SALDA Smarty 2 R VEL plus, Smarty 2 R VER, Smarty 2 R VEL, Smarty 2 R VER plus MOUNTING AND INSTALLATION INSTRUCTION

EN MOUNTING AND INSTALLATION INSTRUCTION

SMARTY R V

1. CONTENTS

2. SYMBOLS AND MARKING 4

3. SAFETY INSTRUCTIONS AND PRECAUTIONS 4

4. INFORMATION ABOUT THE PRODUCT 5

4.1. DESCRIPTION 5

4.2. DIMENSIONS AND WEIGHT 5

4.3. TECHNICAL DATA 5

4.3.1. AIR FLOW DIAGRAMS 7

4.4. OPERATING CONDITIONS 7

4.5. STANDARD PACKAGE OF COMPONENTS 8

4.6. DESCRIPTION OF COMPONENTS 8

4.7. SPARE PARTS 8

5. INSTALATION 9

5.1. RECEPTION OF GOODS 9

5.2. TRANSPORTATION AND STORAGE 9

5.3. UNPACKING 10

5.4. MOUNTING DIAGRAM 10

5.5. MOUNTING 11

5.5.1. MOUNTING ON THE WALL 11

5.5.2. PLACE REQUIREMENTS FOR THE EQUIPMENT AND MOUNTING POSITIONS 11

5.5.3. CONNECTION OF AIR DUCTS 12

5.5.4. AIR FLOW 12

5.5.5. CONNECTION OF THE KITCHEN HOOD 12

5.5.6. SHIELD INSTALLATION 13

5.6. CONNECTION OF THE UNIT TO ELECTRIC NETWORK 13

5.7. START-UP RECOMMENDATIONS 13

5.7.1. SYSTEM PROTECTION 13

5.7.2. PRE-STARTUP RECOMENDATIONS OF THE UNIT (IN THE PRESENCE OF THE ENDUSER) 14

6. MAINTENANCE 14

6.1. SAFETY INSTRUCTION 14

6.2. COVER OPENING 14

6.3. FILTERS MAINTENANCE 15

6.4. FANS MAINTENANCE 15

6.5. HEATER MAINTENANCE 16

6.6. ROTOR MAINTENANCE 16

7. CONTROL 17

7.1. DEVICE CONTROL 17

7.2. MEANING OF THE SYMBOLS USED IN THE INSTRUCTIONS AND ON THE DEVICE 17

7.3. DESCRIPTIONS OF THE FUNCTIONS 17

7.4. DESCRIPTION OF THE UNITS FUNCTIONS 18

7.4.1. SYSTEM MODES 18

7.4.2. SYSTEM CONTROL 19

7.4.3. SYSTEM STATES 20

7.4.4. SETTING DATE AND TIME 20

7.4.5. SUPPLY AIR TEMPERATURE CONTROL AND COMPENSATION 20

7.4.6. FAN CONTROL 21

7.4.7. “BOOST“ FUNCTION 21

7.4.8. WEEKLY SCHEDULE 21

2 | EN SMARTY RV v2019.12

7.4.9. HOLIDAY SCHEDULE 21

7.4.10. WINTER/SUMMER MODE 21

7.4.11. DRYNESS PROTECTION 21

7.4.12. NIGHT COOLING FUNCTION 22

7.4.13. CO2 REDUCTION FUNCTION 22

7.4.14. FILTER PROTECTIONS 22

7.4.15. SYSTEM MODE COMMUNICATION WITH EXTERNAL CONTACTOR 22

7.4.16. FAN SPEEDS FROM AN EXTERNAL SYSTEM CONTACTOR 22

7.4.17. HEAT EXCHANGER CONTROL 23

7.4.18. SYSTEM MONITORING 23

7.4.19. STAND-BY MODE BLOCKING 23

7.4.20. AIR FLOW ADJUSTMENT 23

7.4.21. MANUAL CONTROL OF COMPONENTS 23

7.4.22. CHANGING PASSWORDS 24

7.4.23. RESTORING FACTORY DEFAULTS 24

7.4.24. INDICATIONS OF FUNCTIONS, ALARMS AND WARNINGS 24

7.4.25. DISPLAY AND CONCELLATION OF ALARMS AND WARNINGS 24

7.4.26. EVENT LOG (HISTORY) 25

7.4.27. SYSTEM VERSIONS AND RUNNING TIME 26

8. ACCESSORIES 26

8.1. CONNECTION FO ACCESSORIES 27

8.1.1. SCHEMATIC OF CONTROLLER CONNECTIONS IN MCB 27

8.1.2. CO2 SENSOR OR CONNECTION OF HUMIDITY SENSOR RH 29

8.1.3. ROOM CO

TRANSMITTER INSTALLATION RECOMMENDATION 30

2

8.1.4. CO2 CONCENTRATION ACCORDING TO PETTENKOFER LIMIT 31

8.1.5. FIRE PROTECTION INPUT (NC) 31

8.1.6. EXTERNAL SWITCHES 31

8.1.7. CONNECTION OF REMOTE CONTROL PANEL OR MODBUS 32

8.1.8. “MCB TOOL” PROGRAM DESCRIPTION 32

8.2. THE PRINCIPAL CONNECTION SCHEME OF INTERNAL AND EXTERNAL COMPONENTS 34

8.3. ELECTRICAL CONNECTION OF THE UNITS 48

9. POSSIBLE FAULTS AND TROUBLESHOOTING 49

10. SENSORS AND THEIR TECHNICAL INFORMATION 49

11. INSPECTION OF THE VENTILATION SYSTEM 49

12. ECODESIGN DATA TABLE 50

13. DECLARATION OF CONFOMITY 51

14. WARRANTY 52

14.1. LIMITED WARRANTY COUPON 52

EN | 3SMARTY RV v2019.12

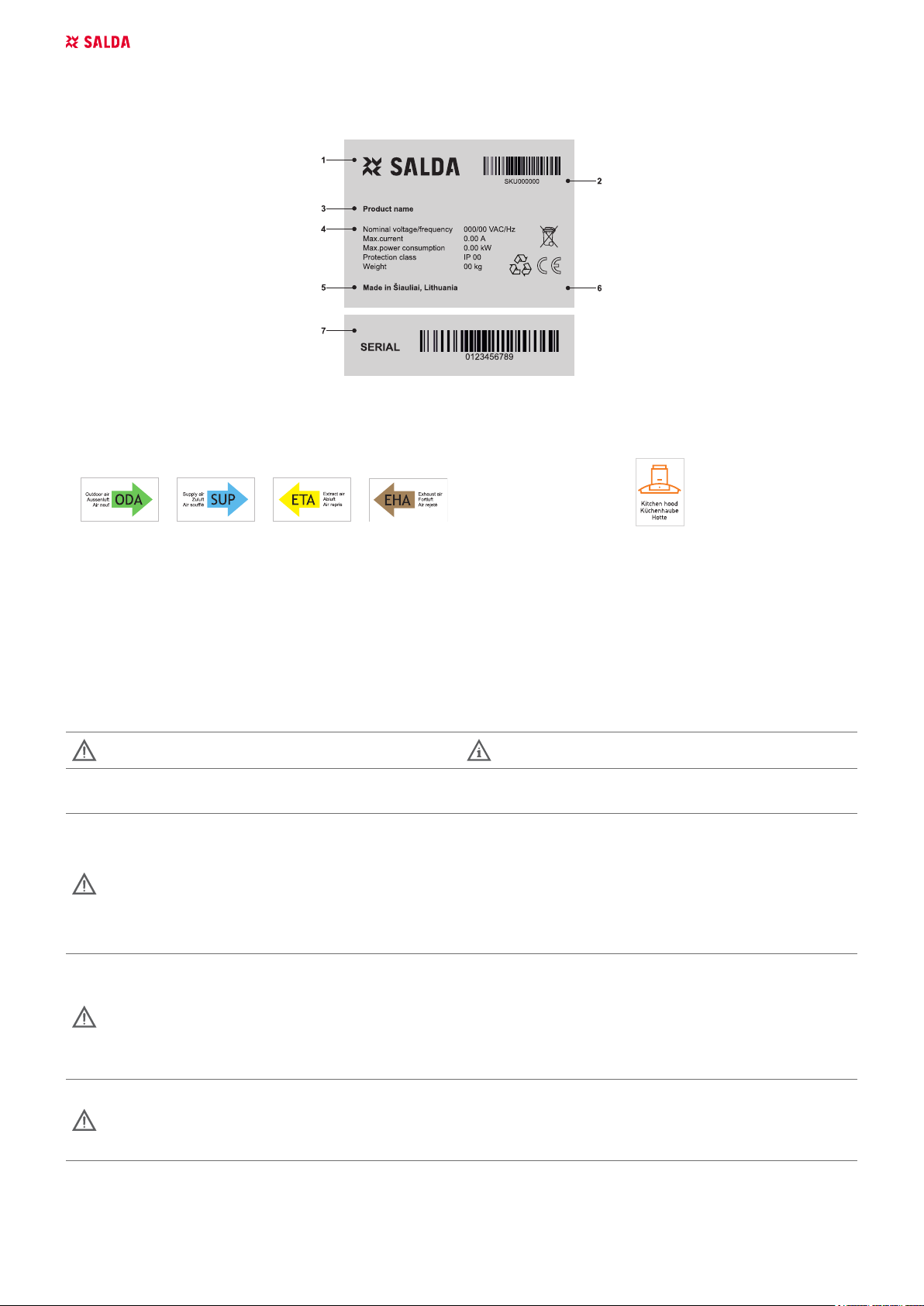

2. SYMBOLS AND MARKING

LN: XX000000

2019.01.01

Stick the auxiliary label on the unit (on an easily accessible place) or on the dashed place of a technical manual in order to keep the important

information about the unit.

LN: XX000000

2019.01.01

Figure 2.1 - Technical label

1 - Logo; 2 - Product code (SKU); 3 - Product name; 4 - Technical data; 5 - Production place; 6 - Batch number and production date; 7 - Serial

number.

Figure 2.2 - Indication for duct connection. Figure 2.3 - indication of kitchen hood

ODA - outdoor air; SUP - supply air; ETA - extract air; EHA - exhaust air.

3. SAFETY INSTRUCTIONS AND PRECAUTIONS

Read this instruction very carefully before installing and using this equipment. Installation, connection and maintenance should be carried out by

a qualifed technician and in accordance with the local rules and legal acts.

