Preface

Thank you for choosing SAJ solar inverter. We are happy to provide you with rst-class products

and quality service.

The manual includes installation, operation, maintenance, troubleshooting, and safety notice. As

long as you follow the instruction of this manual, you will get the professional guidance and our

wholehearted service.

Customer-orientation is our forever commitment. We hope this “User Manual” become your

good helper in solar power generation.

Please check the latest version at www.saj-solar.com

Guangzhou Sanjing Electric Co., Ltd.

User Manual

Contents

1. Information on this Manual

...........................................................................................................................................

1

1.1 Validity

..............................................................................................................................................................................

1

1.2 Target Group

..................................................................................................................................................................,

1

1.3 Symbols Used

................................................................................................................................................................

1

2. Safety

........................................................................................................................................................................................

2

2.1 Intended Use

..................................................................................................................................................................

2

2.2 Safety Precaution

.........................................................................................................................................................

2

2.3 Explanations of Symbols on Inverter

...............................................................................................................

4

3. Product Overview

...............................................................................................................................................................

5

3.1 Product Appearance

...................................................................................................................................................

5

3.2 Major Characteristics

.................................................................................................................................................

5

3.3 Technical Data

...............................................................................................................................................................

6

4. Installation Instructions

..................................................................................................................................................

8

4.1Unpacking

.......................................................................................................................................................................

8

4.2 Mounting Instructions

...............................................................................................................................................

9

4.3 Mounting Procedure

..............................................................................................................................................

11

4.4 Optional Anti-Theft Protection

.........................................................................................................................

13

5. Electrical Connection

....................................................................................................................................................

14

5.1 Safety

..............................................................................................................................................................................

14

5.2 Overview of Connection Area

...........................................................................................................................

14

5.3 Connection Cables Requirements

...................................................................................................................

16

5.4 Miniature circuit breaker

......................................................................................................................................

17

5.5 Connecting the Electricity Grid (AC)

............................................................................................................

18

5.5.1Conditions for the AC Connection

.................................................................................................................

18

5.5.2 AC Connection procedure

................................................................................................................................

18

5.5.3 Connecting the Second Protective Conductor

............................................................................................

20

5.6 Connecting the PV Array (DC)

...........................................................................................................................

21

5.6.1 Conditions for DC Connection

.......................................................................................................................

21

5.6.2 Connection Procedures by H4:

.......................................................................................................................

22

5.7 Communication and Monitoring Setting

......................................................................................................

25

5.7.1 Communication through RS485

....................................................................................................................

25

5.7.2 Communication through Ethernet RJ45

......................................................................................................

27

5.7.3 Extended Wi-Fi Solution with Wi-Fi Bridge

.............................................................................................

27

5.7.4 Communication Cable Assembly Instructions

...........................................................................................

28

6. LCD Operation

..................................................................................................................................................................

31

6.1 LCD Display Overview

..........................................................................................................................................

31

6.2 Startup the Inverter

...................................................................................................................................................

32

6.3 LCD Main Screen

......................................................................................................................................................

33

6.4 LCD Menu Structure

...............................................................................................................................................

34

6.4.1 LCD Graph Submenu

......................................................................................................................................

35

6.4.2 LCD Setting Submenu

.....................................................................................................................................

36

6.5 Error Report Mechanism and Guidance

........................................................................................................

43

7. Recycling and Disposal

.................................................................................................................................................

44

8. Troubleshooting

................................................................................................................................................................

45

9. Guaranty Service

...............................................................................................................................................................

50

10. Contact SAJ

........................................................................................................................................................................

50

User Manual

1

1.Information on this Manual

1.1 Validity

This User Manual describes instructions and detailed procedures for installing, operating,

maintaining, and troubleshooting of the following SAJ grid-tie inverters:

Suntrio-TL6K, Suntrio-TL8K, Suntrio-TL10K, Suntrio-TL12K

Suntrio-TL15K, Suntrio-TL17K, Suntrio-TL20K

Please keep this manual where it will be accessible at all times.

1.2 Target Group

This manual is for qualied electrically skilled person, who must strictly perform the tasks follow

this manual.

1.3 Symbols Used

DANGER

DANGER indicates a hazardous situation which, if not avoided, will result in death or

serious injury.

WARNING

WARNING indicates a hazardous situation which, if not avoided, can result in death or

serious injury or moderate injury

CAUTION

CAUTION indicates a hazardous condition which, if not avoided, can result in minor or

moderate injury.

NOTICE

NOTICE indicates a situation that can result in potential damage, if not avoided.

User Manual

2

2.Safety

2.1 Intended Use

The Suntrio-TL series inverters are PV inverter which converter the direct current of a PV array

into alternating current and feed this into the electricity grid.

The inverters are designed according to the safety rules. However, improper use, alteration or

modication may cause lethal hazards for the operator or third parties, or may result in damage

to the units and other property. SAJ is not responsible for the loss and invalidate these warranty

claims.

Figure 2.1 Grid-tie Solar System with Suntrio inverter

2.2 Safety Precaution

DANGER

● DANGER due to electrical shock and high voltage

● Do not touch the operating component of the inverter; it might result in burning or death.

● To prevent risk of electric shock during installation and maintenance, please make sure that all AC

and DC terminals are plugged out.

● Do not touch the surface of the inverter while the housing is wet, it might lead to electrical shock.

● Do not stay close to the inverters while there are severe weather conditions including storm, lighting,

etc.

● Before opening the housing, the SAJ inverter must be disconnected from the Grid and PV generator;

you must wait at least five minutes to let the energy storage capacitors fully discharged after

disconnecting from power source.

User Manual

3

WARNING

●

The installation, service, recycling and disposal of the inverters must be performed by qualied

personnel only in compliance with national and local standards and regulations.

● Any unauthorized actions including modification of product functionality of any form

may cause lethal hazard to the operator, third parties, the units or their property. SAJ is not

responsible for the loss and deny these warranty claims.

● Suntrio inverters must only be operated with PV generator. Do not connect any other source of

energy to the inverters.

● Be sure that the PV generator and inverter are well grounded in order to protect properties and

persons.

CAUTION

● The PV inverter will become hot during operation. Please don’t touch the heat sink or

peripheral surface during or shortly after operation.

● Risk of damage due to improper modications.

● Never modify or manipulate the inverter or other components of the system.

NOTICE

● The PV inverter is designed to feed AC power directly to the public utility power

grid; do not connect AC output of the inverter to any private AC equipment.

User Manual

5

3.Product Overview

3.1 Product Appearance

Figure 3.1 Suntrio inverters Overview

3.2 Major Characteristics

SAJ Suntrio inverter has following characteristics which make SAJ grid-tied solar inverter

“Higher Efciency, High Reliability and Lower Cost”.

