SAJ 8000m Series, 8000m-2S2R2GH, 8000m-2SR75GH, 8000m-2S1R5GH, 8000m-4T1R5GH User Manual

...

8000m Series Compact AC Drive

User Manual

Version Code :8000m-E-602000600-1705

8000m Series

- 1 -

Preface

First of all, thank you for purchasing 8000m Series Compact AC Drive!

This user manual introduces how to use 8000m series variable frequency drives

(VFDs) properly. Please read this user manual carefully before carrying out works

such as installation, commissioning, maintenance, etc.

Improper usage of VFDs would result in unpredictable accident, please deliver this

user manual to your end user. At the same time, please use VFDs until completely

understands safety instructions.

Attentions:

Illustrations in this user manual are for the convenience of understanding by user,

and it might be a bit different to the product you have purchased. As most of the

illustrations are showing the condition of VFD product with cover or safety guard

removed, please note that cover or safety guard must be installed back as required,

then operate strictly according to this user manual.

SAJ always continually improve the products, all technical parameters are subject to

change without notice. It would be possible that the old version manual is

inconformity to the new products you received. Please always use the user manual

which is included in the same package of product. If the user manual is lost or

incomplete, or there are problems or doubts, please ring the hotline of service center

of SAJ Company on 400-159-0088.

8000m Series

- 2 -

CONTENTS

Preface ................................................................................................... - 1 -

SAFETY INSTRUCTION ................................................................... - 5 -

Manual Conventions ............................................................................ - 9 -

Chapter 1 Introduction to the 8000m series VFD ........................ - 10 -

1.1 Model Description ...................................................................... - 10 -

1.2 Namplate Example ..................................................................... - 10 -

1.3 Model Table ................................................................................ - 11 -

1.4 Specifications ............................................................................. - 11 -

1.5 Dimensions and Sizes ................................................................ - 14 -

1.6 Keypad Tray Dimensions ........................................................... - 15 -

1.7 RS485 Interface .......................................................................... - 16 -

1.8 Braking Resistor Selection Table ............................................... - 16 -

Chapter 2 Installation and Wiring ................................................. - 17 -

2.1 Installation .................................................................................. - 17 -

2.2 Wiring ......................................................................................... - 22 -

Chapter 3 Keypad Operation ............................................................ - 26 -

3.1 Keypad Operation ...................................................................... - 26 -

3.2 Operation Details ....................................................................... - 27 -

Chapter 4 Function Parameter Table ............................................... - 30 -

4.1 Symbol Conventions: ................................................................. - 30 -

4.2 Function Parameter Table ........................................................... - 30 -

8000m Series

- 3 -

Chapter 5 Function Parameter Description ..................................... - 56 -

5.1 F0 Group—Basic Function ........................................................ - 56 -

5.2 F1 Group: Start and Stop Parameters ......................................... - 66 -

5.3 F2 Group: Motor Parameters ..................................................... - 70 -

5.4 F3 Group: Vector Control Parameters ........................................ - 73 -

5.5 F4 Group: V/F Control Parameters ............................................ - 76 -

5.6 F5 Group Input Terminals Parameters ....................................... - 81 -

5.7 F6 Group Output Terminals Parameters ..................................... - 92 -

5.8 F7 Group Display Interface Parameters ..................................... - 98 -

5.9 F8 Group Auxiliary Function Parameters ................................ - 101 -

5.10 F9 Group PID Control Parameters ......................................... - 108 -

5.11 FA Group Protection Parameters and Fault Records .............. - 115 -

5.12 FB Group Swing Frequency and Counting Meter Parameters- 121 -

5.13 FC Group RS485 Communication Parameters ...................... - 124 -

5.14 FD Group Multi-step Speed and Simple PLC Parameters ..... - 127 -

Chapter 6 Trouble Shooting ............................................................ - 130 -

6.1 Fault and Trouble Shooting ...................................................... - 130 -

6.2 Common Faults and Solutions ................................................. - 134 -

Chapter 7 EMC ................................................................................ - 135 -

7.1 Definition ................................................................................. - 135 -

7.2 Introduction to EMC Standard ................................................. - 135 -

7.3 EMC Guideline ........................................................................ - 135 -

Chapter 8 Communication Protocol ............................................... - 139 -

8.1 Communication Interface ......................................................... - 139 -

8.2 Communication Modes ............................................................ - 139 -

8000m Series

- 4 -

8.3 Frame Format ........................................................................... - 139 -

8.4 Protocol Function ..................................................................... - 141 -

8.5 Note .......................................................................................... - 145 -

8.6 CRC Checksum ........................................................................ - 146 -

8.7 Example .................................................................................... - 147 -

8.8 Data Address Table of Function Code ...................................... - 149 -

8000m Series

- 5 -

SAFETY INSTRUCTION

Read this user manual thoroughly before installation, operation, maintenance or

inspection of the variable frequency drive (VFD). In this manual, safety instructions

are classified as “WARNING” or “CAUTION”.

WARNING: Indicate a potentially dangerous situation which, if not avoided,

can result in death or serious injury to personnel.

CAUTION: Indicate a potentially dangerous situation which, if not avoided, can

result in minor or moderate injury and damage to equipment. It may also be used for

warning against unsafe practices.

Even items described as ( CAUTION) may result in a vital accident in some

situations. Please follow these important notes:

■ Checking Before installation

◎Do not install or operate any VFD that is damaged or has missing parts. Failing to follow

this rule can result in facility damage or severe injury.

■ Installation

◎When installing or handling the VFD, please hold the bottom of the product otherwise its case only,

thus prevent its falling and being damaged.

◎

Install the VFD on nonflammable material like metal, and keep away from flammable or

explsive object, heat source, and such environment. Otherwise it may cause a fire.

◎

Make sure that the mounting environment free of metal dust. Otherwise it may cause damage

to the VFD.

◎When VFDs is installed inside an electrical cabinet or other kind of enclosure, please install

fans or other cooling devices, and keep ventilation well enough to ensure the enclosure

temperature below 40

℃, or the VFD may be damaged due to extreme high rise of temperature.

8000m Series

- 6 -

■ Wiring

◎Ensure only qualified electrical engineering personnel for wiring work . Otherwise it

can cause an electrical shock or damage to the VFD.

◎Make sure VFD is isolated from power supply by the circuit breaker. Otherwise it may

cause electrical shock or a fire.

◎Make sure that the ground terminal is grounded correctly. Otherwise it may cause

an electrical shock.

◎Do not touch the main circuit terminals, and keep the wiring of VFD main terminals

from contacting to the enclosure, or it can cause electrical shock.

◎Terminals for brake resistor are (+) and PB. Do not wire to other terminals, otherwise

will cause a fire.

◎Before wiring, ensure the VFD’s rated input voltage and phases is compatible to the

input power source, or it can cause a fire or personal injury.

◎Never connect the AC power supply to output terminals U, V and W. Otherwise the

VFD will be damaged and the guarantee is voided.

◎Never carry out withstand voltage test to the VFD, for example by a megohm meter.

Otherwise it may cause damage to the VFD.

◎VFD’s main circuit wiring and control circuit wiring should be separated, or run

vertically from each other. Otherwise it may cause interference to the control signals.

◎Main circuit wiring cable leads should be crimped with cable lugs in insulated sleeve.

◎If the cable length between the VFD and the motor is greater than 50 meters, it is

recommended to use an output reactor to protect the VFD and the motor.

8000m Series

- 7 -

■ Operating

◎It is only allowed to power on the VFD after the wirng is finished and its cover is

reinstalled. It is strictly prohibit to remove the cover of VFD while power is on, otherwise

it may cause electric shock.

◎Before programming a VFD with fault auto reset or restart option after power off, the

mechanical device need to be implemented with safety measures first, otherwise it can lead

to personal injury.

◎”STOP/RESET” key may become invalid as a result of some function setting. It is

recommended to install an independent emergency circuit breaker for the VFD control

system, otherwise it may result in personal injury.

◎When the power is on, the VFD’s terminals may have electricity also even if it is in stop

mode. Do not touch U, V, W terminals and motor connection terminals. Otherwise it may

cause an electrical shock.

◎Do not use a magnetic contactor to control the start and stop of the VFD. Otherwise it

may cause the VFD to be damaged.

◎Before starting, please make sure that the motor and mechanical device can be run with

the VFD’s accelerating time setting in their safe range. Otherwise may result in device

damage.

◎Do not touch the heat sink or braking resistor. Otherwise it may cause harmful burns to

the body.

◎Never modify the parameters casually in unnecessary conditions, as the VFD’s default

parameter setting has already meet the requirements of most mechanical devices. Even if

some devices have special requirements, it is only needed to modify some necessary

parameters. Otherwise, it may cause device damage by improper parameter modification.

8000m Series

- 8 -

■ Maintenance

◎Never touch the VFD the connection terminals when power is on. Otherwise it may

cause an electrical shock.

◎Only qualified electrical engineering personnal can be authorized to do the jobs of

maintenance, checking, or parts replacement.

◎After the power supply is OFF, make sure the charge LED is OFF , the residual voltage

is not exist, or wait at least 10 minutes, before carrying out maintenance or inspection.

Otherwise it may cause damage or injury.

◎PCB has CMOS integrated circuit parts, never touch with bare hand, or static electricity

may cause damage to the PCB.

■ Other

◎Modification to the VFD without permission is strictly prohibited, otherwise can cause

severe injury. Arbitrarily modification of VFD will result in service guarantee voided.

8000m Series

- 9 -

Manual Conventions

In this manual we refer to 8000m Series Variable Frequency Drives as: drive,

inverter, VFD, 8000m, 8000m drive, AC drive or 8000m Series Compact AC Drive.

8000m Series

- 10 -

Chapter 1 Introduction to the 8000m series VFD

1.1 Model Description

1.2 Namplate Example

8000m Series

- 11 -

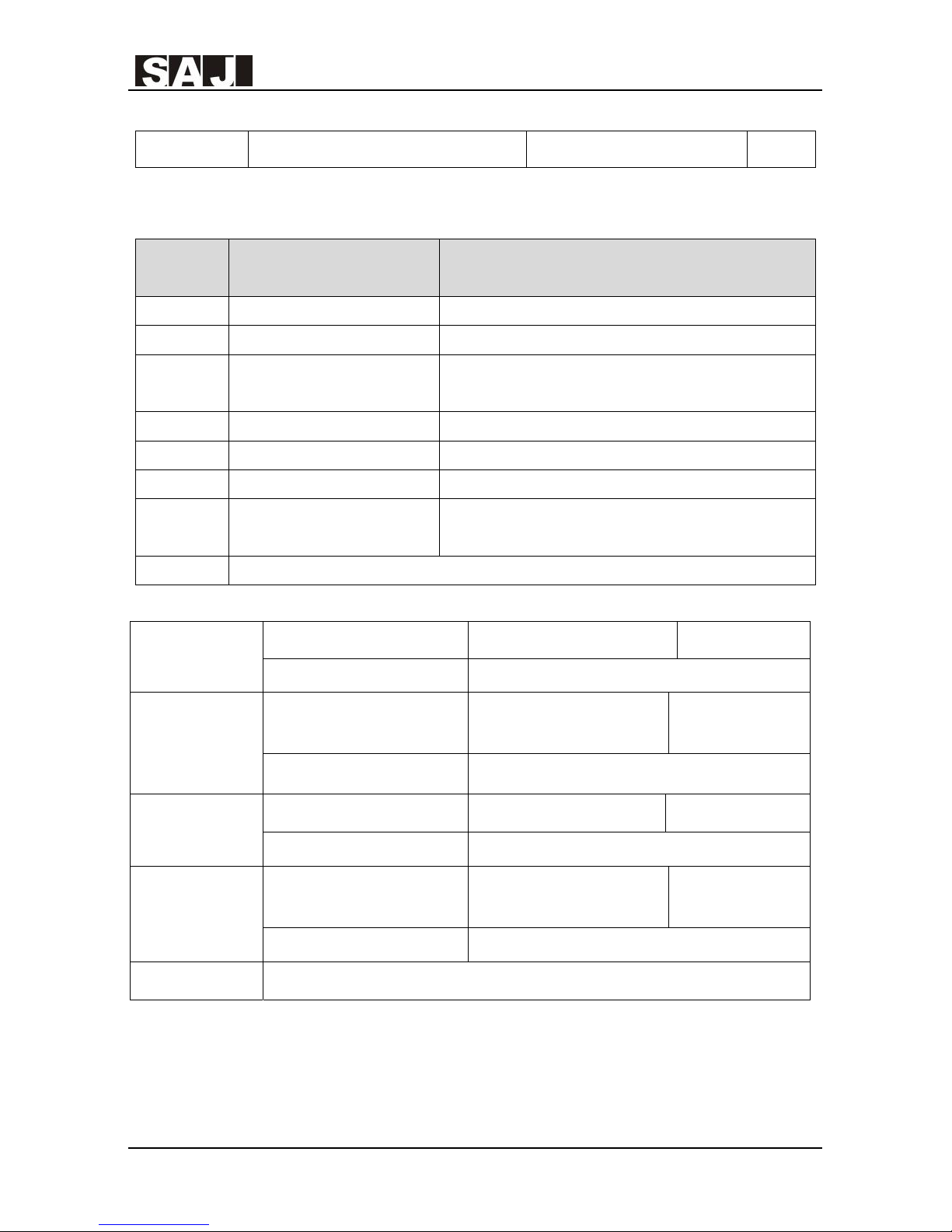

1.3 Model Table

1.4 Specifications

Control Characteristics

Control Mode V/F control

Starting Torque 0.5Hz 100%

Speed Control Range 1:20

Precision of Speed

Regulation

±1.0%

Overload Capacities

Model G: 60 seconds at 150% rated current; one second at 180%

rated current.