The company shall take no responsibility for the injuries suered by the people or for the damaged property, if the safety requirements are not

followed or the device is modifed without the permission of the manufacturer.

Warning – pay attention Additional information

Main safety rules

Danger

• Before performing any electricity or maintenance tasks make sure, that the device is disconnected from the mains, that all moving parts

of the device have stopped.

• Make sure that the fans can not be entered through air ducts or branch openings.

• If you notice liquids on electric parts or connections that bear voltage, stop the operation of the appliance.

• Do not plug the device into the mains, that diers from the one indicated on the label or on the housing.

• Voltage of the mains should comply with the electrotechnical parameters indicated on the label.

• The device should be earthed in accordance with the rules of installation of electric appliances. It is forbidden to turn on and use unearthed device. Follow the requirements of the device’s labels that indicate Danger.

Warnings

• Connection of electricity and maintenance of the device should be performed only by a qualied personnel, in accordance with the

manufacturer’s instructions and valid safety requirements.

• In order to reduce the risk during installation and maintenance, suitable protective clothes should be worn.

• Beware of sharp angles while performing installation and maintenance tasks.

• Do not touch heating elements until they haven’t cooled down.

• Some devices are heavy, thus one should be very careful while transporting and installing. Use suitable lifting equipment.

• While connecting electricity to the mains a circuit breaker of suitable size is necessary.

Warning!

• If the device is installed in a cold environment, make sure that all connections and tubes are properly isolated. Intake and discharge air

ducts should be isolated in all cases.

• Openings of the ducts should be covered during transportation and installation.

• Make sure not to damage the heater when connecting the piping of the water heater. For tightening up, use a wrench/spanner.

4 | EN SMARTY RV v2019.12

Before starting the equipment

320 mm

653 mm

• make sure, that there are no strange objects inside;

• manually check whether fans are not stuck or blocked;

• if rotary heat exchanger is installed in the device, make sure that it is not stuck or blocked;

• check the grounding;

• make sure that all components and accessories are connected in accordance with the project or provided instructions.

Danger: Fumes

Salda Antifrost system uses dis-balancing of the air ow and it may cause negative pressure in premises. Great care should be taken

when using at the same time in premises as another heating appliance what depend on the air in premises. Such appliances include

gas, oil, wood or coal-red boilers and heaters, replaces, continuous ow or other water heaters, gas hobs, cookers or ovens which

draw air in from the room and duct exhaust gases out through a chimney or extraction ducting. The heating appliance can be starved

of oxygen, impairing combustion. In exceptional cases harmful gases could be drawn out of the chimney or extraction ducting back

into the room. In this case we strictly recommend to turn o Salda Antifrost and use an external preheater for heat exchanger anti-frost

protection (see Salda Antifrost function on the Remote controller manual).

4. INFORMATION ABOUT THE PRODUCT

4.1. DESCRIPTION

HRU Residential is a residential air handling unit with a high eciency (up to 75 %) rotor heat exchanger with integrated electrical heater. The unit

provides ventilation in the home and takes the heat from the exhausted air. AHU complies with ErP 2018 requirements. The unit is operated by a

separate remote control panel or though separate MB-Gateway by PC. Remote control panel and MB-Gateway are optional and not included in

standard package.

HRU Residential operates within the limits of the airow diagrams and is suitable for indoor operation only. Required ambient temperatures must

be from -20 oC to +40 oC. For the cold climate zones (air temperatures below -20 oC), optional pre-heater is required.

Unsuitable for operation in pools, saunas and other similar premises.

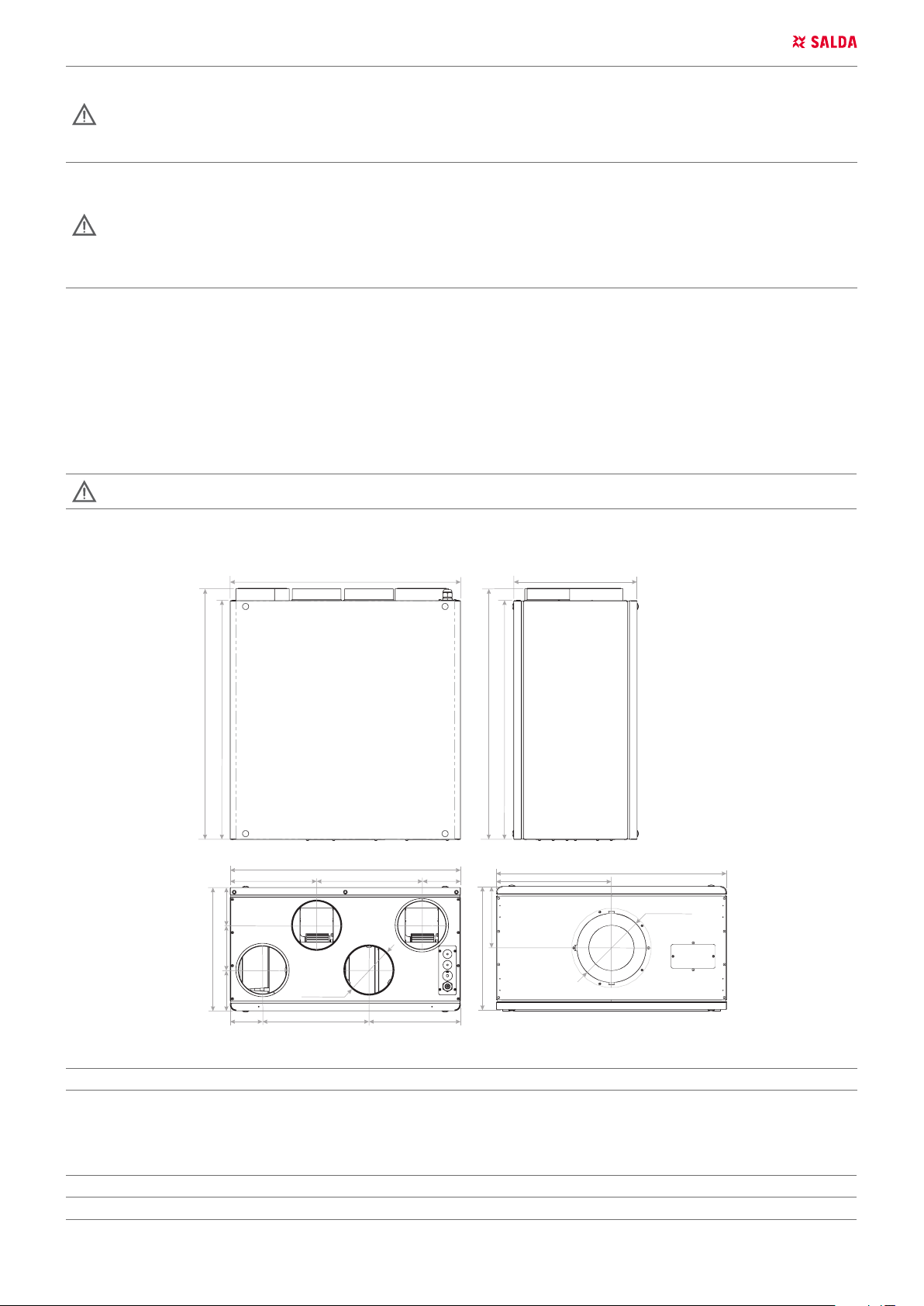

4.2. DIMENSIONS AND WEIGHT

620 mm

224,5 mm

98 mm

320 mm

116,3 mm

105,7 mm

84 mm

Ø 125 mm

276,3 mm

598 mm

598 mm

273,1 mm

237,7 mm

100,4 mm

653 mm

320 mm

160 mm

620 mm

286 mm

598 mm

Ø 175 mm

SMARTY

2R VER 2R VER PLUS

m [kg] 36 36

4.3. TECHNICAL DATA

SMARTY

Heat exchange

- phase/voltage [f/VAC/Hz] ~1/230/50 ~1/230/50

2R VER 2R VER PLUS

EN | 5SMARTY RV v2019.12

- power/current [kW/A] 0,006/0,1 0,006/0,02

-thermal eciency up to 75% 75%

Heater

- power/current [kW/A] 0,6/2,61 0,6/2,61

Exhaust air fan

- phase/voltage

- power/current

- speed

- protection class IP44 IP54

- control imput [VDC] 0-10 0-10

Supply air fan

- phase/voltage

- power/current

- speed

- protection class IP44 IP54

- control imput [VDC] 0-10 0-10

Total

- power/current [kW/A] 0,75/3,91 0,77/4,13

Automatic control integrated

Insulation of walls

Weight

Exhaust air lter

class class ePM10 55% ePM10 65%

width [mm] 270 270

height [mm] 86 85

depth [mm] 46 173

model MPL FMK

Supply air lter

class ePM10 55% ePM10 65%

width [mm] 270 270

height [mm] 86 85

depth [mm] 46 173

model MPL FMK

[f/VAC/Hz] ~1/230/50 ~1/230/50

[kW/A] 0,07/0,6 0,084/0,75

[min-1] 1380 3200

[f/VAC/Hz] ~1/230/50 ~1/230/50

[kW/A] 0,07/0,6 0,084/0,75

[min-1] 1380 3200

+ +

[mm] 20 20

[kg] 36 36

SMARTY 2R VER

Outdoor 62 22 54 61 48 41 27 20 14

Supply 70 29 61 68 59 60 55 49 43

Extract 62 22 54 61 49 36 28 19 14

Exhaust 69 28 60 67 58 58 52 48 41

Surrounding 49 10 40 48 36 31 30 30 29

Measured at 140 m3/h, 50 Pa

SMARTY 2R VER PLUS

Outdoor 60 18 50 58 55 44 28 16 12

Supply 66 23 55 63 61 56 55 48 40

Extract 60 19 50 58 54 40 35 24 17

Exhaust 66 23 55 62 60 56 53 46 36

Surrounding 48 3 34 44 45 32 31 30 29

Measured at 180 m3/h, 50 Pa

NOTE. Subject to technical modication

LWA TOTAL,

DB(A)

LWA TOTAL,

DB(A)

63 Hz 125 Hz 250 Hz 500 Hz 1 kHz 2 kHz 4 kHz 8 kHz

63 Hz 125 Hz 250 Hz 500 Hz 1 kHz 2 kHz 4 kHz 8 kHz

LWA, DB(A)

