VM1000 Series

VM1000 AC Drive

User Manual

资料代码:

‐0‐

Version Code :VM1000-E2016-04-1MB

VM1000 Series

Preface

Thank you for choosing SAJ VM1000 AC drive.

This user manual provides you with technical specification, installation instruction

and detailed function parameters of VM 1000.Before installation, operation,

maintenance or inspection, please read this manual carefully.

Special warning: Please be sure to read and understand the warnings and precautions

in this manual before using VM 1000 and make sure the certificate of relative

electrical engineers is line with the provisions of the labor supervision

department, and the electrics and environment conditions is in conformity with the

country’s standard.

Make sure the wiring is correct before it is power-on; before normally operating and

using this product, make sure the motor rotation meets the requirements by

debugging it.

When installing, using or maintaining the product, if it needs a consultation for

product functions, performance, other technical issues as well as safety precautions,

please contact our customer service center according to the hotline in the manual.

China service hotline: 400-159-0088

‐1‐

VM1000 Series

Content

Preface .............................................................................................. - 1 -

Precautions ...................................................................................... - 4 -

Signs, Abbreviation and Brandmark statement ........................... - 8 -

Chapter 1 Product Information ..................................................... - 9 -

1.1 Production Introduction ................................................................................. - 9 -

1.2 Technical Specification Table ...................................................................... - 10 -

1.3 Product nameplate........................................................................................ - 13 -

1.4 Model Description ....................................................................................... - 14 -

1.5 Dimension of AC Drive ............................................................................... - 14 -

1.6 Dimension of Keyboard ............................................................................... - 17 -

1.7 Specification of Selecting Products ............................................................. - 18 -

1.8 Maintenance ................................................................................................. - 19 -

Chapter 2 Installation ................................................................... - 22 -

2.1 Mechanical Installation ................................................................................ - 22 -

2.2 Electrical wiring ........................................................................................... - 28 -

2.3 Electro Magnetic Compatibility ................................................................... - 43 -

Chapter 3 Panel Display and Operation ................................... - 46 -

3.1 Introduction of Operation&Display Interface .............................................. - 46 -

3.2 Function Code Viewing, Modification Instruction ...................................... - 49 -

3.3 Viewing Methods of Status Parameters ....................................................... - 50 -

3.4 Password Setting ........................................................................................ - 50 -

Chapter 4 Quick Debugging Guide ............................................. - 51 -

4.1 Preparation and Examination Before Commissioning Operation ................ - 51 -

4.2 Panel Operation ............................................................................................ - 53 -

4.3 Start/Stop control of terminal forward rotation ........................................... - 56 -

4.4 Common Control Guideline ......................................................................... - 58 -

4.5 Auto-tuning of Motor Parameters ................................................................ - 62 -

4.6 Faults Query and Reset step ......................................................................... - 64 -

4.7 Parameters Restore as Factory Value ........................................................... - 65 -

‐2‐

Chapter 5 Function Code Datasheet ......................................... - 66 -

Chapter 6 VM1000 Communication Application ..................... - 112 -

6.1 The Content of Protocol ............................................................................. - 112 -

6.2 Application ................................................................................................. - 112 -

6.3 Bus Structure .............................................................................................. - 112 -

6.4 Protocol Instruction .................................................................................... - 113 -

6.5 Communication Frame Description ........................................................... - 113 -

6.6 Register Address ........................................................................................ - 118 -

Chapter 7 Faults and Solutions ............................................... - 126 -

7.1 Fault Code Table ........................................................................................ - 126 -

7.2 Troubleshooting and Solution .................................................................... - 138 -

Appendix A -Selection of External Electrical Components ..... - 140 -

A.1 VM1000 External Electrical Connection Diagram ................................... - 140 -

A.2 Selection Guide of Braking Components ................................................. - 143 -

A.3 Selection of Air Switch,Contactor or Cable .............................................. - 145 -

Appendix B-Manual Revision Record ....................................... - 146 -

VM1000 Series

‐3‐

VM1000 Series

Precautions

The Definition of Manual Warning Signs

In this manual, there are three kinds of warning signs that is respectively

corresponding to three kinds of precautions; once violated, it will probably cause

person injury to different degree.

DANGER: it indicates that it will probably cause death or severe physical

injuries if violate the correct instruction.

WARNING: it indicates that it could cause personal moderate injuries, minor

injuries or damage to the equipment if violates the correct instructions..

NOTE: it indicates that it would cause error or using equipment insecurely if

violates the correct instruction.

The Definition of Product Warning Signs

The product warning signs are right under the case cover.

It indicates that there is high voltage in the product

+10 minutes time delay, which indicates that it needs to wait for capacitor

discharging after power off

Before Installation

Before opening, please confirm that:(1) model and rated values on the nameplates

is same as the goods you order; products, certification accessories, user manual and

warranty card are complete and have not been damaged;(2) Whether the products

are damaged or destroyed with water etc.; If there is damages,losses or other

abnormal phenomenon,please contact our company or your suppliers to solve

problems

‐4‐

VM1000 Series

Warning

◎Do not install or operate the VFD if it is damaged or has missing parts. Otherwise it may

result in equipment damage or physical injuries.

Installation

Warning

◎Please hold the bottom of VFD when installing or moving it. In case that the VFD is

broken or damaged; only holding the shell is not allowed.

◎Keep the VFD away from heat, inflammable and explosive goods; Install VFD on the

metal or other nonflammable objects.

◎If the VFD is mounted in an electric cabinet or other enclosed objects, fans or other cooling

device should be installed inside the cabinet; Setting ventilation opening to ensure ambient

temperature is below 40℃. Otherwise it may be damaged because of high temperature.

Danger

◎Wiring must be completed by qualified electrical engineers. Otherwise it can cause an

electrical shock or VFD damage.

◎Before wiring, make sure the power supply is de-energized. Otherwise it will cause an

electrical shock or a fire.

◎Make sure the ground terminal is grounded safely and correctly. Otherwise there will

be a risk of electrical shock on the shell of VFD.

◎Do not touch the main circuit terminal, and the main circuit terminals of the VFD are not

allowed to contact the shell. Otherwise it may cause an electrical shock.

◎Braking resistor of the connection terminal is (+)and PB. Do not connect the other terminals;

Otherwise it may cause a fire.

‐5‐

VM1000 Series

Wiring

Warning

◎Before connecting, make sure the voltage rating and phase number of VFD is conformed

to the input power voltage, phase number; Otherwise it may cause a fire or physical injuries.

◎Never connect the AC input power supply to the output terminals V, U, W of VFD;

Otherwise it will cause damage to the VFD and you are not guaranteed to enjoy the warranty

services.

◎Never conduct a pressure test on VFD;Otherwise it will cause damage to the VFD.

◎The main circuit wiring of the VFD and the control loop wiring should be separated or

vertical crossed, otherwise the control signal will be interfered.

◎The cable connected to the main circuit terminals should be use lugs with isolated casing.

◎If the length of cable between the VFD and the motor is over 50 meters, an output reactor

is recommended so as to protect the VFD and motor.

Operation

Danger

◎Turn on the input AC power after the wiring of VFD is completed and the front cover is

installed. Do not dismantle the front cover when operating; otherwise it will lead to an

electric shock.

◎When VFD is set with the function of fault automatic reset or auto-restart after power

failure, protection measures for equipment system should be taken in advance. Otherwise it

will cause physical injuries.

◎The key “RUN/STOP” may be lose efficacy because some function had been set, a

separate emergency power switch can be installed in the VFD control system; Otherwise it

may cause damage or physical injuries.

◎Though the VFD terminal is in stop state, the terminal is electrified after power on. Do not

touch; otherwise there will be a risk of electric shock.

Warning

◎Do not use the breaker to control the stop/start of AC drive, or it may damage to the AC

drive.

◎Because the acceleration time is short when AC drive makes motor operates from low to

high speed, make sure the motor and mechanical equipment is within the permitted range

‐6‐

before operation,or it will damage the equipment.

◎The temperature of heat sink and braking resistor is high. Please do not touch. Otherwise,

it may cause burns.

◎When leaving factory, the preset parameters of AC drive have met most of the

operational requirements of equipment. If not necessary, do not arbitrarily change the

parameters. Even some devices have some special requirements; you can only modify the

necessary parameters. Otherwise, arbitrary modification may damage the equipment.

VM1000 Series

Maintenance and Inspection

Danger

◎When power on, do not touch the connection terminals. Otherwise it may cause an

electrical shock.

◎Only qualified electrical engineering personnel can maintain, replace and inspect the SPD.

