No.3498-35760-2

OPERATING & MAINTENANCE INSTRUCTIONS

RAMMER

Series

Be sure to operate, inspect, and maintain the products after you

have read this manual carefully to understand the contents.

RS45, RS65, RS75

Forward

Forward

This manual has been prepared as a guide to operate SAKAI RAMMER, RS45, RS65,

RS75.

It is hoped that the manual is useful for experienced operators to refresh the knowledge and

the experiences as well as for inexperienced operators.

You are requested to use this product after you have fully understood the contents of this

manual. Furthermore, keep this manual at a suitable place for your easy access.

Refer to a separate Engine Operation Manual for operation and maintenance of the engine.

If you lend or let other person to operate the machine, thoroughly explain how to operate

it and guide him to read this manual in advance before operation. In addition, if you transfer the product to someone, provide him with the Engine Operation Manual as well as this

instruction manual.

Please note that the purchased product may be somewhat different in the the contents of the

manual due to our constant efforts to improve its design.

Contents

Contents

When you order parts or get instructions for trouble correction

...........

1

Safety precautions

..................................................................................

2

1. Basic safety precautions

..................................................................

4

2. Sticking position of warning notice (Label)

....................................

7

3. Inspection before operation

.............................................................

9

4. Starting-up

.......................................................................................

13

5. Operation

.........................................................................................

16

6. Shutting down

..................................................................................

17

7. Inspection and Maintenance

............................................................

18

8. Fuel and Lubricant

...........................................................................

20

9. For a long-term storage

....................................................................

21

10. Overall View

....................................................................................

22

1

When you order parts or get instructions for trouble correction

When you order parts or get instructions for trouble cor rection

Be sure to inform us of the MODEL and its CHASSIS NUMBER when you are ordering

parts or getting instructions for trouble correction. The PRODUCT MODEL and BODY

NUMBER(Serial No.) are indicated on the body name plate.

The name plate is stuck on the left hand side of the body.

MODEL CHASSIS NUMBER

RS45 VRS4- 〇〇〇〇〇

RS65 VRS2- 〇〇〇〇〇

RS75 VRS3- 〇〇〇〇〇

MASS

MODEL CHASSIS NUMBER (Serial No.)

Safety precautions

2

Safety precautions

In order to use this product safely, correct operation and periodical maintenance are absolutely essential. Do not operate and/or carry out maintenance of the product until you read

the manual carefully to understand the safety precautions.

The operation and safety precautions illustrated in this manual are only limited for what it

is to be used as a rammer. If the product is to be used for works other than what the manual

covers, every safety consideration must be made on your responsibility.

In this manual, precautions. if they are failed to be observed, which may lead to an accident

resulting in injury or death, are marked as "

DANGER" or " WANING".

Precautions, if they are failed to be observed, which may lead to injury or to serious damage

to the machine, are marked as " CAUTION", and for precautions which may result in

damage to the machine or shortening its service life are marked as "IMPORTANT".

In addition, labels indicating precautions in carrying out safety operation and maintenance

service are stuck on the rammer as follows:

DANGER Indicates extremely high risk of an acci-

dent resulting in serious injury or death if

it is failed to be observed.

(This is marked in red.)

WANING Indicates a possibility to an accident

resulting inserious injury or death if it is

failed to be observed.

(This is marked in orange.)

CAUTION Indicates a possibility resulting in injury

or damage to the machine if it is failed to

be observed.

(This is marked in yellow.)

3

Safety precautions

Do not operate the machine until the

operator has understood the contents

by reading this manual carefully.

Wrong operation may invite an accident resulting in injury or death.

Safety operation of the machine is on

operator's responsibility.

In order to avoid an accident, you are requested to pay close attention to the safety other than

the precautions indicated in this manual and/or on the labels during machine operation, as

they could not cover all the precautions by foreseeing any possible danger.

WANING

☆ Cautions to be taken when making an alteration of the machine:

Making an alteration without our recommendation is a matter of question in terms of safety.

Contact our local sales agent or office in advance for alteration.

We will not bear any responsibility for injury or breakdown of machine resulted from alteration without approval from our side.

☆ Basic safety precautions to be taken in operating the machine are illustrated on the next

page on.

4

1. Basic safety precautions

1. Basic safety precautions

■ Read the instruction manual carefully.

● Understand functions of operation control equipment and

familiarize yourself with where it is and how to control it.