LWA, DB(A)

6 | EN SMARTY RV v2019.12

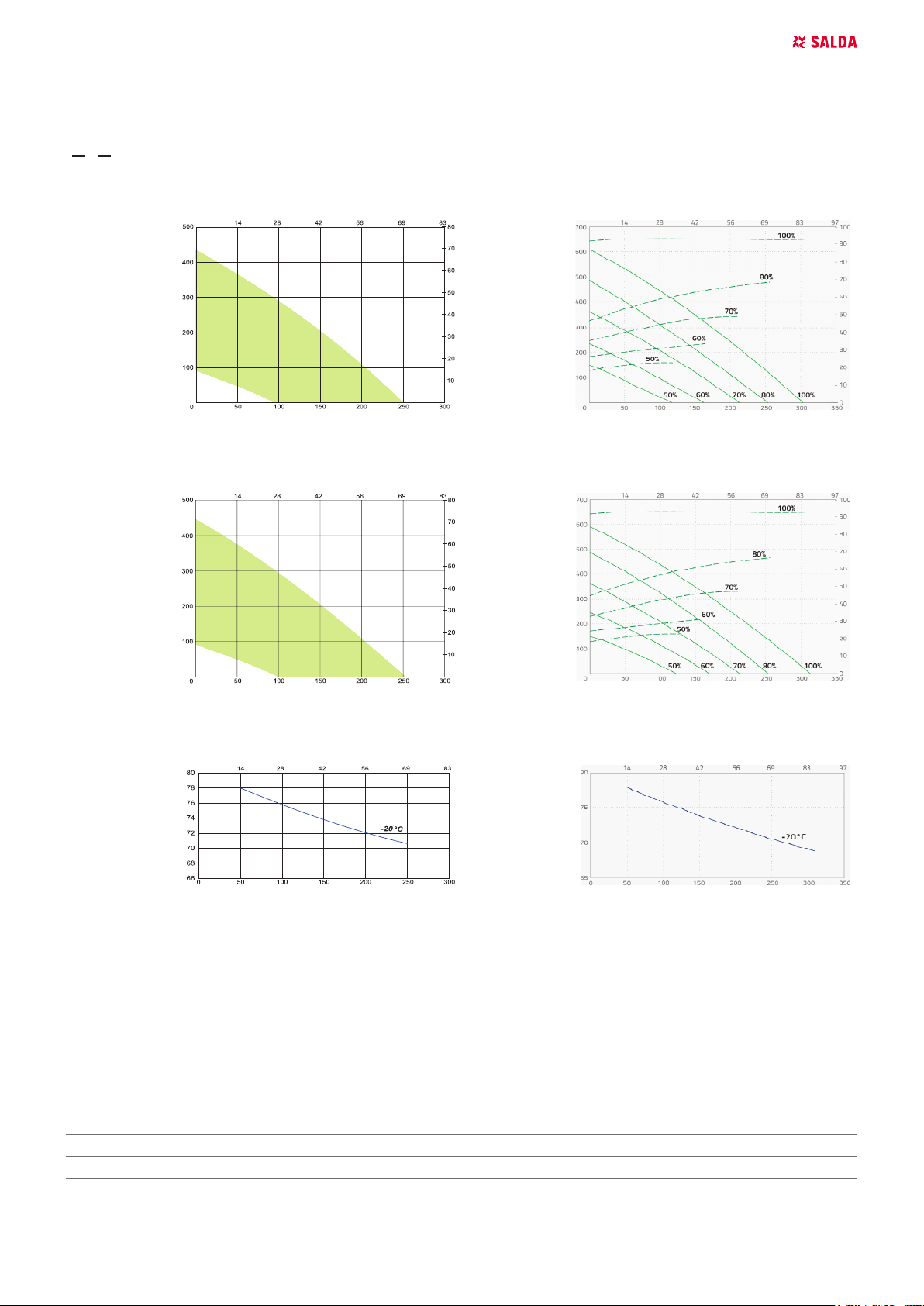

4.3.1. AIR FLOW DIAGRAMS

Performance

Power consumption

SMARTY 2R VER SMARTY 2R VER PLUS

Supply air Supply air

Exhaust air Exhaust air

Temperature eciency Temperature eciency

Temperature eciency (balanced mass ow):

Extract air = - 20 °C / 90 % RH

4.4. OPERATING CONDITIONS

• Unit is designed to operate only indoors.

• It is forbidden to use the unit in potentially explosive environment.

• Unit is designed to supply/extract only clean air (free of chemical compounds causing metal corrosion, of substances aggressive to zinc,

plastic and rubber, and of particles of solid, adhesive and bred materials).

OUTDOOR AIR

- temperature min./max.* [°C] -23 / +40

- humidity [%] 90

EXTRACT AIR

- temperature min./max.*

- max. humidity

[°C] +15 / +40

[%] 60

* Can be used at temperatures below -23 °C with pre-heater, the power of which is over 600W.

EN | 7SMARTY RV v2019.12

+40 C

10

9

10

9

o

+5 C

o

o

+40 C

o

-23 C

Figure 5.4.1 - operating conditions

4.5. STANDARD PACKAGE OF COMPONENTS

Standard package (without optional accessories) includes:

• Mounting brackets (mural and unit parts), Rubber seal for vibration damping.

• Screws M5x25 DIN7985 CT for mounting brackets - 3 pcs.; 5. Spring washers DIN127 5 - 3 pcs.

• Bushing caps - 8 pcs.

• Antivibration stick - 2 pcs.

• Key - 1 pcs.

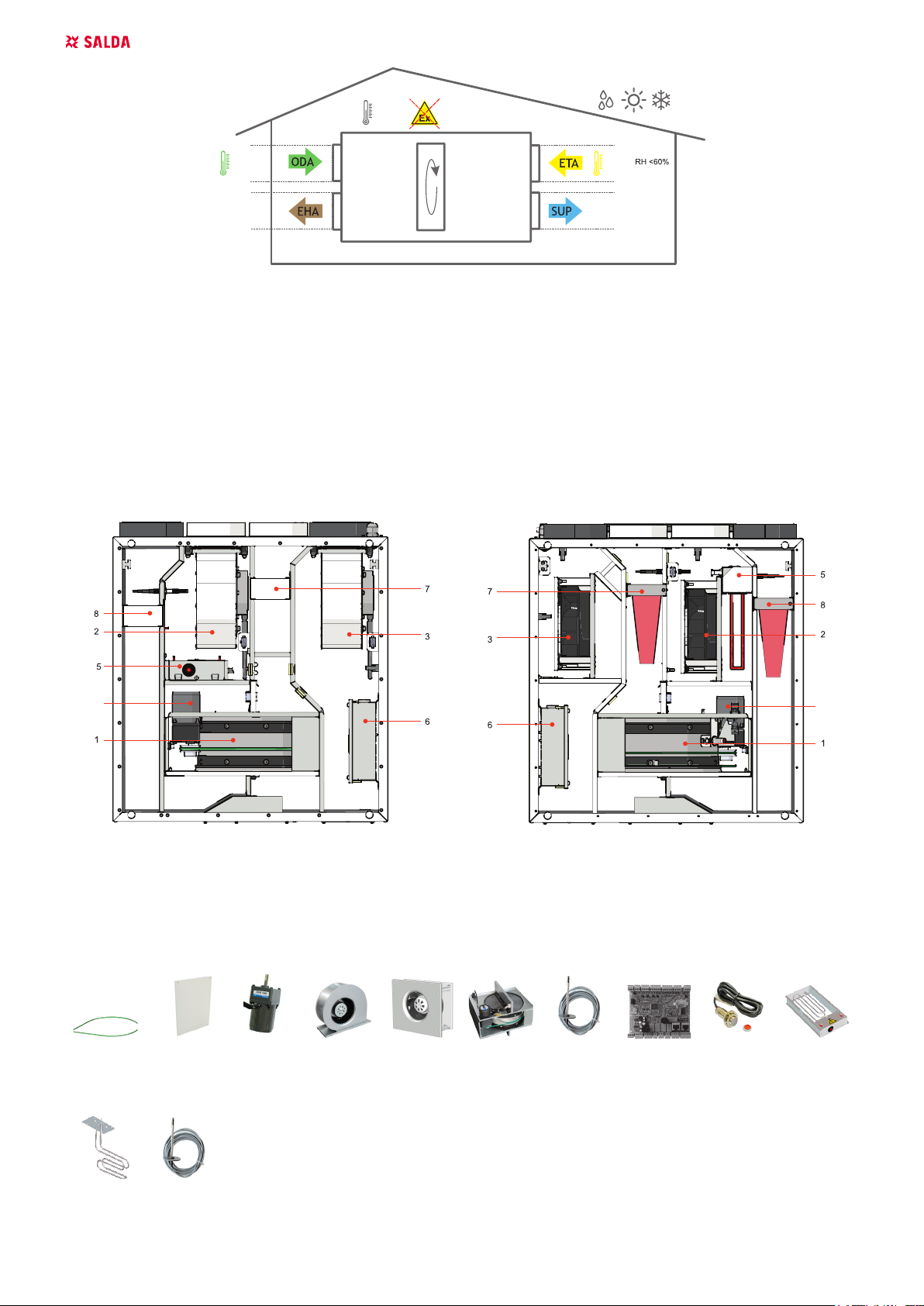

4.6. DESCRIPTION OF COMPONENTS

+40 C

+15 C

o

o

9

9

Figure 5.3.1 - Smarty 2R VER construction Figure 5.3.2 - Smarty 2R VER plus construction

1 - Plate/rotor heat exchanger; 2 - Supply fan; 3 - Exhaust fan; 4 - By-pass damper; 5 - Electrical/water heater/pre-heater; 6 - Control board; 7 -

Extract air lters (panel/pocket); 8 - Supply air lter (panel/pocket); 9 - Rotor motor.

