SALDA Smarty 2 R VEL plus, Smarty 2 R VER, Smarty 2 R VEL, Smarty 2 R VER plus MOUNTING AND INSTALLATION INSTRUCTION

EN MOUNTING AND INSTALLATION INSTRUCTION

SMARTY R V

1. CONTENTS

2. SYMBOLS AND MARKING 4

3. SAFETY INSTRUCTIONS AND PRECAUTIONS 4

4. INFORMATION ABOUT THE PRODUCT 5

4.1. DESCRIPTION 5

4.2. DIMENSIONS AND WEIGHT 5

4.3. TECHNICAL DATA 5

4.3.1. AIR FLOW DIAGRAMS 7

4.4. OPERATING CONDITIONS 7

4.5. STANDARD PACKAGE OF COMPONENTS 8

4.6. DESCRIPTION OF COMPONENTS 8

4.7. SPARE PARTS 8

5. INSTALATION 9

5.1. RECEPTION OF GOODS 9

5.2. TRANSPORTATION AND STORAGE 9

5.3. UNPACKING 10

5.4. MOUNTING DIAGRAM 10

5.5. MOUNTING 11

5.5.1. MOUNTING ON THE WALL 11

5.5.2. PLACE REQUIREMENTS FOR THE EQUIPMENT AND MOUNTING POSITIONS 11

5.5.3. CONNECTION OF AIR DUCTS 12

5.5.4. AIR FLOW 12

5.5.5. CONNECTION OF THE KITCHEN HOOD 12

5.5.6. SHIELD INSTALLATION 13

5.6. CONNECTION OF THE UNIT TO ELECTRIC NETWORK 13

5.7. START-UP RECOMMENDATIONS 13

5.7.1. SYSTEM PROTECTION 13

5.7.2. PRE-STARTUP RECOMENDATIONS OF THE UNIT (IN THE PRESENCE OF THE ENDUSER) 14

6. MAINTENANCE 14

6.1. SAFETY INSTRUCTION 14

6.2. COVER OPENING 14

6.3. FILTERS MAINTENANCE 15

6.4. FANS MAINTENANCE 15

6.5. HEATER MAINTENANCE 16

6.6. ROTOR MAINTENANCE 16

7. CONTROL 17

7.1. DEVICE CONTROL 17

7.2. MEANING OF THE SYMBOLS USED IN THE INSTRUCTIONS AND ON THE DEVICE 17

7.3. DESCRIPTIONS OF THE FUNCTIONS 17

7.4. DESCRIPTION OF THE UNITS FUNCTIONS 18

7.4.1. SYSTEM MODES 18

7.4.2. SYSTEM CONTROL 19

7.4.3. SYSTEM STATES 20

7.4.4. SETTING DATE AND TIME 20

7.4.5. SUPPLY AIR TEMPERATURE CONTROL AND COMPENSATION 20

7.4.6. FAN CONTROL 21

7.4.7. “BOOST“ FUNCTION 21

7.4.8. WEEKLY SCHEDULE 21

2 | EN SMARTY RV v2019.12

7.4.9. HOLIDAY SCHEDULE 21

7.4.10. WINTER/SUMMER MODE 21

7.4.11. DRYNESS PROTECTION 21

7.4.12. NIGHT COOLING FUNCTION 22

7.4.13. CO2 REDUCTION FUNCTION 22

7.4.14. FILTER PROTECTIONS 22

7.4.15. SYSTEM MODE COMMUNICATION WITH EXTERNAL CONTACTOR 22

7.4.16. FAN SPEEDS FROM AN EXTERNAL SYSTEM CONTACTOR 22

7.4.17. HEAT EXCHANGER CONTROL 23

7.4.18. SYSTEM MONITORING 23

7.4.19. STAND-BY MODE BLOCKING 23

7.4.20. AIR FLOW ADJUSTMENT 23

7.4.21. MANUAL CONTROL OF COMPONENTS 23

7.4.22. CHANGING PASSWORDS 24

7.4.23. RESTORING FACTORY DEFAULTS 24

7.4.24. INDICATIONS OF FUNCTIONS, ALARMS AND WARNINGS 24

7.4.25. DISPLAY AND CONCELLATION OF ALARMS AND WARNINGS 24

7.4.26. EVENT LOG (HISTORY) 25

7.4.27. SYSTEM VERSIONS AND RUNNING TIME 26

8. ACCESSORIES 26

8.1. CONNECTION FO ACCESSORIES 27

8.1.1. SCHEMATIC OF CONTROLLER CONNECTIONS IN MCB 27

8.1.2. CO2 SENSOR OR CONNECTION OF HUMIDITY SENSOR RH 29

8.1.3. ROOM CO

TRANSMITTER INSTALLATION RECOMMENDATION 30

2

8.1.4. CO2 CONCENTRATION ACCORDING TO PETTENKOFER LIMIT 31

8.1.5. FIRE PROTECTION INPUT (NC) 31

8.1.6. EXTERNAL SWITCHES 31

8.1.7. CONNECTION OF REMOTE CONTROL PANEL OR MODBUS 32

8.1.8. “MCB TOOL” PROGRAM DESCRIPTION 32

8.2. THE PRINCIPAL CONNECTION SCHEME OF INTERNAL AND EXTERNAL COMPONENTS 34

8.3. ELECTRICAL CONNECTION OF THE UNITS 48

9. POSSIBLE FAULTS AND TROUBLESHOOTING 49

10. SENSORS AND THEIR TECHNICAL INFORMATION 49

11. INSPECTION OF THE VENTILATION SYSTEM 49

12. ECODESIGN DATA TABLE 50

13. DECLARATION OF CONFOMITY 51

14. WARRANTY 52

14.1. LIMITED WARRANTY COUPON 52

EN | 3SMARTY RV v2019.12

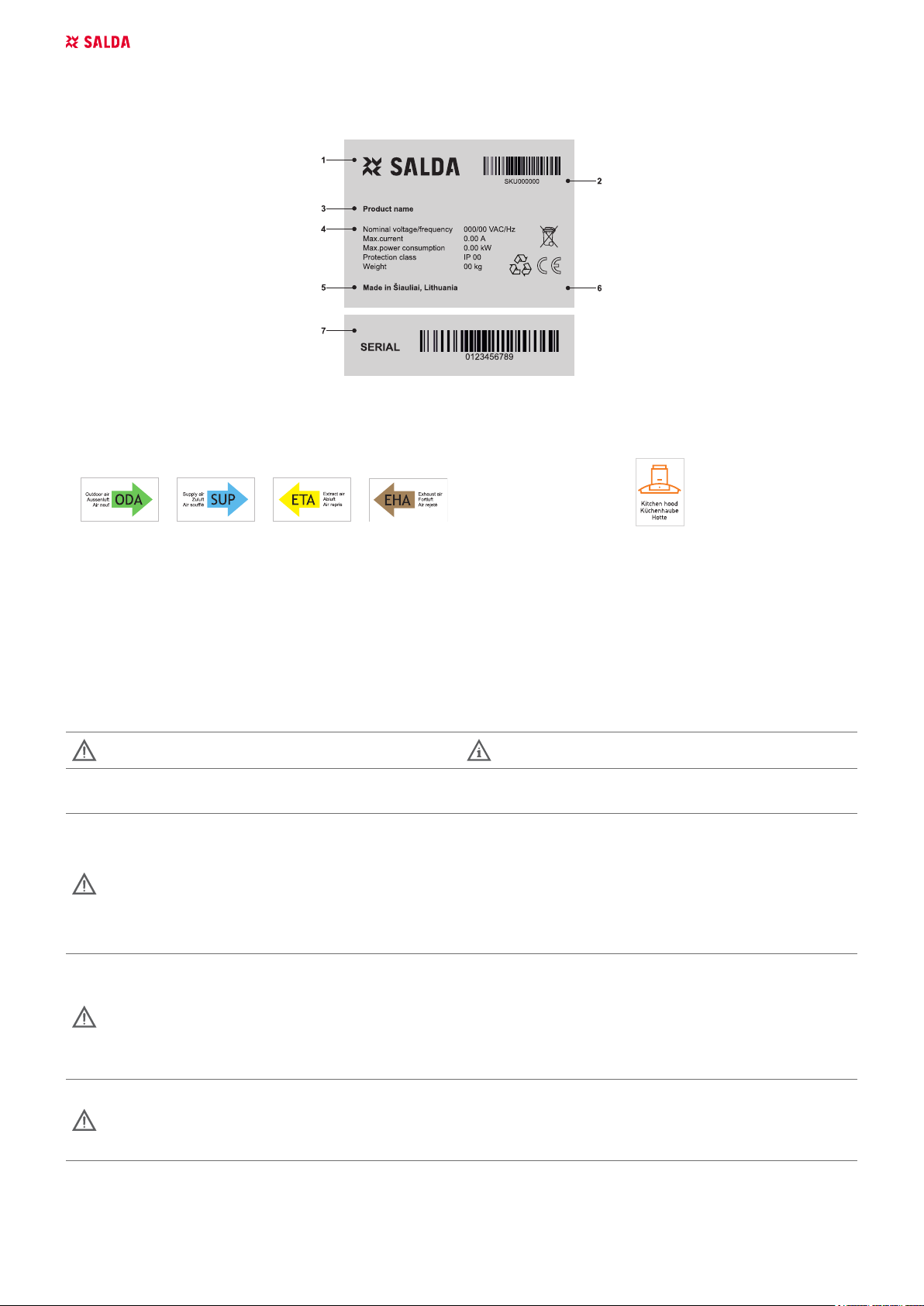

2. SYMBOLS AND MARKING

LN: XX000000

2019.01.01

Stick the auxiliary label on the unit (on an easily accessible place) or on the dashed place of a technical manual in order to keep the important

information about the unit.

LN: XX000000

2019.01.01

Figure 2.1 - Technical label

1 - Logo; 2 - Product code (SKU); 3 - Product name; 4 - Technical data; 5 - Production place; 6 - Batch number and production date; 7 - Serial

number.

Figure 2.2 - Indication for duct connection. Figure 2.3 - indication of kitchen hood

ODA - outdoor air; SUP - supply air; ETA - extract air; EHA - exhaust air.

3. SAFETY INSTRUCTIONS AND PRECAUTIONS

Read this instruction very carefully before installing and using this equipment. Installation, connection and maintenance should be carried out by

a qualifed technician and in accordance with the local rules and legal acts.

The company shall take no responsibility for the injuries suered by the people or for the damaged property, if the safety requirements are not

followed or the device is modifed without the permission of the manufacturer.

Warning – pay attention Additional information

Main safety rules

Danger

• Before performing any electricity or maintenance tasks make sure, that the device is disconnected from the mains, that all moving parts

of the device have stopped.

• Make sure that the fans can not be entered through air ducts or branch openings.

• If you notice liquids on electric parts or connections that bear voltage, stop the operation of the appliance.

• Do not plug the device into the mains, that diers from the one indicated on the label or on the housing.

• Voltage of the mains should comply with the electrotechnical parameters indicated on the label.

• The device should be earthed in accordance with the rules of installation of electric appliances. It is forbidden to turn on and use unearthed device. Follow the requirements of the device’s labels that indicate Danger.

Warnings

• Connection of electricity and maintenance of the device should be performed only by a qualied personnel, in accordance with the

manufacturer’s instructions and valid safety requirements.

• In order to reduce the risk during installation and maintenance, suitable protective clothes should be worn.

• Beware of sharp angles while performing installation and maintenance tasks.

• Do not touch heating elements until they haven’t cooled down.

• Some devices are heavy, thus one should be very careful while transporting and installing. Use suitable lifting equipment.

• While connecting electricity to the mains a circuit breaker of suitable size is necessary.

Warning!

• If the device is installed in a cold environment, make sure that all connections and tubes are properly isolated. Intake and discharge air

ducts should be isolated in all cases.

• Openings of the ducts should be covered during transportation and installation.

• Make sure not to damage the heater when connecting the piping of the water heater. For tightening up, use a wrench/spanner.

4 | EN SMARTY RV v2019.12

Before starting the equipment

320 mm

653 mm

• make sure, that there are no strange objects inside;

• manually check whether fans are not stuck or blocked;

• if rotary heat exchanger is installed in the device, make sure that it is not stuck or blocked;

• check the grounding;

• make sure that all components and accessories are connected in accordance with the project or provided instructions.

Danger: Fumes

Salda Antifrost system uses dis-balancing of the air ow and it may cause negative pressure in premises. Great care should be taken

when using at the same time in premises as another heating appliance what depend on the air in premises. Such appliances include

gas, oil, wood or coal-red boilers and heaters, replaces, continuous ow or other water heaters, gas hobs, cookers or ovens which

draw air in from the room and duct exhaust gases out through a chimney or extraction ducting. The heating appliance can be starved

of oxygen, impairing combustion. In exceptional cases harmful gases could be drawn out of the chimney or extraction ducting back

into the room. In this case we strictly recommend to turn o Salda Antifrost and use an external preheater for heat exchanger anti-frost

protection (see Salda Antifrost function on the Remote controller manual).

4. INFORMATION ABOUT THE PRODUCT

4.1. DESCRIPTION

HRU Residential is a residential air handling unit with a high eciency (up to 75 %) rotor heat exchanger with integrated electrical heater. The unit

provides ventilation in the home and takes the heat from the exhausted air. AHU complies with ErP 2018 requirements. The unit is operated by a

separate remote control panel or though separate MB-Gateway by PC. Remote control panel and MB-Gateway are optional and not included in

standard package.

HRU Residential operates within the limits of the airow diagrams and is suitable for indoor operation only. Required ambient temperatures must

be from -20 oC to +40 oC. For the cold climate zones (air temperatures below -20 oC), optional pre-heater is required.

Unsuitable for operation in pools, saunas and other similar premises.

