Page 1

S.P. RADIO A/S

AALBORG

DENMARK

TECHNICAL MANUAL

FOR

COMPACT HF SSB RE2100

Page 2

Page 3

Please note

Any responsibility or liability for loss or damage in connection with the use of this product and the

accompanying documentation is disclaimed.

The information in this manual is furnished for informational use only, is subject to change without

notice, may contain errors or inaccuracies, and represents no commitment whatsoever.

This agreement is governed by the laws of Denmark.

Doc. no.: M2100GB Issue: B/0401

Page 4

Page 5

RE2100

CONTENTS

1 GENERAL INFORMATION

1.1 INTRODUCTION 1-1

1.2 DESCRIPTION OF SAILOR HF SSB PROGRAMME 1-1

1.3 GENERAL DESCRIPTION OF SAILOR HF SSB RE2100 1 - 2

1.4 TECHNICAL DATA

(complies with SOLAS, ITU, CEPT, MPT, DOC, FTZ, KSR, FCC) 1-3

1.5 CONTROLS 1-5

1.6 PRINCIPLE OF OPERATION 1-7

2 INSTALLATION

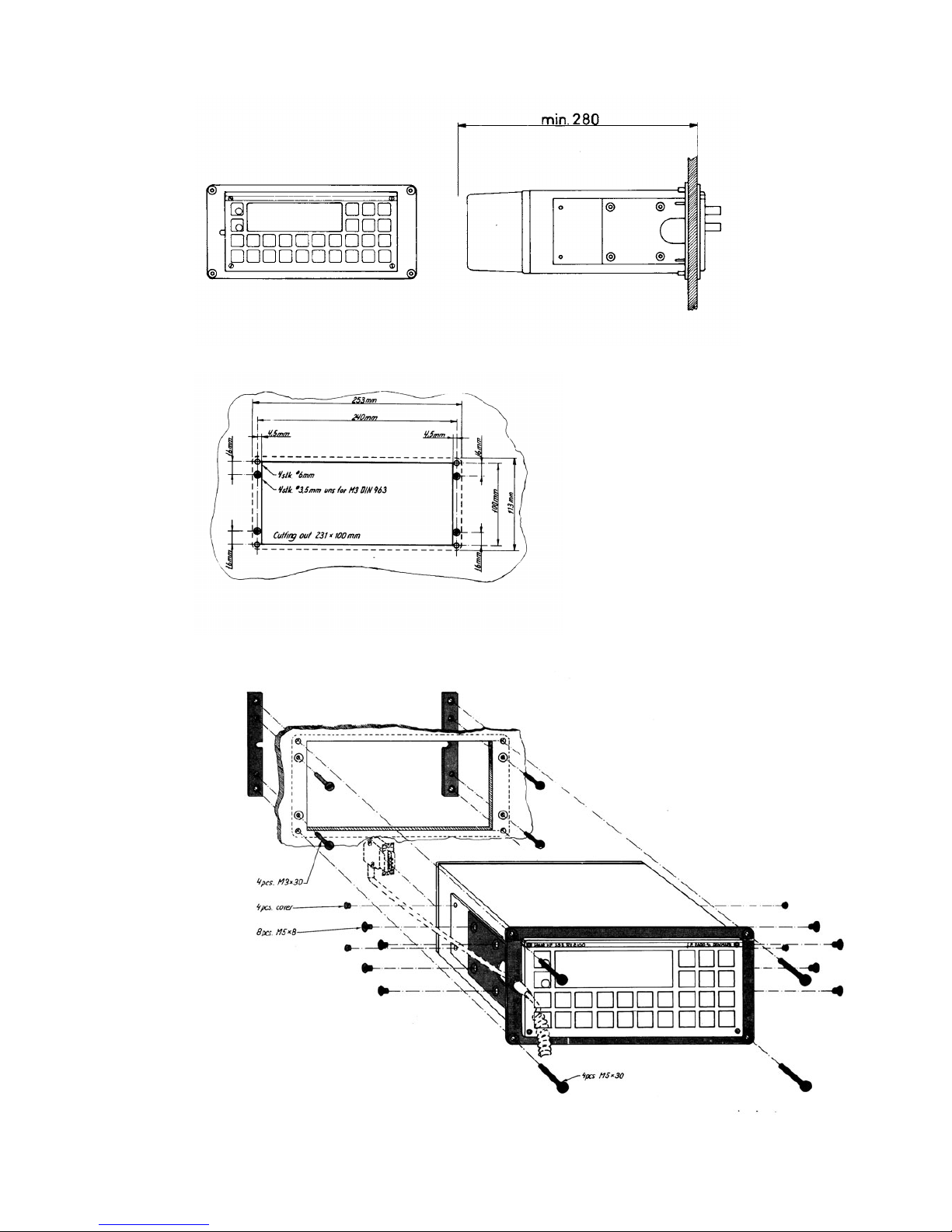

2.1 MOUNTING POSSIBILITIES 2-1

2.2 DIMENSIONS AND DRILLING PLAN 2-3

2.3 ELECTRICAL CONNECTION AND ASSEMBLING 2-8

3 SERVICE

3.1 MAINTENANCE 3-1

3.2 ALIGNMENT INSTRUCTIONS 3-1

3.3 PROPOSAL FOR NECESSARY TEST EQUIPMENT 3-2

3.4 TROUBLE SHOOTING 3-7

3.5 PERFORMANCE CHECK 3-9

3.6 MODULE PERFORMANCE CHECK 3-21

3.7 ADJUSTMENT PROCEDURE 3-47

3.8 NECESSARY ADJUSTMENT AND CHECK AFTER REPAIR 3-56

3.9 FUNCTION CHECK 3-58

3.10 SELECTION AND DESCRIPTION OF THE SERVICE

PROGRAMMES 3-60

4 MECHANICAL DISASSEMBLING AND MODULE LOCATION

4.1 ADJUSTMENTS AND LOCATIONS 4-1

5 CIRCUIT DESCRIPTION AND SCHEMATIC DIAGRAMS

5.1 RECEIVER UNIT (MODULE 1) PART NO. 625631 5-1

5.2 FRONT END UNIT (MODULE 2) PART NO. 625632 5-9

5.3 SYNTHESIZER UNIT (MODULE 3) PART NO. 625633 5-13

5.4 EXCITER UNIT (MODULE 4) PART NO. 625634 5-23

5.5 PROCESSOR UNIT (MODULE 5) PART NO. 625635 5-29

5.6 KEYBOARD UNIT (MODULE 6) PART NO. 625636 5-35

5.7 DISPLAY UNIT (MODULE 7) PART NO. 625637 5-37

5.8 POWER UNIT (MODULE 8) PART NO. 625638 5-41

5.9 INTERCONNECTION CABLE PLAN 5-45

6 MICROTELEPHONE INSTALLATION

6.1 NORMAL INSTALLATION RE2100 AND C2140 6-3

6.2 NORMAL INSTALLATION RE2100 OR C2140 WITH

2 MICRO TELEPHONES 6-4

6.3 MECHANICAL DIMENSIONS FOR HANDSET 6-5

7 PARTS LIST

Page 6

Page 7

RE2100

CONTENTS

1 GENERAL INFORMATION

1.1 INTRODUCTION 1-1

1.2 DESCRIPTION OF SAILOR HF SSB PROGRAMME 1-1

1.3 GENERAL DESCRIPTION OF SAILOR HF SSB RE2100 1 - 2

1.4 TECHNICAL DATA

(complies with SOLAS, ITU, CEPT, MPT, DOC, FTZ, KSR, FCC) 1-3

1.5 CONTROLS 1-5

1.6 PRINCIPLE OF OPERATION 1-7

Page 8

Page 9

PAGE 1-1

9324

1 GENERAL INFORMATION

1.1 INTRODUCTION

SAILOR Compact HF SSB RE2100 is the control unit in SAILOR Compact HF SSB Programme 2000.

SAILOR Compact HF SSB Programme 2000 is a powerful, advanced, high technology short wave

communication system which is extremely easy to operate.

It has been developed on the basis of S. P. Radio’s many years of experience with short wave

communication equipment.

It has the same high reliability as all SAILOR equipment is known for.

It is extremely easy to operate:

1. Select frequency.

2. Make your call when the tune lamp has been extinguished.

It has been constructed so that it fits in with the other units in the SAILOR Compact Programme 2000.

1.2 DESCRIPTION OF SAILOR HF SSB PROGRAMME

The SAILOR HF SSB programme is designed to meet all requirements within HF radio communication.

The SAILOR HF SSB programme consists of one main control unit and three transmitters with different

power levels (250W, 600W, 1200W PEP).

To obtain maximum performance, the systems are designed with aerial couplers, which can be mounted

outdoors. All the aerial couplers have automatic tuning.

Each of these three systems can be extended with:

- remote control units C2140

- telex/DSC sscanning receiver with built-in modem RM2151

- DSC MF/HF watchkeeping receiver with built-in modem RM2150

- duplex receiver R2120

The system may be supplied for 24V DC or 110/220V AC power source.

For the system there are following battery chargers available:

- 30 amp battery charger N2174

- 3 x 30 amp battery charger 2 x N2174

- 60 amp battery charger N2174 Dual

These battery chargers can be used to charge maintenance free lead-acid batteries and Nickel Cadmium

batteries.

The 600W PEP and 1200W PEP transmitters and power supplies are built up of the following units:

RE2100

Page 10

1 GENERAL INFORMATION RE2100

PAGE 1-2

9324

1) TX control unit, consisting of output filter, power supply, and audio amplifier for RE2100 and the

TX-processor.

2) Power amplifier unit, consisting of a 600W power amplifier.

3) Combiner unit, consisting of power splitter and power combiner.

4) 24V DC power unit, consisting of a 24V DC to 28V and 42V DC switch mode power supply, which

supplies the power amplifier unit.

5) 110/220V AC power supply unit, consisting of a 110/220V AC to 28V DC and 42V DC thyristor

controlled power supply, which supplies the power amplifier unit.

1.3 GENERAL DESCRIPTION OF SAILOR HF SSB RE2100

SAILOR HF SSB RE2100 is an all solid state constructed microcomputer controlled SSB short

wave telephony receiver and exciter.

SAILOR HF SSB RE2100 covers the frequency range from 100 kHz to 30 MHz in receive mode and

from 1.6 MHz to 30 MHz in transmit mode.

SAILOR HF SSB RE2100 can operate in both simplex and semi-duplex.

SAILOR HF SSB RE2100 includes all ITU channels from 4 MHz to 25 MHz.

SAILOR HF SSB RE2100 includes channel scanning facilities.

SAILOR HF SSB RE2100 includes 100 quick select frequency pairs.

SAILOR HF SSB RE2100 has continuous tuning in receive mode.

SAILOR HF SSB RE2100 has clarifier function ±150 Hz in 10 Hz steps.

SAILOR HF SSB RE2100 is fully synthesized and has a high stability reference oscillator (TCXO).

SAILOR HF SSB RE2100 has an easy to read display with red light figures.

SAILOR HF SSB RE2100 has a push-button keyboard offering an attractive tactile feeling and a

safe finger-guide in the metal front. The keyboard is fitted with night-

illumination of the lettering.

SAILOR HF SSB RE2100 has one key operation of the distress frequency 2182 kHz.

SAILOR HF SSB RE2100 has integral two tone alarm signal generator in accordance with SOLAS.

SAILOR HF SSB RE2100 has a special serial input (SP-BUS) enabling RE2100 to communicate

with other units.

Page 11

1 GENERAL INFORMATION RE2100

PAGE 1-3

9324

1.4 TECHNICAL DATA

(complies with SOLAS, ITU, CEPT, MPT, DOC, FTZ, KSR, FCC)

GENERAL

Frequency Range: Receiver: 100 kHz to 30 MHz

Transmitter: 1.6 MHz to 30 MHz

Modes: J3E (USB/LSB), R3E and H3E (AM)

Channel Capacity: 100 user defined quick-select channels and ITU defined channels in the

maritime bands. Each channel contains both RX and TX frequency and

mode settings.

Scanning Facilities: 10 scanning prograammes, each able to contain

128 pairs of frequencies.

Distress Call: Quick selection of 2182 kHz

Built-in two tone alarm: 1300 Hz and 2200 Hz

with a duration of 45 secs.

Operating Temperature Range: -15°C to +55°C

Frequency Stability: Better than 0.34 ppm

Primary Voltage: 24V DC - 10% +30%

Current Drain: Receiver (standby)0.9A

Transmit voice 7A

Transmit two-tone 13A (T2130)

Aerials: from 7 - 15 m

TRANSMITTER T2130

Power Output: 250W PEP ±1.4 dB (T2130/I 240W PEP max.)

Intermodulation: better than 32 dB below PEP

Spurious Emission: better than 67 dB below PEP

Harmonics: better than 43 dB below PEP or

better than 67 dB below PEP with aerial coupler AT2110

Carrier Suppression: better than 46 dB below PEP

Audio Response: 350 Hz to 2700 Hz at -6 dB

RECEIVER RE2100

Receive System: Double conversion super heterodyne

1st IF 70 MHz. 2nd 10.73 MHz

Selectivity: J3E (SSB) 350 Hz to 2700 Hz at -6 dB

H3E (AM) ±3.3 kHz at -6 dB

Sensitivity: J3E (SSB) <10 dB/uV for 20 dB SINAD

H3E (AM) <24 dB/uV for 20 dB SINAD

Page 12

1 GENERAL INFORMATION RE2100

Spurious and IF Rejection: better than -70 dB

Cross Modulaton: better than 90 dB/uV (CEPT method of test)

Desensitization: better than 100 dB/uV (CEPT method of test)

AGC: less than 2 dB audio level change from 10 dB/uV to 80 dB/uV.

Fast attack, slow release time.