Also, have a proper understanding of how to operate and

meaning of each symbol.

■ Observe the rules in work site.

● Observe the established rules such as prohibitions in the work site, cautions, and work

procedures.

■ Wear clothes suitable for the work, and protective means.

● Wear clothes suitable for the work, safety shoes, and safety cap.

● Do not wear clothes which are likely to be caught in a projection of the machine, and/or

an ornament. Also, do not wear a clothe stained with oil as it may catch fire easily.

● Never forget to wear protective goggles and a mask when required in the work.

■ Handle with care when hot members are at high temperature.

● Take care not to be burned as the engine as a whole is very hot

during operation or immediately after it has been stopped.

● Do not allow your hand, body and clothe to be touched to the

muffler as it is very hot while the engine is running or immediately after it has been stopped.

● Take care, while the engine is still hot, not to be burned from oil

spray when draining or filling oil.

Be sure to observe the safety precautions to secure safety.

Failure to observe the precautions will

invite accidents or machine troubles.

WANING

5

1. Basic safety precautions

■ Pay attention to fire.

● Bringing a open flame close to fuel and oil may invite a fire.

In particular, fuel can catch fire very easily and it is dangerous.

● Do not bring a fire such as of cigarette or of match close to the

flammable materials.

● Supply fuel with the engine stopped after no fire has been confirmed around the rammer.

● Tighten the caps such as for fuel and for oil securely.

■ Pay attention to ventilation.

● Exhaust gas is harmful for your health. If the engine has to be

run in a room or in a poorly ventilated area, ventilate the area by

opening windows and/or entrances.

■ Check the machine body before operation.

● Check to see if each part of the machine functions properly at a safe place. If it is found

anything wrong, be sure to take corrective measures to start operating the machine.

● Check the machine for unusual noise, unnatural vibration, heat and smell. If it is found

something wrong, stop the machine at a safe place immediately and check and locate the

cause to repair it.

■ Be careful not to be caught in the machine.

● Do not stand close to the machine while operating the machine

because your hand, body, or clothe is likely to be caught in the

rotating members which may result in an injury.

Be careful not to be caught in the machine. Be sure to stop the

engine before performing inspections and maintenance for rotating members and their vicinities.