V/F Curve Options Three options: Linear, Square and Multipoint.

DC Injection Braking

Function

Braking start frequency: 0.00~Max. frequency limit;

Braking time:0.1~50.0s;

Braking current:0 ~150% of rated current(model G);

Braking start waiting time:0.0~50.0s.

Jog Operation

Jog frequency range: 0.00-max.frequency;

Accel./Decel. time of jog operation:0.1~3600s.

Accel./Decel. Time Accel./Decel. time range:0.1~3600s

Torque Boosting Manual setting:0.1~30.0%; Automatic setting:0.0%

Drive Model

Rated Output

Power kW

Rated Input

Current A

Rated Output

Current A

Motor Power

kW

Single-phase 220V±15%

8000m-2SR4GH 0.4 4.5 2.4 0.4

8000m-2SR75GH 0.75 8.2 4.5 0.75

8000m-2S1R5GH 1.5 14.2 7 1.5

8000m-2S2R2GH 2.2 23 10 2.2

Three-phase 380V±15%

8000m-4TR75GH 0.75 3.4 2.5 0.75

8000m-4T1R5GH 1.5 5 3.7 1.5

8000m-4T2R2GH 2.2 5.8 5.0 2.2

8000m Series

- 12 -

Input & Output Characteristics

Start Frequency 0.01~10Hz

Rated Input Voltage

220V/380V ± 15%

Rated Input

Frequency

50/60Hz,fluctuation range:±5%

Frequency Reference

Resolution

Analog signals: max. frequency × 0.1%; Digital setting:0.01Hz

Output Voltage 0: rated input voltage

Output Frequency

Range

0.00~600Hz

Peripheral I/O Characteristics

Digital Input

Terminals

4 inputs (programmable)

Analog Input

Terminals

AVI: 0~10V or 0/4~20mA (Jumper 10)

Relay Output 1 relay output (programmable)

Open Collector

Output

1 channel (programmable)

Analog Output FM: 0~10V; 0/4~20mA (Jumper 12)

Basic Functions

Operating Command

Channels

Three channels: keyboard, control input terminals, serial

communication interface. These channels can be switched by

several methods.

Frequency

References

7 references including panel potential meter, UP/DOWN key digital

setting, communication and PID control, etc.

Auxiliary Frequency

Reference

1 auxiliary frequency references, can be used in frequency

combination or adjustment.

Multi-step speed &

Simple PLC Function

14 steps multi-step speed control can be carried out by control input

terminals or built-in simple PLC function.

Built-in PID Function

Closed loop control of system variables such as pressure, speed or

temperature can be carried out by a built-in Proportional + Integral

+ Derivative (PID) controller.

8000m Series

- 13 -

Swing Frequency

Function

Suitable for some textile and chemical fiber machines by

programmable controlling of the triangular frequency references.

AVR Function

Automatic Voltage Regulation (AVR), automatically keep the

output voltage constant when power supply is not stable.

Stall Prevention

Stall Prevention automatically control the decelerating procedure

by monitoring the bus voltage and prevent overvoltage fault caused

by high inertia or rapid deceleration.

Communication

Function

RS485 communication with standard modbus protocol.

Automatic Energy

Saving Control

Automatic decrease output voltage while in the situation of light

load, to achieve efficient energy saving.

Fault Protection

Function

Over- current , over voltage, under- voltage, over temperature, lack

of phase, etc.

Personalized function

LED Display

16 parameters can by displayed including running frequency, DC

bus voltage, output voltage, output current, etc.

Password Setting

Four-digit non-zero password can be set and become effective after

exit the password programming mode and wait 1 minute.

Parameter Lock

Function

This function can be used to lock the parameter when running or

stop in order to avoid wrong operation.

Application Environment

Efficiency

At rated power

≥ 93% as 45kW and below;

≥ 95% as 55kW and above。

Location

Indoor away from sunlight, dust, corrosive gas, oil fog, driping

water or condensation.

Elevation 1000m or less

Ambient Temperature

-10℃ ~+40℃

Humidity 95% RH or less

Vibration < 5.9 m/s2 (0.6G)

8000m Series

- 14 -

1.5 Dimensions and Sizes

Dimensions Drawing

Single phase 220V 1.5-2.2kW and 3-phase380V 0.75kW-2.2kW

Single phase 220V 0.4-0.75kW

8000m Series

- 15 -

1.6 Keypad Tray Dimensions

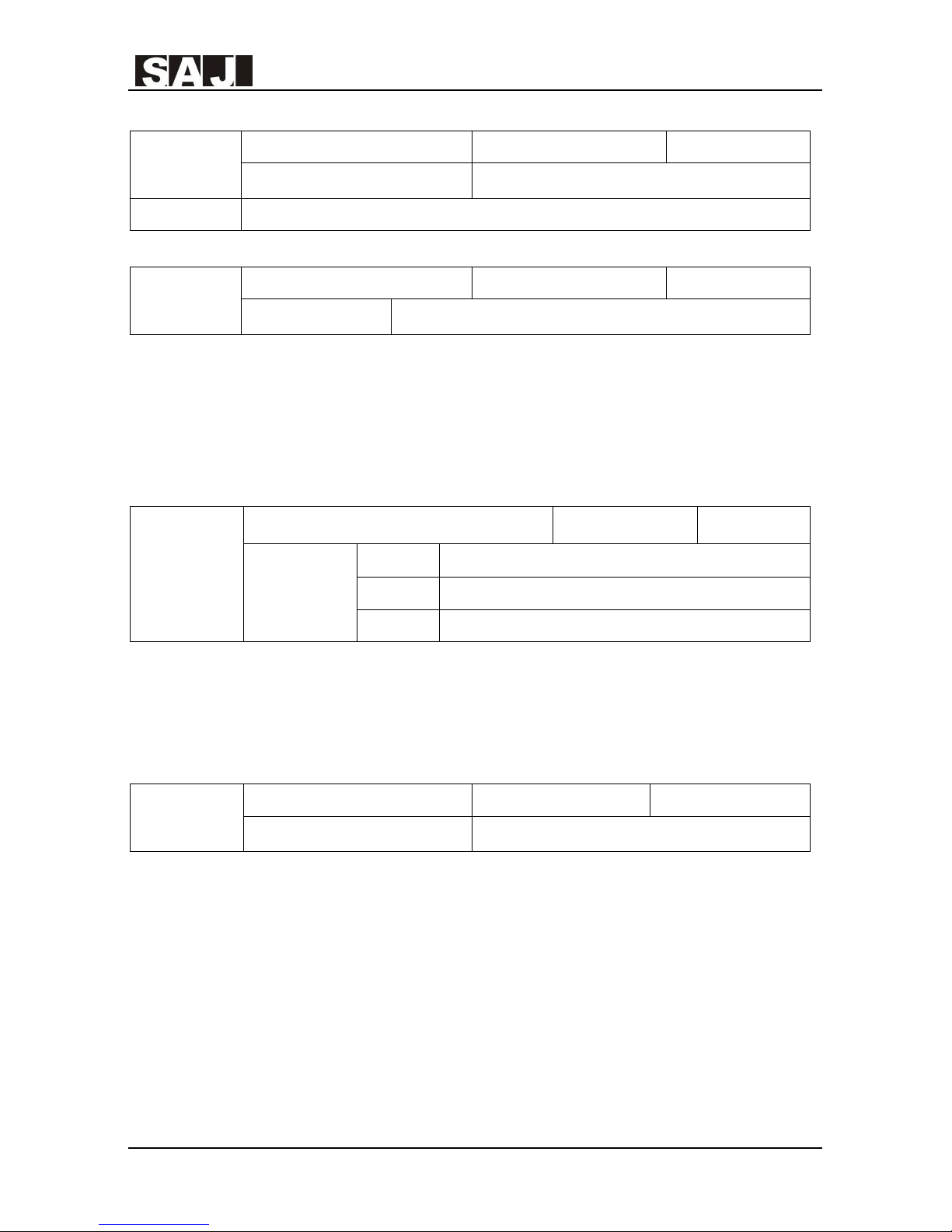

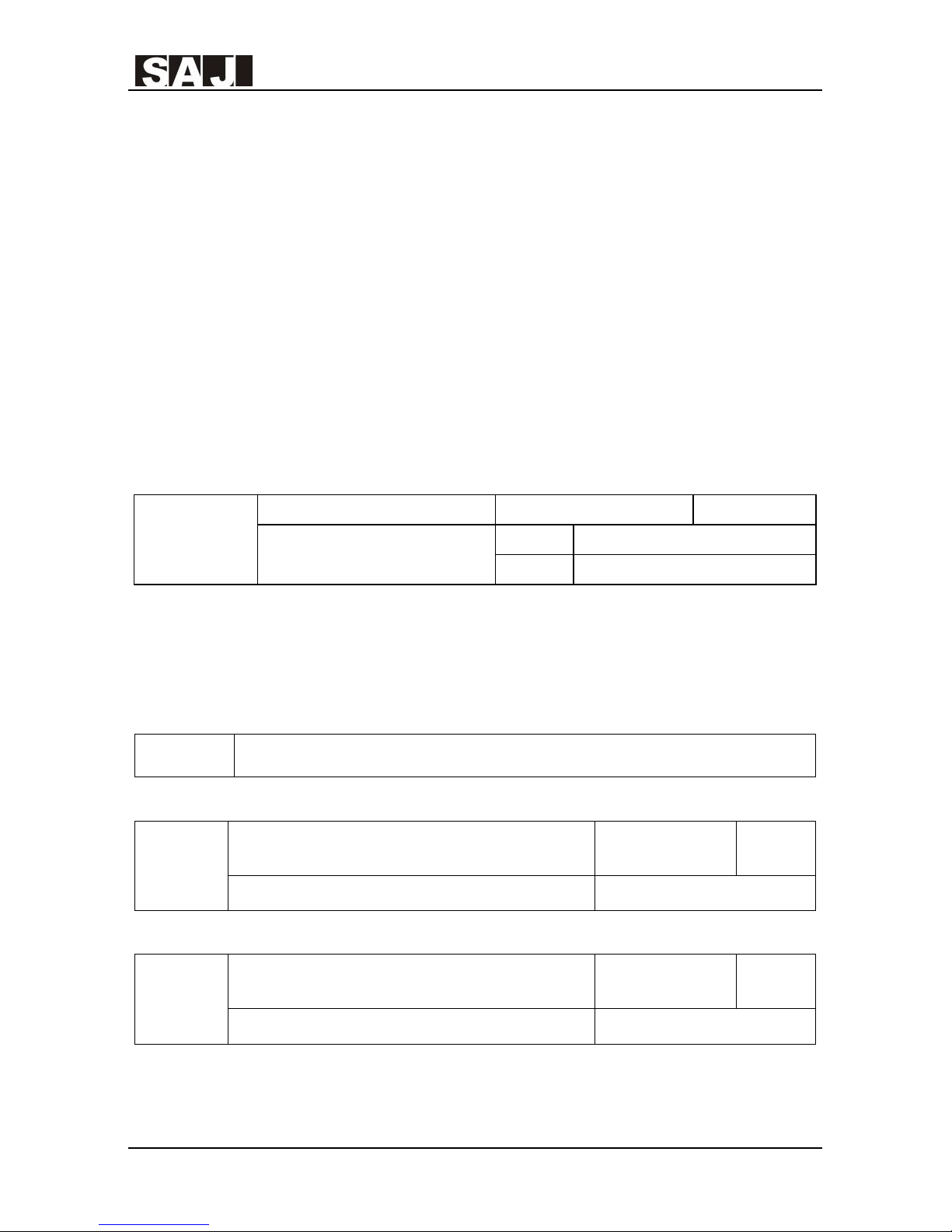

Voltage

Class

Drive Model

Dimensions(mm)

Diameter of

installation

hole(mm0

W W1 H H1 D

Single

Phase

220V

8000m-2SR4GH

81.3 67.4 151.3 133 132.8

Φ5

8000m-2SR75GH

8000m-2S1R5GH

99.3 86.8 164.7 147.4 152

8000m-2S2R2GH

Three

Phase

380V

8000m-4TR75GH

8000m-4T1R5GH

8000m-4T2R2GH

8000m Series

- 16 -

1.7 RS485 Interface

Terminal Symbol

Function Specifications

S+ Positive pole of differential signal

Standard

RS485

interface

S- Negative pole of differential signal

+5V Positive pole of extension power (+5V)

GND Negative pole of extension power

1.8 Braking Resistor Selection Table

Inverter Model

Recommended Power

of Brake Resistor

Recommended

Resistance Value of

Brake Resistor

Brake Unit

8000m-2SR4GH 50W ≥150Ω

Standard

Accessory Inside

8000m-2SR75GH 80W ≥150Ω

8000m-2S1R5GH 100W ≥100Ω

8000m-2S2R2GH 100W ≥70Ω

8000m-4TR75GH 150W ≥300Ω

8000m-4T1R5GH 150W ≥220Ω

8000m-4T2R2GH 250W ≥200Ω

8000m Series

- 17 -

Chapter 2 Installation and Wiring

2.1 Installation

2.1.1 Installation Environment

◎The ambient temperature exerts great influences on the service life of the VFDs

and is not allowed to exceed the specified temperature range (-10℃ to 40℃ ).