Intermodulation: better than 90 dB/uV (CEPT method of test)

Spurious Emission: better than 1 nW into dummy aerial

Clarifier: ±150 Hz in steps of 10 Hz

Squelch: Voice activated, opens for SINAD >6 dB

Audio Power: 5 Watt, 8 ohm, less than 10% distortion

10 Watt, 4 ohm, less than 10% distortion

AERIAL COUPLER AT2110

Power: 250W PEP

Aerials: 7 - 15m

Temperature Range: -25°C to +70°C

Tuning Time: Typically less than 2 secs (learn mode typ. 30 secs)

ACCESSORIES

Loudspeaker: H2054 see special brochure

H2074 see special brochure

Power Supplies: N2160

Input supply: 12V + 30% - 10%

For more information see the manual for N2160

N2161

Input supply: 110V - 127V - 220V - 240VAC

Input frequency: 50 - 60 Hz

For more information see the manual for N2161

Weight: RE2100: 4.5 kg

T2130: 14 kg

AT2110: 4.5 kg

PAGE 1-4

9324

Page 13

1 GENERAL INFORMATION RE2100

PAGE 1-5

9331

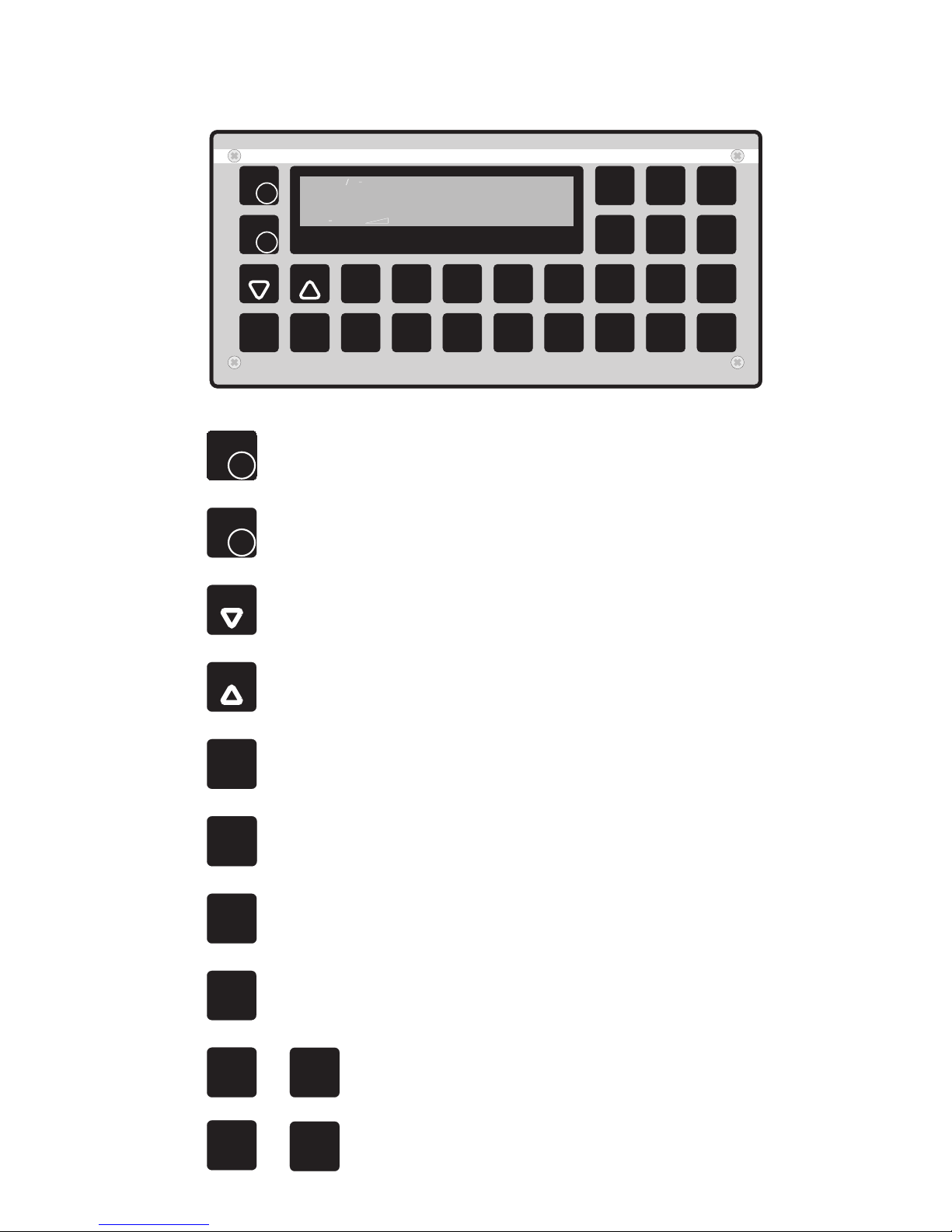

1.5 CONTROLS

29045

VOL

O

F

F

MODE

DEL

1

2

3

ENT

STOP

4

5

6

7

8 9

0

SC

DIM

LOAD

AGC

POWER

SQ

ADD

DUMMY

CH

TX

RX

TUNE

CLARIF

TEST

ALARM

2182

FREQ

ALARM

SEND

FREQ

RF

.

POWER

TX

0

SIGNAL AE

.5 21 3

RX

kHz

kHz

TX

CURRENT

F

F

O

VOL

Volume control and on/off switch for the mains.

RF

Manual RF gain control.

FREQ

Tunes the receive frequency down.

FREQ

Tunes the receive frequency up.

CLARIF

TUNE

Switches between clarifier (10 Hz steps) and tune of receive frequency.

RX

Selects receive functions or converts a channel number to the corresponding frequency.

CH

Selects channel functions.

TX

Selects transmit functions or converts a channel number to the corresponding frequency.

TX

POWER

AGC

Reduce/increase the transmitter output power.

TX

LOAD

DUMMY

DIM

Selects the built-in dummy load in the aerial coupler, and the TX frequency

2206.4 kHz is automatically selected.

Page 14

1 GENERAL INFORMATION RE2100

9331

PAGE 1-6

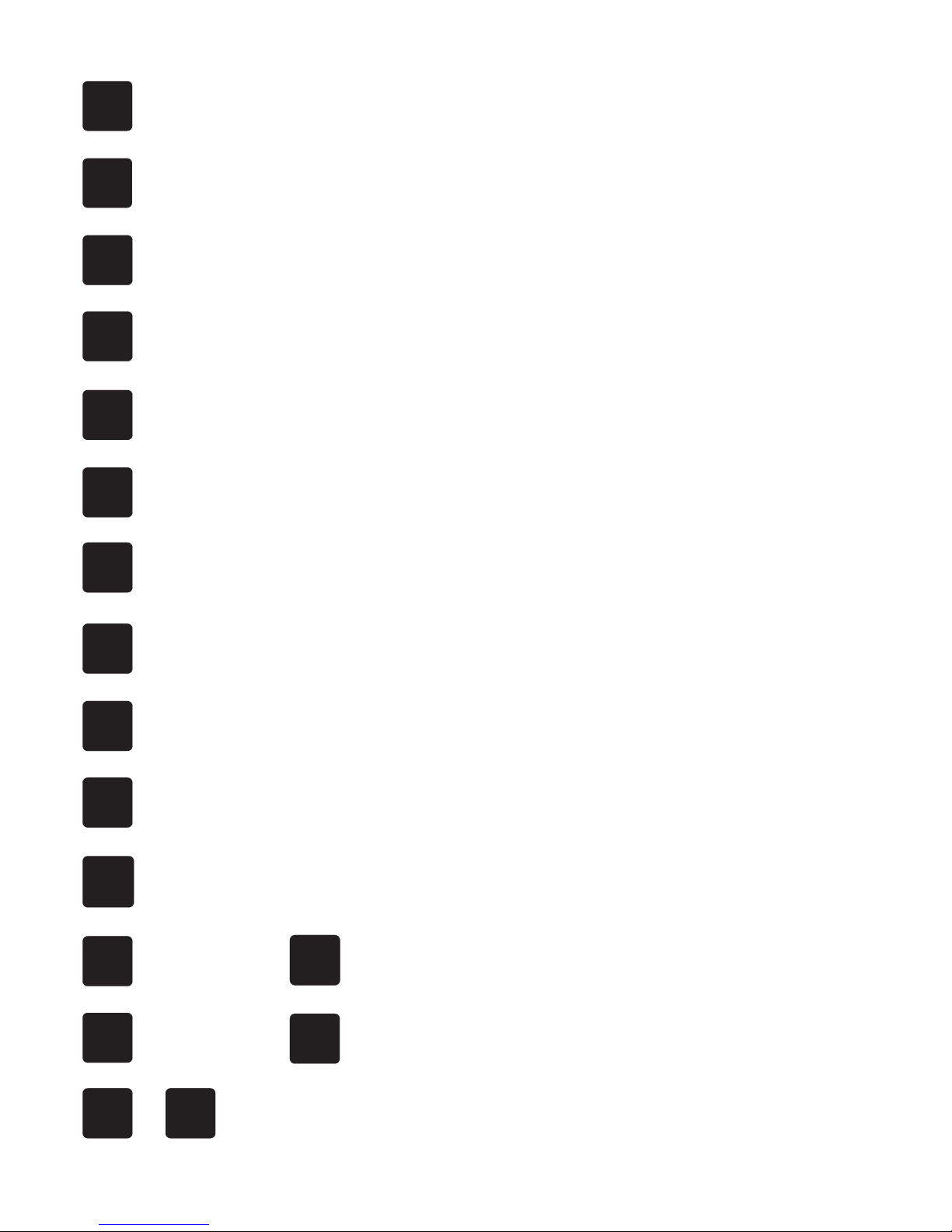

SEND

ALARM

Transmits the distress signal when pressed together with TEST ALARM.

2182

Selects the distress frequency 2182 kHz.

ALARM

TEST

Acoustic check of the alarm signal generator.

LOAD

DUMMY

DIM

Reduces/increases the display light and switches on/off the display and keyboard panel

illumination.

POWER

AGC

Switch the AGC function on/off.

ADD

SQ

Switches the squelch function on/off.

DEL

MODE

Selects modulation type J3E, R3E, H3E and J3E lower side band. (J3E lower side band is

optional).

SC

Selects the scan programme.

7

Digits from 1 to 9 and 0.

STOP

ENT

Terminates the keying-in sequence, stops the alarm signal, stops the scanning, and stops

the TX tuning.

.

Sets the decimal point for the frequency in kHz.

CH

(Digits 0-99)

ADD

SQ

Adds the RX/TX frequency to the channel number.

CH

(Digits 0-99)

DEL

MODE

Deletes the RX/TX frequency from the channel.

TX

CLARIF

TUNE

Resets the tune memory at the selected frequency and starts a new tune-up

cycle.

Page 15

1 GENERAL INFORMATION RE2100

PAGE 1-7

9324

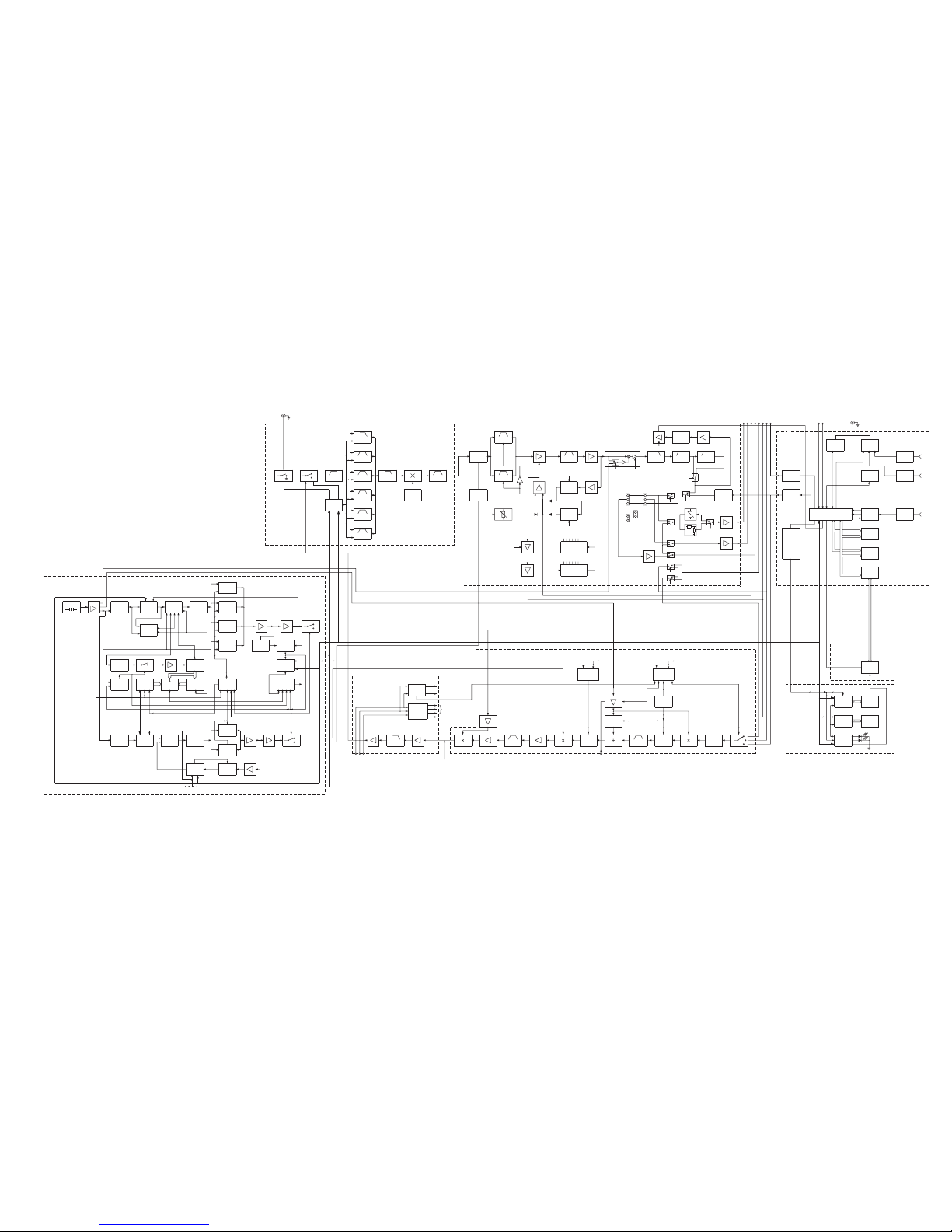

1.6 PRINCIPLE OF OPERATION

SAILOR Compact HF SSB RE2100 is the control unit in SAILOR Compact HF SSB Programme 2000. It

contains following circuits.

