Sailor 500 FleetBroadband, Sailor 250 FleetBroadband, 250 FleetBroadband Installation Manual

Page 1

Page 2

INSTALLATION MANUAL

SAILOR

500/250 FleetBroadband

Page 3

Thrane & Thrane A/S

SAILOR

®

500 FleetBroadband

SAILOR

®

250 FleetBroadband

Installation manual

Document number: TT98-125646-C

Release date: December 13, 2007

Page 4

Information in this document is subject to change without notice and does not represent

a commitment on the part of Thrane & Thrane A/S. We recommend downloading the

latest version of the manual from the Thrane & Thrane Extranet.

Copyright © 2007 Thrane & Thrane A/S. All rights reserved.

Trademark acknowledgements

• Thrane & Thrane is a registered trademark of Thrane & Thrane A/S in the European

Union and the United States.

• SAILOR is a registered trademark of Thrane & Thrane A/S in the European Union, the

United States and other countries.

• Windows and Outlook are registered trademarks of Microsoft Corporation in the

United States and other countries.

• Inmarsat is a registered trademark of International Maritime Satellite Organisation

(IMSO) and is licensed by IMSO to Inmarsat Limited and Inmarsat Ventures plc.

• Inmarsat’s product names are trademarks or registered trademarks of Inmarsat.

• Other product and company names mentioned in this manual may be trademarks or

trade names of their respective owners.

Company addresses

www.thrane.com

Denmark

Denmark

Company headquarters

Norway

Thrane & Thrane Aalborg A/S

Porsvej 2

DK-9200 Aalborg SV

Denmark

Thrane & Thrane A/S

Lundtoftegårdsvej 93 D

DK-2800 Kgs. Lyngby

Denmark

Thrane & Thrane Norway

Bergerveien 12

PO Box 91

1375 Billingstad,

Norway

USA China

Thrane & Thrane, Inc.

509 Viking Drive, Suites

K, L and M

Virginia Beach, VA 23452

USA

Thrane & Thrane Shanghai

Unit 602 - Building 4,

289 Bisheng Rd.

Zhangjiang High-tech Park,

Pudong

201204 Shanghai

P. R. China

Page 5

iii

Safety summary 1

The following general safety precautions must be observed during all

phases of operation, service and repair of this equipment. Failure to comply

with these precautions or with specific warnings elsewhere in this manual

violates safety standards of design, manufacture and intended use of the

equipment. Thrane & Thrane A/S assumes no liability for the customer's

failure to comply with these requirements.

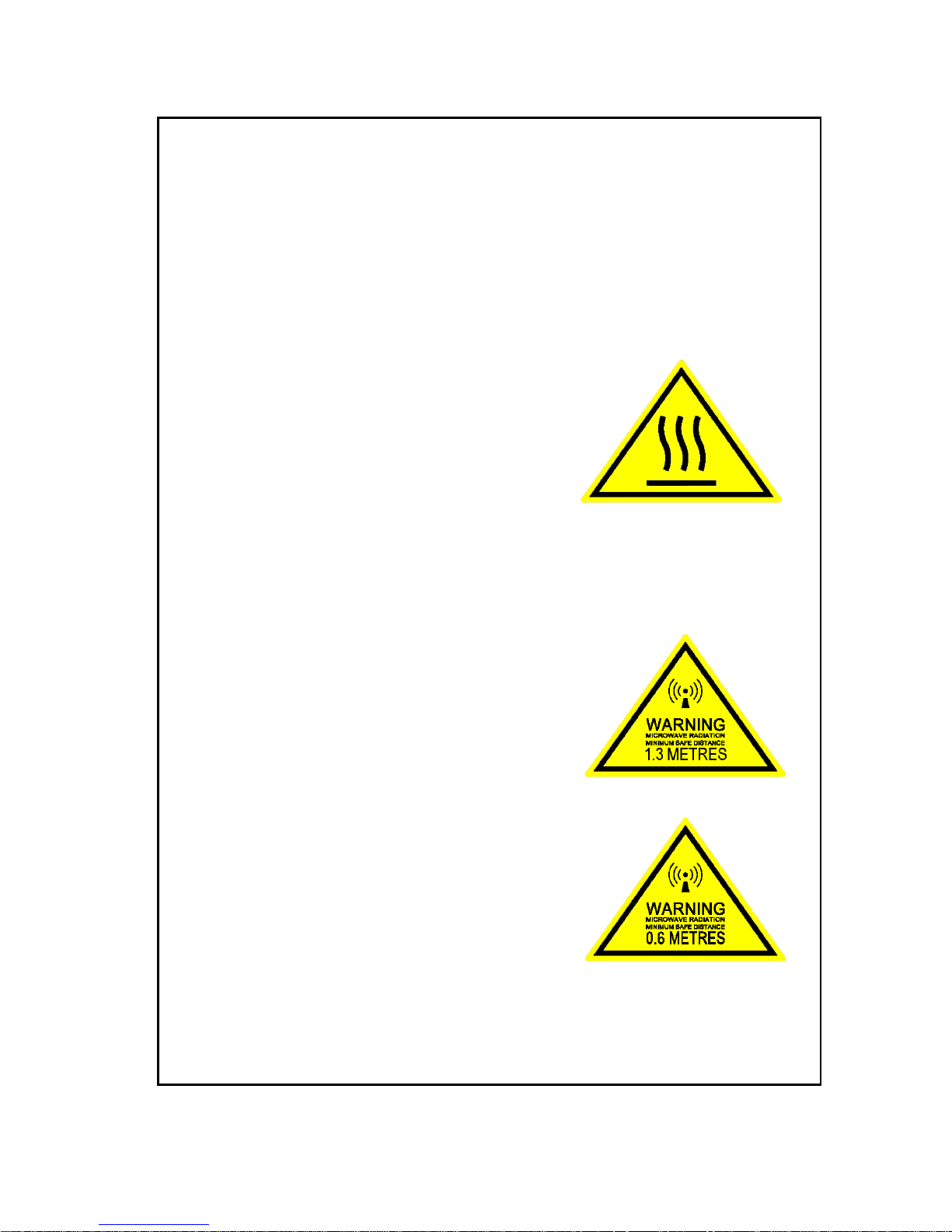

Observe marked areas

Under extreme heat conditions do not touch

areas of the terminal or antenna that are

marked with this symbol, as it may result in

injury.

Microwave radiation hazards

During transmission the antenna in this system radiates microwave power.

This radiation may be hazardous to humans close to the antenna. During

transmission, make sure that nobody gets closer than the recommended

minimum safety distance.

On the SAILOR 500 FleetBroadband, the

minimum safety distance on the focal line to

the antenna panel is 1.3 m, based on a

radiation level of 10 W/m

2

. The radiation level is

100 W/m

2

at a distance of 0.4 m from the

antenna panel. Refer to the drawing on the

next page.

On the SAILOR 250 FleetBroadband, the

minimum safety distance on the focal line to the

antenna panel is 0.6 m, based on a radiation

level of 10 W/m

2

. The radiation level is 100

W/m

2

at a distance of 0.2 m from the antenna

panel. Refer to the drawing on the next page.

Page 6

iv

Distance to other equipment

Do not move the antenna closer to radars than the minimum safe distance

specified in Radar distance on page 12 - it may cause damage to the

antenna. The equipment must be installed with the following minimum safe

distances to magnetic steering compass:

SAILOR FleetBroadband terminal: min. 0.3 m.

SAILOR 500 FleetBroadband antenna: min. 1.0 m

SAILOR 250 FleetBroadband antenna: min. 1.1 m

Service

User access to the interior of the terminal is prohibited. Only a technician

authorized by Thrane & Thrane A/S may perform service - failure to comply

with this rule will void the warranty. Access to the interior of the antenna is

allowed, but only for replacement of certain modules - as described in this

manual. General service may only be performed by a technician authorized

by Thrane & Thrane A/S.

Do not service or adjust alone

Do not attempt internal service or adjustments unless another person,

capable of rendering first aid resuscitation, is present.

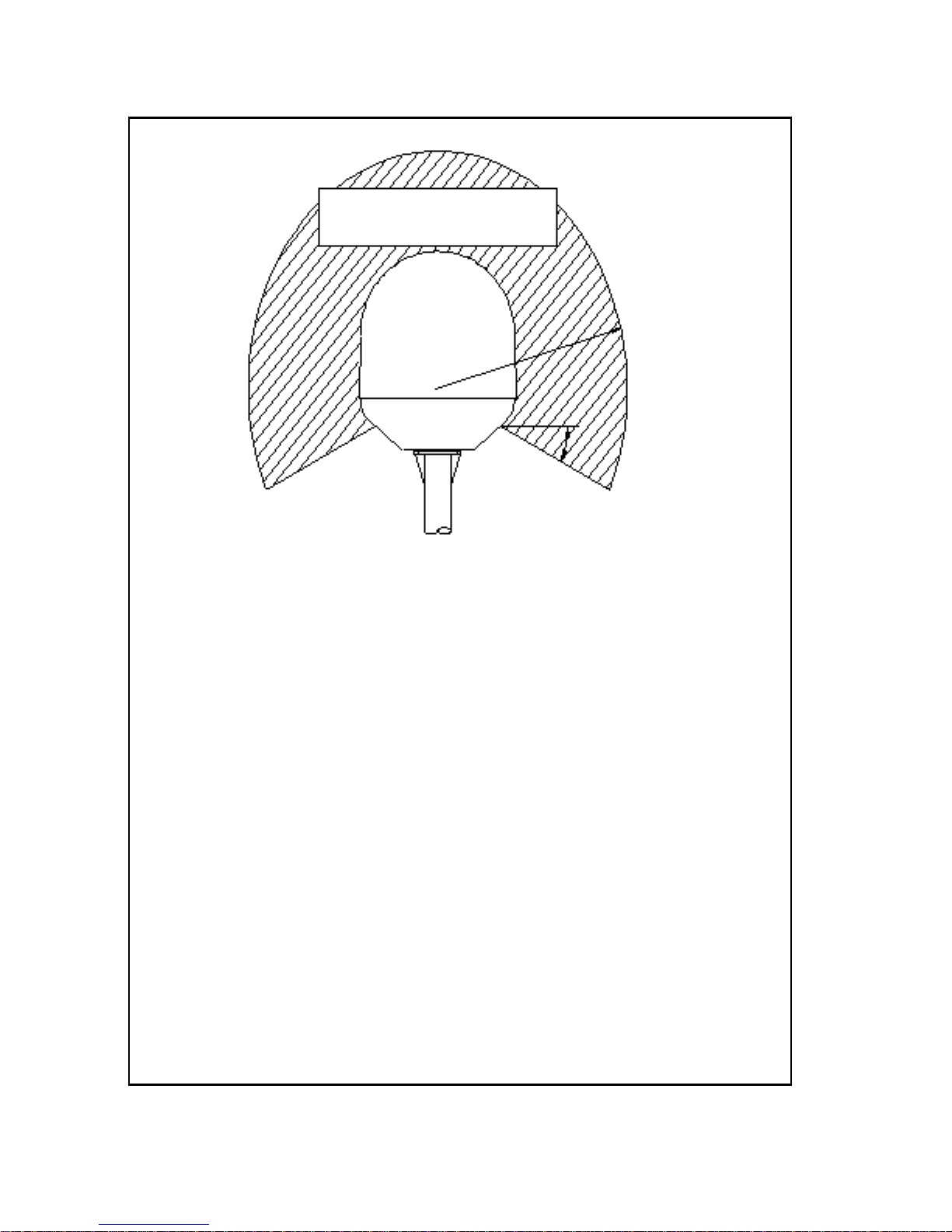

SAILOR 500:

MICROWAVE RADIATION

No personnel within safety distance

25° for SAILOR 500

60° for SAILOR 250

Safety distance:

(0.4 m, 100 W/m

2

)

1.3 m, 10 W/m

2

SAILOR 250:

(0.2 m, 100 W/m

2

)

0.6 m, 10 W/m

2

Page 7

v

Grounding, cables and connections

To minimize shock hazard, the equipment chassis and cabinet must be

connected to an electrical ground. The terminal must be grounded to the

ship. For further grounding information refer to Grounding and RF

protection on page 109.

