Page 1

e

s

r

Instructions for SAITO FA-120R3 (AAC) 4-Stroke Engine

We would like to express our sincere thanks for your purchase of the SAITO FA-120R3

engine. Please read our instructions carefully and treat your engine with care. If there’re

any manufacturing defects, SAITO Seisakusho co., ltd. will make necessary repairs free

of charge. You are requested to strictly avoid disassembling the engine since assembled

with the use of special tools and jigs to assure perfect construction.

In the case of breakage or trouble, if encountered due to crash or others, please send the

engine to our service station.

Please notice that our guarantee will not cover any breakage or trouble on the engine

caused by your disassembling or modification.

Please refer to the following data.

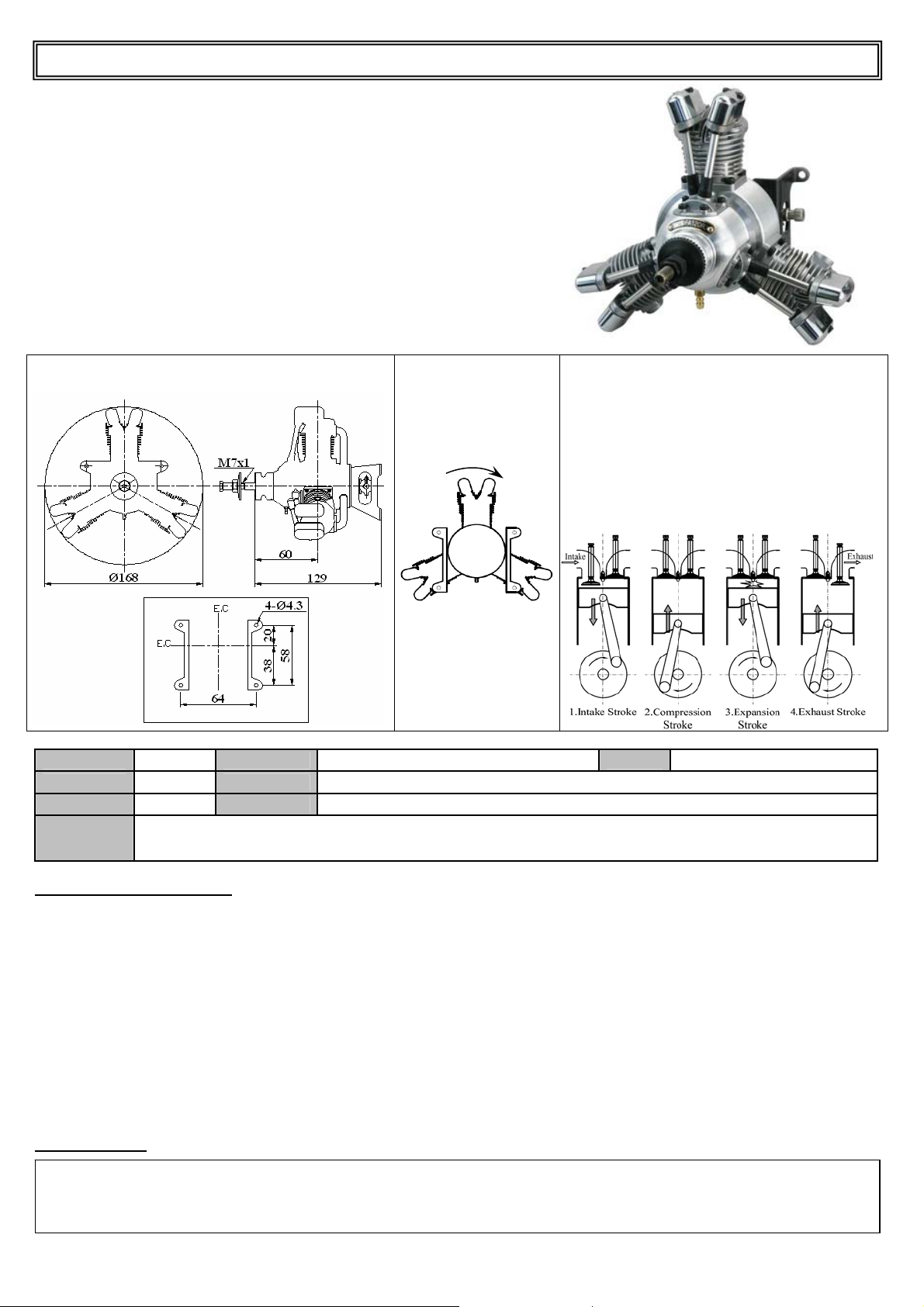

Principal outside dimensions

Explosion order

(1-3-2)

Prop rotational direction

1

Mechanism of 4-Stroke Engin

The 4-Stroke engine provides 4 individual piston

movements as illustrated below. The “Stroke” means the

piston movement from the Top Dead Center to the Bottom

Dead Center. In the 4-Stroke engine, one cycle of operation

in change of gas state inside the cylinder and valve

movement are completed at every 4 strokes of piston that is

every 2 revolutions of the crankshaft. Formally the engine is

called the 4-stroke one-cycle engine.

23

Cylinder numbers viewed

from the rea

Bore 22.4mm×3 Weight Approx. 890g (with mufflers) Propeller Standard APC13"×8"-14"×6"

Stroke 16.2mm×3 Practical Speed 1,800-10,000rpm max range on the ground: 8,500-9,500rpm

Stroke volume 19.18cc Static thrust Approx. 3.5kgf (by APC14"×6"prop)

Fuel flow

Unique features of SAITO F A-120R3

• Optimum for small-size scaled airplane

• Low vibration (assured by constant-interval explosion)

• Real sound of the exhaust.

• The engine is designed to equalize fuel mixture and minimize misfire due to insufficient distributing at idling by means of special port type intake manifold

originally developed by SAITO.