◎A VFD is easy to generate large amount of heat during operation. Thus VFDs

should be mounted vertically with screws on the surface of incombustible objects,

with sufficient spaces nearby for heat sinking.

◎VFDs should be mounted in the place without vibration or with vibration of less

than 0.6G, especially away from those kinds or machine such as punch.

◎The inverter should be mounted in locations away from direct sunlight, high

humidity, condensate, corrosive gas, explosive gas, oil dirt, dust, and metal powder

etc.

2.1.2Installation Orientation & Clearance

Single Drive & multi drives (Side by Side) Installation

8000m Series

- 18 -

Multi Drive (up and down) Installation

When take up and down installation, air deflector should be installed between upper

and lower VFD, as illustrated below.

8000m Series

- 19 -

2.1.4 Electric Elements and Material

Peripheral Electric Elements

Connection Diagram

8000m Series

- 20 -

2.1.5 Descriptions of External Electrical Parts

Name Mounting Location Function

Circuit

Breaker

Front end of input circuit

Disconnect the power supply when the

backward equipment is over current.

Contactor

Between the circuit breaker

and inverter input side

Power ON/OFF of inverter. Do not use the

contactor as the switch of inverter. Otherwise,

it may cause damage to the inverter.

AC Reactor

at the Input

Side

Input side of inverter

1. Improve the power factor of the input side.

2. Eliminate the harmonic wave at the input

side effectively and prevent other equipment

from damage.

3. Eliminate the input current unbalance

caused by unbalance between the power

phases.

EMC Input

Filter

Input side of inverter

1. Reduce the external conduction and

radiation interference of inverter.

2. Decrease the conduction interference

flowing from the power end to the inverter and

improve the anti-interference capacity of the

inverter.

AC Reactor

at the

Output Side

Between inverter output side

and motor. Close to inverter.

The inverter output side generally has higher

harmonics. When the motor is far from

inverter, since there are many distributed

capacitors in the circuit, certain harmonics

may cause resonance in the circuit and bring

the following two impacts:

1. Degrade the motor insulation performance

and damage the motor when running for long

time.

2. Generate large leakage current and cause

frequent inverter protection.

Generally, installation of output AC reactor is

recommended when the distance between

inverter and motor exceeds 50m.

2.1.6 Table of Recommended Circuit Breaker, Contactor and Wire

8000m Series

- 21 -

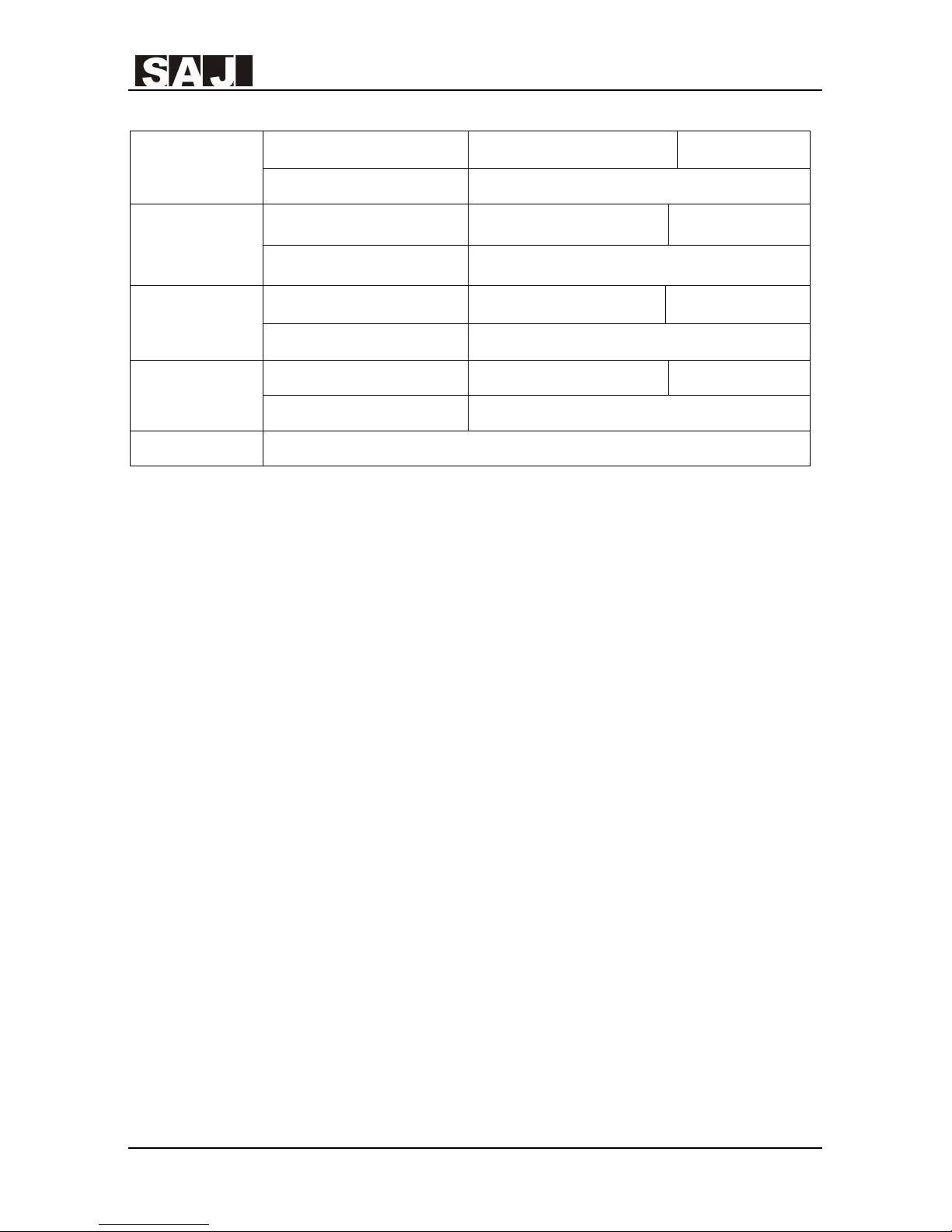

Inverter Model

Circuit

Breaker

(MCCB) (A)

Recommend

ed Contactor

(A)

Conducting

Wire of Main

Circuit at the

Input Side

(mm2)

Conducting

Wire of Main

Circuit at the

Input Side

(mm2)

Conducting

Wire of

Control

Circuit

(mm2)

8000m-2SR75GB 16 10 2.5 2.5 1.0

8000m-2SR75GB 16 10 2.5 2.5 1.0

8000m-2S1R5GB 20 16 4.0 2.5 1.0

8000m-2S2R2GB 32 20 6.0 4.0 1.0

8000m-4TR75GB 10 10 2.5 2.5 1.0

8000m-4T1R5GB 16 10 2.5 2.5 1.0

8000m-4T2R2GB 16 10 2.5 2.5 1.0

2.1.7 Table of Recommended Reactor

Inverter Model

AC Reactor at the Input

Side

AC Reactor at the output

Side

Voltage

Current (A)

Inductance

(mH)

Current (A)

Inductance

(mH)

8000m-2SR75GB 2 7 2 7

220V

8000m-2SR75GB 2 7 2 7

8000m-2S1R5GB 5 3.8 5 3.8

8000m-2S2R2GB 7.5 2.5 7.5 2.5

8000m-4TR75GB 2 7 2 3

380V

8000m-4T1R5GB 5 3.8 5 1.5

8000m-4T2R2GB 7 2.5 7 1

8000m Series

- 22 -

2.2 Wiring

2.2.1 Wiring Diagram

Note:

1. ◎ refers to terminals of main circuit; ○ refers to terminals of control circuit.

2. For 220V single phase inverter, the terminals of main circuit are R and S.

8000m Series

- 23 -

2.2.2 Main Circuit Terminals

Terminals Descriptions

R, S and T

AC power inputterminals.

3-phase: R, S and T

Single phase: R and S

U, V and W AC power output terminals (For connecting motor)

(+) DC bus terminal of positive pole

PB Terminal for connecting brake resistor outside

Grounding terminal

2.2.3 Jumper Options

FM Jumper J2 Note

0-10VDC

Default

0-20mA

AVI Jumper J10 Note

0-10VDC

Default

0-20mA

8000m Series

- 24 -

2.2.4 Precautions on Main Circuit Wiring

2.2.4.1 Terminals R, S and T

The wiring at the input side of inverter has no phase sequence requirement. When

input single-phase power, use terminal R and T.

2.2.4.2 DC Bus Terminals (+) and PB of Brake Resistor

The (+) terminal of DC bus have residual voltage right after power-off.

Wait until the CHARGE indicator is OFF and make sure that the voltage is less

than 36V before wiring. Otherwise it may cause electrical shock.

The cable length of brake resistor should be less than 5m.

2.2.4.3 Terminals U, V and W

Capacitor device or surge absorber cannot be connected to inverter output side by

terminals U, V and W. Otherwise, it may cause frequent inverter protection or

damage to inverter.

If motor cable is too long, it may generate electrical resonance easily due to the

impact of distributed capacitance and thus damage the motor insulation or generate

higher leakage current to cause inverter protection. When the length of motor cable

is longer than 50m, installing AC reactor at the output side is necessary.

2.2.4.4 Grounding Terminal

The terminal should be grounded reliably. The resistance value of grounding cable

should be less than 10Ω. Otherwise, it may cause fault or damage to the inverter.

Do not share the grounding terminal with zero line of power supply.

8000m Series

- 25 -

2.2.5 Control Circuit Terminals

Symbol Terminal Name Function

M1~M4

Multi-functional digital

input terminals

Do not connect additional power source

directly.

A digital input is ON when it is connected to

GND, and will be OFF when it is opened.

Action current is 10mA.

GND Ground terminal Zero potential of +10V and +24V

MO1

Multi-functional open

collector output terminal

(Optical coupling isolating)Max. DC

48V/50mA

AVI Analog input terminal

Default: Input voltage range DC 0~10V (input

impedance:20kΩ)

Option: DC current 0-20mA (Jumper J10)

10V Analog reference voltage 10V ±5%, Max. current: 30mA

FM Analog output terminal

Default: DC voltage 0-10V

Option: DC current 4-20mA (Jumper J2)

TA/TB/ TC

Programmable Relay

Output

TA-TB: normally open;

TB-TC: normally closed;

Contact capacity:

AC 250V / 3A/ normally open

AC 250V / 3A / normally closed

+24V +24V power supply

Output current: Maxi. 200mA, usually used as

power of digital input/output terminals and

external sensor.

2.2.5 Precautions for Connecting Control Circuit Terminals

It is necessary to use shielded cable and twisted pair cable well-grounded (inverter

side). The cable should be more than 20cm away from power electricity cables and

conductors. Do not run the control cable paralleling to power electricity cables, try

vertically.