Leading technology

• Max. efciency 98.1%

• MPPT accuracy up to 99.9% efciency

User-friendly

• 5 inch LCD display with comprehensive information

• Embedded webserver monitoring

• Easy installation

Flexible

• Multi-country conguration

• RS485 / Ethernet / Wi-Fi communication

• Wide range of DC input voltage

• IP65 for indoor and outdoor

User Manual

6

3.3 Technical Data

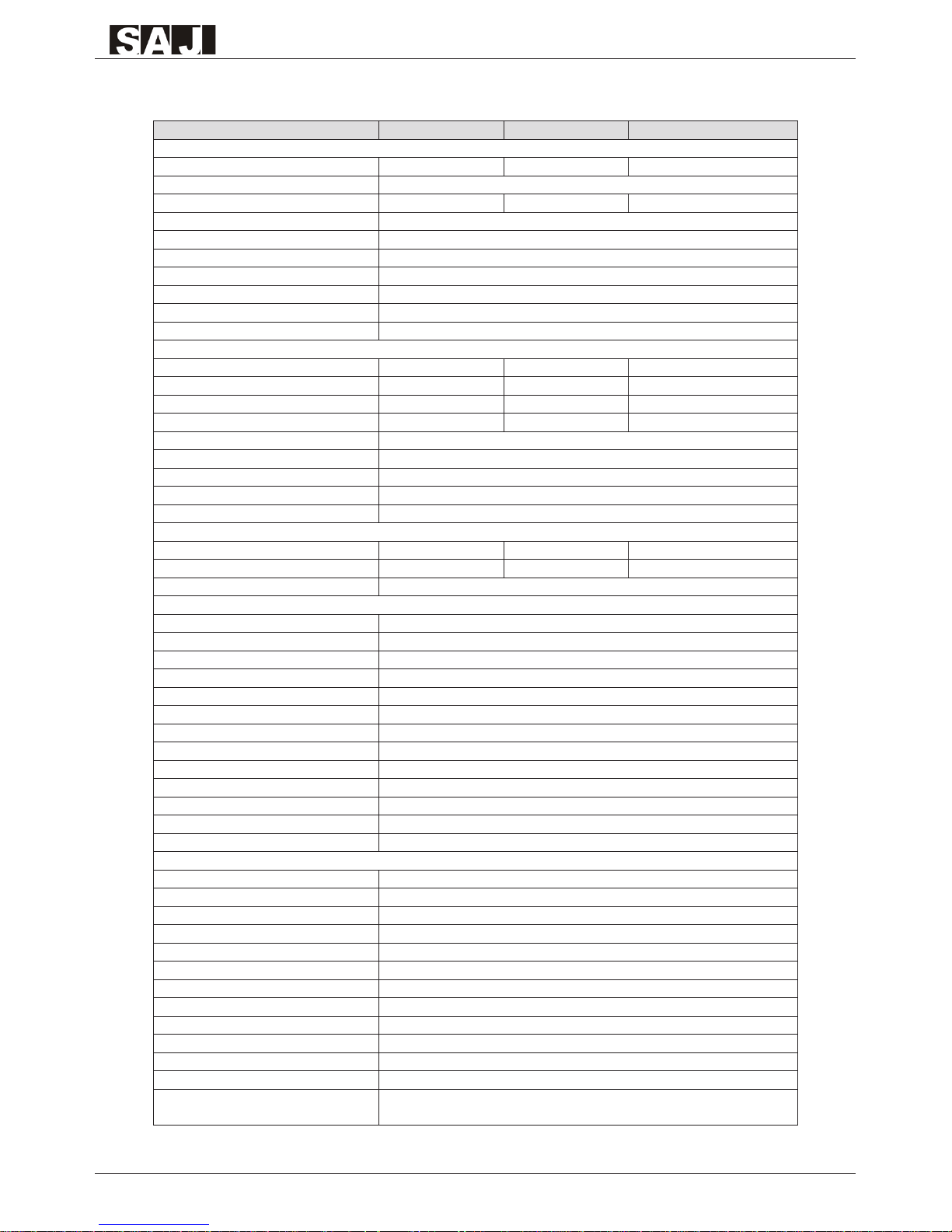

Type Suntrio-TL6K Suntrio-TL8K Suntrio-TL10K

Input (DC)

Max. DC Power [W] 6300 8200 10400

Max. DC Voltage [V] 1000V

MPPT Voltage Range [V] 240~800 240~800 240~800

Nominal DC Voltage 600

Start Voltage[V] 300

Min. DC Voltage[V] 200

Max. DC input Current PV1 / PV2 [A] 16 / 16

Number of MPPT 2

String(s) per MPPT 2

DC Switch Optional

Output (AC)

Rated AC Power [W](@230V,50Hz) 6000 8000 10000

Max. AC Apparent Power [VA] 6000 8000 10000

Rated AC Current[A] 8.7 11.6 14.5

Max. AC Current [A] 9.7 12.9 15.8

Nominal AC voltage/ range 3/N/PE, 220/380V,230/400V,240/415V;180V-280V/312V-485V

Grid frequency/ range 50Hz,60Hz /44Hz-55Hz,54-65Hz

Total Harmonic Distortion (THDi) < 3%(at nominal power)

Power factor, adjustable 0.9 leading~0.9 lagging

Feed-in Phase / Connection Phase 3 / 3

Efciency

Max. Efciency 97.9% 97.9% 98.0%

Euro Efciency (at 600Vdc) 97.3% 97.3% 97.5%

MPPT Accuracy >99.5%

Protection

Internal Overvoltage Protection Integrated

DC Insulation Monitoring Integrated

DCI Monitoring Integrated

GFCI Monitoring Integrated

Grid Monitoring Integrated

AC Short Circuit Current Protection Integrated

Thermal Protection Integrated

Anti-island protection monitoring AFD

Interface

DC Connection H4/MC4

LCD Display Graphic LCD Display, Backlight, Inverter Parameter and Data Display

Display Language Multi Language

Datalogger & Communication RS485,Ethernet(Webserver embedded), WiFi(Optional),

Device Data

Topology Transformerless

Consumption at Night [W] <1

Consumption at Standby [W] <12

Operating Temperature Range :-20°C to +60°C(45°C to 60°C with derating)

Cooling Method Fans

Ambient Humidity 0% to 95% Non-condensing

Altitude Up to 2000m without power derating

Noise [dBA] <40dB

Ingress Protection IP65

Dimensions [WxHxD] [mm] 480×680 ×200

Weight [kg] 35

Standard Warranty [Year] 5 / 10 (Optional)

Certicates

AS4777, AS 3100, VDE0126-1-1/A1, G83-2,G59-2, C10/11, UTE C15-712-1,

TF3.2.1, EN 50438, IEC 62116, IEC 61727, IEC61000-6-2/3, IEC 62109-1/2

User Manual

7

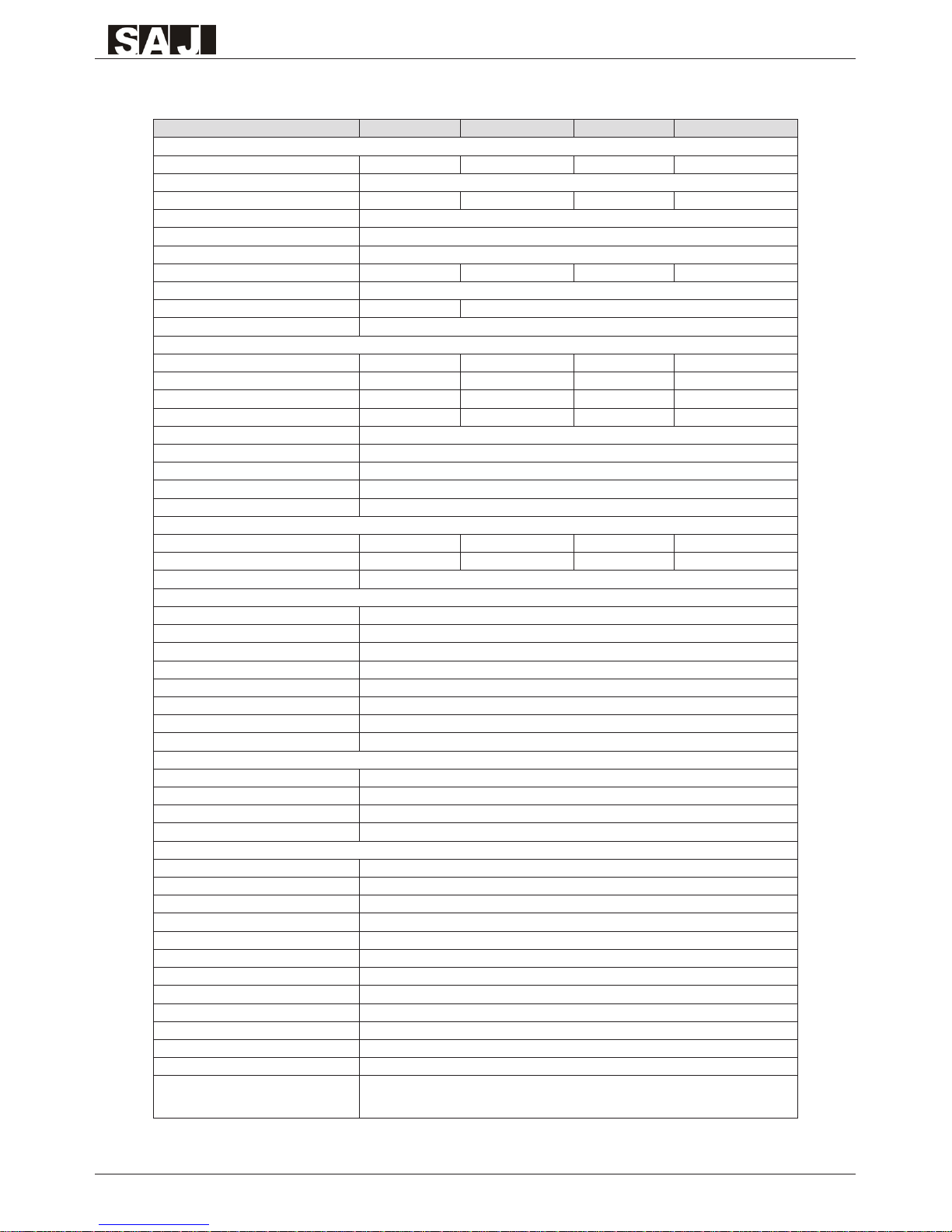

Type Suntrio-TL12K Suntrio-TL15K Suntrio-TL17K Suntrio-TL20K

Input (DC)