PROCESSOR UNIT

This unit controls all modules and operate as interface between the user and the radio (keyboard, display).

Nearly all communication from the microprocessor to the modules is done on an internal serial bus (SPI).

The unit holds all memory, and all user defined memory is in an EEPROM, so even when supply voltage

is removed, the contents of the memory is preserved. If the supply voltage to the RE2100 gets too low,

the display will show error 20, and the performance of the RE2100 will be reduced.

There is also an external serial bus (SP-Bus). This bus is used to communicate with other units in the

SAILOR Compact HF SSB Programme 2000, e.g. the transmitter T2130.

The microprocessor also generates the alarm tones (1300 Hz, 2100 Hz).

DISPLAY UNIT

This unit contains the display and the field strength meter.

SYNTHESIZER UNIT

This unit contains all frequency generating parts.

There is only one reference oscillator which is a temperature compensated crystal oscillator (TCXO) with

a frequency of 10.73 MHz.

Both receiver and exciter are using two LO-signals. These signals are generated in two separate PLL’s,

one having output frequencies from 70 MHz to 100 MHz and the other having output frequencies of 59.27

MHz and 80.73 MHz.

The synthesizer which covers from 70 to 100 MHz is a fractional synthesizer with a resolution of 10 Hz.

The other synthesizer is a conventional synthesizer. It has two output frequencies, one for lower sideband

80.73 MHz and another for upper sideband 59.27 MHz.

RECEIVER FRONT END

This unit contains input protection circuit, input filters, mixer and 70 MHz IF.

The input filter is a mixture of lowpass, highpass and bandpass filter to obtain max. performance in the

entire band from 100 kHz to 30 MHz.

The mixer is a FET mixer with a high level LO-injection to give the mixer good high signal quality. The mixer

is followed by a 70 MHz bilitic quartz filter with a bandwidth of 15 kHz.

RECEIVER UNIT

This unit contains all necessary circuits to convert a 70 MHz IF signal to an audio signal.

It starts with the second mixer which is a FET mixer. From the mixer the signal is fed to a high order

monolitic quartz filter, one for AM and one for SSB. The type of filter is selected from the microprocessor.

From the filter the signal is fed to the 10.73 MHz IF amplifier. The gain of this amplifier is regulated from

the AGC amplifier. The regulated IF amplifier is followed by a ceramic filter to reduce the wideband noise.

The signal is from here fed to the demodulator, which can operate as an SSB detector or an AM detector

controlled from the microprocessor. The detector is followed by a filter circuit. In AM mode the filter width

is from 70 Hz to 3000 Hz, and in SSB mode the filter is from 300 Hz to 3000 Hz. From here the AF signal

passes some switches and then it is amplified in three AF amplifiers, one for the microtelephone earpiece,

one for the 0 dBm output, and an amplifier with volume control for the AF signal to the AF power amplifier

in T2130.

The signal from the AF filters is also fed to the voice controlled squelch. This contains a limiting amplifier,

a frequency to voltage converter, and a threshold amplifier. On/off switching of the squelch is controlled

by the microprocessor.

In scan mode the squelch is used to detect if there is signal on the channel in question.

Page 16

1 GENERAL INFORMATION RE2100

EXCITER UNIT

This unit contains all necessary circuits to generate an SSB/AM signal in the frequency range from 1.6

- 30 MHz.

It starts with a compressor and AF amplifier.

The AF signal is fed to the balanced modulator to produce a double sideband signal on 10.73 MHz.

The DSB signal is fed to the LSB filter where only the

lower sideband passes through. The LSB signal is

fed to a step attenuator, which is controlled from the microprocessor. From the step attenuator the signal

is fed to the first mixer, and the frequency is converted to 70 MHz. If 59.27 MHz LO-signal is used, the

signal will be lower sideband. If 80.73 MHz LOsignal is used, the signal will be upper sideband. From the

mixer the signal is fed to an amplifier, 70 MHz crystal filter and an amplifier. From the amplifier the signal

is fed to the second mixer which converts the frequency from 1.6 MHz to 30 MHz.

After the mixer a lower side signal is converted to an upper sideband signal, and an upper sideband signal

is converted to a lower sideband signal. The output of the mixer is fed to the power unit.

POWER UNIT

This unit contains the final amplifying and filtering of the RF signal, and produces all necessary supply

voltages for the modules in RE2100.

The signal from exciter unit is first amplified, then filtered in a 30 MHz lowpass filter and then amplified

to a level of approx. 2 mW.

The input voltages from T2130 is ±18V and 9V. These voltages passes through seven series regulators

to produce the necessary supply voltages to RE2100. A special ±15V for the exciter is controlled from the

microprocessor, so when the transmitter has not been used for two minutes, it is switched off to reduce

the power consumption in standby.

9324

PAGE 1-8

Page 17

1 GENERAL INFORMATION RE2100

PAGE 1-9

9324

BLOCK DIAGRAM RE2100

4-0-25751C

SYNTHESIZER

POWER (MODULE 8)

EXCITER (MODULE 4)

KEY BOARD

(MODULE 6)

DISPLAY

(MODULE 7)

PROCESSOR

(MODULE 5)

RECEIVER (MODULE 1)

RECEIVER FRONT END

(MODULE 2)

(MODULE 3)

TCXO

Buffer

2nd

Divider Divider

Reference

detector

Phase

Filter

Loop

logic

Control

Mirror

Current

Logic

1/n Curr.

register

Fraction

overflow

Adder

clock

Sum latch

Converter

A/D

Reference

Divider

2nd

Divider

Phase

detector

Loop

Filter

92.5-85MHz

VCO II

100-92.5MHz

VCO I

85-77.5MHz

VCO III

77.5-70MHz

VCO IV

Shift reg.

VCO 1

VCO 2

Prescaler

divider

Programmed

VCO-Buffer

Prescaler

Programmed

divider

Prescaler

LO-Buffer

buffer

Prescaler

buffer

VCO-Buffer

LO-Buffer

Modulus

Control

Logic

Filter

Bandpass

18-30MHz

9-18MHz

Bandpass

Filter

4.5-9MHz

Bandpass

Filter

1.6-4.5MHz

Bandpass

Filter

0.385-1.6MHz

Bandpass

Filter

0.385MHz

Lowpass

Filter

Filter

Lowpass

30MHz

Highpass

Filter Filter

70MHz

Shift reg.

1.st

Mixer

1.st LO

Buffer

300kHz BW

LSB-Filter

10.73MHz

10.73MHz

AM-Filter

2.nd

Mixer

2.nd

Lo-buffer

IF

AMP

IF

AMP

SSB/AM Demodulator

AGC

Detector

Hang Time

AGC

AMP

AGC

3 kHz

Lowpass

70 Hz

Highpass

300 Hz

Highpass

Frequency

to voltage

converter

Threshold

Limeting

AMP

Buffer

AMP

S-Meter

AMP

0 dBm

AMP

Buffer Amp

Loudsp.

AMP

Earpiece

Filter

Bandpass

H1G1

F2

G2

F1

C2

SSB/AM

Squelch Switch

Loudsp. Switch

Earpiece Switch

A1

B1

C1

0 dBm Switch

Aux AF Switch

Mic. Switch

E1

S-Meter on/off

SSB/AM

C2

E2

Det. Mute

Dependent

on Squelch

Independent

on Squelch

Tune/Alarm/Ringing

Tones on/off

Volume contr.

Switch

Distress

driver

Tune/alarm

generator

u-Processor

select

SPI-adress

+5V power

supply

-5V power

supply

+5V power

supply

Watch dog

EPROM

EEPROM

Keyboard

buffer

SCI-baud

Rote-gen

SCI-TxSCI-Rx

Keyboard

4x8 Matrix

EPROM

Rx and Tx

Meter

Display

driver

Meter

driver

Dimmer

Dummy load

Tune

AF-

compressor

Balanced

Modulator

Modulations

Level-control

Mode-

selector

Carrier

buffer

Carrier

Insertion

Step

attenuator

Carrier

Level-control

LSB-filter

10.73MHz

Mixer

1.st

70 MHz

IF AMP

70 MHz

Filter

AMP

70 MHz

2.nd

Mixer

LO-buffer

Shift reg.Shift reg.

Lowpass

Filter

Supply

EX

Supply

Rx/Tx

Switch

Rx

Ex

Switch

Rx/Tx

Mute

Rx

Tx

ResetExVAPI

Sample/Hold

1.6-30 MHz

-18V

+18V from T2130

+9V

+9V

-18V

+18V

+15V

-15V

+5V

+3.5V

-15V

+15V

To exciter module

To exciter module

To all modules

To processor module

To display module

LO2 EX 70-100 MHz

59.23/80.73 MHz LO1 EX

10.73 MHz

RF on/off

Ex on/off

AF-selector

Mode-selector

Mode Ex

ATT Ex

Switch

Rx/Tx

Telex

Alarm/tune tones

Mic. in

RF in/out

to T2130

B2

Hang AGC on/off

H2

Shift Register 1

Shift Register 2

H2G2

F2E2D2C2B2A2

A1B1C1D1E1 F1

G1 H1

C2

SSB/AM

A2

Manual RF-gain

10.73MHz

LO2 Rx 59.27 MHz/80.73 MHz

AGC on/off

Volume contr.

D1

Squelch reset

SP-bus

VF/AE-current

Rx Mute

Hand Key

BA

QQ

DATA-BUS/8

ADRESS-BUS/16

Ex RF

AUX AF to TX

Distress out

Mic in

0 dBm output

Ext. RF-gain controle

To microtelephone edv.

AF to AFamp. T2130

Rx

6

1

1

1

1

1

2

3

1

4

2

1

1

1

2

1

3

1

4

4

1

1

1

1

1

1

21

14

2

1

6

1

7

1

2

4

3

7

3

33

46

2

4

1

3

102

10

10

Control on/off

+-

Vref

Limit

Amp

Carrier Reinjection for SSB 10.73 MHz

LO1 Rx 70-100 MHz

Page 18

Page 19

RE2100

CONTENTS

2 INSTALLATION

2.1 MOUNTING POSSIBILITIES 2-1

2.2 DIMENSIONS AND DRILLING PLAN 2-3

2.3 ELECTRICAL CONNECTION AND ASSEMBLING 2-8

Page 20

Page 21

PAGE 2-1

RE2100

2 INSTALLATION

2.1 MOUNTING POSSIBILITIES

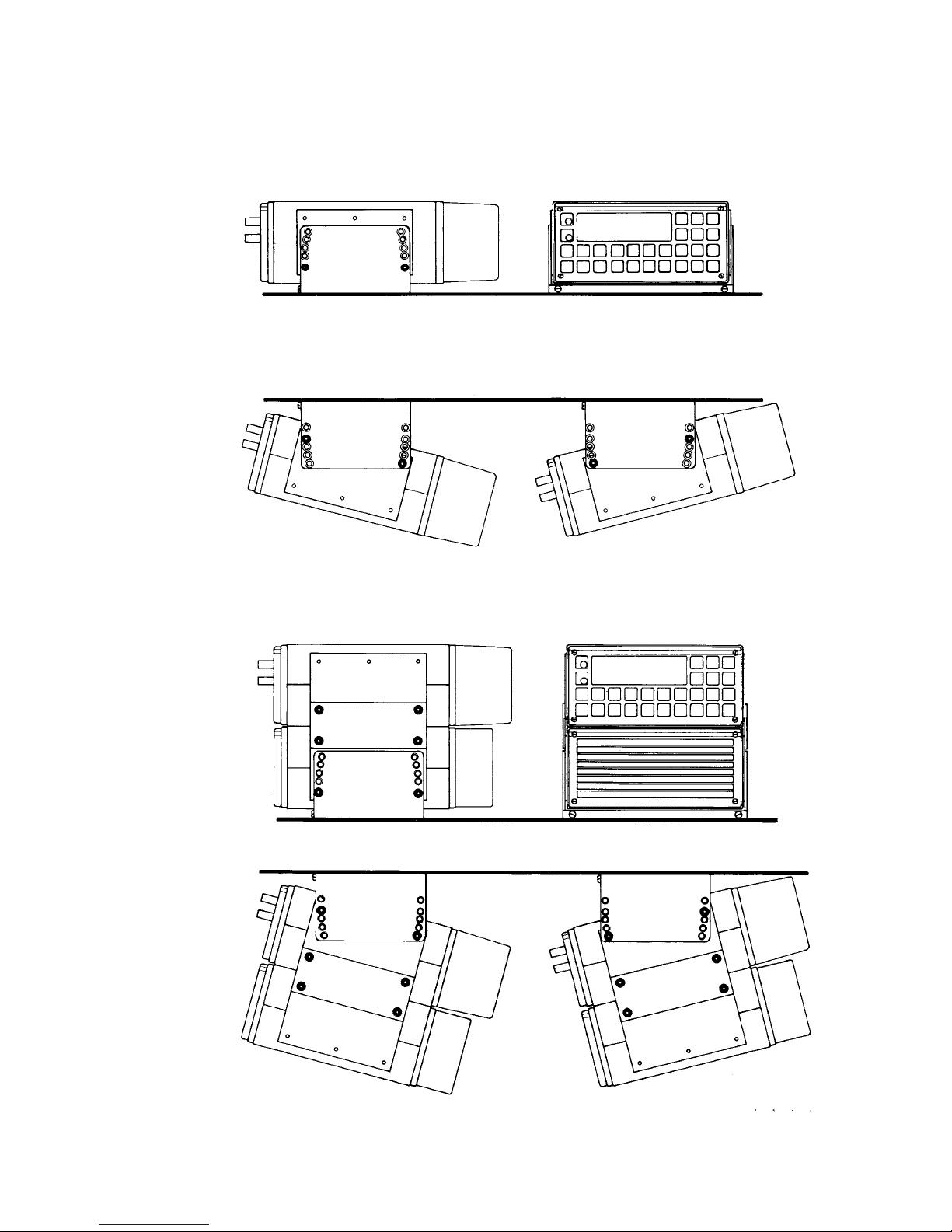

TABLETOP AND DECKHEAD

Mounting bracket H2055 which offers the same possibilities for the loudspeakers H2054 and H2074.