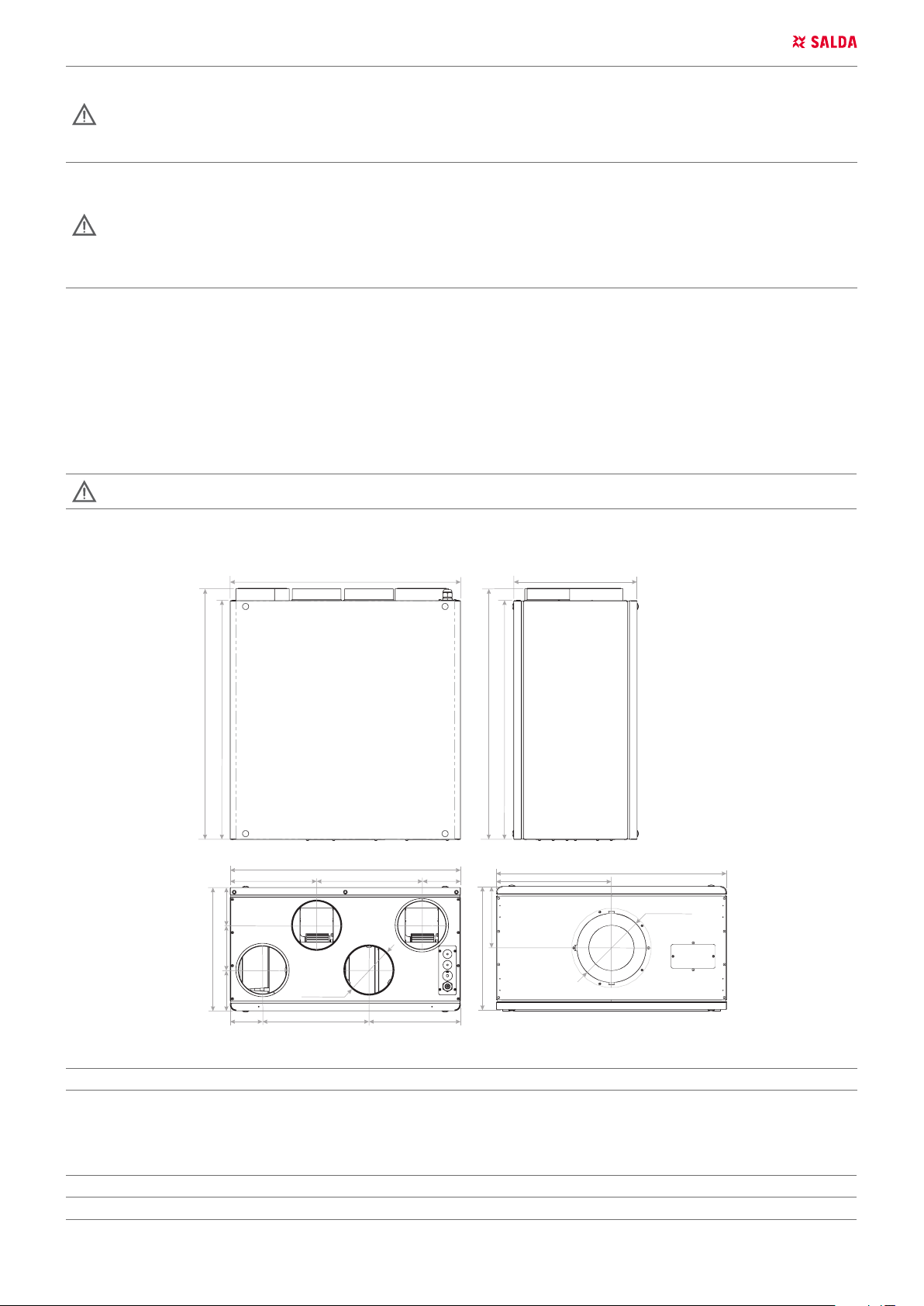

4.2. DIMENSIONS AND WEIGHT

620 mm

224,5 mm

98 mm

320 mm

116,3 mm

105,7 mm

84 mm

Ø 125 mm

276,3 mm

598 mm

598 mm

273,1 mm

237,7 mm

100,4 mm

653 mm

320 mm

160 mm

620 mm

286 mm

598 mm

Ø 175 mm

SMARTY

2R VER 2R VER PLUS

m [kg] 36 36

4.3. TECHNICAL DATA

SMARTY

Heat exchange

- phase/voltage [f/VAC/Hz] ~1/230/50 ~1/230/50

2R VER 2R VER PLUS

EN | 5SMARTY RV v2019.12

- power/current [kW/A] 0,006/0,1 0,006/0,02

-thermal eciency up to 75% 75%

Heater

- power/current [kW/A] 0,6/2,61 0,6/2,61

Exhaust air fan

- phase/voltage

- power/current

- speed

- protection class IP44 IP54

- control imput [VDC] 0-10 0-10

Supply air fan

- phase/voltage

- power/current

- speed

- protection class IP44 IP54

- control imput [VDC] 0-10 0-10

Total

- power/current [kW/A] 0,75/3,91 0,77/4,13

Automatic control integrated

Insulation of walls

Weight

Exhaust air lter

class class ePM10 55% ePM10 65%

width [mm] 270 270

height [mm] 86 85

depth [mm] 46 173

model MPL FMK

Supply air lter

class ePM10 55% ePM10 65%

width [mm] 270 270

height [mm] 86 85

depth [mm] 46 173

model MPL FMK

[f/VAC/Hz] ~1/230/50 ~1/230/50

[kW/A] 0,07/0,6 0,084/0,75

[min-1] 1380 3200

[f/VAC/Hz] ~1/230/50 ~1/230/50

[kW/A] 0,07/0,6 0,084/0,75

[min-1] 1380 3200

+ +

[mm] 20 20

[kg] 36 36

SMARTY 2R VER

Outdoor 62 22 54 61 48 41 27 20 14

Supply 70 29 61 68 59 60 55 49 43

Extract 62 22 54 61 49 36 28 19 14

Exhaust 69 28 60 67 58 58 52 48 41

Surrounding 49 10 40 48 36 31 30 30 29

Measured at 140 m3/h, 50 Pa

SMARTY 2R VER PLUS

Outdoor 60 18 50 58 55 44 28 16 12

Supply 66 23 55 63 61 56 55 48 40

Extract 60 19 50 58 54 40 35 24 17

Exhaust 66 23 55 62 60 56 53 46 36

Surrounding 48 3 34 44 45 32 31 30 29

Measured at 180 m3/h, 50 Pa

NOTE. Subject to technical modication

LWA TOTAL,

DB(A)

LWA TOTAL,

DB(A)

63 Hz 125 Hz 250 Hz 500 Hz 1 kHz 2 kHz 4 kHz 8 kHz

63 Hz 125 Hz 250 Hz 500 Hz 1 kHz 2 kHz 4 kHz 8 kHz

LWA, DB(A)

LWA, DB(A)

6 | EN SMARTY RV v2019.12

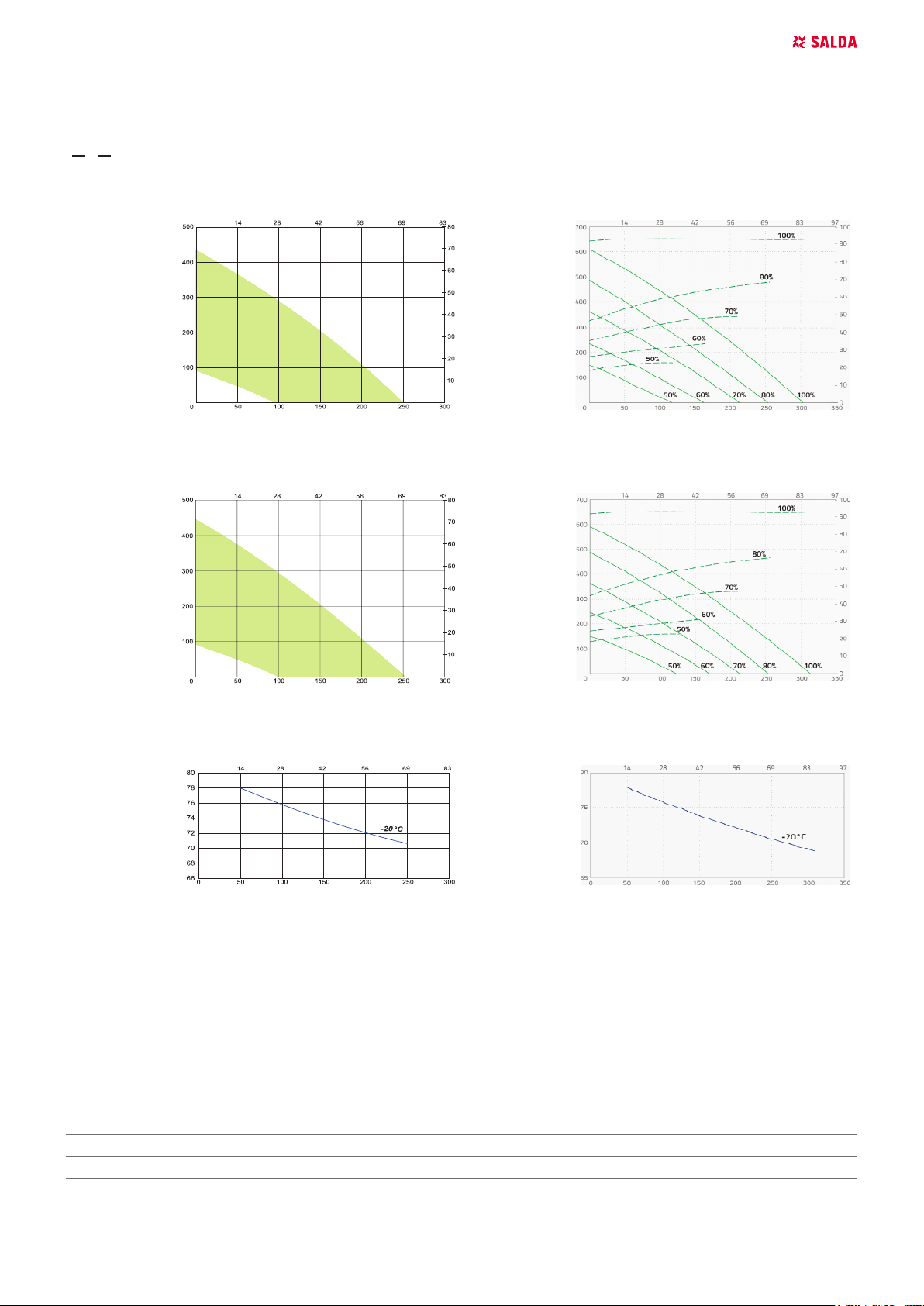

4.3.1. AIR FLOW DIAGRAMS

Performance

Power consumption

SMARTY 2R VER SMARTY 2R VER PLUS

Supply air Supply air

Exhaust air Exhaust air

Temperature eciency Temperature eciency

Temperature eciency (balanced mass ow):

Extract air = - 20 °C / 90 % RH

4.4. OPERATING CONDITIONS

• Unit is designed to operate only indoors.

• It is forbidden to use the unit in potentially explosive environment.

• Unit is designed to supply/extract only clean air (free of chemical compounds causing metal corrosion, of substances aggressive to zinc,

plastic and rubber, and of particles of solid, adhesive and bred materials).

OUTDOOR AIR

- temperature min./max.* [°C] -23 / +40

- humidity [%] 90

EXTRACT AIR

- temperature min./max.*

- max. humidity

[°C] +15 / +40

[%] 60

* Can be used at temperatures below -23 °C with pre-heater, the power of which is over 600W.

EN | 7SMARTY RV v2019.12

+40 C

10

9

10

9

o

+5 C

o

o

+40 C

o

-23 C

Figure 5.4.1 - operating conditions

4.5. STANDARD PACKAGE OF COMPONENTS

Standard package (without optional accessories) includes:

• Mounting brackets (mural and unit parts), Rubber seal for vibration damping.

• Screws M5x25 DIN7985 CT for mounting brackets - 3 pcs.; 5. Spring washers DIN127 5 - 3 pcs.

• Bushing caps - 8 pcs.

• Antivibration stick - 2 pcs.

• Key - 1 pcs.

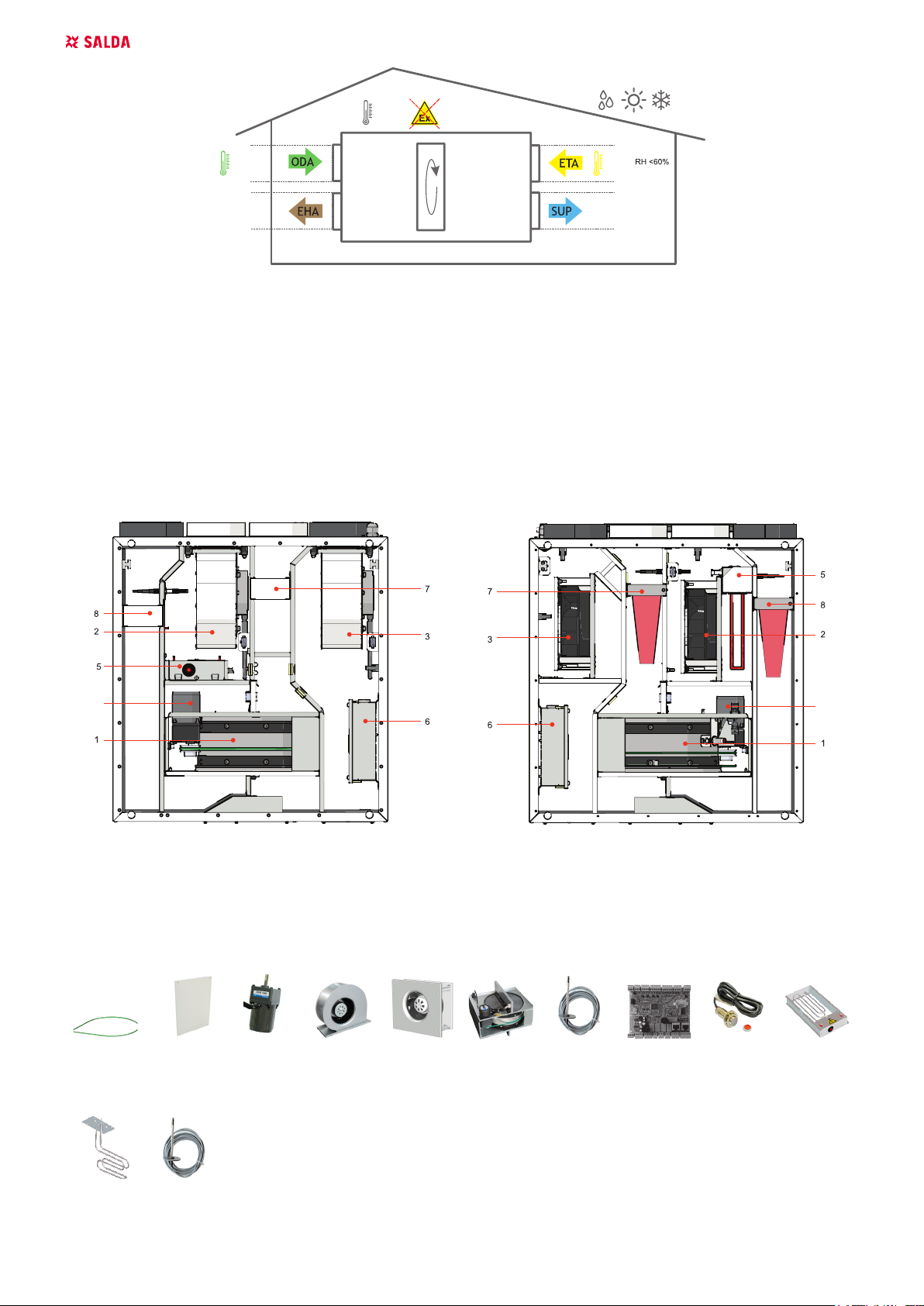

4.6. DESCRIPTION OF COMPONENTS

+40 C

+15 C

o

o

9

9

Figure 5.3.1 - Smarty 2R VER construction Figure 5.3.2 - Smarty 2R VER plus construction

1 - Plate/rotor heat exchanger; 2 - Supply fan; 3 - Exhaust fan; 4 - By-pass damper; 5 - Electrical/water heater/pre-heater; 6 - Control board; 7 -

Extract air lters (panel/pocket); 8 - Supply air lter (panel/pocket); 9 - Rotor motor.