Max. DC Power [W] 12500 15600 17700 20600

Max. DC Voltage [V] 1000V

MPPT Voltage Range [V] 240~800 240~800 240~800 240~800

Nominal DC Voltage 600

Start DC Voltage[V] 300

Minimum DC Voltage[V] 200

Max. DC input Current PV1 / PV2 [A] 18/18 22/22 22/22 22/22

Number of MPPT 2

String(s) per MPPT 2 3

DC Switch Optional

Output (AC)

Rated AC Power [W](@230V,50Hz) 12000 15000 17000 20000

Max. AC Apparent Power [VA] 12000 15000 17000 20000

Rated AC Current[A] 17.4 21.7 24.6 29.0

Max. AC Current [A] 19.0 25.0 27.0 29.0

Nominal AC voltage/ range 3/N/PE,220/380V,230/400V,240/415V;180V-280V/312V-485V

Grid frequency/ range 50Hz,60Hz /44Hz-55Hz,54-65Hz

Total Harmonic Distortion [THDi] < 3%(at nominal power)

Power factor, adjustable 0.9 leading~0.9 lagging

Feed-in Phase / Connection Phase 3 / 3

Efciency

Max. Efciency 98.1% 98.1% 98.1% 98.1%

Euro Efciency (at 600Vdc) 97.4% 97.5% 97.5% 97.5%

MPPT Accuracy >99.5%

Protection

Internal Overvoltage Protection Integrated

DC Insulation Monitoring Integrated

DCI Monitoring Integrated

GFCI Monitoring Integrated

Grid Monitoring Integrated

AC Short Circuit Current Protection Integrated

Thermal Protection Integrated

Anti-island protection monitoring AFD

Interface

DC Connection H4/MC4

LCD Display Graphic LCD Display, Backlight, Inverter Parameter and Data Display

Display Language Multi Language

Datalogger & Communication RS485,Ethernet(Webserver embedded), WiFi(Optional),

Device Data

Topology Transformerless

Consumption at Night [W] <1

Consumption at Standby [W] <12

Operating Temperature Range :-20°C to +60°C(45°C to 60°C with derating)

Cooling Method Fans

Ambient Humidity 0% to 95% Non-condensing

Site Altitude Up to 2000m without power derating

Noise Emission (dBA) <45dB(with fan<50dB)

IP Protection IP65

Dimensions (WxHxD) [mm] 480×680 ×200

Weight [kg] 42

Standard Warranty (Year) 5 / 10 (Optional)

Certicates

AS4777, AS 3100, VDE0126-1-1/A1, G59-2, C10/11, UTE C15-712-1, TF3.2.1, EN

50438, IEC 62116, IEC 61727, IEC61000-6-2/3, IEC 62109-1/2

User Manual

8

4.Installation Instructions

4.1Unpacking

Check the delivery for completeness and for any visible external damage. Contact your specialist

dealer if anything is damaged or missing.

A B C D E

F G H I

Figure 4.1 Inverter and Accessories

Object Quantity Description

A 1 SAJ Suntrio solar inverter

B 1 Rear panel

C

4 sets for Suntrio-TL6K/8K/10K/12K

6 sets for Suntrio-TL15K/17K/20K

DC connector

D 7 M6×50 Expansion screw

E 7 Expansion tube

F 1 RS485 connector(if attached)

G 4 M4×12 Cylinder head screw and Lock washer

H 1 User manual, including installation guide

I 1 Warranty card

Table 4.1 Detail Information of Inverter and Accessories

User Manual

9

4.2 Mounting Instructions

Figure 4.2 Mounting Instructions

Mounting on a solid surface out door or indoor.

● Site altitude is less than 2,000m above the sea level.

● The mounting location must be clear and safely accessible at all times without the use

of additional aids such as scaffolding or lifting platforms. If this is not the case, service

work may be restricted.

● Mount vertically or tilted backwards by max. 15°

● The connection area must point downwards.

● Never install the inverter forward tilt, sideways tilt, horizontally or even upside down.

● Install the inverter at eye level for convenience checking the LCD display and possible

maintenance activities.

● Given the weight of the device, this will facilitate disassembly for service work.

● The ambient temperature should be below 45°C to ensure optimum operation. Choose

locations with sufcient air exchange. Ensure additional ventilation, when necessary.

● Do not expose the inverter to direct solar irradiation as this could cause power

derating due to overheating.

● In order to avoid audible vibrations in living areas, do not mount the unit on

plasterboard walls or similar.

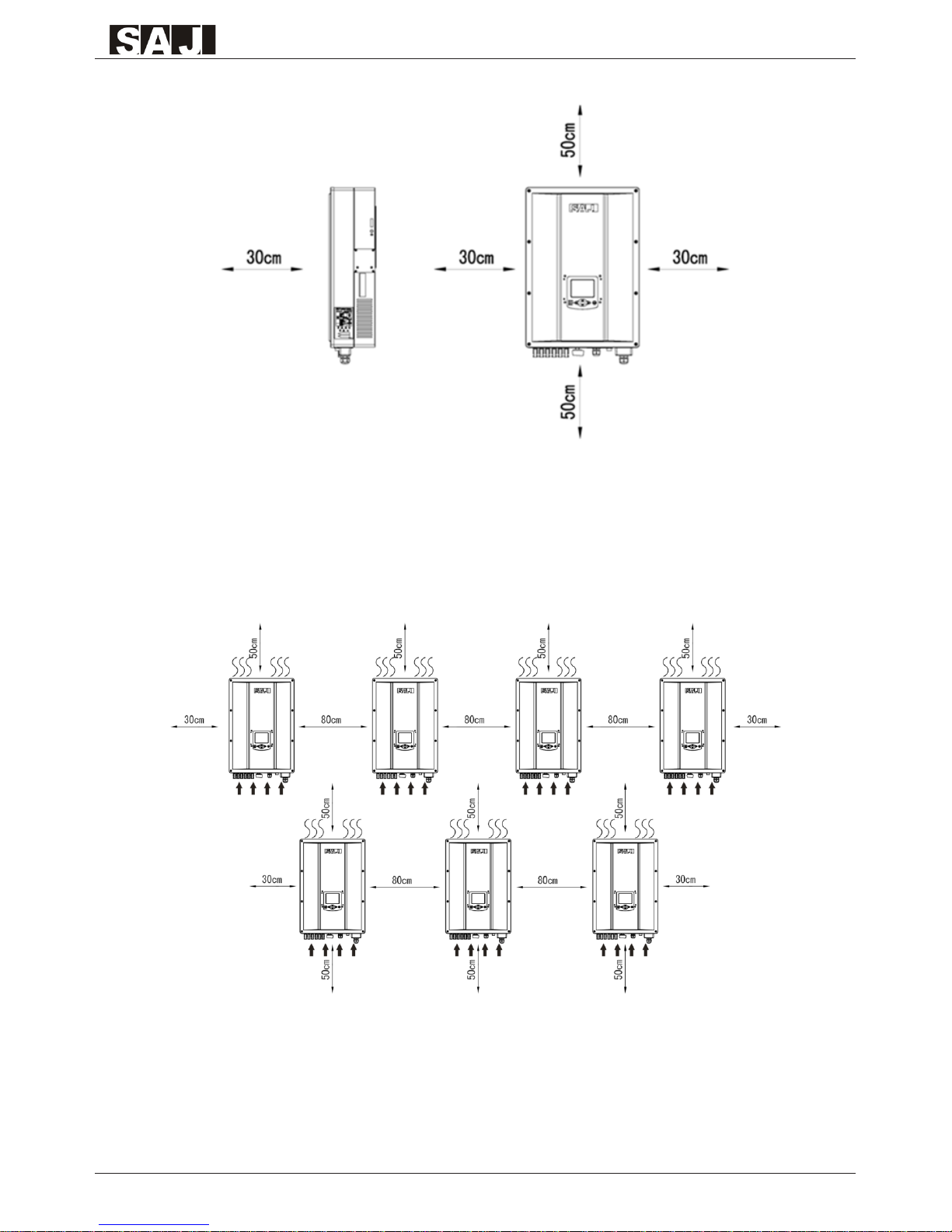

● Observe the recommended clearances to walls, other inverters or other objects, as

shown in the follow diagram. That ensures sufcient heat dissipation and gives you

enough space to unplug the PV Connector, communication port and operate the DC-

switch.