8000m Series

- 26 -

Chapter 3 Keypad Operation

3.1 Keypad Operation

3.1.1 Keypad Outline

3.1.2 Keys Description

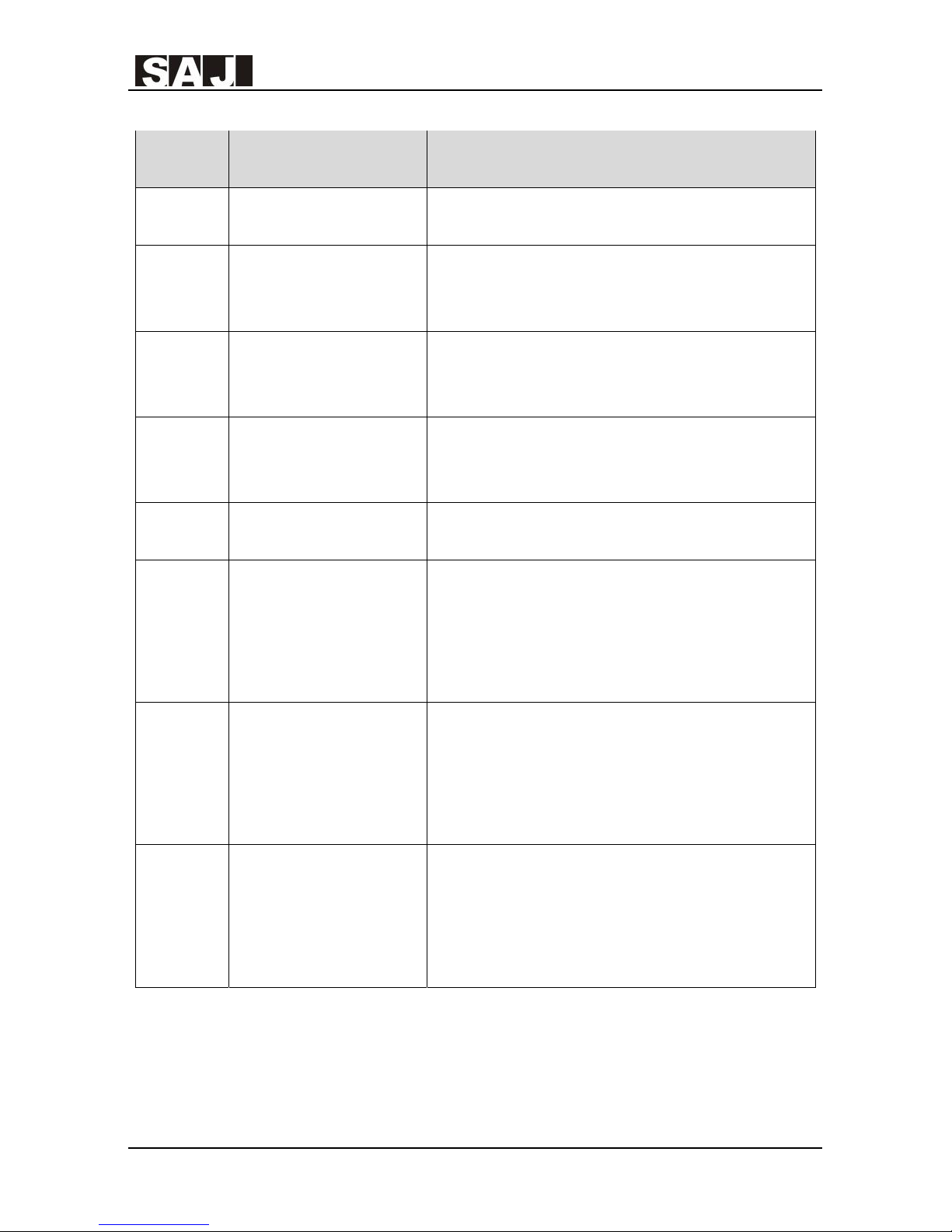

Symbol Key Name Function Description

PRGM Program/ Exit key Enter or exit of menu, parameter modification

ENT Enter key Progressively enter menu and confirm parameter

UP

increase key

Progressively increase data or function codes.

DOWN decrease

key

Progressively decrease data or function codes.

8000m Series

- 27 -

<<

Shift key

Use it to select displayed parameters cyclically during

running or stop status. In parameter setting mode, press

this key to select the bit to be modified.

RUN/STOP

Run/Stop/Reset

key

For start, stop and reset operation, depends on control

mode setting.

3.1.3 Indicator Light Description

Indicator Light Description

Run light on: Drive running

Hz light on: Frequency Display

V light on: Voltage Display

A light on: Current Display

3.2 Operation Details

3.2.1 Parameter Setting

Three levels of menu are as following:

· Function code group (first-class)

· Function code (second-class)

· Setting parameter of function code (third-class)

Remarks:

Pressing PRGM or ENT can return to the second-class menu from the third-class

menu. The difference is: Pressing ENT will save the setting parameters into control

board, and return to the second-class menu with shifting to the next function code

automatically. While pressing PRGM will directly return to the second-class menu

without saving the parameters, and keep staying at the current function code.

8000m Series

- 28 -

For example:

Change function code F1.01 from 0.50Hz into 05.00Hz as shown in the following

flow chart:

Flow Chart of Parameter Setting

Under the third-class menu, if the parameter has no flickering bit, it means that the

function code cannot be modified. The possible reasons include:

(1) The parameter of this function code can’t be modified, such as actually detected

parameter, operation records and so on.

(2) This function code can’t be modified during running status, but can be modified

during stop status.

8000m Series

- 29 -

3.2.2 Fault Reset

When inverter malfunction occurs, it will display the relative fault information. Use

the RUN/STOP key or terminals (determined by F5 group) to reset the fault. After

fault reset, inverter is at stand-by status. If not reset when inverter is at fault status, it

will keep operation protection status and cannot run.

3.2.4 Password Setting

When F7.00 is set to be non-zero, the parameter will be the user’s password.

After exit the function code editing status, the password will be effective after

one minute. And then press the PRGM key again to try to access the function

code editing mode, the inverter panel will display “0.0.0.0”. The password

must be input correctly to access it. If it is necessary to cancel the password

function, set F7.00 to zero.

Notice: When the inverter is powered on, system will execute initialization first and

inverter panel displays “A13” with four lights on. After initialization, inverter

accesses into stand-by status.

8000m Series

- 30 -

Chapter 4 Function Parameter Table

4.1 Symbol Conventions:

“○”: The parameters can be modified both at stop and running status.

“◎”: The parameters cannot be modified at running status.

“●”: The parameters are actual-detecting record value or factory preserved settings

and cannot be modified.

4.2 Function Parameter Table

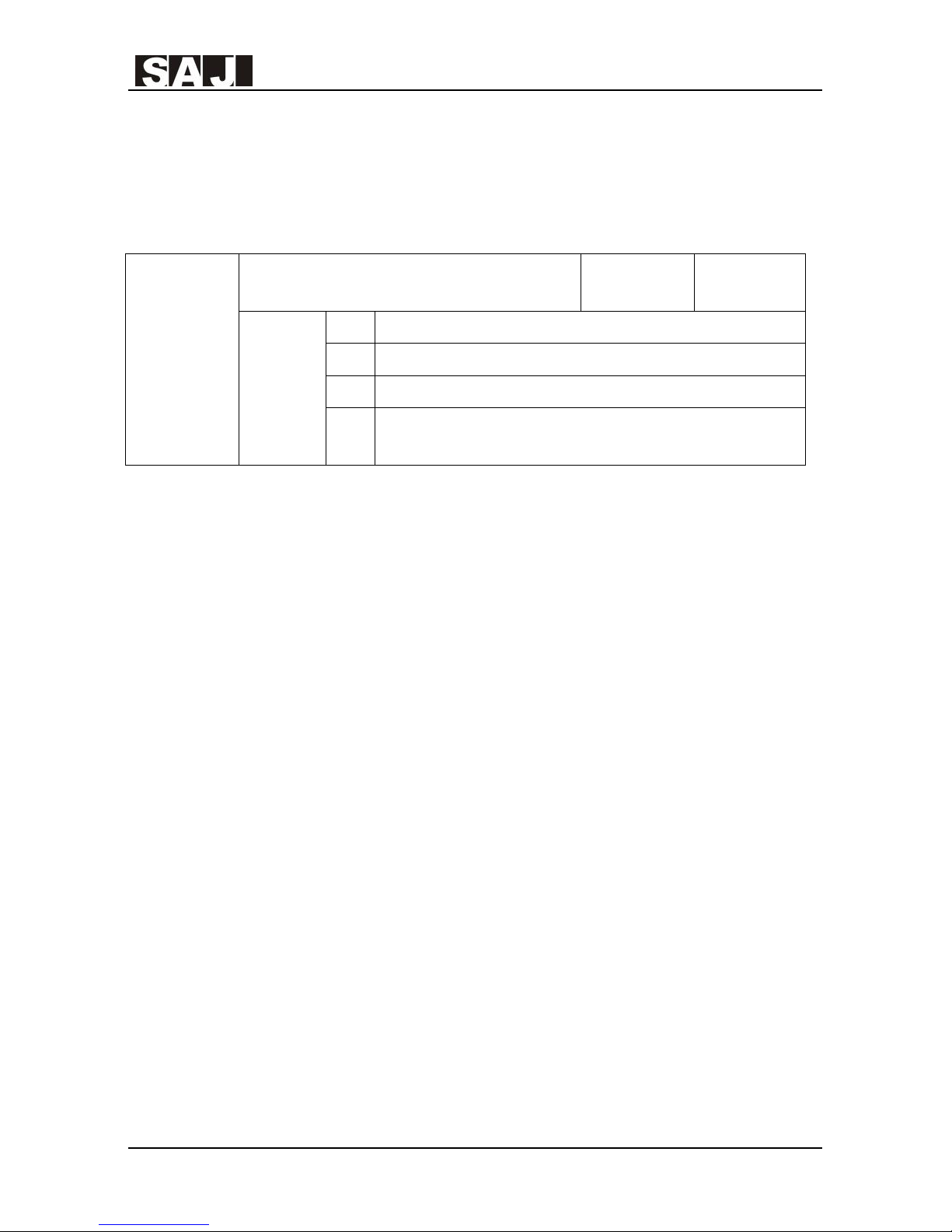

Function

Code

Function Descriptions

Minimum

Unit

Factory

Setting

Modification Type

F0 Group: Basic Parameters

F0.00

Control mode

selection

0: Reserved

1:V/F control

1 ●

F0.01

Control command

source

0:Keypad

1:Terminals

2: Communications (RS485)

0 ●

F0.02

Options for keypad

/ terminals

frequency

ascending and

descending control

0: Valid and saved when

power-off

1: Valid and not saved when

power-off

2: Invalid

3: Valid at running status.

Changed into the setting value

of F0.08 when restart after stop.