• Cylinder head: Improved semi-spherical combustion chamber assures better combustion efficiency and volumetric ef ficiency .

• Cylinder: The aluminum cylinder is directly hard-chrome plated on its in ner surface without installing liners to reduce weight and increase durabilit y . The monolithic

structure of cylinder head and cylinder prevents distortion and improves cooling efficiency.

• Piston: The piston is made of high silicon content aluminum and a ttached with a compression ring to heighten engine performance.・

• Crankshaft: Has a forged solid construction made of chrome molybdenum steel, and supported by two ball bearings.

• Cam: Features high cam providing longer maximum lift time.

• Carburetor: High-performance of slow throttling type.

• Propeller nut: designed to have double nuts preventing loosening and fall-off for the safety .

Standard Accessories

1. Wrench for tappet adjusting screw 1 pc. 5. Glow plug [SAI-GP01, P-SS] 3 pcs.

2. Limit gauge (0.1t) for tappet adjusting 1 pc. (Attached to the engine)

3. Hexagonal wrench (1.5mm) 1 pc. 6. Plug heating connector set 1 set

4. Muffler complete 1 set (3pcs. of red cord, 1pc. of black, 2pcs. of fixture)

24cc/min (At full throttle, Fuel of synthetic oil with 15% of nitro content,APC13"×6"prop at approx 9,400rpm)

*Fuel flow varies depends upon prop load. More fuel flow with larger load and less fuel flow with smaller load.

-1-

Page 2

Page 3

(B) Manual starting method (For safety, wear gloves and use a safety stick)

1. - 2. Same procedure as (A) describes.

3. Prime the engine. Open the throttle valve fully by using the throttle stick. Insert a proper

length of silicone tube into the priming nipple. Use an injector to fill a proper amount

(1-2cc) of fuel into the carburetor.

4. Manually crank the engine 2 to3 turns to supply fuel in cylinders. Then use the throttle stick

to fully close the throttle valve.

5. Open the throttle valve about 1/4 to1/3 from the full close position by using the throttle stick.

(Starting with excessively opened throttle is dangerous since the airplane jumps forward.)