4.7. SPARE PARTS

Rotor belt Door Rotor mo-

tor

Fan Fan Rotor box TJ MCB Hall H1A-

D12P24-1

SRR 0,6-1f

EC-1k

SRR V-0,6-

TL/TA

1f

8 | EN SMARTY RV v2019.12

Rotor box belt Rotor belt GNG00062

Smarty 2R VE door Door GNG00061

Rotor box motor Rotor motor ZVAR0133

Fan supply/exhaust

Fan

(Smarty 2R VER)

Fan

(Smarty 2R VER plus)

GPUVRA009

GVESMARTY001

Rotor box Rotor box GPURSD085_330

Temperature sensor 3 m TJ PJUT0063

Temperature sensor 1,5 m TL/TA PJUT0062

Controler MCB V1.0 ZED00985

Hall sensor Hall H1A-D12P24-1 PJUT0006

Electrical heater

SRR 0,6-1f EC-1k

(Smarty 2R VER)

SRR V-0,6-1f

(Smarty 2R VER plus)

ZESSRR028

ZESSRR032

5. INSTALATION

5.1. RECEPTION OF GOODS

Each device is thoroughly checked before transportation. When receiving goods it is recommended to check whether devices were damaged

during transportation. If damage to the device is identied, immediately inform the representatives of a transport company. Please inform a representative of the manufacturer, if any deviation from the order is noticed.

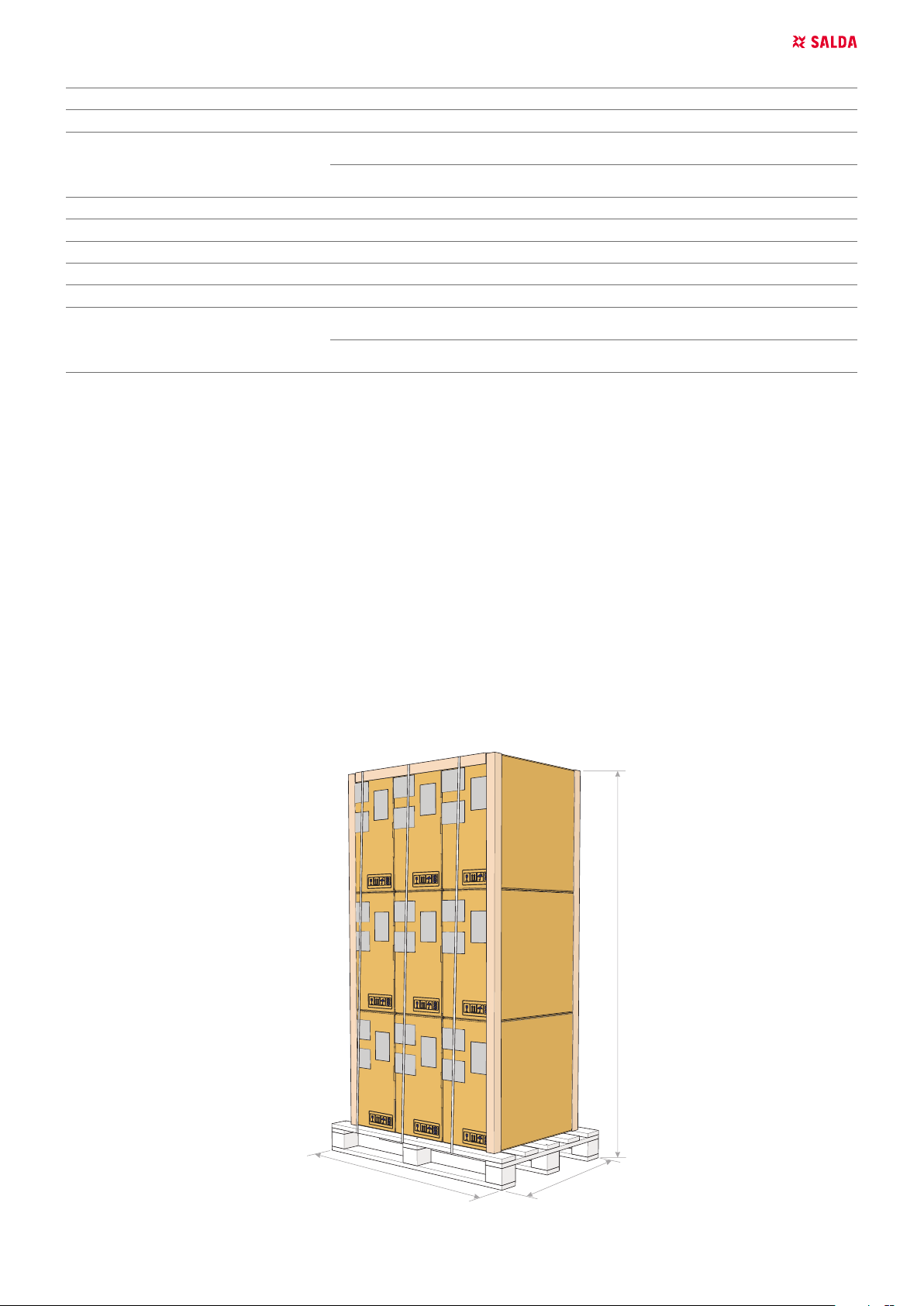

5.2. TRANSPORTATION AND STORAGE

• All units are packed in the factory to withstand regular conditions of transportation.

• Upon unpacking, check the unit for any damages caused during transportation. It is forbidden to install damaged units!!!

• The package is only for protection purpose!

• While unloading and storing the units, use suitable lifting equipment to avoid damages and injuries. Do not lift units by holding on power sup-

ply cables, connection boxes, air extract or exhaust anges. Avoid hits and shock overloads. Before installation units must be stored in a dry

room with the relative air humidity not exceeding 70% (at +20 °C) and with the average ambient temperature ranging between +5 °C and +30

°C. The place of storage must be protected against dirt and water.

• The units must be transported to the storage or installation site using forklifts.

• The storage is not recommended for a period longer than one year. In case of storage longer than one year, before the installation it is necessary to verify whether the bearings of fans and motor rotate easily (turn the impeller by hand) and if the electric circuit insulation is not damaged

or the moisture is accumulated.

2020 mm

1200 mm

780 mm

EN | 9SMARTY RV v2019.12

5.3. UNPACKING

M

CO

2

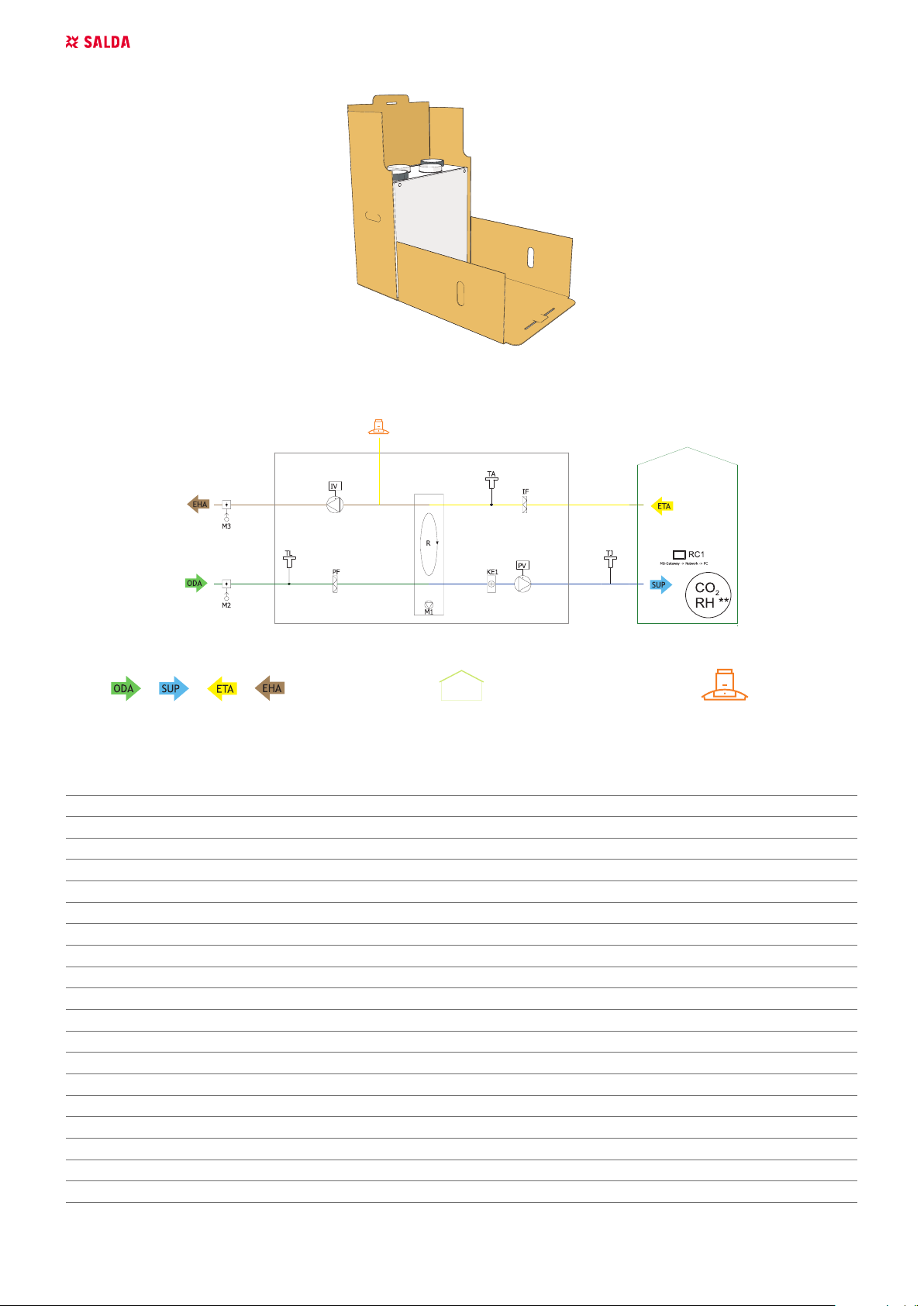

5.4. MOUNTING DIAGRAM

Figure 5.4.1 - Smarty RV (** Only one sensor can be used at a time)

Figure 5.4.2 - Indication for duct connection. Figure 5.4.3 - Ventilated premises Figure 5.4.4 - Air from cooing hood

LIST OF COMPONENTS

C Plate heat exchanger A1 Fire alarm damper actuator I

PV Supply air fan A2 Fire alarm damper actuator II

IF Extract air lter TJ Supply air temperature sensor

PF Supply air lter TL Outdoor air temperature sensor

IV Exhaust fan TE Exhaust air temperature sensor

KE1 Electric heater DTJ Extract air temperature and RH sensor

PE1 Electric pre-heater T2 Cooler changeover thermostat

KV2 Water pre-heater TV2 Water preheater temperature sensor

KV3 Water cooler TV3 Water cooler temperature sensor

DX DX cooler U3 PV pressure transmitter

M1 By-pass damper U4 IV pressure transmitter

M2 Outdoor air damper actuator CO

M3 Exhaust air damper actuator RH RH sensor*

M5 Water cooler valve motor PC Computer

M12 Water pre-heater valve actuator RC1 Stouch or SA-Control remote control panel

M14 Water cooler circulation pump RC2 Stouch, Flex or SA-Control remote control panel

M15 DX cooler valve actuator MB-Gateway Network module

M16 Water pre-heater circulation pump NET Network

R Rotor heat exchanger

2

CO2 sensor*

10 | EN SMARTY RV v2019.12

POSSIBLE PCB INPUTS/OUTPUTS

FA Fire alarm H1 Working indication output

FPP Fireplace protection H2 Alarm indication output

System mode switch (START/STOP) Fans speed switch (BOOST)

* Compone

5.5. MOUNTING

• Installation should only be performed by qualied and trained sta.

• When connecting air ducts, consider the notices indicated on the casing of the unit.

• Before connecting to the air duct system, the connection openings of ventilation unit should be closed.

• Do not connect the bends close to connection anges of the unit. The minimum distance of the straight air duct between the unit and the rst

branch of the air duct in the supply air duct must be 1xD, in air exhaust duct 3xD, where D is diameter of the air duct.

• It is recommended to use the accessories-holders. This will reduce vibration transmitted by the unit to the air duct system and environment.

• Enough space must be left for opening of the maintenance door and lter covers.

• If the installed ventilation unit is adherent to the wall, it may transmit noise vibrations to the premises. Though the level of noise caused by the

fans is admissible, it is recommended to mount the unit at the distance of 400 mm from the nearest wall. If it is not possible, the mounting of

the unit is recommended on the wall of the room where the level of noise is not important.

• Ducts are connected to the unit in such way that they could be easily disassembled and the heater could be removed from the unit when

performing service or repair works.

5.5.1. MOUNTING ON THE WALL

90

90

30 mm

a c d

b

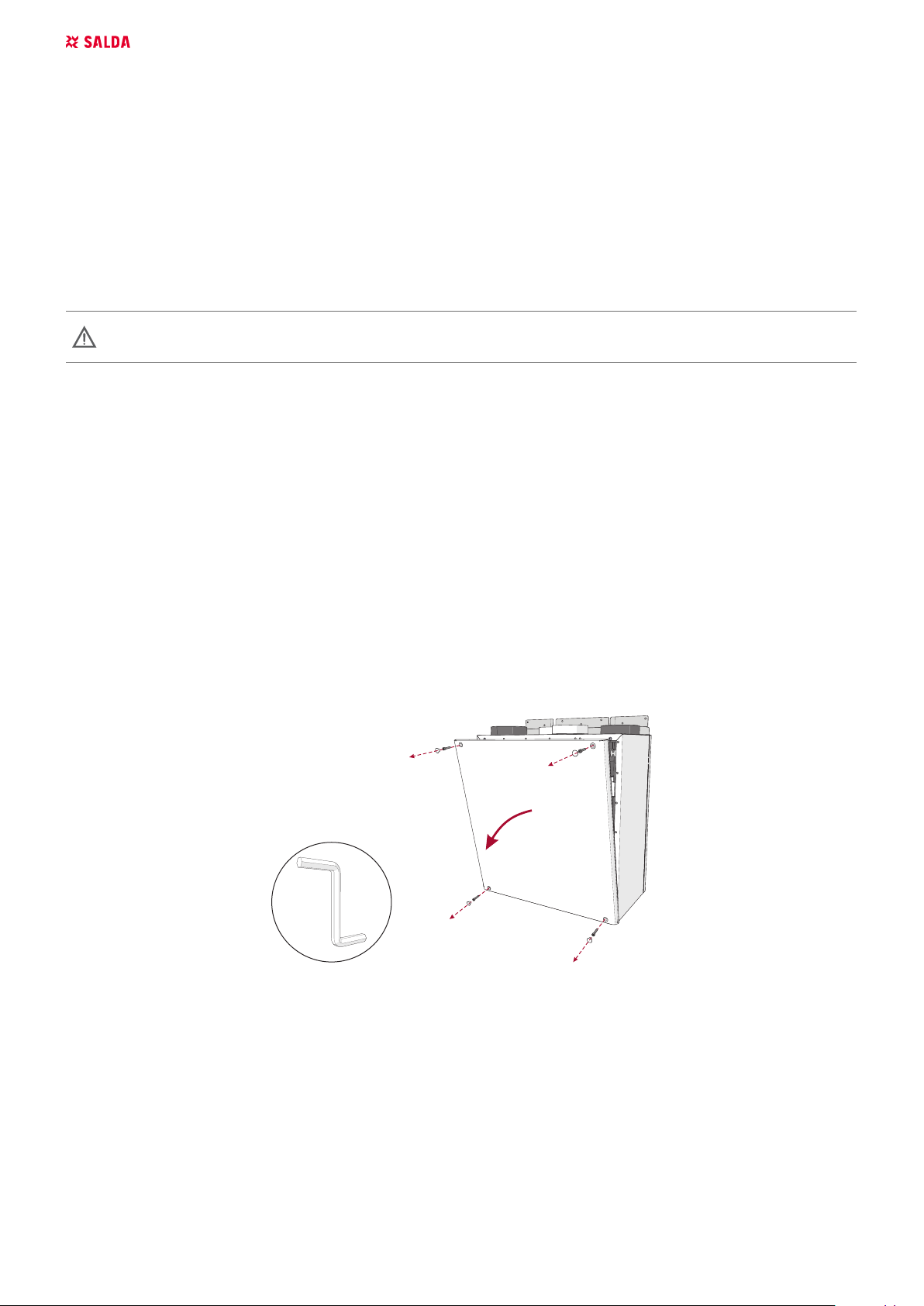

Mounting on the wall:

a) To reduce the vibration stick the insulating tape on the unit‘s casing side which touches the wall before mounting the unit on the wall.

b) The unit has to be mounted on the mounting brackets.

c) AHU mounting drawing.

d) After the unit is mounted two wall bracket tabs has to be folded to 90o angle by pliers to avoid the accident fall of the unit.

