Saia Burgess Controls PCD7.D412DTPF, PCD7.D412DT5F, PCD7.D457VT5F, PCD7.D410VT5F User Manual

Manual

I/O-modules

PCD7.D412DTPF standard SVGA MB Panel and

PCD7.D4xxxT5F programmable pWeb Panel

Document 27-620 | Release ENG07 | 2019-06-20

for PCD1 / PCD2 series

and for PCD3 series

Saia-Burgess Controls AG

0 Content

0 Content

0.1 Document versions ............................................................................... 0-4

0.3 Brands and trademarks ........................................................................ 0-4

1 Quickstart

1.1 Introduction ........................................................................................... 1-1

1.2 Denition of the connectors ................................................................... 1-1

1.3 Voltage supply of the panel ................................................................... 1-2

1.4 Dimensions and cut-out (in mm) ........................................................... 1-3

1.4.1 12.1" panel ............................................................................................ 1-3

1.4.2 10.4" panel ............................................................................................ 1-3

1.4.3 5.7" panel .............................................................................................. 1-3

1.5 Installation of the panels ....................................................................... 1-4

1.5.1 Installation in control cabinet ................................................................. 1-4

1.5.2 Drywall mounting set for MB panels ...................................................... 1-5

1.6 Operation and handling of the touchscreen .......................................... 1-5

1.7 Setting up communications for displaying a website ............................. 1-6

1.7.1 HTTP Direct over ethernet RJ-45 connector ......................................... 1-6

1.7.2 USB port as Service port ....................................................................... 1-7

1.7.3

Getting started with the Web Editor on the MicroBrowser panel PCD7.D4xx 1-7

Content

Content

0

2 Technical data for the two panel types

2.1 Technical data of the SVGA MicroBrowser panel .................................. 2-1

2.2 Technical data for the pWeb panels ...................................................... 2-2

2.2.1 Overview ............................................................................................... 2-2

2.2.2 Product-related presentation ................................................................. 2-2

2.2.2 Battery of the pWeb panel ..................................................................... 2-3

3 Logic controller of the programmable pWeb panel

3.1 Communications interfaces ................................................................... 3-4

3.1.1 On-board RS-485 .................................................................................. 3-4

3.1.2 Additional communications ports using slot A (Port no. 1) .................... 3-5

3.1.2.1 PCD7.F110S Serial Interface Module RS-485/RS-422 ........................ 3-7

3.1.2.2 PCD7.F121S Serial interface module RS-232

suitable for modem connection ............................................................. 3-8

3.1.2.3 PCD7.F150S Serial Interface Module RS-485 with Electrical Isolation 3-9

3.1.2.4 PCD7.F180S Serial Interface Module Belimo MP-Bus ........................ 3-10

3.2 Conguration of the hardware settings in PG5 ..................................... 3-11

3.2.1 General information ............................................................................... 3-11

3.2.2 Running the device congurator ........................................................... 3-12

3.3 Firmware version ................................................................................... 3-13

3.4 Downloading the program and backup ................................................. 3-14

3.4.1 Downloading the user program with PG5 ............................................. 3-14

3.4.2 Backing up and restoring the user program .......................................... 3-15

3.5 LED and operating status (12" pWeb panel, only) ................................ 3-16

3.6 Software Watchdog ............................................................................... 3-17

3.7 RIOs ...................................................................................................... 3-17

Manual PCD7.D412DTPF & PCD7.D4xxxT5F │ Document 27-620 – Release ENG07 │ 2019-06-20

0-1

Saia-Burgess Controls AG

4 Using the Setup menu

on the SVGA MB panels and pWeb panels

4.1 Opening the Setup menu ...................................................................... 4-1

4.2 Customising the start screen ................................................................. 4-2

4.3 Changing the password ........................................................................ 4-2

4.4 Saving and exiting ................................................................................. 4-3

5 Structure and description of the Setup menu

5.1 Network ................................................................................................. 5-2

5.1.1 DCHP On .............................................................................................. 5-2

5.1.2 TCP/IP address ..................................................................................... 5-2

5.1.3 Subnet Mask ......................................................................................... 5-2

5.1.4 Default Gateway .................................................................................... 5-2

5.1.5 Primary DNS Server .............................................................................. 5-2

5.1.6 Secondary DNS Server ......................................................................... 5-2

5.2 Logic Controller (pWeb panels, only) .................................................... 5-3

5.2.1 Program Name ...................................................................................... 5-3

5.2.2 Status: RUN or HALT ............................................................................ 5-3

5.2.3 S-BUS ................................................................................................... 5-3

5.3 Web Connection .................................................................................... 5-5

5.3.1 Connection ............................................................................................ 5-5

5.3.2 Type (no selection for pWeb) ................................................................ 5-5

5.3.3 Start page .............................................................................................. 5-5

5.3.4 Remote Host IP ..................................................................................... 5-5

5.3.5 Remote Port .......................................................................................... 5-5

5.3.6 Connection List ..................................................................................... 5-5

5.4 System .................................................................................................. 5-6

5.4.1 Production data ..................................................................................... 5-6

5.4.2 Info ........................................................................................................ 5-6

5.4.3 Settings ................................................................................................. 5-7

5.4.4 Special Settings .................................................................................... 5-8

5.4.5 Log ........................................................................................................ 5-8

5.4.6 Restart ................................................................................................... 5-8

5.5 Display .................................................................................................. 5-9

5.5.1 Brightness ............................................................................................. 5-9

5.5.2 Backlight [min] ....................................................................................... 5-9

5.5.3 Rotation ................................................................................................. 5-9

5.5.4 Calibrate Touchscreen ........................................................................... 5-9

5.6 Keyboard ............................................................................................... 5-9

5.6.1 SIP (Virtual Keyboard) ........................................................................... 5-9

5.6.2 Name of the rst keyboard .................................................................... 5-9

5.6.3 Width of the Focus (in Pixels) ............................................................... 5-9

5.7 Password .............................................................................................. 5-10

5.8 Language .............................................................................................. 5-10

Content

Content

0

Manual PCD7.D412DTPF & PCD7.D4xxxT5F │ Document 27-620 – Release ENG07 │ 2019-06-20

0-2

Saia-Burgess Controls AG

6 Localles/localserver

6.1 Connecting via FTP access ................................................................... 6-1

6.2 INTFLASH/WEBPAGES ........................................................................ 6-2

7 Updating and special settings

7.1 Firmware update ................................................................................... 7-1

7.1.1 Additional information on downloading FW ........................................... 7-1

7.1.2 Safe Firmware Download via USB ........................................................ 7-1

7.2 Reset / Resetting the device to factory settings .................................... 7-2

7.3 Backlight ................................................................................................ 7-2

7.4 Typefaces supported by MB panel PCD7.D4xx .................................... 7-3

7.5 Special Unicode fonts ........................................................................... 7-5

7.5.1 General information ............................................................................... 7-5

7.5.2 Multi-languages: Example ..................................................................... 7-7

7.5.3 Analysing incorrect fonts, font sizes or format templates ...................... 7-9

7.5.4 Web Editor ............................................................................................. 7-9

7.6 Internal special functions ....................................................................... 7-10

7.6.1 Container variable for SVGA MB panel ................................................. 7-10

7.6.2 uBT_BackLight Containerdiagramm ..................................................... 7-15