Do not extend the cables beyond the lengths specified for the equipment.

The cable between the terminal and antenna can be extended if it complies

with the specified data concerning cable losses etc.

All cables for your SAILOR FleetBroadband system are shielded and should

not be affected by magnetic fields. However, try to avoid running cables

parallel to AC wiring as it might cause malfunction of the equipment.

Power supply

The voltage range is 10.5 - 32 V DC; 14 A - 5.5 A. It is recommended that the

voltage is provided by the 24 V DC power bus on the ship. Be aware of high

start-up peak current: 20 A at 24 V, 5 ms.

If a 24 V DC power bus is not available, an external 115/230 VAC to 24 V DC

power supply can be used.

Equipment ventilation

To ensure adequate cooling of the terminal, 5 cm of unobstructed space

must be maintained around all sides of the unit (except the bottom side).

The ambient temperature range of the terminal is: -25° to +55°C.

Do not operate in an explosive atmosphere

Do not operate the equipment in the presence of flammable gases or fumes.

Operation of any electrical equipment in such an environment constitutes a

definite safety hazard.

Keep away from live circuits

Operating personnel must not remove equipment covers. Component

replacement and internal adjustment must be made by qualified

maintenance personnel. Do not replace components with the power cable

connected. Under certain conditions, dangerous voltages may exist even

with the power cable removed. To avoid injuries, always disconnect power

and discharge circuits before touching them.

Failure to comply with the rules above will void the warranty!

Page 8

vi

Mandatory safety instructions to installers &

users of SAILOR

®

250 FleetBroadband 2

Use only manufacturer or dealer supplied antenna.

Antenna minimum safe distance: 0.415 m.

Antenna gain 12.2 dBi referenced to isotropic.

The Federal Communications Commission has adopted a safety

standard for human exposure to RF (Radio Frequency) energy,

which is below the OSHA (Occupational Safety and Health Act)

limits.

Antenna mounting

The antenna supplied by the manufacturer or radio dealer must

not be mounted at a location such that during radio transmission,

any person or persons can come closer than the above indicated

minimum safe distance to the antenna i.e. 0.415 m.

To comply with current FCC RF Exposure limits, the antenna must

be installed at or exceeding the minimum safe distance shown

above, and in accordance with the requirements of the antenna

manufacturer or supplier.

Base Station Installation: The antenna should be fixed-mounted

on an outdoor permanent structure. RF Exposure compliance must

be addressed at the time of installation.

Antenna substitution

Do not substitute any antenna for the one supplied or

recommended by the manufacturer or radio dealer. You may be

exposing person or persons to excess radio frequency radiation.

You may contact your radio dealer or the manufacturer for further

instructions.

Page 9

vii

Warning

Maintain a separation distance from the antenna to a person(s) of

at least 0.415 m.

You, as the qualified end-user of this radio device must control the

exposure conditions of bystanders to ensure the minimum

separation distance (above) is maintained between the antenna

and nearby persons for satisfying RF Exposure compliance. The

operation of this transmitter must satisfy the requirements of

Occupational/Controlled Exposure Environment, for work-related

use. Transmit only when person(s) are at least the minimum

distance from the properly installed, externally mounted antenna.

Note

Thrane & Thrane recommends a minimum safety

distance of 0.6 m to the SAILOR 250 FleetBroadband

antenna.

Page 10

viii

About the manual 3

Intended readers

This is an installation manual for the SAILOR 500 FleetBroadband

and the SAILOR 250 FleetBroadband systems. The readers of the

manual include installers of the system and service personnel.

Personnel installing or servicing the system must be properly

trained and authorized by Thrane & Thrane. It is important that

you observe all safety requirements listed in the beginning of this

manual, and install the system according to the guidelines in this

manual.

Manual overview

Note that this manual does not cover general use of the system nor

does it cover how to use the IP handset that comes with the

system. For this information, refer to the user manual for this

system and the user manual for the IP handset, both listed in the

next section.

This manual has the following chapters:

• System units contains a short description of each main unit in

the system.

• Installing the system describes where to place the system units,

how to mount them, special considerations for grounding,

distance to other equipment etc.

• Connecting power explains how to connect the terminal to

power and gives recommendations for cables.

• Hardware interfaces describes each interface on the terminal

and shows pin-out for the connectors.

• Starting up the system explains how to insert the SIM card,

power up the system and enter the PIN. It also gives a short

overview of how to use the system.

• Service and repair describes how to replace modules for

service.

Page 11

ix

• Troublesho otin g describes the function of the Reset button and

the light indicators on the terminal. It also describes event

messages that may appear in the web interface.

This manual may not always reflect the latest software

functionality of your transceiver. To obtain the latest version of the

manual, please enter the Thrane & Thrane Extranet and download

the latest version, or acquire it from your distributor.

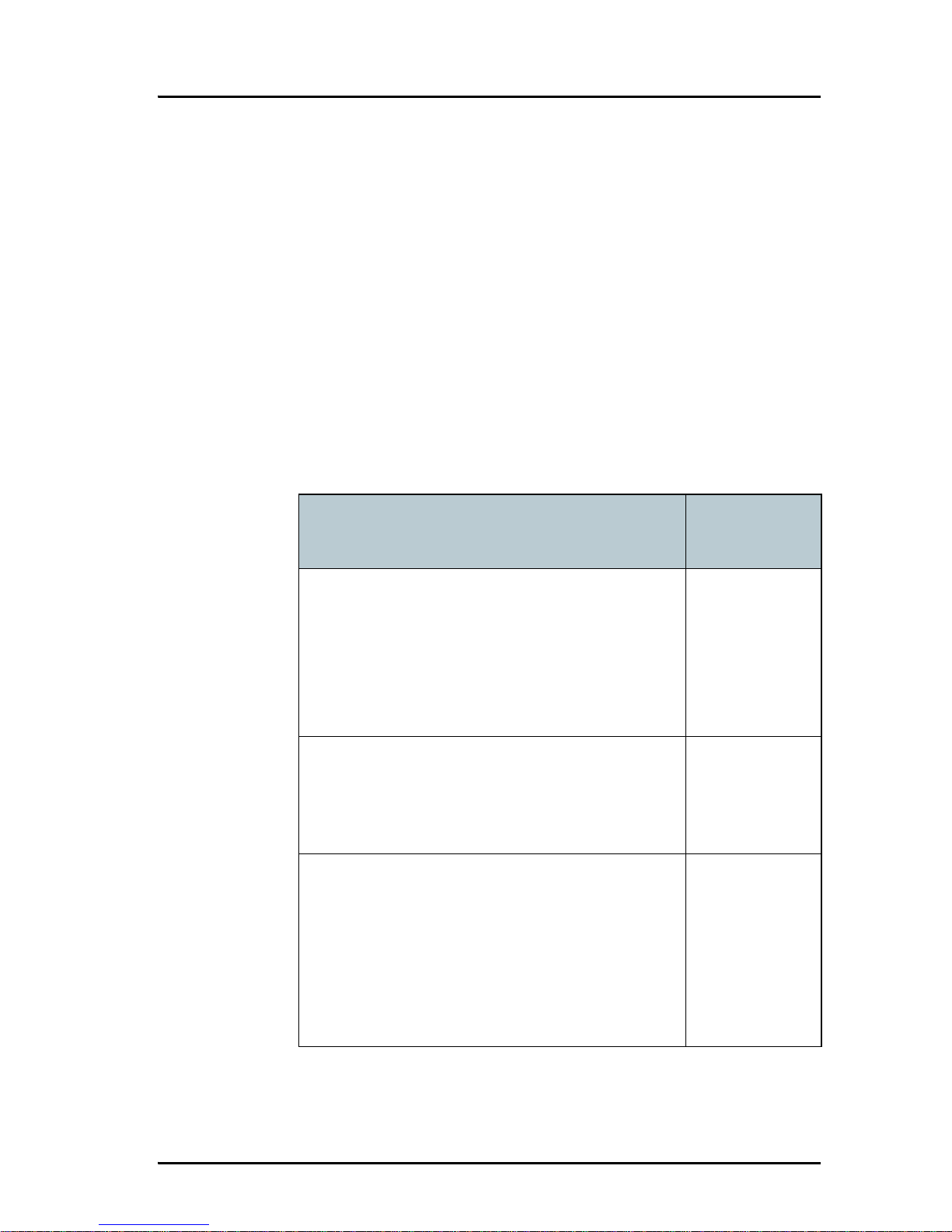

Related documents

The below list shows the documents related to this manual and to

the SAILOR 500 FleetBroadband and SAILOR 250 FleetBroadband

systems.

Title and description

Document

number

SAILOR 500 FleetBroadband

SAILOR 250 FleetBroadband

User Manual

Explains how to set up and use the

SAILOR FleetBroadband systems.

TT 98-125645

SAILOR 500/250 FleetBroadband, Quick Guide

A short guide to the most important functions

of the SAILOR FleetBroadband systems.

TT98-125647

Thrane & Thrane IP Handset, User Manual

Explains the features and functions of the

Thrane & Thrane IP handset. The IP handset

works as a standard IP handset, but also

serves as a user interface for the

SAILOR FleetBroadband systems.

TT98-126059

Page 12

x

Typography

In this manual, typography is used as indicated below:

Bold is used for the following purposes:

• To emphasize words.

Example: “Do not touch the antenna”.

• To indicate what the user should select in the user interface.

Example: “Select Settings > LAN”.

Italic is used to emphasize the paragraph title in cross-

references.

Example: “For further information, see Connecting Cables on

page...”.

COURIER is used to indicate low level commands such as AT

commands.

Example: “In your terminal program, type ATD”.

Page 13

xi

Table of contents

Chapter 1 System units

1.1 Introduction ............................................................... 1

1.2 Terminal .................................................................... 1

1.3 SAILOR

®

500 FleetBroadband antenna .......................2

1.4 SAILOR

®

250 FleetBroadband antenna .......................3

1.5 IP handset and cradle ................................................4

Chapter 2 Installing the system

2.1 Unpacking .................................................................7

2.2 Placing the antenna ...................................................8

2.3 Installing the antenna ...............................................21

2.4 Placing the terminal ................................................27

2.5 Installing the terminal .............................................28

Chapter 3 Connecting power

3.1 Power source ...........................................................37

3.2 Power cable selection ..............................................38

3.3 To connect power ....................................................42

3.4 Remote on/off ..........................................................43

Chapter 4 Hardware interfaces

4.1 The connector panel ................................................45

4.2 Antenna interface on terminal .................................46

4.3 DC power input ........................................................47

4.4 Ground stud .............................................................49

Page 14

Table of contents

xii

4.5 Analog Phone/Fax interface .................................... 50

4.6 ISDN interface .......................................................... 51

4.7 LAN interface ...........................................................53

4.8 Discrete I/O interface ...............................................55

4.9 L-Band interface ..................................................... 58

Chapter 5 Starting up the system

5.1 Using the SIM card ...................................................59

5.2 Powering the system ................................................ 61

5.3 Entering the SIM PIN for the terminal ......................62

5.4 Operating the system ...............................................64

Chapter 6 Service and repair

6.1 Introduction .............................................................65

6.2 Replacing modules .................................................65

Chapter 7 Troubleshooting

7.1 Reset button ............................................................75

7.2 Status signaling .......................................................78

7.2.3 Logging of events .....................................................83

App. A Part numbers

A.1 System units ........................................................... 85

A.2 Spare parts, SAILOR

®

500 FleetBroadband .............. 86

A.3 Spare parts, SAILOR

®

250 FleetBroadband ...............87

A.4 Accessories ............................................................. 88

Page 15

Table of contents

xiii

App. B Technical specifications

B.1 Overview ..................................................................89

B.2 SAILOR

®

500 FleetBroadband antenna .....................89

B.3 SAILOR

®

250 FleetBroadband antenna .....................95

B.4 Minimum distance to transmitters. ......................... 100

B.5 SAILOR FleetBroadband terminal ............................ 101

App. C Grounding and RF protection

C.1 Why is grounding required? ....................................109

C.2 General about marine DC systems .......................... 110

C.3 General about marine grounding ............................ 112

C.4 Grounding Recommendations ................................. 114

C.5 Alternative grounding for steel hulls ....................... 116

C.6 Alternative grounding for aluminum hulls .............. 118

C.7 Alternative grounding for fiberglass hulls ...............120

C.8 Alternative grounding for timber hulls ....................122

C.9 Separate ground cable ............................................124

C.10 RF interference .......................................................128

C.11 Electrostatic Discharge ............................................129

Glossary ........................................................................................ 131

Index ........................................................................................135

Page 16

Table of contents

xiv

Page 17

1

Chapter 1

1111

System units

System units 1

1.1 Introduction

The basic system consists of three units: The terminal, the antenna and the IP

handset with cradle.