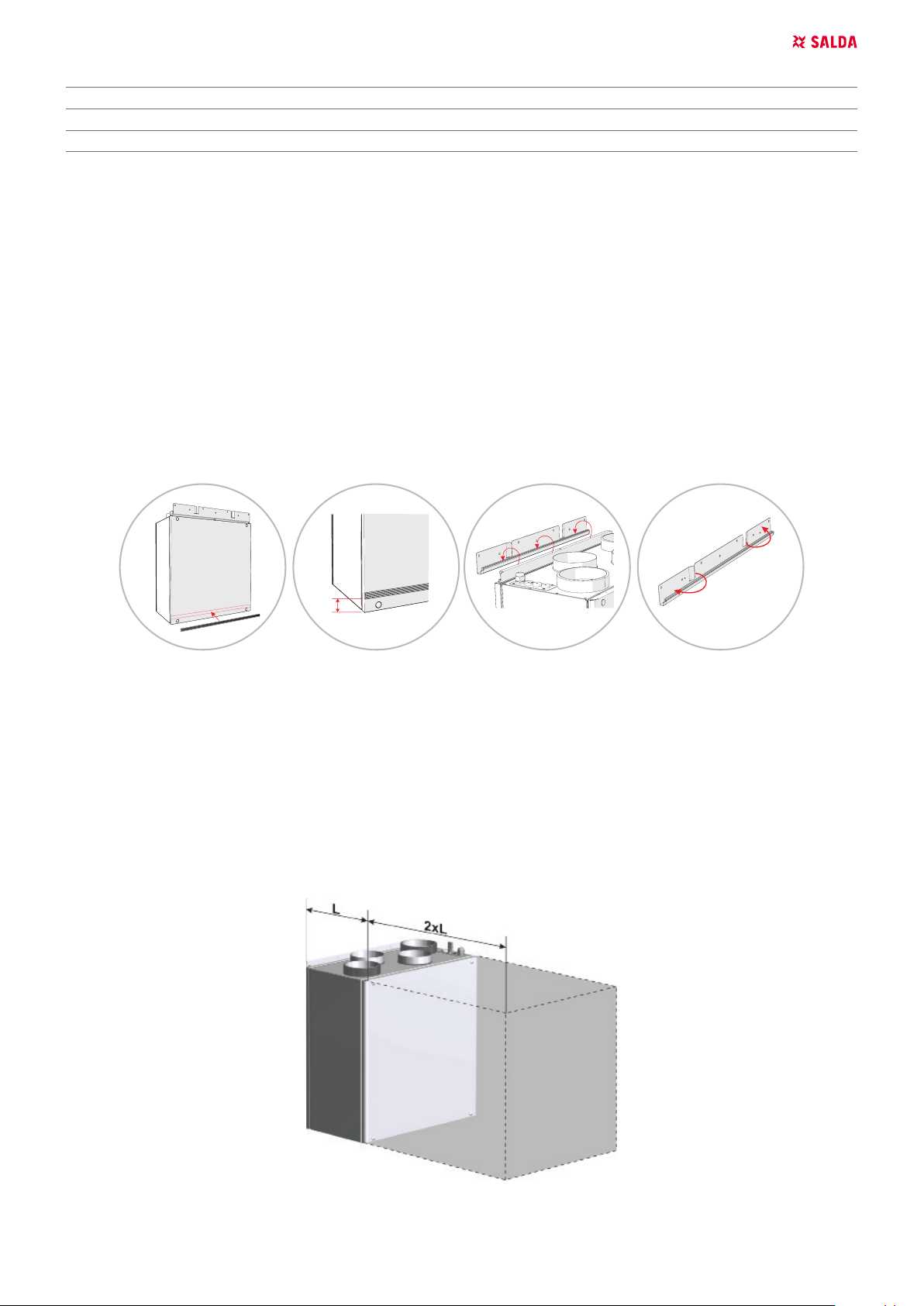

5.5.2. PLACE REQUIREMENTS FOR THE EQUIPMENT AND MOUNTING POSITIONS

1. The installation position only in the horizontal direction.

2. Install the supporting legs.

3. AmberAir Compact are assembled from separate sections.

4. They must be adjusted without a gradient.

5. Leave space in the front (2xL) that it would be sucient to open the doors and to remove or install a required component.

EN | 11SMARTY RV v2019.12

5.5.3. CONNECTION OF AIR DUCTS

• Connected air ducts must be straight and have their own xing.

• Make sure that the fans can not be accessed through air duct heads. If it is possible to access the fan, protective grid should be installed. You

can choose it in our website.

• Do not reduce the diameter of the piping near air inlet or exhaust ducts. If you want to reduce the speed of air in the system, drop of pressure

and noise level, you can increase the diameter.

• In order to reduce the level of the noise in the air supply system, install silencers (see chapter on their installation).

• In order to reduce air loss in the system, the air ducts and prole parts should be of class C and higher. Their catalog can be found in our

website.

• If air handling unit is installed in heated premises, outdoor and exhaust air ducts must be insulated in order to avoid heat loses and condensing.

If AHU is installed outdoors, it’s recommended to insulate all the air ducts.

• It is recommended to maintain a distance of up to 8 meters between air intake and air exhaust ducts. Air supplying system should be installed

further from potential air pollution sources.

• Use holders while installing air ducts next to the ventilation equipment. They suppress vibration and ensure a rm installation of various system

parts.

• Necessary holders can be found in our catalog or website.

• A common mistake is that air ducts are attached to improper airow connection. On the ventilation equipment there are signs, indicating the air

duct to be connected. Before starting the system carefully check whether the work was performed properly.

5.5.4. AIR FLOW

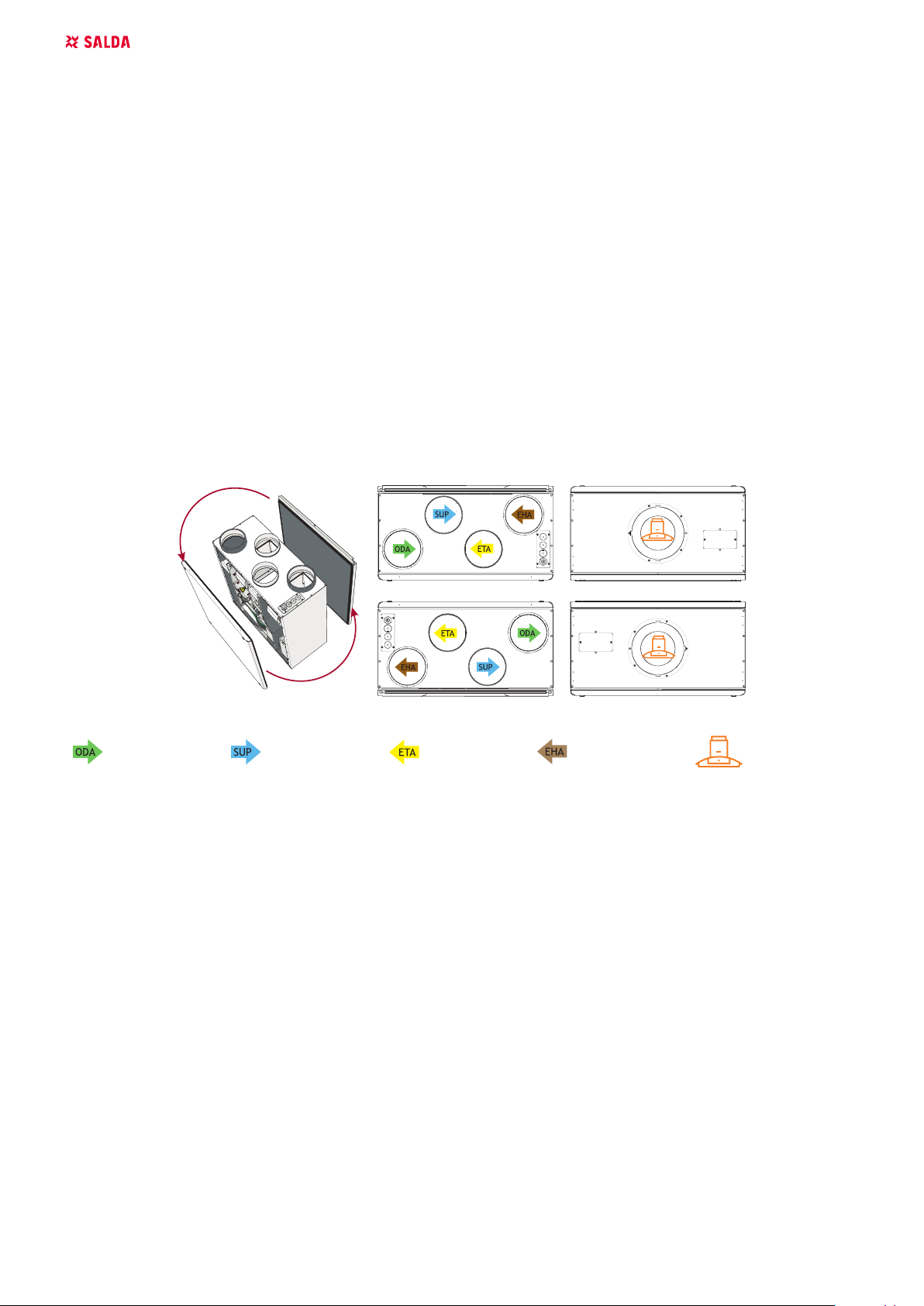

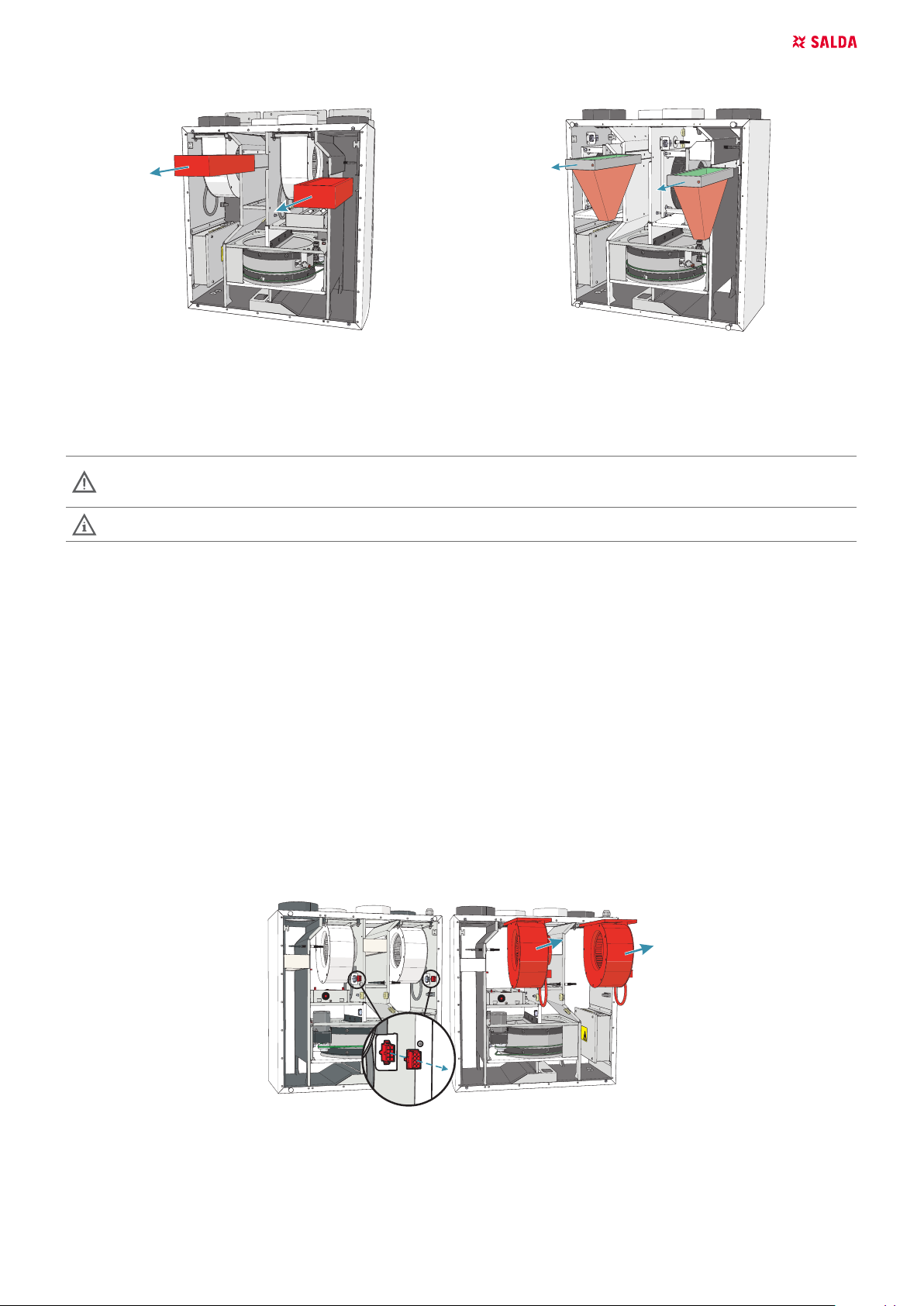

The maintenance side can be changed for the ventilation unit, i.e. it can be mounted with the left ambient air inlet or the right ambient air inlet. That

can be implemented by switching over the back door and the front door. The default version of the ventilation unit is right.