6

1. Basic safety precautions

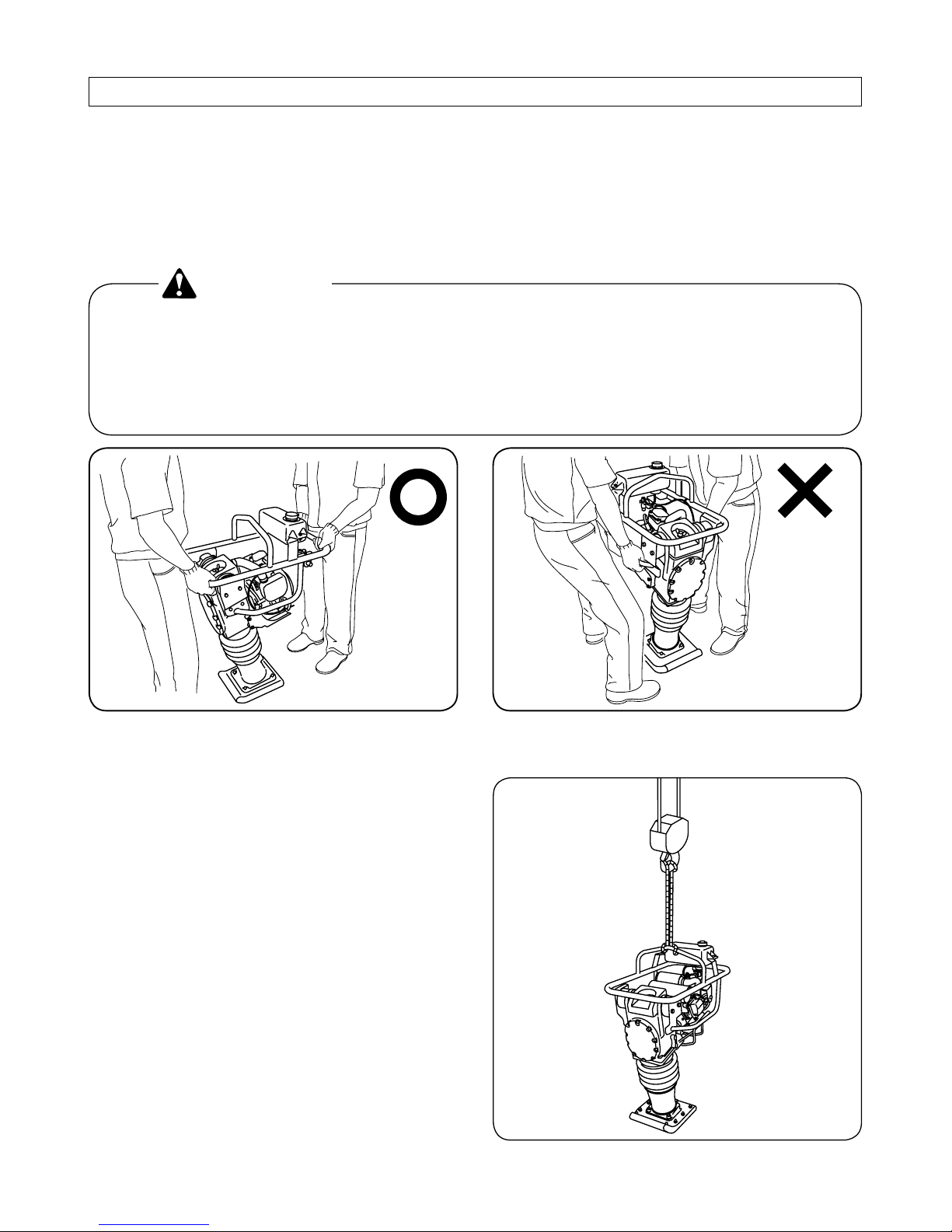

■ Cautions to be taken when loading and unloading using a crane.

● Surely bind the guard with a wire rope

as shown in the figure on the right.

■ Cautions to be taken when loading and unloading the machine.

● Load and unload the machine in/from a transporting vehicle with two persons in order to

avoid an accidental drop of the machine.

● Drain fuel from the fuel tank, the carburetor, and the fuel strainer before transporting it

on a long distance or on a rough road.

When lifting up the machine by holding the handle, hold

the handle at its front and rear part to prevent your finger

and/or hand from being caught between the handle and the

machine body.

•

DANGER

7

2. Sticking Position of Warning Notice(Label)

①②③

2. Sticking Position of Warning Notice (Label)

For safety's sake, warning notice (label) is sticked to below mentioned position of our products.

Keep the label clean and free of breakage. If it is broken or missed, replace it with a new one.

When ordering labels, be sure to mention the relative part number printed at the bottom right

corner of it.

8

2. Sticking Position of Warning Notice(Label)

① 3998-36001-0

② 3998-06140-0

③ 3998-16491-2

• Read the operator's manual thoroughly before operating

the machine.

• Incorrect operation can cause severe injury or death.

• It is your responsibility to operate the machine safely.

3998-16491-2

WARNING

Detail of Warning Notice (Label)

9

3. Inspection before operation

3.1. Engine

Refer to a separate Engine Operation Manual for the engine.