There are two different types of antennas, depending on whether you have a

SAILOR 500 FleetBroadband system or a SAILOR 250 FleetBroadband system.

1.2 Terminal

The terminal – which contains the primary electronic parts – is designed for

wall or desktop installation.

The terminal supplies 18-29 V DC to the antenna through a single coaxial

cable.

The DC input for the terminal is designed for both 24 V DC and 12 V DC power

supply.

Page 18

Chapter 1: System units

2SAILOR

®

500 FleetBroadband antenna

1.3 SAILOR®500 FleetBroadband antenna

The SAILOR 500 FleetBroadband antenna is a BGAN Class 8 mechanical

tracking antenna, consisting of a stabilized antenna with RF-unit, antenna

control unit and GPS antenna. All communication between the antenna and

terminal passes through a single coaxial cable. The antenna unit is protected

by a fibre glass radome.

Page 19

Chapter 1: System units

SAILOR®250 FleetBroadband antenna 3

1111

System units

1.4 SAILOR®250 FleetBroadband antenna

The SAILOR 250 FleetBroadband antenna is a BGAN Class 9 mechanical

tracking antenna. All communication between the antenna and terminal

passes through a single coaxial cable. The antenna unit is protected by a

thermo-plastic radome.

Page 20

Chapter 1: System units

4 IP handset and cradle

1.5 IP handset and cradle

1.5.1 Thrane & Thrane IP handset

Besides the normal functions of an IP handset, the Thrane & Thrane IP

handset also provides a user interface for the SAILOR FleetBroadband system.

The IP handset connects to the LAN interface of the terminal, and is power

supplied with Power over Ethernet (PoE) through the LAN interface.

For further information on the IP handset, refer to the user manual for the

Thrane & Thrane IP handset.

Page 21

Chapter 1: System units

IP handset and cradle 5

1111

System units

1.5.2 Thrane & Thrane IP cradle

The IP cradle serves as a holder for the IP handset. It is power supplied from

the terminal using Power over Ethernet (PoE). The cradle is connected to the

handset with a coil cord and to the terminal with a standard LAN cable.

Page 22

Chapter 1: System units

6 IP handset and cradle

Page 23

7

Chapter 2

2222

Installing the system

Installing the system 2

2.1 Unpacking

Unpack your SAILOR FleetBroadband system and check that the following

items are present:

• TT-3738A SAILOR FleetBroadband terminal

• TT-3052A SAILOR 500 FleetBroadband antenna or

TT-3050A SAILOR 250 FleetBroadband antenna

• TT-3670A IP handset and cradle

• Basic cable support kit

•Power cable

• Antenna cable

•LAN cable

• I/O connector

•User manual

• Installation manual (this manual)

•Quick guide

Inspect all units and parts for possible transport damage.

Note

For information on how to install the IP handset and cradle, refer to

the user manual for the handset.

Page 24

Chapter 2: Installing the system

8 Placing the antenna

2.2 Placing the antenna

2.2.1 Obstructions

The antenna rotates 360° and down to –25° for the

SAILOR 500 FleetBroadband and -60° for the SAILOR 250 FleetBroadband in

pitch and roll, to allow for continuous pointing even in heavy sea conditions.

Any obstructions within this volume can cause signal degradation.

The amount of degradation depends on the size of the obstruction and the

distance from the antenna. As a rule of thumb any obstruction that subtends

an angle of less than 3° at the antenna has limited effect. The table below

gives a guideline for obstruction sizes, which will cause limited degradation.