Converted service side to Left version

Standard version (Right)

outdoor air supply air extract air exhaust air kitchen hood

5.5.5. CONNECTION OF THE KITCHEN HOOD

• Installation works must be performed only by trained and qualied personnel.

• If you have any questions regarding the save installation and use of the product, please contact the manufacturer or the representative.

• Before installing the unit, unscrew the lid a covering the opening for connection of the kitchen hood and remove the middle part of the insulating ring.

• Cut the connecting opening as indicated on the insulation material.

• Carefully remove the lid, which covers the electric connection for the connection of the electrical part of the kitchen hood to the ventilation unit.

• Mount the hood to the ventilation unit. Fasten with self-tapping screws to the designated connection points.

• It is necessary to ensure the tight and reliable connection of the air ducts of the kitchen hood to the ventilation unit and the electrical contact

of the control circuit.

• The subsequent installation of the device is performed according the description in chapter “Mechanic installation”.

• Properties, assembly, control, use and maintenance of the kitchen hood are described in its instalation manual.

12 | EN SMARTY RV v2019.12

Use cooker hood supplied by our company only. Equipment is not tested with other cooker hoods and company holds no

responsibility for malfunction or failures of the equipment in this case.

5.5.6. SHIELD INSTALLATION

5.6. CONNECTION OF THE UNIT TO ELECTRIC NETWORK

• Supply voltage to the unit must be connected by a qualied specialist following the manufacturer’s instructions and eective safety instructions.

• The unit’s power network voltage must correspond to electrotechnical parameters of the unit indicated in the technical decal.

• The unit’s voltage, power and other technical parameters are provided in the unit’s technical decal (on the unit casing). The unit must be con-

nected to the voltage plug socket of the grounded power network in compliance with the eective requirements.

• The unit must be earthed according to the rules on installing electrical equipment.

• It is prohibited to use extension wires (cables) and power network plug socket distribution devices.

• Prior to carrying out any ventilation unit installation and connection activities (until its hand-over to the customer), the unit must be disconnected from the power network.

• After installation of the ventilation unit, the power network plug socket must be accessible at any time and disconnection from the power network is performed through the two-pole circuit breaker (by disconnecting phase pole and neutral).

• The unit must be thoroughly checked against damages (execution, control, measurement nodes) during transportation before it is connected

to the power network.

• The power cable can be replaced only by a qualied specialist upon the evaluation of the rated power and current.

The manufacturer does not assume any liability for personal injuries and property damage due to non-conformance with

the provided instructions.

5.7. START-UP RECOMMENDATIONS

5.7.1. SYSTEM PROTECTION

Control system of the unit has an integrated protection against short-circuit for these functional components. The controllers have the following

protections:

MCB

F1, F2 - 1A(5x20) MCB protection

To ensure safe maintenance of the unit, it is necessary to remove the plug from the power network.

EN | 13SMARTY RV v2019.12

5.7.2. PRE-STARTUP RECOMENDATIONS OF THE UNIT (IN THE PRESENCE OF THE ENDUSER)

Prior to start-up the system must be thoroughly cleaned. Check whether:

• operation systems and unit elements as well as automation and automation devices were not damaged during installation,

• all consumers are connected to power supply and t for service,

• all necessary automation elements are installed and connected to power supply and MCB terminal blocks,

• cable connection to MCB terminal blocks comply with the existing power connection diagrams,

• all electrical equipment protection elements are properly connected (if they are additionally used),

• cables and wires correspond to all applicable safety and functional requirements, diameters, etc.,

• earthing and protection systems are properly installed,

• condition of all seals and sealing surfaces is proper.

6. MAINTENANCE

Unplug unit from mains before opening the door (disconnect the power plug from the outlet or if there is a two-pole automatic

circuit breaker installed – disconnect it as well. It is necessary to ensure that it won’t be turned on by third parties) and wait

until the full stop of the fans (for about 2 min.).

6.1. SAFETY INSTRUCTION

• Do not use the unit for purposes other than its’ intended.

• Do not disassemble or modify the unit in any way which may lead to mechanical failure or injury.

• Use special clothing and be careful while performing maintenance and repair jobs – the unit’s and its components’ edges may be sharp and cutting.

• Do not wear loose clothing that could be entangled in to operating unit.

• If a outside object enters the unit, immediately disconnect power source. Before removing object, make sure that any mechanical motion has

stopped, the heater has cooled down and the restart is not possible.

• Do not connect to any other power source than indicated on the model label.

• Do not place or operate unit on unsteady surfaces and mounting frames.

• Mount the unit rmly to ensure safe operating.

• Never use this unit in the environment containing any explosive or aggressive elements.

• Do not use the unit if external connections are broken or damaged. If there are any defects, stop operating the unit and replace the damaged parts

immediately. That can be performed only by qualied electrician.

• Do not use water or another liquid to clean electrical parts or connections.

• If you notice condensat on electrical parts or connections, stop operating the unit.

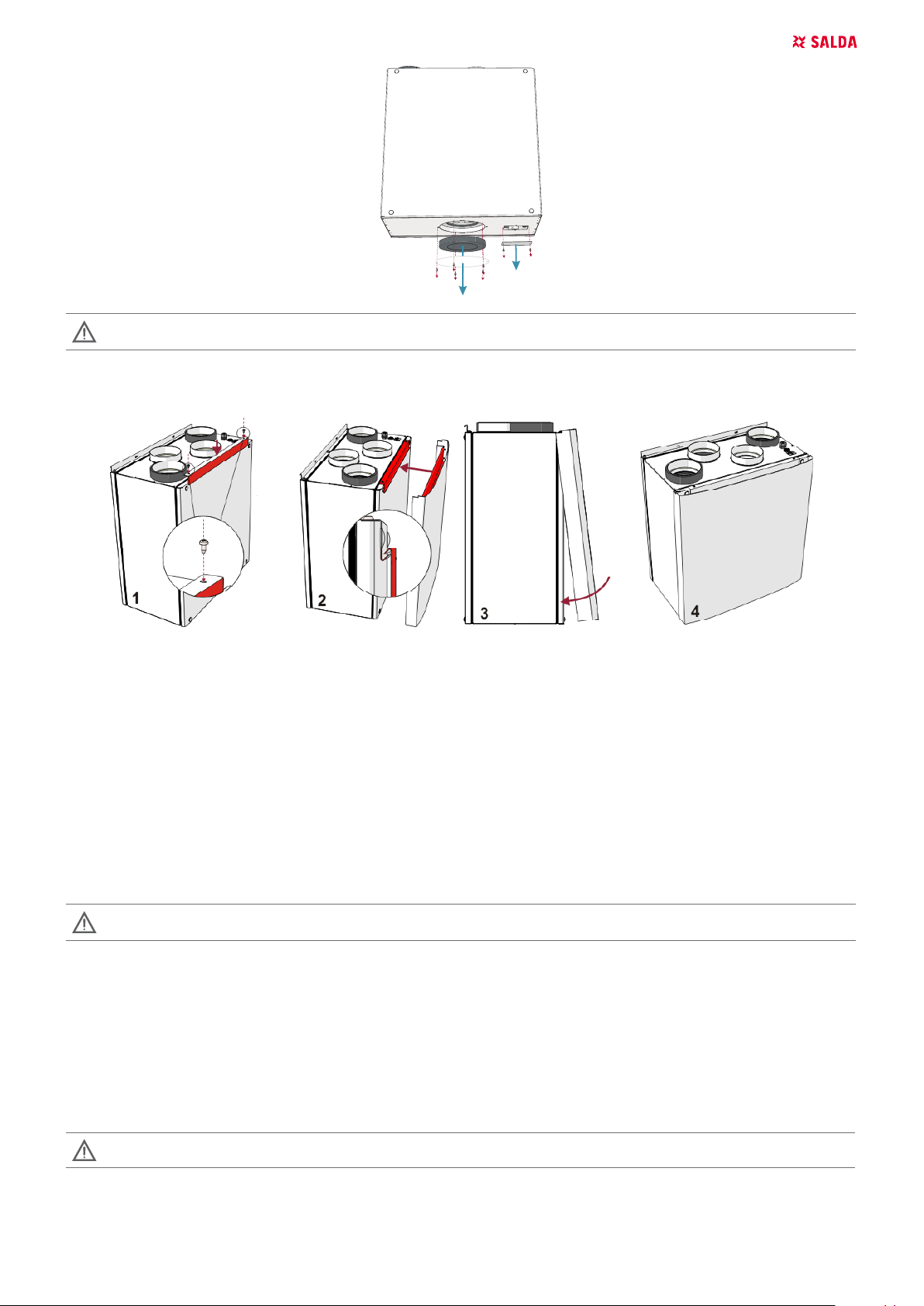

6.2. COVER OPENING

14 | EN SMARTY RV v2019.12

6.3. FILTERS MAINTENANCE

Figure 6.3.1 - Smarty 2R VER Figure 6.3.2 - Smarty 2R VER plus

Dirt increases air resistance in the lter, therefore less air is supplied into the premises.

Taking o the lters:

• Open cover.

• Remove the lter.

Changing lters, lters reload timer control. Description of remote control panel functions is provided in the remote control

panel technical documentation or on the website www.salda.lt.

Allowed to operate the unit without lters!

It is recommended to change the lters every 3-4 months, or in accordance to lter timer.

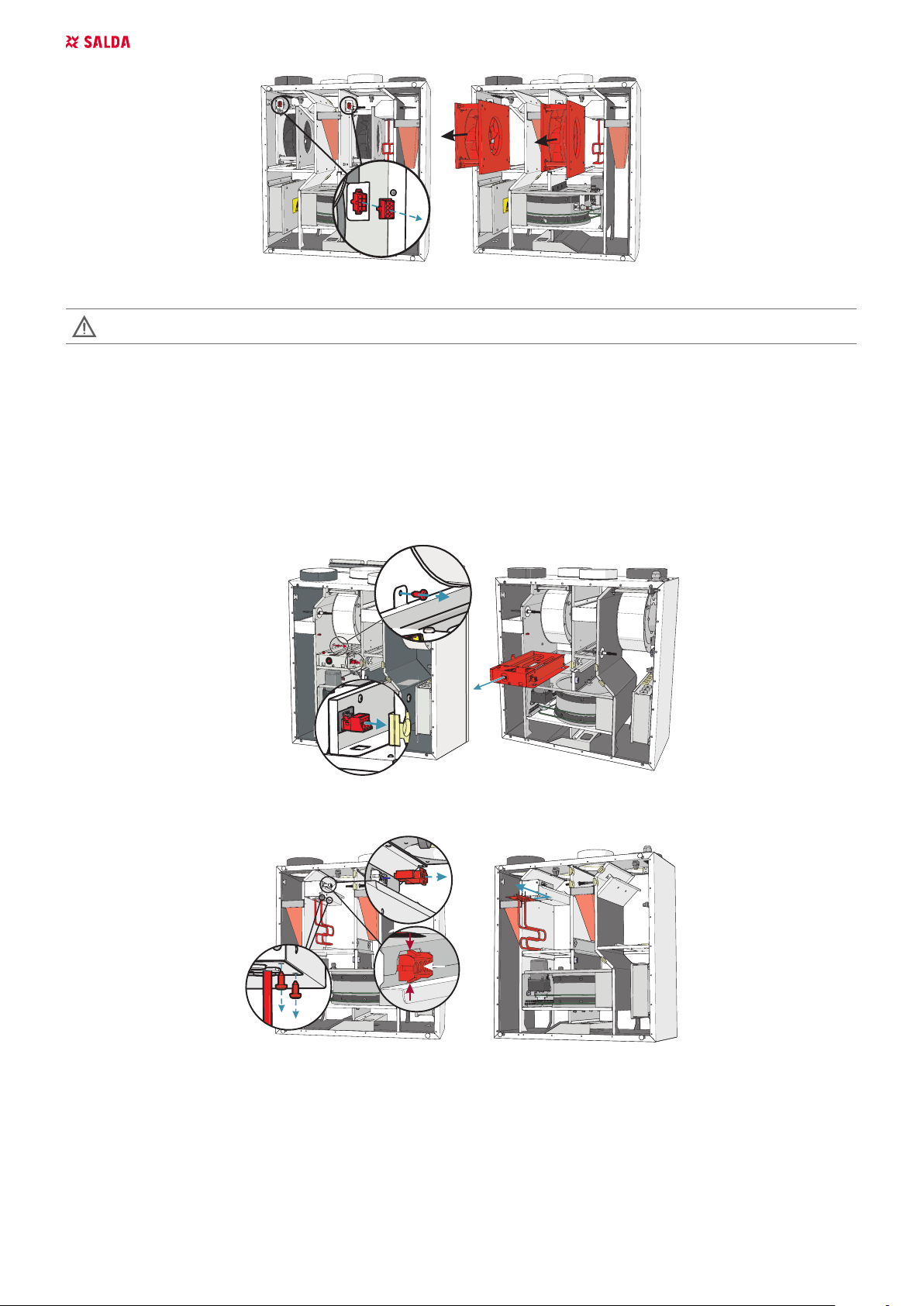

6.4. FANS MAINTENANCE

• Maintenance should be performed only by experienced and trained sta.

• The fan should be inspected and cleaned at least once a year.

• Be sure the fan is disconnected from power source before performing any maintenance or repair.

• Proceed to maintenance and repair after any rotation in the fan is stopped.

• Observe sta safety regulations during maintenance and repair.

• The motor is of heavy duty ball bearing construction. The motor is completely sealed and requires no lubrication for the life of the motor.

• Detach fan from the unit.

• Impeller should be specially checked for buil-up material or dirt which may cause an imbalance. Excessive imbalance can lead to accelerated

wear on motor bearings and noise, vibration.

• Clean impeller and inner housing with mild detergent, water and damp, soft cloth.

• Do not use high pressure cleaner, abrasives, sharp instruments or caustic solvents that may scratch or damage housing and impeller.

• Do not plunge the motor into any uid while cleaning impeller.

• Make sure, that impeller ’s balance weights are not moved.

• Make sure the impeller is not hindered.

• Mount the fan back into the unit. Connect the fan to power supply source.

• If after maintenance the fan does not start or stop itself, contact the producer. Malfunction of the fan can be identied according to the pressure

in the system (when pressure switches are connected). When there is a fault in fans’ motor, any separate notice is shown on the control panel.

Figure 6.4.1 - Smarty 2R VER

EN | 15SMARTY RV v2019.12

Figure 6.4.2 - Smarty 2R VER plus

Be sure the unit is disconnected from power source before performing any maintenance or repair.