0 ○

F0.03

Settings of master

frequency source X

0: Up/down key

1: Potentiometer of panel

2: AVI terminal

1 ●

8000m Series

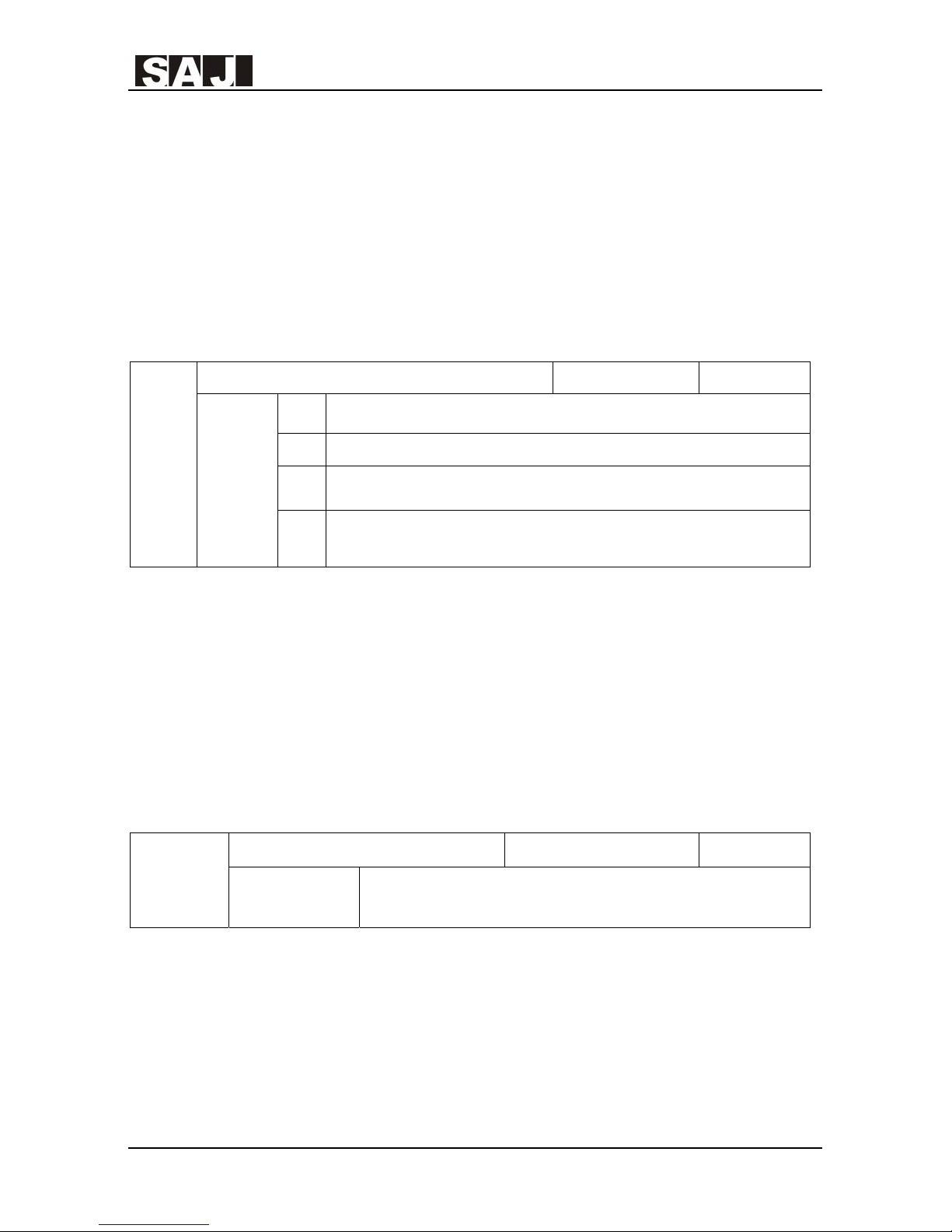

- 31 -

Function

Code

Function Descriptions

Minimum

Unit

Factory

Setting

Modification Type

F0.03

Settings of master

frequency source X

3: Reserved

4: Reserved

5: Reserved

6: Multi-function digital input

terminals

7: PLC

8: PID

9: Communication interface

1 ●

F0.04

Settings of

auxiliary

frequency source Y

0: AVI terminal

1: Reserved

2: Reserved

1 ●

F0.05

Setting range of

auxiliary

frequency source Y

when it is

superposed

0 : Relative to the maxi.

Frequency

1: Relative to master frequency

setting source X

0 ●

F0.06 Reserved

F0.07

Frequency

reference selection

0:X

1: Y

2: X and Y

3: Max. value of (X, Y)

0 ○

F0.08

Keypad setting

frequency

0.00Hz~ F0.10 0.01Hz 50.00 Hz ○

F0.09

Running direction

selection

0: Forward

1: Reverse

2: Reverse running prohibited

0 ●

F0.10

Max. output

frequency

10.00~600.00Hz 0.01Hz 50.00Hz ●

F0.11

Upper limit

frequency source

selection

0: Keypad (F0.12)

1: AVI terminal

2: Reserved

3: Multi-function digital input

terminals

4: Communication interface

0 ○

8000m Series

- 32 -

Function

Code

Function Descriptions

Minimum

Unit

Factory

Setting

Modification Type

F0.12

Upper limit

frequency

F0.14~ F0.10 0.01Hz 50.00Hz ○

F0.13 Reserved

F0.14

Lower limit

frequency

0.00Hz~ F0.12 0.01Hz 0.00Hz ○

F0.15

The function of

lower limit

frequency

0 : Running at lower limit

frequency

1: Stop frequency point

2: Sleep frequency point

0 ○

F0.16

Carrier frequency

setting

1.0~15.0kHz 1kHz

Different

according

to the

inverter

type

○

F0.17

PWM mode

selection

0:PWM mode 1

1:PWM mode 2

2:PWM mode 3

0 ●

F0.18

Acceleration time

1

0.1~3600.0s 0.1s

Different

according

to the

inverter

type

○

F0.19

Deceleration time

1

0.1~3600.0s 0.1s

Different

according

to the

inverter

types

○

F0.20

Default setting

restoring

0: No operation

1: Restore to factory setting

2: Fault record clearing

0 ●

F0.21

Parameter lock and

unlock

0: Unlock parameter

1: Lock parameter

0 ○

8000m Series

- 33 -

Function

Code

Function Descriptions

Minimum

Unit

Factory

Setting

Modification Type

F0.22~

F0.24

Reserved

F0.25

Cooling fan

running method

0: Keep running when power on

1: Reserved

1 ○

F1 Group: Start and Stop Parameters

F1.00 Start mode

0:Start directly

1:DC braking first and then start

2:Speed tracing and start

0 ●

F1.01 Start frequency 0.00~10.00Hz 0.01Hz 1.50Hz ○

F1.02

Hold time of start

frequency

0.0~50.0s 0.1s 0.0s ○

F1.03

DC braking current

before start

0.0~150.0% 0.10% 0.00% ○

F1.04

DC braking time

before start

0.0~50.0s 0.1s 0.0s ○

F1.05 Stop mode

0: Deceleration to stop

1: Coast to stop

0 ○

F1.06

Trigging frequency

of DC braking at

stop

0.00~ F0.10 0.01Hz 0.00Hz ○

F1.07

Waiting time

before DC braking

at stop

0.0~50.0s 0.1s 0.0s ○

F1.08

DC braking current

at stop

0.0~150.0% 0.10% 0.00% ○

F1.09

DC braking time at

stop

0.0~50.0s 0.1s 0.0s ○

F1.10

Dead time between

FWD and REV

0.0~3600.0s 0.1s 0.0s ○

F1.11 Terminals control 0: Disabled 1 ○

8000m Series

- 34 -

Function

Code

Function Descriptions

Minimum

Unit

Factory

Setting

Modification Type

option when power

on

1: Enabled

F1.12 ~

F1.17

Reserved

F1.18

Wake-up time

delay

0.0~3600s 0.1s 0.0s ○

F1.19

Restart option after

power-off

0: Disabled

1:Enabled

0 ○

F1.20

Waiting time of

restart after

power-off

0.0~3600s 0.1s 0.0s ○

F1.21

Over modulation

option

0: Disabled

1:Enabled

0 ○

F2 Group: Motor Parameters

F2.00 Drive model

0:General model (G)

1:Pump model (P)

0 ●

F2.01 Motor rated power 0.4~7.5kW 0.1kW

Different

according

to

inverter

model

●

F2.02

Motor rated

frequency

10.00Hz~ F0.10 0.01Hz 50.00Hz ●

F2.03

Motor rated

rotation speed

0~36000rpm 1rpm

Different

according

to

inverter

model

●

F2.04

Motor rated

voltage

0~480V 1V ●

F2.05 Motor rated current 0.8~2000A 0.1A ●

8000m Series

- 35 -

Function

Code

Function Descriptions

Minimum

Unit

Factory

Setting

Modification Type

F2.06

Motor stator

resistance

0.001~65.53Ω 0.001Ω ○

F2.07

Motor rotator

resistance

0.001~65.53Ω 0.001Ω ○

F2.08

Motor stator

inductance

0.1~6553mH 0.1mH ○

F2.09

Motor rotator

mutual inductance

0.1~6553mH 0.1mH ○

F2.10

Motor no-load

current

0.1~655.3A A ○

F2.11 Reserved

F2.12 Reserved

F3 Group: Vector Control Parameters

F3.00

Proportional gain 1

of speed loop

0~100 20 ○

F3.01

Integral time 1 of

speed loop

0.01~10.00s 0.01s 0.50s ○

F3.02

Low frequency

point of switch

0.00Hz~F3.05 0.01Hz 5.00Hz ○

F3.03

Proportional gain 2

of speed loop

0~100 1 25 ○

F3.04

Integral time 2 of

speed loop

0.01~10.00s 0.01s 1.00s ○

F3.05

High frequency

point of switch

F3.02~F0.10 1Hz 10.00Hz ○

F3.06

Coefficient of slip

compensation at

VC control mode

50~200% 1% 100% ○

F3.07 Upper limit torque

0.0 ~200.0% (Drive rated

current)

0.10% 150.00% ○

8000m Series

- 36 -

Function

Code

Function Descriptions

Minimum

Unit

Factory

Setting

Modification Type

F3.08~F

3.09

Reserved

F3.10

Pre-alarm option

when overload

0: Not detect

1: Effective during running and

keep running after alarm

2: Effective during running

and stop after alarm (fault

code:E023)

3: Effective during constant

running and keep running after

alarm

4: Effective during constant

running and stop after alarm

1 ○

F3.11

Detecting level of

pre-alarm when

overload

1.0~200.0% (referred to inverter

rated current)

0.10% 150.00% ○

F3.12

Detecting time of

pre-alarm when

overload

0~600s 1s 1s ○

F4 Group: V/F Control Parameters

F4.00 V/F curve selection

0: Linear curve

1: User-defined curve

2: 1.3 square torque-step-down

curve

3: 1.7 square torque-step-down

curve

4: 2 square torque-step-down

curve

0 ●

F4.01 Torque boost 0.0 %(auto) 0.1%~30.0% 0.10% 1.00% ○

F4.02

Torque boost

cut-off frequency

0.0~50.0% (relative to motor

rated frequency)

0.10% 20.00% ●

F4.03 V/F frequency 1 0.00Hz~F4.05 0.01Hz 0.00Hz ●

8000m Series

- 37 -

Function

Code

Function Descriptions

Minimum

Unit

Factory

Setting

Modification Type

F4.04 V/F voltage 1 0.0%~100.0% 0.10% 0.00% ●

F4.05 V/F frequency 2 F4.03~F4.07 0.01Hz 25.00Hz ●

F4.06 V/F voltage 2 0.0%~100.0% 0.10% 50.00% ●

F4.07 V/F frequency 3 F4.05~motor rated frequency 0.01Hz 50.00Hz ●

F4.08 V/F voltage 3 0.0%~100.0% 0.10% 100.00% ●

F4.09

Coefficient of V/F

Slip compensation

0.0%~200.0% 0.10% 0.00% ○

F4.10

Energy-saving

selection

0:Disabled

1:Enabled automatically

0 ○

F4.11 Reserved

F4.12

Low-frequency

threshold of

restraining

oscillation

0~10 2 ○

F4.13

High-frequency

threshold of

restraining

oscillation

0~10 0 ○

F4.14 Reserved

F4.15

Boundary

frequency of

restraining

oscillation

0.00Hz~F0.10 (Maxi.

frequency)

0.01Hz 30.00Hz ○

F4.16 Reserved

F4.17

AVR function

selection

0:Invalid

1:Valid all the time

2: Only invalid during

deceleration

1 ○

8000m Series

- 38 -

Function

Code

Function Descriptions

Minimum

Unit

Factory

Setting

Modification Type

F5 Group: Input Terminals Parameters

F5.00

M1 terminal

function

0:Invalid 1:Forward run (FWD)

2:Reverse run (REV)

3:3-wire control

4:Forward jog run (FJOG)

5:Reverse jog run (RJOG)

6: Coast to stop

7: Fault reset (RESET)

8: Pause running

9: External fault input N. O.