3. Inspection before operation

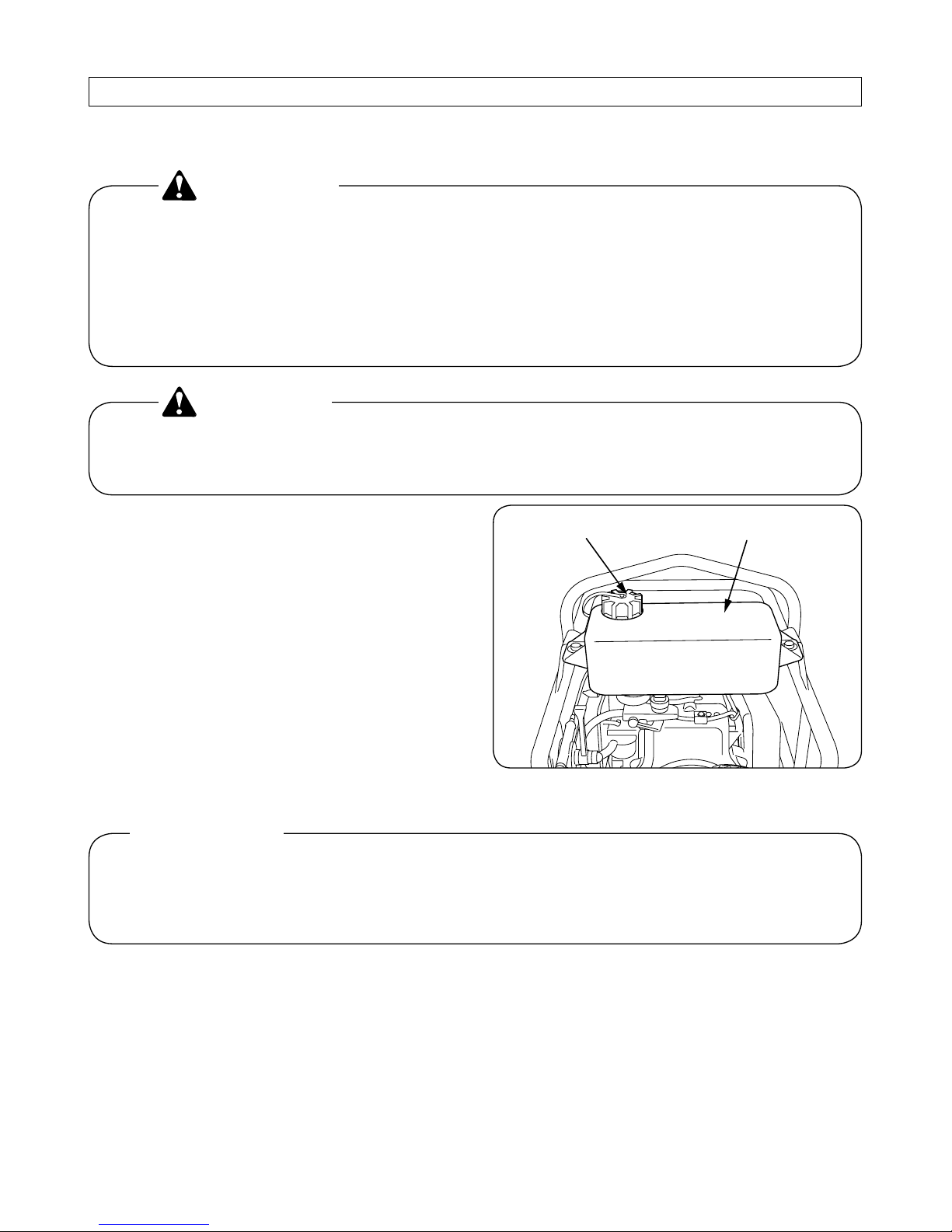

Oil gauge

Fill port

Drain plug

Maximum oil level

Minimum oil level

(Refill is required)

① Remove the oil gauge and wipe off oil

stuck on the gauge with a rag.

② Push the oil gauge against the oil fill port

without screwing it in to check oil level.

③ Refill oil until it comes to the upper limit

mark when the level is insufficient.

Be sure to check and refill oil with the engine held level.

Check the oil level again at approx. 3 minutes after it has been refilled.

Do not supply oil more than the specified since over-supply of oil may

result in blowing out of oil and poor output of the engine.

Shortage of oil may cause seizure of the engine.

If an oil other than the specified is used, service life of engine is likely to

be shortened.

•

•

•

•

IMPORTANT

Screw in the oil gauge securely after oil level has been

checked and refilled .

•

CAUTION

3.2. Checking oil in the engine chamber

10

3. Inspection before operation

Be sure to check and refill oil with the rammer shoe held level.

Run the engine for a while after oil has refilled then check the oil level

again at approx. 3 to 5 minutes after engine has been stopped. If oil has

been filled sore than the specified, malfunction results. Be sure to wipe it

off when over-filled.

If an oil other than the specified is used, service life of engine is likely to

be shortened.

•

•

•

IMPORTANT

Remove the fill plug located in the lower

cylinder case with the rammer shoe held

level and check that the oil is filled up to the

mouth of the port.

If it is found insufficient, supply oil to the

extent that it comes full to mouth of the

port.

Drain plug

3.3. Checking oil in the rammer cylinder

11

3.4. Checking fuel

3. Inspection before operation

Remove the cap on the fuel tank to check

remaining oil visually. Refill fuel if it is

found insufficient.

Fuel to be employed:

Regular gasoline for automobile

Wipe off fuel thoroughly when it has been spilled out.

Be sure to stop the engine when filling fuel.

Tighten the cap on the fuel tank securely after fuel has been

filled up.

Be sure to check if it is the right fuel before refilling fuel.