4.7. SPARE PARTS

Rotor belt Door Rotor mo-

tor

Fan Fan Rotor box TJ MCB Hall H1A-

D12P24-1

SRR 0,6-1f

EC-1k

SRR V-0,6-

TL/TA

1f

8 | EN SMARTY RV v2019.12

Rotor box belt Rotor belt GNG00062

Smarty 2R VE door Door GNG00061

Rotor box motor Rotor motor ZVAR0133

Fan supply/exhaust

Fan

(Smarty 2R VER)

Fan

(Smarty 2R VER plus)

GPUVRA009

GVESMARTY001

Rotor box Rotor box GPURSD085_330

Temperature sensor 3 m TJ PJUT0063

Temperature sensor 1,5 m TL/TA PJUT0062

Controler MCB V1.0 ZED00985

Hall sensor Hall H1A-D12P24-1 PJUT0006

Electrical heater

SRR 0,6-1f EC-1k

(Smarty 2R VER)

SRR V-0,6-1f

(Smarty 2R VER plus)

ZESSRR028

ZESSRR032

5. INSTALATION

5.1. RECEPTION OF GOODS

Each device is thoroughly checked before transportation. When receiving goods it is recommended to check whether devices were damaged

during transportation. If damage to the device is identied, immediately inform the representatives of a transport company. Please inform a representative of the manufacturer, if any deviation from the order is noticed.

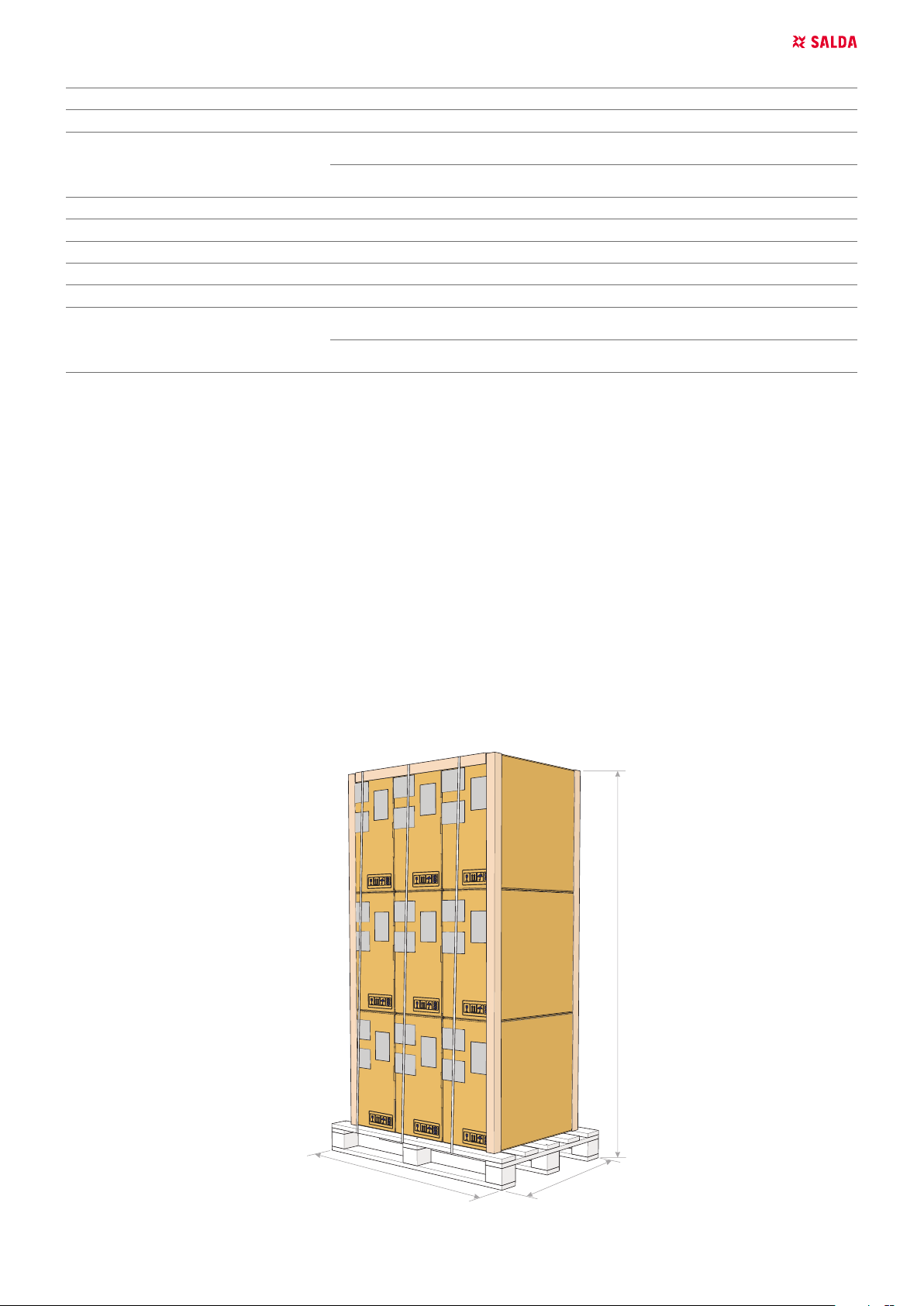

5.2. TRANSPORTATION AND STORAGE

• All units are packed in the factory to withstand regular conditions of transportation.

• Upon unpacking, check the unit for any damages caused during transportation. It is forbidden to install damaged units!!!

• The package is only for protection purpose!

• While unloading and storing the units, use suitable lifting equipment to avoid damages and injuries. Do not lift units by holding on power sup-

ply cables, connection boxes, air extract or exhaust anges. Avoid hits and shock overloads. Before installation units must be stored in a dry

room with the relative air humidity not exceeding 70% (at +20 °C) and with the average ambient temperature ranging between +5 °C and +30

°C. The place of storage must be protected against dirt and water.

• The units must be transported to the storage or installation site using forklifts.

• The storage is not recommended for a period longer than one year. In case of storage longer than one year, before the installation it is necessary to verify whether the bearings of fans and motor rotate easily (turn the impeller by hand) and if the electric circuit insulation is not damaged

or the moisture is accumulated.

2020 mm

1200 mm

780 mm

EN | 9SMARTY RV v2019.12

5.3. UNPACKING

M

CO

2

5.4. MOUNTING DIAGRAM

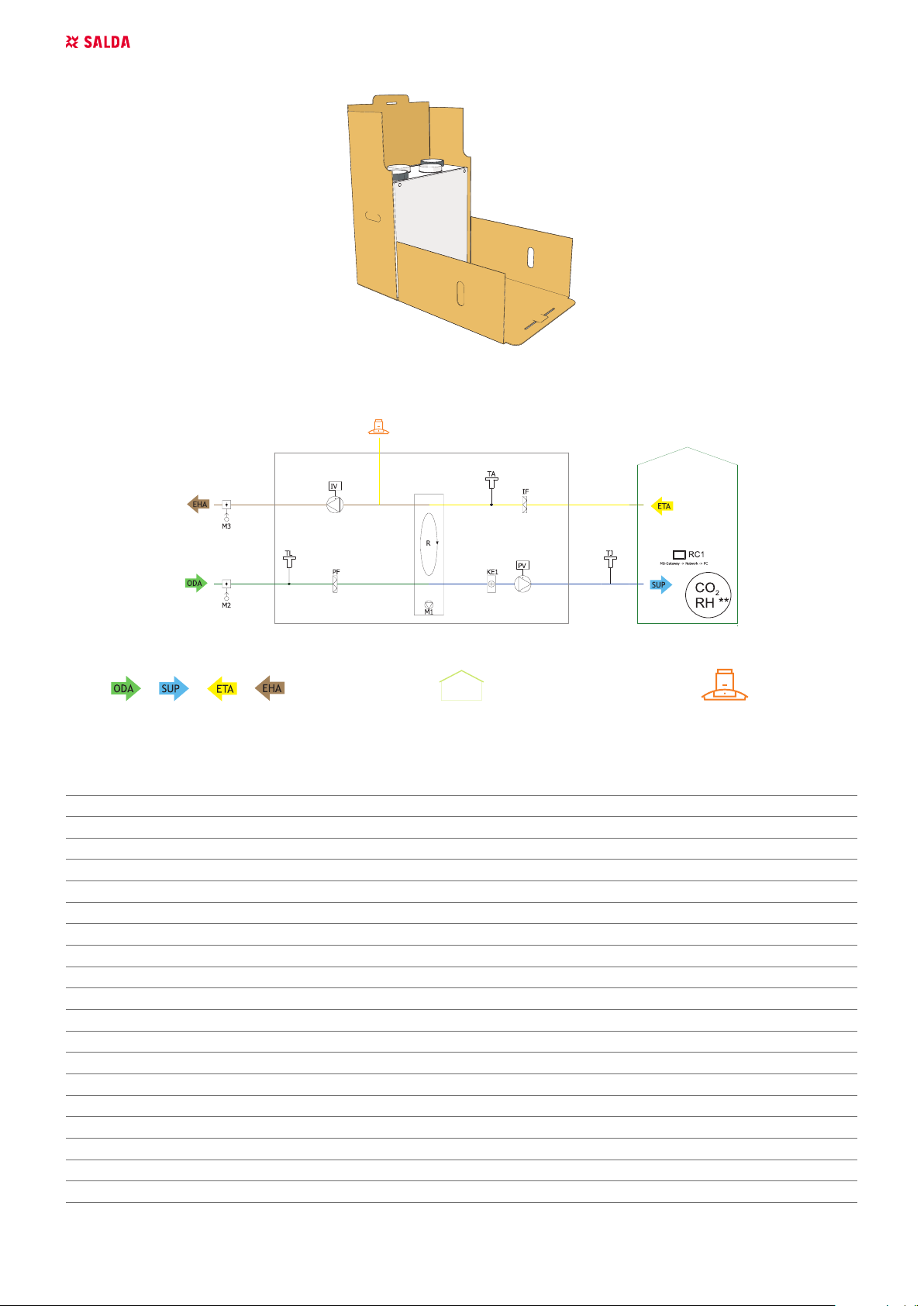

Figure 5.4.1 - Smarty RV (** Only one sensor can be used at a time)

Figure 5.4.2 - Indication for duct connection. Figure 5.4.3 - Ventilated premises Figure 5.4.4 - Air from cooing hood

LIST OF COMPONENTS

C Plate heat exchanger A1 Fire alarm damper actuator I

PV Supply air fan A2 Fire alarm damper actuator II

IF Extract air lter TJ Supply air temperature sensor

PF Supply air lter TL Outdoor air temperature sensor

IV Exhaust fan TE Exhaust air temperature sensor

KE1 Electric heater DTJ Extract air temperature and RH sensor

PE1 Electric pre-heater T2 Cooler changeover thermostat

KV2 Water pre-heater TV2 Water preheater temperature sensor

KV3 Water cooler TV3 Water cooler temperature sensor

DX DX cooler U3 PV pressure transmitter

M1 By-pass damper U4 IV pressure transmitter

M2 Outdoor air damper actuator CO

M3 Exhaust air damper actuator RH RH sensor*

M5 Water cooler valve motor PC Computer

M12 Water pre-heater valve actuator RC1 Stouch or SA-Control remote control panel

M14 Water cooler circulation pump RC2 Stouch, Flex or SA-Control remote control panel

M15 DX cooler valve actuator MB-Gateway Network module

M16 Water pre-heater circulation pump NET Network

R Rotor heat exchanger

2

CO2 sensor*

10 | EN SMARTY RV v2019.12

POSSIBLE PCB INPUTS/OUTPUTS

FA Fire alarm H1 Working indication output

FPP Fireplace protection H2 Alarm indication output

System mode switch (START/STOP) Fans speed switch (BOOST)

* Compone

5.5. MOUNTING

• Installation should only be performed by qualied and trained sta.