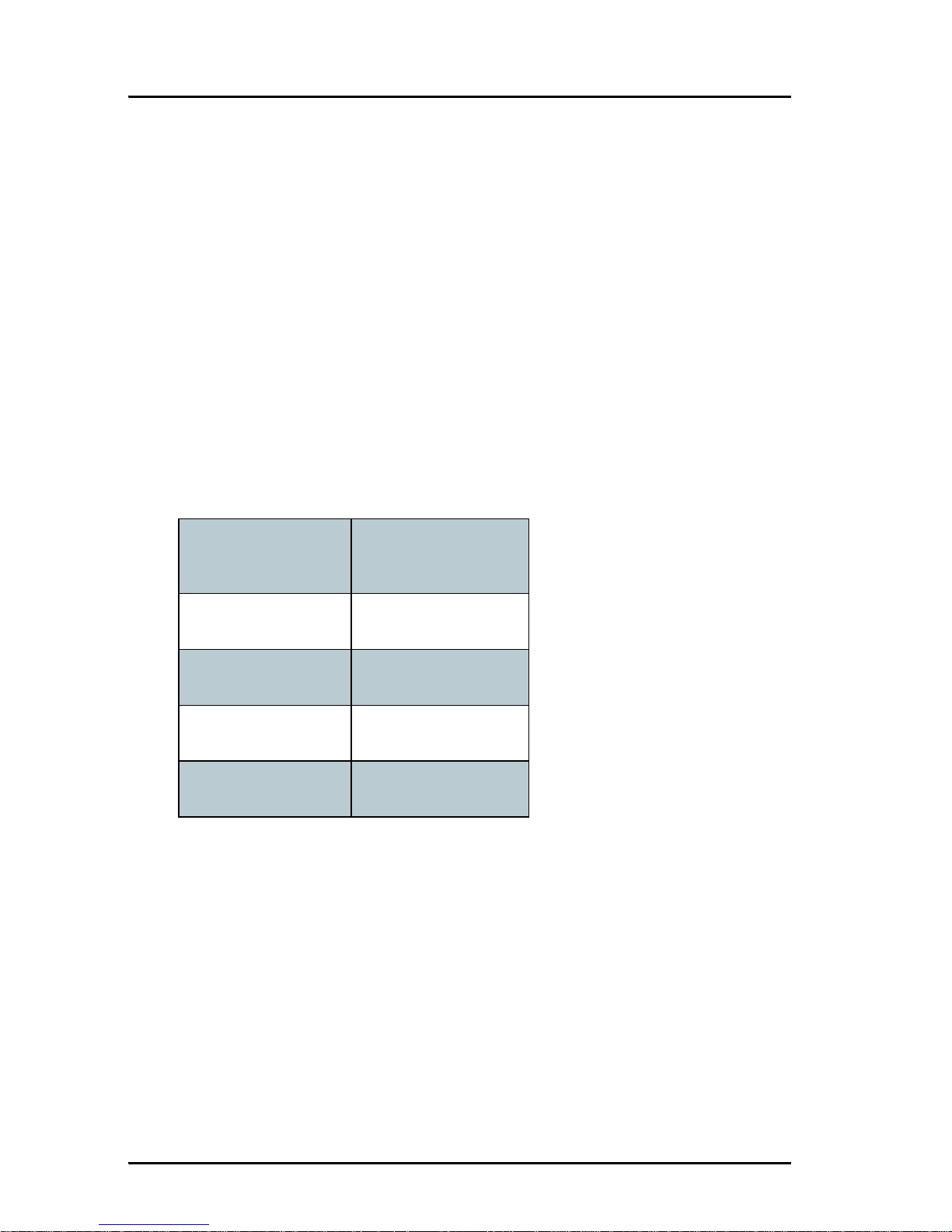

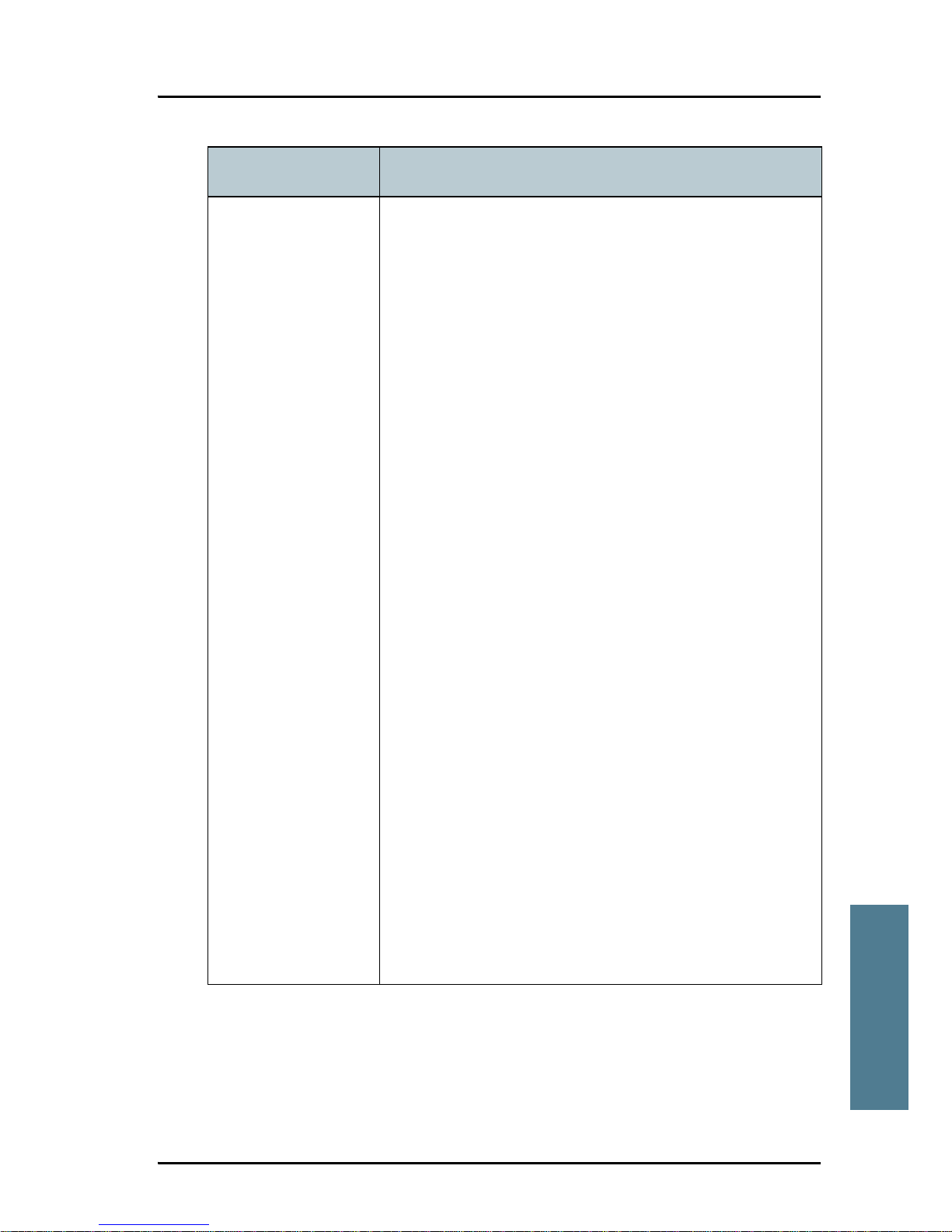

Distance of

Obstruction

Size of Obstruction

3m 16cm

5m 26 cm

10 m 52 cm

20 m 104 cm

Page 25

Chapter 2: Installing the system

Placing the antenna 9

2222

Installing the system

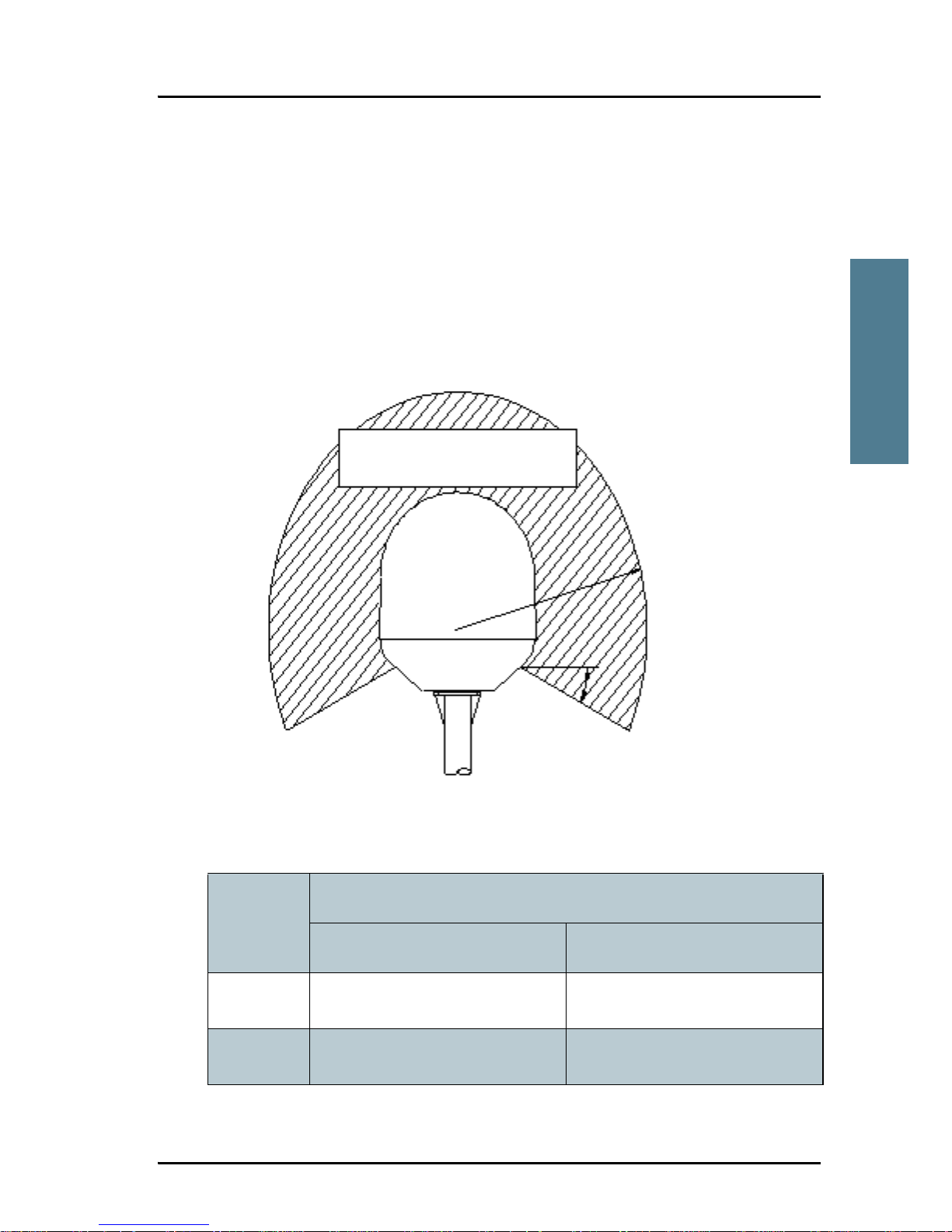

2.2.2 Radiation hazard

The SAILOR 500 FleetBroadband antenna radiates 22 dBW EIRP. This

translates to a minimum safety distance of 1.3 m from the antenna while it is

transmitting, based on a radiation level of 10 mW/cm

2

.

The SAILOR 250 FleetBroadband antenna radiates 16.1 dBW EIRP. This

translates to a minimum safety distance of 0.6 m from the antenna while it is

transmitting, based on a radiation level of 10 mW/cm

2

.

For higher radiation levels, see the table below.

Radiation

level

Distance

SAILOR 500 FleetBroadband SAILOR 250 FleetBroadband

100 W/m

2

0.4 m 0.2 m

10 W/m

2

1.3 m 0.6 m

MICROWAVE RADIATION

NO PERSONNEL

based on 10 W/m

2

SAILOR 500:

Safety distance:

1.3 m, 10 W/m

2

SAILOR 250:

0.6 m, 10 W/m

2

25° for SAILOR 500

60° for SAILOR 250

Page 26

Chapter 2: Installing the system

10 Placing the antenna

2.2.3 Interference

Overview

The antenna must be mounted as far away as possible from the ship’s radar

and high power radio transmitters (including other Inmarsat based systems),

because they may compromise the antenna performance. RF emission from

radars might actually damage the antenna.

The SAILOR FleetBroadband antenna itself may also interfere with other radio

systems. Especially other Inmarsat systems and GPS receivers with poor

frequency discrimination are vulnerable to the radiation generated by the

SAILOR FleetBroadband antennas.

Page 27

Chapter 2: Installing the system

Placing the antenna 11

2222

Installing the system

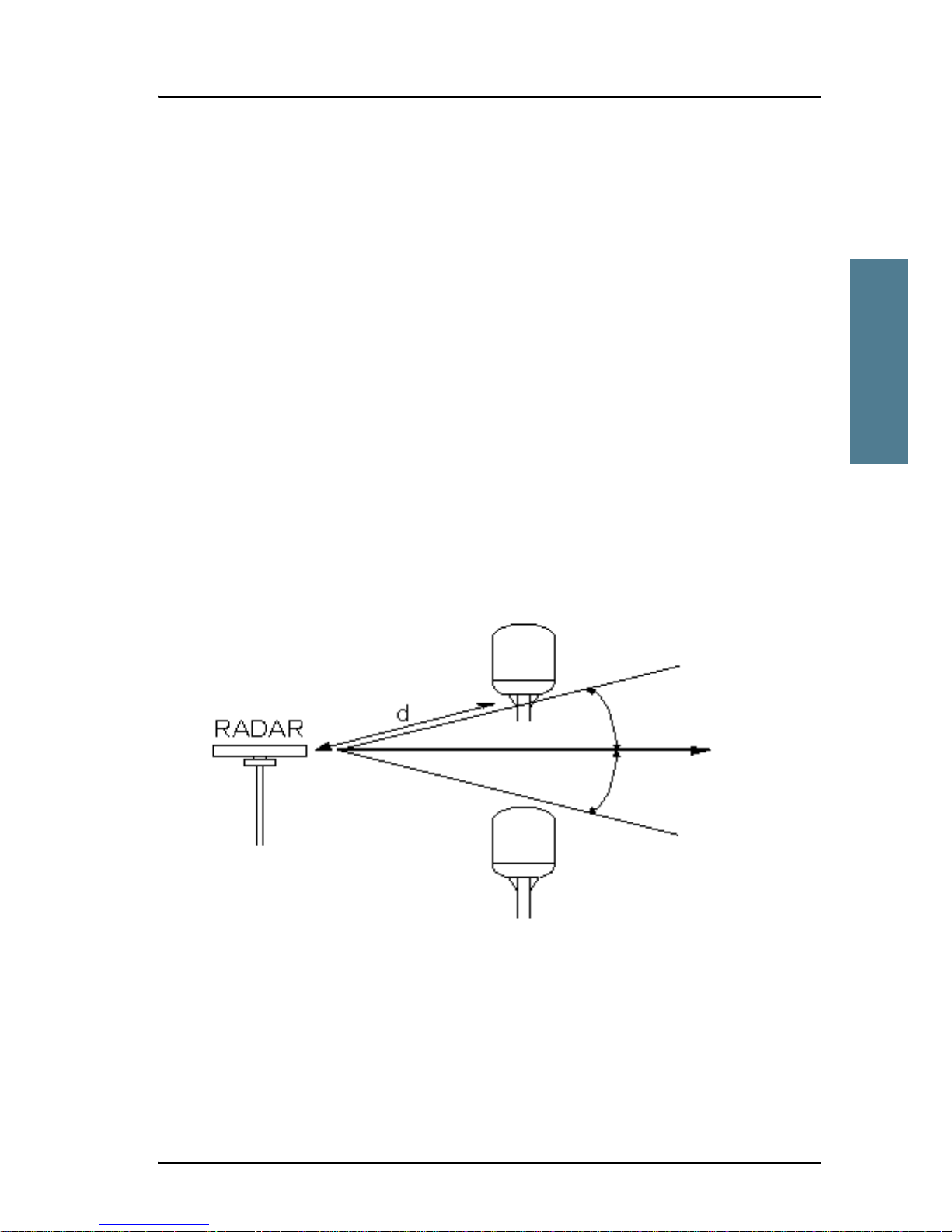

Radar

It is difficult to give exact guidelines for the minimum distance between a

radar and the antenna because radar power, radiation pattern, frequency and

pulse length/shape vary from radar to radar. Further, the antenna is typically

placed in the near field of the radar antenna and reflections from masts, decks

and other items in the vicinity of the radar are different from ship to ship.

However, it is possible to give a few guidelines:

Since a radar radiates a fan beam with a horizontal beam width of a few

degrees and a vertical beam width of up to +/- 15°, the worst interference can

be avoided by mounting the antenna at a different level – meaning that the

antenna is installed minimum 15° above or below the radar antenna. Due to

near field effects the benefit of this vertical separation could be reduced at

short distances (below approximately 10 m) between radar antenna and the

SAILOR FleetBroadband antenna. Therefore it is recommended to ensure as

much vertical separation as possible when the SAILOR FleetBroadband

antenna has to be placed close to a radar antenna.

Min. 15°

Min. 15°

Page 28

Chapter 2: Installing the system

12 Placing the antenna

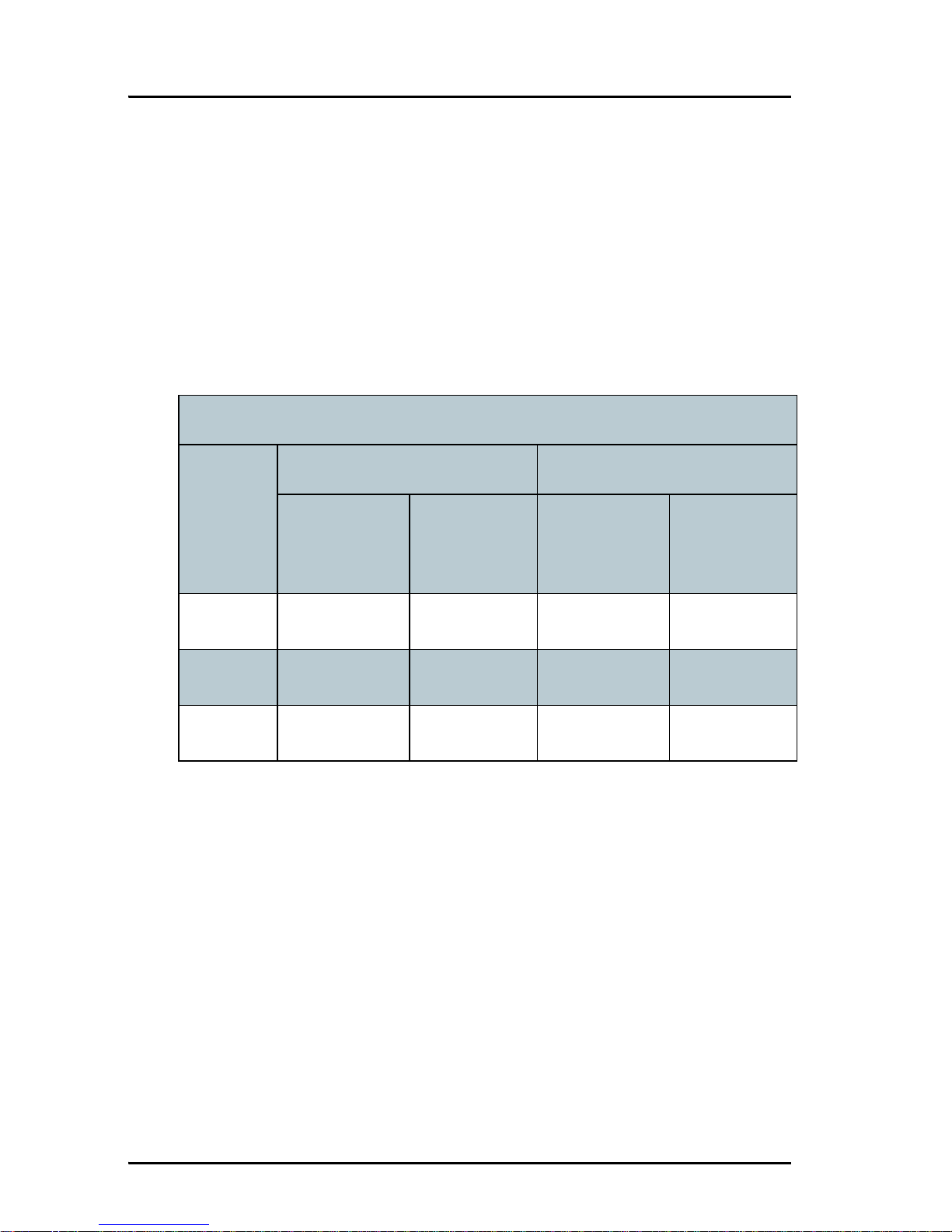

Radar distance

The minimum acceptable separation (d min.) between a radar and the

antenna is determined by the radar wavelength/frequency and the power

emitted by the radar. The tables below show some “rule of thumb” minimum

separation distances as a function of radar power at X and S band. If the d

min. separation listed below is applied, antenna damage is normally avoided.

