating mode and after carrying out the

possible corrective actions, it is necessary to correctly insert

the modules to their original position and fix them with their

screws.

4.3.3.5. Parallel-Redundant mode.

This operating mode allows to obtain a greater capacity, reliability or both, being able to be configured like extension of

power or like redundancy.

As a consideration to be taken into account when the cabinets

are in parallel, the controller included in each one guarantees

the automatic distribution of the load in all of them and all of

its modules.

4.3.3.6. ECO mode.

Fig. 18. Conceptual diagram of the UPS in Bypass mode.

4.3.3.4. Manual Bypass mode (maintenance bypass).

If the UPS requires intervention due to breakdown or maintenance (for example, because there is a power module, the

bypass or the LCD with anomalies), there is the possibility of

continuing to supply the loads through the internal manual bypass (maintenance bypass).

When the UPS is operating in ‘Manual Bypass Mode’

(maintenance or repair period), the connected equipment is not protected against power cuts or micro-cuts, overvoltages, voltage and/or frequency variations, etc. when fed

directly from the commercial AC network.

Inverter

DC / AC

AC output

AC input

Bypass

AC input

Rectifier

Manual bypass

Static bypass

PFC rectifier

AC / DC

BAT / DC

ECO mode saves energy. In this mode, when the input voltage

of the Bypass is within the ECO voltage range, the static bypass

that supplies power directly to the loads is activated, leaving

the inverter in standby. When the Bypass voltage or frequency

is out of range, the UPS transfers the output to Inverter.

During the transfer of the load on the inverter from ECO

mode, a small interruption (less than 10 ms) occurs. It is

very important to ensure that the critical load powered in this

UPS mode tolerates that interruption time.

AC / DC

BAT / DC

Charger

Manual bypass

Inverter

DC / AC

Connection strips between

phases for mains.

AC output

AC input

Bypass

AC input

Rectifier

Batteries

Static bypass

PFC rectifier

DC / DC Battery

Fig. 20. Conceptual diagram of the UPS in ECO mode.

Batteries

DC / DC Battery

Charger

Connection strips between

phases for mains.

Fig. 19. Conceptual diagram of the UPS in manual Bypass

mode (maintenance).

4.3.3.7. Frequency converter mode.

When operating in this mode, the device supplies a fixed

output frequency of 50 or 60 Hz, or different input and output.

When operating in this mode, the static bypass is inhibited

and the manual bypass switch should not be operated due to

the consequences it could have on the loads connected to the

output.

20 SALICRU

Loading...

Loading...