• When connecting air ducts, consider the notices indicated on the casing of the unit.

• Before connecting to the air duct system, the connection openings of ventilation unit should be closed.

• Do not connect the bends close to connection anges of the unit. The minimum distance of the straight air duct between the unit and the rst

branch of the air duct in the supply air duct must be 1xD, in air exhaust duct 3xD, where D is diameter of the air duct.

• It is recommended to use the accessories-holders. This will reduce vibration transmitted by the unit to the air duct system and environment.

• Enough space must be left for opening of the maintenance door and lter covers.

• If the installed ventilation unit is adherent to the wall, it may transmit noise vibrations to the premises. Though the level of noise caused by the

fans is admissible, it is recommended to mount the unit at the distance of 400 mm from the nearest wall. If it is not possible, the mounting of

the unit is recommended on the wall of the room where the level of noise is not important.

• Ducts are connected to the unit in such way that they could be easily disassembled and the heater could be removed from the unit when

performing service or repair works.

5.5.1. MOUNTING ON THE WALL

90

90

30 mm

a c d

b

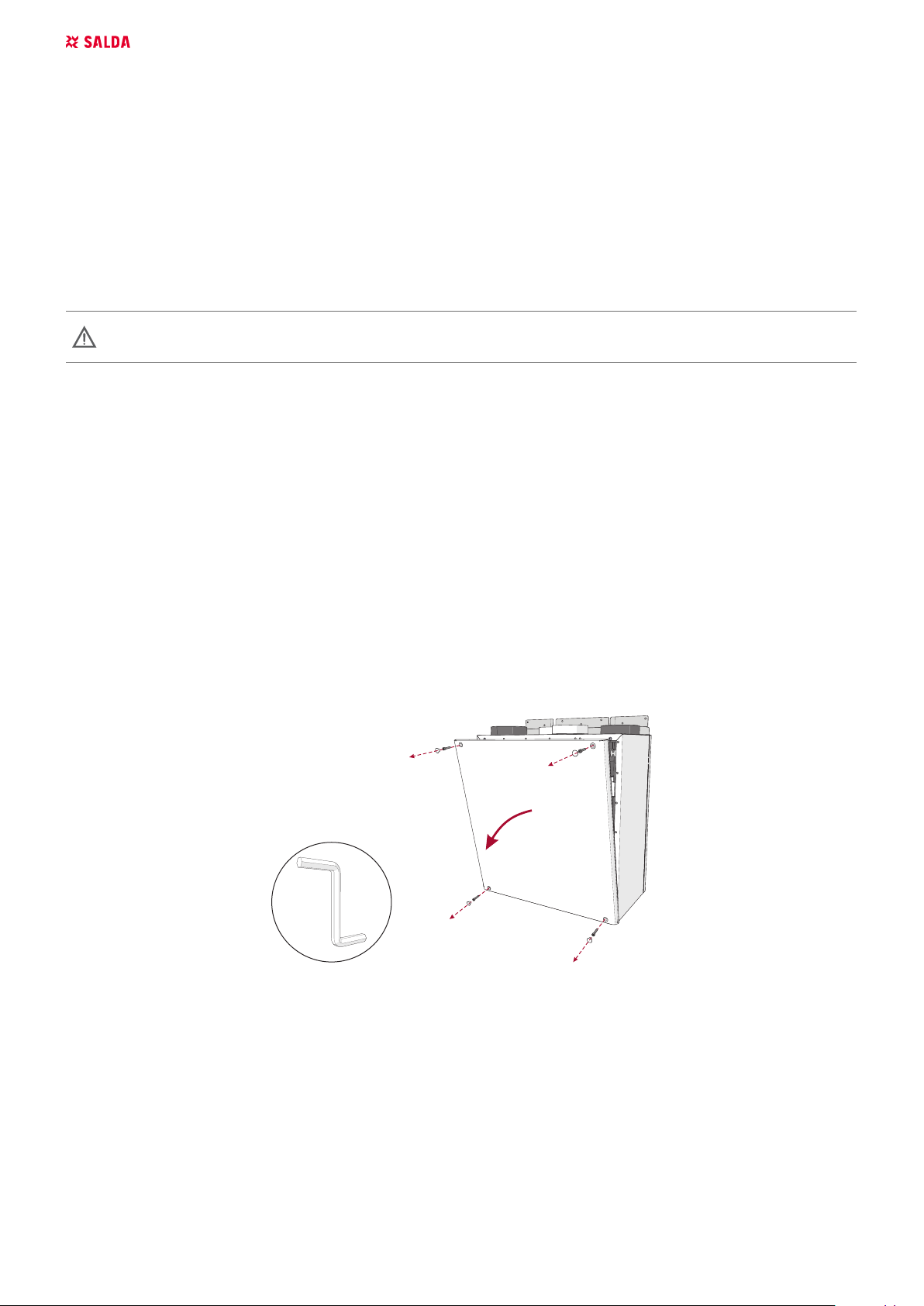

Mounting on the wall:

a) To reduce the vibration stick the insulating tape on the unit‘s casing side which touches the wall before mounting the unit on the wall.

b) The unit has to be mounted on the mounting brackets.

c) AHU mounting drawing.

d) After the unit is mounted two wall bracket tabs has to be folded to 90o angle by pliers to avoid the accident fall of the unit.

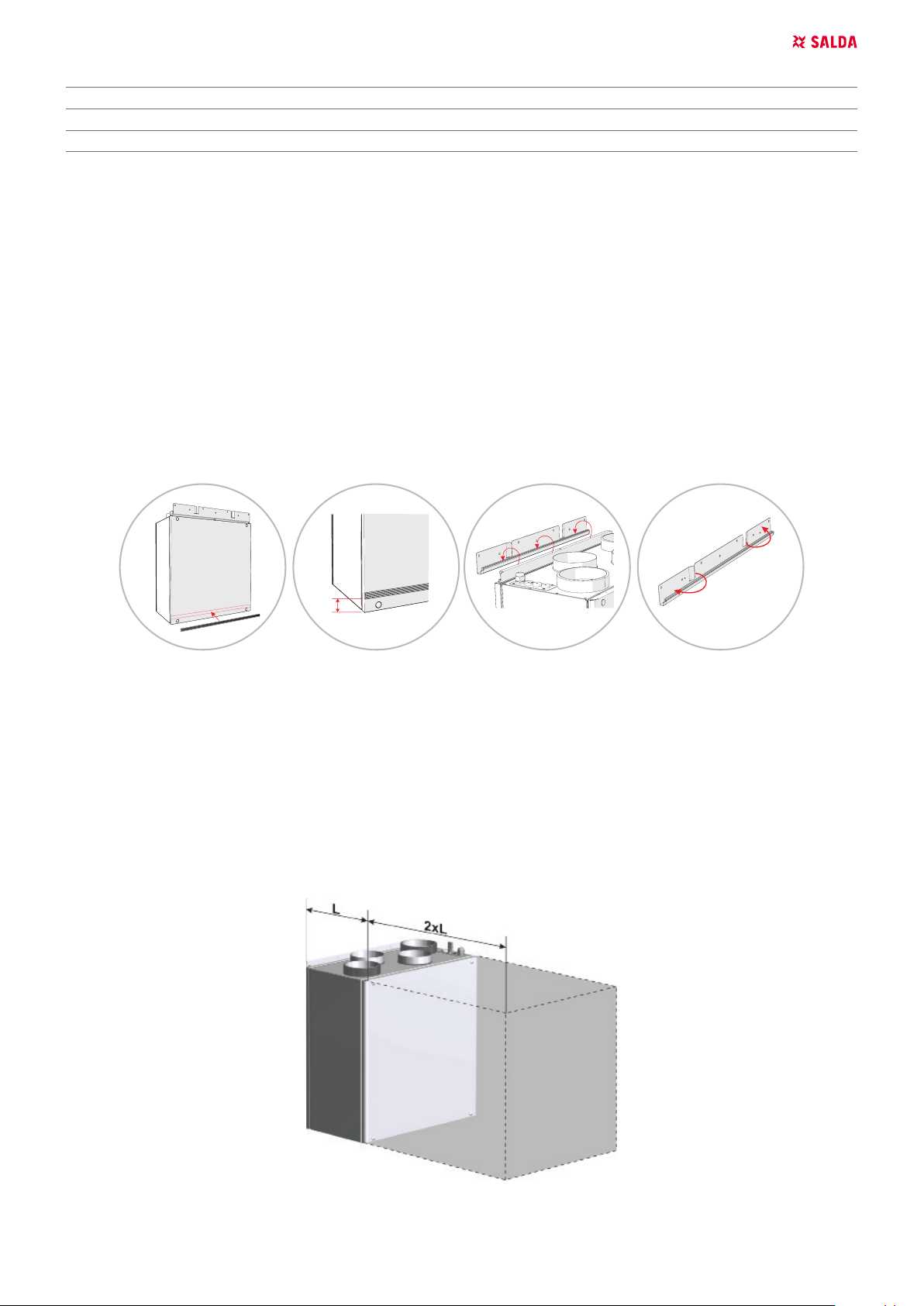

5.5.2. PLACE REQUIREMENTS FOR THE EQUIPMENT AND MOUNTING POSITIONS

1. The installation position only in the horizontal direction.

2. Install the supporting legs.

3. AmberAir Compact are assembled from separate sections.

4. They must be adjusted without a gradient.

5. Leave space in the front (2xL) that it would be sucient to open the doors and to remove or install a required component.