Mounting kit H2068 and H2055

4-0-25931,4-0-25932,4-0-25933

Page 22

2 INSTALLATION RE2100

PAGE 2-2

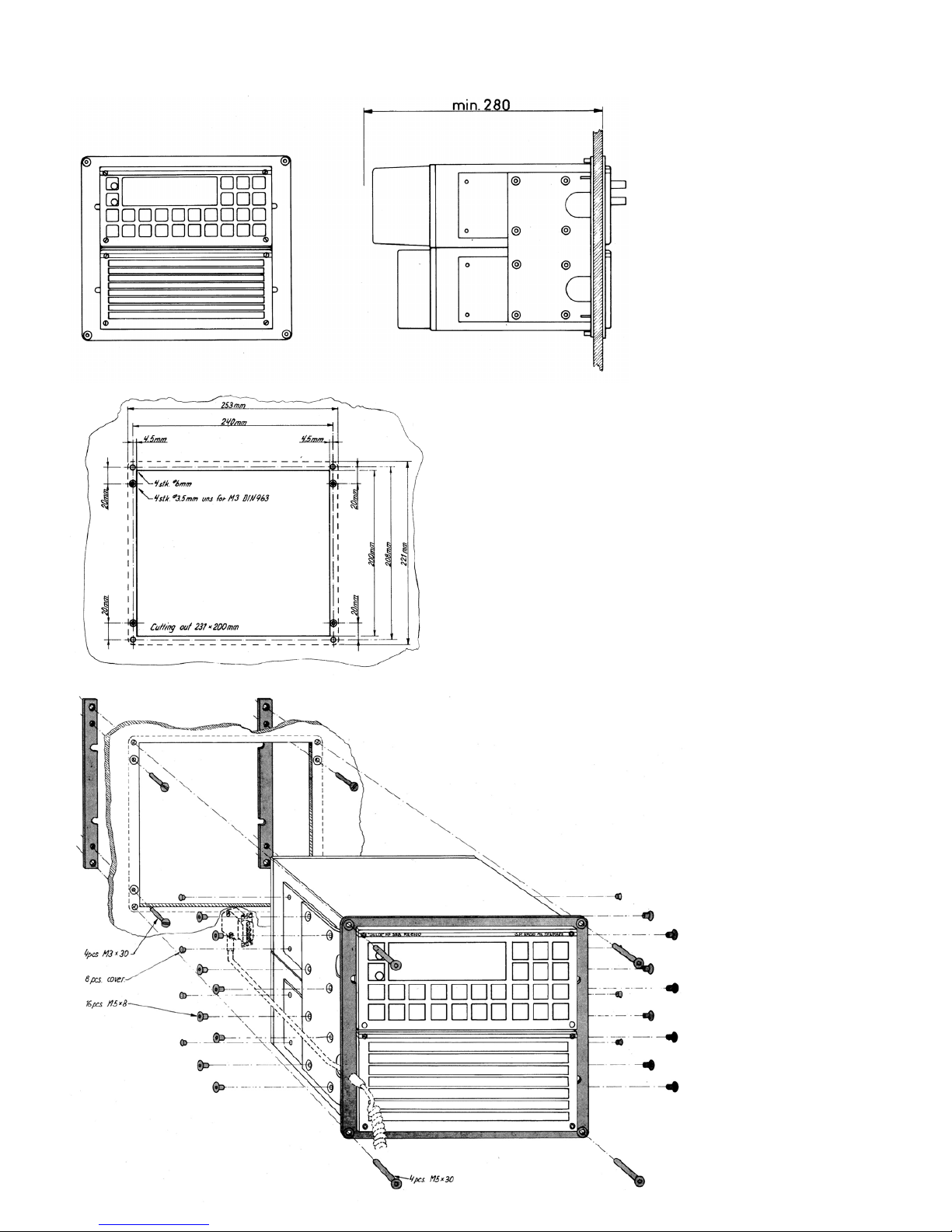

BULKHEAD AND CONSOLE

Mounting kit H2063 which offers the same possibilities for the loudspeakers H2054 and H2074.

Mounting kit H2062 or

Mounting kit H2064.

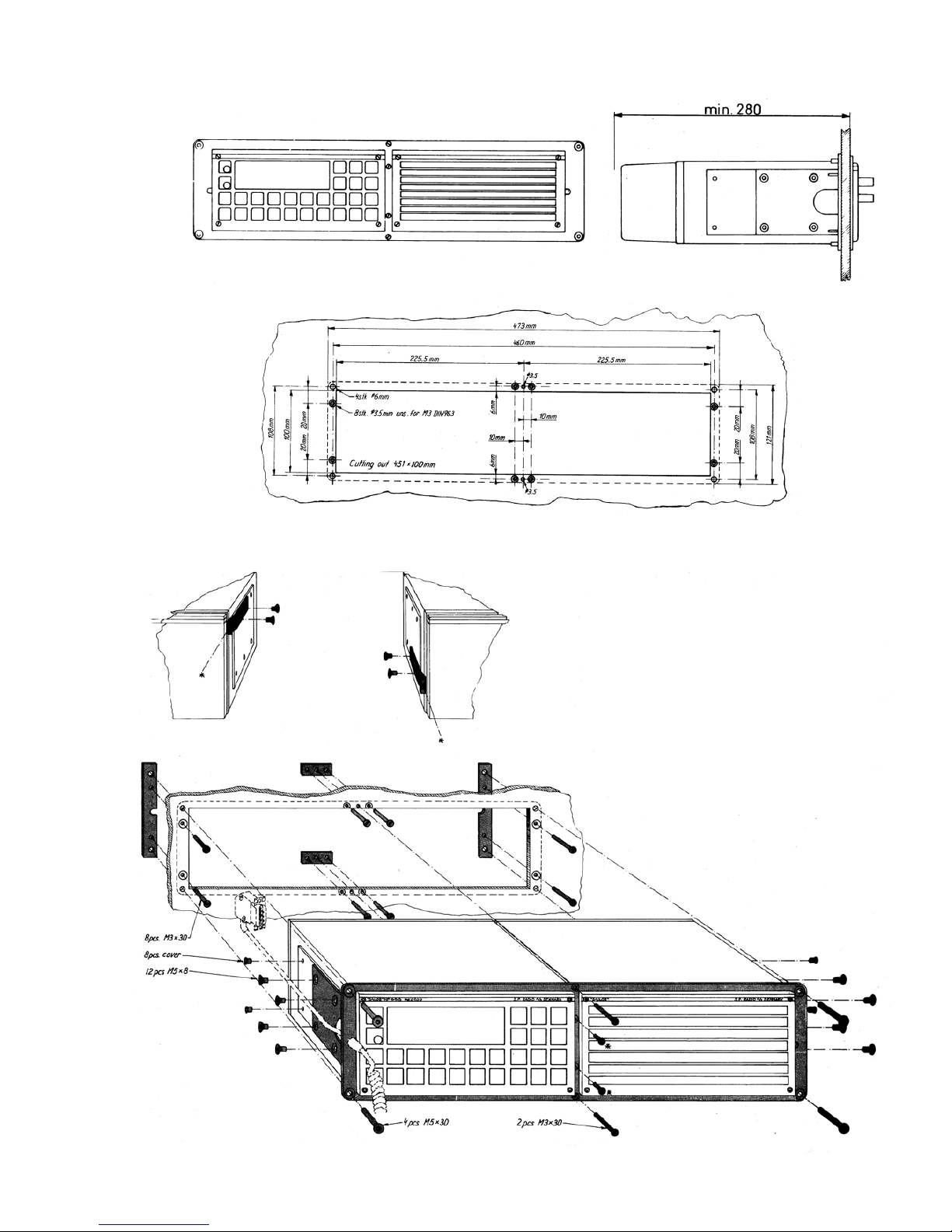

IN CONJUNCTION WITH OTHER SAILOR EQUIPMENT

Look up the INSTALLATION section for the SAILOR unit in question

4-0-25926,4-0-25927

Page 23

2 INSTALLATION RE2100

PAGE 2-3

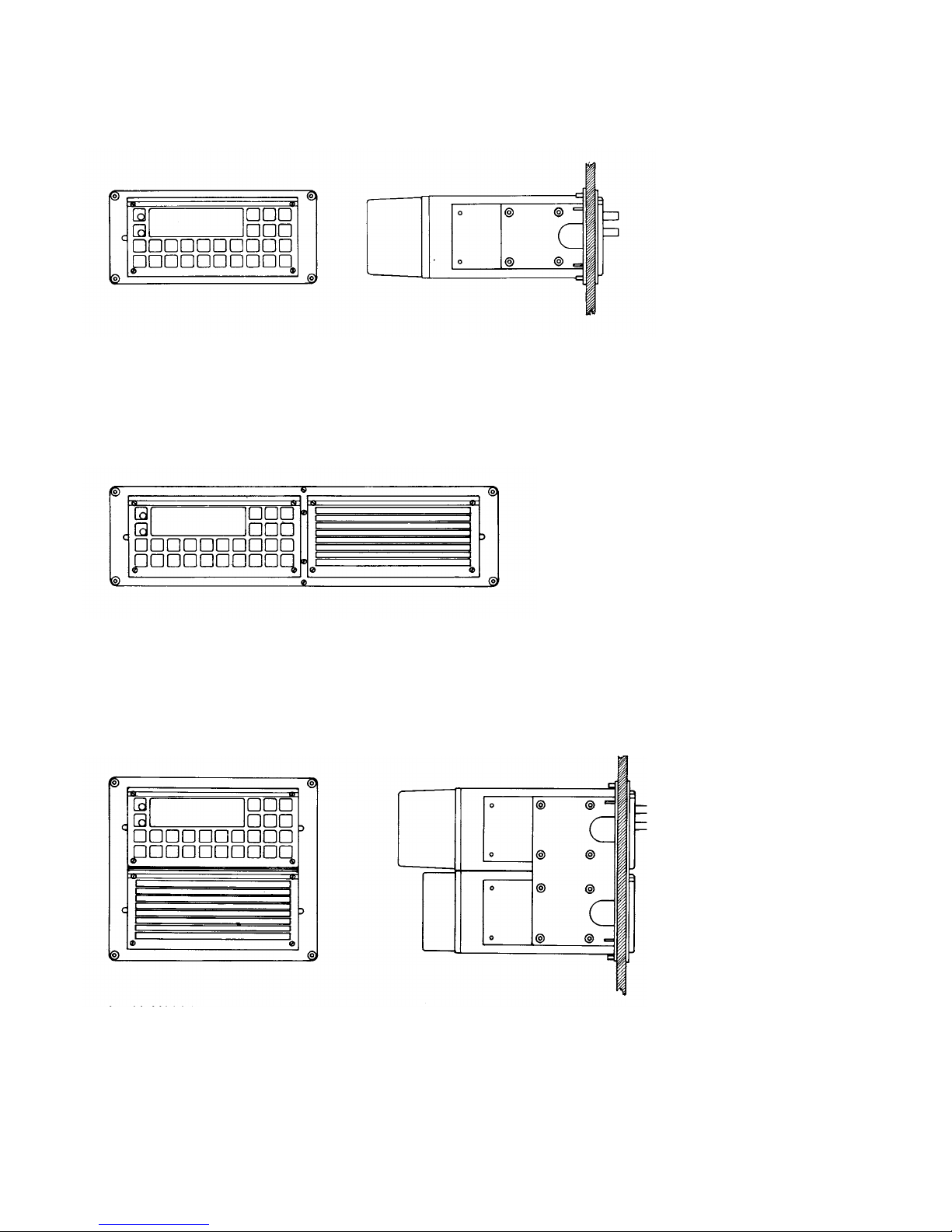

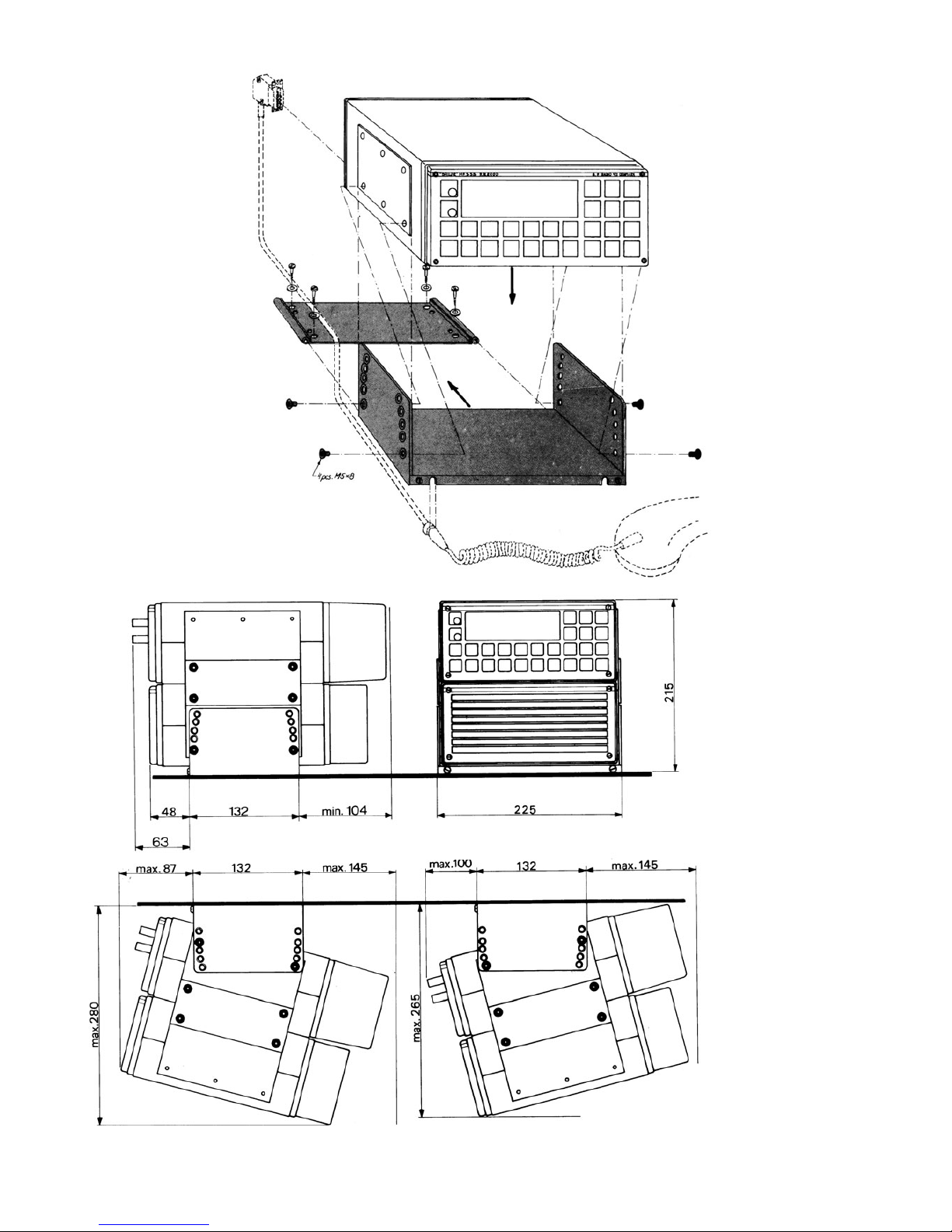

2.2 DIMENSIONS AND DRILLING PLAN

UNIVERSAL MOUNTING BRACKET H2055

Permits a wide variety of installation possibilities, such as tabletop, bulkhead or deckhead. For other

possibilities such as console installation, the SAILOR 19" rack or all units in the Compact programme

assembled on the bulkhead, see special information concerning installation of the Compact programme.