◎Wait at least 10 minutes after the power failure, or make sure that is no residual voltage

before carry out maintenance and inspection, otherwise it may cause damage.

Note

◎PCB board has CMOS integrated circuit, do not touch, otherwise the static electricity may

damage PCB board.

Others

Danger

◎It is strictly forbidden to transform the VFD, otherwise it may cause casualties. After

arbitrarily changing VFD, will no longer enjoy the warranty service.

‐7‐

VM1000 Series

Signs, Abbreviation and Brandmark statement

■ Signs

Protective Earthing: PE

Signal Ground: GND

Shield: SHIELD

■ Name Abbreviation

1. In this user manual, VM1000 AC drive has another name or abbreviation:

Variable frequency drive, VM1000, inverter, speed controller, VFD product and

product.

2. VFD parameter is as follows:function parameters, function code, parameters

code

3. SAJ, Sanjing Electric、SAJ Electric are all the standard abbreviation of

Guangzhou Sanjing Electric Co. Ltd

4. Common Technical Terms,Similar or Equal Name:

Voltage frequency ratio control mode: VF control

Open-loop vector control mode: SVC control

Three-phase induction motor: asynchronous motor, squirrel-cage asynchronous

motor

■ Trademark

1. Modbus○R is the trademark of Schneider Electric

2. SAJ○R is the trademark of Guangzhou Sanjing Electric Co. Ltd

3. Other trademark that may occur or product names belong to respective owners

‐8‐

VM1000 Series

Chapter 1 Product Information

1.1 Production Introduction

The Usage of VM1000 AC drive

VM1000 AC drive is the new generation product with high performance and multi

usages, which usually apply in the regular three-phase induction motor for speed

control. Power range is 11~110kW;It can select V/F control mode or SVC control

mode.

Key Design Points

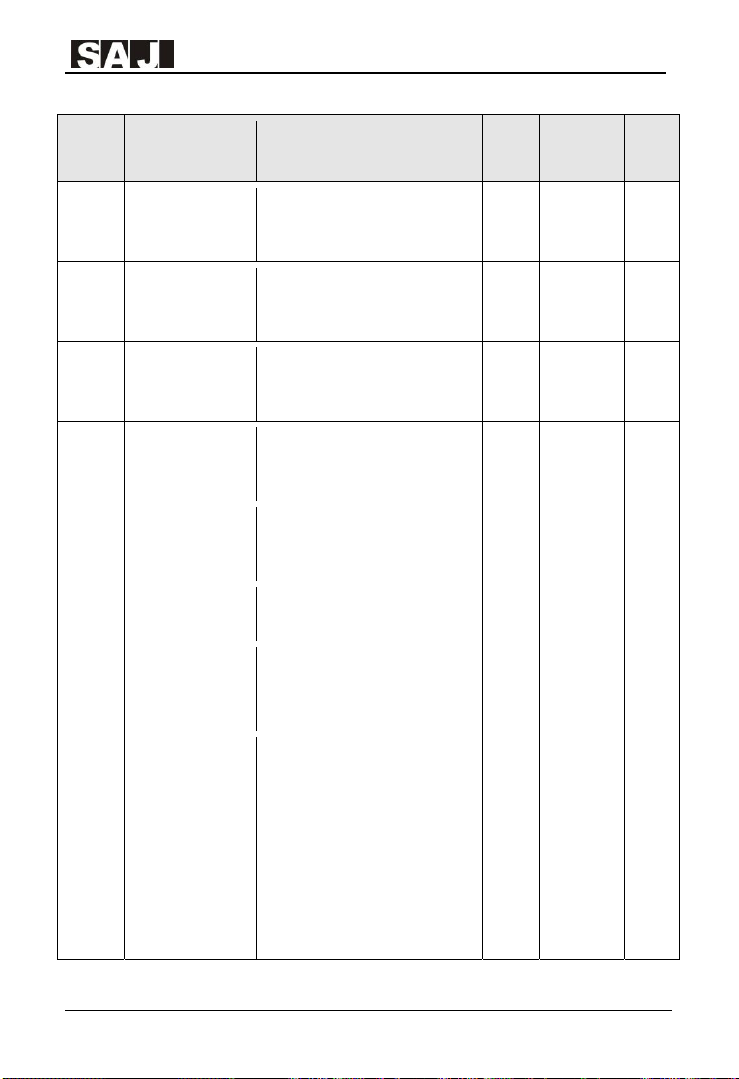

Design Points Instruction

1.Product adopts: large capacity power module,high accuracy detection

hardware and brandnew control platform

Control

performance and

function

2.Function upgrade: mainly includes torque control,S curve,given

frequency,vector control, V/F separation, Two groups of PID

parameters,input、output and auxiliary function,faults protection and

user-defined protection action

3. Meanwhile,it maintain the compatibility for previous products

Input/Output and

communication

interface

G/P load types

Structure design

Support 5 common inputs, 1 high-speed pulse input, 1 high-speed

pulse output( also work as open collector output DO), 2 relay output, 2

analogue output, 2 analogue input, 1 RS485 communication interface

Whole series support heavy load(G) and normal load(P) rating

characteristics.

G load type: typical constant torque load, such as conveyor, lift, crane,

etc.

P load type: typical variable torque load, such as pump and fan.

Structure optimization, dimension decrease, good heat dissipation,

industrial protection, simple case

‐9‐

Wiring installation

New keyboard

design

1. Main circuit adopt increased superior terminal array,large power

type and independent terminal,and equipped with dual GND ports.

2. Control terminal is vertical arranged on the left of the control board

and print with PCB logo.

1. Adopt potentionmeter of electrical impulse,standard keyboard

adopts 5 bits digital tube to display and match LED lights;

2. Common keyboard supports short distance installation externally,

and adopts LCD keyboard to realize long-distance external leading by

cables

VM1000 Series

Faults detection

EMC Level

Faults type and strategy are more refined, user can define faults

protection action

standard product satisfy IEC61800-3 C3 requirements

external filter satisfy IEC61800-3 C2 requirements

Table 1-1 Product Key Design

1.2 Technical Specification Table

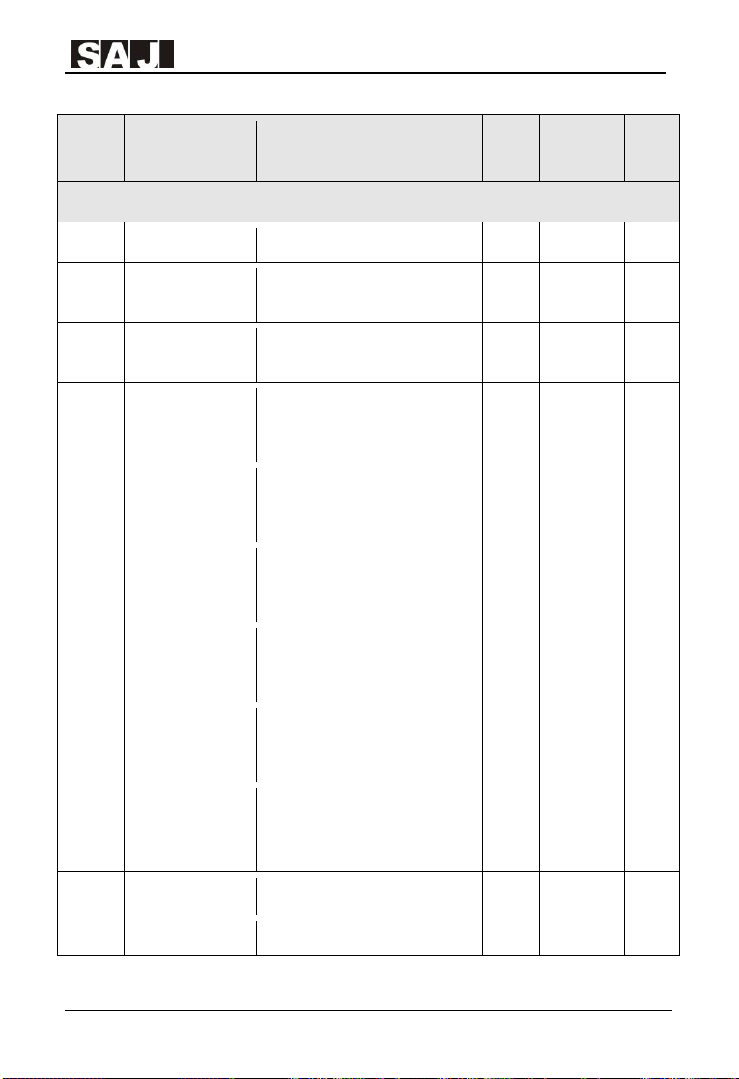

Item Specification

High frequency V/F control:0 ~ 1000Hz;vector control:0 ~ 400Hz

0.5kHz ~ 16kHz ; it can adjust load frequency

automatically according to the load character

G load type :0.5Hz/150%( SVC ) P load type:

0.5Hz/100%

1:100 (SVC)

±0.5%(SVC)

±5%(SVC)

G load type:60s for150% rated current;1s for180%

rated current

Personalized

Function

Carrier frequency

Control mode V/F control;SVC control;Torque control

Starting torque

Speed adjustable

range

Speed-holding

precision

Torque control

Accuracy

Overload capacity

‐10‐

P load type:60s for120% rated current;1s for 180%

rated current

Torque boost

V/F curve Three types: Linear, multipoint square V/F curve

V/F separation Whole separation,semi separation

Acceleration and

deceleration Time

DC braking

JOG control

Simple

PLC,multi-speed

control

Integrated PID It is convenient to realize closed-loop control system

AVR

Control of

overvoltage,

overcurrent, speed

stall

Rapid current limit

Torque limit and

control

Power peripheral

and safety

self-checking

MF.K Key

0.0% auto torque boost ; customized torque boost

0.1% ~ 30.0%

Linear mode and S curve acceleration and deceleration

time;Four kinds of acceleration and deceleration time;

the range of acceleration and deceleration time is

0.0 ~ 6500.0s

Braking time: 0.0s ~ 100.0s;Braking action current

value: 0.0% ~ 100.0%

JOG frequency range:0.00Hz ~max frequency;JOG

acceleration and deceleration time 0.0s ~ 6500.0s

16 section speed(at most) can be realized by integrated

PID and control terminals

When grid voltage changes,it keeps output voltage

constant automatically.

The current and voltage are limited automatically

during the running process so as to avoid frequent

tripping due to overvoltage/overcurrent.

Decrease overcurrent at max, protect VFD to operate

regularly

It can limit the torque automatically and prevent

frequent over current tripping during the running

process.

To realize self checking of peripheral equipment at

power on, such as grounding fault, short circuit fault,

etc.

Programmable:command channel switch,forward

rotation and reverse rotation/JOG function selection

VM1000 Series

‐11‐

VM1000 Series

Running

Display and

keyboard

operation

Textile swing

frequency control

control function of multiple triangular-wave frequency

Timing control Timing control: setting time range: 0h ~ 65535h

Operation command

channel

Frequency source

Auxiliary frequency

source

Input terminal

Output terminal

Three channels: operation panel given, control terminal

given, and communication given. It can be switched by

various methods.

There are 10 frequency sources in total: digital setting, analog

voltage setting, analog current setting, pulse setting and serial

communication port setting etc. It can be switched by these

frequency sources in various methods.

There are ten auxiliary frequency sources. It can implement

fine tuning of auxiliary frequency and frequency synthesis.

There are 6 digital input terminals. One of them can be used as

high speed pulse input, which can reach 100KHz at max. All

of them support supports active PNP and NPN input.

2 analog input (AI) terminals, one of which only supports

voltage input and the other supports voltage input or current

input

1.High-speed pulse output terminal (open-collector) that

supports 0–100 kHz square wave signal output, which can

realize the output of setting frequency and output frequency 2

relay output terminal

2 analog output (AO) terminal that supports 0/4mA–20 mA

current output or 0/2V–10 V voltage output, which can realize

the output of setting frequency and frequency etc.

LED display Displayed parameters

LCD display Optional; operation content indicated.

Parameters copy

Key locking and

function selection

Protection function

Iit can be achieved parameters’ fast copy via LCD

keypad option

It can lock the keys partially or completely and define

the function range of some keys so as to prevent

mis-operation.

Motor short-circuit detection at power-on, input/output phase

loss protection, overcurrent protection, overvoltage protection,

undervoltage protection, overheat protection and overload

‐12‐

Accessories

selection

Installation location

Altitude

Environment

Ambient

temperature

Humidity Less than 95%RH, without condensing

Vibration Less than 5.9m/s2(0.6g)

Storage temperature - 40℃~+ 70℃

Table 1-2 Technical Specification

1.3 Product nameplate

VM1000 Series

protection etc.

LCD operation panel, braking unit etc.

Indoor, free from direct sunlight, dust, corrosive gas,

combustible gas, oil smoke, vapour, drip or salt.

Lower than 1000m,higher than 1000m ,it is used at

derating

-10°C to +40°C (de-rated if the ambient temperature is

between 40°C and 50°C)

Figure 1-1 Product nameplate

‐13‐

VM1000 Series

1.4 Model Description

VM1000 – 4 T 18R5G/022P

① ② ③ ④ ⑤

Field Sign Sign Instruction Specification

Product

abbreviation

Voltage class ② Voltage class 2:220VAC; 4:380VAC

input power

phase

Rated power 1 ④ Power of G load type

Rated power 2 ⑤ Power of P load type

① Product abbreviation

③ Sign of power phase S:single-phase ;T:three-phase

Table 1-3 VM1000 Field Annotation

VM1000 : General vector control

variable frequency drive, “Vector

Master” series

18R5-18.5kW, R represents decimal

point

G—constant torque load

B—built-in braking unit

022-22kW

P—variable torque load

B—built-in braking unit

1.5 Dimension of AC Drive

Table 1-2 11kW-15kW Installation Dimension

‐14‐

VM1000 Series

Table 1-3 18.5kW-22kW Installation Dimension

Table 1-4 30kW-37kW Installation Dimension

‐15‐

VM1000 Series

Table 1-5 45kW-55kW Installation Dimension

Table 1-6 75kW-110kW Installation Dimension

‐16‐

VM1000 Series

1.6 Dimension of Keyboard

VM1000 operation keyboard is directly plug in the control board socket and is

buttoned on the keyboard tray.There is a keyboard frame for the the front cover.

After installation, the frame is fixed around operation keyboard. Please refer to 2-1.

If keyboard needs to be extended externally, please cut a rectangle hole on the

control panel or the door carbinet for the keyboard installation according to the

following dimension.

RESET

Table 1-7 Keyboard Dimension

■ Dimension Instruction

(1) There are four keyboard buckles; the distance between bottom and keyboard

surface is 7.6mm

(2)When cutting a rectangle hole for keyboard, it suggests adding 1mm more for the

length and width based on the dimension in this picture. Namely is Length 101.1mm

is increased to 102.1mm, and width 72.1mm is increased to 73.1mm.

■ Cover of Keyboard Window

It can select one window panel for installing keyboard externally in order to cover

the AC drive keyboard window.

‐17‐

1.7 Specification of Selecting Products

VM1000 Series

VFD Module (G/P load

type)

VM1000-4T011GB/015PB 11/15 17/21 26/35 25/32 11/15 15/20

VM1000-4T015GB/18R5PB 15/18.5 21/24 35/38.5 32/37 15/18.5 20/25

VM1000-4T18R5GB/022PB 18.5/22 24/30 38.5/46 37/45 18.5/22 25/30

VM1000-4T022GB/030PB 22/30 30/40 46.5/62 45/60 22/30 30/40

VM1000-4T030G/037P 30/37 40/57 62/76 60/75 30/37 40/50

VM1000-4T037G/045P 37/45 57/69 76/92 75/91 37/45 50/60

VM1000-4T045G/055P 45/55 69/85 92/113 91/110 45/55 60/70

VM1000-4T055G/075P 55/75 85/114 113/157 112/150 55/75 70/100

VM1000-4T075G/090P 75/90 114/134 157/180 150/170 75/90 100/125

VM1000-4T090G/110P 90/110 134/160 180/214 170/210 90/110 125/150

VM1000-4T0110G/132P 110/132 160/185 214/240 210/250 110/132 150/180

Rated

Power

(kW)

power

capacity

kVA A A kW HP

input

current

Output

current

Fitted Motor G/P

Table 1-4 Specification of Selecting Products

‐18‐

VM1000 Series

1.8 Maintenance

1.8.1 Routine Maintenance

The influence of the ambient temperature, humidity, dust and vibration will cause

the aging of the devices in the AC drive, which may cause potential faults or

reduce the service life of the AC drive. Therefore, it is necessary to carry out

routine and periodic maintenance.

(1) Routine maintenance involves checking:

• Whether the motor sounds abnormally during running

• Whether the motor vibrates excessively during running

• Whether the installation environment of the AC drive changes.

• Whether the AC drive's cooling fan works normally

• Whether the AC drive overheats

(2) Routine cleaning involves:

• Keep the AC drive clean all the time.