“d min.” is defined as the shortest distance between the radar antenna (in any

position) and the surface of the SAILOR FleetBroadband antenna.

X-band (~ 3 cm / 10 GHz) damage distance

Radar

power

SAILOR 500 FleetBroadband SAILOR 250 FleetBroadband

d min. at 15°

vertical

separation

d min. at 60°

vertical

separation

d min. at 15°

vertical

separation

d min. at 60°

vertical

separation

0 – 10 kW 0.8 m 0.4 m 0.8 m 0.4 m

30 kW 2.4 m 1.2 m 2.4 m 1.2 m

50 kW 4.0 m 2.0 m 4.0 m 2.0 m

Page 29

Chapter 2: Installing the system

Placing the antenna 13

2222

Installing the system

The separation distance for C-band (4-8 GHz) radars should generally be the

same as for X-band radars.

Interference

Even at distances greater than “d min.” in the previous section the radar

might still be able to degrade the performance of the SAILOR FleetBroadband

system.

The presence of one or more X-band radars within a radius up to 100 m could

cause a minor degradation of the signal-to-noise ratio during high speed and

data calls. The degradation will be most significant at high radar pulse

repetition rates.

As long as receiving conditions are favorable, this limited degradation is

without importance. However, if receiving conditions are poor – e.g. due to

objects blocking the signal path, heavy rainfall or icing, low satellite elevation

and violent ship movements – the small extra degradation due to the radar(s)

could cause poor call quality. A voice call might become noisy and perhaps fail

while a data connection might decrease in speed and performance.

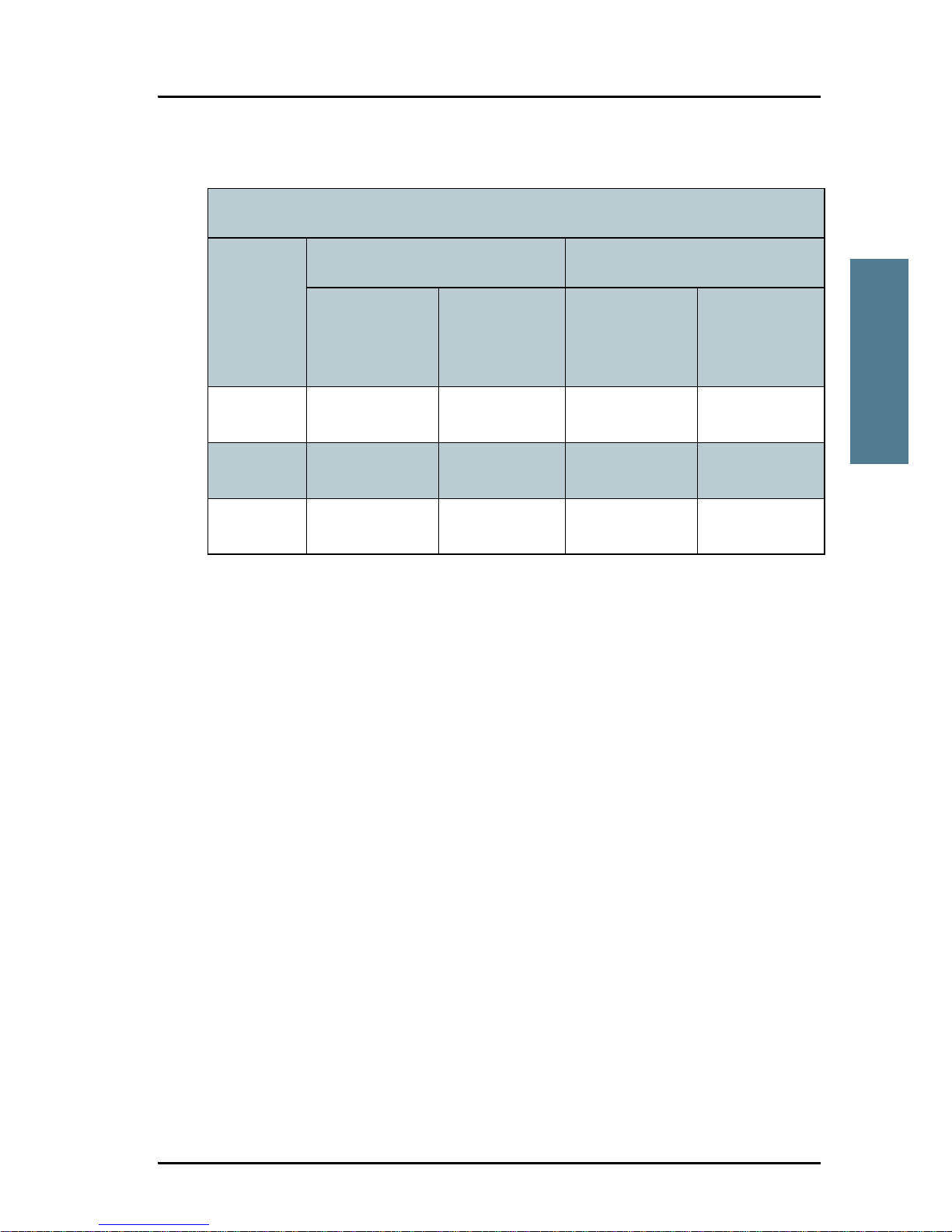

S-band (~ 10 cm / 3 GHz) damage distance

Radar

power

SAILOR 500 FleetBroadband SAILOR 250 FleetBroadband

d min. at 15°

vertical

separation

d min. at 60°

vertical

separation

d min. at 30°

vertical

separation

d min. at 75°

vertical

separation

0 – 10 kW 0.4 m 0.2 m 0.4 m 0.2 m

30 kW 1.0 m 0.5 m 1.0 m 0.5 m

50 kW 2.0 m 1.0 m 2.0 m 1.0 m

Page 30

Chapter 2: Installing the system

14 Placing the antenna

The presences of S-band radar(s) are unlikely to cause any performance

degradation – as long as the minimum distances (d min.) listed in the previous

section are applied.

It is strongly recommended that interference free operation is verified

experimentally before the installation is finalized.

Other Inmarsat systems

Recommended minimum safe distance to other Inmarsat antennas is 10 m.

GPS receivers

Good quality GPS receivers will work properly very close to the antenna typically down to one meter outside the main beam, and down to a few meters

inside the main beam. However, simple GPS receivers with poor frequency

discrimination could be affected at longer range (typically 10 m). It is always

recommended to test the GPS performance before the installation is finalized.

Other transmitters

See Minimum distance to transmitters. on page 100 in Appendix B for

minimum recommended distance to transmitters in the frequency range below

1000 MHz.

Other precautions

Do not place the antenna close to a funnel, as smoke deposits are corrosive.

Furthermore, deposits on the radome can degrade performance.

Caution! The antenna must never be installed closer to a radar

than “d min.” - even if experiments show that

interference free operation can be obtained at shorter

distances than “d min.” in the previous section.

Page 31

Chapter 2: Installing the system

Placing the antenna 15

2222

Installing the system

2.2.4 Antenna mast design

Overview

The antenna mast must be designed to carry the weight of the antenna unit,

which is approximately

• 16 kg (+ the weight of the mast flange) for the SAILOR 500 FleetBroadband

antenna and

• 3.9 kg (+ 1.1 kg for the mast mount kit) for the SAILOR 250 FleetBroadband

antenna.

The mast must also be able to withstand onboard vibrations and wind forces

up to 108 knots on the radome, even in icing conditions.

The SAILOR 500 FleetBroadband and SAILOR 250 FleetBroadband antennas

use different methods for mast mounting. The following sections describe the

the two methods separately.

SAILOR®500 FleetBroadband antenna mast flange

The top of the SAILOR 500 FleetBroadband antenna mast should be fitted with

a flange with holes matching the bushes in the radome.

The flange thickness must be at least 10 mm. The antenna is to be mounted on

the flange by means of 4 M10 bolts. The length of the bolts must be such that

they engage into the bushes of the radome with minimum 6 mm and

maximum 12 mm. Drill a hole in the centre of the flange for the antenna cable

and for drainage from the radome. For recommended dimensions of the

flange, see Outline dimensions, SAILOR 500 flange on page 94 in Appendix B.

Important

Avoid sharp edges where the flange is in direct contact with the

radome. Round all edges as much as possible to avoid

damaging the surface of the radome.

Page 32

Chapter 2: Installing the system

16 Placing the antenna

SAILOR®250 FleetBroadband antenna mast mounting

Mast mount kit:

The top of the SAILOR 250 FleetBroadband antenna mast should be fitted with

the dedicated mounting kit, see SAILOR

®

250 FleetBroadband mast mount kit

on page 88.

Assemble the mast mount kit according to the assembly instruction included

with the kit.

The mast mount kit interfaces to a 1½” pipe (OD 48.3 mm). If the supplied

plastic sleeve is omitted, a maximum diameter OD of 52 mm can be used.

Custom mast mounting:

For a custom mast mounting, use 4 M6 bolts (A4) in the threaded bushes on

the 175.4 mm diameter circle in the bottom of the antenna (see outline

drawing SAILOR

®

250 FleetBroadband antenna on page 99). The length of the

bolts must be such that they engage into the bushes of the radome with min.

6 mm and max. 12 mm. No drainage hole is necessary. Drill a hole for the

cable or use an angled connector.

Page 33

Chapter 2: Installing the system

Placing the antenna 17

2222

Installing the system

Mast length and diameter

The placement of the antenna must ensure a rigid structural connection to the

hull or structure of the ship. Parts of the ship with heavy resonant vibrations

are not suitable places for the antenna.

A small platform or short mast shall provide rigid support for the antenna

fastening bolts and a rigid interface to the ship.

If it is necessary to use a tall mast, use the tables on page 19 and page 20 to

obtain the maximum free length of the mast. Note that these values depend on

rigid antenna-ship interfaces. The cross-sectional properties and the

corresponding maximum free length give a natural frequency above 30 Hz.

It is recommended to shorten the mast length as much as possible to obtain

higher frequencies. Alternatively, mount stays or wires to stabilize the mast

further.

Note

The hole in the lower part of the mast is necessary for drainage and

ventilation for the SAILOR 500 FleetBroadband antenna. Please refer

to Condensation, SAILOR

®

500 FleetBroadband on page 24.

Free mast length (m)

OD (mm)

Page 34

Chapter 2: Installing the system

18 Placing the antenna

The tables in the next sections give some suggested design values for the free

part of the mast (shown on the previous page).

High masts or installations on ships with high vibration levels should be

further stabilized by stays or wires from the mast flange. Also mount vibration

isolators between the flange and the radome, as described in Vibration,

SAILOR

®

500 FleetBroadband on page 25. For SAILOR 250 FleetBroadband,

the vibration isolators are included in the Mast mount kit.