WEIGHT

Mounting kit H2055: 1.5 kg

Loudspeaker H2054: 5.5 kg

Loudspeaker H2074: 4.0 kg

HF SSB RE2100: 4.5 kg

4-0-25930,4-0-25922

Page 24

2 INSTALLATION RE2100

PAGE 2-4

4-0-25934, 4-0-25928, 4-0-25929

MOUNTING KIT H2068 AND H2055

WEIGHT

Lashing kit H2068: 1.5 kg

Mounting kit H2055: 1.5 kg

Loudspeaker H2054: 5.5 kg

Loudspeaker H2074: 4.0 kg

HF SSB RE2100: 4.5 kg

Page 25

2 INSTALLATION RE2100

PAGE 2-5

MOUNTING KIT H2063

Free distance must be kept to allow

free air circulation ambient temperature max. 40°C.

WEIGHT

Mounting kit H2063: 1.0 kg

Loudspeaker H2054: 5.5 kg

Loudspeaker H2074: 4.0 kg

HF SSB RE2100: 4.5 kg

4-0-25935, 4-0-25936, 4-0-24703

Page 26

2 INSTALLATION RE2100

MOUNTING KIT H2064

Free distance must be kept to allow

free air circulation ambient temperature max. 4o°C.

WEIGHT

Mounting kit H2064: 1.5 kg

Loudspeaker H2054: 5.5 kg

Loudspeaker H2074: 4.0 kg

HF SSB RE2100: 4.5 kg

4-0-25937, 4-0-24704, 4-0-25942

PAGE 2-6

Page 27

2 INSTALLATION RE2100

MOUNTING KIT H2062

Free distance must be kept to allow

free air circulation ambient temperature max. 40oC.

WEIGHT

Mounting kit H2062: 1.5 kg

Loudspeaker H2054: 5.5 kg

Loudspeaker H2074: 4.0 kg

HF SSB RE2100: 4.5 kg

4-0-25943,4-0-24732, 4-0-25944

PAGE 2-7

Page 28

2 INSTALLATION RE2100

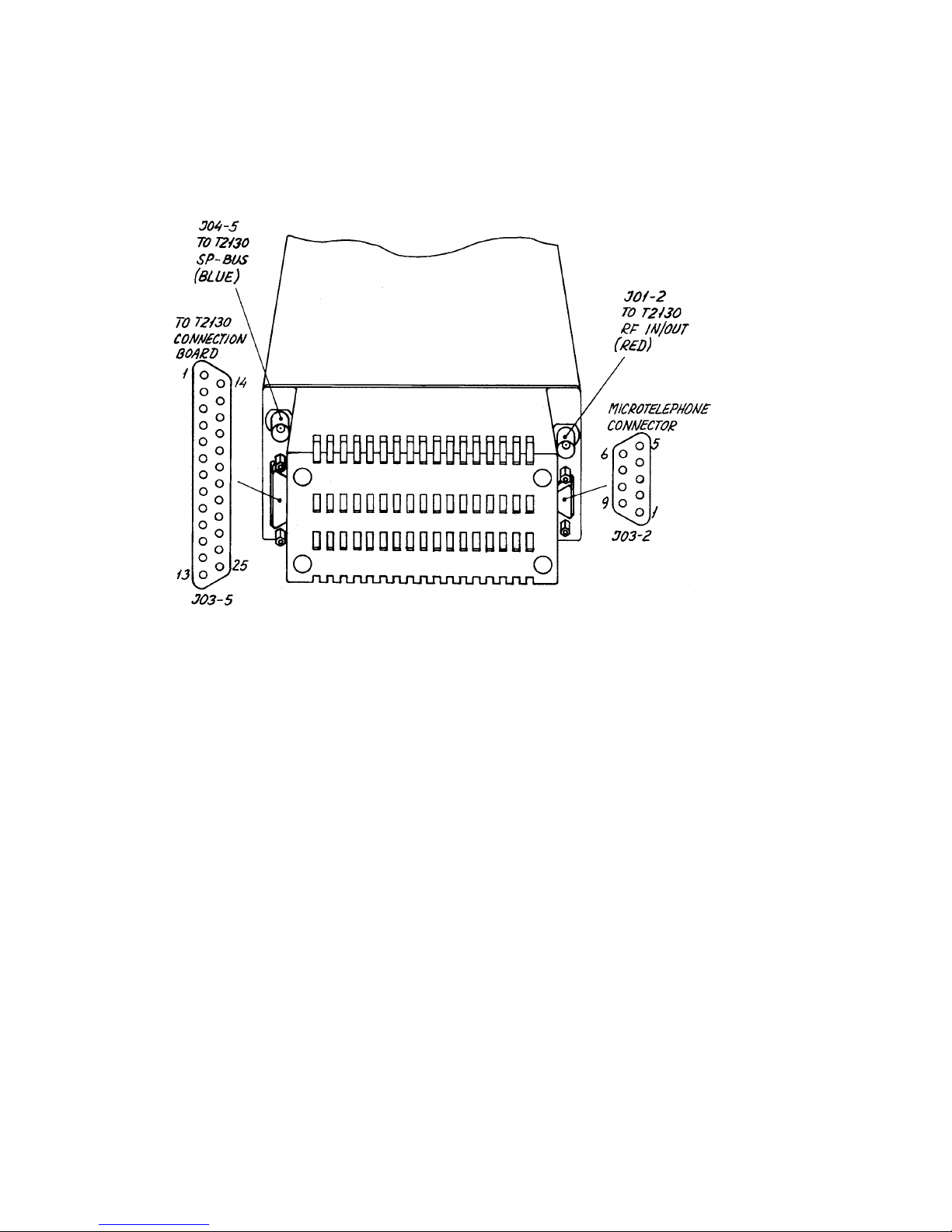

2.3 ELECTRICAL CONNECTION AND ASSEMBLING

HF SSB RE2100 is the control unit in SAILOR compact HF SSB programme 2000. RE2100 can therefor

be the control unit in a 250W transmitter system or a 600/1200W system. For information how to

interconnect this units with RE2100 please consult the technical manuals describing the units to be

interconnected to

25816

J03-5 J03-2

Pin no. 1 Mute RX Black Pin no. 1 Telephone Red

Pin no. 2 AF to AMP common Brown Pin no. 2 GND Yellow

Pin no. 3 Pin no. 3 Signal GND White

Pin no. 4 Pin no. 4 Mic Blue

Pin no. 5 GND Shield Pin no. 5 Mic key Brown

Pin no. 6 SP BUS interrupt Red Pin no. 6 Ext. SQ on/off

Pin no. 7 Orange Pin no. 7 Distress

Pin no. 8 Yellow Pin no. 8 Ser.+

Pin no. 9 AUX AF to TX common Green Pin no. 9 +18V

Pin no. 10 -18V Blue

Pin no. 11 +9V Violet

Pin no. 12 +18V Grey

Pin no. 13 Supply on/off White

Pin no. 14 Mic key Brown/pink

Pin no. 15 VF/AE-current Brown/yellow

Pin no. 16 AF to AMP Brown/green

Pin no. 17 0 dBm out common Brown/grey

Pin no. 18 0 dBm out White/pink

Pin no. 19 Ext. RF control White/yellow

Pin no. 20 AUX AF to TX White/green

Pin no. 21 RF on/off White/blue

Pin no. 22 GND White/grey

Pin no. 23 +9V Violet

Pin no. 24 +18V Grey/orange

Pin no. 25 -battery Red/blue

9324

PAGE 2-8

Page 29

RE2100

CONTENTS

3 SERVICE

3.1 MAINTENANCE 3-1

3.2 ALIGNMENT INSTRUCTIONS 3-1

3.3 PROPOSAL FOR NECESSARY TEST EQUIPMENT 3-2

3.4 TROUBLE SHOOTING 3-7

3.5 PERFORMANCE CHECK 3-9

3.5.1 PERFORMANCE CHECK OF DISPLAY AND KEYBOARD 3-9

3.5.2 PERFORMANCE CHECK OF RECEIVER 3-11

3.5.3 PERFORMANCE CHECK OF EXCITER 3-18

3.6 MODULE PERFORMANCE CHECK 3-21

3.6.1 MODULE PERFORMANCE CHECK OF RECEIVER UNIT 3-22

3.6.2 MODULE PERFORMANCE CHECK OF FRONT END UNIT 3-32

3.6.3 MODULE PERFORMANCE CHECK OF SYNTHESIZER UNIT 3-37

3.6.4 MODULE PERFORMANCE CHECK OF EXCITER UNIT 3-40

3.6.5 PERFORMANCE CHECK OF MICROPROCESSOR MODULE 5 3-42

3.6.8 MODULE PERFORMANCE CHECK OF POWER UNIT 3-47

3.7 ADJUSTMENT PROCEDURE 3-47

3.7.1 ADJUSTMENT PROCEDURE FOR FRONT END

AND RECEIVER UNIT 3-47

3.7.2 ADJUSTMENT PROCEDURE FOR SYNTHESIZER UNIT 3-50

3.7.3 ADJUSTMENT PROCEDURE FOR EXCITER UNIT 3-52

3.7.4 ADJUSTMENT PROCEDURE FOR POWER UNIT. 3-55

3.8 NECESSARY ADJUSTMENT AND CHECK AFTER REPAIR 3-56

3.9 FUNCTION CHECK 3-58

3.10 SELECTION AND DESCRIPTION OF THE SERVICE

PROGRAMMES 3-60

3.10.1 HOW TO SELECT A SERVICE PROGRAMME 3-60

3.10.2 DESCRIPTION OF SERVICE PROGRAMMES 3-60

Page 30

Page 31

PAGE 3-1

RE2100

3 SERVICE

3.1 MAINTENANCE

PREVENTIVE MAINTENANCE

If the HF SSB RE2100 has been installed in a proper way the maintenance can, dependent on the

environments and working hours, be reduced to a performance check at the service workshop at intervals,

not exceeding 12 months. A complete performance check list is enclosed in this manual, chapter 3.5

PERFORMANCE CHECK.

Inspection of the antenna, cables, and plugs for mechanical defects, salt deposits, corrosion, and any

foreign bodies shall be done at regular intervals not exceeding 12 months.

Along with each RE2100 a test sheet is delivered in which all the measurements, made in the test

department of the factory, are listed. If the control measurings made in the service workshop should not

show the same values as those listed in the test sheet, the set must be adjusted as specified in chapter

3.7 ADJUSTMENT PROCEDURE.

3.2 ALIGNMENT INSTRUCTIONS

INTRODUCTION

The measuring values indicated in chapter 5. CIRCUIT DESCRIPTION AND SCHEMATIC DIAGRAMS

are typical values and as indicated it will be necessary to use instruments in absolute conformity with the

below list:

Page 32

3 SERVICE RE2100

PAGE 3-2

3.3 PROPOSAL FOR NECESSARY TEST EQUIPMENT

OSCILLOSCOPE:

Bandwidth DC-35 MHz

Sensitivity 2mV/div

Output Impedance 1 Mohm//20 pF

E.g. Philips type PM3050

PASSIVE PROBE:

Attenuator 20 dB

Input Impedance 10 Mohm//15 pF

Compensation Range 10-30 pF

E.g. Philips type PM8936/091

MULTIMETER:

Sensitivity DC (f.s.d.) 100 mV

Input Impedance 10 Mohm

Accuracy DC (f.s.d.) 1.5%

E.g. Philips type PM2505

FREQUENCY COUNTER:

Frequency Range 100 Hz - 120 MHz

Resolution 1 Hz at f = 100 MHz

Accuracy 1 . 10-7

Sensitivity 100 mV RMS

Input Impedance 1 Mohm/30 pF

E.g. Philips type PM6669/031

HF SIGNAL GENERATOR:

Frequency Range 100 kHz - 100 MHz

Output Voltage: 0dB/uV - 120 dB/uV

Output Impedance 50 ohm

Type of Modulation AM

Modulation Frequency External

E.g. Marconi type 2019

LF SIGNAL GENERATOR:

Frequency Range 10 Hz - 10 kHz

Output Voltage 20 mV

RMS

- 1V

RMS

Output Impedance 600 ohm

Output Waveform sine wave

E.g. Philips type PM5110

LF DISTORTION METER:

Frequency Range f = 1000 Hz

Distortion Range (f.s.d.) 1-10%

Input Impedance 1 Mohm

Accuracy (f.s.d.) 3%

E.g. Philips type PM6309

Page 33

3 SERVICE RE2100

PAGE 3-3

AA119

AA119

ceramic

1nF

1nF

ceramic

To multimeter

RF

Metal tube

Insulating material

10.00 12.00 70.00

ø10

25079

LAYOUT OF THE PROBE

TEST PROBE

50 OHM DUMMY LOAD

50 ohm -> 50 ohm: EMF-loss 20 dB

Page 34

3 SERVICE RE2100

PAGE 3-4

POWER SUPPLY:

Vout1 18V DC

Vout2 18V DC

Iout1 2 Amp DC

Iout2 0.5 Amp DC

E.g. 2 pcs. ELCANIC type 3010

TESTBOX

To test all the functions of the RE2100 is very difficult when no transmitter T2130 is available. For that

reason S. P. Radio has developed and produced a testbox. When using this testbox it is possible in an

easy way to test all the inputs and outputs of the RE2100.