•

•

•

•

WARNING

In order to prevent fuel from being blocked. be sure to fill up

fuel through a filter.

•

CAUTION

Since shortage of fuel can cause irregular tamping motion due to uneven

fuel supply to the engine by vertical (vibrating) motion of the machine,

refill fuel a little earlier.

•

IMPORTANT

Fuel tankCap

12

3.5. Checking bolts and nuts for their tightness

Re-tighten bolts and nuts in each section after each operation and once a week.

Bolts and nuts are likely to become loose due to vibration of the machine body.

If it is operated with the bolts and/or nuts losened, malfunction and damage to the machine

may result.

In particular, be sure to check bolts and nuts securing tamping shoe before starting operation.

Since crankcase and its related members are made of aluminum, be careful not to over-tighten them.

•

CAUTION

3.6. Handle height adjustment

Handle height can be adjusted in two(2)

steps to meet the operator's height.

It can easily be adjusted by relocating handle counting bolts.

3. Inspection before operation

Although there are three (3) holes in the handle, do not use

the uppermost hole.

•

CAUTION

13

4. Starting-up

4. Starting-up

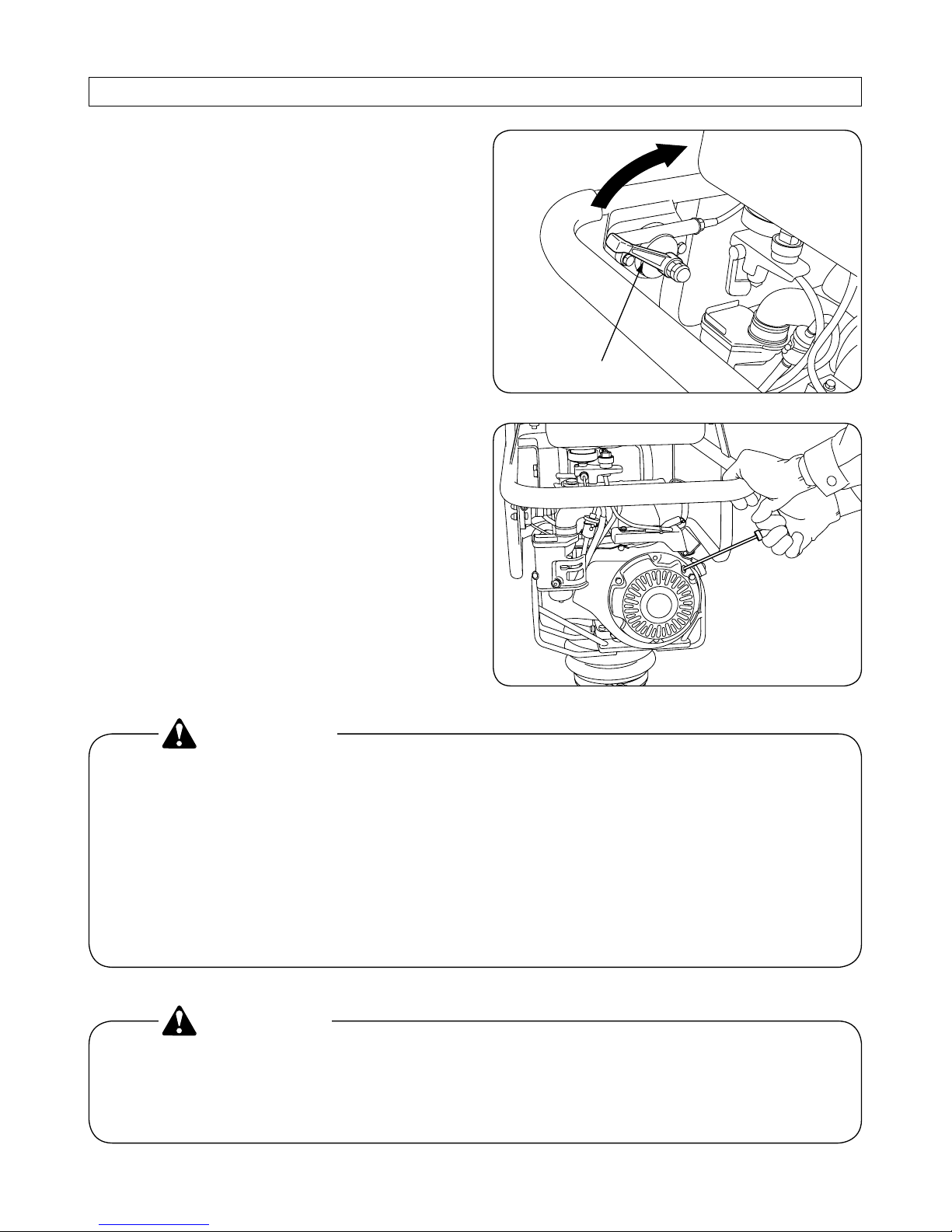

(1) Turn “ON” the engine switch serving

also as fuel cock.