Note

The tables list the values for steel masts.

For aluminium masts, the free mast length is reduced to 75% of the

values for steel.

Note

Stays and rigid masts can still not prevent vertical vibration if the

mast is attached to a deck plate that is not rigid. Make every effort to

mount the mast on a surface that is well supported by ribs. If this is

not possible, provide extra deck plate propping.

Page 35

Chapter 2: Installing the system

Placing the antenna 19

2222

Installing the system

SAILOR®500 FleetBroadband antenna mast length

The below table shows the values for a SAILOR 500 FleetBroadband antenna

mast without stays or wires. Note that these values are only guidelines always consider the environment and characteristics of the ship before

deciding on the mast dimensions.

OD

(mm)

Wall

Thickness

(mm)

Weight

(kg/m)

Inertia

(X10

6

mm4)

Max. free mast length

(steel), m

88.9 4.05 8.47 0.974 < 0.9

88.9 4.85 10.1 1.14

100 5 11.7 1.69 < 1.0

101.6 5 11.9 1.77

114.3 4.5 12.1 2.34 < 1.2

114.3 5.4 14.4 2.75

139.7 4.85 16.1 4.68 < 1.4

139.7 5.4 17.9 5.14

165.1 4.85 19.2 7.85 < 1.6

165.1 5.4 21.3 8.65

200

a

a. The diameter of the circle where the bolts are to be mounted on the antenna is

Ø183.8. Since the mast diameter is larger, you must use a tapered end on the

mast, or find other means of accessing the mounting bushes.

52414.6 < 2.0

200

a

10 46.9 27

300

a

7.5 5 4.1 73.75 < 2 .7

300

a

15 105.4 136.7

Page 36

Chapter 2: Installing the system

20 Placing the antenna

SAILOR®250 FleetBroadband antenna mast length

The below table shows the values for a SAILOR 250 FleetBroadband antenna

mast without stays or wires. Note that these values are only guidelines always consider the environment and characteristics of the ship before

deciding on the mast dimensions.

The mast mount kit interfaces to a 1½” tube (OD 48.3 mm - absolute maximum

OD 52 mm). Masts with larger diameters must be tapered and the upper part

of the tube (approximately 50 mm) must have a diameter of 1½”.

OD

(mm)

Wall

Thickness

(mm)

Weight

(kg/m)

Inertia

(X10

6

mm4)

Max. free mast length

(steel), m

48.3 3.25 3.61 0.117 < 0.6

48.3 4.05 4.43 0.139

50 3.00 3.48 0.123

60.3 3.65 5.10 0.262 <0.8

60.3 4.50 6.17 0.309

76.1 3.65 6.80 0.547 < 1.0

76.1 4.50 7.90 0.651

88.9 4.05 8.47 0.974 < 1.1

88.9 4.85 10.10 1.140

Page 37

Chapter 2: Installing the system

Installing the antenna 21

2222

Installing the system

2.3 Installing the antenna

2.3.1 Antenna grounding

You may ground the antenna using the mounting bolts.

If the antenna cannot or should not be electrically connected directly to the

mounting surface, you can use a separate grounding cable to make the

connection between the antenna and the common ground to which the

terminal is also connected. For example, you can connect a separate

grounding cable when vibration isolators are used at the mounting bolts.

To obtain a good ground connection, the metal underneath the head of at

least one bolt must be clean of insulating protective coating and a serrated

washer should be used. After tightening the bolts we recommend that you seal

the area suitably in order to avoid corrosion of the grounding point.

Use stainless steel bolts and washers.

For further grounding information read Appendix C Grounding and RF

protection on page 109.

2.3.2 Antenna cables

Guidelines

A coaxial cable for connection between the antenna and terminal is delivered

with the system. If you need a different cable, make sure that the cable meets

the requirements. Preferably choose one of the cable types in Recommended

antenna cables on page 22.

Select a suitable area for installation of the terminal, antenna and cradle.

Where the cables are exposed to mechanical wear - on deck, through

bulkheads, etc. - protect the cables with steel pipes. Otherwise, follow

standard procedures for cabling in ship installations.

The maximum allowed RF-loss in the antenna cable is 20 dB at 1660 MHz. This

is to ensure the performance of the system.

Page 38

Chapter 2: Installing the system

22 Installing the antenna

Recommended antenna cables

The table below shows recommended cable types and maximum cable lengths

for both SAILOR 500 FleetBroadband and SAILOR 250 FleetBroadband.

Check in the data sheet from the cable supplier that both the RF- attenuation

and the DC-resistance are kept within the maximum specified values:

• Antenna cable RF-attenuation max: 20 dB incl. connector at L-band.

• Antenna cable modem-attenuation max: 4 dB at 54 MHz, 3 dB at 36 MHz.

• Antenna cable loop DC-resistance max: 1 Ω.

Also ensure that the specified minimum bending radius is respected. If this is

not the case, the loss in the cable will increase. Check the instruction from the

cable supplier.

Cable Type Absolute maximum length

G02232-D 6 m

RG223-D 25 m

RG214/U 50 m

S 07272B-05 95 m

Page 39

Chapter 2: Installing the system

Installing the antenna 23

2222

Installing the system

2.3.3 Important mounting notes

Line of sight

Place the antenna with free line of sight in all directions to ensure proper

reception of the satellite signal. Do not place the antenna close to large

objects that may block the signal.

Water intrusion

After having connected the antenna cable to the antenna - ensure that the

connector assembly is properly protected against seawater and corrosion. As a

minimum, use self-amalgamating rubber.

If possible, install the radome such that direct spray of sea water is avoided.

It is recommended not to use pneumatic tools for cleaning the radome,

specially at a short distance and directly at the split between top and bottom.

Make sure the requirements to drainage are met. See Condensation,

SAILOR

®

500 FleetBroadband on page 24.

Page 40

Chapter 2: Installing the system

24 Installing the antenna

Condensation, SAILOR®500 FleetBroadband

In some cases there will be condensation inside the radome. The gasket in the

bottom center of the SAILOR 500 FleetBroadband antenna is designed to lead

any water away from the radome.

Make sure this draining gasket is not blocked. If the antenna is mounted on a

pole, make sure the pole is hollow inside and open at the bottom, allowing

water from the gasket to escape and providing ventilation for the antenna.

If the antenna is mounted on a flat surface, use 10 mm spacers (washers) at

each bolt so that the gasket in the center of the antenna bottom is free and

water can escape.

Gasket with drainage

10 mm spacer

Antenna bottom

Page 41

Chapter 2: Installing the system

Installing the antenna 25

2222

Installing the system

Vibration, SAILOR®500 FleetBroadband

Install the antenna where vibrations are limited to a minimum. If you cannot

avoid heavy vibrations, we recommend using vibration isolators between the

hull/mast and the radome. E.g. use Paulstra isolators (530903 11) together

with Paulstra washers. Mount the isolators as shown in the drawings below.

Always use all 4 screws when installing. It is recommended to use screws of

A4 quality / stainless steel.

Note

The mounting bolts alone cannot be used for grounding the antenna

when the isolators are mounted. If the antenna should be grounded,

you can use a separate grounding cable. For further information, see

Grounding and RF protection on page 109.

Page 42

Chapter 2: Installing the system

26 Installing the antenna

2.3.4 Mounting the antenna

Overview

The radome can now be installed on the ship with 4 stainless steel bolts

fastened to the hull or to a mast.

For information on mast mounting, see Antenna mast design on page 15.

Mounting the SAILOR®500 FleetBroadband antenna onto the hull

Make sure the antenna has line of sight to the satellites. When the antenna is

mounted directly on the hull, it may be difficult to obtain line of sight,

especially down to -25°, which is the maximum rotation angle (pitch and roll)

for the SAILOR 500 FleetBroadband antenna.

Use M10 bolts for mounting the SAILOR 500 FleetBroadband antenna.

The bolt thread must not penetrate more than 12 mm (or 8 turns of the bolt) and not less than 6 mm (or 4 turns of the bolt)- into the threaded part of the

bushes in the radome. Fasten the bolts with 25 ±5 Nm torque.

The only electrical connector is a single N-connector in the center bottom of

the radome.

Mounting the SAILOR®250 FleetBroadband antenna onto the hull

Make sure the antenna has line of sight to the satellites. When the antenna is

mounted directly on the hull, it may be difficult to obtain line of sight,

especially down to -60°, which is the maximum rotation angle (pitch and roll)

for the SAILOR 250 FleetBroadband antenna.

Use M6 bolts for mounting the SAILOR 250 FleetBroadband antenna.

The bolt thread must not penetrate more than 12 mm (or 8 turns of the bolt) and not less than 6 mm (or 4 turns of the bolt)- into the threaded part of the

bushes in the radome. Fasten the bolts with 7-8 Nm torque.

The only electrical connector is a single TNC-connector in the bottom of the

radome.

Page 43

Chapter 2: Installing the system

Placing the terminal 27

2222

Installing the system

2.4 Placing the terminal

2.4.1 Where to place the terminal

Temperature conditions

The terminal must be placed in a ventilated area with free space around all

sides of the unit, except the bottom side.

Ambient temperature range is –25° to +55°C.

If the terminal is installed in a location where the ambient temperature may

exceed 50°C, we recommend placing the terminal where unintentional contact

is avoided. If the maximum ambient temperature does not exceed 50°C, the

terminal can be placed in a public area.

Grounding access

The terminal is designed with a cabinet for bulkhead or desktop installation.

The cabinet is equipped with mounting brackets, making it possible to secure

the unit on a bulkhead.

See Outline dimensions, terminal on page 104 in Appendix B.

Important

The terminal must be placed in an area where access to the

hull or equivalent grounding can be reached within 0.5 m.

Page 44

Chapter 2: Installing the system

28 Installing the terminal

2.5 Installing the terminal

2.5.1 Grounding the terminal

Antenna cable

The antenna is connected to the terminal by means of a coax cable.

For the SAILOR 500 FleetBroadband antenna the coax cable is connected with

a TNC connector at the terminal end and an N connector at the antenna end.

For the SAILOR 250 FleetBroadband antenna the coax cable is connected with

a TNC connector at both ends.

For information on antenna grounding, see Antenna grounding on page 21.

At the terminal end, it is strongly recommended to ground the antenna cable.

• If you are using the Extended cable support for the terminal the TNC

connector is grounded through the cable support, which must be

connected to the hull or other common ground. For further information on

the Extended cable support, see Mounting the Extended cable support on

page 33.

• If you are not using the Extended cable support, it is still strongly

recommended to connect the antenna cable to common ground at the

terminal end. Use a short coax cable from the terminal to the grounding

point, where the short cable is connected to the antenna cable.

Page 45

Chapter 2: Installing the system

Installing the terminal 29

2222

Installing the system

Ground stud

To ensure that the terminal is grounded – also if the cable is disconnected

from the terminal, connect an extra ground wire to the ground stud on the

terminal. This ground wire must be a heavy wire or braid cable with a larger

diameter than the coax cable. The ground stud is located next to the power

switch.

Extending the ground plane

In some cases it is not possible to access the hull and at the same time place

the terminal in a suitable place.

A way to insure good grounding and at the same time make it possible to

ground the coax cable - is to extend the ship ground plane by means of copper

foil. The maximum length of the foil is determined by the width of the foil.

Copper foil 5 cm wide: Max 50 cm

Copper foil 10 cm wide: Max 100 cm

Copper foil 20 cm wide: Max 200 cm

Ground stud

Note

The foil must be at least 0.1 mm thick.

Page 46

Chapter 2: Installing the system

30 Installing the terminal

Connect the foil to the hull by plenty of screws or hard–soldering. Run the foil

past the place where the short antenna cable is to be grounded and mount the

grounding kit on top of the foil.

For further grounding information read Appendix C Grounding and RF

protection on page 109.

2.5.2 Cable support systems

Thrane & Thrane offers two cable support systems.

•The Basic cable support comes with the terminal as part of the delivery. It

is a simple system to which you can secure your cables using cable strips.

For information on how to mount the Basic cable support, see the next

section Mounting the Basic cable support.