The testbox has a built-in AF amplifier, which makes it possible to connect a loudspeaker directly to the

testbox.

The testbox has a built-in unit to control the function of the SP-BUS output. By means of the built-in light

emitting diodes and switches it is possible to control all the functions of the RE2100.

Specification of measuring instruments, which can be connected to the testbox is given in the beginning

of this chapter, and to this list an 8 ohm loudspeaker can be added.

The below diagram shows the electric wiring inside the testbox:

COMPONENT LOCATION TESTBOX

5-0-26206 / 4-6-26206A

Page 35

3 SERVICE RE2100

PAGE 3-5

DIAGRAM TESTBOX

Page 36

3 SERVICE RE2100

The below diagram shows how to connect the testbox with the RE2100 and the external instruments.

4-0-26236A

If no testbox is available, it is possible to operate the RE2100 by connecting the power supply directly to

the 25-pin connector, which is located at the back of the RE2100. In this 25 pin connector it is possible

to find all the other inputs, outputs, and testpoints. The pin configuration for this connector is listed in

chapter 2.3 ELECTRICAL CONNECTION AND ASSEMBLING. But it is only necessary to establish the

following connections:

pin No. 10 -18V/0.2 Amp.

pin No. 11 + 9V/0.5 Amp.

pin No. 12 +18V/0.8 Amp.

pin No. 5 GND

The handset is connected directly to the 9-pin connector at the back of the RE2100.

PAGE 3-6

Page 37

3 SERVICE RE2100

3.4 TROUBLE SHOOTING

Trouble shooting should only be performed by persons with sufficient technical knowledge, who have the

necessary measuring instruments at their disposal, and who have carefully studied the operation

principles and structure of the SAILOR Compact HF SSB System.

SAILOR HF SSB RE2100 has a number of trimming cores and trimmers, which must not be touched,

unless adjustments as specified in chapter 3.7 ADJUSTMENT PROCEDURE, can be made.

When measuring the units, short-circuits must be avoided as the transistors would then be spoiled.

LOCATING THE FAULTY UNIT

When a fault has been observed in the HF SSB system, it can be difficult to find out in which unit the fault

can be located.

The first thing to check, is whether the fault is somewhere in the aerial circuit, the handset or in the power

source.

If the fault is not found there, check if an error message has been shown in the RX display of the RE2100.

The error codes listed below are error messages, which are generated by the RE2100, and they therefore

indicate a fault in this unit.

ERROR CODES

00 Internal power supply is low.

Check the power connections to the RE2100, or check the internal power regulators.

11 Illegal transmitting frequency.

The TX frequency, of which a tone sequence has been tried, is not legal.

12 Illegal transmitting mode.

The TX emission mode is not legal for transmitting.

15 Key sequence is not finished by the <ENT> key.

20 The communication link to the transmitter T2130 is interrupted.

Check the coax cable to the T2130 from RE2100.

21 The communication link between RE2100 and control unit C2140 or DSC/telex RM2150/

RM2151 has been stopped. Check the SP-BUS coax cable to the external equipment. If the

“Error 21” flashes up again after the button <STOP/ENT> has been pressed, then check the

SP-BUS interrupt line (J03-5 pin 6). This line has to be normal “High” (approx. +5V).

22 The communication link between the RE2100 and the Duplex/Telegraphy Reveiver R2120T

has been stopped. Check the SP-BUS coax cable between these units.

The error codes listed below are error messages, which are generated by the HF transmitter T2130, and

they therefore indicate a possible fault in this unit.

PAGE 3-7

Page 38

3 SERVICE RE2100

These error codes are described more detailed in the instruction manual for T2130, chapter

2.3 SYSTEM DESCRIPTION AND TROUBLE SHOOTING, and in the chapter 3.4 TROUBLE SHOOTING.

ERROR CODES

70 Motor circuit error AT2110.

See instruction manual for T2130, chapter 3.4.

71 Internal signal error.

See instruction manual for T2130, chapter 3.4.

72 Internal signal error.

See instruction manual for T2130, chapter 3.4.

73 High standing wave ratio (SWR) in the tuning of the AT2110.

Check the aerial and see instruction manual for T2130, chapter 3.4.

74 Transmitter temperature too high.

Let the transmitter T2130 have a pause and see instruction manual for T2130, chapter 3.4.

75 High standing wave ratio (SWR) when transmitting.

Check the aerial and see instruction manual for T2130, chapter 3.4.

76 Battery voltage low.

Check the condition of the batteries and the power cables. See instruction manual for T2130,

chapter 3.4.

77 Temperature sensor error.

See instruction manual for T2130, chapter 3.4.

78 Internal high standing wave ratio (SWR).

See instruction manual for T2130, chapter 3.4.

If the error codes indicate that the fault may be found in the RE2100, the fault is probably no transmitter

signal from the RE2100. The exciter can then, without any damage to the transmitter, be set on by

activating the test programme SP-05-0.

The error codes do not indicate any receiver fault.

A receiver fault can be in the aerial coupler AT2110, in the transmitter T2130, or in the receiver unit.

To separate a fault in these units, disconnect the aerial cable at the back of RE2100 and connect a wire

to the RE2100 coax socket. Try to find a broadcast station and check the receiver. If the fault is still

present, it must be located in the RE2100 unit.

LOCATING THE FAULTY MODULE

If the fault has been located to the RE2100, the exciter can be activated in test programme SP-05-0. The

receiver is always activated, when no test programme is activated.

Check the connections to the modules in the RE2100.

The power supply should be the first thing to control, the voltage is indicated in the diagram of each

module.

If the power supply is present, control the amplitude of the local oscillator signals.

The next thing to control is whether the other inputs to the module are present. They are indicated in the

diagrams of each module with reference to a special set-up of the RE2100.

It should now be possible to locate the faulty module.

LOCATING THE FAULTY CIRCUIT

When the faulty module has been found, it can be difficult to find the faulty circuit or component.

One way is to change the module. If this is not possible, the faulty component or circuit can be found in

a more systematic way by using the chapter 3.6 MODULE PERFORMANCE CHECK.

Chapter 3.6 MODULE PERFORMANCE CHECK is divided into sections with a headline indicating a

possibility of checking some main parameters, and this may be a great help.

PAGE 3-8

Page 39

3 SERVICE RE2100

3.5 PERFORMANCE CHECK

GENERAL

A performance check is intended to be used as a check after repair and before reinstallation of the

equipment.

A performance check can be used to check the equipment after a certain time to make sure that the

equipment is according to the required technical specifications.

The performance check is divided into three sections, and it is possible to perform one of the sections or

all of them.

Connect the RE2100 with the testbox for the RE2100 and connect the power supply and the handset to

the testbox as described in chapter 3.3 PROPOSAL FOR NECESSARY TEST EQUIPMENT.

If no testbox is available, it is possible to operate the RE2100 by connecting the power supply directly to

the 25 pin connector, which is located at the back of the RE2100. The pin configuration for this connector

is listed in chapter 2.3 ELECTRICAL CONNECTION AND ASSEMBLING. But it is only necessary to

establish the following connections:

pin No. 10 -18V/0.2 Amp.

pin No. 11 + 9V/0.5 Amp.

pin No. 12 +18V/0.8 Amp.

pin No. 5 GND

The handset is connected directly to the 9 pin connector at the back of the RE2100.

This chapter includes a number of measurements where a signal generator is needed. The output level

of the generator is, in this manual, expressed in terms of the Electromotive Force (EMF), and it is

measured in terms of the unit: dB/uV = 20 log(EMF/1uV), (dB above one microvolt).

The output level from signal generators in general is sometimes expressed in terms of the available power

P

a

, which is measured in terms of the unit: dBm = 10 log(Pa/1mW), (dB above one milliwatt). For this

reason the conversion formulas between EMF and available power and vice versa are given here:

Pa (dBm) = EMF (dB/uV) - 113 dB

EMF (dB/uV) = P

a

(dBm) + 113 dB

where P

a

is the available power and EMF is the Electromotive Force of the generator.

3.5.1 PERFORMANCE CHECK OF DISPLAY AND KEYBOARD

Connect the RE2100 with the testbox for RE2100. Connect the power supply +/-18V/2A, the loudspeaker,

and a coax cable from the RE2100, SP-BUS output socket to the proper input terminals on the testbox.

The necessary test equipment to carry out a performance check is described in this manual chapter 3.3

PROPOSAL FOR NECESSARY TEST EQUIPMENT.

3.5.1.1 PERFORMANCE CHECK OF DISPLAY

1. Select test programme SP-00-2.

2. Control that the display is switched between all possible combinations of lighted bars.

3. Control that the mode indicating bars are toggled.

4. Control that the power reduction bars are alight.

PAGE 3-9

Page 40

3 SERVICE RE2100

5. Press the keyboard ENT key.

6. Select test programme SP-00-3.

7. Control that the two led’s marked SP-BUS-TEST on the testbox are alight.

8. Press the keyboard TUNE button.

9. Turn the RF GAIN button fully counter clockwise.

10. Control that the bars in the signal meter are all alight.

11. Turn the RF gain fully clockwise.

3.5.1.2 PERFORMANCE CHECK OF KEYBOARD

1. Turn the VOL-OFF button fully counter clockwise and then fully clockwise.

2. Control that the testbox led marked SUPPLY ON/OFF can be switched on and off by the VOL-OFF

button.

3. Press the keyboard buttons to key-in the receiver frequency 12345.6 kHz.

4. Press the keyboard button ENT.

5. Control that noise is heard from the loudspeaker.

6. Press the handset button TX.

7. Control that the point in the TX frequency window is toggled.

8. Press the keyboard buttons while the point is toggled to key-in the transmitter frequency 7890.0

kHz.

9. Press the keyboard button ENT.

10. Pres the keyboard button CH.

11. The display will now show ‘CH-----’.

12. Press the keyboard button SC.

13. The display will now show ‘SC X’.

14. Press the keyboard button RX.

15. The display will now show ‘12345.6 kHz’

‘7890.0 kHz’.

16. Control that the emission mode can be toggled by pressing the keyboard button MODE.

17. Control that the display light can be dimmed by pressing the keyboard button DIM.

18. Control that the led marked AGC can be toggled by pressing the keyboard button AGC.

19. Control that the led marked SQ can be toggled by pressing the keyboard button SQ.

20. Press the keyboard TUNE/CLARIF button.

21. Control that the RX frequency displayed changes to show the 10 Hz decimal ‘12345.60 kHz’.

PAGE 3-10

Page 41

3 SERVICE RE2100

22. Press the keyboard FREQ error buttons to toggle the 10 Hz decimal up and down.

23. Press the keyboard TUNE/CLARIF button.

24. Press the keyboard FREQ error buttons to toggle the 100 Hz decimal up and down.

25. Press the keyboard 2182 button.

26. Control that the display shows ‘2182.0 kHz’

‘2182.0 kHz’

27. Press the keyboard TEST ALARM button.

28. Control that the alarm tones can be heard in the handset earpiece.

29. Press the keyboard button ENT.

30. Press the keyboard buttons SEND ALARM and TEST ALARM.

31. Control that the display shows ‘Error 20’

‘2182.0 kHz’

when these two buttons are pressed simultaneously.

3.5.2 PERFORMANCE CHECK OF RECEIVER

Connect the RE2100 with the testbox for RE2100 and connect the power supply and a loudspeaker to

the proper inputs on the testbox.

The necessary test equipment to carry out a performance check is described in this manual, chapter 3.3

PROPOSAL FOR NECESSARY TEST EQUIPMENT.

This chapter contains the following sections:

3.5.2.1. PERFORMANCE CHECK OF RECEIVER SENSITIVITY

3.5.2.2. PERFORMANCE CHECK OF RECEIVER DISTORTION

3.5.2.3. PERFORMANCE CHECK OF RECEIVER AUDIO PASSBAND

3.5.2.4. PERFORMANCE CHECK OF RECEIVER CLARIFIER AND FREQUENCY

3.5.2.5. PERFORMANCE CHECK OF RECEIVER AGC

3.5.2.6. PERFORMANCE CHECK OF RECEIVER SQUELCH

3.5.2.7. PERFORMANCE CHECK OF RECEIVER EXTERNAL CONNECTIONS

3.5.2.1 PERFORMANCE CHECK OF RECEIVER SENSITIVITY

1. Connect the signal generator to the aerial socket through the 50 ohm dummy load described in this

manual, chapter 3.3.

2. Connect a voltmeter or a distortion meter to the 0 dBm output on the testbox.

3. Choose receiver frequency f

RX

, generator frequency fG, and generator output level VG according to

table in point 5.

4. Measure the signal to noise ratio SND/N with the distortion meter or the voltmeter as described in

point 6. The measured signal to noise ratio shall be better than 20 dB.

PAGE 3-11

Page 42

3 SERVICE RE2100

5.

6. Measurement of the signal to noise SND/N.

With the specified test signal applied to the receiver, the measurement of SND/N is performed as

described below.

SSB MODE

a. Turn the RF-GAIN control fully clockwise and make sure that the AGC is operative.

b. Notice the output LF level by means of a voltmeter.

c. Turn the AGC OFF and adjust the RF-GAIN control to achieve the output level found in point

6.b.

d. Change the signal generator frequency fG to fRX + 30 kHz and notice the reduction of the

LF output level, which expresses the signal to noise ratio.