EN | 11SMARTY RV v2019.12

5.5.3. CONNECTION OF AIR DUCTS

• Connected air ducts must be straight and have their own xing.

• Make sure that the fans can not be accessed through air duct heads. If it is possible to access the fan, protective grid should be installed. You

can choose it in our website.

• Do not reduce the diameter of the piping near air inlet or exhaust ducts. If you want to reduce the speed of air in the system, drop of pressure

and noise level, you can increase the diameter.

• In order to reduce the level of the noise in the air supply system, install silencers (see chapter on their installation).

• In order to reduce air loss in the system, the air ducts and prole parts should be of class C and higher. Their catalog can be found in our

website.

• If air handling unit is installed in heated premises, outdoor and exhaust air ducts must be insulated in order to avoid heat loses and condensing.

If AHU is installed outdoors, it’s recommended to insulate all the air ducts.

• It is recommended to maintain a distance of up to 8 meters between air intake and air exhaust ducts. Air supplying system should be installed

further from potential air pollution sources.

• Use holders while installing air ducts next to the ventilation equipment. They suppress vibration and ensure a rm installation of various system

parts.

• Necessary holders can be found in our catalog or website.

• A common mistake is that air ducts are attached to improper airow connection. On the ventilation equipment there are signs, indicating the air

duct to be connected. Before starting the system carefully check whether the work was performed properly.

5.5.4. AIR FLOW

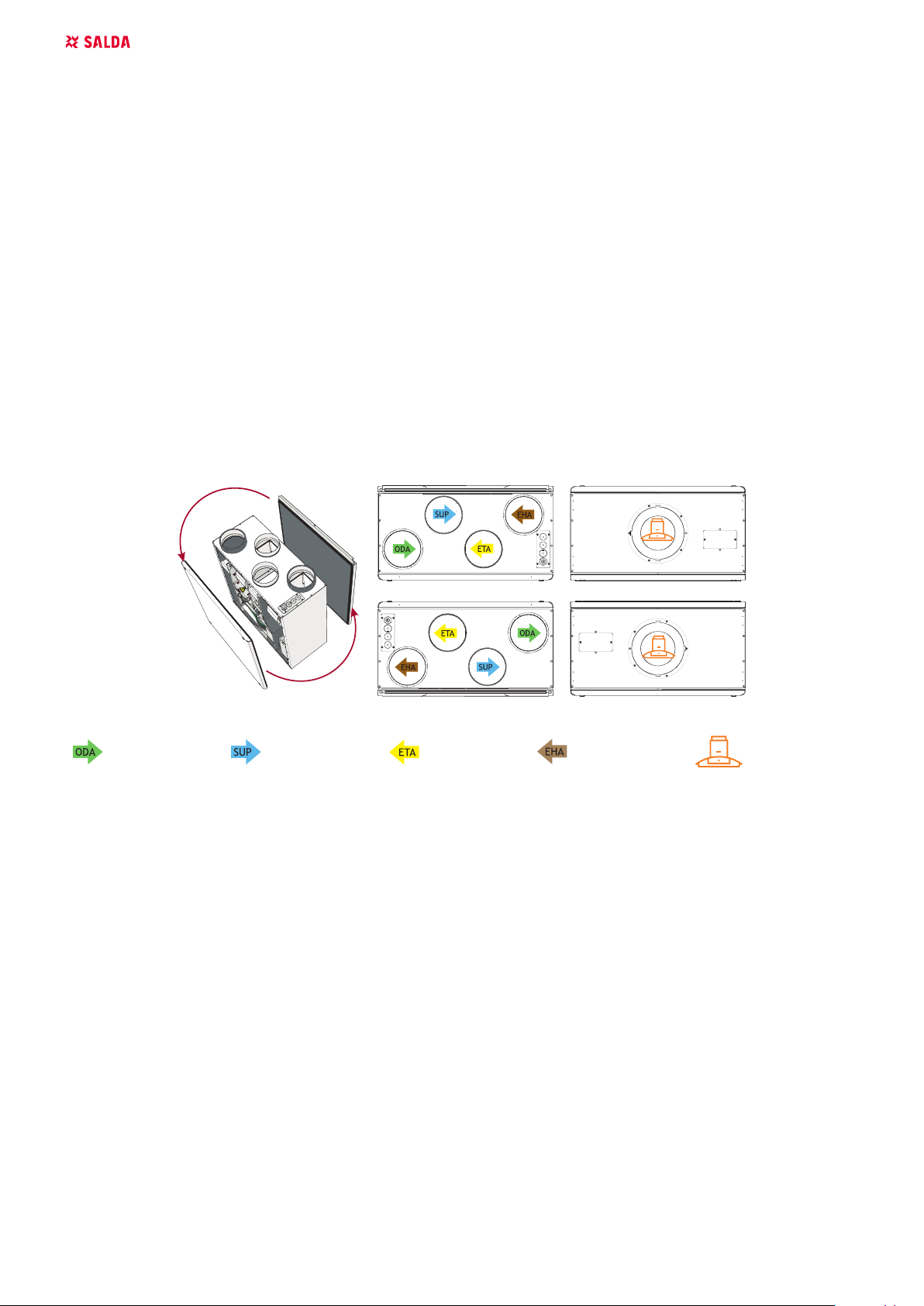

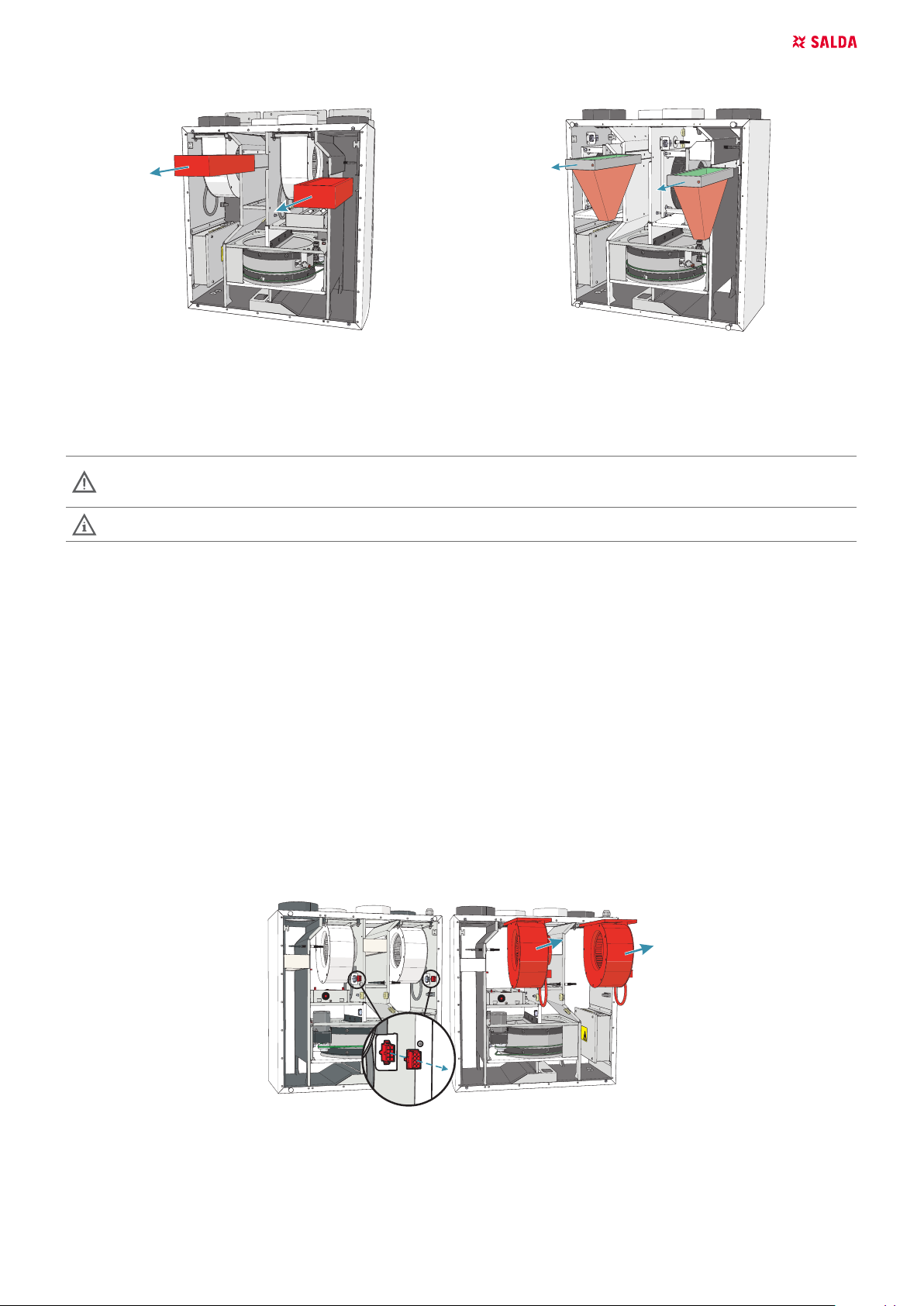

The maintenance side can be changed for the ventilation unit, i.e. it can be mounted with the left ambient air inlet or the right ambient air inlet. That

can be implemented by switching over the back door and the front door. The default version of the ventilation unit is right.

Converted service side to Left version

Standard version (Right)

outdoor air supply air extract air exhaust air kitchen hood

5.5.5. CONNECTION OF THE KITCHEN HOOD

• Installation works must be performed only by trained and qualied personnel.

• If you have any questions regarding the save installation and use of the product, please contact the manufacturer or the representative.

• Before installing the unit, unscrew the lid a covering the opening for connection of the kitchen hood and remove the middle part of the insulating ring.

• Cut the connecting opening as indicated on the insulation material.

• Carefully remove the lid, which covers the electric connection for the connection of the electrical part of the kitchen hood to the ventilation unit.

• Mount the hood to the ventilation unit. Fasten with self-tapping screws to the designated connection points.

• It is necessary to ensure the tight and reliable connection of the air ducts of the kitchen hood to the ventilation unit and the electrical contact

of the control circuit.

• The subsequent installation of the device is performed according the description in chapter “Mechanic installation”.