6. Set the prop at the point of 30-45deg from the horizontal position, with the engine turned in

forward direction (CCW) to the position to be compressed.

Then heat the plugs.

7. Swiftly crank the engine in forward direction (CCW) to start the engine..

G. Break-in

As Break-in is an important procedure to pull out the maximum performance of the engine, it must be cautiously implemented.

1. After filling up the fuel tank, start the engine as described in the above section F. After starting the engine use the throttle stick to open the throttle valve to about half

Caution: The purpose of break-in is initial adjusting of the master rod, link rod, bearings, gears and other mobile parts under the condition with rich fuel mixture.

Never make the fuel mixture lean. Lean fuel mixture could cause seizure even if the engine drops to idling and runs at low speed.

2. Next adjust the main needle and throttle valve opening to run the engine in rich fuel condition at 7,000 – 8,000 rpm for full tank fuel consumption. (In this stage also

3. Next fully open the throttle valve and adjust the main needle to run the engine at approximately 9,000 rpm for full tank fuel consumption.

4. Finally adjust the main needle to run the engine at peak speed and less speed (richer) alternately. When the engine comes to run at a peak speed stably, ground break-in

Note: Rotary units and slide ways of the engine have been lubricated at assembly with black molybdenum oil to prevent wearing or seizure. Hence black exhaust oil

comes out of the breather nipple and muffler at break-in operation. This could not be a trouble and you can continue the operation.

H. Handling and Adjustment of Carbur etor

Note: Strictly avoid changing the direction of carburetor installation. Failure to do this will cause engine malfunction.

The SAITO carburetor has been adjusted on its slow needle to our reference value at factory default. The slow needle requires some correction depending on various factors

including the installation position, types of prop/fuel/plug, or climate conditions. Readjust the slow needle referring to the figure shown below .

[Reference value (only for a guide)]

Main needle: Open the needle by 2 turns from the full close point.

Slow needle: Fully close the throttle valve and slow needle CW to the end. Then open the slow needle by about 3 turns from the full close point.

1. After filling up the fuel tank, start the engine as described in the previous section F .

2. Fully open the throttle valve. Adjust the main needle while observing tachometer , exhaust noise and exhaust smoke, to attain th e speed peak.

Caution: Excessive closing of main needle could cause knocking and give damage onto the engine. In such occasion, immediately turn the main needle CCW to make

fuel mixture rich.

3. Next control the throttle stick to gradually close the throttle valve to run the engine stably in the

4. Once idling speed is set, fully open the throttle valve slowly. If the speed becomes irregular or

5. When the above adjustment is completed, quickly change the speed from idling to the peak. If

6. When all conditions are set, return the adjustment of main needle slightly to lower the

Suppose the peak speed with the tank filled full with fuel is at 9,500rpm, set the main needle to reduce the peak speed by 300 rpm at 9,200rpm. Run the engine at a

speed about 300rpm lower than the peak to prolong the service life of the engine and minimize rusting on bearings.

open. Adjust the main needle while observing tachometer, exhaust oil concentration and exhaust concentration from the breather, to run the engine at 5,000rpm or

lower speed in rich condition for full tank fuel consumption. (Run the engine with plugs powered as required.)

observe tachometer reading, exhaust oil concentration and exhaust concentration from the breather .)

has been completed for the time being. Now adjust valve clearance by following procedure of maintenance described later. Then adjust carburetor according to the

next article and make test flights at less speed around ten times to complete break-in. (Thereafter make flights at less speed, to prolong engine life.)

range of around 2,000-2,500rpm. (Adjust the throttle stick while observing tachometer.

Exhaust smoke concentration, or exhaust/intake noise.)

a. Rich fuel mixture: Turn the slow needle CW to make fuel mixture leaner .

b. Lean fuel mixture: Turn the slow need le CCW to make fuel mixture richer .

suddenly increases on the way, carefully adjust the slow needle so that the engine speed

changes linearly from the idling to the peak speed.

the speed does not reach the peak on opening the throttle valve to full open point, return the

main needle by the amount single knurl notch gives. Then quickly change the speed again.