• Remove the dust, especially metal powder on the surface of the AC drive, to

prevent

the dust from entering the AC drive.

• Clear the oil stain on the cooling fan of the AC drive.

1.8.2 Periodic Inspection

Perform periodic inspection in places where inspection is difficult.

Periodic inspection involves:

• Check and clean the air duct periodically.

‐19‐

VM1000 Series

• Check whether the screws become loose.

• Check whether the AC drive is corroded.

• Check whether the wiring terminals show signs of arcing;

1.8.3 The Replacement of Vulnerable Components

The vulnerable components of the AC drive are cooling fan and filter electrolytic

capacitor. Their service life is related to the operating environment and

maintenance status. Generally, the service life is shown as follows:

Components name Lifetime

Fan 2 ~ 3 Year

Electrolytic capacitor 4 ~ 5 Year

Table 1-5 Lifetime of Wearing Parts

User can decide the replacing time according to its operation

(1) Cooling Fan

Damage causes: bearing wear, leaf aging

Judge standard: whether there is crack on the fan blase; whether there is abnormal

vibrating when turn on

(2) Filter Electrolytic Capacitor

Damage causes: the quality of input power is bad; the ambient temperature is relatively high;

frequent load jump, electrolyte aging

Judge standard: Whether there is liquid leakage or protrusion of safety valve or not,

electrostatic capacitance and insulation resistance measurement.

‐20‐

1.8.4 Storage of the AC Drive

For storage of the AC drive, pay attention to the following two aspects:

(1) Pack the AC drive with the original packing box provided by SAJ

(2) Long-term storage degrades the electrolytic capacitor. Thus, the AC drive

must be energized once every 2 years, each time lasting at least 5 hours. The input

voltage must be increased slowly to the rated value with the regulator.

VM1000 Series

‐21‐

Chapter 2 Installation

2.1 Mechanical Installation

2.1.1VM1000 Structure

E: Keyboard Tray

VM1000 Series

B: Fan

C: Front cover

D: Operation Keyboard

E: Keyboard

frame

Figure 2-1 VM1000 Structure

‐22‐

G: Cable Inlet

A: VM1000 housing

2.1.2 Removal Steps

(1)Example of Cover Removal and Installation

VM1000 Series

Figure2-2 Cover Removal

(2)Keyboard Removal Example

Figure2-3 Keyboard Removal

‐23‐

(3)Fan Removal Example

VM1000 Series

11-55kW

75-110kW

Figure 2-4 Fan Removal

2.1.3 Environment Requirements

VFD is power electrical equipment. In order to use regularly, make sure the

operation and storage environment meets the requirements. The following is the

detailed index sheet. If there are other items that involves with electric installation,

please refer to relative national or regional standards.

Item Index Instruction

Installation place: VM1000’s ingress protection is IP20. With power input

and high voltage output, it needs to be installed in indoors or equivalent

places. In order to keep away from accidental contact, invasion and prevent

rats and insects, it is suggested to install in the distribution box that has

sufficient protection effect or control box.

Installation

places and

Precaution

AC drive need to be installed on the surface of incombustible object such as

support, panel and solid architectural facade, and fix the AC drive with

screws and bolts.

Since a great amount of heat will be generated when VFD is running there

needs to have sufficient space around for heat dissipation. If necessary, it also

needs to equip with mandatory ventilation and heat dissipation devices.

Because the channel for ventilation and heat dissipation is designed

vertically, the VFD needs to be installed horizontally other than horizontally

or transversely.

‐24‐

Free from direct sunlight, high humidity and condensation

Free from corrosive, explosive and flammable gas

Free from oil dirt, dust and metal powder

VM1000 Series

Environmental

temperature

Humidity

Storage

temperature

Altitude

Vibration

When VFD is with normal rated load, the permitted environmental

temperature is -10℃+~40℃, service in derated capacity for 40℃~50℃.

Notes: 1) Derate 4% capacity for every 1℃ increased. 2) If the ambient

temperature is too low, it needs to take measures to increase the temperature.

≤95%RH, no water condensation

Notes: If there is condensation may occur due to environmental factors, install

electrical heating device in the control cabinet.

-40℃~ 70℃。

Lower than 1000m, use according to the normal load standard

Higher than 1000m, it needs derating. Derate 1% capacity every 100m.

Please install in the place that is not easy to generate vibration. Vibration

should not exceed 0.6G. Special Notes: 1. Do not be installed on the punching

machine etc; 2. Do not use as VOBC (Vehicle on Board Controller); 3. When

it is applied to moving equipment like cranes etc., ensure VFD is installed

according to the stability of equipment and make sure VFD won’t occur

uncontrollable shaking or other abnormal condition.

Table 2-1 Index List for Environmental Requirements

‐25‐

2.1.4 Installation Guide

(1) Single-drive Installation

It needs to keep space around the VFD in order to have abundant airflow.

Requirements of recommended spatial distance are shown as table 2-2

VM1000 Series

Figure 2-5 Spatial Distances

Power Level

11kW-15kW ≥ 100mm no requirements

18.5kW-37kW ≥ 200mm ≥ 50mm

45kW-110kW ≥ 300mm ≥ 50mm

Table 2-2 Recommended Spatial Distance

Dimension

B A

‐26‐

VM1000 Series

(2) Top/Bottom Installation

Insulation guide plate needs to be installed between two VFDs so as to separate airflow. Refer

to the requirements of recommended spatial distance.The picture below is the example of

Insulation guide plate.

Insulation guide plate

Figure 2-6 Diagram of Insulation Guide Plate

When two VFDs or more are installed side by side, increase 50mm at least for

every two; increase 100mm at least for the left and right, top and bottom

(3) Installation Method

Wall-mounting(11~110kW)

(4) Protection requirements

① Complete water-proof measures

② Preventing insects invasion,including adopt anti-rats and anti-pests measures

‐27‐

VM1000 Series

2.2 Electrical wiring

2.2.1 Electrical Operation Condition

VM1000 AC drive is applicable to the low-voltage power electrical system. Make

sure that the following conditions meet the requirements when conducting wiring. If

necessary, please refer to relative national or regional standards.

Item Instruction

Power

distribution

system

Three-phase four-wire system, three-phase five-wire system

Voltage and

frequency range

Power range

GND

requirements

Leakage

protection

Short-circuit

protection

Start/stop

control

380VAC,50/60Hz

Voltage:Three phase 380VAC, permitted fluctuation range ±15%,

Frequency:50/60Hz, permitted fluctuation range ±5%

The protective earthing,signal ground should be separately wired

With the VFD installed, power distribution line, it can not use circuit

breaker with leakage protection etc.As for the VFD application, please

complete equipment grounding measures to ensure the security.

VFD power supply need to connect with the circuit breaker with short

circuit protection or rapid fuse protector

Under normal situation, VFD conduct start /stop control by its panel, control

terminals and other methods.

Usually, it is not suggested to adopt contactor as the switch device at VFD

power-supply side, nor use it as motor’s start/stop control device at VFD output

side. If it is done and contactor is disconnected when operating, it will easily

damage VFD.

Notes: Some industries or equipment (such as elevator) is required to use

contactor as security isolation device at VFD power-supply side and output

side, which is in conformity with the above requirements.

Table 2-3 Electrical Running Condition

‐28‐

VM1000 Series

2.2.2 Electrical Safety Precautions

When installing, operating or maintaining VFD and other relative equipment, it

needs to take measures to prevent static electricity and electricity shock .Please refer

to precautions in this manual.

2.2.3 Product Electrical Components

The electrical components are as shown on the picture below

Control terminals

Signal ground

Cable inlet

Operation keyboard

Control board

External keypad socket

Main circuit terminals

& Ground terminals

Figure 2-7 Electrical Components

‐29‐

2.2.4 Main Circuit Wiring

VM1000 Series

Figure 2-8 11~22kW Main Circuit Wiring

The external components

P

Brake unit

Earth ground

Output terminal at

GND

variable frequency

AC reactor

MCCB MC

Earth ground

Figure 2-9 30~110kW Main Circuit Wiring

‐30‐

(1)11~15kW Main Circuit Terminals

VM1000 Series

Figure 2-10 11~15kW Main Circuit Terminals

(2)18.5~22kW Main Circuit Terminals

Figure 2-11 18.5~22kW Main Circuit Terminals

(3)30~37kW Main Circuit Terminals

Figure 2-12 30~37kW Main Circuit Terminals

‐31‐

(4)45~55kW Main Circuit Terminals

VM1000 Series

Figure 2-13 45~55kW Main Circuit Terminals

(5)75~110kW Main Circuit Terminals

Figure 2-14 75~110kW Main Circuit Terminals

‐32‐

VM1000 Series

(6)Main circuit terminal and function are as shown on the table below

Terminal

sign

R、S、T

(+)、(-)

(+)、PB

P、(+)

U、V、W VFD output terminals Connect to a three-phase motor

Three phase power supply input

terminals

Positive and negative AC bus

terminals

Connecting terminals of brake

resistor

Connecting terminals of external

reactor

Grounding terminal

Name Instruction

Connect to three phase AC power supply

Common DC bus input point(connect the

external braking unit to AC drive of 30kw

or above)

Connect to braking resistor for AC drive

of 22kw and below

Connect to an external reactor

Ground Terminals

Table 2-4 Main Circuit Terminals and Function

(7)Wiring Precautions

A: Input Power R、S、T

The cable connection on the input side of the AC drive has no phase sequence

requirement.