10: UP Key command

11: DOWN Key command

12: Clear UP/DOWN setting

13: Frequency setting source

switch between X and Y

14: Frequency setting source

switch between X and (X+Y)

15: Frequency setting source

switch between Y and (X+Y)

16: Multi-step speed terminal 1

17: Multi-step speed terminal 2

18: Multi-step speed terminal 3

19: Multi-step speed terminal 4

20: Multi-step speed pause

21: Acceleration/deceleration

time selection terminal 1

22: Acceleration/deceleration

time selection terminal 2

23: Restart simple PLC af ter

pause

1 ●

F5.01

M2 terminal

function

2 ●

F5.02

M3 terminal

function

7 ●

F5.03

M4 terminal

function

0 ●

8000m Series

- 39 -

Function

Code

Function Descriptions

Minimum

Unit

Factory

Setting

Modification Type

F5.04 Reserved

24: Simple PLC pause

25: PID pause

26: Swing frequency pause

(maintain at current frequency)

27: Reset after swing frequency

pause (reset to central

frequency)

28: Counter reset

29:Reserved

30:Acceleration/deceleration

prohibited

31:Counter triggering

32:Clear UP/DOWN setting

temporarily

33: Reserved

34: Length counting input

35: Length counting clear up

36: Command source switch

37: Terminal input delay output

38: Reserved

F5.05 Reserved 0 ●

F5.06 ~

F5.08

Reserved

F5.09

VDI Virtual Input

terminal

function(Note:

VDI input is VDO

output, without

limit by On/off

filter times F5.10)

0 ●

F5.10 On/off filter times 1~10 5 ○

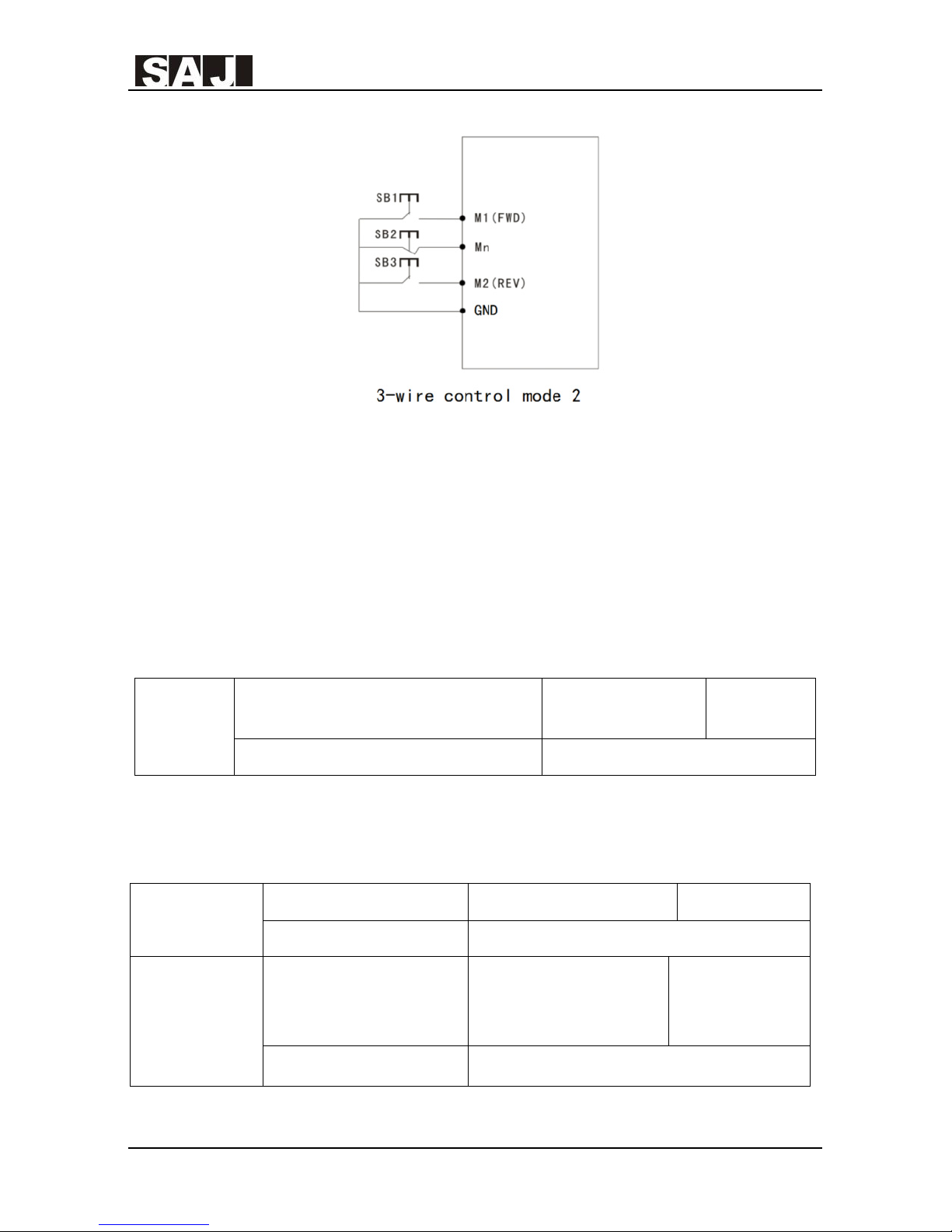

F5.11

Terminal control

mode

0:2-wire control mode 1

2:2-wire control mode 2

3:3-wire control mode 1

4:3-wire control mode 2

0 ●

F5.12

Frequency

changing rate

through UP/

DOWN terminal

adjusting

0.01~50.00Hz/s 0.01Hz/s 0.50Hz/s ○

F5.13 AVI lower limit 0.00V~10.00V 0.01V 0.00V ○

8000m Series

- 40 -

Function

Code

Function Descriptions

Minimum

Unit

Factory

Setting

Modification Type

F5.14

Setting value

corresponding to

AVI lower limit

-100.0%~100.0% 0.10% 0.00% ○

F5.15 AVI upper limit 0.00V~10.00V 0.01V 10.00V ○

F5.16

Setting value

corresponding to

AVI upper limit

-100.0%~100.0% 0.10% 100.00% ○

F5.17

AVI input filter

time

0.00s~10.00s 0.01s 0.10s ○

F5.18~F

5.22

Reserved

F5.23 M1 On delay 0.0s ~ 6000.0s 0.1s 0.0s ○

F5.24 M1 Off delay 0.0s ~ 6000.0s 0.1s 0.0s ○

F5.25 M2 On delay 0.0s ~ 6000.0s 0.1s 0.0s ○

F5.26 M2 Off delay 0.0s ~ 6000.0s 0.1s 0.0s ○

F5.27 ~

F5.32

Reserved

F6 Group: Output Terminals Parameters

F6.00

MO1 output

selection

0: No output

1: Motor forward running

2: Motor reverse running

3: Fault output

4: Frequency detecting level

FDT output

5: Frequency reached

6: Running at zero speed

7: Upper limit frequency

reached

1 ○

F6.01 Reserved

8000m Series

- 41 -

Function

Code

Function Descriptions

Minimum

Unit

Factory

Setting

Modification Type

F6.02

Relay 1 output

selection

8: Lower limit frequency

reached

9:Frequency setting value less

than lower limit frequency

10:FDT reached

11:Accumulative running time

reached

12:PLC cycle completed

13: VFD overload pre-alarm

14: User customized output

15:Running frequency detection

16: Terminal input delay output

17: VFD stand-by

3 ○

F6.03~F

6.04

Reserved

F6.05

FM output lower

limit

0.0~100.0% 0.10% 0.00% ○

F6.06

FM lower limit

corresponding to

output

0.00V~10.00V 0.01V 0.00V ○

F6.07

FM output upper

limit

0.0~100.0% 0.10% 100.00% ○

F6.08

FM upper limit

corresponding to

output

0.00V~10.00V 0.01V 10.00V ○

F6.09

FM output

selection

0:Running frequency

1:Setting frequency

2:Running rotation speed

3:Output current

4:Output voltage

5:Reserved

6:Reserved

7:Reserved

8: Analog AVI input value

9: Reserved

10: Reserved

0 ○

8000m Series

- 42 -

Function

Code

Function Descriptions

Minimum

Unit

Factory

Setting

Modification Type

F6.10~F

6.13

Reserved

F6.14

User defined

output

variability option

(EX)

0:Running frequency

1:Setting frequency

2:DC bus voltage

3:Output current

4:Output voltage

5:Sign of start and stop status

6:Sign of control status

7:Counter value

8:Counting meter value

9:Inverter module temperature

10:AVI input value

11:Reserved

F6.15

Comparison

method of user

defined output

Units digit: comparison test

method

0: Equal (EX==X1)

1: Equal or greater than

2: Equal or less than

3: Interval comparison

(X1≤EX≤X2)

4:Units digit test (EX&X1=X2)

Tens digit : output method

0: False value output

1: Real value output

0 ○

F6.16

User defined

output dead zone

0~65535 0 ○

F6.17

Output comparison

value X1

0~65535 0 ○

F6.18

Output comparison

value X2

0~65535 0 ○

F7 Group: Display Interface Parameters

F7.00 User password 0~9999 0 ○

8000m Series

- 43 -

Function

Code

Function Descriptions

Minimum

Unit

Factory

Setting

Modification Type

F7.01~F

7.03

Reserved

F7.04

RUN/STOP key

stop function

0:Only valid for keypad setting

1:Valid for both keypad setting

and terminals setting

2:Valid for both keypad setting

and communication interface

setting

3:Valid for all control mode

0 ○

F7.05 Reserved

F7.06

Running status

display selection 1

0~0xFFFF

BIT0:Running frequency

BIT1:Setting frequency

BIT2:DC bus voltage

BIT3:Output voltage

BIT4:Output current

BIT5:Running speed

BIT6:Linear speed

BIT7:Reserved

BIT8:Reserved

BIT9:PID setting value

BIT10:PID feedback value

BIT11:Input terminals status

BIT12:Output terminals status

BIT13:Reserved

BIT14:Counter value

BIT15:Current step of

multi-step

speed and PLC

35 ○

8000m Series

- 44 -

Function

Code

Function Descriptions

Minimum

Unit

Factory

Setting

Modification Type

F7.07

Running

status display

selection 2

1~0xFFFF

BIT0:AVI value

BIT1: Reserved

BIT2:Reserved

BIT3: Motor overload ratio

BIT4: Inverter overload ratio

BIT5:Running time

BIT6:Counting meter value

BIT7~BIT15: Reserved

0 ○

F7.08

Stop status display

selection

0~0xFFFF

BIT0: Setting frequency

BIT1: DC bus voltage

BIT2:Input terminal status

BIT3:Output terminal status

BIT4:PID setting value

BIT5:PID feedback value

BIT6:AVI value

BIT7:Reserved

BIT8:Reserved

BIT9: Current step of multi-step

speed and PLC

BIT10:Reserved

BIT11:Counting meter value

BIT12~BIT15:Reserved

3 ○

F7.09

Inverter module

temperature

0~100℃ 1℃

◎

F7.10

Inverter software

version

◎

F7.11

Accumulative

running time

0~9999h 1hour

◎

F7.12

Accumulative

power-on time

0~9999h 1hour

◎

F7.13 Reserved

8000m Series

- 45 -

Function

Code

Function Descriptions

Minimum

Unit

Factory

Setting

Modification Type

F8 Group: Auxiliary Function Parameters

F8.00

Jog running

frequency

0.00~F0.10 0.01Hz 5.00Hz ○

F8.01

Jog running

acceleration time

0.1~3600s 0.1s

Defined

by

inverter

model

○

F8.02

Jog running

deceleration time

0.1~3600s 0.1s ○

F8.03

Acceleration time

2

0.1~3600s 0.1s ○

F8.04

Deceleration time

2

0.1~3600s 0.1s ○

F8.05

Acceleration time

3

0.1~3600s 0.1s ○

F8.06

Deceleration time

3

0.1~3600s 0.1s ○

F8.07

Acceleration time

4

0.1~3600s 0.1s ○

F8.08

Deceleration time

4

0.1~3600s 0.1s ○

F8.09 Jump frequency 1 0.00~F0.10 0.01Hz 0.00Hz ○

F8.10 Jump frequency 2 0.00~F0.10 0.01Hz 0.00Hz ○

F8.11

Jump frequency

width

0.00~F0.10 0.01Hz 0.00Hz ○

F8.12

Frequency

detection

value(FDT)

0.00~F0.10 0.01Hz 50.00Hz ○

F8.13 FDT hysteresis 0.0~100.0% 0.10% 5.00% ○

F8.14

Detecting range of

reached frequency

0.0~100.0% (Maxi. Frequency) 0.10% 0.00% ○

8000m Series

- 46 -

Function

Code

Function Descriptions

Minimum

Unit

Factory

Setting

Modification Type

F8.15

Braking threshold

voltage

115.0~140.0% (Standard DC

bus voltage)

0.10% 120.00% ○

F8.16

Speed display

coefficient

0.1~999.9% 0.10% 100.00% ○

8.17

Option as running

time reached

0:Keep running

1:Stop

0 ○

F8.18

Running time

setting

0~9999h 1h 9999 ○

F8.19 Droop control 0.00Hz~10.00Hz 0.01Hz 0.00Hz ○

F8.20

Panel

p

otentiometer filter

time selection

0.00~10.00s 0.01s 0.10s ○

F8.21

Output delay time

selection

0~9999s 0.1s 0.0s ○

F8.22

Lower limit of

frequency

detecting

0.00~Maxi. Frequency 0.01Hz 20.00Hz ○

F8.23

Upper limit of

frequency

detecting

0.00~Maxi. Frequency 0.01Hz 40.00Hz ○

F8.24 Reserved

F8.25

Inverter rated

power

0.4~700.0kW 0.1kW

Defined

by

inverter

model

◎

F8.26

Inverter rated

current

0.0~2000A 0.1A

◎

F8.27

Linear speed

display coefficient

0.1~ 999.9% (linear speed =

mechanical speed * F8.27)