•The Extended Cable support is longer than the Basic cable support, and

has connectors for the cables, providing a better ground connection. For

information on how to mount the Extended cable support, see Mounting

the Extended cable support on page 33.

Page 47

Chapter 2: Installing the system

Installing the terminal 31

2222

Installing the system

2.5.3 Mounting the Basic cable support

The Basic cable support comes with the terminal as part of the delivery.

When mounted on the terminal the Basic cable support offers a number of

holders to which you can secure the cables from the terminal, using cable

strips.

To mount the Basic cable support, do as follows:

1. Remove the two rubber feet from the bottom of the terminal at the

connector panel end. The mounting bushes are underneath the rubber

feet.

Page 48

Chapter 2: Installing the system

32 Installing the terminal

2. Fasten the Basic cable support to the two mounting bushes close to the

connector panel on the terminal, using two M4 x 6 mm countersunk

screws.

3. Install the terminal as described in Installing the terminal on a bulkhead

on page 34 or Installing the terminal on a desktop on page 36.

Page 49

Chapter 2: Installing the system

Installing the terminal 33

2222

Installing the system

2.5.4 Mounting the Extended cable support

The Extended cable support is available

from Thrane & Thrane. For part number,

see Cable support on page 88.

The Extended cable support offers

connectors and grounding for the

antenna cable, as well as a number of

holders to which you can secure the

cables from the terminal, using cable

strips.

To mount the Extended cable support, do

as follows:

1. Fasten the cable support to the terminal from the bottom, using the screws

in the Extended cable support kit.

2. Install the terminal with the cable support as described in the following

sections.

Page 50

Chapter 2: Installing the system

34 Installing the terminal

2.5.5 Installing the terminal on a bulkhead

Terminal with no cable support

Do as follows to mount the terminal on a bulkhead:

1. Insert four screws through the holes in the mounting bracket and into the

mounting surface. If the mounting surface is used for grounding, make

sure that you have a good electrical connection to the surface.

2. Connect all cables.

Make sure that the grounding requirements are met. See Grounding and

RF protection on page 109.

Page 51

Chapter 2: Installing the system

Installing the terminal 35

2222

Installing the system

Terminal with Basic cable support

First mount the Basic cable support on the terminal as described in Mounting

the Basic cable support on page 31.

1. Mount the terminal with the Basic cable support on the bulkhead by

inserting four screws through the holes in the mounting bracket and into

the mounting surface.

2. Connect all cables.

Make sure that the grounding requirements are met. See Grounding and

RF protection on page 109.

3. Secure the cables to the cable support using cable strips.

Terminal with Extended cable support

First mount the Extended cable support on the terminal as described in

Mounting the Extended cable support on page 33.

1. Mount the Extended cable support with the terminal on the bulkhead by

inserting six screws through the holes in the Extended cable support and

into the mounting surface.

2. Connect the short cables between the terminal and the cable support.

3. Connect all other cables.

Make sure that the grounding requirements are met. See Grounding and

RF protection on page 109.

4. Secure the cables to the cable support using cable strips.

Page 52

Chapter 2: Installing the system

36 Installing the terminal

2.5.6 Installing the terminal on a desktop

Four rubber feet make the terminal well suited for desktop installation. Simply

place the terminal on a desktop and connect all cables. Make sure the

grounding requirements are met. See Grounding and RF protection on

page 109.

If required, fasten the terminal to the desktop with four screws, as described in

the previous section Installing the terminal on a bulkhead.

Page 53

37

Chapter 3

3333

Connecting power

Connecting power 3

3.1 Power source

There are different options for the power supply:

• The 24 V DC ship supply provides power for the terminal.

• A 12 V DC supply provides power for the terminal. Be aware that the

maximum allowed source impedance is much lower for a 12 V DC supply

than for a 24 V DC supply.

• A 230 V AC supply provides power through an AC/DC power supply.

Be aware of high start-up peak current: 20 A at 24 V, 5 ms.

The terminal is equipped with an internal 20 A Fuse, so no external fuse is

necessary in order to protect the terminal. However, in order to avoid short

circuit in the power cable/connector, the ships DC outlet should be protected

by a 30 A fuse or circuit breaker.

Page 54

Chapter 3: Connecting power

38 Power cable selection

3.2 Power cable selection

3.2.1 Source impedance

The length of the terminal power cable depends on the type of cable used and

the source impedance of the ship’s DC power installation.

The maximum allowed source impedance depends on the utilization of the

power range of the terminal DC input (10.5 - 32 V DC; 14 - 5.5 A).

Select a power outlet from the ship’s DC system, and measure the source

impedance of the ship installation as described in Measuring the ship source

impedance on page 107 in Appendix B.

For further recommendations on power cable selection, see the next section.

Note

If the total source impedance is higher than the limits stated in this

section, the terminal may start to on/off oscillate.

Page 55

Chapter 3: Connecting power

Power cable selection 39

3333

Connecting power

3.2.2 Power cable recommendations

Overview

The terminal is delivered with a power cable, which can be extended

according to the recommendations below:

When extending the power cable, positive and negative supply wires must be installed

closely together side by side to keep cable inductance low.

Ensure that cable inductance for the selected cable at the desired length is below the

50 μH requirement.

If you are going to use the Remote on/off function, also extend the two wires (green

and orange) used for this function. For further information, see Remote on/off on

page 43.

Red: +

Black: -

Page 56

Chapter 3: Connecting power

40 Power cable selection

Calculating the maximum power cable extension

For 24 V DC operation, the total impedance must be max. 500 mΩ, including

the ship’s source impedance.

For 12 V DC operation, the total impedance must be max. 85 mΩ, including

the ship’s source impedance.

The total impedance is made up of the following:

• the ship’s source impedance

• the cable impedance of the supplied power cable, including the

impedance in the joint of the two cables. In the following example, the

impedance of the cable and joint is set to 10 mΩ (1 m power cable). Note

that if the cable length or type is changed, the impedance will change

accordingly.

• the extension cable impedance.

To calculate the maximum cable extension, do as follows:

1. First measure the ship’s source impedance as shown in Measuring the

ship source impedance on page 107.

2. Then find the resistance per meter for the cable type you are going to use.

For 4 mm

2

/AWG 11, the value is 4 mΩ/m at 20°C

For 1.5 mm

2

/AWG 15, the value is 10 mΩ/m at 20°C

For other cable types, refer to the data sheet for the cable.

3. Calculate the maximum allowed impedance in the extension cable as

follows:

Max. allowed impedance in extension cable = max. total impedance (measured source impedance + impedance of the supplied cable).

4. Then calculate the max. extension cable length as follows:

Max. impedance in extension cable (from

step 3)

Max. length = 0.5 x impedance/meter (from step 2)

The length is multiplied by 0.5 above because there are two conductors in

the cable. If you need more length, you can double the maximum allowed

Page 57

Chapter 3: Connecting power

Power cable selection 41

3333

Connecting power

length by connecting two cables in stead of one, or you can use a cable

with a larger diameter.

Example:

Ship supply voltage: 12 V DC

Ship source impedance (measured): 50 mΩ

Extension cable type: 4 mm

2

(AWG 11)

85 m

Ω - (50 mΩ + 10 mΩ)

Max. cable extension = 0.5 x 4 mΩ/m = 3.12 m

Page 58

Chapter 3: Connecting power

42 To connect power

3.3 To connect power

Do as follows:

1. Connect the power cable to the ship’s 24 V DC supply according to the

recommendations in the previous section.

2. Connect the D-sub connector on the power cable to the DC input connector

on the terminal.

For information on pin-out, see DC power input on page 47.

For specifications of the DC input on the terminal, see SAILOR FleetBroadband

terminal on page 101.

Note

If you need a remote on/off function, connect the wires from pin

2 (green wire) and 5 (orange wire) in the power connector to a

switch or similar which can connect/disconnect these two pins.

See the next section for details.

Page 59

Chapter 3: Connecting power

Remote on/off 43

3333

Connecting power

3.4 Remote on/off

The terminal has a remote on/off function. When the terminal power switch is

in the “on” position you can remote control the power function.

By installing a switch that can short-circuit the “Remote on/off” pins (2 and 5)

in the power connector you can power the terminal on or off with this “remote

switch”.

When pins 2 and 5 are not short-circuited and valid input power is present the

terminal is powered on, provided the Power switch is in the “on” position.

For pin-out for the power connector and a description of the wire colors in the

power cable, see Pin-out on page 48.

Page 60

Chapter 3: Connecting power

44 Remote on/off

Page 61

45

Chapter 4

4444

Hardware interfaces

Hardware interfaces 4

4.1 The connector panel

The connector panel is placed at one end of the terminal and has the following

connectors:

• 1 L-Band connector for reception of maritime data

• 1 Antenna connector (TNC)

• 2 Phone/Fax connectors

• 1 ISDN connector

• 4 LAN connectors with Power over Ethernet (PoE)

• 1 DC power input connector for connection to 10.5-32 V DC, with remote

on/off

• 1 Input/Output connector with 5 inputs/outputs for external control or

signaling

• 1 ground stud with wing nut

For information on how to connect to a specific interface, see the next

sections.

Page 62

Chapter 4: Hardware interfaces

46 Antenna interface on terminal

4.2 Antenna interface on terminal

4.2.1 Overview

The antenna interface on the terminal connects to the TT-3052A antenna in

the SAILOR 500 FleetBroadband system or to the TT-3050A antenna in the

SAILOR 250 FleetBroadband system.

The antenna connector on the terminal is a TNC female connector placed in

the connector panel.

For information on cables and how to install and connect the antenna, see

Installing the antenna on page 21.

4.2.2 Pin-out

The below drawing shows the TNC female connector in the terminal.

Signal

GND

Page 63

Chapter 4: Hardware interfaces

DC power input 47

4444

Hardware interfaces

4.3 DC power input

4.3.1 Overview

The DC power input for the terminal is a 10.5 - 32 V DC; 14 - 5.5 A input with a

remote on/off function. The input is protected against reverse polarity. For

information on power recommendations and how to connect, see Connecting

power on page 37. The power connector is a D-sub connector placed in the

connector panel.

Page 64

Chapter 4: Hardware interfaces

48 DC power input

4.3.2 Pin-out

The power connector is a Mixed D-Sub connector 7W2, control pin male /

power pin male. The below table shows the pin-out for the connector and the

colors of the corresponding wires.

Pin

number

Pin function

Color of wire in

power cable

A1 Vin+ Red

A2 Vin- Black

1 not connected (Black)

2 Remote on/off Green

3 not connected (Brown)

4 not connected (Red)

5 Remote on/off Orange

2 1

5 4 3

A2 A1

Mixed D-Sub connector,

7W2, male

Page 65

Chapter 4: Hardware interfaces

Ground stud 49

4444

Hardware interfaces

4.4 Ground stud

The terminal has a ground stud with a wing nut. The ground stud is located in

the connector panel and is used for grounding the terminal.

For information on how to ensure proper grounding of the terminal, see

Grounding the terminal on page 28 and Grounding and RF protection on

page 109.

Page 66

Chapter 4: Hardware interfaces

50 Analog Phone/Fax interface

4.5 Analog Phone/Fax interface

4.5.1 Overview

The terminal has two RJ-11 ports, which can be used for connection of analog

phones, fax machines or analog modems.

4.5.2 Pin-out

The Phone/Fax connectors are RJ-11, 6/4 female connectors. The table and

figure below show the pin-out for the connectors.

Phone/Fax 2

Phone/Fax 1

Pin number Pin function

1-

2 not connected

3Tip

4 Ring

5 not connected

6 -

123456

RJ-11 female connector

Page 67

Chapter 4: Hardware interfaces

ISDN interface 51

4444

Hardware interfaces

4.6 ISDN interface

4.6.1 Overview

The terminal has one ISDN connector for connecting an ISDN phone or an

ISDN modem. The ISDN interface supports 56/64 kbps data rate. It is

configured as the network side, i.e. Rx is an input and Tx is an output.

Page 68

Chapter 4: Hardware interfaces

52 ISDN interface

4.6.2 Pin-out

The figure and table below show the connector outline and pin assignments.