B: DC bus terminals (+), (-)

Terminals (+) and (-) of DC bus have residual voltage after the AC drive is

switched off. Before touching the equipment, wait until power indicator goes off

and make sure it is lower than 36V. Otherwise, you may get electric shock.

–– connecting external braking components for the AC drive of 30 kW or above.

‐33‐

VM1000 Series

Do not reverse poles (+) and (-). Otherwise, it may damage the AC drive and even

cause a fire.

–– The cable length of the braking unit shall be no longer than 10 m. Use twisted

pair wire or pair wires for parallel connection.

–– Do not connect the braking resistor directly to the DC bus. Otherwise, it may

damage the AC drive and even cause fire.

C: Braking resistor connecting terminals (+)、PB

The connecting terminals of the braking resistor are effective only for the AC drive

of 22kw and configured with the built-in braking unit.

The cable length of the braking resistor shall be less than 5 m. Otherwise, it may

damage the AC drive.

D: External reactor connecting terminals P、(+)

For the AC drive of 33 kW and above, it support external DC reactor. Remove the

jumper bar across terminals P and (+) and install the reactor between the two

terminals.

E: AC drive output terminals U, V, W

The capacitor or surge absorber cannot be connected to the output side of the AC

drive. Otherwise, it may cause frequent AC drive fault or even damage the AC

drive.

If the motor cable is too long, electrical resonance will occur due to the existance

of distributed capacitance. This will damage the motor insulation or generate

higher leakage current, causing the AC drive to trip in overcurrent protection. If

the motor cable is greater than 50m, an AC output reactor should be installed close

to the AC drive.

‐34‐

F: PE Terminal

This terminal must be reliably connected to the main earthing conductor and

resistance range must less than 0.1Ω. Otherwise, it may cause mal-function or even

damage to the AC drive.

Do not connect the earthing terminal to the neutral conductor of the power supply.

Notes: The peripheral circuit includes breakers, braking resistor, braking unit and

wiring specification guide such as optional guidance, please see Appendix A.

VM1000 Series

‐35‐

2.2.5 Control circuit wiring

VM1000 Series

Figure 2-15 Control Circuit Wiring

‐36‐

(1)Control Terminals Diagram

VM1000 Series

Figure2-16 Control Terminals

‐37‐

(2)Control terminals and functions

Type Terminal Name Function description

VM1000 Series

Power supply

Analog input

Digital input

+10 V

+10V-GND

power supply

external

connection.

+24 V

+24V-COM

power supply

external

connection

Input terminal of

OP

external power

supply

AI1-GND analog input 1

AI2-GND analog input 2

DI1 Digital input 1

DI2 Digital input 2

DI3 Digital input3

DI4 Digital input4

DI5 Digital input5

Provide +10 V power supply to external

unit. Maximum output current: 10 mA.

for

Generally, it provides power supply to

external, potentiometer with resistance

range of 1–5 kΩ.

Provide +24 V power supply to external

unit. Generally, it

for

digital input, output terminals and external

sensor. The max output current: 200mA

is used as power supply for

Connect with +24 V power supply or COM

by choosing lug plate on the control board.

Factory default is connecting to +24 V.

When using external signal to drive DI1~

DI6, OP needs to be connected with external

power supply

plate among terminals OP-24V.

after removing the default lug

1.input voltage range:DC 0V ~ 10V

2.input impedance 22kΩ

1.Input range:DC 0V ~ 10V/4mA ~

20mA,decided by J8 jumper on control

board.

2. input impedance 22kΩ,current input

500Ω

1.Optical coupling isolation, 2.compatible

with dual polarity input

Impedance: 2.4 kΩ

3.Voltage range for level input: 9–30 V

‐38‐

VM1000 Series

DI6

AO1-GND analog output 1 A01 is decided by J5 jumper on the control

analog output

Digital output FM-CME

Relay output

Communicati

on terminal

and socket

AO2-GND analog output 2

T1/A-T1/B

T1/A-T1/C

T2/A-T2/B

RS+ RS485 differential signal+

RS- RS485 differential signal-

RJ45 socket External LCD keyboard interface

High-speed pulse

input

Digital output 1/

High-speed pulse

output

Normally closed

terminal

Normally open

terminal

Normally open

terminal

Except for DI1~DI5, it can also work as

High-speed pulse input

Max input frequency:100kHz

board, A02 is voltage input

output voltage:0V ~ 10V

output current:0mA ~ 20mA

Optical coupling isolation, dual polarity

open collector output

Output voltage range: 0–24 V

Output current range: 0–50 mA

Note that CME and COM are internally

insulated, but they are shorted by jumper

externally. In this case DO1 is driven by +24

V by default. If you want to drive DO1 by

external power supply, remove the jumper.

Contact driving capacity:

AC250V,3A,COS

DC 30V,1A

ø=0.4。

Table 2-5 Control Terminal and Function

‐39‐

VM1000 Series

(3)Wiring Standard of Control Terminal

According to the input signal and internal design of terminals, there are A, B, C

three conditions as following.

A: Analog input terminal

Weak analog voltage signals are easy to suffer external interference, and therefore

the shielded cable must be used and the cable length should be less than 20 m, as

shown in following picture2-17.In applications where the analog signal suffers

severe interference, install filter capacitor or ferrite magnetic core at the analog

signal source,as shown in following picture 2-18.

+10V

AI1

GND

PE

Figure 2-17 Analog input terminals

Figure 2-18 Analog input terminals handling

‐40‐

VM1000 Series

B:Digital Input Terminal

Generally, select shielded cable no longer than 20 m. When active driving is adopted,

necessary filtering measures shall be taken to prevent the interference to the power supply. It

is recommended to use mechanical contact input for control.

SINK Wiring

Figure 2-19 SINK Wiring

Sink wiring is the most commonly used wiring mode. To apply external power

supply, remove jumpers between +24 V and OP and connect the positive pole of

external power supply to OP and negative pole to COM.

‐41‐

VM1000 Series

Figure 2-20 Source Wiring

To source wiring, OP must be changed to connect to COM(for example by lug plate), and

connect +24v to public terminal of external controller.If using external power, it also

needs to connect the negative pole of external power to OP.

C:Digital Output Terminal

When the digital output terminal needs to drive the relay, an absorption diode shall

be installed between two sides of the relay coil. Otherwise, it may cause damage to

the 24 VDC power supply.

Do not reverse the polarity of the absorption diode during installation, as shown in

Figure2-21. Otherwise, the 24 VDC power supply will be damaged immediately

once there is digital output.

‐42‐

VM1000 Series

Figure 2-21 Wiring of Digital Output Terminal

2.3 Electro Magnetic Compatibility

2.3.1 Eletromagnetic Interference and Installation Precautions

The electromagnetic interference includes two situations: one is electromagnetic

noise from the surroundings having interference on VFD; the other interference is

the interference to other equipment generating by VFD

Precautions:

(1)VFD and other electrical product should be well grounded.

(2)Try not to install the power input and output cables of the AC drive and

weak-current signal cables (such as control cable) in parallel. Install vertically if it

has conditions.

(3)It is recommended to use shield cable in the VFD output power or and the

shielding should be grounded completely.For the extension cable of interfered

equipment, it is suggested to use twisted shield cable and shielding should be well

grounded.

(4)If motor cable is longer than 50m, it requires to install output filter and reactor.

.

‐43‐

VM1000 Series

2.3.2 Solutions of Interfering VFD by Electromagnetic Equipment

Generally, the reason that VFD has an influence on electromagnetic is there are a large number

of relays, contactors, or electromagnetic brakes around VFD.When VFD is interfered and

malfunction, the following methods are recommended:

① Install a surge suppressor for the part that generates interference

②Install a filter at VFD intput side, refer to 2.3.5 for more details

③Use shield cables in VFD control signal line and detection cable, shielding should be well

grounded.

