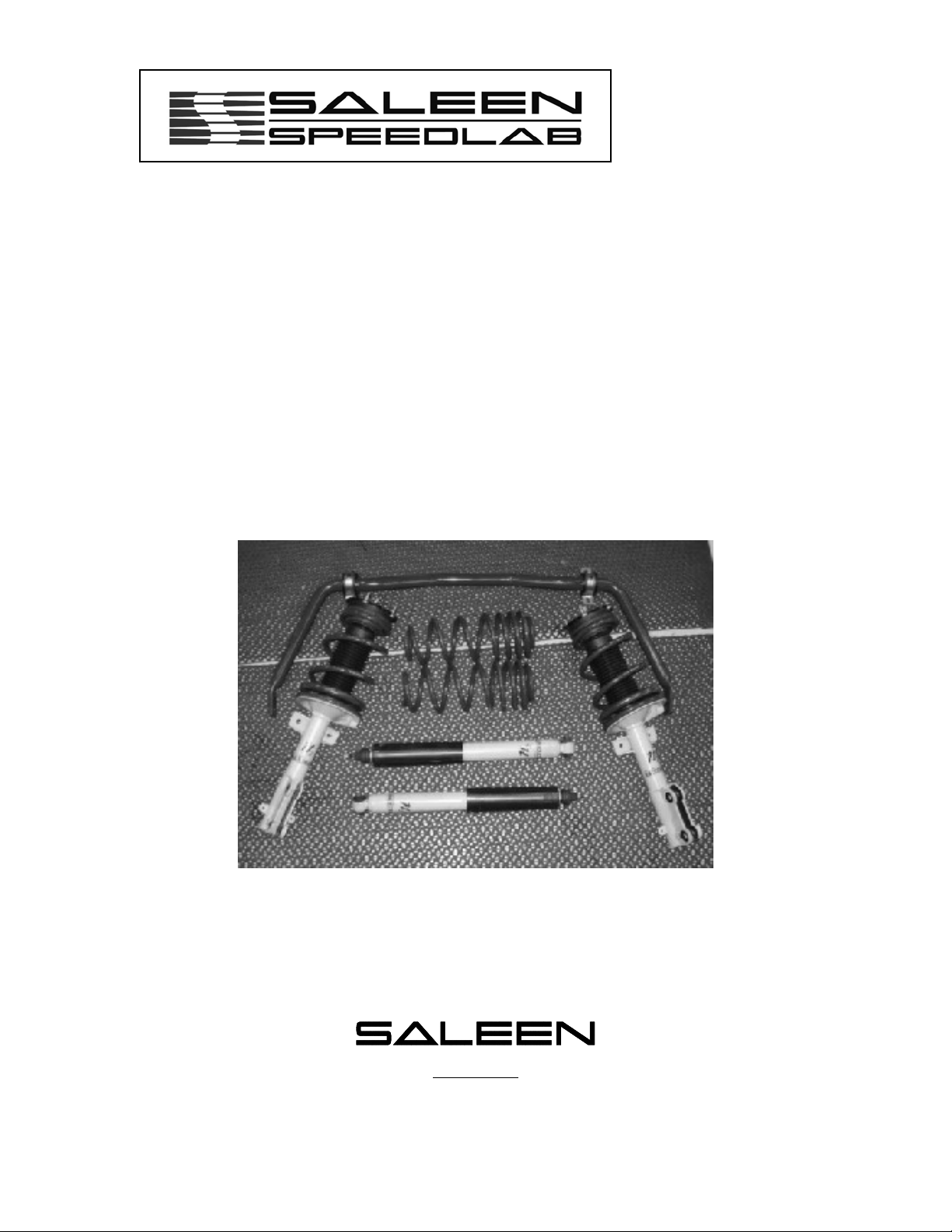

Saleen 10-8002-C11790A User Manual

=

SALEEN SPEEDLAB

SUSPENSION KIT

INSTALLATION MANUAL: 2005 Mustang

P/N: 10-8002-C11790A

Saleen Performance, Inc. 76 Fairbanks Irvine, CA 92618 949-597-4900

www.saleen.com

IF YOU ARE NOT EXPERIENCED IN THE

AREA OF AUTOMOTIVE MECHANICS, WE

STRONGLY URGE THAT YOU REFER THIS

INSTALLATION TO A CERTIFIED INSTALLER

OR TECHNICIAN

2

Saleen Speedlab Suspension Kit

Installation Guide for 2005 Mustang

WELCOME!