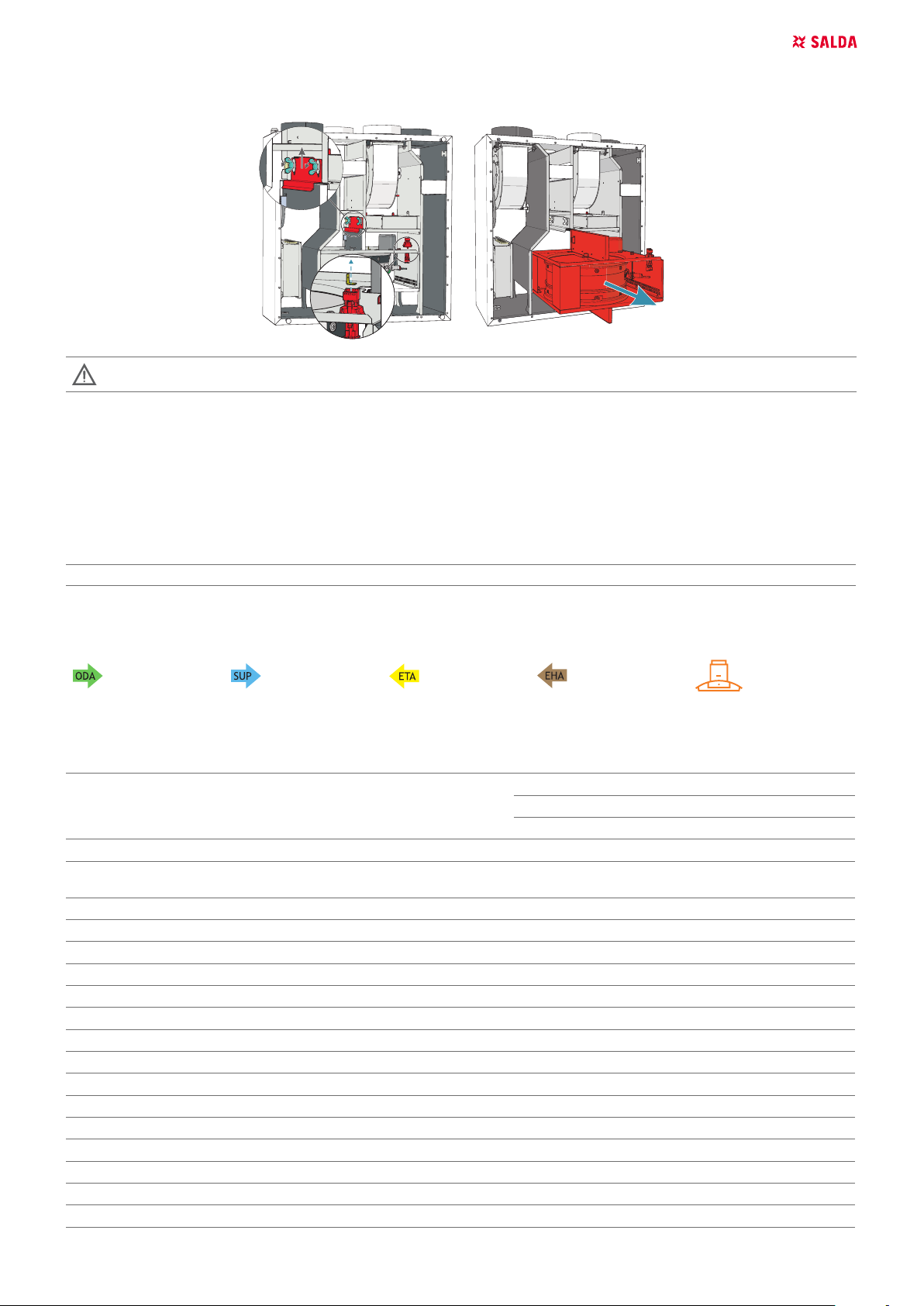

6.5. HEATER MAINTENANCE

• Electrical heater does not need to be serviced additionally. It is compulsory to change lters as described above.

• Heaters have 2 thermal protections: automatically self-resetting, which activates at +50°C and the manually restored, which activates at

+100°C.

• After the activation of the manually restored protection, the unit must be disconnected from the power supply. Wait until the heating elements

cool down and the fans stop rotating. After identifying and removing the reason of failure, to start the unit, press the “reset” button. The failure

can be identied only by a qualied professional.

• If necessary, the electric heater can be removed. Disconnect the electrical connector from the heater and remove the heater.

Figure 6.5.1 - Smarty 2R VER

1

a

b

a

2

3

Figure 6.5.2 - Smarty 2R VER plus

6.6. ROTOR MAINTENANCE

• Rotor heat exchanger must be serviced once a year.

• Ensure that the gaps of the heat exchanger are clean, the brushes are not worn, the belt drive is not worn and the clamping nodes of the rotor

heat exchanger are tight.

• Rotor heat exchanger can be easily removed from the unit. The power cord of the motor of the heat exchanger is disconnected. The clamp of

rotor heat exchanger section is released and raised and the heat exchanger is removed.

• The heat exchanger is cleaned using the solution of warm water and non-corrosive toward aluminum alkaline agent or the air stream. It is not

recommended to apply direct stream of liquid as it can harm the device.

16 | EN SMARTY RV v2019.12

• While cleaning, protect the motor of heat exchanger from entry of moisture and uids.

• After reinstalling the heat exchanger, fasten the heat exchanger section with the clamp. Connect the heat exchanger motor.

CAUTION: the heat exchanger can not be used when the lters are removed!

7. CONTROL

7.1. DEVICE CONTROL

Ventilation unit can be controlled using a remote control, web interface via MB-Gateway and building management system. More information about

the possibilities of controlling is provided in the table below.

MB-Gateway + WIFI + SALDA AIR app Stouch FLEX MCB SA-Control MB-Gateway BMS

+ + + + + Modbus RTU

7.2. MEANING OF THE SYMBOLS USED IN THE INSTRUCTIONS AND ON THE DEVICE

outdoor air supply air extract air exhaust air kitchen hood

7.3. DESCRIPTIONS OF THE FUNCTIONS

MCB

Functions

Date and time settings

System modes for easy and-user friedly control (Stand-by, Building protection,

Economy, Comfort)

BOOST function (Fans operate at highst speed)

Comfortable air temperature function

Cold/heat recovery

Heating season (from a selected date, 3-day temperature average or manually)

Dryness protection

Weekly/holiday schedule

User and service control levels

Manual air ow balancing

CO2 level indication and reduction function

Night cooling function

Relative humidity (RH) level indication and reduction function

Software and conguration update possibility

Supply air temperature control according to the extract air sensor

Monitoring function (all sensors and I/O) Mode switch (start/stop)

Manual components control

Smarty 2R VER Smarty 2R VER plus

E E

● ●

● ●

● ●

● ●

● ●

● ●

○ ○

● ●

● ●

● ●

○ ○

● ●

○ ○

● ●

● ●

● ●

● ●

EN | 17SMARTY RV v2019.12

Functional units

Fans

Speed synchronous/asynchronous 0-10V control

Electrical heater

Overheat protection (additional protection software)

Filter pollution minitoring

Rotor

Air temperature sensors

temperature sensor failure protection (with emergency mode)

Dampers

Emergency signals and inputs/outputs

Remote controllers

Switching the speed of the fans

Soft start and stop

Protection by RPM

On/o control

By lter timer

On/o control

Motor belt levers protection

Rotation speed indication

Service timer

Supply air temperature sensor

Outdoor air temperature sensor

Extract air temperature sensor

open/close

Fire protection input ● ●

Congurable digital inputs ● ●

Stouch ○ ○

SA-Control

MB Gateway

● ●

● ●

● ●

● ●

● ●

● ●

● ●

● ●

● ●

● ●

● ●

● ●

● ●

● ●

● ●

○ ○

○ ○

○ ○

● standard feature

○ for the feature to function an accessory is needed

- it is not possible to use the feature

7.4. DESCRIPTION OF THE UNITS FUNCTIONS

All functions indicated in this section are installed in the software of the control board. However, operation and control of the device depends on

the following:

1. Selected control panel. Full functionality and conguration possibility can be assured only by MB-Gateway web interface SA-Control, SALDA

AIR app.

2. Connected external devices: external heaters, dampers, sensors and etc. (see the description of the acquired air handling system).

3. Internal components of the device: type of heat exchanger (plate or rotor), integrated dampers, sensors and etc. (see components of the

chosen device).

4. Control board type.

Air Handling Unit uses MCB board.

The unit can be congured only with SA-Control remote con trol panel, MB-Gateway web application or SALDA AIR app.

The following control board functions can be fully con trolled only with SA-Control remote con trol panel, MB-Gateway web

application or SALDA AIR app. In case of Stouch remote con trol panel use the description of remote control panel functions

for MCB control board.

7.4.1. SYSTEM MODES

• Stand-by;

• Building protection;

• Economy;

• Comfort.

18 | EN SMARTY RV v2019.12

In Stand-by mode the system is shut down for a permissible period (based on the Stand-by mode blocking function settings).

The Building protection mode is designed to protect premises against moisture accumulation. The system operates at speed 1. Based

on manufacturer’s parameters (by default) this mode controls the temperature (the desirable one is indicated), but, if necessary, it can

be switched o, i.e. to activate the energy saving mode. Also, if necessary, full recirculation function is activated. (ADJUSTER › USER SETTINGS

› BUILDING PROTECTION MODE TEMPERATURE or USER › MENU › SETTINGS › BUILDING PROTECTION).

After activating the energy saving mode, temperature is maintained only by the heat exchanger. It will seek to maintain the current

temperature in the room; however, if the supply air temperature falls below the minimal supply air temperature level, heaters will be

activated and they will maintain a temperature one degree above the minimum. Also, if the supply air temperature rises above the

maximal supply air temperature level, coolers will be activated and they will maintain a temperature one degree below the maximum.

Economy mode is designed to save energy when people are absent from the premises. The system operates at speed 2. Based on

manufacturer’s parameters this mode controls the temperature maintaining (the desirable one is indicated), but, if necessary, it can

be switched o, i.e. to activate the energy saving mode. Also full recirculation function is activated. (ADJUSTER › USER SETTINGS › ECONOMY MODE

TEMPERATURE or USER › MENU › SETTINGS › ECONOMY MODE).

Comfort mode is running when people are present in the premises. The system operates at speed 3. In this mode the temperature is

always maintained – it is set in the main window (ADJUSTER › VENTILATION CONTROL or USER › SET POINT).

7.4.2. SYSTEM CONTROL

System modes are changed by the following functions (indicated in a sequential order):

• Weekly Schedule;

• Switching on is activated from an external contactor;

• Manual mode selection;

• Holiday Schedule;

• Stand-by mode blocking.

Based on the Weekly Schedule the system decides in what mode it will be operating; however, the user may change it manually. The system

informs when the next mode change is scheduled. After power loss the mode is selected based on the Weekly Schedule; however, if it is not set,

the mode that was set before the power loss will be activated.

The user may change modes even when the switching on is activated from an external contactor. The only case when it is not possible – active

period of Holiday Schedule of which the system informs and which must be changed to avoid blocking.

Stand-by mode can be blocked by selected parameters. If at least one of the above functions changes its mode into Stand-by mode, it must be

checked whether this mode is not currently blocked. If it is blocked, the previous mode shall be activated.

The function order is provided below.

Start

› Reading of input data;

› Weekly Schedule;

› Mode external switch;

› User entered data;

› Holiday Schedule;

› Stand-by mode schedule;

› Stand-by mode blocking;

› Protection against Dryness;

› Boost ventilation;

› Air handling unit operating algorithm;

End

› Protection;

› Blocking of air handling unit operating algorithm;

› Manual Control of Components;

› Data entering into outputs and user environment.

EN | 19SMARTY RV v2019.12

7.4.3. SYSTEM STATES

This eld informs a user about the existing system state. It is displayed in the main window ADJUSTER › VENTILATION CONTROL or the main window of the user

environment. The table below shows possible system states.

SYSTEM STATE DESCRIPTION

Stand-by mode System operates in Stand-by mode

Building protection mode System operates in Building protection mode

Economy mode System operates in Economy mode

Comfort mode System operates in comfort mode

Emergency run System operates in emergency mode (for details refer to alarms section)

Preparing System is preparing for operation (pre-heating of water heaters, etc.)

Opening dampers Dampers are opened

BOOST function activated BOOST function is active

Cooling heaters Electric heaters are cooled down prior to shutdown of fans

Closing dampers Dampers are closed

Critical alarm Critical failure, system is shut down (for details refer to alarms section)

Fire alarm Fire protection from an external contactor is activated

Heat exchanger frost protection activated Heat exchanger frost protection is activated

Change lters Warning about clogged lters (pressure switches are activated or lter timer is

Room RH 3 days average is lower than 30%. Limiting speed.

DX cooler defrosting

Fire damper testing

activated)

Reduced airow because of too low exhaust air moisture

Dissolving the DX cooler / heater

Checking re dampers

7.4.4. SETTING DATE AND TIME

For smooth execution of schedules, event log and winter/summer function, it is necessary to set proper date and time in section ADJUSTER › USER SETTINGS

› DATE AND TIME SET and click a button DATE AND TIME SET. It can also be indicated in user environment USER › MENU › SETTINGS › DATE AND TIME. Fast synchronization

with the computer time is possible in user and adjuster environment.

7.4.5. SUPPLY AIR TEMPERATURE CONTROL AND COMPENSATION

Temperature for supply air or premises temperature may be indicated. In the service environment section SERVICE › MAIN › SUPPLY AIR TEMPERATURE CONTROL you

can control it based on supply or exhaust air temperature. If control by premises temperature is selected, then it is calculated what kind of air is to

be supplied so that the proper room temperature is maintained. It is limited by allowable limits of supply air temperature.

The air handling unit is not designed to heat premises, therefore it is not necessary to use full capacity for low temperature dierences – the

compensation in percentage is provided for this purpose. This parameter indicates a percentage of the temperature dierence (between the set

temperature and premises temperature) to be compensated for by this function. E.g. set point is 20 °C, temperature in the premises is 16 °C,

compensation is 50 %, dierence between the indicated and existing temperatures is 20-16=4 °C. Since 50 % is compensated, then 4*50 %=2

°C. When the received value is added to the set temperature we get the required supply air temperature – 2+20=22 °C. This temperature is not

limited as it is within the supply air temperature protection limits. In this case the system maintains the supply air temperature at 22 °C. The closer

the premises temperature is to the set temperature (20 °C), the faster the supply air temperature reaches 20 °C.

It may be too hot in the premises, therefore this function both heats and cools. Preferred (compensated) temperature is displayed in the window

MONITORING (REQUIRED SUPPLY). If the displayed temperature is 0 °C, it means that temperature maintaining of supply air is switched o.

The temperature of supply air is maintained by the following components (indicated in a sequential order):

• Fans (operate slower, if it is too hot);

• Recirculation valve (if the ambient air temperature is favourable);

• Water cooler;

• DX cooler;

• Recirculation damper and CO2 (in case of favorable outdoor temperature);

• Bypass damper or rotor (in case of favorable outdoor temperature);

• Recirculation damper and CO2 (in case of favorable outdoor temperature);

• DX heater;

• Water heater;

• Water cooler/heater;

• Electrical heater;

• Fans (operate slower, if it is too cold).

Firstly the system tries to maintain the supply air temperature by means of a heat exchanger. In case of a plate heat exchanger, the bypass damper

is controlled, and in case of a rotary heat exchanger, the rotor rotating speed or interval is changed. The heat exchanger can both heat and cool –

it depends on outdoor and room air temperatures. It is controlled by a PID controller whose coecients are indicated in the adjuster environment

section ADJUSTER › PID CONTROLLERS ADJUSTING › HEAT EXCHANGER CONTROL BY SUPPLY AIR TEMPERATURE.