7.6.3 Additional uBTerminal container for "Save logs to File” function ........... 7-15

7.7 List of message box messages ............................................................. 7-16

Content

Content

0

8 Handling: precautionary measures

8.1 Glass touchscreen ................................................................................ 8-1

8.2 Information on the LCDs of the MB panel display ................................. 8-1

8.3 Care ...................................................................................................... 8-1

9 General recommendations for the Web Editor

9.1 In the "Project congurations" ............................................................... 9-1

9.2 In the Web Editor project (general information) ..................................... 9-1

9.3 Denition of an object in the Web Editor ............................................... 9-2

9.4 Handling ................................................................................................ 9-2

9.5 Some rules regarding gif images .......................................................... 9-2

9.5.1 Decompression in the video cache at startup using the Gif list ............. 9-3

9.5.2 Decompression of Gif les in the video cache at startup

using a dummy start screen .................................................................. 9-4

9.5.3 Decompression of Gif les: analysis/calculation ................................... 9-4

9.6 Expanded error messages for the SVGA panel .................................... 9-5

9.7 Extended alarm macros ........................................................................ 9-5

9.8 Trend macros for MB panels with "save logs to les" ........................... 9-5

A Appendix

A.1 Icons ...................................................................................................... A-1

A.2 Safety information ................................................................................. A-2

A.3 Waste of Electrical and Electronic Equipment (WEEE) disposal .......... A-3

A.4 Contact .................................................................................................. A-4

Manual PCD7.D412DTPF & PCD7.D4xxxT5F │ Document 27-620 – Release ENG07 │ 2019-06-20

0-3

Saia-Burgess Controls AG

Content

Document versions | Brands and trademarks

0.1 Documentversions

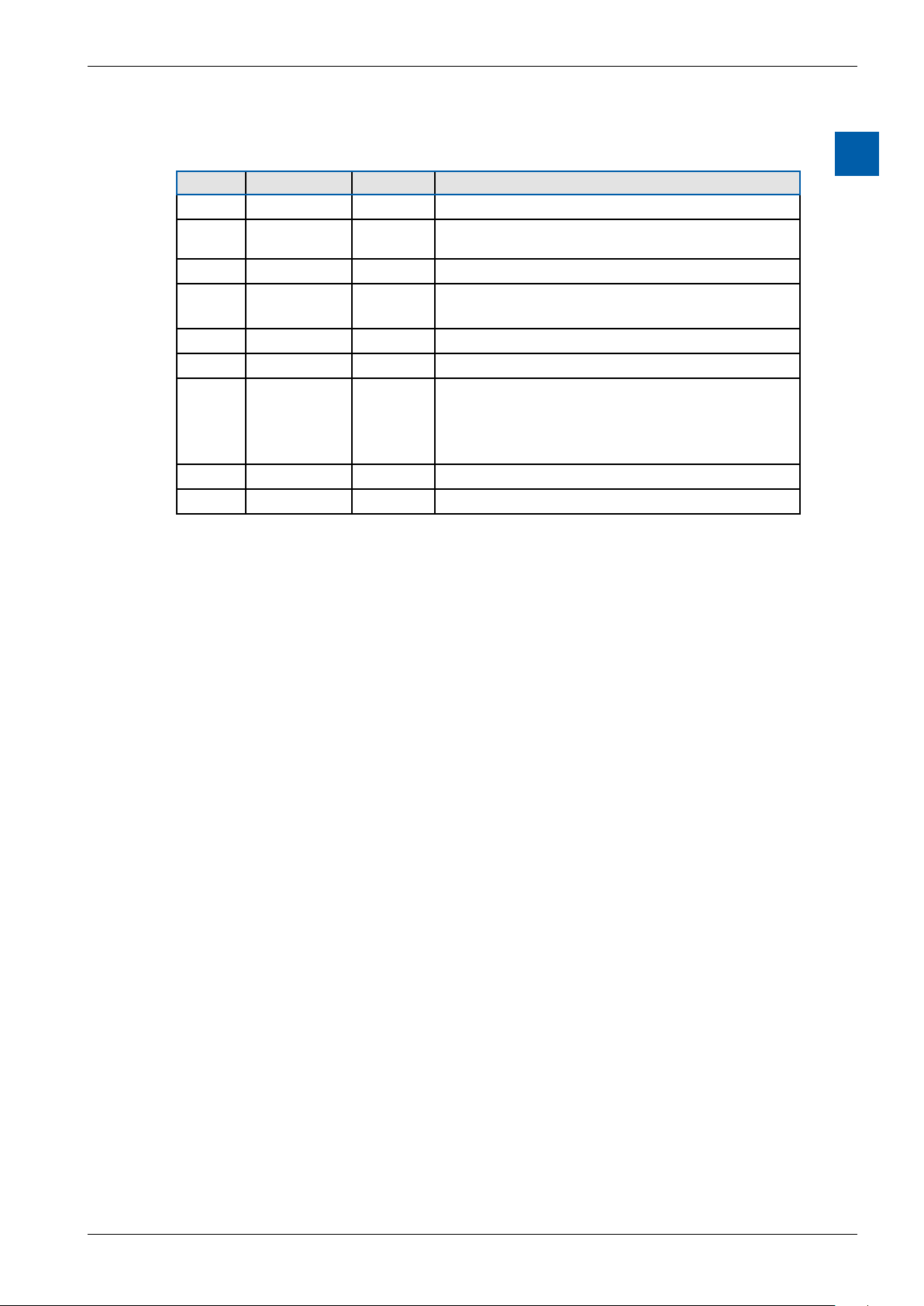

Version Published Redactor Remarks

EN01 2012-10-10 ErDa First version of manual

EN02 2012-11-28 HaMa

EN03 2013-12-18 ErDa Chapter 7.6.2 Container variables removed

EN04 2013-05-31 HaMa Chapter 3.1.2 Description oft the communica-

EN05 2014-01-20 HaMa New logo and new company name

ENG06 2016-01-27 HaMa New xation set

ENG07 2019-06-20 HaMa - Added the crossed bin logo for “Waste of

0

■ Ch1.2 Connection SD » D and /SD » D

■ Ch3.1.1 Picture RS-485-Network replaced

tion modules PCD7.F1xxS for Slot A

Electrical and Electronic Equipment (WEEE)”

disposal

- copied from Word to InDesign

0.3 Brands and trademarks

Saia PCD® and Saia PG5®

are registered trademarks of Saia-Burgess Controls AG.