0.10% 1.00% ○

F8.28 ~

F8.29

Reserved

F9/FE Group PID Control Parameters

8000m Series

- 47 -

Function

Code

Function Descriptions

Minimum

Unit

Factory

Setting

Modification Type

F9.00 PID setting source

0:Keypad (F9.01)

1:Analog terminal AVI

2:Reserved

3:Communication interface

4:Muli-function digital input

terminals

0 ○

F9.01 PID preset value 0.0%~100.0% 0.10% 0.00% ●

F9.02

PID feedback

selection

0:Analog terminal AVI

1:Reserved

2:Reserved

3:Communication interface

0 ○

F9.03

PID output

characteristic

0: Positive

1: Negative

0 ○

F9.04

Proportional gain

(Kp)

0.0~100.0 0.1 0.1 ○

F9.05 Integral time (Ti) 0.01~10.00s 0.01s 0.10s ○

F9.06

Differential time

(Td)

0.00~10.00s 0.01s 0.00s ○

F9.07

Sampling period

(T)

0.01~100.0s 0.01s 0.10s ○

F9.08

PID control

deviation limit

0.0~100.0% 0.10% 0.00% ○

F9.09

Feedback loss

detecting time

0.0~100.0% 0.10% 0.00% ○

F9.10

Feedback lost

detecting time

0.0~3600.0s 0.1s 1.0s ○

F9.11

PID sleep function

option

0: PID normal working

1: PID sleep

0 ○

F9.12

PID sleep detecting

delay time

0.0~3600.0s 0.1s 3.0s ○

8000m Series

- 48 -

Function

Code

Function Descriptions

Minimum

Unit

Factory

Setting

Modification Type

F9.13

PID wake-up

threshold

0.0~100.0% 0.10% 0.00% ○

F9.14

PID wake-up

detecting delay

time

0.0~3600.0s 0.1s 3.0s ○

F9.15

Lower retaining

frequency of PID

sleep detecting

0.00Hz~20.00Hz 0.01Hz 10.00Hz ○

F9.16

PID Lower

retaining

frequency running

time

0.0~3600.0s 0.01s 10.0s ○

F9.17~F

9.18

Reserved

FA Group: Protection and Malfunction Parameters

FA.00

Motor overload

protection

0: Protection Disabled

1: Normal motor with low speed

compensation

2: Variable frequency motor

without low speed

compensation

2 ●

FA.01

Motor over load

protection current

20.0%~120.0% (motor rated

current)

0.10% 100.00% ○

FA.02

Threshold for

frequency reducing

at instantaneous

power failure

70.0%~110.0% (standard bus

voltage)

0.10% 80.00% ○

FA.03

Frequency

reducing rate at

instantaneous

power failure

0.00Hz~F0.10 0.01Hz 0.00Hz ○

FA.04

Over-voltage

stalling protection

0:Disabled

1:Enabled

0 ○

8000m Series

- 49 -

Function

Code

Function Descriptions

Minimum

Unit

Factory

Setting

Modification Type

FA.05

Over-voltage

stalling protection

point

110~150% 1% 120% ○

FA.06

Auto current

limiting level

50~200% 1% 160% ○

FA.07

Frequency

decrease rate

during current

limiting

0.00~50.00Hz/s 0.01Hz/s

10.00Hz/

s

○

FA.08

Auto current

limiting selection

0:Enabled

1: Disabled at constant speed

1 ○

FA.09

Fault auto-reset

times

0~3 0 ○

FA.10

Fault auto-reset

interval

0.1~100.0s 0.1s 1.0s ○

FA.11 Reserved

FA.12

Phase-lack

protection of input

0:Disabled

1:Enabled

1 ○

FA.13

Phase-lack

protection of

output

0: Disabled

1:Enabled

1 ○

FA.14

Fault type last two

time

0: No fault

1: Inverter module fault

(E001)

2. Over-current during

acceleration

(E002)

3: Over-current during

deceleration

(E003)

4: Over-current at constant

◎

FA.15 Fault type last time

◎

8000m Series

- 50 -

Function

Code

Function Descriptions

Minimum

Unit

Factory

Setting

Modification Type

FA.16 Current fault type

speed (E004)

5: Over-voltage during

acceleration

(E005)

6: Over-voltage during

deceleration (E006)

7: Over-voltage at constant

speed (E007)

8: Hardware overvoltage (E008)

9: Under voltage of DC bus

(E009)

10: Drive overload (E010)

11: Motor overload (E011)

12: Phase-lack of input (E012)

13: Phase-lack of output (E013)

14: Module overheat (E014)

15: External fault (E015)

16: Communication fault (E016)

17: Reserved

18: Current detection fault

(E018)

19: Reserved

20: Reserved

21: Reserved

22: EEPROM fault (E022)

23: Overload pre-alarm (E023)

24: PID feedback loss fault

(E024)

25: Running time reached

(E025)

26: Counting meter reached

(FULL)

◎

FA.17

Running frequency

at current fault

Hz

◎

8000m Series

- 51 -

Function

Code

Function Descriptions

Minimum

Unit

Factory

Setting

Modification Type

FA.18

Output current at

current fault

A

◎

FA.19

DC bus voltage at

current fault

V 0.0V

◎

FA.20

Input terminal

status when fault

occurs

0

◎

FA.21

Output terminal

status when fault

occurs

0

◎

FB Group: Swing Frequency and Counting Meter Parameters

FB.00

Swing frequency

range

0.0~100.0% (relative to setting

frequency)

0.10% 0.00% ○

FB.01

Skip frequency

range

0.0~50.0% (relative to swing

frequency bandwidth)

0.10% 0.00% ○

FB.02

Rising time of

swing frequency

0.1~3600.0s 0.1s 5.0s ○

FB.03

Dropping time of

swing frequency

0.1~3600.0s 0.1s 5.0s ○

FB.04

Fixed length

control mode

0:Start from zero when power

on

1:Start from counting meter of

the last time

0.1s 5.0s ○

FB.05

Roller perimeter

for fixed length

control

0~9999cm 1cm 100cm ○

FB.06

Fixed length

setting

0~9999m 1m 1000m ○

8000m Series

- 52 -

Function

Code

Function Descriptions

Minimum

Unit

Factory

Setting

Modification Type

FB.07 Clear length value 0:Invalid 1:Valid 0 ○

FB.08

Counter value

setting

FB.09~9999 0 ○

FB.09

Designated counter

value

0~FB.08 0 ○

FB.10

Length unit

selection

0 :Actual counting length =

displayed length* 1m

1: Actual counting length=

displayed length* 10m

0 ○

FC Group: RS485 Communication Parameters

FC.00 Local address

1~247, 0 refers to the broadcast

address

1 ○

FC.01 Baud rate selection

0:1200BPS

1:2400BPS

2:4800BPS

3:9600BPS

4:19200BPS

5:38400BPS

3 ○

FC.02

Data bit check and

format

0: No check (N, 8, 1) for RTU

1: Even parity check (E, 8, 1) for

RTU

2: Odd parity check (0, 8, 1) for

RTU

3: No check (N, 8, 2) for RTU

4: Even parity check (E, 8, 2) for

RTU

5: Odd parity check (0, 8, 2) for

RTU

0 ○

FC.03

Communication

response delay

time

0~200ms 1ms 5ms ○

8000m Series

- 53 -

Function

Code

Function Descriptions

Minimum

Unit

Factory

Setting

Modification Type

FC.04

Communication

timeout fault

setting

0.0 (invalid), 0.1~100.0s 0.1s 0.0s ○

FC.05

Method of

disposing

communication

timeout fault

0:Alarm and coast to stop

1:No alarm and continue to run

2:No alarm but stop according

to

F1.05 (only when F0.01= 2)

3: No alarm but stop according

to F1.05

1 ○

FC.06

Transmission

response action

Unit’s digit:

0: Response to writing

1: No response to writing

Ten’s place:

0:Value not saved when

poweroff

1: Value saved when power-off

0 ○

FD Group:Multi-step Speed and Simple PLC Parameters

FD.00

Simple PLC

operation method

0:Stop after operation once time

1:Keep the f inal value af ter

operation once time 2:Operation

in cycles

0 ○

FD.01

Memory option of

simple PLC when

power-off

0: Invalid 1:Valid 0 ○

FD.02 Multi-step speed 0 -100~100% 0.10% 0.00% ○

FD.03

0

th

step running

time

0.0~6553s(m) 0.1s(m) 0.0s ○

FD.04 Multi-step speed 1 -100~100% 0.10% 0.00% ○

FD.05

1

st

step running

time

0.0~6553s(m) 0.1s(m) 0.0s ○

8000m Series

- 54 -

Function

Code

Function Descriptions

Minimum

Unit

Factory

Setting

Modification Type

FD.06 Multi-step speed 2 -100~100% 0.10% 0.00% ○

FD.07

2

n

d

step running

time

0.0~6553s(m) 0.1s(m) 0.0s ○

FD.08 Multi-step speed 3 -100~100% 0.10% 0.00% ○

FD.09

3

r

d

step running

time

0.0~6553s(m) 0.1s(m) 0.0s ○

FD.10 Multi-step speed 4 -100~100% 0.10% 0.00% ○

FD.11

4

th

step running

time

0.0~6553s(m) 0.1s(m) 0.0s ○

FD.12 Multi-step speed 5 -100~100% 0.10% 0.00% ○

FD.13

5

th

step running

time

0.0~6553s(m) 0.1s(m) 0.0s ○

FD.14 Multi-step speed 6 -100~100% 0.10% 0.00% ○

FD.15

6

th

step running

time

0.0~6553s(m) 0.1s(m) 0.0s ○

FD.16 Multi-step speed 7 -100~100% 0.10% 0.00% ○

FD.17

7

th

step running

time

0.0~6553s(m) 0.1s(m) 0.0s ○

FD.18 Multi-step speed 8 -100~100% 0.10% 0.00% ○

FD.19

8

th

step running

time

0.0~6553s(m) 0.1s(m) 0.0s ○

FD.20 Multi-step speed 9 -100~100% 0.10% 0.00% ○

FD.21

9

th

step running

time

0.0~6553s(m) 0.1s(m) 0.0s ○

8000m Series

- 55 -

Function

Code

Function Descriptions

Minimum

Unit

Factory

Setting

Modification Type

FD.22

Multi-step speed

10

-100~100% 0.10% 0.00% ○

FD.23

10

th

step running

time

0.0~6553s(m) 0.1s(m) 0.0s ○

FD.24

Multi-step speed

11

-100~100% 0.10% 0.00% ○

FD.25

11

th

step running

time

0.0~6553s(m) 0.1s(m) 0.0s ○

FD.26

Multi-step speed

12

-100~100% 0.10% 0.00% ○

FD.27

12

th

step running

time

0.0~6553s(m) 0.1s(m) 0.0s ○

FD.28

Multi-step speed

13

-100~100% 0.10% 0.00% ○

FD.29

13

th

step running

time

0.0~6553s(m) 0.1s(m) 0.0s ○

FD.30~F

D.33

Reserved

FD.34

Acceleration time

of 0

th~7th

steps

0~0xFFFF 0 ○

FD.35

Acceleration time

of 8

th

~15th steps

0~0xFFFF 0 ○

FD.36 PLC restart method

0: Restart from 1

st

step

1: Restart from break-off

frequency

0 0 ○

FD.37

PLC operation

time unit

0: second (s) 1: minute (m) 0 ○

FE~FF Group: Reserved Factory Parameters

8000m Series

- 56 -

Chapter 5 Function Parameter Description

5.1 F0 Group—Basic Function

Select one operation mode for the drive.

0: Reserved

1: V/F control

V/F control is suitable to applications which do not require high accuracy of torque

and speed control, such as fans and pumps etc. In those applications, a VFD can

drive multiple motors simultaneously.

Select the channel of the control command of the VFD.

The control command of a VFD includes: start, stop, forward, reverse and jogging.

0: keypad

The command of start and stop can be executed through the key of RUN/STOP on

the keypad.

1: terminals

The VFD is controlled by multi-function digital input terminals M1~M4.

2: communications

F0.00

Control Mode Selection Factory Setting 1

Setting

Options

0 Reserved

1 V/F control

F0.01

Control command source Factory Setting 0

Setting

Options

0 Keypad

1 Terminals

2 Communication (RS485)

8000m Series

- 57 -

The upper controller gives the command of start and stop through the method of

communication.

The frequency of the VFD can be set through “▲”and “▼” and UP/DOWN

terminal(frequency ascending control/frequency descending control), it has the

highest priority and can be combined with any other channels used for frequency

setting. Its main function is to finish the fine adjustment of output frequency of the

VFD in commissioning process of control system.

0: valid, and the VFD can save data when powered off. The frequency data of VFD

can be set, and after powered off, the VFD can save the set value. When powered

on next time, the previous saved value can be combined with the present setting

value automatically.