ON

Fuel cock

(2) Close the choke lever in the carburetor.

RS45, RS65

Choke lever

Closed

RS75

Choke lever

Closed

Position the lever to a to a halfway between Closed and Fully open when

temperature is wars or the engine is still hot. Likewise, position the lever

to Closed when temperature is low.

•

IMPORTANT

14

4. Starting-up

(3) Turn the throttle lever to Fully Closed

position.

(4) Pull the starting knob forcibly.

Closed

Throttle lever

Do not pull out the rope up to its extreme. And when returning the rope, return it slowly as an abrupt release of the rope

will cause damage to the cover with a shock.

•

CAUTION

Start the engine after looking around to confirm the safety of

its surroundings .

Hold the handle securely with your left hand to fix the

machine body and pull the starter knob forcibly with your

right hand to start the engine.

Pull up the starter knob so that your hand will not hit the

handle.

•

•

•

WARNING

15

4. Starting-up

(5) Shift the choke lever to Fully open position after the engine has been started.

Warm-up the engine at an idling speed for approx. 5 minutes

after the engine has been started.

If the engine fails to start, check the spark plug and the fuel

system for blockage.

•

•

CAUTION

16

5. Operation

5. Operation

(1) Shift the throttle lever to Fully Open

position after the warm-up operation has

been completed.

Rammer starts ramming and moving forward.

Throttle lever

Open

During operation, do not lift up the machine by holding the

handle.

•

DANGER

Do not operate the engine with an intermediate speed as the

centrifugal clutch repeats ON and OFF in this speed which

may result in seizure of the engine.

Shift the throttle lever swiftly to Fully Open position.

If throttle lever is shifted slowly, it will cause irregular

machine motion and say damage clutch, springs, and tamping shoe.

Do not operate the rammer for driving a pile or on a solid

ground exceeding capacity of the machine such as surface

paved with asphalt, concrete, cobblestone, and solid rock.

Otherwise, this may cause damage to the machine as too

much stress is applied to the machine body.

Do not get your hands off the handle while operating.

When operating the rammer on a ground surface with a large

roughness and a large level difference, or on a steep slope,

take care that you will not be injured in your wrist due to

overturn or slip of the machine body.

In addition, this may cause earlier damage to the machine as

an excessive stress is also applied to the machine body.

Be sure to stop the engine before leaving the rammer unattended.

•

•

•

•

•

•

CAUTION

17

6. Shutting down

6. Shutting down

(1) Return speed control lever to the lowest

speed position and allow the engine to

run for 1 to 2 minutes for cooling.

Return the throttle lever swiftly as in the start-up operation.

Do not stop engine immediately after high-speed operation.

otherwise oil deteriorates or motion members are stuck fast

since the engine temperature rises suddenly.

•

•

CAUTION

(2) Turn “OFF” the engine switch serving

also as fuel cock and push it up for more

than 3 seconds to stop the engine.

Closed

Throttle lever

Fuel cock

OFF

18

7. Inspection and Maintenance

7. Inspection and Maintenance

7.1. Engine

Refer to a separate Engine Operation Manual for the engine.

7.2. Rammer body

Wipe off dust. dirt, and oil stuck on the body and inspect it for anything unusual.

Also, check bolts and nuts for tightness.

7.3. Spark plug

Remove the spark plug to clean off carbon deposit on the plug every 50 hours of

operation. Adjust electrode gap to between

0.6mm and 0.7mm.

Spark plugs to be employed:

RS65 CR5HSB (NGK)

7.4. Air cleaner

Remove the air-cleaner element (only the

part made of urethane) and clean it with

wash oil (kerosene) every 50 hours of operation.

After cleaning, dip it in blended oil (mixture

in the ratio of 1 for engine oil to 3 for kerosene) and squeeze it hard for reassembling.