Technical modications are based on the current state-of-the-art technology.

Saia-Burgess Controls AG, 2012. © All rights reserved.

Published in Switzerland

Manual PCD7.D412DTPF & PCD7.D4xxxT5F │ Document 27-620 – Release ENG07 │ 2019-06-20

0-4

Saia-Burgess Controls AG

1 Quickstart

Quickstart

Introduction | Denition of the connectors

1.1 Introduction

This manual covers the technical aspects of the PCD7.D412DTPF SVGA MB panel and the PCD7.D4xxxT5F programmable pWeb panel. The aim of the Quickstart

chapter is to facilitate the rapid installation of components of the PCD7.D4xxxT5F.

The following are discussed:

■ Denition of the connectors

■ Power supply and consumption

■ Dimensions

■ Possible communications modes

In other chapters, more details can be found about:

■ Hardware

■ Software (Setup menu step-by-step and conguration)

■ Usage, rmware update, etc.

■ Maintenance

Complementary manuals:

■ PG5 2.0 User guide | 26-732

■ File System and FTP Server | 26-855

■ Ethernet TCP/IP | 26-766

■ Smart RIO PCD3.T665 | 26-892

■ PCD3 series (conguration of the communications interfaces) | 26-789

1

1.2 Denitionoftheconnectors

PROTECTIVE EARTH MUST BE CONNECTED!

Manual PCD7.D412DTPF & PCD7.D4xxxT5F │ Document 27-620 – Release ENG07 │ 2019-06-20

1-1

Saia-Burgess Controls AG

Connections

Power Supply PCD7.F1xxS

Connector

pins

RS 485

Connector

pins

Signal

1 24 V (+)

2 GND (-)

Signal

1 GND

2 NC

3 /D

4 D

Quickstart

Denition of the connectors | Voltage supply of the panel

Connector

pins

0 GND GND

1 TXD232 SD

2 RXD232 /SD

3 RTS232

4 CTS232

5 GND GND

6 DTR232

7 DSR232

8 COM232

9 DCD232

Signal

RS 232

Signal

RS 485

1

Power supply

Communications

Reset button

Earth (-) / 24V (+) Connector, 2-pole

2× Ethernet (switch !) 2× RJ-45 with LED indicator

USB Standard USB slave

Pushbutton

1.3 Voltage supply of the panel

Pin Signal

1 24V (+)

2 Earth (-)

Current supply:

→ 24 VDC +30% / –20%

or

→ 19 VAC ±15% current supply with full-wave rectier

Current consumption Power output without back-

PCD7.D412DT5F

PCD7.D410VT5F

PCD7.D457VT5F

PCD7.D412DTPF Max 600 mA 5 W

Max 600 mA

Max 600 mA

max 500 mA

light

5 W

5 W

5 W

Current supply with jack plug for cable of max. 1.5 mm2.

Manual PCD7.D412DTPF & PCD7.D4xxxT5F │ Document 27-620 – Release ENG07 │ 2019-06-20

1-2

Saia-Burgess Controls AG

1.4 Dimensions and cut-out (in mm)

1.4.1 12.1" panel

62 6

Quickstart

Dimensions and cut-out (in mm)

1

Front panel W × H, 319 × 264

Display W × H, 245 × 185

1.4.2 10.4" panel

Front panel W × H, 281 × 221

Display W × H, 211 × 150

1.4.3 5.7" panel

Cut-out W × H, 300 × 244

62 6

Cut-out W × H, 262 × 202

50 6

Front panel W × H, 202 × 156

Display 5.7" W × H, 117 × 88

Manual PCD7.D412DTPF & PCD7.D4xxxT5F │ Document 27-620 – Release ENG07 │ 2019-06-20

Cut-out W × H, 189 × 142

1-3

Saia-Burgess Controls AG

1.5 Installation of the panels

1.5.1 Installation in control cabinet

■ The installation position is horizontal. Slide the unit into the installation cut-out.

■ Make sure that the ventilation slots are not covered, to allow air circulation and

the device does not overheat.

■ Install 4 mounting clamps for 5.7" (2 on top and 2 on the bottom), 6 clamps for

10.4" (2 on top, 2 on the bottom and 2 on the sides) and 8 clamps for the 12.1"

(3 on top, 3 on the bottom and 2 on the sides). Refer to the photos below.

Quickstart

Installation of the panels

1

Mounting parts of 12.1" panels

Mounting parts of 10.4" panels

Mounting parts of 5.7" panels

Note:

■ It is helpful to have somebody hold the unit from the front side of the panel

while the brackets are being installed.

■ The bolts require a 2.5 mm Allen key.

■ Screw the bolts into the brackets up to the point when you can still clip them

onto the MicroBrowser without being obstructed by the plate.

■ Clip them onto the unit then tighten the bolts until they touch the plate.

■ The required torque to seal the gasket is 20 cNm. To avoid breaking the clamp,

do not exceed 30 cNm.

How to ensure spray water protection according to IP65:

The device must be mounted on a at surface or wall. Tighten the bolts until the

front plate of the PCD7.D4xx is just touching the mounting surface/wall.

Manual PCD7.D412DTPF & PCD7.D4xxxT5F │ Document 27-620 – Release ENG07 │ 2019-06-20

1-4

Saia-Burgess Controls AG

1.5.2 Drywall mounting set for MB panels

The MicroBrowser panels are not just for mounting in the control cabinet; They

also look very good in the oce or living room, or mounted on a wall. This is why

we provide wall mounting kits for solid and cavity wall mounting.

Quickstart

Installation of the panels | Operation and handling

1

In-wall

Mounting kit for the 5.7” MB panel PCD7.D457-IWS2 PCD7.D457-OWS2

Mounting kit for the 10.4” MB panel PCD7.D410-IWS PCD7.D410-OWS

Mounting kit for the 12.1” MB panel PCD7.D412-IWS PCD7.D412-OWS

On-wall

In-wall(cavitywalls) On-wall (solid walls)

1.6 Operation and handling of the touchscreen

To operate the touchscreen, use only your nger, the stylus or a soft nger stylus.

Do not use sharp tools (e.g., sharp metallic objects, paperclips or a screwdriver,

etc.).

Manual PCD7.D412DTPF & PCD7.D4xxxT5F │ Document 27-620 – Release ENG07 │ 2019-06-20

1-5

Saia-Burgess Controls AG

Setting up communications for displaying a website

1.7 Setting up communications for displaying a website

1.7.1 HTTPDirectoverethernetRJ-45connector

The quickest communications port is the ethernet port via RJ-45, with the HTTP

Direct protocol selected. The speed is either 10 MBit/s or 100 MBit/s after an autonegotiation protocol with the connected device.