When the heat exchanger operates at full capacity and preferred temperature is not reached, the recirculation damper, then the heater or cooler

etc. is activated (if necessary). Only the components congured for temperature maintaining are activated. It takes 10 s for the system to switch

20 | EN SMARTY RV v2019.12

between the elements.

7.4.6. FAN CONTROL

The preferred air-ow can be indicated in percentage or in 4 xed speeds where each of them is dedicated to a relevant system mode:

• Building protection;

• Economy;

• Comfort;

• Maximum power.

Fan speed can be controlled by:

• Percentage - speed in percentage is indicated in the adjuster environment window ADJUSTER › AIR FLOWS ADJUSTING: 0 % corresponds to 0, and 100

% – 10 V control signal voltage;

• Pressure - the maximum system pressure is indicated, which based on speed settings in the adjuster environment ADJUSTER › AIR FLOWS ADJUSTING

means 100 % air-ow;

• Air-ow (m3/h) - K factors of supply and exhaust air and the maximum system air-ow (m3/h) are displayed, which based on speed settings in

the adjuster environment ADJUSTER › AIR FLOWS ADJUSTING means 100 %.

Fans based on air-ow and pressure are controlled by PID controller and its coecients are indicated in the adjuster environment section ADJUSTER

› PID CONTROLLERS ADJUSTING › FANS SPEED CONTROL BY AIR FLOW OR PRESSURE. Each fan is controlled individually.

In the service environment window SERVICE › FANS › FANS SPEED CONTROL you can limit the minimum and maximum fan control signal voltage. Based on

manufacturer set parameters, the minimum 2V voltage is indicated, which means that 0V voltage signal is sent when fans are o, and 2V voltage

signal is immediately switched on when rotation is required.

It is possible to specify the nominal ows of supply and exhaust air. Then, the maximal air ow is calculated automatically.

7.4.7. “BOOST“ FUNCTION

Boost ventilation function is used for fast ventilation of premises. It activates the maximum air-ow (speed 4). Boost ventilation has be temporary,

i.e. it must be a nal condition (e.g. CO2 limit, time). The reason for this limitation – protection against dryness. High air ow reduces humidity, and

dry air is harmful for health.

The function is activated by pressing ON and deactivated by pressing OFF button in the BOOST section, or by means of an external contactor

(FANS SPEED SWITCH), which is congured in the service environment (SERVICE › MAIN › FANS SPEED SWITCH) section.

The function is inactive when Stand-by mode is on. Time limit is indicated (ADJUSTER › USER SETTINGS › BOOST TIMER or USER › MENU › SETTINGS › BOOST TIMER). Once the

function is activated, the time is set by the timer and the time is counted till its deactivation. It may be adjusted in real-time, i.e. when the function

is on, in ADJUSTER › VENTILATION CONTROL or in the user environment main window.

7.4.8. WEEKLY SCHEDULE

A weekly schedule consists of 10 weekly events. They can be added, deleted, activated and deactivated. One event indicates time, mode/BOOST

function, days of the week. Also it is possible to indicate the change of settable mode temperature.

The system changes modes according to the Weekly Schedule only at the indicated times, therefore a user can always change the existing mode

manually. This schedule noties of the upcoming mode change by indicating the time remaining till the next event.

The schedule is edited in user environment USER › MENU › SCHEDULE.

7.4.9. HOLIDAY SCHEDULE

This schedule is used when the unit has to operate in uniform mode during holidays. The user interface shows when the schedule period is active

as nobody can change the mode activated by this function (except for protection). In order to control the system in a normal manner, the Holiday

Schedule period must be deactivated, i. e. zero values must be indicated or dates must be changed. Up to ve holiday periods can be set.

The schedule is edited in the user environment USER › MENU › HOLIDAY.

7.4.10. WINTER/SUMMER MODE

The winter/summer function is set during the cold periods, because some parts of the system have to be protected against cold outdoor air. During

winter it is recommended to leave the unit switched on, therefore it is possible to set blocking of switch-o. Water heaters must always be switched

on during the entire winter.

The winter mode may be indicated

• Manually;

• By date;

• Based on 3-day mean outdoor temperature, to be calculated only when the fresh air (outdoor) pre-heater is o.

7.4.11. DRYNESS PROTECTION

This function is designed to protect premises against dryness. If the function is active, it calculates the 3-day mean humidity of extract air from the

premises. If the mean drops below set limit (30%), fans start operating in speed 2 in comfort mode. A user is notied of the activated protection

and limited air ow.

If the humidity mean exceeds set limit (30%) or the function is switched o manually, fans start operating in speed 3 in comfort mode.

The function is switched on/o in the section ADJUSTER › USER SETTINGS › DRYNESS PROTECTION or in the window USER › MENU › SETTINGS › OTHER.

EN | 21SMARTY RV v2019.12

7.4.12. NIGHT COOLING FUNCTION

This function is designed to save energy in the morning, when a fresh night air is used to cool down the building. The function is active only in

summer. If it is switched on but not active yet, activation conditions are checked:

• System time from function start to the end (hours/minutes);

• Time is exactly every hour from the start;

• If STAND-BY mode is set, the unit operates in BUILDING PROTECTION mode for 5 minutes so that the actual temperature data is available. The temperature is checked after purging. If it is not suitable, the unit returns to STAND-BY mode;

• Outdoor temperature is higher than the set outdoor temperature;

• Exhaust air temperature is higher than the set temperature;

• Exhaust air temperature is higher than the outdoor temperature by at least 2 °C;

• Summer.

If all conditions are met the unit starts operating in COMFORT mode (without temperature maintaining). The main window shows that the Night cooling

function is active. When it is active continuously, the deactivation conditions are checked:

• Time does not correspond to the start/end interval;

• Exhaust air temperature drops below the set temperature;

• Outdoor temperature drops below the set temperature;

• Mode other than COMFORT was switched or the unit has been shut down.

If at least one condition is met, the unit switches o the Night cooling function and it switches to the mode that was on prior to activating the function.

The function is congured in the section ADJUSTER › USER SETTINGS › NIGHT COOLING FUNCTION or in the window USER › MENU › SETTINGS › NIGHT COOLINGS.

7.4.13. CO2 REDUCTION FUNCTION

This function is designed to maintain a proper quality of room air. To activate it the exhaust air CO2 sensor must be connected and properly congured in the service environment window SERVICE › SENSORS. When completed, the exhaust air CO2 value is displayed in the section MONITORING.

In the service environment window SERVICE › MAIN › CO2 REDUCTION FUNCTION you can switch on/o the function, indicate preferred CO2 level and allowable

limit; when it is exceeded (CO2 set + allowable excess) CO2 is reduced, information is displayed and air-ow is increased. When CO2 reaches the

set point, reduction is switched o.

CO2 protection is inactive in the stand-by and building protection modes.

7.4.14. FILTER PROTECTIONS

Filter Timer Settings

The lter timer limit is set in the service environment window SERVICE › MAIN › AIR FILTERS PROTECTIONS. The maximum setting is 1 year.

7.4.15. SYSTEM MODE COMMUNICATION WITH EXTERNAL CONTACTOR

This function activates the preferred system switching on by means of external contactor; it indicates what signal will be sent to input. Possible

types of signals:

• Not used;

• Upon pressing a button the selected system mode is activated. After receipt of the rst impulse the function is activated, and after second

impulse – deactivated;

• On/o; selected system mode is activated. The mode is active while the contactor is on;

• PIR sensor. When the sensor is activated, the selected system mode is activated. If the signal is not received for 30 minutes, the mode is

activated.

Function is set in the service environment section SERVICE › MAIN › SYSTEM MODE SWITCH.

7.4.16. FAN SPEEDS FROM AN EXTERNAL SYSTEM CONTACTOR

This function is designed to activate/deactivate the boost ventilation function or preferred combination of fan speeds by means of an external

contactor.

The function indicates a type of a signal to be sent to the input and components controlled by it. Possible combinations of signal types and func-

tions:

• Not used;

• On/o – selected fan speed combination is activated. Function is on when contactor is on;

• Button click – selected fan speed combination is activated. Function is activated when it receives an impulse. It is deactivated when it receives

the impulse again;

• On/o – Boost ventilation function is controlled. Function is on when contactor is on. If the boost ventilation function is not terminated by means

of this function within the boost ventilation time limit, force shutdown is used after the time expires;

• Button click – Boost ventilation function is controlled. Function is activated when it receives an impulse. It is deactivated when it receives the

impulse again;

• If the boost ventilation function is not terminated by means of this function within the boost ventilation time limit, force shutdown is used after

the time expires.

It is also indicated whether boost ventilation will be activated or combination of fan speeds is preferred, i.e. it is possible to indicate preferred supply

and extract air fan speeds individually.

22 | EN SMARTY RV v2019.12

7.4.17. HEAT EXCHANGER CONTROL

Cold - Heat Recuperation

Cold-heat recovery function is designed to control a heat exchanger. Its power is controlled by:

• Using plate heat exchanger - bypass damper. When it is closed, the heat exchanger is operating at full capacity. Its power is reduced by opening the damper.

• Rotary heat exchanger power is controlled by changing its rotating speed or interval. When the rotor rotates at full speed, the heat exchanger

is used at full capacity. The power is reduced by slowing down the rotating speed or increasing the interval.

The heat exchanger can both heat and cool – it depends on air temperature. If it is colder outside than in the premises, the heat exchanger preheats the outdoor air by using the room heat. If it is colder in the premises than outside, the heat exchanger cools down the outdoor air temperature

by room air. Its power is reduced to the minimum when the target supply air temperature is the same as outdoor one. The higher the dierence

between the preferred and supply air temperatures, the higher heat exchanger power is used. When it is operating at maximum capacity, it is allowed to activate other heating/cooling components.

For this function suitable heat exchanger type is indicated in the window SERVICE › HEAT EXCHANGER and PID controller coecients – in the window ADJUSTER

› PID CONTROLLERS ADJUSTING.

PID controller output limits are set for rotor or bypass damper, at which their operation starts.

• If rotor is controlled by 0..10 V signal, at low voltages it does not rotate, the motor heats up, thus the minimum control signal output is limited. If

On/O rotary heat exchanger is used, PID percentage for activating the rotor is indicated in the window SERVICE › HEAT EXCHANGER.

• If the bypass damper opens only a few percent, noise can occur, thus minimum opening is limited, which also applies when coming to the full

opening. If the plate heat exchanger with a 3-way bypass damper is used, the opening time of the bypass damper is indicated in the window

SERVICE › HEAT EXCHANGER.

• If a plate heat exchanger with segment valves is controlled by an external controller is used, then the type of the bypass damper “REMOTE CONTROL

LER” is shown in the window “SERVICE › HEAT EXCHANGER”.

• If a plate heat exchanger with segment valves connected to a controller is used, then the type of the bypass damper is shown in the window

“SERVICE HEAT EXCHANGER” as either “2 SEGMENTS” or “3 SEGMENTS”. In the case of heat recovery control, segments are closed in sequence, i.e. if heat

recovery is not required, then all the segments are closed and the bypass damper is opened.

When the fans are switched on during the heating season, the heat exchanger runs for 10 minutes at full power, until the system stabilizes.

7.4.18. SYSTEM MONITORING

The service and adjuster environment have the window MONITORING where you can monitor operation of the entire system, i.e. see controller

input and output, CO2 values, versions of connected modules, date and time, speed of fans, temperatures, pressure, etc. The amount of informa-

tion depends on the system conguration. This tool is designed for preventive maintenance of the system.

7.4.19. STAND-BY MODE BLOCKING

This function is designed to protect the system against the impermissible unit shutdown and it is recommended to limit the unit shutdown up to 1

hour within 12 hours during the winter season. Possible function modes:

• Always allow shutdown;

• Block shutdown;

• Block shutdown in winter;

• Block shutdown in summer.

It must be indicated for how long the shutdown is permissible within 12 hours. If it is blocked and the system is shut down, the system counts and

informs the user on the remaining time. This function is congured in the service environment (SERVICE › MAIN › SYSTEM BLOCKING).

If the time has expired and Stand-by mode is blocked, the user is informed by the function indication.

7.4.20. AIR FLOW ADJUSTMENT

Air-ows are adjusted in the adjuster environment window ADJUSTER › AIR FLOWS ADJUSTING. There are 4 of them in the system and they are dedicated to

specic modes:

• Building protection;

• Economy;

• Comfort;

• Maximum power (BOOST function).

Air-ows are arranged in an ascending order, i.e. upon setting lower air-ow in COMFORT mode then in ECONOMY mode, the air-ow of the latter is reduced automatically. With respect to the system conguration, air-ows are indicated in percentage, pressure or amounts of air. 100 % value of

air-ow is indicated in service environment window SERVICE › FANS › FAN SPEED CONTROL.

7.4.21. MANUAL CONTROL OF COMPONENTS

This function manually activates/deactivates the components controlled by digital and analogue outputs. The latter ones are controlled in percentage, and digital ones – by ON/OFF. Based on manufacturer’s parameters (by default) the status of all components is AUTO , which means that control

is based on air handling unit operating algorithm. Components are displayed by the system conguration. Settings must be saved so they remain

active after power loss.

The lowest power consumption is when the Stand-by mode is on, and position of components – AUTO.

Prior to using the manual control function, it is recommended to activate the force shutdown function, which blocks the air handling unit operating

algorithm.

EN | 23SMARTY RV v2019.12

This can be useful, if you need to check if everything is properly connected. Moreover, in the event of failure, certain components can be activated

so that the unit operates irrespective of sensors and protections. Of course, this method should be applied in exceptional cases until the failure

is rectied.

If the service environment window SERVICE › SENSORS displays an external (REMOTE) type of a temperature sensor, its temperature may be indicated manually. The values may be indicated via the Modbus interface.

7.4.22. CHANGING PASSWORDS

In the service environment section SERVICE › MAIN › PASSWORD › PASSWORD CHANGING MODE › ON you can change login passwords. For this it is necessary to acti-

vate the change and after entering a preferred password (4 digits), click a button SET. To review and change the parameters without a password,

just set 0.

7.4.23. RESTORING FACTORY DEFAULTS

If set parameters result in incorrect operation of the system, you can always restore the factory defaults in the service environment window SERVICE

› MAIN › FACTORY SETTINGS.

7.4.24. INDICATIONS OF FUNCTIONS, ALARMS AND WARNINGS

User about active functions, warnings or alarms is notied in the window ADJUSTER › ALARMS or USER › ALERT. Functions are displayed in the main window

ADJUSTER › VENTILATION CONTROL or in the user environment window. The table below provides indications and their descriptions.