User Manual

10

Figure 4.3 Safety Clearance of Single Inverter

●Multiple inverters are mounted in an area,the below clearances between the inverters are

recommended.This ensure the flow of the air inlet and air outlet openings and optimize heat

dissipation.

Figure 4.4 Safety Clearance of Multiple Inverters

User Manual

11

4.3 Mounting Procedure

1) Use the rear panel in the package as a drilling template and drill 7 holes with 8mm diameter

and depth in 50mm, as illustrated below, (Units: mm)

Figure 4.5 Holes Position

2) Fix the rear panel on the wall with the expansion tubes and expansion screw.

Figure 4.6 Mounting Real Panel

User Manual

12

3) Hang the inverter on the rear panel, and check whether the pothook is installed in place. If

there are any errors, remove the inverter, reinstall, as shown below.

Figure 4.7 Mounting the Inverter

4) After Conrming the inverter is installed well, tight the inverter with M4 Phillips pan head

screws.

Figure 4.8 Secure the Inverter

5)Please carefully check the accessories and original carton to make sure during the installation

every necessary part is used and nothing is missed.

User Manual

13

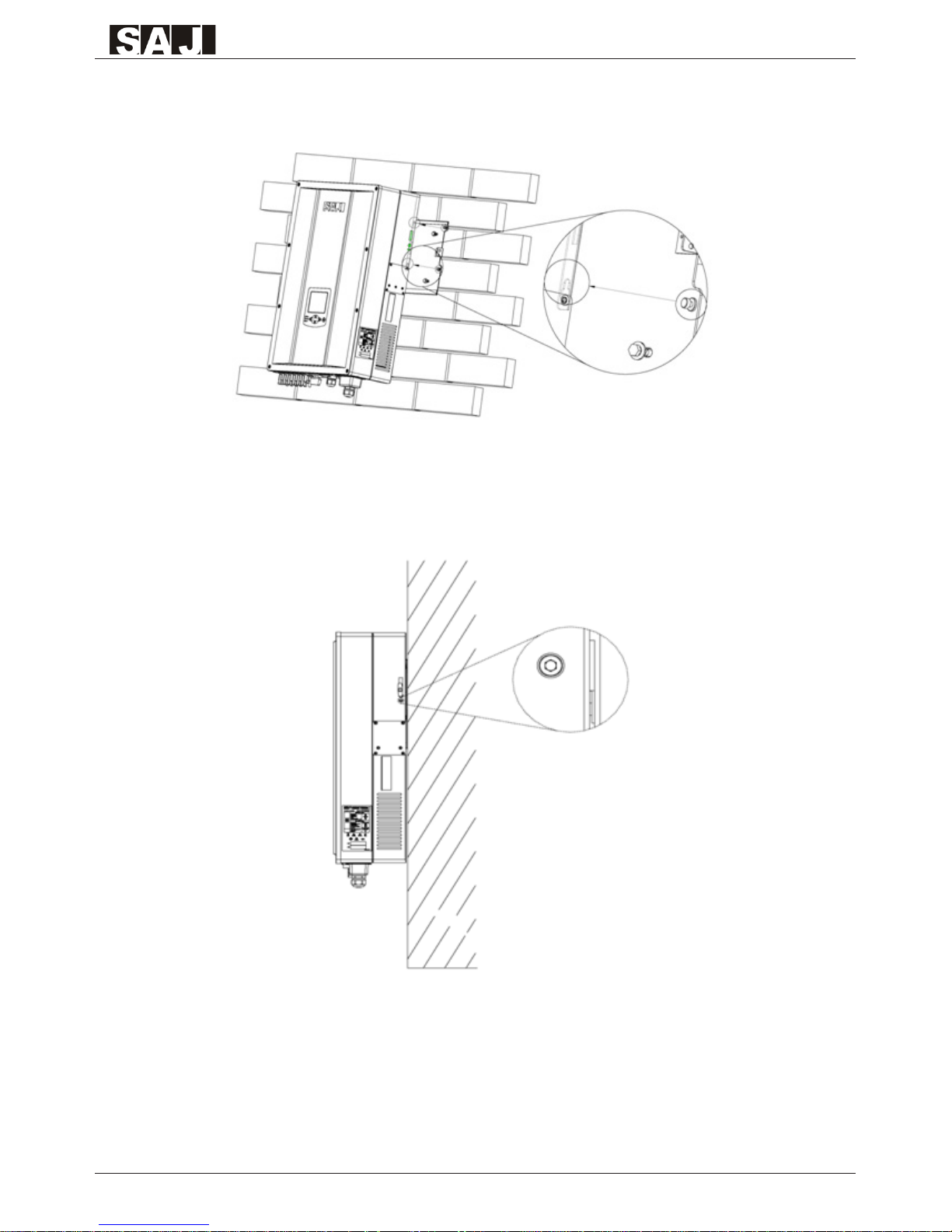

4.4 Optional Anti-Theft Protection

To protect the inverter from theft, you can lock inverter with a padlock. The padlock must meet

the following requirements:

Size:

A:6 mm – 8 mm diameter

B:23mm – 29 mm

C:23mm – 28 mm

D:39mm – 50 mm

E:13mm – 18 mm

Figure 4.9 Padlock for Anti-theft Protection

Installation of the padlock

Put the shackle of the padlock through the hole and close the padlock, as following picture.

Figure 4.10 Secure the Inverter with Padlock

User Manual

14

5.Electrical Connection

5.1 Safety

. NOTICE

●Internal components of the inverter can be damaged by Electrical discharge,

take measurement to avoid Electrical discharge during relevant operation.

●Earth yourself before touching any components.

5.2 Overview of Connection Area

A B C D E

F G

Figure 5.1 Connection Area Overview of Suntrio-TL6K/8K/10K/12K

User Manual

15

A B C D E

F G

Figure 5.2 Connection Area Overview of Suntrio-TL15K/17K/20K

Object Description

A DC input terminals (PV1 and PV2)

B DC switch (optional)

C EXT port

D Ethernet RJ45 interface

E AC cover terminal

F RS485 interface

G Grounding terminal

Table 5.1 Description of Connection Area

User Manual

16

5.3 Connection Cables Requirements

The user can select connection cable according the table below.

Model

DC Side AC Side

cross section (cu) Mini cross section (cu)

Suntrio-TL6K/8K 4mm2 / 6mm

2

4mm

2

Suntrio-TL10K/12K 4mm2 / 6mm

2

4mm

2

Suntrio-TL15K 4mm2 / 6mm

2

6mm

2

Suntrio-TL17K 4mm2 / 6mm

2

6mm

2

Suntrio-TL20K 4mm2 / 6mm

2

6mm

2

Table 5.2 Connection cables requirements

Note:The cable loss due to the cross section and the length, to avoid too much power loss,

user can select the proper cable according the actual situation. The below chart specic the

relationship among the Cable Loss, cross section, cable length.

Figure 5.3

User Manual

17

5.4 Miniature circuit breaker

DANGER

When more than one inverter is connected in parallel to the same miniature circuit-breaker, the

protective unction of the miniature circuit-breaker is no longer guaranteed. This could result in

a cable re or destruction of the inverter.