Internal connection for programmed pWeb panels

The programmed panels are connected internally directly to the programmable

logic controller, via an ethernet connection. It therefore suces, in this case, to

simply set the local host IP address 127.0.0.1 and HTTP Direct connection in the

Setup menu under Web connection. The programmable pWeb panels are obviously also capable of displaying websites from controllers located within the network.

The procedure for this is the same as with the standard 12” SVGA panel.

Connectingtoexternaldevices

If an ethernet connection to an Automation Server exists, the HTTP connection

can be established between our PCD7.D4xx and any SBC controller. In the case

of the programmable panels, the panel is generally connected to the internal con-

troller.

Quickstart

1

Ethernet http direct

Quick test of the SVGA panel

■ First the Saia PCD must have a web program loaded which was created with

the Web Editor (see 26-838_Manual_Web-Editor). You can ask the SBC Support Team for some examples. They will also soon be available on our website.

■ Using a CAT5 cable, you can connect our PCD7.D4xx terminal to the SBC

device. The current controllers support auto-crossing; a crossover cable is thus

no longer required.

■ Using PG5, dene the HW settings of the Saia PCD device: S-bus support

must be selected together with the TCP/IP channel where a valid IP address is

entered.

Manual PCD7.D412DTPF & PCD7.D4xxxT5F │ Document 27-620 – Release ENG07 │ 2019-06-20

1-6

Saia-Burgess Controls AG

Setup settings of the SVGA panel:

Congure the SVGA panel by opening the Setup menu (refer to chapter 5):

Quickstart

Setting up communications for displaying a website

Î First, be sure that you are on the same network subnet. For example, if the

Saia PCD has the IP address 192.168.12.92, give your terminal (in the Network

menu) an IP address like 192.168.12.90, as normally the subnet mask is set to

255.255.255.0.

Î In the Conguration menu, enter the Address of the start page that corre-

sponds to the IP address of the Saia PCD, and also enter its HTML start page

name.

Your MB panel should now be connected to the Saia PCD and the start page selection should be displayed on the screen. You can now navigate your web pages.

1.7.2 USBportasServiceport

The USB port on the programmable panels is used mainly to download the user

program onto the controller with PG5.

On SVGA standard MB panels, this port is generally used as a Service port. It is

used mainly to download new rmware programs onto the device.

The USB port meets the USB 1.1 specication. Maximum speed: 12 MBit/s.

1.7.3

Getting started with the Web Editor on the MicroBrowser panel PCD7.D4xx

1

Detailed documentation can be downloaded from our website. See manual 26-838

Manual Web Editor. To get started with programming the MB panel, some particular features must be observed:

■ If no assistance is available from the Wizard when creating a new project, the

project must be set up as follows:

● Using the virtual keyboard with SVGA MB panels

● See Chapter 5.6 Keyboard

● If you want to use the le Background.teq or foreground.teq, you rst need

to generate these les. Why is this? Before objects or text and elds can appear, these les must rst be positioned on each page.

● Once the project is ready to download, enter the desired HTML le name

and generate a Build Project. Then make a Webserver Build in the Saia PG5

Project Manager, so that all the les are held in the PCD. If you just want to

access the PCD with MB panel PCD7.D4xx and not with a PC browser, you

can reduce the amount of data by deleting the .jar les, as they are already

included on the panel.

Manual PCD7.D412DTPF & PCD7.D4xxxT5F │ Document 27-620 – Release ENG07 │ 2019-06-20

1-7

Saia-Burgess Controls AG

Technical data of the SVGA MicroBrowser panel

2 Technical data for the two panel types

The hardware of the SVGA MicroBrowser panels and the programmable pWeb

panels is dierentiated in several areas by the Programmable Logic Controller on

the pWeb panels. These are described in the following sections:

2.1 Technical data of the SVGA MicroBrowser panel

Display

Display size 12.1" TFT

Resolution SVGA 800 × 600

Backlight LED

Colours 65,536

Contrast adjustment Ye s

On Board File System 128 MByte

Operating system

Internetservices

Interfaces

Ethernet 10 / 100 M 2× RJ45 (switch)

Current consumption

Voltage supply

Protection class (front)

Temperature

Relativehumidity

Processor

Real Time Clock (RTC)

Saia PCD COSinuS with SBC MicroBrowser expansion

Automation Server, SBC MicroBrowser

Max 600 mA

24 VDC±20 %

IP65

Operation: 0 … 50°C

Storage: –25 … +70°C

Operation: 10 … 80%

Storage: 10 … 98% (non-condensing)

Coldre CF5373L, 240 MHz

Yes, with Supercap

Technical data

2

Manual PCD7.D412DTPF & PCD7.D4xxxT5F │ Document 27-620 – Release ENG07 │ 2019-06-20

2-1

Saia-Burgess Controls AG

Technical data of the SVGA MicroBrowser panel

2.2 Technical data for the pWeb panels

2.2.1 Overview

Logic controller

User program, ROM /DB/text 1 MByte

RAM/DB/text 1 Mbyte

Media 14,336 ags / 16,384 registers

Backup for user User program is saved to the integrated micro SD card

File system for user 128 MBytes, on-board

Program cycle time 10 cycles / sec maximum

Protocolsoneldlevel

Internetservices

Interfaces

Ethernet 10 / 100 M 2× RJ45 (switch)

USB (1.1 / 2.0) 1× client

Serial interfaces RS-485 & socket for PCD7.F1xxS communications module

Temperature range

Relativehumidity

Processor

Real Time Clock (RTC)

Battery

Serial-S-bus, Ether-S-bus, Ether-S-I/O, Modbus RTU,

TCP or M-bus

SBC MicroBrowser, Automation Server

Operation: 0 … 50°C

Storage: –25 … +70°C

Operation: 10 … 80%

Storage: 10 … 98% (non-condensing)

Coldre CF5373L, 240 MHz

Yes, with battery back-up

Lithium Renata CR 2032 (lifetime 1-3 years)