• Properties, assembly, control, use and maintenance of the kitchen hood are described in its instalation manual.

12 | EN SMARTY RV v2019.12

Use cooker hood supplied by our company only. Equipment is not tested with other cooker hoods and company holds no

responsibility for malfunction or failures of the equipment in this case.

5.5.6. SHIELD INSTALLATION

5.6. CONNECTION OF THE UNIT TO ELECTRIC NETWORK

• Supply voltage to the unit must be connected by a qualied specialist following the manufacturer’s instructions and eective safety instructions.

• The unit’s power network voltage must correspond to electrotechnical parameters of the unit indicated in the technical decal.

• The unit’s voltage, power and other technical parameters are provided in the unit’s technical decal (on the unit casing). The unit must be con-

nected to the voltage plug socket of the grounded power network in compliance with the eective requirements.

• The unit must be earthed according to the rules on installing electrical equipment.

• It is prohibited to use extension wires (cables) and power network plug socket distribution devices.

• Prior to carrying out any ventilation unit installation and connection activities (until its hand-over to the customer), the unit must be disconnected from the power network.

• After installation of the ventilation unit, the power network plug socket must be accessible at any time and disconnection from the power network is performed through the two-pole circuit breaker (by disconnecting phase pole and neutral).

• The unit must be thoroughly checked against damages (execution, control, measurement nodes) during transportation before it is connected

to the power network.

• The power cable can be replaced only by a qualied specialist upon the evaluation of the rated power and current.

The manufacturer does not assume any liability for personal injuries and property damage due to non-conformance with

the provided instructions.

5.7. START-UP RECOMMENDATIONS

5.7.1. SYSTEM PROTECTION

Control system of the unit has an integrated protection against short-circuit for these functional components. The controllers have the following

protections:

MCB

F1, F2 - 1A(5x20) MCB protection

To ensure safe maintenance of the unit, it is necessary to remove the plug from the power network.

EN | 13SMARTY RV v2019.12

5.7.2. PRE-STARTUP RECOMENDATIONS OF THE UNIT (IN THE PRESENCE OF THE ENDUSER)

Prior to start-up the system must be thoroughly cleaned. Check whether:

• operation systems and unit elements as well as automation and automation devices were not damaged during installation,

• all consumers are connected to power supply and t for service,

• all necessary automation elements are installed and connected to power supply and MCB terminal blocks,

• cable connection to MCB terminal blocks comply with the existing power connection diagrams,

• all electrical equipment protection elements are properly connected (if they are additionally used),

• cables and wires correspond to all applicable safety and functional requirements, diameters, etc.,

• earthing and protection systems are properly installed,

• condition of all seals and sealing surfaces is proper.

6. MAINTENANCE

Unplug unit from mains before opening the door (disconnect the power plug from the outlet or if there is a two-pole automatic

circuit breaker installed – disconnect it as well. It is necessary to ensure that it won’t be turned on by third parties) and wait

until the full stop of the fans (for about 2 min.).

6.1. SAFETY INSTRUCTION

• Do not use the unit for purposes other than its’ intended.

• Do not disassemble or modify the unit in any way which may lead to mechanical failure or injury.

• Use special clothing and be careful while performing maintenance and repair jobs – the unit’s and its components’ edges may be sharp and cutting.

• Do not wear loose clothing that could be entangled in to operating unit.

• If a outside object enters the unit, immediately disconnect power source. Before removing object, make sure that any mechanical motion has

stopped, the heater has cooled down and the restart is not possible.

• Do not connect to any other power source than indicated on the model label.

• Do not place or operate unit on unsteady surfaces and mounting frames.

• Mount the unit rmly to ensure safe operating.

• Never use this unit in the environment containing any explosive or aggressive elements.

• Do not use the unit if external connections are broken or damaged. If there are any defects, stop operating the unit and replace the damaged parts

immediately. That can be performed only by qualied electrician.

• Do not use water or another liquid to clean electrical parts or connections.

• If you notice condensat on electrical parts or connections, stop operating the unit.

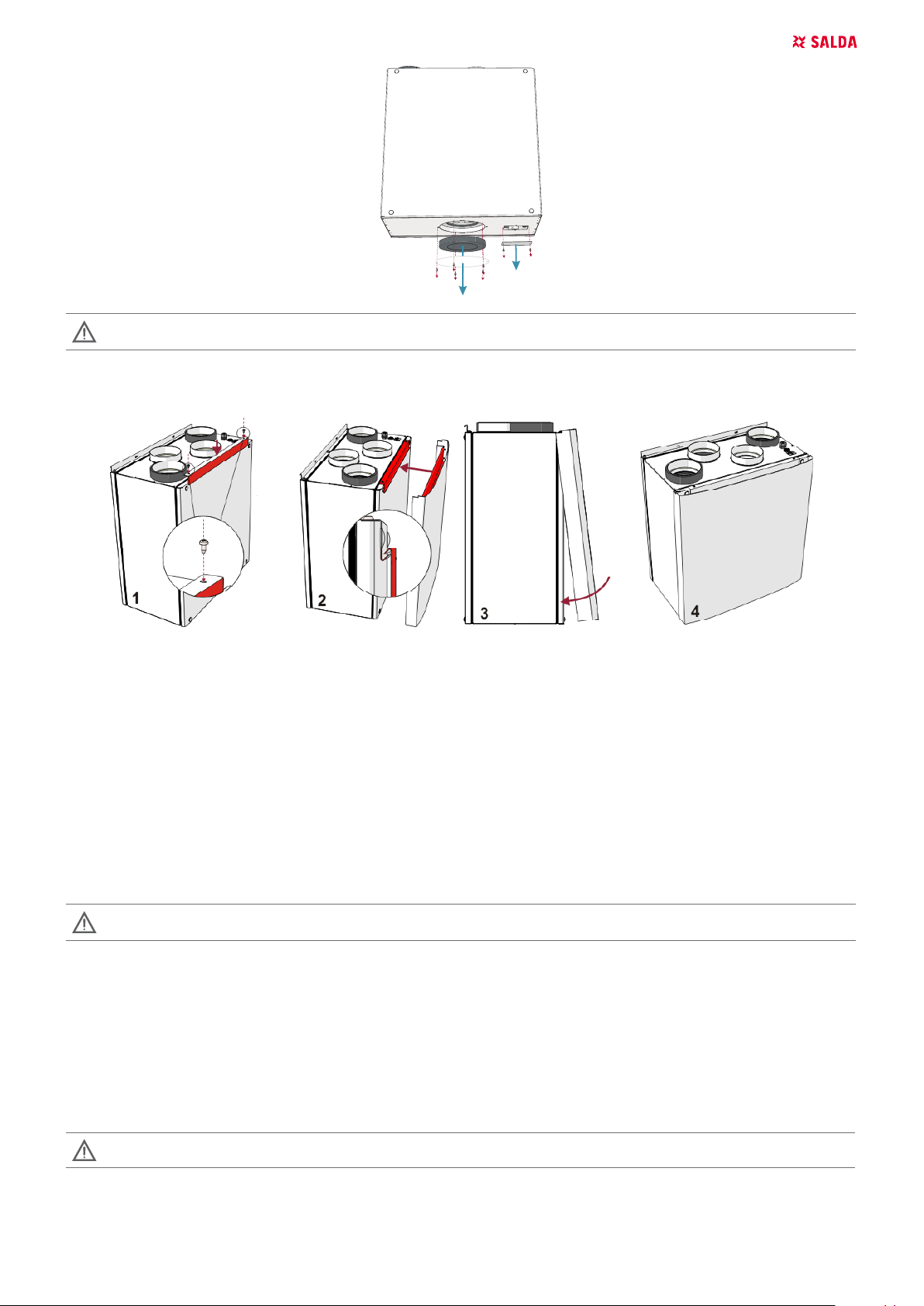

6.2. COVER OPENING

14 | EN SMARTY RV v2019.12

6.3. FILTERS MAINTENANCE

Figure 6.3.1 - Smarty 2R VER Figure 6.3.2 - Smarty 2R VER plus

Dirt increases air resistance in the lter, therefore less air is supplied into the premises.

Taking o the lters:

• Open cover.

• Remove the lter.

Changing lters, lters reload timer control. Description of remote control panel functions is provided in the remote control

panel technical documentation or on the website www.salda.lt.

Allowed to operate the unit without lters!

It is recommended to change the lters every 3-4 months, or in accordance to lter timer.