RS75 BP4ES (NGK)

RS45,RS65

RS45 CR4HSB (NGK)

19

7. Inspection and Maintenance

7.5. Rammer cylinder

Change oil after initial 50 hours of operation

for the first time, and every 200 hours of

operation thereafter. Wipe off the oil stuck

on the rammer after oil has been changed.

How to change oil:

Remove the drain plug and tilt the rammer

to discharge oil, then fill in the new oil.

Position the tamping shoe to be level to supply oil until it will overflow out of the drain

plug.

Quantity specified

RS45 : 500cc

RS65 : 800cc

RS75 : 900cc

Drain plug

7.6. Checking bolts in each section for their tightness

Check the mounting bolts for tightness. In particular, pay special attention around to the bolts

securing engine, crankcase, tamping shoe, and control handle.

RS45,RS65

RS75

20

8. Fuel and Lubricant

8. Fuel and Lubricant

8.1. Fuel

Fuel to be employed : Regular gasoline for automobile

Fuel tank capacity : 2.2 liters

8.2. Engine oil/Vibrator oil

Season Ambient temperature Viscosity rating

Summer

Spring/Autumn

Winter

All-year-round

25℃ and above

25℃〜 10℃

10℃〜 -10℃

Regardless of temperature

SAE#30

SAE#30 or #20

SAE#20

SAE 10W-30

21

9. For a long-term storage

9. For a long-term storage

(1) Drain fuel from the fuel tank and the carburetor completely and close the fuel cock.

(2) Pull the starter knob slowly until resistance is felt and leave it in this condition.

(3) Check the engine and the vibrator for oil leakage.

(4) Wipe off oil stains, if any, on the rubber dampers.

(5) Check bolts and nuts for tightness and re-tighten them as necessary.

(6) Put the cover over the rammer and store it in a dust-free, dry area.

(7) Remove the ignition plug to inject approximately 5cc of engine oil into the cylinder.

Then fit the plug and tighten it after the starter knob has been pulled up 2 or 3 times

repeatedly.