Thank you for buying the Saleen Speedlab Suspension Kit for the 2005 Mustang. We

appreciate your business, and we hope you enjoy your product.

For your benefit, please read the following instructions completely and thoroughly before

attempting to install the suspension kit. Many questions we have received from customers

about the installation of our products could have been easily solved by information listed

in the accompanying installation guide. We want you to enjoy the product in its fully

functional state, and reading this tutorial is a great first step to getting you on your way to

a more rare and better handling Mustang.

NOTE: Please keep all hardware you remove from your stock Mustang, as much of it will

be reused to install the new suspension kit pieces.

Please take caution in installing this kit; the car will be up on jack stands and the car can

fall and cause serious injury if not properly placed on jack stands.

Again, thank you for choosing Saleen!

3

Table of Contents

Saleen Chassis Fasteners and Torques…………………………………..6

I Wheel Removal…………………………………….…………….………7

II Front Struts Removal………………………………………..…...…….8

III Front Sway Bar Removal……………………………………..…...….10

IV Front Strut Subassembly…………………………………….…...…...11

V Front and Rear Shock Decal Installation…………………….….……13

VI Front Struts Installation…………………….…………………..….…14

VII Front Sway Bar Subassembly………..………….…...……….….….15

VIII Front Sway Bar Installation…………………….…...……….…….16

IX Rear Suspension Removal……….……………….…...……….….….17

X Rear Suspension Installation……..……….……….…...……….…….18

4

OBTAIN THE FOLLOWING TOOLS:

• Spring compressor

• 10 mm wrench

• ¼” wrench

• ½” drive Ft-lb torque wrench

• ½” drive impact gun

• ½” drive 13/16” deep socket

• ½ ” drive 13mm deep socket

• ½ ” drive 15mm deep socket

• ½ ” drive 15 mm shallow wobbly socket

• ½” drive 18mm deep socket

• ½ ” drive 21 mm deep socket

• 3/8” drive impact gun

• 3/8” drive 10mm socket

• 3/8” drive 13mm deep socket

• 3/8” drive 15mm deep socket

• 3/8” drive 15 mm shallow wobbly socket

• 3/8” drive 18mm deep socket

• Tape measure

• Grease

• Small flat head screw driver

• Needle nose pliers

Hack saw

•

•

Polyurethane grease intended for automotive

application

5

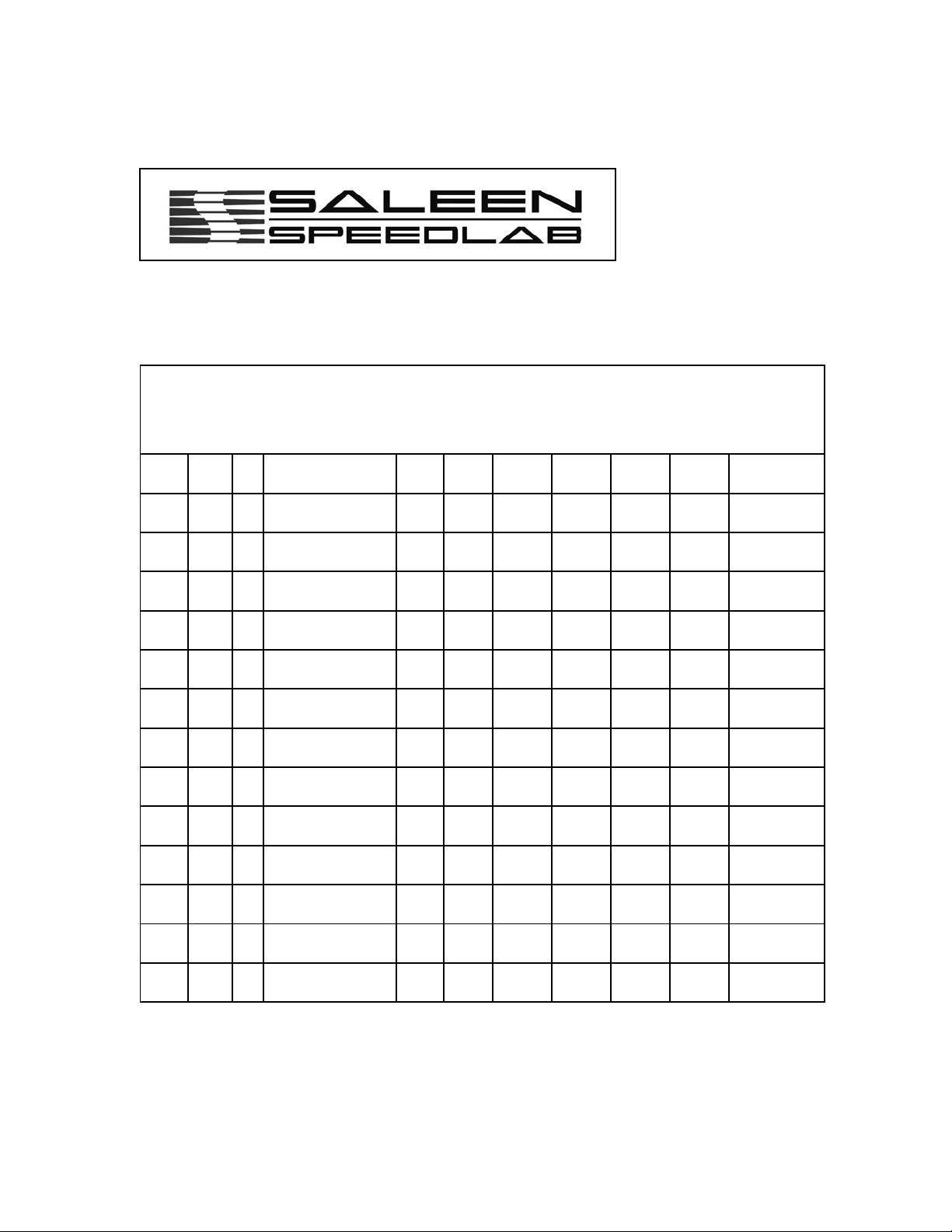

The following table lists the proper torque values to follow when fastening all suspension

components; note also the recommendations for the use of Loctite in the last column.

Saleen Chassis Fasteners and Torques

Locktite (L)

(B)olt

Ref

Number

(N)ut

(F)itting Qty Joint description

Min Spec

Torque

(Nm)

Nom

Spec

Torque

(Nm)

Max Spec

Torque

(Nm)

Min Spec

Torque

(lbf-ft)

Nom Spec

Torque

(lbf-ft)

Max Spec

Torque

(lbf-ft)

Nilock (N)

MechLck (M)

DefNut (D)

Plain (P)

N 2 front strut to mount 53.1

1

N 8 front strut mount to body 29.7

2

N 2 Linkage to strut 97.7

3

B 4 knuckle to strut 170

4

N 2 sta-bar to linkage 97.7

5

N4

6

N 2 rear shock to body 34

7

B2

8

B2

9

B 2 front caliper mounting bolt 87.5

10

B 4 jounce bumper brkt to axle 28

11

N 20 Lug Nuts 113

12

N 4 Rear Stabilizer Bar to Axle 59.5

13

B 2 Rear Stabar Link to Body 97.7

14

sta-bar brackets to #1 xmember

rear shock to rear axle

Torque at Ride Height

CAPSCRW SCKT HD

M12x1.75x75mm ST

59.5

97.7

103

62.5

35

115

200

115

70

40

115

130

103

30

133

70

115

71.9 39.2

40.3 21.9

132.3 72.1

230 125.4

132.3 72.1

80.5 43.9

46 25.1

132.3 72.1

155 76.0

118.5 64.5

32 20.7

153 83.3

80.5 43.9

132.3 72.1

46.1

25.8

84.8

147.5

84.8

51.6

29.5

84.8

95.9

76.0

22.1

98.1

51.6

84.8

53.0 N

29.7 P

97.6 N

169.6 P

97.6 N

59.4 P

33.9 P

97.6 N

114.3 L

87.4 L

23.6 P

112.8 P

59.4 P

97.6 N

6

Loading...

Loading...