●

Never connect several inverters to a single miniature circuit-breaker.

In order to securely disconnect the inverter from the PV generate and the public-Grid, SAJ

recommend to install circuit breaker at DC Input and AC output as gure 2.1 shown.

Breaker specication:

Model

DC input AC output

Recommended DC breakers Recommended AC breakers

Suntrio-TL6K DC1000V,C20A,2P AC400V,C20A,4P

Suntrio-TL8K DC1000V,C20A,2P AC400V,C20A,4P

Suntrio-TL10K DC1000V,C20A,2P AC400V,C20A,4P

Suntrio-TL12K DC1000V,C20A,2P AC400V,C25A,4P

Suntrio-TL15K DC1000V,C25A,2P AC400V,C32A,4P

Suntrio-TL17K DC1000V,C25A,2P AC400V,C32A,4P

Suntrio-TL20K DC1000V,C25A,2P AC400V,C40A,4P

Table 5.3 Miniature circuit breaker requirements

User Manual

18

5.5 Connecting the Electricity Grid (AC)

5.5.1Conditions for the AC Connection

You must comply with the connection requirements of your network operator

.

Residual Current monitoring

The inverter is equipped with an integrated all-pole-sensitive residual-current monitoring unit.

The inverter can automatically differentiate between residual currents and normal leading leakage

currents.

If an external RCD or residual-current device (RCMU breaker) is strictly required, you must use

a switch that trips at a residual current 100mA≤ Ifn ≤300mA.

The external RCMU breaker should be installed between inverter and Grid. No load should not

connected to the inverter directly.

Connection of a Second Protective Conductor

In some installation countries, a second protective conductor is required in order to prevent a

contact current in the event of failure of the original protective conductor.(See section 5.5.3)

IEC standard 62109 requirements:

• Installation of the protective earthing conductor at AC terminal with a cross-section of at least

10mm2 (copper), or 16mm2 (aluminum).

UTE C15-712-1:2010 requirements:

• The inverter body conductive accessories must be connected to the equipotential bonding

via a conductor with a minimum cross-section of 6mm² Cu or equivalent and to the protective

conductor at AC terminal.

5.5.2 AC Connection procedure

1)Strip the cable with the length 12mm, be careful NOT to nick conductors.

User Manual

19

2)Please insert the striped cable into bootlace ferrule and crimp the contact.

3)Screw off the AC cover and insert the 5 wires into AC cover assembly with the following

sequence.

4)Release the ve screws at the cable terminal. Then route the 5 wires into the cable terminal

according to the marks on the front case while L1(R), L2(S), L3(T) represent 3 Live line, N

represent Neutral line and PE is ground.

NOTE:

• The PE conductor must be 5 mm longer than the L and N conductor.

• L and N must not be swapped.

• The direction of rotation of L1, L2 and L3 is not relevant.

User Manual

20

5)Screw the cap nut of the cable tightly.

5.5.3 Connecting the Second Protective Conductor

If required by the installation, the earth terminal can be used to connect a second protective

conductor or as equipotential bonding.

Procedure

Take out parts from the packing and insert the earthing wire to “PE” terminal located at the right

of the inverter, then tighten the screw.

User Manual

21

5.6 Connecting the PV Array (DC)

5.6.1 Conditions for DC Connection

NOTE:

Suntrio-TL6K/8K/10K/12K: Dual MPPT(PV1 and PV2), two DC input connection sets per

MPPT.

Suntrio-TL15K/17K/20K: Dual MPPT(PV1 and PV2), three DC input connection sets per

MPPT.

● For input area PV1 or PV2, The PV modules must meet the following requirements:

Same type

Same number of in-series-connected PV modules

Identical direction

Identical tilt

The open circuit voltage of each string should never exceed 1000VDC.

User Manual

22

5.6.2 Connection Procedures by H4:

Connect the PV generator and the inverter using H4 connectors, as follows.

Note: If using MC4 connector, the operating procedures are similar to that of H4 connector.

The DC connectors come pre-assembled and the caps are loose. The whole connector will

include the male side and female side as showed below:

Male side connector (M) Female side connector (F)

Assembly Instructions:

1)Strip the cable with the length of 0.276 inches (9/32”)-(7mm) and please be careful NOT to

nick conductors.

2)Use specied strip tool in this step. Adjust the strip stopper and put the cable in corresponding

notch to strip the length of 7mm.

User Manual

23

3)Insert stripped cable into contact barrel and insure all conductor strands are captured in the

contact barrel and the conductors are visible in the contact barrel observation hole.

Barrel observation hole

Conductor should be visible

Barrel observation hole

Conductor should be visible

4)Crimp contact barrel by using the hex crimping die. Ensure it is xed.

Crimped socket contact

Cable Requirements

Cable Size Cable pull – out force requirement

4 mm² Min. 400 N.m(90Lbs)

6 mm² Min.450N.m(100Lbs)

10 mm² Min.500N.m(110Lbs)

5)Insert contact cable assembly into back of male and female connector. A“click” should be

heard or felt when the contact cable assembly is seated correctly.

User Manual

24

6)Wrest the cap by using the torque of 2.6~2.9N·m.

7)After wrested the cap tightly, align the 2 half connectors and mate them together by hand until

a “click” is heard or felt.

8)Connect the positive and negative terminals from the PV panels to positive and negative

terminals on the PV inverter.

Note: In order to seal the inverter, all DC inputs that are not required have to be closed.

User Manual

25

5.7 Communication and Monitoring Setting

SAJ offers 2 standard communication interfaces for Suntrio-TL series solar inverters: RS485 and

Ethernet RJ45. All the SAJ products involved in the solar monitoring system are:

SAJ Logger:

data logger for local monitoring and maintenance of large solar power plants.

SAJ Web Portal: free monitoring application through web, IPhone, IPAD and Android App.

Internet access must be ensured for the inverter network conguration before SAJ Web Portal

service registration.

SAJ Web Server:

the local web monitoring application through web browser built in all SAJ

inverters.

For more details, please refer to SAJ Monitoring Solution through www.saj-soalr.com

5.7.1 Communication through RS485

RS485 is used for multi-point communication.

Note:

1)RS485 can communicate and monitor up to 32 inverters.

2)The MAX. length of the communication cable should not exceed 1000m.

SAJ Logger Multi-point Monitoring

Figure 5.19 SAJ Logger Multi-point Monitoring

User Manual

26

PC+SAJ Logger Multi-point Monitoring

Figure 5.20 PC+SAJ Logger Multipoint Monitoring

Connection Procedures

1)Inverter 1 connects to Inverter 2 through RS485 cable; Inverter 2 connects to Inverter 3 through

RS485 cable. In the same way to connect all inverters.

2)Inverter 1 connects to SAJ Logger through RS485-L cable.

3)Connect SAJ Logger to PC through Router.

4)Open the internal Web Server of SAJ Logger for plant and inverter monitoring.

User Manual

27

5.7.2 Communication through Ethernet RJ45

When users choose Ethernet communication solution, users can access to Inverter real-time

information through Inverter IP address, or through SAJ Logger IP address. The conguration is

shown in Figure 5.21 as below:

Figure 5.21 Communications through Ethernet RJ45

5.7.3 Extended Wi-Fi Solution with Wi-Fi Bridge

We choose EW-7228APn of EDIMAX as the Wi-Fi bridge reference

All the Wi-Fi bridge or repeater(For example, Edimax EW-7228APn) which has Ethernet RJ45

port can connect to SAJ solar inverters with RJ45 cable and to Wi-Fi router wirelessly.(For

details please refer to the document “SAJ Monitoring Solution with Integrated RJ45 Plus Wi-Fi

Bridge.pdf” from www.saj-solar.com)

User Manual

28

5.7.4 Communication Cable Assembly InstructionsAll cables

All cables mentioned in this mentioned in this Manual are 5E Shielded Cable, as shown in

Figure 5.22.