22

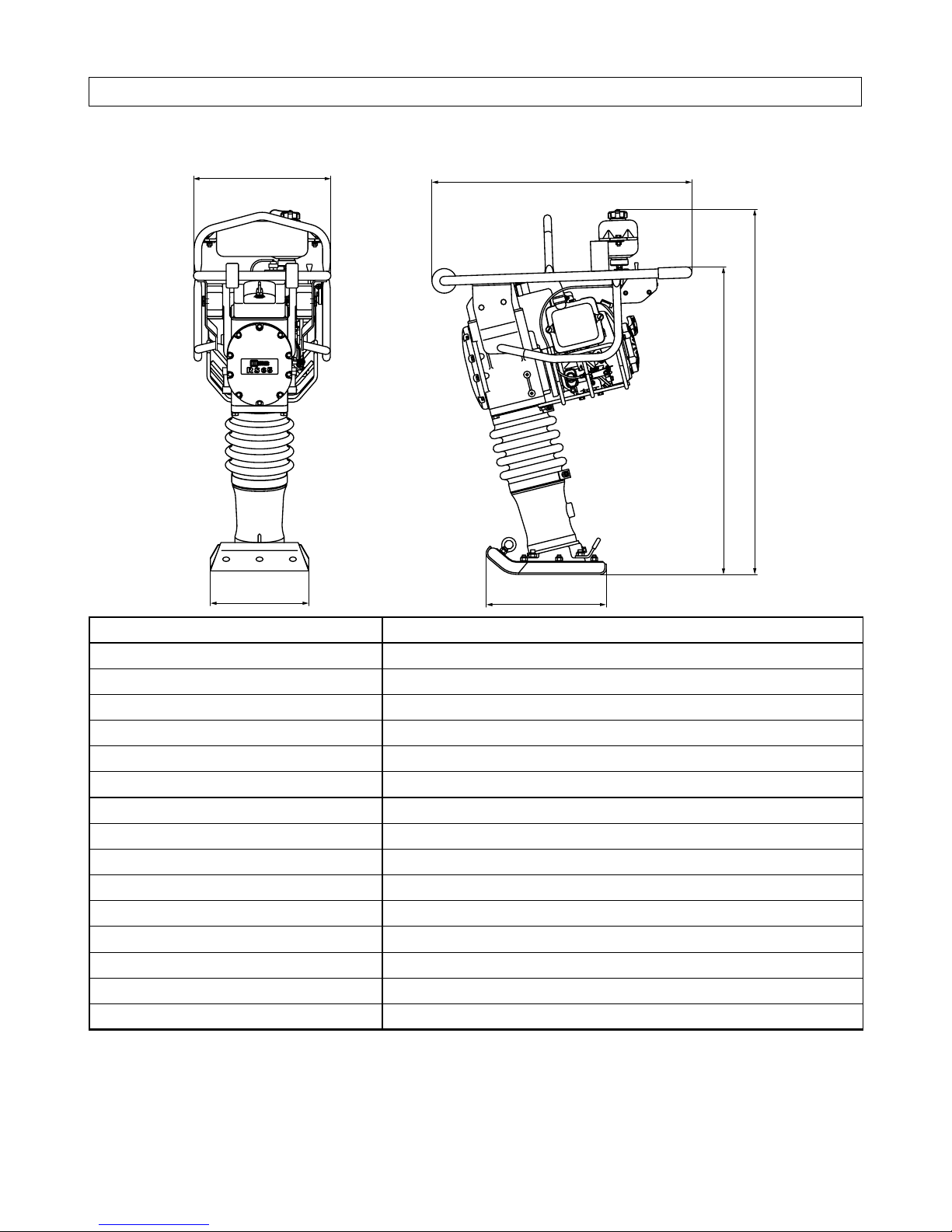

10. Overall View(RS45)

10. Overall View

RS45

370

230

340

700

870

965

Model RS45

Physical

Machine Weight *1 49kg

Total Length 700mm

Total Width 370mm

Total Height 965mm

Size of Tamping Plate 340mm(L) × 230mm(w)

Performance

Traveling stroke 40~60mm

Frequency 10.8~11.5Hz (650~690vpm)

Traveling Speed 8~12m/min

Engine

Manufacturer's Model HONDA model GX100KR

Maximum Output *2 2.2kW (3.0ps)/3600min

− 1

(rpm)

Fuel Gasoline

Starting System Recoil starter

*1. Indicating condition of the weight:

The weight to be indicated includes half the weight of fuel of the tank capacity and does not

include the weight of water for sprinkling use.

*2. Engine output indication:

This indicates maximum output at the operating speed.

23

10. Overall View(RS65)

RS65

390

280

340

740

875

1040

Model RS65

Physical

Machine Weight *1 71kg

Total Length 740mm

Total Width 390mm

Total Height 1040mm

Size of Tamping Plate 340mm(L) × 280mm(w)

Performance

Traveling stroke 50~70mm

Frequency 10.7~11.3Hz (640~680vpm)

Traveling Speed 16~20m/min

Engine

Manufacturer's Model HONDA model GX100KR

Maximum Output *2 2.2kW (3.0ps)/3600min

− 1

(rpm)

Fuel Gasoline

Starting System Recoil starter

*1. Indicating condition of the weight:

The weight to be indicated includes half the weight of fuel of the tank capacity and does not

include the weight of water for sprinkling use.

*2. Engine output indication:

This indicates maximum output at the operating speed.

24

RS75

10. Overall View(RS75)

415

280

340

795

875

1040

Model RS75

Physical

Machine Weight *1 80kg

Total Length 795mm

Total Width 415mm

Total Height 1040mm

Size of Tamping Plate 340mm(L) × 280mm(w)

Performance

Traveling stroke 50~70mm

Frequency 10.3~12.0Hz (680~720vpm)

Traveling Speed 17~21m/min

Engine

Manufacturer's Model HONDA model GX120K1

Maximum Output *2 2.8kW (3.7ps)/3600min

− 1

(rpm)

Fuel Gasoline

Starting System Recoil starter

*1. Indicating condition of the weight:

The weight to be indicated includes half the weight of fuel of the tank capacity and does not

include the weight of water for sprinkling use.

*2. Engine output indication:

This indicates maximum output at the operating speed.

2009.11.200 ② C.D

SAKAI HEAVY INDUSTRIES, LED.

Head office: 1-4-8, Shiba-Daimon, Minato-ku

Tokyo, Japan

Cable address: "SKWSAKAI" TOKYO

Telex: 242-3525 SKWMONJ

Telphone: Tokyo(03)3431-9971

November-2009

MODEL RS45, RS65, RS75

OPERATING & MAINTENANCE INSTRUCTIONS

Loading...

Loading...