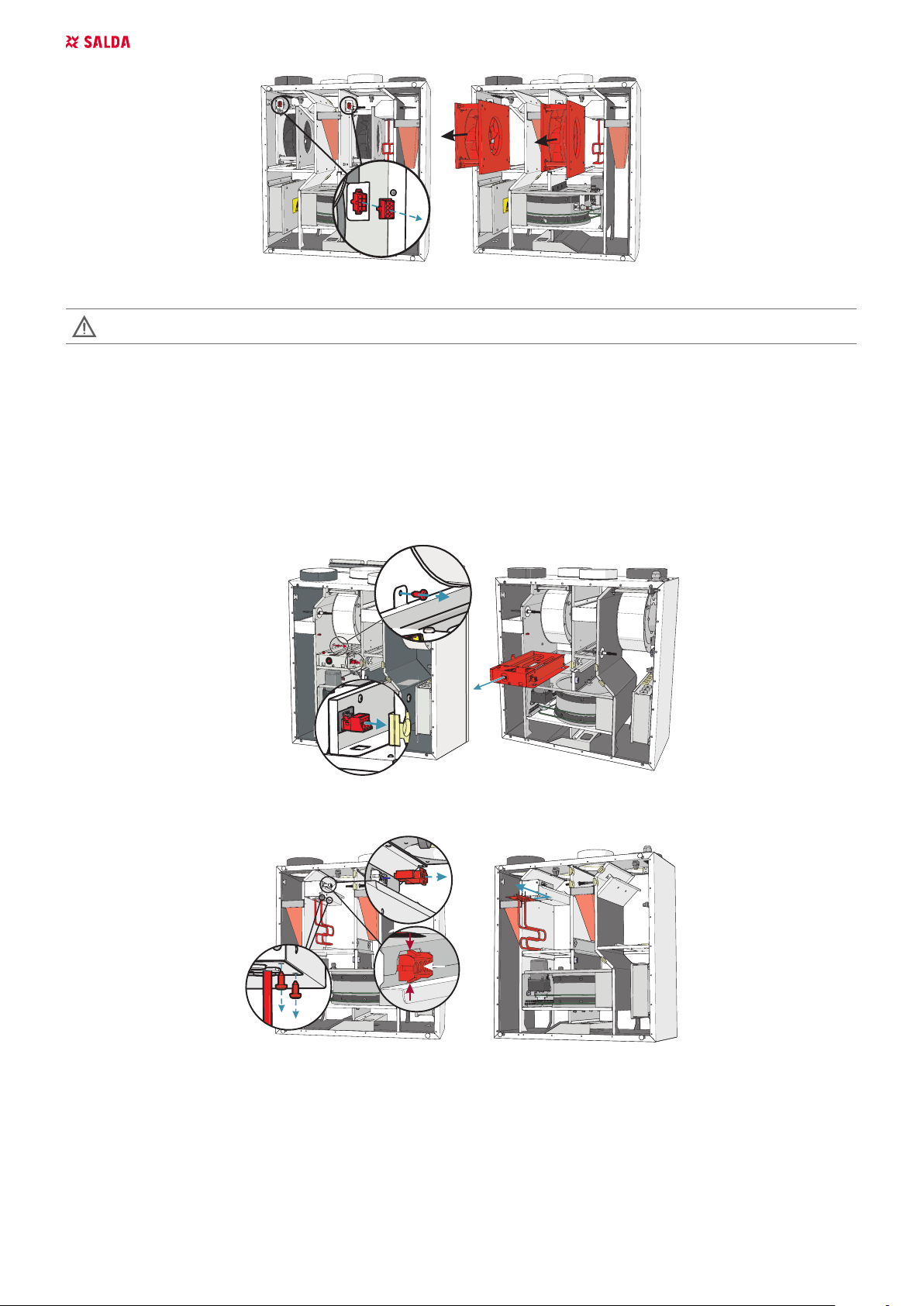

6.4. FANS MAINTENANCE

• Maintenance should be performed only by experienced and trained sta.

• The fan should be inspected and cleaned at least once a year.

• Be sure the fan is disconnected from power source before performing any maintenance or repair.

• Proceed to maintenance and repair after any rotation in the fan is stopped.

• Observe sta safety regulations during maintenance and repair.

• The motor is of heavy duty ball bearing construction. The motor is completely sealed and requires no lubrication for the life of the motor.

• Detach fan from the unit.

• Impeller should be specially checked for buil-up material or dirt which may cause an imbalance. Excessive imbalance can lead to accelerated

wear on motor bearings and noise, vibration.

• Clean impeller and inner housing with mild detergent, water and damp, soft cloth.

• Do not use high pressure cleaner, abrasives, sharp instruments or caustic solvents that may scratch or damage housing and impeller.

• Do not plunge the motor into any uid while cleaning impeller.

• Make sure, that impeller ’s balance weights are not moved.

• Make sure the impeller is not hindered.

• Mount the fan back into the unit. Connect the fan to power supply source.

• If after maintenance the fan does not start or stop itself, contact the producer. Malfunction of the fan can be identied according to the pressure

in the system (when pressure switches are connected). When there is a fault in fans’ motor, any separate notice is shown on the control panel.

Figure 6.4.1 - Smarty 2R VER

EN | 15SMARTY RV v2019.12

Figure 6.4.2 - Smarty 2R VER plus

Be sure the unit is disconnected from power source before performing any maintenance or repair.

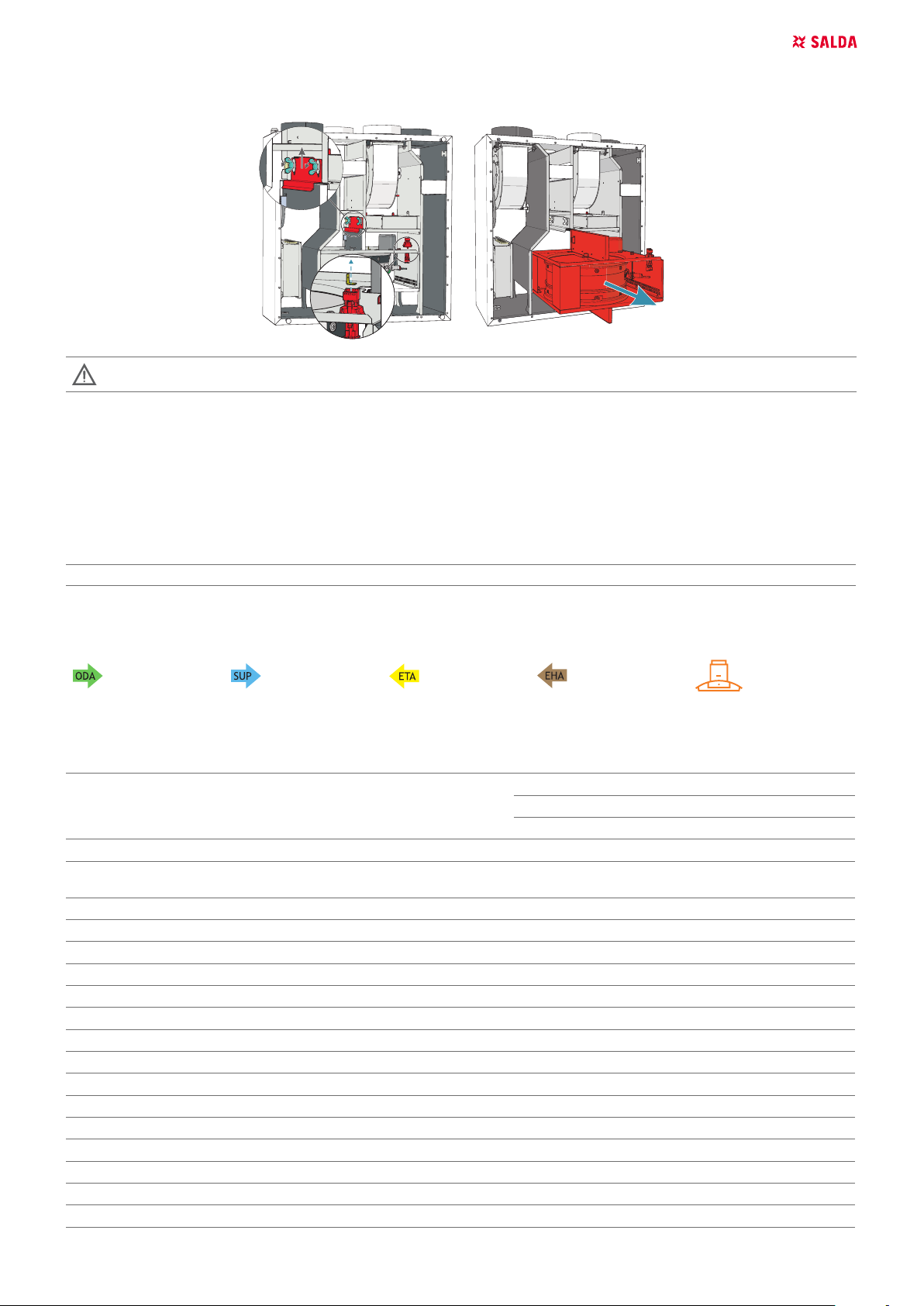

6.5. HEATER MAINTENANCE

• Electrical heater does not need to be serviced additionally. It is compulsory to change lters as described above.

• Heaters have 2 thermal protections: automatically self-resetting, which activates at +50°C and the manually restored, which activates at

+100°C.

• After the activation of the manually restored protection, the unit must be disconnected from the power supply. Wait until the heating elements

cool down and the fans stop rotating. After identifying and removing the reason of failure, to start the unit, press the “reset” button. The failure

can be identied only by a qualied professional.

• If necessary, the electric heater can be removed. Disconnect the electrical connector from the heater and remove the heater.

Figure 6.5.1 - Smarty 2R VER

1

a

b

a

2

3

Figure 6.5.2 - Smarty 2R VER plus

6.6. ROTOR MAINTENANCE

• Rotor heat exchanger must be serviced once a year.

• Ensure that the gaps of the heat exchanger are clean, the brushes are not worn, the belt drive is not worn and the clamping nodes of the rotor

heat exchanger are tight.

• Rotor heat exchanger can be easily removed from the unit. The power cord of the motor of the heat exchanger is disconnected. The clamp of

rotor heat exchanger section is released and raised and the heat exchanger is removed.

• The heat exchanger is cleaned using the solution of warm water and non-corrosive toward aluminum alkaline agent or the air stream. It is not

recommended to apply direct stream of liquid as it can harm the device.

16 | EN SMARTY RV v2019.12

• While cleaning, protect the motor of heat exchanger from entry of moisture and uids.

• After reinstalling the heat exchanger, fasten the heat exchanger section with the clamp. Connect the heat exchanger motor.

CAUTION: the heat exchanger can not be used when the lters are removed!

7. CONTROL

7.1. DEVICE CONTROL

Ventilation unit can be controlled using a remote control, web interface via MB-Gateway and building management system. More information about

the possibilities of controlling is provided in the table below.

MB-Gateway + WIFI + SALDA AIR app Stouch FLEX MCB SA-Control MB-Gateway BMS

+ + + + + Modbus RTU

7.2. MEANING OF THE SYMBOLS USED IN THE INSTRUCTIONS AND ON THE DEVICE

outdoor air supply air extract air exhaust air kitchen hood

7.3. DESCRIPTIONS OF THE FUNCTIONS

MCB

Functions

Date and time settings

System modes for easy and-user friedly control (Stand-by, Building protection,

Economy, Comfort)

BOOST function (Fans operate at highst speed)

Comfortable air temperature function

Cold/heat recovery

Heating season (from a selected date, 3-day temperature average or manually)

Dryness protection

Weekly/holiday schedule

User and service control levels

Manual air ow balancing

CO2 level indication and reduction function

Night cooling function

Relative humidity (RH) level indication and reduction function

Software and conguration update possibility

Supply air temperature control according to the extract air sensor

Monitoring function (all sensors and I/O) Mode switch (start/stop)

Manual components control

Smarty 2R VER Smarty 2R VER plus

E E

● ●

● ●

● ●

● ●

● ●

● ●

○ ○

● ●

● ●

● ●

○ ○

● ●

○ ○

● ●

● ●

● ●

● ●

EN | 17SMARTY RV v2019.12

Loading...

Loading...