Pin number Pin function

1 not connected

2 not connected

3 Rx+ (c) input

4 Tx+ (d) output

5 Tx- (e) output

6 Rx- (f) input

7 not connected

8 not connected

RJ-45 female connector

Page 69

Chapter 4: Hardware interfaces

LAN interface 53

4444

Hardware interfaces

4.7 LAN interface

4.7.1 Overview

The terminal has four Ethernet LAN ports with Power over Ethernet (PoE). The

Ethernet ports are standard IEEE 802.3 af ports using RJ-45 connectors.

4.7.2 Power over Ethernet (PoE)

One power supply powers all four interfaces with a floating 48 V DC supply

(44 - 57 V DC). Therefore, the interfaces are not galvanically separated from

each other. All Tx signals are DC connected to the Positive PoE Voltage and all

Rx signals to the Negative PoE Voltage.

The total output power from all 4 interfaces is set to 61.2 Watt, so all interfaces

can support devices of power class 1, 2 and 3 (4, 7 and 15.4 Watt).

In case of power hold-up (failure on input power), PoE will be turned off.

Page 70

Chapter 4: Hardware interfaces

54 LAN interface

4.7.3 Pin-out

The figure and table below show the connector outline and pin assignments.

4.7.4 Connecting an IP handset

To connect the Thrane & Thrane IP handset to the terminal, do as follows:

Connect the cable from the IP cradle to one of the LAN connectors on the

terminal. For information on how to install the IP handset, refer to the user

manual for the handset.

The cable between IP cradle and terminal must be maximum 80 m.

Pin number Pin function

1TxD+ input

(positive PoE)

2 TxD-input

(positive PoE)

3RxD+ output

(negative PoE)

4 not connected

5 not connected

6 RxD- output

(negative PoE)

7 not connected

8 not connected

RJ-45 female connector

Note

If you insert a switch or similar between the cradle and the terminal,

make sure that it conforms to the industry standard IEEE 802.3 af

(using data pairs).

Page 71

Chapter 4: Hardware interfaces

Discrete I/O interface 55

4444

Hardware interfaces

4.8 Discrete I/O interface

4.8.1 Overview

The terminal has an I/O connector with 5 configurable inputs/outputs.

The connector is a WieCon Type 8513S connector.

A mating I/O connector is included in the delivery.

Page 72

Chapter 4: Hardware interfaces

56 Discrete I/O interface

4.8.2 Pin-out

The figure and table below show the connector outline and pin assignments.

Pin number Connection Default configuration

a

a. The default functions of the I/O pins are described in the next section.

1 GPIO 1 Radio silence acknowledge

output, active high

2 GPIO 2 Mute input, active high

3 GPIO 3 Radio silence input, active

high

4 GPIO 4 Ringer output, active high

5 GPIO 5 Ignition input

6 Chassis GND

7 DC out 9-15 V DC, 50 mA

8 DC in (ignition input)

12345678

WieCon Type 8513S connector

Page 73

Chapter 4: Hardware interfaces

Discrete I/O interface 57

4444

Hardware interfaces

4.8.3 Default configuration of I/O pins

The built-in web interface of the terminal offers a page for configuring the I/O

pins.

The default configuration of the I/O pins is as follows:

• Pin 1: Radio silence acknowledge output.

This pin changes state from low to high as soon as deregistration

completes and transmission has stopped as a result of activating pin 3.

• Pin 2: Mute input.

When high (active) the terminal is muted so that the Phone/Fax interface,

the ISDN interface and the IP handsets do not ring, and the Ringer output

on pin 4 is silenced as well. The IP handset is allowed to indicate ringing

in the display. When the pin is low, the terminal is in normal operation.

• Pin 3: Radio silence input.

When high (active) the terminal observes Radio Silence. The terminal

gracefully closes all open connections, and deregisters from the BGAN

network. No transmission is allowed until the pin is deactivated.

• Pin 4: Ringer output.

This pin changes state from low to high when the terminal is notified of an

incoming call from the satellite interface. When the call is answered, or

the caller gives up and releases the call, the pin changes back to low.

• Pin 5: Ignition input.

Normally not used in maritime installations. Use Remote on/off in the

power connector instead.

Pin 7 (non-configurable): Apart from the 5 configurable inputs/outputs, the DC

connector has an additional output pin, pin 7 DC output, which can be

connected to a ringer, relay or similar. The output voltage is 9-15 V, 50 mA.

For information on how to configure the I/O pins, see the user manual for the

SAILOR 500 FleetBroadband and SAILOR 250 FleetBroadband systems.

Page 74

Chapter 4: Hardware interfaces

58 L-Band interface

4.9 L-Band interface

4.9.1 Overview

The terminal has an L-Band output for automatic delivery of maritime

broadcast data. Use a coax cable with an SMA connector to connect a

broadcast receiver for maritime data to the L-band output.

4.9.2 Pin-out

The figure below shows the pin-out for the SMA female connector.

Signal

GND

Page 75

59

Chapter 5

5555

Starting up the system

Starting up the system 5

5.1 Using the SIM card

5.1.1 Inserting the SIM card

The SIM card is provided by your Airtime Provider. Insert the SIM card as

follows:

1. Open the SIM cover in the left

side of the connector panel.

2. Insert the SIM card into the SIM

slot.

Place the card with the gold-

plated side facing up as shown.

3. Press gently until it clicks.

4. Slide the lock in front of the

SIM card.

5. Close the cover for the SIM slot.

Page 76

Chapter 5: Starting up the system

60 Using the SIM card

Removing the SIM card

Remove the SIM card as follows:

1. Open the SIM cover in the left

side of the connector panel.

2. Slide the lock aside.

3. Gently push the SIM card and

let it pop out.

4. Remove the SIM card and

close the cover for the SIM

slot.

Note

When the SIM card is removed, you cannot use the BGAN menu of

the IP handset nor make calls or start data sessions.

Only emergency calls are allowed, and only if permitted by the

network.

However, if you have an administrator user name and password, you

can upload software using the web interface without having a SIM

card. For further information, see the user manual.

Page 77

Chapter 5: Starting up the system

Powering the system 61

5555

Starting up the system

5.2 Powering the system

5.2.1 Switching the terminal on

To switch on the terminal, use

the Power switch in the

connector panel It normally

takes one or two seconds for the

terminal to switch on.

5.2.2 Switching the terminal off

To switch off the terminal, change the position of the Power switch again.

5.2.3 Remote on/off

Alternatively, you may use the Remote on/off function. In this case, leave the

power switch in the On position and switch off the terminal remotely using a

switch or similar connected to the Remote on/off pins in the DC power

interface. For further information, see Remote on/off on page 43.

Caution! When the system is powered on, stay clear of the

antenna! The antenna emits radio frequency energy, not

only when the system is used. Always keep a minimum

distance of 1.3 m from the SAILOR 500 FleetBroadband

antenna and 0.6 m from the SAILOR 250 FleetBroadband

antenna.

Note

Wait at least 5 seconds after power off, before trying to power on the

system again.

Page 78

Chapter 5: Starting up the system

62 Entering the SIM PIN for the terminal

5.3 Entering the SIM PIN for the terminal

5.3.1 Overview

You normally have to enter a PIN to use the system. You can enter the PIN

using a standard or ISDN phone, the IP handset or the web interface.

For information on how to connect the handset or computer you are going to

use, refer to the user manual.

5.3.2 Entering the PIN using a phone or IP handset

If you have a phone connected to the terminal, you can use it to enter the PIN

at start up.

Do as follows:

Dial the PIN the same way you would dial a phone number:

• For an analog or ISDN phone:

Pick up the phone. When the terminal is waiting for a PIN, you will hear 2

beeps - pause - 2 beeps - etc.

Dial <PIN> followed by #.

When you hear a “busy” tone or a dialing tone, the PIN has been accepted

and you can hang up or dial a number.

• For an IP handset:

Select the BGAN menu, enter the user name and password for the

terminal. Then enter the PIN for the terminal.

Wrong PIN

Analog phone or ISDN phone: If, instead of the busy tone or dialing tone, you

continue to hear 2 beeps - pause - 2 beeps - etc., it means the PIN was not

accepted. Check that you have the correct PIN and try again.

If a wrong PIN has been entered three times, you will hear 3 beeps - pause - 3

beeps - etc. This means you have to enter the PUK (PIN Unblocking Key)

provided with your SIM card.

Page 79

Chapter 5: Starting up the system

Entering the SIM PIN for the terminal 63

5555

Starting up the system

After entering the PUK, you must enter a new PIN of your own choice (4 to 8

digits long).

Dial the following:

<PUK> * <New PIN> * <New PIN> followed by # or off-hook key.

Example: If the PUK is 87654321 and the new PIN is 1234, dial

87654321 * 1234 * 1234 followed by # or off-hook key.

If you enter 10 wrong PUKs, the SIM card will no longer be functional. Contact

your Airtime Provider for a new SIM card.

IP handset: After having entered the user name and password for the terminal

You have 3 attempts to enter the terminal PIN, before you are asked to enter

the PUK (Pin Unblocking Key). The PUK is supplied with your terminal SIM

card.

Enter the PUK followed by a new PIN of your own choice. The PIN must be

from 4 to 8 digits long.

If you enter a wrong PUK 10 times, the SIM card will no longer be functional,

and you have to contact your BGAN Airtime Provider for a new SIM card.

Entering the PIN using the web interface

If the PIN has not yet been entered when you start up the web interface, the

start-up page will be the PIN page. Enter the PIN and click OK.

For further information on how to enter the PIN using the web interface, see

the user manual.

Page 80

Chapter 5: Starting up the system

64 Operating the system

5.4 Operating the system

5.4.1 General use

The user manual for the SAILOR FleetBroadband systems describes general

use of the system and goes through all the functions of the web interface. It

also contains a brief description of how to use the Thrane & Thrane IP handset

with the terminal.

5.4.2 User interfaces

Overview

The main user interfaces for operation of the system are

• the built-in web interface

• the Thrane & Thrane IP handset

Built-in web interface

The built-in web interface is used for easy configuration and daily use. You

access the web interface from a computer connected to the terminal, using an

Internet browser. No installation of software is needed.

An Administrator password is required to access advanced configuration of

the system.

For further information on the web interface, refer to the user manual for the

SAILOR FleetBroadband systems.

IP handset

Apart from the standard functions of an IP handset, the Thrane & Thrane IP

handset contains a display menu for setting up and using the

SAILOR FleetBroadband system. For further information on the Thrane &

Thrane IP handset, refer to the user manual for the IP handset.

Page 81

65

Chapter 6

6666

Service and repair

Service and repair 6

6.1 Introduction

The Thrane & Thrane SAILOR FleetBroadband systems are designed to operate

without preventive routine maintenance.

Although the system is designed and built very service friendly, we strongly

recommend that any acting service technician is trained specifically on the

product. Repair or repair attempts performed by unqualified personnel may

limit the warranty. The warranty on the system is defined and outlined by the

distributor that supplied the system.

For further information on warranty and service, you may also use the Thrane

& Thrane home page at http://www.thrane.com.

6.2 Replacing modules

6.2.1 Overview

We do not recommend repairing the terminal on board the ship. Replace the

defective unit and have it repaired at a qualified workshop on shore.

Some of the modules in the SAILOR 500 FleetBroadband antenna can be

replaced. See the next sections for details.

Page 82

Chapter 6: Service and repair

66 Replacing modules

6.2.2 Modules in the SAILOR®500 FleetBroadband antenna

Remove the top of the radome to access the antenna modules.

The electronic part of the antenna consists of a number of modules.

The following modules are available as spare parts. See Appendix A.

• HPA Module (High Power Amplifier)

• ATB/LNA Module (Antenna Tracking Board/Low Noise Amplifier)

• GPS module (Global Positioning System)

HPA module

GPS module

ATB/LNA module

Page 83

Chapter 6: Service and repair

Replacing modules 67

6666

Service and repair

6.2.3 High Power Amplifier (HPA)

Removing the HPA module

To remove the HPA from the antenna, do as follows:

1. Disconnect the six plugs indicated in the drawing below. Remember to

release connector latches on the connectors. Do not pull the wires - pull