Figure 5.22 5E Shielded Cable

Terminals:

According to different communication solutions, users may need at least one of the below

terminals. They are 3Pin Connector and RJ45 Plug as shown in Figure 5.23 and Figure 5.24

Figure 5.23 3Pin Connector

User Manual

29

Figure 5.24 RJ45 Plug and Pin Number

Tools

When making a communication cable, the professional tools shown in Figure 5.25 below are

needed.

Figure 5.25 Tools for Making a Communication Cable

RS485 Cable

When using RS485 for monitoring, users need RS485 cables to connect between inverters for

multi-point monitoring. In this case, we provide connection by using the 3Pin connectors as

shown in Figure 5.23.

Each cable should be connected to the connectors according to below Table 5.4

Connector No. Color

1 Blue & White

2 Blue

3 Metal shielded wire

Table 5.4 Connector No and Color

User Manual

30

RS485-L Cable

RS485-L cable is used to connect Inverter and SAJ Logger when inverters are monitored via

RS485. One end of the cable uses 3Pin Connector, and the other end uses RJ45 Plug. Connection

is shown in Table 5.5 as below:

Wire Connector No. RJ45 plug's Pin NO

Blue & White 1 5

Blue 2 4

Table 5.5 RS485-L Cable Assembly Order

RJ45 Cable

RJ45 cable is the standard cable for Ethernet communication. Users can buy this cable in stores,

or can assemble RJ45 cable as below:

Each end of the cable must be connected to RJ45 Plug according to Table 5.6. Make sure they

are xed well.

RJ45 plug's Pin NO

One RJ45 plug's

Wire color

One RJ45 plug's

Wire color

1 White & Green White & Orange

2 Green Orange

3 White & Orange White & Green

4 Blue Blue

5 White & Blue White & Blue

6 Orange Green

7 White & Brown White & Brown

8 Brown Brown

Table 5.6 RJ45 Cable Assembly Order

User Manual

31

6. LCD Operation

6.1 LCD Display Overview

Figure 6.1 Inverter HMI (Human Machine Interface)

Object Description

A

Power status indicator

Yellow light on: Inverter power systerm normal

B

Inverter status indicator:

Flashing red light: Inverter faulty status.

Green light on: Inverter normal status.

Red light and Green light are both off: inverter initialization status or inverter counting

down to connect to grid.

C

Communication status indicator:

Flashing blue light: receiving data.

Flashing yellow light: transmitting data.

D(▲) Move the cursor/focus up or increase the setting value.

E( )

Move the cursor/focus left.

F(▼) Move the cursor/focus down or decrease the setting value.

G( ) Move the cursor/focus right.

H Start the menu/conrm

Table 6.1 Inverter HMI Description

All the running information, including energy yield, error record, communication settings and

inverter settings can be viewed from the LCD.

User Manual

32

6.2 Startup the Inverter

Suntrio inverter can be congured for various countries, if it is the rst time the inverter starts

up after installation, LCD will quickly switch to and stay at the country setting interface. Only

the inverter is set to comply with a certain country, it will work and display normally. Otherwise,

LCD will always stay at the “Please Set The country First” interface.

There are 28 countries for choosing

1 Australia 15 Italy

2 Austria 16 Portugal

3 Belgium 17 China

4 Brazil 18 Thailand

5 Denmark 19 Default

6 Finland 20 Hungary

7 France 21 Croatia

8 Luxembourg 22 Czech Republic

9 Netherland 23 Germany

10 Norway 24 Israel

11 Poland 25 Greece

12 Sweden 26 Malaysia

13 Switzerland 27 New Zealand

14 UK 28 Spain

Note: if you can’t find the country you want, please directly select ‘Default’.Default mode

represent the VDE 0126-1-1.

After Country conguration, Inverter will have a self-check when starting up. If no malfunction

is found and grid connection requirement is met, inverter LCD will go to the countdown screen,

as shown in Figure 6.2.

User Manual

33

Figure 6.2 Connect to the Gird Countdown

6.3 LCD Main Screen

When inverter countdown nishes and starts to connect to grid, LCD will display the main screen

as below. The main screen consists of menu bar, main display area, auxiliary display area, status

bar (including inverter status, description of main display area, data and time). Please refer to

Table 6.2 for inverter status description, Table 6.3 for auxiliary display area items description.

Information in main display area varies according to menu selected. Please refer to the next

section.

Figure 6.3 LCD main Screen

User Manual

34

6.4 LCD Menu Structure

Menu structure is shown as Figure 6.4.Menu can be selected by pressing the ‘▲’, ‘▼’, ‘ ’, ‘

’ and conrmed by pressing ‘Enter’, then LCD main display area will display the information

accrodingly. “Exit” option in every submenu exit selected menu stat

Inverter State Explanation

Init The inverter is on self-checking

Wait The inverter in stand-by state

Normal The inverter in normal (function) operation

Error A fault occurs during operation

Update The state of updating rmware

Table 6.2 Inverter status description

Data name Explanation Unit

Power The inverter generated power W

E-Today The generated energy of current day kWh

E-Total

The total energy generated by the inverter and total generated

energy of the year.

kWh

T-today The operating time of current day h

T-total Total hours of operation time h

Table 6.3 Auxiliary display area items description

Figure 6.4 Menu structure

User Manual

35

6.4.1 LCD Graph Submenu

Graph submenu consists of E-Today, E-Month, E-Year and E-Total. LCD main display area will

display the corresponding information after conrming the Graph submenu by pressing ‘Enter’.

The Figure 6.5 below is the E-Month Screen.please refer to the Table 6.4 for E-Today, E-Month,

E-Year and E-Total display information explanation.

Figure 6.5 E-Month Screen

Item Display information explanation

E-Today Bar chart of energy yield today

E-Month Bar chart of energy yield every day of this month

E-Year Bar chart of energy yield every month of this year

E-Total Bar chart of energy yield every year

Table 6.4 Graph submenu explanation

User Manual

36

6.4.2 LCD Setting Submenu

Setting submenu includes the below setting of the inverter:

Ethernet:

Figure 6.6 is the Ethernet setting screen.Either the IP address is set to be obtained auto or

manually, the IP address displayed on the screen is the current IP address of the inverter. The

focus can be moved by pressing the ‘ ’, ‘ ’, and IP address/IP address obtain method can be

changed by pressing the ‘▲’, ‘▼’. The change will be saved by pressing ‘Enter’. ‘Web server

Port’ is the inverter embedded Web Server listening port. Inverter embedded Web Server will

monitor two ports, and the default one is port 80.

How to visit Web Server: if the inverter and your PC/Mobile phone are in the same network,

inverter embedded Web Server can be visited by typing inverter IP address in the web browser.

Another listening port can be changed in the screen. And ‘: web Server port’ is required to be

added after the IP address. For example, as shown in Figure 6.6, the address to be typed in web

browser should be http://192.168.1.111:81, and the Web Server screen is shown in Figure 6.7.

Figure 6.6 LCD Ethernet Screen

User Manual

37

Figure 6.7 Inverter Embedded Web Server Screen

Language & Time:

Move the focus to the setting item by using ‘ ’, ‘ ’ , and the setting can be changed by pressing

‘▲’, ‘▼’. The setting will be saved by moving the focus to ‘OK’ and press ‘Enter’.

Figure 6.8 Language & Time setting Screen

User Manual

38

Grid Compliance:(only for SAJ or SAJ representative)

Different country has different grid connection standard for inverter. The grid compliance of

the inverter can be changed by this setting menu when the inverter is run for the rst time or the

country selection is wrong.

Enter the Grid Compliance submenu and confirm the password, then the country which the

inverter installed in can be selected. After the selection, press ‘ ’ to move the focus to button

‘OK’, then press ‘Enter’.

Clear Errors:

After entering the Clear Errors submenu, the LCD will display as below. The operation by

moving the focus to button ‘OK and pressing ‘Enter’ will delete the error record saved in the

inverter permanently. If you want to exit, press ‘ ’ to move the focus to button ‘Cancel’ and

press ‘Enter’

Figure 6.9 Clear Errors operation Screen

Clear Energy:

After entering the Clear Energy submenu, the LCD will display as Figure 6.10. The operation by

moving the focus to button ‘OK and pressing ‘Enter’ will delete the energy yield data saved in

the inverter permanently. If you want to exit, press ‘ ’ to move focus to button ‘Cancel’ and

press ‘Enter’

User Manual

39

Figure 6.10 Clear Energy Operation Screen.