FUNCTIONS DESCRIPTION

Working indication output

Alarm indication output

System mode switch Switching on from an external contactor is activated

Custom fans speed switch Selected fans speed from an external contactor is activated

Winter Winter mode is active

Stand-by mode blocking activated Stand-by mode blocking is activated

Slowing down fans Fans are slowed down

Slowing down fans by temperature Fans are slowed down depending on supply air temperature

Night cooling function activated Night cooling function is activated

Hydronic pump exercise activated Preventive maintenance of circulation pumps is activated

Service stop function

Working indication output is activated

Failure indication output is activated

Blocking of air handling unit operating algorithm; Service activities are carried

out

Holidays

Reducing CO2 level

Full recirculation Full recirculation function is activated

Holiday Schedule interval is active. System mode can be changed only upon

changing the Holiday Schedule interval

CO2 reduction function is activated

7.4.25. DISPLAY AND CONCELLATION OF ALARMS AND WARNINGS

The system noties the user about the system failures by warnings that are canceled automatically and by alarms that have to be canceled manually. The latter are recommended to be canceled by a specialist prior to nding out the causes of the alarm. Information on alarms and warnings

is also displayed

in the main window ADJUSTER › VENTILATION CONTROL. If at least one alarm is active, the system is shut down and external failure indication is activated.

Alarms and warnings can be reviewed and canceled in the window ADJUSTER › ALARMS or USER › ALERT. All possible alarms and warnings are provided in

24 | EN SMARTY RV v2019.12

the table below.

INDICATION ALARMS LIST INDICATION ALARMS LIST

.

A.2

.3

.

A.5

.6

A.7

.

.

A.

A.

.2

.3

.

A.5

.6

.7

.

.

.2

.2

.22

.23

A.2

A.25

A.26

A.27

A.2

A.2

A.3

Warning! Rotor broken belt alarm

Alarm! Fireplace protection activated

Warning! Dryness protection activated

Warning! Plate heat exchanger frost protection

activated

Alarm! Plate heat exchanger frost protection system stopped

Warning! Plate heat exchanger frost protection

(pressure relay)

Alarm! Hydronic heater frost protection. System

stopped

Warning! Too low supply temperature

Warning! Too high supply temperature

Alarm! Too low supply temperature. System

stopped

Alarm! Too high supply temperature. System

stopped

Warning! Change supply air lter (pressure relay)

Warning! Change extract air lter (pressure relay)

Warning! Change supply and extract lters (time-

out)

Alarm! Power supply failure. Please, check F1 fuse

Warning! Supply air temperature sensor failure.

Emergency run

Warning! Extract air temperature sensor failure.

Emergency run

Warning! Exhaust air temperature sensor failure.

Emergency run

Warning! Outdoor air temperature sensor failure.

Emergency run

Warning! Hydronic heater water temperature sensor failure. Emergency run

Warning! Hydronic pre-heater water temperature

sensor failure. Emergency run

Warning! Hydronic cooler water temperature sensor

failure. Emergency run

Warning! Controller cabinet temperature sensor

failure. Emergency run

Alarm! Supply air temperature sensor failure.

System stopped

Alarm! Extract air temperature sensor failure.

System stopped

Alarm! Exhaust air temperature sensor failure.

System stopped

Alarm! Outdoor air temperature sensor failure.

System stopped

Alarm! Hydronic heater water temperature sensor

failure. System stopped

Alarm! Hydronic pre-heater water temperature sensor failure. System stopped

Alarm! Hydronic cooler water temperature sensor

failure. System stopped

A.3

.32

.33

A.3

.35

A.36

.37

A.3

A.3

.

A.

A.2

A.3

A.

A.5

A.6

A.7

.

.

.5

A.5

.52

.53

.5

.55

.56

.57

A.5

A.5

W.6

Alarm! Controller cabinet temperature sensor failure. System stopped

Fire damper test OK

Warning! Fire damper test failed

Alarm! Heater manual protection. System stopped!

Warning! Heater automatic protection

Alarm! Pre-heater manual protection. System

stopped!

Warning! Pre-heater automatic protection

Alarm! Supply fan failure

Alarm! Extract fan failure

Warning! DX cooler failure

Alarm! Fire

Alarm! Supply fan pressure protection. System

stopped

Alarm! Extract fan pressure protection. System

stopped.

Alarm! Internal system error.

Alarm! Heater manual protection. Boosting.

Alarm! Pre-heater manual protection. Boosting.

Alarm! Internal communication error

Warning! DX cooler defrosting

Warning! Too high 3 days extract humidity. Increas-

ing air ow.

Warning! Too high extract humidity. Boosting.

Alarm! Rotor broken belt alarm. System stopped.

Warning! Gas heater failure

Warning! Gas pre-heater failure

Warning! Too high condensation level

Warning! Supply fan failure. Emergency run

Warning! Extract fan failure. Emergency run

Warning! Too low supply air ow for DX cooler

Alarm! Bypass damper failure. System stopped.

Alarm! Hydronic heater/pre-heater circ.

pump failute. System stopped.

Warning! Hydronic heater/pre-heater circ.

pump failute.

7.4.26. EVENT LOG (HISTORY)

The system records 50 recent events (failures, alarms, re damper testing results, etc.).

The log stores the description of events and time.

The event log may be reviewed in the window ADJUSTER › HISTORY or USER › MENU › HISTORY.

EN | 25SMARTY RV v2019.12

7.4.27. SYSTEM VERSIONS AND RUNNING TIME

In the section ADJUSTER › USER SETTINGS › ABOUT you may see software and conguration versions that are saved in the production line namely to every unit.

Next to them the running time since the unit has been manufactured is also displayed. It is calculated when the fans are rotating.

8. ACCESSORIES

Filters

panel

Filters

pocket

Heater

electrical

Damper

circular

Cooker

hood

Silencer

circular

Front

cover

Bracket Stouch SA-Control

circular

MB Gate-

way

CM24-F-L S-KCO2 S-KFF-U S-RFF-U-

D-F2

S-RCO2-F2 Coupling

without

Clamp TL-

WR802N

IR24

sealing

PA-

AL

TROL_701

Panel lter

Pocket lters

Electrict pre-heater

Humidity sensor

CO2 sensor

MPL (M5/M5)

(Smarty 2R V)

MPL (F7/F7)

(Smarty 2R V)

FMK (M5/M5)

(Smarty 2R V plus)

EKA NV 125-0,6-1f PH

(Smarty 2R V)

EKA NV 125-0,9-1f PH

(Smarty 2R V plus)

PSIEKANVPH1250.6_1

PSIEKANVPH1250.9_1

S-RFF-U-D-F2 ZAKKT0050

S-KFF-U ZAKKT0051

S-RCO2-F2 ZAKKT0048

S-KCO2 ZAKKT0049

GKOFIL0015

GKOFIL0016

GFIRIRS3002

Cooker hood for stainless steel Cooker hood ZPGKT0042

Cooker hood for white Cooker hood ZPGKT0041

Front coover mounting bracket Mounting bracket GNGKRON17

Front cover white Front cover GNGGAUBT022

Front cover stainless steel Front cover GNGGAUBTSS1

Silencer

Remote control

Silencer, 350 mm GSORIRS168_152

Silencer, 750 mm GSORIRS168_324

Stouch PRGPU51

SA-Control PRGPU051

Net module MB Gateway PRGPU082

Actuator for damper CM24-F-L ZAKP0029

Damper SKG-A 125 GSKSKG028

26 | EN SMARTY RV v2019.12

8.1. CONNECTION FO ACCESSORIES

8.1.1. SCHEMATIC OF CONTROLLER CONNECTIONS IN MCB

MCB

Connector Contact No. Contact name Dunctional block name

A

X1

1 MCB FDI TACHO K_1(GND)

2 MCB FDI TACHO A_1(+10V)

3 MCB FDI TACHO K_2(GND)

4 MCB FDI TACHO A_2(+10V)

Supply fan speed (RPM)

Extract fan speed (RPM)

EN | 27SMARTY RV v2019.12

X2

X3

X4

X5

X6

X7

X8

X9

1 PE Rotor speed (RPM)/

2 GND Too high condensation (NO)

3 +24VDC

4 MCB HOLO

Supply air electrical heater automatic protection (NC)/

1 MCB DI1

2 +12VDC

3 MCB DI2 Supply air electrical heater manual protection/

4 +12VDC Water heater protection (thermostat) (NC)

5 MCB DI3

6 +12VDC

1 MCB DI4

2 +12VDC

3 MCB DI5

4 +12VDC

5 MCB DI6 Rotor alarm (NC)/

6 +12VDC Heat exchanger pressure relay (NC)

7 MCB DI7

8 +12VDC

1 MCB AI1 (NTC)

2 GND

3 MCB AI2 (NTC)

4 GND

5 MCB AI3 (NTC)

6 GND

7 MCB AI4 (0-10V)

8 GND

1 MCB AI5 (NTC)

2 GND

3 MCB AI6 (NTC)

4 GND

5 MCB AI7 (NTC)

6 GND

1 +24VDC

2 +3,3VDC

3 GND

4 I2C_SDA

5 I2C_SCL

1 PE

2 GND

3 +24VDC

4 GND

5 RS485 A (D+)

6 RS485 B (D-)

7 RS485 B (D-)

8 RS485 A (D+)

1 PE

2 GND

3 +24VDC

4 GND

5 RS485_B

6 RS485_A

Supply air Hydronic cooler heating/cooling changeover thermostat (NC/NO)/Water heater circulation pump fail

Supply air fan protection (NC)

Fire protection input (NC)

By-pass closed input (NC)

Extract air fan failure (NC)

Supply air temperature sensor

Fresh air temperature sensor

Exhaust air temperature sensor

Heat exchanger pressure transmitter

Extract air temperature sensor

Reserved

Hydraulic heater ret. uid temperature sensor

Connection with EX2-X47

B

BMS connection (RS485)

Remote Control connection (RS485)

28 | EN SMARTY RV v2019.12

1 MCB PE

X10

X11

X12

X13

X14

X15

X18 Remote Control connection (RS485)

X19 BMS connection (RS485, congurable via SL1)

2 MCB GND

3 MCB RECIRC_+24VDC_OPEN (DO4)

4 MCB RECIRC_+24VDC_CLOSE (DO5)

1 MCB PE

2 MCB GND

3 MCB BYPASS_+24VDC_OPEN (DO2)

4 MCB BYPASS_+24VDC_CLOSE (DO3)

1 PE

3 +24VDC

1 +24VDC

2 STEP_B/

3 STEP_B

4 STEP_A/

5 STEP_A

6 +24VDC

1 GND

2 MCB AO1(0-10VDC)

3 GND

4 MCB AO2(0-10VDC)

5 GND

6 MCB AO3(0-10VDC)

1 +24VDC

3 PE

C

Recirculation damper control 3P

By-pass damper control 3P

24VDC Power supply for water heater actuator2 GND

By-pass step motor control

Supply air fan control output (0-10VDC)

Extract air fan control output (0-10VDC)

Supply air heater control output (0-10VDC)

MCB Power supply 24VDC2 GND

8.1.2. CO2 SENSOR OR CONNECTION OF HUMIDITY SENSOR RH

Settings:

CO2 converter (S-KCO2 or S-RCO2-F2)

1. Set that next to 0.10 V input an extracted air CO2 converter is connected “SERVICE › SENSORS › 0-10 VDC SENSORS › AIR QUALITY SENSOR 1” (choose “Extract CO2”)

2. Indicate:

• “Air quality sensor MIN”: 0

• “Air quality sensor MAX”: 2000

3. CO2 reduction function is activated “SERVICE › MAIN › CO2 REDUCTION FUNCTION” (controlled recirculation damper and fans)

4. To see the CO2 level: “ADJUSTER › MONITORING › EXTRACT AIR CO2”

Humidity RH converter (S-KFF-U) or room RH converter (S-RFF-U-D-F2)

1. Set that next to 0.10 V input an extracted air RH converter is connected “SERVICE › SENSORS › 0-10 VDC SENSORS › AIR QUALITY SENSOR 2” (choose “Extract RH”)

2. Indicate:

• “Air quality sensor MIN”: 0 (0*0.1=0.0 %)

• “Air quality sensor MAX”: 1000 (1000*0.1=90.0 %)

3. You can see the level of extracted air RH in: “ADJUSTER › MONITORING › EXTRACT AIR RH”

EN | 29SMARTY RV v2019.12

Electric installation:

RH sensor of the extracted air is used to calculate the freezing point

In order to reduce the CO2 concentration in the premise (-s), it is necessary to connect CO2 converter (canal or installed in the premises).

Purpose of the connectors contacts:

MCB:

X7:1 – power supply of the converter +24 V DC

X5:7 – analogue input 0–10 V DC

X5:8 – general GND

8.1.3. ROOM CO

Where the channel CO2 transmitter is used: it must be installed in the extract air duct. Tool for drilling holes are required

for its installation.

TRANSMITTER INSTALLATION RECOMMENDATION

2

30 | EN SMARTY RV v2019.12

8.1.4. CO2 CONCENTRATION ACCORDING TO PETTENKOFER LIMIT

3000 Eect on an individual

2500

2000

concentration [ppm]

2

CO

1500

Reduced concentration, drowsiness, headache, etc.

1000 Pettenkofer limit

500 Pleasant

0

0 1 2 3 4

Duration of the presence in the room in hours

Outdoor air

Pettenkofer limit Disturbs

8.1.5. FIRE PROTECTION INPUT (NC)

Fire protection signal input has to be normally closed, until the re protection system is not connected. In factory the short-circuiter is applied. KEFA

KF2EDGKD-2.5/8P X4 connector 1 and 2 contacts.

Fire protection signal:

MCB:

X4: 1, 2

8.1.6. EXTERNAL SWITCHES

Functions are activated using external switches.

• Pressure compensation after steam extraction – KEFA KF2EDGKD-2.5/8P X4 connector 5 and 6 contacts;

• External switch – KEFA KF2EDGKD-2.5/8P X4 connector 3 and 4 contacts.

EN | 31SMARTY RV v2019.12

8.1.7. CONNECTION OF REMOTE CONTROL PANEL OR MODBUS

SL1 DIP switch 1 2 3 4 5

Purpose (ON position)

A+Y (RS422-

>RS485)

B+Z (RS422-

>RS485)

120R line termination

resistor

1kR connection line

pull-up resistor

1kR connection line

pull-down resistor

8.1.8. “MCB TOOL” PROGRAM DESCRIPTION

The app ‘MCB tool’ is for importing control board MCB settings from MCB to the media in a computer, and to export MCB settings from the media

in a computer to MCB. Download the app from http://www.salda.lt/en/products/category/download_page/.

1. Choose connection type

a. Modbus RTU (connect with RS485 converter)

B2

B1

I1

B3

I1 Connection status

B1 Select connection type

B2 Set Modbus slave ID

B3 Select COM port of RS485 converter

32 | EN SMARTY RV v2019.12

b. Modbus TCP/IP (connect with TCP/IP Modbus gateway (MB-GATEWAY))

B4 Set IP of TCP/IP Modbus gateway (MB-GATEWAY)

B5 Press to connect

2. Connect to device (press “CONNECT” button)

B4

B5

I2

B7

B8

B6

I3

I4

I2 Device software version

I3 Conguration read status

I4 Conguration write status

B6 Press to disconnect from device

B7 Press to read conguration from device

B8 Press to write conguration to device

3. Read conguration from device and save to your computer (press “READ CONFIG FROM BOARD” button and write conguration le name)

EN | 33SMARTY RV v2019.12

4. Write conguration to device from your computer (press “WRITE CONFIG TO BOARD” button and select conguration le)