Technical data

2

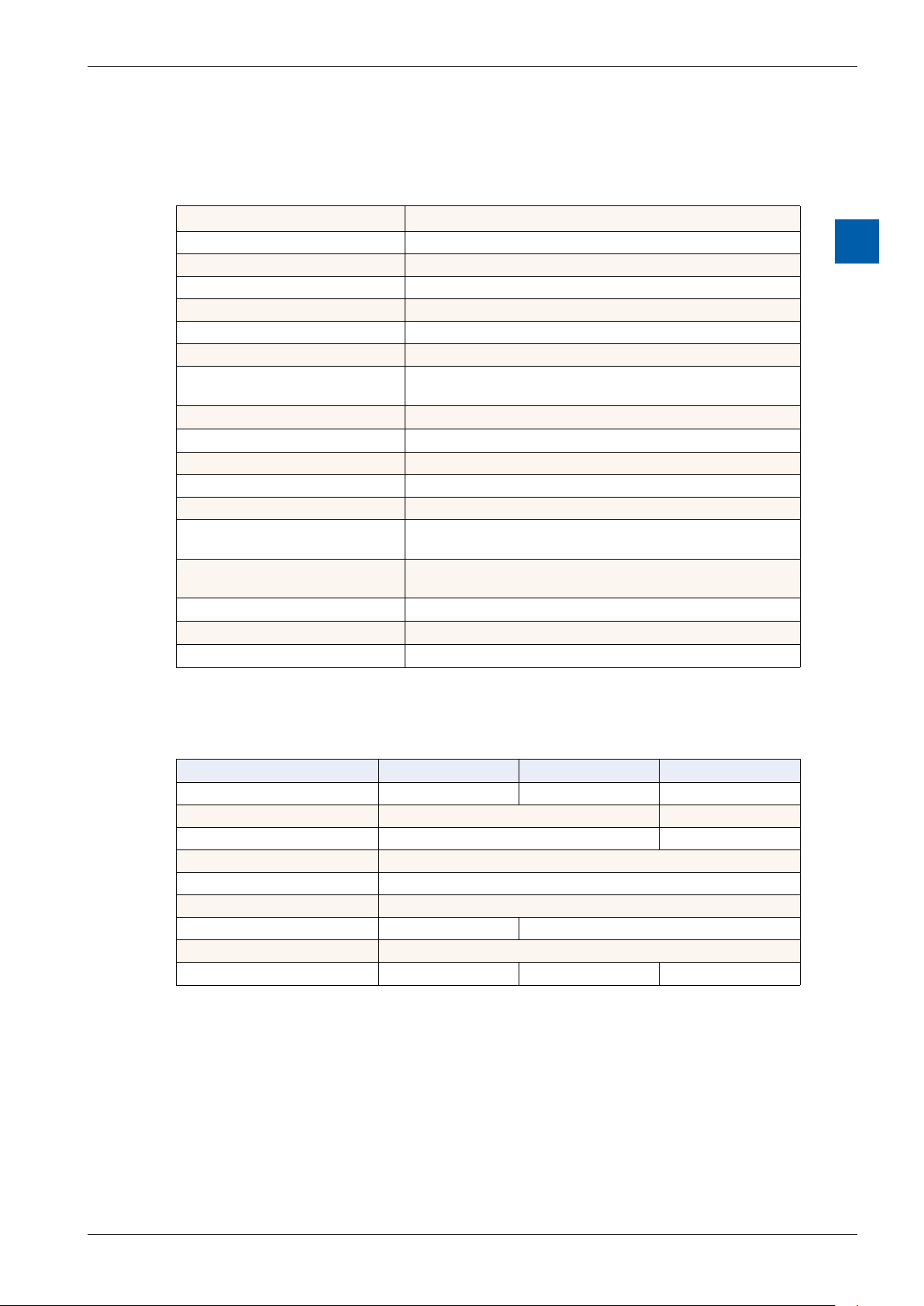

2.2.2 Product-related presentation

Technical data PCD7.D457VT5F PCD7.D410VT5F PCD7.D412DT5F

Display size 5.7 TFT 10.4 TFT 12.1 TFT

Resolution/Pixels VGA 640 × 480 SVGA 800 × 600

Touchscreen Resistive four-wire Resistive ve-wire

Contrast adjustment yes

Backlight LED

Voltage supply 18 - 32V

Current consumption Max. 500 mA Max. 600 mA

Protection class (front) IP 65

Front status LED No No Yes

Manual PCD7.D412DTPF & PCD7.D4xxxT5F │ Document 27-620 – Release ENG07 │ 2019-06-20

2-2

Saia-Burgess Controls AG

2.2.2 Battery of the pWeb panel

The hardware components are maintenance-free, with the exception of the CPUs

for the pWeb panel, whose battery requires occasional replacement.

Technical data

Technical data of the SVGA MicroBrowser panel

The components do not contain any user-replaceable parts. If hardware problems

occur, please return the components to Saia-Burgess Controls.

The resources (register, ags, timer, counters, etc.) and the character strings/DBs

are stored in the RAM. In order to prevent these from being lost, and to enable

the hardware clock to carry on running during a power failure, the devices are

equipped with a back-up battery:

CPU model Buer Buertime

PCD7.D4xxx Renata CR 2032 lithium battery 1-3 years

1)

Depending on the ambient temperature: The higher the temperature, the shorter the buer time.

1)

New controllers include batteries in the scope of delivery, and these must be

inserted during commissioning. Pay attention to the polarity of the batteries.

CPUs with lithium batteries are not maintenance-free. The battery voltage is monitored by the CPU. The status LED lights up (12” pWeb panel only) and XOB 2 is

called if:

■ the battery voltage is lower than 2.4 V;

■ the battery is missing.

2

In order to avoid data-loss, we recommend changing the batteries while the panel

is connected to the power supply.

■ Disconnect from the voltage supply.

■ Remove the cover of the pWeb panel.

■ To prevent data loss while changing the battery 119B, reconnect to the voltage

supply.

■ Push the terminal holder back slightly (see arrow in gure).

■ Remove the battery.

■ Insert a Renata CR 2032 button battery so that the positive terminal is in con-

tact with the terminal holder.

■ Disconnect from the voltage supply and reattach the back wall of the panel.

Manual PCD7.D412DTPF & PCD7.D4xxxT5F │ Document 27-620 – Release ENG07 │ 2019-06-20

2-3

Saia-Burgess Controls AG

Communications interfaces

3 Logic controller of the programmable pWeb panel

3.1 Communications interfaces

Various communications interfaces are integrated into the programmable logic

controller. These can also be expanded by installing an additional module.