AM MODE

e. Turn the RF-GAIN fully clockwise and make sure that the AGC is operative.

f. Notice the output level by means of a voltmeter.

g. Remove modulation from the generator signal and notice the reduction of the output, which

expresses the signal to noise ratio.

3.5.2.2 PERFORMANCE CHECK OF RECEIVER DISTORTION

To carry out the check as described below, it is necessary to have a distortion meter at your disposal. If

this is not possible, the check can be done by an oscilloscope, but please note that it should not be possible

to see a distortion of 10% or less on the oscillocope.

1. Connect a distortion meter to the 0 dBm output on the testbox.

2. Connect a signal generator to the aerial socket through a 50 ohm dummy load.

3. Choose receiver frequency f

RX

generator frequency fG and generator output level VG according to

point 5.

PAGE 3-12

Page 43

3 SERVICE RE2100

4. Measure the signal distortion SND/ND with the distortion meter. The measured distortion SND/ND

shall be better than the figures given in the table in point 5.

5.

3.5.2.3 PERFORMANCE CHECK OF RECEIVER AUDIO PASSBAND

1. Connect the signal generator to the aerial socket through a 50 ohm dummy load.

2. Connect a voltmeter to the 0 dBm output on the testbox.

3. Choose receiver frequency f

RX

, generator frequency fG, generator output level VG according to point

7.

4. USB-SSB MODE

a. Set the f

RX

, fG and VG according to point 1 in the table in point 7.

b. Turn the RF-GAIN control fully clockwise and make sure that the AGC is operative.

c. Notice the AF output level by means of the voltmeter.

d. Turn the AGC off and adjust the RF-GAIN control to achieve the output level found in

point 4.c.

e. Change the signal generator frequency fG, and the generator output level VG according to

point 2 in table 7, and control the voltage on 0 dBm output to be above the value found in

point 4.c.

f. Change f

G

according to point 3 in table 7 and control the voltage on 0 dBm output to be below

the value found in point 4.c.

5. LSB-SSB MODE

Carry out point 4. USB-SSB MODE, but use the figures mentioned in point 7, under “lower sideband

audio passband”.

6. AM MODE

a. Set f

RX

, fG and VG according to point 4 in table 7.

b. Notice the AF output level by means of the voltmeter.

c. Change the modulation frequency according to the figures in point 5 in table 7, and control

that the voltage on 0 dBm output has not dropped 6 dB below the value found in point 6.b.

d. Change the modulation frequency according to the figures in point 6 in table 7, and control

that the voltage on 0 dBm output has dropped more than 20 dB below the value found in

point 6.b.

PAGE 3-13

Page 44

3 SERVICE RE2100

7.

3.5.2.4 PERFORMANCE CHECK OF RECEIVER CLARIFIER AND FREQUENCY

1. Connect the signal generator to the aerial socket through a 50 ohm dummy load.

2. Choose receiver frequency f

RX

, signal generator frequency fG, and the generator output level V

G

according to point 6.

3. Connect a frequency counter to 0 dBm output on the testbox.

4. Activate the frequency tune and let the frequency f

RX

change in 100 Hz steps and control with the

counter that this happens.

5. Activate the clarifier tune and let the frequency f

RX

change in 10 Hz steps and control with the

counter that this happens.

6.

7. With the frequency and clarifier tune, set the frequency fRX to 25000.07 kHz.

PAGE 3-14

Page 45

3 SERVICE RE2100

8. Control with the counter the output frequency to be 930 Hz +/-10 Hz.

NOTE!

The frequency tolerance of the signal generator shall be better than +/-2.5 Hz 0.1 ppm. If not and

if the counter has a frequency tolerance of 0.1 ppm, carry out the measurement in section 3.5.3.2.

Performance Check of Exciter Frequency.

3.5.2.5 PERFORMANCE CHECK OF RECEIVER AGC

1. Connect the signal generator to the aerial socket through a 50 ohm dummy load.

2. Connect a voltmeter to the 0 dBm output on the testbox.

3. Choose receiver frequency f

RX

, generator frequency fG, and generator output level VG according to

the table in point 4.

4.

5. Turn the RF-GAIN control fully clockwise, and make sure that the AGC is operative.

6. Notice the AF output level by means of the voltmeter at the 0 dBm output.

7. Increase the output level of the signal generator to 28 dB/uV.

8. The increase in AF output level measured with the voltmeter shall be less than 3 dB.

9. Notice the AF output level by means of the voltmeter at the 0 dBm output.

10. Turn the AGC OFF and adjust the RF-GAIN control to achieve the output level found in point 9.

11. Disconnect the signal generator from the aerial socket and notice the reduction of the AF output

level, which shall be at least 35 dB.

12. Reconnect the signal generator to the aerial socket.

13. Turn the RF-GAIN control fully clockwise and make sure that the AGC is operative.

14. Notice the AF output level by means of the voltmeter at the 0 dBm output.

15. Increase the output level of the signal generator to 78 dB/uV.

16. The increase in AF output level measured with the voltmeter shall be less than 2 dB.

17. Connect 0 dBm output from the testbox to channel A on the oscilloscope.

18. Connect the SP-BUS output socket on RE2100 to channel B on the oscilloscope.

19. Select test programme SP-04-6.

20. Set the timebase on the oscilloscope to 20 msecs/div.

21. Set the oscilloscope to trig on channel B.

22. Control that the oscilloscope displays the response shown in figure SSB attack.

PAGE 3-15

Page 46

3 SERVICE RE2100

SSB ATTACK

A = 0.5V/div 20 msecs/div

B = 5V /div.

23. Set the timebase on the oscilloscope to 200 msecs/div.

24. Control that the oscilloscope displays the response shown in figure SSB decay.

SSB DECAY

A = 0.5V/div. 200 msecs/div.

B = 5V /div.

25. Select test programme SP-04-7.

26. Set the timebase on the oscilloscope to 50 msecs/div.

27. Set the signal generator in amplitude modulation mode, modulating LF signal 1.0 kHz and

modulating index M = 0.3.

28. Control that the oscilloscope displays the response shown in figure AM attack and decay.

PAGE 3-16

Page 47

3 SERVICE RE2100

AM ATTACK AND DECAY

A = 1.0V/div. 50 msecs/div.

B = 5.0V/div.

3.5.2.6 PERFORMANCE CHECK OF RECEIVER SQUELCH

1. Connect a signal generator to the aerial socket through a 50 ohm dummy load.

2. Choose the receiver frequency f

RX

, signal generator frequency fG, and the generator output level

V

G

according to table in point 8.

3. Make sure that the AGC and SQUELCH are active and adjust the AF volumen until a tone is heard

in the loudspeaker.

4. Disconnect the signal generator from the aerial socket on the RE2100. You will now hear the

receiver noise from the loudspeaker.

5. Control that the AF output is muted after about 10 secs.

6. Connect the signal generator to the aerial socket again.

7. Control that the squelch opens instantly and that you now hear a 1 kHz tone from the loudspeaker.

8. Control that the squelch closes after about 10 secs.

9.

3.5.2.7 PERFORMANCE CHECK OF RECEIVER EXTERNAL CONNECTIONS

1. If no testbox for RE2100 is available, the connections can be found and checked in the 25 pin

connector and the 9 pin connector at the back of the RE2100.

2. Press the front panel key <2182> fixed.

3. Control that the light emitting diodes names distress and +18 handset at the testbox are alight.

PAGE 3-17

Page 48

3 SERVICE RE2100

4. Connect a signal generator to the aerial socket through a 50 ohm dummy load.

5. Choose receiver frequency f

RX

, signal generator frequency fG and the generator output V

G

according to table in point 6.

6.

7. A 1 kHz tone shall be heard from the loudspeaker and approx. seven bars in the signal strength

meter are alight.

8. Activate the RX mute switch on the testbox.

9. No tone or noise shall now be heard from the loudspeaker and approx. 2 bars in the signal strength

meter are alight.

10. Release the RX mute switch.

11. Activate the TEST ALARM button on RE2100 and control that the alarm tones can be heard in the

handset earpiece

3.5.3 PERFORMANCE CHECK OF EXCITER

Connect the RE2100 with the testbox for RE2100.

Connect a +/-18V/2A power supply, an LF signal generator, and the handset to the proper inputs on the

testbox.

The necessary test equipment for executing the performance check is described in this manual, chapter

3.3. PROPOSAL FOR NECESSARY TEST EQUIPMENT.

This chapter consists of the following sections:

3.5.3.1. Performance Check of Exciter Output Signal

3.5.3.2. Performance Check of Exciter Frequencies and Classes of Emission

3.5.3.3. Performance Check of Exciter Microphone Amplifier and LF Response

3.5.3.4. Performance Check of Exciter Step Attenuator

3.5.3.1 PERFORMANCE CHECK OF EXCITER OUTPUT SIGNAL

1. Connect a 50 ohm resistor to the aerial socket. Two 100 ohm resistors in parallel soldered on a coax

cable connected to the aerial socket are sufficient.

2. Connect an oscilloscope through a 10:1 probe to the 50 ohm resistor.

3. Connect the LF signal generator to the AF TO TX input on the testbox.

4. Select test programme SP-05-1 (fTX = 22.000 kHz).

5. Set the testbox switch RF ON/OFF on.

6. Adjust the LF signal generator to an output of 1Vpp (0.350V

RMS

) and a frequency of 1600 Hz.

7. Control that the HF output shown on the oscilloscope is 3.50 +/-0.50Vpp.

8. Readjust the oscilloscope gain until full deflection (8 div.) is seen on the screen.

PAGE 3-18

Page 49

3 SERVICE RE2100

9. Select test programme SP-05-5 (fTX = 14.900 kHz).

10. Control that deflection now seen is approx. 8.0 +/-1.0 div.

11. Select test programme SP-05-4 (fTX = 28.000 kHz).

12. Control that deflection now seen is approx. 8.0 +/-1.0 div.

13. Select test programme SP-05-6 (fTX = 1.600 kHz).

14. Control that deflection now seen is approx. 8.0 +/-1.0 div.

15. Set the testbox switch RX ON/OFF off.

16. Select test programme SP-05-0 (fTX = 22.000 kHz).

17. Set the testbox switch MIC.KEY on.

18. Control that the HF output shown on the oscilloscope is 4.0 +/-0.5Vpp and that it is a two tone signal

which is displayed.

19. Control that approx. 7 bars in the signal strength meter are alight.

20. Set the testbox switch MIC.KEY off.

21. Activate the handset key and control that the two tone signal is displayed on the oscilloscope

screen.

22. Activate the keyboard button TUNE.

23. Activate the keyboard button TEST ALARM.

24. Control that the alarm tone can be heard in the handset earpiece.

3.5.3.2 PERFORMANCE CHECK OF EXCITER FREQUENCIES AND CLASSES

OF EMISSION

1. If only this section is performed, please start by carrying out the section 3.5.3.1. point 1, 2, and 3.

2. Select test programme SP-05-6 (fTX = 1.600 kHz).

3. Set the testbox switch RF ON/OFF on.

4. Adjust the LF signal generator to an output of 1Vpp (0.35V

RMS

) and a frequency of 1600 Hz.

5. Adjust the oscilloscope gain until full deflection (8 div.) is seen on the screen.

6. Toggle the MODE switch on RE2100 between J3E, R3E, H3E, and TELEX, and control that the

deflection is approx. the same in all the classes of emission 8.0 +/-1.0 div.

7. Disconnect the LF signal generator.

8. Select the emission mode H3E on RE2100 and control that the deflection seen on the oscilloscope

is 4.6 +/-0.5 div.

9. Select the emission mode R3E on RE2100 and control that the deflection seen on the oscilloscope

is 1.2 +/-0.2 div.

10. Select test programme SP-05-4 (fTX = 28.000 MHz).

11. Select the emission mode H3E on RE2100.

PAGE 3-19

Page 50

3 SERVICE RE2100

12. Connect a frequency counter through a 10:1 probe to the 50 ohm resistor at the HF output socket.

13. Control that the frequency is 28,000,000 +/-10 Hz.

NOTE! The frequency tolerance of the counter shall be better than 0.1 ppm.

14. Set the testbox switch RF 50% DUTY CYCLE on.

15. Connect the oscilloscope through a 10:1 probe to the 50 ohm resistor at the HF output socket, and

disconnect the frequency counter.

16. The HF signal seen on the oscilloscope screen is switched on for 250 msecs and then off for 250

msecs.

17. Control that the attack time of the HF signal is not more than 2 msecs, and that the decay time is

not more than 3 msecs.

18. Set the testbox switch RF 50% DUTY CYCLE off and the testbox switch RF ON/OFF off.

If TELEX MODE is possible carry out the following points, if not go to the next section 3.5.3.3.

19. Connect the LF signal generator to the AF TO TX input on the testbox.

20. Adjust the LF signal generator output to 3Vpp/1600 Hz.

21. Select the emission mode TELEX on RE2100.

22. Set the testbox switch MIC.KEY on.

23. Control that the HF output shown on the oscilloscope is 4.0 +/-0.5Vpp.

3.5.3.3 PERFORMANCE CHECK OF EXCITER MICROPHONE AMPLIFIER AND

LF RESPONSE

1. If only this chapter is performed, please start by carrying out the section 3.5.3.1. point 1, 2, and 3.

2. Select test programme SP-05-6 (f

TX

= 1.600 kHz).

3. Set the testbox MIC-KEY on.

4. Set the LF signal generator frequency to 1Vpp/1600 Hz.

5. Adjust the LF signal generator frequency until the deflection seen on the oscilloscope is max.

approx. 1600 Hz.

6. Adjust the oscilloscope gain until full deflection (8 div.) is seen on the screen.

7. Adjust the LF signal generator frequency to 350 Hz and to 2700 Hz and control that the deflection

seen on the oscilloscope screen is above 4.0 div.