2.3.3 Solutions of interfering peripheral equipments by VFD

Noise in this part is classified into two kinds:One is VFD radiated interference;The other one

is VFD conducted interference. Both kinds of interference generate eletro magnetic and

electrostatic induction around the equipment, which result in equipment malfunction. Refer to

the following solutions according to various interference situations

(1)Generally the signal of meter, receiver and sensor etc for measuring is relatively

weak. If they are closed to VFD or in the same cabinet, it will cause interference and

malfunction to them easily.It is suggested to adopt the following solutions:Try to keep away

from the interference source;Do not arrange signal cable and power cable in parallel,especially,

do not tie together.Signal cable and power cable should use shield cable and ground

well;Install ferrite ring on VFD output side(suppressing frequency range from 30~1000MHz),

and coil 2 ~ 3 turns. For bad conditions, it can install an EMC output filter as option.

(2)When the equipment and VFD use same power, it will cause conducted interference. If the

solutions above can not eliminate interference, it needs to install EMC filter between VFD and

power (For model selection, refer to 2.3.5)

(3)Peripheral equipment ground independently, which can eliminate interference that caused

by leakage current of VFD ground cable when it is in common -ground.

‐44‐

VM1000 Series

2.3.4 Leakage Current and Handling

There are two forms of leakage current while using VFD: one is earth leakage current,the other

is leakage current between cable and cable.

(1)Factors that influenced earth leakage current and solutions

There exists distributed capacitance between wire and earth.The bigger the distributed

capacitance, the larger the leakage current.It can decrease the carrier frequency in order to

decrease leakage current. However, to decrease carrier frequency will increase motor noise.

Please note that the installation of the reactor is also an effective way to solve the leakage

current.

Leakage current increases with the loop current. When motor power is high, the corresponding

leakage current is high.

(2)The factors that caused leakage current between cable and cable and solutions

There exists distributed capacitance in VFD output circuits. It is likely to cause resonance and

bring about leakage current if the current in the circuits contains higher harmonics. If thermal

relay is put into use at this time, it will cause malfunction.

Solutions: decrease carrier frequency or install output reactor. When using VFD, it is suggested

to use its electronic overload protection, and do not install a thermal relay before the motor.

Precautions of installing EMC input filter at power input side

①Notes:Strictly comply with the ratings when using the EMC filter. The EMC filter is

category I electric apparatus, and therefore, the metal housing ground of the filter should be in

good contact with the metal ground of the installation cabinet on a large area, and requires good

conductive continuity. Otherwise, it will result in electric shock or poor EMC effect.

②As result of EMC test, it founds that the ground of the EMC filter and the PE conductor of

the AC drive must be tied to the same common ground. Otherwise, the EMC effect will be

affected seriously.

③The EMC filter should be installed as closely as possible to the power input side of the AC

drive.

‐45‐

VM1000 Series

Chapter 3 Panel Display and Operation

3.1 Introduction of Operation&Display Interface

You can modify the parameters, monitor the working status and start or stop the VFD

by operating the operation panel. Its shape and functions are as shown in the

following figure.

Figure 3-1 Operation Panel

‐46‐

VM1000 Series

(1)Indicator Instruction

RUN: ON indicates that the AC drive is in the running state, and OFF indicates that the AC

drive is in the stop state.

LOCAL/REMOT: Keyboard operation, terminal operation and remote operation

(communication control) indicators. OFF indicates keyboard operation control; ON indicates

terminal operation control, FLICKER indicates remote operation control

FWD/REV:ON indicates reverse rotation, and OFF indicates forward rotation.

TUNE/TC:When the indicator is ON, it indicates the auto-tuning state. When the indicator is

blinking, it indicates the fault state.

(2)Unit Indicators

Hz: unit of frequency

A: unit of current

V: unit of voltage

RPM(Hz+A): unit of rotational speed

%(A+V): Percentage

(3)Digital Display

The 5-digit LED display is able to display the set frequency, output frequency, monitoring data

and alarm codes.

(4)Pulse Electronic Knob

VDF panel has a pulse electronic knob. It can be used as frequency reference. When using this

configuration of the drive knob as frequency source, turning it clockwise is the increased

setting and counterclockwise is reduced setting. There are icons on the panel to present you

operation direction.

‐47‐

(5)Keys and Functions of Operation Panel

Key Name Function

PRG Programming Enter Level I menu; exit one level from present sub-menu.

VM1000 Series

ENT Confirm

Increment Increase data or function code.

Decrement Decrease data or function code.

》 Shift

RUN RUN Start the AC drive in the operation panel control mode.

STOP/ RESET Stop/Reset

MF.K

Multi-function

key

Enter the sub-menu display level by level; confirm the parameter

setting.

Select the displayed parameters in cyclic turn when in the stop or

running state, and select the digit to be modified when modifying

parameters.

Stop the AC drive when it is in the running state and perform the

reset operation when it is in the fault state. The functions of this key

are restricted in F7-02.

Select function switchover according to the setting of F7.01.

Table 3-1 Keypad Instruction

‐48‐

VM1000 Series

3.2 Function Code Viewing, Modification Instruction

The operation panel of VM1000 adopts three level menus to conduct parameter

setting.

The three-level menu is:function code group (Level I) →function code (Level II)

→ function code setting value (level III), as shown figure 3-2.

Table 3-2 Operation Flowchart of Three-level Menu

Instruction: In Level III, you can return to Level II by pressing PRG or ENTER.

The difference between them is: it will save the parameter setting, return to Level

Two, and then shift to the next function code by pressing ENT. While you press

PRG, the system will directly return to Level Two without saving the parameter

setting.

For example: Modify F4.02 from 10.00Hz to 15.00Hz

Table 3-3 Flowchart of Function Code Modification

In Level III: if there is no flicker bit in parameters, it indicates the function code

can not be modified. The possible reason is:

a. The function code is unchangeable parameters. eg: actual detection parameters,

running record parameters.

b. Function code can not be modified at running statue. It can be modified after

stopping.

‐49‐

VM1000 Series

3.3 Viewing Methods of Status Parameters

In stop or running status, it can separately demonstrate various status parameters

by using “》”. Whether parameters are displayed is determined by the binary bits of

values converted from the values of F7.03(parameter 1 LED displayed at running),

F7.04(parameter 2 LED displayed at running), and F7.05(parameter 3 LED

displayed at stop) in the hexadecimal format

In stop status, a total of 12 status parameters can be displayed: setting frequency,

bus voltage, DI input status, DO output status, Analog inputAI1 voltage, Analog

inputAI2 voltage, actual count value, actual length value, PLC (running steps),

load speed, PID setting, PULSE input frequency and three reserved parameters.

Pressing “》” to select the parameters.

In running status, there are 29 status parameters: running frequency, setting

frequency, bus voltage, output voltage,output current are default display.Other

display parameters:output power, output torque, DI input status, DO output status,

analog input AI1 voltage, analog input AI2 voltage, analog input AI3

voltage,actual count value, actual length value,linear speed, PID setting, PID

feedback are displayed by the binary bits of values converted from the values of

F7.03, F7.04. Pressing “》”and then switch the keys sequencely to display the

selected parameter.

When VFD is power-on again, the display parameters are defaulted as the selected

parameters before power off.

3.4 Password Setting

VM1000 offer protection function of user password. When FE.00 set as nonzero,

namely user password, the password come into effect after exiting the function code editing.

Press PRG again, it will indicate “.....”. User password must be correctly input in

order to access common menu. Otherwise, it cannot enter.

If you want to cancel code protection function, it needs to use passwords to enter and

set FE.00 as 0.

‐50‐

VM1000 Series

Chapter 4 Quick Debugging Guide

4.1 Preparation and Examination Before Commissioning

Operation

VM1000 is the electrical appliance that used in motor drive and speed adjustment.

Therefore, it needs to make a preparation for electric and mechanic conditions

before operating, and examine the commissioning operation. The following table

4-1 is relevant items

Item Instruction

Stabilization

&

Installation

of VM 1000

Input

connection

in main

circuit

Output

connection

in main

circuit

Motor

installation

condition

In case loose wiring caused by moving or damages incurred by equipment drop, VFD

should be installed firmly. Please refer to 2.1.3 and 2.1.4 to confirm the installation.

For temporary power-on operation, like product detection test, VFD should be placed on

the platform stably and can’t be operated for a long time.