Logic Controller

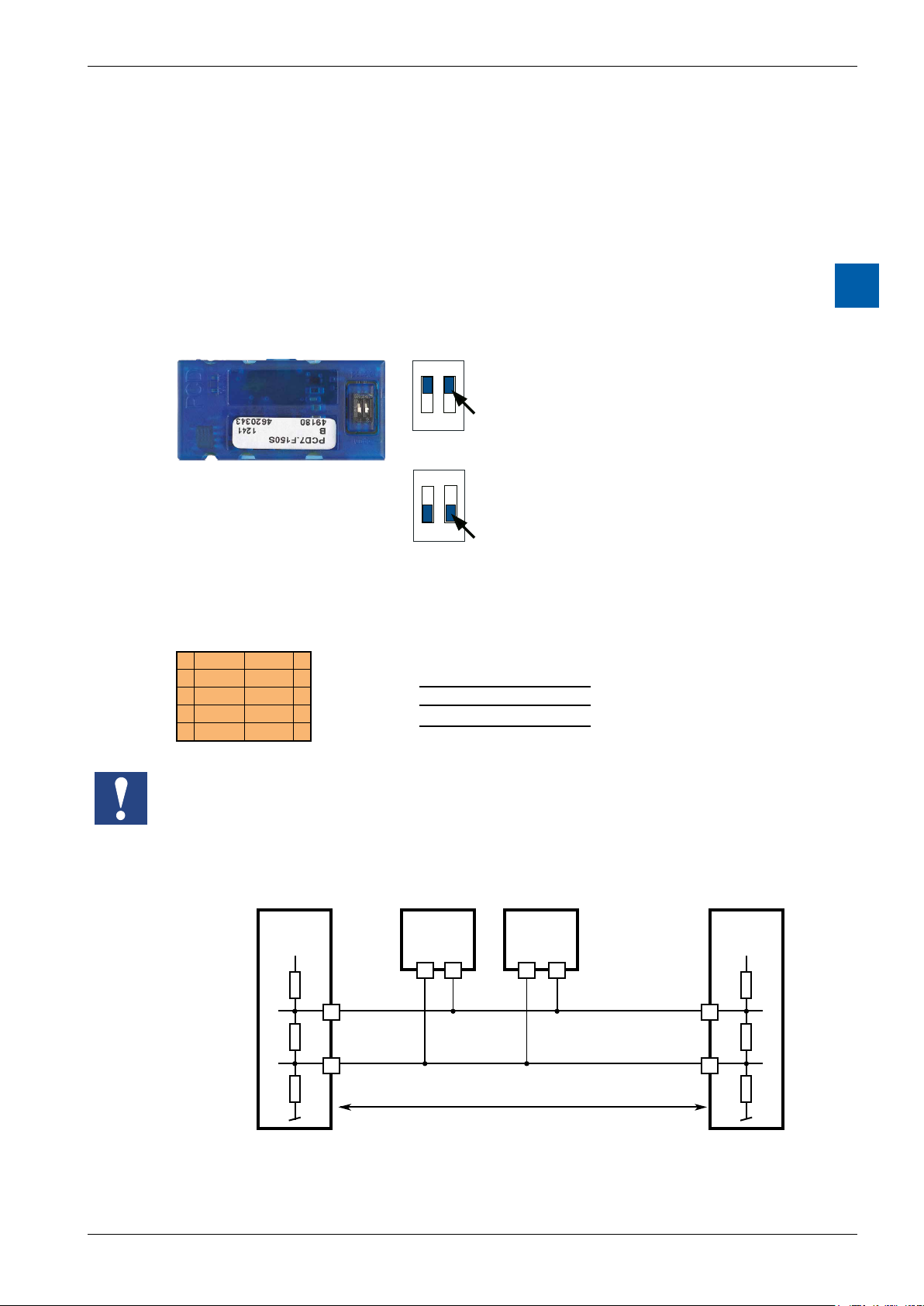

3.1.1 On-board RS-485

PCD4.DxxxT5F PCD3.Mxxxx PCD2.M5xxx PCD1.M2xxx

GND

/D

D

The pin nos of the connected PCD are explained in the respective manual.

Make sure that the terminators are properly terminated.

In the example below, you can see a possible connection between the terminals

and PCDs. In order to avoid reection on the communications channel, the network should be terminated with termination resistors. The PCD7.D4xx has a switch

for this:

3

RS-485-Network

Pull up

330 Ohm

Termination

Resistor

150 Ohm

Pull down

330 Ohm

First station Middle stations

PCD1.M2_

Port #1

+5 V

/n

n n

PCD1.M2_

PCD2.M5_

n n

Bus RS485

Segment length max. 1200 m

PCD3.Mxxxx

max. 32 stations

End station

PCD7.D457VT5F

PCD7.D410VT5F

PCD7.D412DT5F

+5 V

/n/n

/RX - /TX

RX - TX

/n

Manual PCD7.D412DTPF & PCD7.D4xxxT5F │ Document 27-620 – Release ENG07 │ 2019-06-20

3-4

Saia-Burgess Controls AG

Thefollowinggureshowsyouwhereitislocated.

Î If the switch is in the top position, the network is closed.

Î If the switch is in the bottom position, the network is open.

Conguration can either be performed directly, via the Setup menu on the pWeb

panel, or indirectly, via the Hardware conguration on the PG5. Overwrite the

current conguration the same as when making a change.

Logic Controller

Communications interfaces

3

3.1.2 Additional communications ports using slot A (Port no. 1)

Slot A on the pWeb panels allows you to plug in optional modules for communications interfaces. Only modules of the PCD7.F1xxS series are supported.

Installation - PCD7-D412DT5F

Earth 2 × Ethernet

(switch)

USB Reset

Switch

PCD7.F1xxS RS-485 Power Supply

Multi-colored front LED

Manual PCD7.D412DTPF & PCD7.D4xxxT5F │ Document 27-620 – Release ENG07 │ 2019-06-20

3-5

Saia-Burgess Controls AG

Installation - PCD7.D410VT5F

Logic Controller

Communications interfaces

Earth 2 × Ethernet

(switch)

Installation - PCD7.D457VT5F

Earth 2 × Ethernet

(switch)

USB Reset

Switch

USB Reset

Switch

PCD7.F1xxS RS-485 Power Supply

3

PCD7.F1xxS RS-485 Power Supply

Connections

PCD7.F1xxS

Connector

pins

0 GND GND

1 TXD D

2 RXD /D

3 RTS

4 CTS

5 GND GND

6 DTR

7 DSR

8 COM

9 DCD

Signal

RS-232

Signal

RS-485

RS-485

Connector

pins

1 GND

2 NC

3 /D

4 D

Power Supply

Connector

pins

1 24 V (+)

2 GND (-)

Signal

Signal

Manual PCD7.D412DTPF & PCD7.D4xxxT5F │ Document 27-620 – Release ENG07 │ 2019-06-20

3-6

Saia-Burgess Controls AG

3.1.2.1 PCD7.F110S Serial Interface Module RS-485/RS-422

Termination resistors can be connected (CLOSED) or disconnected (OPEN) with

slide switchs.

PCD7.F110S RS-485 terminator

Slider

O

C

21

Open not terminated

(factory setting)

Logic Controller

Communications interfaces

3

Slider

O

C

21

Closed terminated

RS-422 connection

Port x.1 - 10 pin spring-loaded terminal block

RS-422

0 PGND Tx 1

2 /Tx Rx 3

4 /Rx PGND 5

6 RTS /RTS 7

8 CTS /CTS 9

Terminal

Pin

PGND 10

TX 11

/TX 12

RX 13

/RX 14

PGND 15

RTS 16

/RTS 17

CTS 18

/CTS 19

RS-422

Peripherie-

device

PGND

TX

/TX

RX

/RX

SGND

RTS

/RTS

CTS

/CTS

RS 485 connection (Electrically connected RS-485 interface)

Port x.1 - 10 pin spring-loaded terminal block

RS-485

0 PGND Rx-Tx 1

2 /Rx-/Tx 3

4 PGND 5

6 7

8 (SGD) 9

PCD Modul

RX - TX

/RX - /TX

Terminal

x0

x1

x2

RS-485

GND

RS-485

RS-485

Peripherie-

device

PGNDPGND

RX - TX

/RX - /TX

For more details, see Manual 26-740, section "Installation components for RS-485

Networks."