Repeat this procedure cautiously to attain the best response.

maximum speed by 200-300rpm (make fuel mixture richer).

Priming Method

Needle adjustment

-3-

Page 4

I. Normal Operation and Maintenance

(a) Do not operate your engine too lean at full throttle since the engine might be overheated.

Adjust the main needle slightly open than the peak. (Too lean operation causes knocking,

stoppage or negative influence on the connecting rods and cam gear.)

(b) After completing ground break-in or operating the engine for one hour, adjust tappet gaps

(valve clearances) by following procedure to compensate initial wearing, while the engine is

cold.

1. Remove plugs and rocker arm covers of all cylinders.

2. For instance start adjusting from the No.1 cylinder. Turn the prop slowly forward by

hand, to stop the rocker arm of the No.1 cylinder.. Further turn the prop, to bring the

piston to the TDC (T op Dead Center) of compression stroke.

3. Use the attached wrench and hexagonal wrench to adjust the gaps indefinitely close to zero within the range compression exists.

4. On checking the gap, securely tighten (but not excessively) the lock nut.

* In the case of the engines for vehicle, small gap is given to tappets to absorb valve elongation. In the case of SAITO engines, gap becomes larger during operations

due to thermal expansion of the cylinder (made of aluminum). Therefore set the gap indefinitely close to zero while the engine is cold.

Occasionally check tappet gap by those procedure. When the attached gauge (limit gauge, t=0.1mm) comes to be inserted, gap has been enlarged be yond the allowable

limit. Make an adjustment to lessen the gap. Tappet gap is one of the most important factor in the maintenance of 4-stroke engines. Operating the engine with the tappet

gap enlarged excessively will cause poor performance or troubles.

(c) Lubricate the rocker arm and valve area at inspection as required.

(d) When connecting the exhaust pipe to the cylinder or attaching the prop nut, apply thin coat of silicon rubber (not excessivel y) on the thread section before tightening.

This prevents leakage or loosening.

(e) Occasionally tighten the prop nut and exhaust nut (while it is hot).

(f) After a flight, lubricate the entire engine with spray type preserve lubricant through the carburetor or breather.

(g) If the engine in not operated for longer period of time, lubricate the entire en gine before placing a plastic cover on.

J. Internal Lubrication of Engine and Waste Oil Disposal

Oil contained in fuel enters into the crankcase through the clearance between the piston and cylinder to lubricate the piston, connecting rod, bearings, cams and gears. Waste

oil is discharged from the breather nipple located at the lower part of crankcase. Connect a silicone tube to the breather nipple and clamp the other end of tube at the end of

exhaust pipe by using bands.

k. Supplementary Notes:

(a) Precautions for wiring of attached connector set to heat plugs:

To equalize current, bind cables without cutting them even if it’s long.

* The engine adjusted properly does not require plug heating at idling (2,000-2,500rpm) once it starts.

(b) Causes of reversing at starting:

• Priming amount is inadequate.

• Manual-cranking speed is insufficient.

• Voltage or current for plug heating is low .

(c) Please notice that our guarantee will not cover any breakage or trouble on the engine caused by your disassembling or modification.

If disassembling becomes necessary , observe the following precautions.

(d) Notes for purchasing parts:

Please give orders to the shop you purchased from with a sheet with engine name, part name or number, and marking (alphabet on the lower face of rear cover).

(e) Take an extreme care for safet y when operating the engine or flying the model airplane not to bother others.

(f) An engine for a model airplane is not a toy . Handle it with an extreme care.

All specifications and models are subject to change without notice.

T appet adjustment

SAITO SEISAKUSHO, CO., LTD.

22-7, 3-chome, T okagi, Ichikawa-shi, Chiba prefecture 272-0024, Japan

Phone: 047-378-4156 FAX: 047-378-4155

-4-

Loading...

Loading...