1. Be sure input voltage and capacity is conform to the requirements of VFD rated

value.Please refer to the nameplate in 1.3 and data in 1.6 section

2. Be sure cable connection is correct and firm, meanwhile, the cable

specification is complied with the reference data of cable selection in Section 3

of Annex A.

1. Make sure the rated voltage of motor is corresponding to the output rated value of VFD;

make sure the connection is stable and secure.

2. Be sure cable connection is correct, meanwhile, the cable specification is

complied with the reference data of cable selection in Section 3 of Annex A.

1. Make sure the installation of motor is stable and secure, and is corresponding to the

requirements of mechanical design. The motor that is not securely installed will likely

cause an accident.

2. For the idle motor or the motor with a load, ensure that the start will not cause damage

to persons and equipment. Even if the test running should be in the same case. For those

equipment that prohibit reversed rotation, it must remove the coupling between motor and

mechanical first.,After confirming rotation is correct by commissioning operation, it can

restore the mechanical connection.

3. In the torque control mode of VFD,it needs to ensure that there will be no

‐51‐

danger of runaway in motor and equipment, while it needs to set and examine

vfd max frequency of torque control rotation correspondingly (F3.12 and

F3.13). NOTE: Runaway refers to a state that is out of control because of a

sudden and rapid acceleration with no load.

4. Make sure that the insulation of the motor is normal. When testing motor insulation,

VFD output wiring must be disconnected. Please refer to safety precautions in the

manual.

VM1000 Series

Mechanical

safety

inspection

Control

circuit

connection

VFD

parameters

1. Make sure there are enough security measures for the drive motor and machine.

2. It is suggested to conduct no-load test in the first operation,

1. Adopt the cable selection which is conforming to A.3.

2. For the wiring of control circuit, please refer to 2.2.5 for design and inspection.

Please check that the drive parameter settings is corresponding to mechanical design or

control mode required by product testing.If not, it will likely result in accidents after

starting.

For the drives applied in vector control mode, it also need for auto-tuning of motor

parameters, Please refer to Section 4.5.

Table 4-1 Examination of Commissioning Operation

After completion of commissioning operation, it can be energized and conduct

subsequent tests in accordance with the formal operation of electrical safety

standards

‐52‐

VM1000 Series

4.2 Panel Operation

(1)Application

It usually adopt panel operation for the single-drive VFD which doesn’t need

external operating or control devices as well as regular product inspection. At the

same time, it can use a knob or digital setting in the frequency setting principal.

(2)Typical Wiring

Only after main circuit wiring, it can be operated by panel, including start/stop.

Figure 4-1 VFD Main Circuit Wiring

(3)VFD Parameter Setting

Function

code

F0.00

Name Setting Instruction Notes

Control

Mode

Selection

1 V/F control

Setting factory value as 1, adopt

V/F control.When debugging,

except rated value of motor, the

other motor parameters don’t

need to be adjust.

2. If it is changed as 0, vector

control, please refer to section

4.5 to conduct auto-tuning of

motor parameter.

‐53‐

When it is in

simple

application,

keep the

factory setting

value

unchanged

VM1000 Series

F0.01

F0.03

F0.08

F0.09

F0.10

X

0:Command

channel of

operation panel

(light off)

0:Eletronic

potentiometer(

non-retentive at

power off)

1: Digital

setting

(retentive at

power

off) ……

0.00Hz ~max

frequency

F0.10

0:Forward

1:Reverse

50.00Hz ~

400.00Hz(V/F

at max

is1000.0Hz)

The factory value is 0,it can

implement start/stop control by

panel operation

When the factory value is set as

0, conduct the frequency given

by the EVR of control panel

It can be changed as 1, namely to

modify the F0.08 frequency

given value by operation panel

When F0.03 is set as 1, it needs to

set this parameters as running

given frequency.

When the running direction of

motor is not corresponding with

the use requirements, the rotate

direction can be changed by

modifying this parameters

In accordance with the motor

nameplate, ensure that the VFD

output does not exceed the rating

of the motor.

NOTE: Under certain

circumstances, the motor can be

adjusted according to frequency

range allowed by motor.

Control

Command

Source

Master

Frequency

Reference

Selection

Setting

Frequency

Running

direction

selection

Max output

frequency

Table 4-2 Common Parameters Setting of Operation Panel

Remain

unchanged

When using

eletronic

potentiometer,

keep the

factory value

unchanged

To modify this

parameters is

equivalent to

commutation

and wiring of

motor

Factory value

50.00Hz

Other parameters that may be adjusted: F0.18 acceleration time 1, F0.19

deceleration time 1 etc.

‐54‐

b

VM1000 Series

(4)Steps of Panel Operation

Step Operation Panel display Indicator Note

5- digit LED

Start Press “Run” Key

Viewing

running

status

Press “”key,

switch display

status in turn

display become

non-flicker from

flicker when

operating

there are four items

of default display:

running

frequency,setting

frequency,bus

voltage,output

current

RUN indicator become

lighter

Turn on the Hz,A,V

separately or turn them

on in group

Refer to 3.1

Refer to 3.1

Stop

Press

“STOP/RESET”

5- digit LED display

ecome flicker from

non-flicker

RUN Light off Refer to 3.1

Table 4-3 Panel Operation Procedure

‐55‐

VM1000 Series

4.3 Start/Stop control of terminal forward rotation

(1)Application

VFD common control mode is start/stop control. Generally, it is used in conveyor,

fan, and pump etc.

(2)Typical Wiring

In the control circuit, it can adopt 2 wiring or 3 wiring. The following is 2 wiring

scheme

Figure 4-2 Start/Stop Control of Forward

(3)VM 1000 Parameter Setting

In F0 group, except F0.01, other parameter can refer to Table 4-2

Function

code

F0.01

Name Setting Instruction Note

1. Modify the setting

as 1, namely conduct

the start and stop

control by terminal

input signal

2. Terminals(with

LOCAL/REMOTE

Control

Command

Source

0: Keypad(with

LOCAL/REMOTE light off)

1: Terminals(with

LOCAL/REMOTE light on)

2: Communication(with

LOCAL/REMOTE LED

‐56‐

flashing) light on)

VM1000 Series

Factory value has

been set as 0, namely

adopt two wiring

control mode 1

Factory value has

been set as 0, namely

adopt two wiring

control mode 1

Factory value

remain

unchanged

Factory value

remain

unchanged

F5.00

F5.16

DI1

terminal

function

Terminal

control

mode

Setting range:0~50

1 indicates: forward

rotation(FWD)

Setting range:0~3

0 indicates: 2 wiring scheme

1

Table 4-4 Common Parameters Setting of FWD Start/Stop

(4)Operation Procedure

Steps Operation Panel display Indicator Note

Start

Viewing

running

status

Stop

Connect DI1 and COM

Usually, it adopts one

manual switch or PLC

output

Press “”key, switch

display status in turn

Disconnect DI1 and

COM

5- digit LED display

become non-flicker

from flicker when

operating

There are four items of

default display:running

frequency,setting

frequency,bus

voltage,output current

5- digit LED display

become flicker from

non-flicker

RUN Lights on

Turn on the

Hz,A,V

separately or turn

them on in group

RUN Light off

Refer to

Refer to

Refer to

3.1

3.1

3.1

Table 4-5 Running Procedures of FWD Start/Stop

‐57‐

VM1000 Series

4.4 Common Control Guideline

4.4.1 Multi- step Speed Control

(1) Multi-step Speed

It indicates the selection of VFD preset out frequency is completed by the DI

input terminals. It supports a maximum of 16 preset value.Usually, this mode is used

for switching multiple operation speed in turn. It often applied in escalator,conveyor

and large washing equipment etc.

(2) Typical wiring

The following is the wiring diagram of multi- step speed mode that adopt DI2 and

DI3

Figure 4-3 VM1000 FWD Multi-step Speed Control

(3) Parameter setting

This application is the control terminal control; start/stop can be 2-wire or 3-wire.