Manual PCD7.D412DTPF & PCD7.D4xxxT5F │ Document 27-620 – Release ENG07 │ 2019-06-20

3-7

Saia-Burgess Controls AG

3.1.2.2 PCD7.F121S Serial interface module RS-232 suitable for modem connection

PCD7.F121S

RS-232 connection

Port x.1

RS-485

0 PGND TxD 1

2 RxD RTS 3

4 CTS PGND 5

6 DTR DSR 7

8 COM DCD 9

10 pin spring-loaded terminal block

Logic Controller

Communications interfaces

3

RS-232 connection to DTE RS-232 connection to DCE

cable

External modem

(ETCD) DCE

PGND

TX

RX

RTS

CTS

SGND

DTR

DSR

DCD

0 PGND

1 TXD

2 RXD

3 RTS

4 CTS

5 PGND

6 DTR

7 DSR

8 Reserve

9 DCD

cable

Peripherie

device (DTE)

PGND

TX

RX

RTS

CTS

SGND

DTR

DSR

DCD

0 PGND

1 TXD

2 RXD

3 RTS

4 CTS

5 PGND

6 DTR

7 DSR

8 Reserve

9 DCD

Manual PCD7.D412DTPF & PCD7.D4xxxT5F │ Document 27-620 – Release ENG07 │ 2019-06-20

3-8

Saia-Burgess Controls AG

Communications interfaces

3.1.2.3 PCD7.F150S Serial Interface Module RS-485 with Electrical Isolation

Electrical isolation is achieved with three optocouplers and a DC/DC converter.

Data signals are protected against overvoltage with an anti-surge diode (10 V).

Electrical isolation is achieved using three optical couplers and a DC/DC converter.

The data signals are protected against excess voltages by a suppressor diode

(10 V).

The line terminator for port x.1 is integrated into the module and can be activated

using the silde switch on the module.

PCD7.F150S RS-485 terminator

ON

C

O

1 2

ON

C

O

1 2

Closed terminated

Slider

Open not terminated

(factory setting)

Logic Controller

3

Slider

RS 485 connection - 10 pin spring-loaded terminal block

Port x.1

RS-485

0 PGND Rx-Tx 1

2 /Rx-/Tx 3

4 PGND 5

6 7

8 (SGD) 9

PCD Modul

RX - TX

/RX - /TX

Terminal

x0

x1

x2

RS-485

GND

RS-485

RS-485

Peripherie-

device

PGNDPGND

RX - TX

/RX - /TX

When using this module, the permitted ambient temperature for the control unit is

reduced by 5°C.

Line terminator:

First station Middle stations End station

+5 V

/n

Pull up

330 Ohm

Termination

Resistor

150 Ohm

Pull down

330 Ohm

+5 V

n n

28

Bus RS-485

29 n

Segment length max. 1200 m

max. 32 stations

/n/n

/RX - /TX

RX - TX

More details are available in the manual 26-740 “Installation components for

RS-485 networks”.

Manual PCD7.D412DTPF & PCD7.D4xxxT5F │ Document 27-620 – Release ENG07 │ 2019-06-20

3-9

Saia-Burgess Controls AG

3.1.2.4 PCD7.F180S Serial Interface Module Belimo MP-Bus

Up to 8 actuators and sensors can be connected.

PCD7.F180S

Belimo connection

Port x.1

Belimo MP-Bus

0 PGND MP 1

2 ‘MFT’ ‘IN’ 3

4 PGND 5

6 7

8 (SGD) 9

10 pin spring-loaded terminal block

Logic Controller

Communications interfaces

3

MP-Bus cabling

0 PGND Earth connection, MP line

1 MP Multi-point

The MP-Bus is the Belimo master slave

bus. Up to 8 slaves can be connected to

a master device.

These are:

■ MFT(2) ap drives

■ MFT(2) valve drives

■ MFT re damper drives

■ VAV NMV-D2M compact controller

2 ‘MFT’ MFT programming unit (internal MP-Bus)

3 ‘IN’ detection of MFT programming unit

(input 10 kΩ, Z5V1)

5 PGND Earth connection, MFT programming unit

Manual PCD7.D412DTPF & PCD7.D4xxxT5F │ Document 27-620 – Release ENG07 │ 2019-06-20

3-10

Saia-Burgess Controls AG

Conguration of the hardware settings in PG5

3.2 CongurationofthehardwaresettingsinPG5

Conguration of the programmable panel is usually performed via PG5, which is

also used to generate the project. However, it can also be congured directly on

the panel, using the Setup menu described in Chapter 5.2.

3.2.1 General information

Logic Controller

The following description assumes that the user is familiar with the PG5 software.

If this is not the case, we recommend reading the manual 26/733 „PG5, software

requirements, PG5 V 2.0" The device congurator denes direct access to programming instructions, for reading values from the peripheral input module and

writing values to the peripheral output module.

3

Manual PCD7.D412DTPF & PCD7.D4xxxT5F │ Document 27-620 – Release ENG07 │ 2019-06-20

3-11

Saia-Burgess Controls AG

3.2.2 Runningthedevicecongurator

The device congurator is used for hardware conguration, setting up logs, and

I/O handling.

Double click on the project tree icon to start the device congurator.

Logic Controller

Conguration of the hardware settings in PG5

3

Use a right click to select the Device and use Change Device Type to set the panel

to be congured.

The Download button can be used to download the conguration onto the pWeb

Panel.

Manual PCD7.D412DTPF & PCD7.D4xxxT5F │ Document 27-620 – Release ENG07 │ 2019-06-20

3-12

Saia-Burgess Controls AG

3.3 Firmwareversion

The rmware of the programmable panel is stored on an SD card soldered to the

motherboard. A rmware update can be applied by downloading a new version

with the PG5. When doing so, pay attention to the following procedure:

● Open www.sbc-support.com and download the latest rmware version

● Establish a connection between PG5 and the CPU, the same way as when

downloading an application (in accordance with the available devices, serial

with PGU cable, modem1), USB, Ethernet).

● In the Tools menu, select "Update Firmware” and use the Browse function to

select the path for the le with the new rmware version. Make sure that only

one le is selected for download.

● Start the download.

1)

see chapter “"3.1.2.2 PCD7.F121S Serial interface module RS-232

suitable for modem connection" on page 3-8”

Logic Controller

Firmware version

3

Manual PCD7.D412DTPF & PCD7.D4xxxT5F │ Document 27-620 – Release ENG07 │ 2019-06-20

3-13

Saia-Burgess Controls AG

3.4 Downloading the program and backup

The user program is downloaded to the pWeb panel in the same way as performing device conguration with the PG5 software. This process is described below.