1: valid, but the VFD cannot save data when powered off. The frequency data of

VFD can be set, however after power-off, the VFD will not save this setting value.

2:invalid, the “▲”and “▼” on keypad and the function of UP/DOWN terminal is

invalid, and the settings will be cleared automatically.

3:When the VFD is in running condition, the control of “▲”and “▼” on keypad

and the function of UP/DOWN terminal is valid. When stopped, the settings of

“▲”and “▼” on keypad and the UP/DOWN terminal will be zeroed out.

Note: when users restore the default value of the functional parameters of the VFD,

the setting frequency value of the keypad and UP/DOWN terminal will be zeroed

out.

F0.02

Options for keypad / terminals frequency

ascending and descending control

Factory

Setting

0

Setting

Options

0 Valid and saved when power-off

1 Valid and not saved when power-off

2 Invalid

3

Control is valid while running, and is invalid while stop.

When stopped or power off, the VFD will not save data

8000m Series

- 58 -

Select the input channel of master frequency of the VFD. Altogether 8 master

frequency channels are available:

0: digital setting of the panel

The initial value is the value of F0.08 “keypad setting frequency”.

The settings of frequency value of the VFD can be adjusted through ▲and ▼ key

and the multi-function digital input terminal UP/DOWN terminal.

1: settings by a potentiometer of the panel

2: AVI

Option of AVI is that the frequency is determined by one of the analog input

terminals. A standard VFD unit has 2 analog input terminals, among them AVI is

input by voltage 0~10V;by using jump line selection, ACI can be chose in the way

of 0~10V voltage and 0/4~20mA current.

3: Reserved

4: Reserved

5: Reserved

6: Multi-step speed terminals

F0.03

Settings of master frequency source X Factory Setting 1

Setting Options

0 Digital setting Up/down key

1 Potentiometer of panel

2 AVI terminal

3 Reserved

4 Reserved

5 Reserved

6 Multi-step speed terminals

7 Simple PLC

8 PID

9 Communication interface

8000m Series

- 59 -

Select the running method of multi-function digital input. The parameters of F5

group “input terminals” and FD group “Multi-step Speed and Simple PLC

Parameters” need to be set in order to determine the corresponding relation between

the command signal and the command frequency.

7: Simple PLC

Select the mode of simple PLC. When the source of frequency is Simple PLC, the

parameters of FD group “Multi-step Speed and Simple PLC Parameters” need to be

set in order to determine the command frequency.

PID:Select PID control. And the F9 group “PID function” parameters need to be set.

The running frequency of the VFD is the output of PID’s function. As for the

implication of PID setting source, preset value and feedback source etc please see

the introduction of F9 group “PID function”.

Communication interface

This means the master source of frequency is given by the upper controller through

communication methods.

F0.04

Settings of auxiliary frequency source Y Factory Setting 0

Setting Options

0 AVI

1 Reserved

2 Reserved

When the auxiliary frequency source is used as an independent frequency command

channel(that is the selection of frequency changes from X to Y), its direction for

usage is the same as master frequency source X.

F0.05

Setting range of auxiliary frequency source Y

when it is superposed

Factory Setting 0

Setting Options

0 Relative to the max. frequency

1 Relative to the master frequency source X

F0.06 Reserved

When the frequency source is selected as superposed frequency source(set F0.07 as

8000m Series

- 60 -

1 or 3), the two parameters are used to determine the adjustable range of the

auxiliary frequency source. F0.05 can determine the corresponding range reference

for the auxiliary frequency source, if the corresponding object is the maximum

frequency(F0.10), the range of the auxiliary frequency source will be fixed; if the

corresponding object is the master frequency source X, the range of the auxiliary

frequency source will change along with the change of master frequency source X.

F0.07

Frequency reference selection Factory Setting 0

Setting

Options

0 Mater frequency source X

1 Auxiliary frequency source Y

2 Mater frequency source X plus auxiliary frequency source Y

3

Max. value of (mater frequency source X, auxiliary frequency

source Y)

0: Present frequency reference is master frequency source X

1: Present frequency reference is auxiliary frequency source Y

2: Present frequency reference is master frequency source X plus auxiliary

frequency source Y

3: Select the bigger one of the value of master frequency source X and auxiliary

frequency source Y as the frequency reference

F0.08

Keypad setting frequency Factory Setting 50.00 Hz

Setting Options

0.00Hz~ F0.10 (the setting value is valid when the master or

auxiliary frequency source is digital setting)

When the master frequency source is selected as “digital setting UP/DN key”, the

value of this functional code is the original value of the frequency settings of the

VFD.

8000m Series

- 61 -

F0.09

Running direction selection Factory Setting 0

Setting Options

0 Forward

1 Reverse

2 Reverse running prohibited

The turning direction of the motor can be changed through setting options of this

functional code. It is equivalent to adjusting any two lines (U, V, W) of the motor for

changing the turning direction.

Note: The turning direction of electric motor will return to its original state after

initialization of parameters. Please use this very cautiously under the occasion that

the system has finished debugging procedures and any change of the turning

direction of electric motor is prohibited.

F0.10

Max. output frequency Factory Setting 50.00Hz

Setting Options

10.00~600.00Hz

F0.11

Upper limit frequency source selection Factory Setting 0

Options

0 Keypad setting (F0.12)

1

AVI terminal (100% corresponds to the setting

frequency of F0.12)

2 Reserved

3

Multi-step speed terminals (Multi-step speed frequency

setting is the upper limit frequency)

4 Communications interface

Define the source of the upper limit frequency. The upper limit frequency can come

from keypad settings (F0.12), or from analog inputs. When using an analog input to

set the upper limit frequency, the value of 100% of the analog input is corresponding

to F0.12.

8000m Series

- 62 -

F0.12

Upper limit frequency Factory Setting 50.00Hz

Setting Options

F0.14~ F0.10

F0.13 Reserved

F0.14

Lower limit frequency Factory Setting 0.00Hz

Setting Options

0.00Hz~ Upper limit frequency F0.12

When the VFD starts running, it will starts from the start frequency. In the

running process, if the command frequency is lower than the lower limit frequency,

the VFD will run at the lower limit frequency, stop or run at zero speed, and the

running mode at this situation can be set by F0.15.

F0.15

The function of lower limit frequency Factory Setting 0

Setting

Options

0 Running at lower limit frequency

1 Stop

2 Sleep

Selecting the running mode of the VFD when the set frequency is lower than the

lower limit frequency. In order to avoid the long term low speed operation of the

electric motor, this functional parameter can be used to select the stop mode.

F0.16

Carrier frequency setting Factory Setting According to model

Setting Options

1.0~15.0kHz

This function can adjust the carrier frequency of the VFD. By adjusting carrier

frequency, the motor noises can be improved, the resonance point of mechanical

system can be avoided and the influences of earth leakage and interference from

VFD can be reduced.

When the value of carrier frequency is set higher, the motor loss will drop, the

temperature rise of motor will decrease, but the loss of VFD will rise, the

temperature rise of the VFD will increase and the interference to VFD will also

increase.

8000m Series

- 63 -

Following is Influences to the corresponding performances while adjusting the

carrier frequency:

Carrier frequency Low → High

Motor noises Loud → Low

Output current waveform Bad → Good

Temperature rise of motor High → Low

Temperature rise of VFD Low → High

Leakage current Small → Large

Exterior radiation interference Small → Large

0:PWM mode 1, this mode is a normal PWM mode, when the frequency is low, the

motor noise is low, on the contrary the noise is loud.

1: PWM mode 2, the motor noise is low when the motor runs in this mode, but the

motor temperature rise is high. The rated power of the VFD should be degraded if

this function is chosen.

2: PWM mode 3,the motor noise is loud when the motor runs in this mode, but this

mode has a very good inhibiting effect for electric-mechanic oscillation.

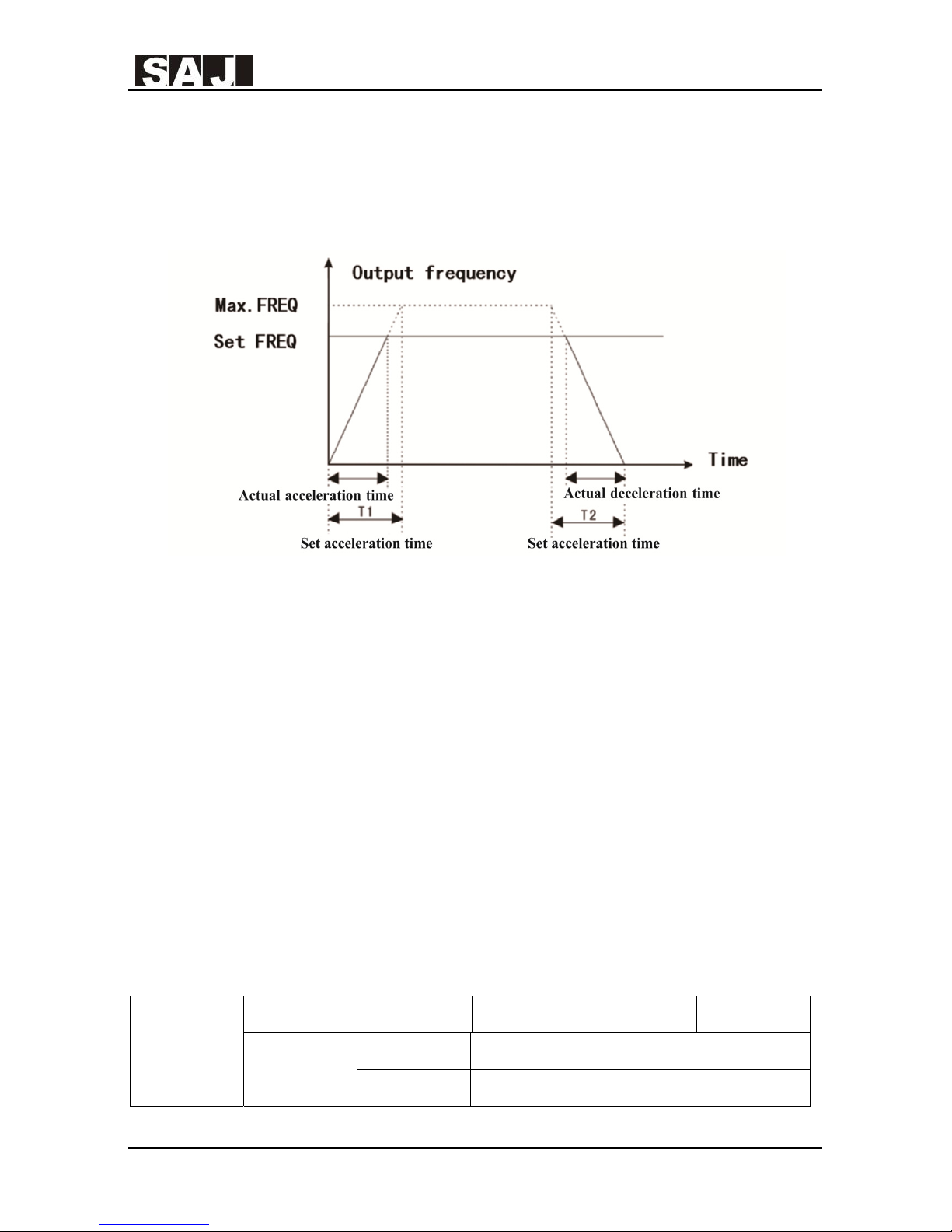

F0.18

Acceleration time 1 Factory Setting According to model

Setting scope

0.1~3600.0s

F0.19

Deceleration time 1 Factory Setting According to model

Setting scope

0.1~3600.0s

Acceleration time 1 means the needed time T1 that the VFD accelerate from 0Hz to

the Max. output frequency(F0.10).

F0.17

PWM mode selection Factory Setting 0

Setting

Options

0 PWM mode 1

1 PWM mode 2

2 PWM mode 3

8000m Series

- 64 -

Deceleration time 1 means the needed time T2 that the VFD decelerate from the

Max. output frequency(F0.10)to 0Hz.

See the diagram below:

Figure xx Sketch Map of Acceleration and Deceleration Time

Note: The difference between the actual acceleration/deceleration time and the set

acceleration/ deceleration time.

Totally 4 groups of acceleration and deceleration time are optional.

Group 1: F0.18, F0.19;

Group 2: F8.03, F8.04

Group 3: F8.05, F8.06

Group 4: F8.07, F8.08.

The acceleration and deceleration time can be selected through the multi-function

digital input terminals (F5.00~F5.03).

F0.20

Default Setting Restoring Factory Setting 0

Setting