8. Set the LF signal generator frequency to 1.0Vpp/1000 Hz.

9. Adjust the oscilloscope gain until full deflection (8 div.) is seen on the screen.

10. Adjust the LF signal generator output level until the HF output level seen on the osilloscope is

approx. 7.5 div.

11. Control that the LF signal generator level at the input of the testbox is now 100 +/-50 mVpp.

PAGE 3-20

Page 51

3 SERVICE RE2100

3.5.3.4 PERFORMANCE CHECK OF EXCITER STEP ATTENUATOR

1. If only this chapter is performed, please start by carrying out the section 3.5.3.1. point 1 and 2.

2. Select test programme SP-05-2.

3. Check that the stairs and staircase waveform seen on the oscilloscope screen has a continuous

decreasing amplitude as shown below

4-0-26207

3.6 MODULE PERFORMANCE CHECK

GENERAL

A module performance check is intended to be used as an integral part of the trouble-shooting, because

it gives the technician a chance to control the individual modules and parts of the circuit on each module.

The module performance check is divided into subsections, which correspond to the individual modules,

and each of these subsections contains a number of check procedures.

The module performance check is carried out with all modules mounted in the HF SSB RE2100, and if

a testbox is available, it should be used. The RE2100, the power supply, and the handset are all connected

to the testbox as described in chapter 3.3. PROPOSAL FOR NECESSARY TEST EQUIPMENT.

If no testbox is available, it is possible to operate the RE2100 by connecting the power supply directly to

the 25 pin connector, which is located at the back of the RE2100. The pin configuration for this connector

is listed in chapter 2.3. ELECTRICAL CONNECTION AND ASSEMBLING. But it is only necessary to

establish the following connections:

pin No. 10 -18V/0.2A

pin No. 11 + 9V/0.5A

pin No. 12 +18V/0.8A

pin No. 5 GND

The handset is connected directly to the 9 pin connector at the back of the RE2100.

This chapter includes a number of measurements where a signal generator is needed. The output level

of the generator is, in this manual, expressed in terms of the Electromotive Force (EMF), and it is

measured in terms of the unit: dB/uV = 20 log(EMF/1uV), (dB above one microvolt).

PAGE 3-21

Page 52

3 SERVICE RE2100

The output level from signal generators in general is sometimes expressed in terms of the available power

P

a

, which is measured in terms of the unit: dBm = 10 log(Pa/1mW), (dB above one milliwatt). For this

reason the conversion formulas between EMF and available power and vice versa are given here:

Pa (dBm) = EMF (dB/uV) - 113 dB

EMF (dB/uV) = P

a

(dBm) + 113 dB

where P

a

is the available power and EMF is the Electromotive Force of the generator.

3.6.1 MODULE PERFORMANCE CHECK OF RECEIVER UNIT

This chapter contains the following sections:

3.6.1.1. Check of Sensitivity (RX-Module)

3.6.1.2. Check of LO2 and Reinjection Signals

3.6.1.3. Check of Crystal Filters (2nd IF)

3.6.1.4. Check of 2nd IF Amplifier

3.6.1.5. Check of AGC Circuit

3.6.1.6. Check of Detector

3.6.1.7. Check of AF Filters

3.6.1.8. Check of Earpiece Amplifier

3.6.1.9. Check of Squelch Circuit

3.6.1.1 CHECK OF SENSITIVITY (RX_MODULE)

The sensitivity of the receiver unit is mainly determined by the Second Mixer because of its relatively large

power gain of about 8 dB. It is therefore most likely that a degradation of the sensitivity is caused by the

mixer; but be aware that this is not the only possible failure.

A degradation of the sensitivity could also be caused by a failure in the IF-amplifier, detector, audio

frequency circuit, or simply by a missing local oscillator signal (LO2 or carrier reinjection).

To obtain a correct measurement of sensitivity, it is necessary to feed the generator signal through an

impedance matching network as shown below.

4-0-26211

Impedance matching between generator and receiver module.

1. Connect the generator to receiver module through the impedance matching network shown above.

2. Connect the voltmeter to earpiece output at testpoint TR2-1 for measuring the AC-voltage.

3. Turn the RE2100 on.

4. Choose generator frequency f

G

and generator output level VG as specified in point 6. Select the

wanted Receiver Module (SSB/AM).

5. Measure the signal to noise ratio SND/N at the earpiece output and check that it is above 20 dB.

(see section 3.5.2.1., point 6 for instructions about how to measure SND/N).

PAGE 3-22

Page 53

3 SERVICE RE2100

6.

3.6.1.2 CHECK OF LO2 AND REINJECTION SIGNALS

The LO2 signal is used in the mixing process from the 1st IF at 70.00064 MHz to the 2nd IF at 10.73152

MHz. The frequency of the LO2 signal is 59.26912 MHz when receiving a H3E signal or J3E-USB signal.

In J3E-LSB mode the frequency of the LO2 signal is 80.73216 MHz.

The carrier reinjection signal is used in the detection of signals with a reduced carrier or signals without

any carrier. The frequency of the carrier reinjection signal is 10.73152 MHz and is given by the TCXO.

1. Turn the RE2100 on and select J3E-USB mode.

2. To check the LO2 signal, connect the diode probe across the resistor R188-1, which is located at

the output of the LO buffer at the Receiver Unit (module 1).

3. Check the measured DC voltage to be 3.3V +/-0.5V.

4. To check the reinjection signal connect a DC voltmeter through the diode probe to pin 8 at the

detector IC (LM3189).

5. Check the measured DC voltage to be 300 mV +/-50 mV.

3.6.1.3 CHECK OF CRYSTAL FILTERS (2nd IF)

The selectivity of the second intermediate frequency is given by the crystal filters (SSB or AM filter), which

form an important part of the overall receiver selectivity.

If the 2nd IF selectivity cannot fulfil the specified requirements, it is probably caused by a mistuning of the

two crystal filters or by a mistuning of the 1st IF filter at 70 MHz.

The crystal filters are tuned by the trimming capacitor C18-1, which is located at the receiver unit. The

adjustment procedure for this capacitor is described in section 3.7.1.3.

The 1st IF filter is tuned by three trimming coils and two transformers. The adjustment procedure for these

components is described in section 3.7.1.1.

In this test of selectivity, the 6 dB bandwidth and the stop band attenuation is controlled. The test is

performed by using variations in the level detector output voltage, which can be measured at testpoint

TP1-1 in the AGC circuit. The voltage can be measured by using an analog multimeter, but it is easier

to use a digital multimeter, because the variations in the level detector output voltage are relatively small

(about 200 mV).

PAGE 3-23

Page 54

3 SERVICE RE2100

SSB MODE

1. Connect the generator to the aerial socket at the front end unit (module 2).

2. Connect the voltmeter to testpoint TP1-1 for measuring the DC voltage at the level detector output.

3. Connect the counter to earpiece output at testpoint TP2-1.

4. Turn the RE2100 on.

5. Turn the RF gain control fully clockwise and make sure that the AGC is operative.

6. Choose generator frequency f

G

, generator output level VG and receiver frequency fRX according to

the table in point 20.

7. Make sure that J3E mode (SSB) is selected and that the AF signal frequency is approx. 1 kHz.

8. Wait 15 min. before proceeding, to temperature stabilize the receiver.

9. Turn off the AGC and adjust the manual RF GAIN Control to achieve a voltage of about 5 volt at

testpoint TP1-1.

10. Finetune the receiver frequency by means of the arrow keys until maximum meter deflection, when

measuring at testpoint TP1-1.

11. Readjust the manual RF GAIN to achieve a voltage of 5 volt at testpoint TP1-1.

12. To measure the 6 dB bandwidth, increase V

G

by 6 dB and notice that the measured voltage will

increase to about 14 Volt.

13. Increase the receiver by means of the upward arrow key until the voltage at testpoint TP1-1 is just

about 5V.

14. Activate the clarifier function by pressing the <CLARIF> key and finetune the receiver frequency

with the arrow keys until the voltage measured at testpoint TP1-1 is just above 5 volt. Now notice

the receiver frequency in the display.

15. Deactivate the clarifier function by pressing the <CLARIF> key and decrease the receiver

frequency by means of the downward arrow key until the measured voltage is just about 5 volt.

16. Key-in point 14.

17. Calculate the difference between the two frequencies found in points 14 and 16. This difference

is equal to the 6 dB bandwidth, which must be above 2550 Hz.

18. To check the stopband attenuation, increase generator output level VG by 20 dB relative to VG in

point 20.

19. Key-in the frequencies 1987.7 kHz and 1991.2 kHz and remember to turn off the AGC in each case.

Control in both cases the DC voltage at testpoint TP1-1 to be below 5 volt.

20.

PAGE 3-24

Page 55

3 SERVICE RE2100

AM MODE

21. Repeat points 1, 2 and 4-6.

22. Make sure that H3E mode (AM) is selected.

23. Repeat point 8-11.

24. Increase generator output level V

G

by 6 dB.

25. To check the 6 dB bandwidth, key-in the frequencies 986,7 kHz and 993.3 kHz, and control in each

case the voltage at testpoint TP1-1 to be above 5 volt. Remember in each case to turn off the AGC.

26. Increase generator output level V

G

by 36 dB relative to VG in point 20.

25. To check the stopband attenuation, key-in the frequencies 982,9 kHz and 997,1 kHz, and control

in each case the voltage at testpoint TP1-1 to be below 5 volt. Remember in each case to turn off

the AGC.

3.6.1.4 CHECK OF 2nd IF AMPLIFIER

In this test the gain of the 2nd IF amplifier is controlled by checking the threshold level of the Automatic

Gain Control.

This threshold level is defined in the figure below, where the AGC-characteristic is sketched.

4-0-26210

AGC-characteristic used to define the sensitivity or threshold level of the AGC.

PAGE 3-25

Page 56

3 SERVICE RE2100

Below the threshold level the input signal is too weak to be detected by the AGC circuit. The gain of the

2nd IF amplifier is then unregulated and the receiver output level will increase as 1:1 with increasing input

level.

Above the threshold level the input signal is large enough to be detected by the AGC. The gain of the 2nd

IF amplifier will then be regulated and the output from the receiver will idealistically be kept at a constant

level. However, in practice the receiver output level will increase slightly with increasing input level,

because a constant output level would require an infinite gain of the 2nd IF amplifier.

The performance of the AGC above the threshold level is checked by measuring the “flatness” of the AGC

characteristic. This measurement is also included in the check procedure given below, because it is

measured in the same manner as the threshold level.

The threshold level must, as indicated in the AGC characteristic, be less than the sensitivity level of the

receiver to ensure correct function of the AGC. The threshold level is determined by the level detector

and the open loop gain from the aerial input to the level detector input. To study this in more details, the

simplified block diagram is used in the following description.

4-0-26212

Simplified block diagram for the entire receiver.

PAGE 3-26

Page 57

3 SERVICE RE2100

In the level detector, which is built-up around the transistor Q14-1, the base-emitter diode is used to

convert the received AC signal to a DC signal. Thus the input voltage to the level detector is almost a

constant and is equal to the diode cut-in voltage. The open loop gain from the aerial input to the level

detector input must then be sufficiently high to produce the required peak voltage of about 0.65V with an

input signal at the receiver sensitivity level.

In the simplified block diagram, the amplification from the aerial input to the level detector input is divided

into four blocks, which are:

1. Front End Unit

2. 2nd Mixer plus 2nd IF Filter

3. 2nd IF Amplifier

4. AGC Amplifier.

If the receiver does not pass the test of the threshold level given below, it is probably caused by a loss

of gain in one of the four blocks.

The gain of the Front End Unit can be controlled directly by the test procedure given in the section 3.6.2.5.,

while the gain of the 2nd mixer and the 2nd IF filter can only be controlled indirectly by the sensitivity test

of the RX module given in section 3.6.1.1.

The gain of the AGC amplifier can be controlled by measuring the detector output level, which must be

almost constant from one module to another, because of the rectifying diode in the level detector. To

control the detector output level, use the check procedure given in section 3.6.1.6.

If the Front End Unit, the 2nd mixer and 2nd IF filter, and the AGC amplifier all perform as expected, the

2nd IF amplifier must finally be examined. The problem may be solved by adjusting the reference voltage

VREF in the AGC circuit. The adjustment is performed by the trimming resistor R203-1 and is described

in section 3.7.1.4.

1. Connect the generator to the aerial socket at the front end unit (module 2).

2. Connect the voltmeter to testpoint TP2-1 for measuring the AC voltage at the earpiece output.

3. Turn the RE2100 on and turn the RF gain control fully clockwise.

4. Choose generator frequency fG, generator output level VG, and receiver frequency fRX according to

point 9.

5. Measure the signal to noise ratio SND/N at the earpiece output (see section 3.5.2.1., point 6 for

instructions about how to measure SND/N).

If the signal to noise ratio SND/N is different from 20 dB, the generator output level must be adjusted

until this value is obtained.

6. Notice the earpiece output at testpoint TP2-1.

7. To control the threshold level of the AGC, increase the generator output level V

G

by 20 dB and

control that the earpiece output level does not increase by more than 2 dB relative to the level

measured in point 6.

8. To control the flatness of the AGC, increase the generator output level V

G

by 50 dB so the total

increase is 70 dB. Control that the earpiece output level does not increase by more than 3 dB

relative to the level measured in point 6.

9.

PAGE 3-27

Page 58

3 SERVICE RE2100

3.6.1.5 CHECK OF AGC CIRCUIT

In this test the attack and decay time of the automatic gain control is controlled by measuring the step

response of the AGC circuit.

In J3E mode (SSB) the attack time is determined by the resistors R89-1, R91-1 and capacitor C72-1, while

the decay time is determined by R63-1 and C69-1.

In H3E mode (AM) the attack time and decay time are determined by R89-1, R91-1 and C71-1.

The measurement of step response is performed by a sudden increment or decrement of the RF input

level. This step in input level is obtained by toggling the RX mute relay, which is located at the front end

unit. The relay is controlled by two different service programmes.

The step response will be displayed on an oscilloscope, which with advantage may be a storagescope.

1. Connect the generator to aerial socket at the front end unit (module 2).

2. Connect the oscilloscope to testpoint TP3-1 for measuring the AGC voltage and select AC

coupling.