LCD Setting:

LCD setting includes: LCD backlight brightness and LCD backlight Time-out, as shown in

Figure 6.11.Press ‘ ’, ‘ ’to move the focus and press ‘▲’, ‘▼’ to change the value. After the

change, move the focus to button ‘OK’ and press ‘Enter’.

Figure 6.11 LCD Setting Screen

User Manual

40

Factory Reset: (only for SAJ or SAJ representative)

The user will set inverter to factory setting and delete all data saved in the inverter, for example,

Error Records and Energy. The operation requires a password. After inputting the password,

move the focus to button ‘OK’, and press ‘Ent er’.

Figure 6.12 Factory Reset Screen

Change Password (only for SAJ or SAJ representative)

SAJ or SAJ representative can change the passwords for ‘Grid Compliance’ and ‘Factory

Setting’. After entering this menu, the old password will be required. After passing the old

password verication, the screen will be displayed as below, as shown in Figure 6.13.

Figure 6.13 Change Password Screen

User Manual

41

■Run-Info

AC-Parameters:

Inverter AC output data can be viewed in the menu, as shown in Figure 6.14 .

Figure 6.14 AC Parameters Screen

DC-Parameters:

DC data can be viewed in this screen, as shown in Figure 6.15.

Figure 6.15 DC Parameters interface

User Manual

42

Error-Records:

Inverter error record can be viewed in this menu, as shown in Figure 6.16. The screen can be

scrolled by pressing ‘▲’, ‘▼’. Error record can be ipped over to another one by moving the

cursor to button ‘Previous’ or ‘Next’ and press ‘Enter’. Please refer to chapter eight for error

description and guidance.

Figure 6.16 Error Records

About

When the focus is moved to “About”, press “Enter” to enter the “About Screen”, as shown in

Figure 6.17. Please refer to Table 6.5 for description of the items in it.

Figure 6.17 About Screen

User Manual

43

Item Descripiton

InverterType Inverter Model

Inverter SN: Inverter Serial Number

Inverter PC Inverter Product Code

HMI SW: Human Machine Interface Software Version

Master Ctrl. SW (Control Board Master MCU Software Version)

Slave Ctrl. SW

(Control Board Slave MCU Software Version)

Portal ID

Portal ID. The Portal account ID for Web portal registration: http://webportal.saj-solar.

com. The inverter has to be connected to internet, otherwise it will keep displaying

‘Getting…’, If the inverter is connected to the internet, but it still keeps displaying

‘Getting…’, please exit the ‘About’ interface and enter it again to get the account ID.

Attention: if the inverter just starts up, the Portal ID can be obtained after two minutes.

Table 6.5 About Screen Description

6.5 Error Report Mechanism and Guidance

When there is fault in the solar system or inverter itself, an error report window will pop up, as

shown in Figure 6.18. Please refer to error description and guidance in chapter eight.

Figure 6.18 Error Report Window

User Manual

44

7.Recycling and Disposal

To comply with European Directive 2002/96/EC on waste Electrical and Electronic Equipment

and its implementation as national law, electrical equipment that has reached the end of its life

must be collected separately and returned to an approved recycling facility. Any inverter that you

no longer required must be returned to your dealer or you must nd an approved collection and

recycling facility in your area.

Ignoring this EU Directive may have severe affects on the environment and your health.

User Manual

45

8.Troubleshooting

Error Code

LCD Display

Message

Phenomenon and Possible Cause

Phenomenon and

Possible Cause

1 Relay Error M

1 ) A f au lt ha s o c c u r r e d i n t h e

Relay(Suntrio Series have 8 relays at

the AC side of the inverter) when the

invert er detects itself durin g start-up.

2) T h e Gr i d vo l t a ge at b o t h s i d e s

o f t h e r el a ys i s i nt e rf e re d wh e n

t he re la ys sw it ch on an d o ff .

If this error occurs often, please

contact local agent or SAJ

Service line.

2 Eeprom Error M The EEPROM Device Error.

If this error occurs often, please

contact local agent or SAJ

Service line.

3 Temp. High Err M

1)The thermal resistance is defective. 2)

Environment temperature too high or

too low.

If the th erma l res i s tanc e is

de fect ive, cha nge it. Chec k

the ambie nt and i nst allat ion

co n d i t i o n . If ev e r ything is

correc t, please contact loca l

ag e n t or SA J Service l i n e .

4 Temp. Low Err M

5 Lost Com. M<->S M

C o m mu ni c at io n b e t we en M a st er

an d Sl a v e Mi c r o - c o n t r o l l e r s fa i l s .

Please contact local agent or

SAJ Service line.

6 GFCI Device Err M

The i nternal sensor ha s detected that

the GFCI Devic e i s out of f uncti on.

Please contact local agent or

SAJ Service line.

7 DCI Device Err M

The i nternal sensor ha s detected that

th e DCI Device is o u t of fu ncti o n .

Please contact local agent or

SAJ Service line.

8 Curr Sensor Err M

A fau l t ha s occu r r e d in the on e or

more current senso rs o f the inverter.

Please contact local agent or

SAJ Service line.

9 L1 Voltage High M

1)The local Grid voltage is beyond the

permitted range.

2)The connection between Grid and

inverter has problems.

Chec k t he Grid Com pli anc e

of th e in v e r t er (G e rma n y,

Italy, A ustral i a , De n m a r k,

Belgium, Netherlands, etc) and

Grid voltage. If everything is

correc t, you need to contact

local agent or SAJ Service line.

10 L1 Voltage Low M

11 L2 Voltage High M

12 L2 Voltage Low M

13 L3 Voltage High M

14 L3 Voltage Low M

User Manual

46

Error Code

LCD Display

Message

Phenomenon and Possible Cause

Phenomenon and

Possible Cause

15 L1 Volt 10Min High M

Average of output voltage out of range.

16 L2 Volt 10Min High M

17 L3 Volt 10Min High M

18 L1 Freq High M

1)The local Grid Frequency is beyond

the permitted range.

2)The connection between Grid and

inverter has problem.

Check the Grid Compliance of

the i nv er te r (Germany, Ital y,

Australia, Denmark, Belgium,

Ne t h e r lands , et c) and Gr i d

fr e q u e ncy. If ev e rythi n g is

correc t, you need to contact

local agent or SAJ Service line.

19 L1 Freq Low M

20 L2 Freq High M

21 L2 Freq Low M

22 L3 Freq High M

23 L3 Freq Low M

24 L1 No Grid Err M

The connection between Grid an d

inve rt er has pro blems or i s mis si ng.

Check the AC connection. If

everything is correct, you need

to contact local agent or SAJ

Service line.

25 L2 No Grid Err M

26 L3 No Grid Err M

27 GFCI Error M

A Ground fault has occurred at the DC

or AC side.

Ch eck the ins u lat i on of t h e

mo dul e s a nd e xte r nal surge

protection. Check the ambient

c o n di t io n ( h u mi d it y c an

in c r e a s e the pro b a b i l i ty of

th i s err or ) . Che c k int erna l

ground connection. If the error

is still active ,please contact the

local agent or SAJ Service line.

28 L1 DCI Error M

1)The DCI value of the output current is

beyond limit.

2)The quick variation of the output

current causes this problem.

If the error is still active, please

contact the local agent or SAJ

Service line.

29 L2 DCI Error M

30 L3 DCI Error M

31 ISO Error M A Ground fault has occurred at the DC side.

C h ec k t he i ns ul a ti o n o f

th e mod u l e s an d ex t er n a l

surg e pro tec tio n. Check the

amb ient conditio n( humidity

ca ninc r eas e the pro b abil ity

of this error ). Check internal

ground connection. If the error

is still active, please contact the

local agent or SAJ Service line.

User Manual

47

Error Code

LCD Display

Message

Phenomenon and Possible Cause

Phenomenon and

Possible Cause

32 Bus Volt Bal.Err M

1)The Voltage of the BUS middle point

is beyond half of the BUS voltage.

2)If random, a possible cause is the

quick

variation of grid voltage.

If the error is still active, please

contact the local agent or SAJ

Service line.