Control parameters can be found in the above Table 4-4. Table 4-6 is the parameter

example of Figure 4-3 that adopts two DI terminals at 4- step speed

‐58‐

VM1000 Series

Function

code

F5.01

Name Setting Instruction Note

DI2 terminal

function

DI3

F5.02

terminal

function

FD.00

FD.01

FD.02

FD.03

Multi-step

speed 0

Multi-step

speed 1

Multi-step

speed 2

Multi-step

speed 3

Table 4-6 FWD Control Parameter at Multi-step Speed

4.4.2 PID control

Setting range:0~50

12~15 indicates multi-step speed

1~4

Setting range:0~50

12~15 indicates multi-step

speed 1~4

-100.0%~100.0% (100.0% refers

to maximum frequency F0.10)

-100.0% ~ 100.0%

-100.0% ~ 100.0%

-100.0% ~ 100.0%

Modify the setting as 12,

namely DI2 is Multi-step

speed 1

Modify the setting as 13,

namely DI3 is Multi-step

speed 2

Setting according to the

applied requirements

Setting according to the

applied requirements

Setting according to the

applied requirements

Setting according to the

applied requirements

(1)PID control

It refers to PID algorithm- a control mode that is used for conducting process

adjustment on controlled objects. In this mode, the VFD output is used to adjust

some physical quantities such as speed, temperature, pressure, flow, etc., and the

corresponding target values can be set via digital, analog given, and other

communications given. It is often used in variable frequency air compressor,

draw-bench, constant-pressure water supply, HVAC, and so on.

‐59‐

VM1000 Series

(2)Typical wiring

The following the water supply system wiring diagram that adopts given digital and

analog feedback

M

Figure 4-4 VM1000 PID Control

(3) Parameters setting

This control application is terminal control, which start and stop is 2-wire or 3-wire.

The master frequency needs to be modified as PID. Part of the control parameters

can be found in the above Table 4-4. The following Table 4-7 is the PID para

example in Figure 4-4 that adopts AI2 analog feedback.

Function

code

F0.03

F5.23

Name Setting Instruction Notes

0: Eletronic

Master

Frequency

Reference X

Selection

AI2 lower

potentiometer

(non-retentive at

power off)……

8:PID

9:Communication

given

0.00V ~ F5.20

Modify the setting as 8;

adopt PID output as

master frequency

reference

Setting according to the Used for checking

‐60‐

F5.24

limit applied requirements analog signal

AI2 setting

value

correspondin

g to AI2

lower limit

-100.0% ~

+100.0%

Setting according to the

applied requirements

VM1000 Series

Used for checking

analog signal

F5.25

F5.26

F9.00

F9.01~

F9.32

AI2 upper

limit

AI2setting

value

correspondin

g to AI2

upper limit

PID given

source

other

parameters in

PID group

Table 4-7 VM1000 PID Control Parameters

F5.18 ~

+10.00V

-100.0% ~

+100.0%

setting range:0~

6

0 indicates

function code

F9.01 given

-100.0% ~

100.0%

Setting according to the

applied requirements

Setting according to the

applied requirements

Factory value has been

set as 0, namely set

F9.01 as digital setting

Set and adjust according

to the applied

requirements

Used for checking

analog signal

Used for checking

analog signal

Keep the factory

value unchanged

Some parameters

need to be adjusted

in order to get the

proper value

‐61‐

VM1000 Series

4.5 Auto-tuning of Motor Parameters

Selection of vector control mode:Before the drive operates ,you must input the

exact nameplate parameters of motor, the standard motor parameters is equipped

with 8000H inverter according to parameters on the nameplate; vector control has a

high dependence on motor parameters.In order to get good control performance,it

must receive the correct parameters of controlled motor.

Procedures of motor auto tuning are as follows:

First, the control command source (F0.02) is selected as keypad.

Then input the following parameters according to the actual motor parameters

(according to the current motor selection):

F2.00: GP Type Display Selection

F2.01: motor rated power

F2.02: motor rated voltage

F2.03: motor rated current

F2.04: motor rated frequency

F2.05: motor rated speed

If the motor is completely disconnected from the load, select 2 in F2.11 (auto-tuning

completely), and then press the “RUN ”on the keypad , the VFD will automatically

calculate following parameter of the motor:

F2.06: asynchronous motor stator resistance

F2.07: asynchronous motor rotor resistance

F2.08: asynchronous motor leakage inductance

F2.09: asynchronous mutual inductance

F2.10: Motor no load current

The motor parameter automatic tuning above is completed

If the motor can not be completely disconnected with load, select 1 in the F2.11

(static auto tuning), and then press the RUN key on the keyboard.

‐62‐

If VFD will measure the stator resistance, rotor resistance and leakage inductance

instead of the mutual inductive reactance and load current,the user can calculate

these two parameters on their own according to the motor nameplate. The

parameters that used for calculating motor nameplate are: rated voltage U, rated

current I, rated frequency and power factor η:

The calculation methods of motor no-load current and motor mutual inductance is as

follows: Lσ indicates motor leakage inductance.

VM1000 Series

no-load current : Io=

calculation of mutual inductance: Lm=

o:no-load current

I

L

m:mutual inductance

L

σ:leakage inductance

‐63‐

VM1000 Series

4.6 Faults Query and Reset step

(1)Faults Status and Reset

In start/stop and running status, the VFD will access to fault status subject to various

internal and external constraints or internal abnormalities. When security conditions

and the devices permit, you need to reset the fault manually so as to return to normal

standby status. Also, automatic fault reset function can be set on the VFD.

(2)Faults Query and Reset Steps

Steps Operation Panel display Indicator Note

Viewing

fault

status

Viewing

fault

record

Reset

Viewing fault

code

1. Viewing E0

parameters for

the latest fault

information

2. E1 ~ E4 are

historical fault

information

Deal with the the

influence of

failure, confirm

the cause of the

malfunction and

eliminate it.

2. Press the

"STOP /

RESET" button

and reset 1

Table 4-8 Faults Query and Reset Step

Failure panel displays fault

codes beginning with an E,

and flashes to remind

In fault status, it can not only

check fault information but

also enter and view various

parameters, modify parameter

values.

Under the qualified

conditions, the error code is no

longer displayed and return to

the stop/standby status.

‐64‐

TUNE/TC

Lights

flash

——

TUNE/TC

Lights off

Indicator refer to 3.1

Fault code refer to

8.1

Indicator refer to 3.1

VM1000 Series

4.7 Parameters Restore as Factory Value

Before restoring the parameters as factory value, please confirm the recovery does

not pose a safety hazard to the equipment (such as control failure), nor lost some

parameters after the commissioning. If necessary, it should make records. Note:

You can copy the parameters by LCD keypad.

Steps:

(1) Turn on F0 group; enter F0.20 (parameter initialization).

(2) Select 1 is factory parameters restoring (not including the motor parameters and

record values)

(3) Select 2 is recorded value clearance, including a variety of accumulated data

such as running time.

‐65‐

VM1000 Series

Chapter 5 Function Code Datasheet

(1)Parameter Protection

When FE-00 is set to a non-zero number, parameter protection code is enabled. You

must use the correct user password to enter the menu.If you cancel the code, it needs

to set FE.00 as 0.The parameters in shortcut menu is not included in the code

protection.

(2)Symbol and Legend

The modification method of parameters in function code are marked with graphic

symbols. The descriptions are as follows:

"☆": The parameter can be modified when the AC drive is in either stop or running

state.

"★": The parameter cannot be modified when the AC drive is in the running state.

"●": The parameter is the actually measured value and cannot be modified.

"◎": The parameter is factory parameter and can be set only by the manufacturer.

Function

code

F0.00

F0.01

Description Set range Unit Default

F0 Group: Basic Parameters

Control Mode

Selection

Control Command

Source

0: Sensorless Vector

Control(SVC)

1: V/F Control

0: Keypad(with

LOCAL/REMOTE light off)

1: Terminals(with

LOCAL/REMOTE light on)

2: Communication(with

LOCAL/REMOTE flashing)

1 1 ★

1 0 ☆

‐66‐

Modifi

-cation

level

VM1000 Series

Function

code

F0.02

F0.03

Description Set range Unit Default

Base frequency for

UP/

DOWN

modification

during

running

Master Frequency

Reference X

Selection

0:Running Frequency

1:Preset Frequency

0:Digital setting of F0.08 Preset

Frequency(Adjustable by pulse

knob & Up/Down keys,

non-retentive at power off)

1:Digital setting of F0.08 Preset

Frequency(Adjustable by pulse

knob & Up/Down keys

modification, retentive at power

off)

2:AI1

3:AI2

4:Reserved

5:PULSE Input(DI6)

6:Multi-Step Speed Input

Frequency References

7:Simple PLC

8:PID

9:Communication

1 1 ★

1 0 ★

Modifi

-cation

level

F0.04

F0.05

Auxiliary

Frequency

Reference Y

Selection

Auxiliary

Frequency

Reference Y's

Range Reference

while in

superposition of X

and Y.

As the same as F0.03 1 0 ★

0:Refer to Maximium Frequency

1:Refer to Frequency Reference

X.

1 0 ☆

‐67‐

VM1000 Series

Function

code