33 Bus Volt High M

1)The open-circuit voltage of the PV

generator is higher than the maximum

DC input voltage of the inverter.

2)Sudden DC surge.

If the error is still active, please

contact the local agent or SAJ

Service line.

34 Bus Volt Low M

1)Boost MOSFET/IGBT damaged or the

PV string conguration is not correct.

2)Happens during Sunset. Can reproduce

daily.

If the error is still active, please

contact the local agent or SAJ

Service line.

35 L1 Current High M

The output current is beyond the rmware

limited value.

If random, a possible cause is the quick

variation of grid voltage.

Repetitive error means rmware failure

(Iac sensor).

C h ec k th e Gr i d - vo l t ag e

stability and AC conn ection.

If th e er r o r is st i l l ac t i v e ,

p l ea se co nt ac t t he l o ca l

ag e n t or SAJ Se rvice li n e .

36 L2 Current High M

37 L3 Current High M

38 HWBus Volt High M

1)The voltage of PV string connect

to the inverter is higher than the

HW limited value.

2)Sudden DC surge.

C h e c k t h e P V s t r i n g

c o nf ig u r at i o n. T he SA J

D e s i gn e r ca n h el p y ou .

I f e v er yt hi ng i s c o rr ec t,

you ne e d t o co n ta c t lo cal

ag e n t or SAJ Se rvice li n e .

39 HWPV1 Curr.High M

Input current sensing circuit damaged or

wrong string conguration .

C h e c k t h e P V s t r i n g

c o nf ig u r at i o n. T he SA J

D e s i gn e r ca n h el p y ou .

I f e v er yt hi ng i s c o rr ec t,

you ne e d t o co n ta c t lo cal

ag e n t or SAJ Se rvice li n e .

40 HWPV2 Curr.High M

41 HWL1 Curr. High M

The output current is beyond the HW

limited value.

If random, a possible cause is the quick

variation of grid voltage.

Repetitive error means HW failure (Iac

sensor)

C h ec k th e Gr i d - vo l t ag e

stability and AC conn ection.

If th e er r o r is st i l l ac t i v e ,

p l ea se co nt ac t t he l o ca l

ag e n t or SAJ Se rvice li n e .

42 HWL2 Curr. High M

43 HWL3 Curr. High M

44 Reserved(bit 46) M

45 Fan1 Error M

Fan locked or damaged.

Check the fans under the case

of the inverter. If fans are good,

please clean them. If the error

is still active, please contact the

local agent or SAJ Service line.

46 Fan2 Error M

47 Fan3 Error M

48 Fan4 Error M

User Manual

48

Error Code

LCD Display

Message

Phenomenon and Possible Cause

Phenomenon and

Possible Cause

49 Reserved(bit 52) M

50 Lost Com. M<->S S

Co m m u nicat i o n betw e e n Maste r

and Slav e Micro-con tr ollers fails.

Please contact local agent or SAJ

Service line.

51 L1 Volt Consis Err S

The redundant measurement HW circuit

of th e Gr i d vo l t a g e ha s pr o b l e ms.

If the error is still active, please

contact the local agent or SAJ

Service line.

52 L2 Volt Consis Err S

53 L3 Volt Consis Err S

54 L1 Freq Consis Err S

The redundant measurement HW circuit

of the Grid frequency has problems.

If the error is still active, please

contact the local agent or SAJ

Service line.

55 L2 Freq Consis Err S

56 L3 Freq Consis Err S

57 GFCI Consis Err S

Th e r e d u nd a nt me a s ur e m en t H W

ci r c u i t of th e GFCI has prob l e m s .

If the err o r is st i l l ac t i ve,

p l ea se c on ta c t t h e l oc al

ag e n t or SA J Service l i n e .

58 L1 DCI Consis Err S

Th e r e d u nd a nt me a s ur e m en t H W

ci r c u it of t h e DC I has pr ob l e m s.

If the err o r is st i l l ac t i ve,

p l ea se c on ta c t t h e l oc al

ag e n t or SA J Service l i n e .

59 L2 DCI Consis Err S

60 L3 DCI Consis Err S

61 L1 Voltage High S

1 ) T h e l o c a l G r i d v o l t a g e i s

b e y o n d t h e p e r m i t t e d r a n g e .

2 ) T he c on ne ct io n b e tw ee n G r id

a n d i n v e r t e r h a s p r o b l e m s .

Chec k t he Grid Com pli anc e

of th e in v e r t er (G e rma n y,

Italy, A ustral i a , De n m a r k,

B el g i u m, N e t he r l a n d s ,

e tc ) a n d G r i d v ol t a g e .

I f e ve ry th in g i s c o rr ec t,

yo u ne ed to c o n t ac t loc a l

ag e n t or SA J Service l i n e .

62 L1 Voltage Low S

63 L2 Voltage High S

64 L2 Voltage Low S

65 L3 Voltage High S

66 L3 Voltage Low S

67 L1 Freq High S

1 ) Th e lo c al G ri d F re q u en c y i s

b e y o n d t h e p e r m i t t e d r a n g e .

2 ) T he c on ne ct io n b e tw ee n G r id

a n d i n v e r t e r h a s p r o b l e m s .

Chec k t he Grid Com pli anc e

of th e in v e r t er (G e rma n y,

Italy, A ustral i a , De n m a r k,

B el g i u m, N e t he r l a n d s ,

et c ) a n d Gr i d F r eq u en c y.

I f e ve ry th in g i s c o rr ec t,

yo u ne ed to c o n t ac t loc a l

ag e n t or SA J Service l i n e .

68 L1 Freq Low S

69 L2 Freq High S

70 L2 Freq Low S

71 L3 Freq High S

72 L3 Freq Low S

User Manual

49

Error Code

LCD Display

Message

Phenomenon and Possible Cause

Phenomenon and

Possible Cause

73 L1 No Grid Err S

The connection between Grid an d

inve rt er has pro blems or i s mis si ng.

Check the A C co n n e c t i o n.

I f e ve ry th in g i s c o rr ec t,

yo u ne ed to c o n t ac t loc a l

ag e n t or SA J Service l i n e .

74 L2 No Grid Err S

75 L3 No Grid Err S

76 PV1 Volt High S

1)The open -circuit voltage of the P V

generator is higher than the maximum

DC in p u t vo l t a g e of th e inv e r t e r.

C h e c k t h e P V s t r i n g

c o n f ig ur a t io n. Th e S A J

D e s i gn er c a n he l p y ou .

I f e ve ry th in g i s c o rr ec t,

yo u ne ed to c o n t ac t loc a l

ag e n t or SA J Service l i n e .

77 PV2 Volt High S

78 PV1 Curr. High S

1)The PV in p u t cu rrent is beyond

the Max. Input Current. The valu e is

specied in the datasheet of the inverter.

2)The internal current sensor is damaged.

If the err o r is st i l l ac t i ve,

p l ea se c on ta c t t h e l oc al

ag e n t or SA J Service l i n e .

79 PV2 Curr. High S

80 PV Voltage Low S The voltage of the PV input is too low.

C h e c k t h e P V s t r i n g

c o n f ig ur a t io n. Th e S A J

D e s i gn er c a n he l p y ou .

I f e ve ry th in g i s c o rr ec t,

yo u ne ed to c o n t ac t loc a l

ag e n t or SA J Service l i n e .

81 Lost Com. D<->C D

Communication between Control board

and Display board fails.

Check the connection between

Co n t r o l board an d Di splay

board. If everything is correct,

yo u ne ed to c o n t ac t loc a l

ag e n t or SA J Service l i n e .

2)Sudden DC surge.

User Manual

50

9.Guaranty Service

Please refer to the warranty card.

10.Contact SAJ

If you have technical problems concerning our products, contact the SAJ Service line.

Technical Support & Service:

International Service & Technical Support

Addr: No.17, Xiangshan Road Guangzhou Science City,Guangdong,R.China.

Tel: +86 20 6660 0082

Fax: +86 20 6660 8589

E-mail: service@saj-solar.com

SAJ Europe Service Center

Addr: Maagdenstraat 44, 9600 Ronse, Belgium

Tel: +32 484 945 445

E-mail: service.europe@saj-solar.com

Loading...

Loading...