3.4.1 Downloading the user program with PG5

Logic Controller

Downloading the program and backup

1 Create and compile the user program

The le your_project.pcd contains the following information:

User program (FUPLA, IL, etc.)

Conguration les (in some cases)

Data for rst initialisation

2 Program download

Clicking on the Download button shows the

following window.

The user program is downloaded as a le in

a particular partition of the internal le system. The user is not able to see this partition.

4 Options after download

Execute program

(RUN)

Remain STOPPED After the download,

Sets the PLC to RUN,

once the download is

successfully completed

PLC remains

STOPPED

3

■ It is not possible to download only those blocks which have been modied.

■ The user program is downloaded into the on-board memory in a le and, after

a restart of the system, the process is complete.

■ If the download is not successfully completed, the FW deletes all les inside

the system folder.

Once the download has been successfully completed, start the controller:

After the system restart, the user program and ROM DB/text are transferred into

the execution memory. This is a write-protected memory and thus does not need

to be backed up; all data is stored in the pWeb panel le system.

The data for the user program is transferred to the execution memory after the

pWeb panel device starts up.

Manual PCD7.D412DTPF & PCD7.D4xxxT5F │ Document 27-620 – Release ENG07 │ 2019-06-20

3-14

Saia-Burgess Controls AG

3.4.2 Backing up and restoring the user program

Backup with PG5

Select a backup with "Backup To Flash”

Logic Controller

Downloading the program and backup

3

Since the user program is already stored in the on-board ash memory, only the

RAM DB/text for the on-board ash memory are stored to the folder PLC_SYS (not

visible to the user).

Note: Registers, ags, timers and counters are not stored.

During a restore, the DB/text are copied back into the SRAM memory.

BackuptoINTFLASHlesystem

The values RAM DB/text are stored in the internal PCD_Backup folder. This allows

the backup les to be accessed via the FTP server and then uploaded to a PC.

Manual PCD7.D412DTPF & PCD7.D4xxxT5F │ Document 27-620 – Release ENG07 │ 2019-06-20

3-15

Saia-Burgess Controls AG

LED and operating status (12" pWeb panel, only)

3.5 LED and operating status (12" pWeb panel, only)

The CPU is capable of the operating statuses listed in the following table. On the

12" pWeb panel, the status is indicated by a multicoloured LED. On the other panels, the status can be shown on the display.

Status Description LED

No power No power connected aus

Run Normal processing of the user program

after startup

Run (conditional) Conditional Run status A condition has

been set in the debugger (Run until...),

which has not yet been fullled

Run with error The same as Run, but with an error mes-

sage

Run (conditional) with

error

Stop The status Stop occurs in the following

Stop with error The same as Stop, but with an error mes-

Halt The status Halt occurs in the following

The same as Run (conditional), but with an

error message

cases:

■ Downloading with the option “Remain in

Stop status”

■ PGU stopped by programming unit

sage

cases:

■ Halt instruction processed;

■ Serious error in the user program;

■ Hardware fault;

■ No program loaded;

■ No communications mode on the S-Bus

PGU or Gateway Master Port.

System diagnostics Description LED

Battery fault in Run Flashes at interval of 500 ms orange green orange green

Battery fault in Run

conditional

Battery fault in stop /

halt

No SD memory card red blue green red blue green

SD memory card but

no rmware

green

green…green…green

green

green…green…green

red

red

red

red green red green

red…red…red

red green blue red green blue

Logic Controller

3

Manual PCD7.D412DTPF & PCD7.D4xxxT5F │ Document 27-620 – Release ENG07 │ 2019-06-20

3-16

Saia-Burgess Controls AG

3.6 Software Watchdog

The pWeb panels have a Software Watchdog, which is a self-monitoring function

of the pro-cessor which restarts the CPU in the event of a malfunction or loop. The

core of the Software Watchdog is the instruction SYSER K 1000. The rst time this

is output, the Watchdog function is activated. This instruction must then be output at least every 200 ms, otherwise the Watchdog is triggered and the controller

restarted.

Instruction:

SYSWR K 1000 ; Software Watchdog instruction

R/K x ; Parameters according to following table

; K constant or entered value Register

Logic Controller

Software Watchdog | RIOs

3

x = 0

x = 1

x = 2

XOB 0 calls are entered in the PCD History as follows:

«XOB0WDOGSTART» if XOB0 was triggered by the Software Watchdog

«XOB0STARTEXEC» if XOB0 was triggered by a supply fault

3.7 RIOs

Smart-RIO PCD3.T66x modules can be used for decentralised expansion via ethernet (see also manual 26-892):

The Software Watchdog is deactivated

The Software Watchdog is activated; if the instruction is not repeated within 200 ms,

a cold start is performed.

The Software Watchdog is activated; if the instruction is not repeated within 200 ms,

XOB 0 is called, then a cold start is performed.

Manual PCD7.D412DTPF & PCD7.D4xxxT5F │ Document 27-620 – Release ENG07 │ 2019-06-20

3-17

Saia-Burgess Controls AG

4 Using the Setup menu

on the SVGA MB panels and pWeb panels

This chapter describes the menu structure of the SVGA MicroBrowser panel and

programmable pWeb panel.

MicroBrowser SVGA panel

● PCD7.D (12.1” SVGA)

Using the Setup menu

Opening the Setup menu

ProgrammablepWebpanels(rmware1.19.34):

● PCD7.D412DT5F (12.1” SVGA)

● PCD7.D410VT5F (10.4” VGA)

● PCD7.D457VT5F (5.7” VGA)

4.1 Opening the Setup menu

4

To call up the Setup menu:

Î Touch any area on the screen (except the buttons) for 4 seconds at any time

Î Touch the icon displayed during startup (see section 5. TITLE

Î The SETUP menu also contains an ONLINE help function (touch the Help icon)

Manual PCD7.D412DTPF & PCD7.D4xxxT5F │ Document 27-620 – Release ENG07 │ 2019-06-20

4-1

Saia-Burgess Controls AG

4.2 Customising the start screen

The title screen is displayed for a few seconds, immediately after the panel is

switched on with ON. The greeting and welcome screen can be dened under

System Start screen (see “5.4.3 Settings” on page 5-7)

Using the Setup menu

Customising the start screen | Changing the password

4

Available for a few seconds only,

pressing on this icon will take you

directly to the Setup menu.

= Animated icon for “Please wait, data loading”

User-dened System Start screen: “5.4.3 Settings” on page 5-7

4.3 Changing the password

MB panels of the PCD7.D4xxxx series are supplied without a password on the

Setup menu.

If, however, access to the Setup menu is subsequently restricted with a password,

the correct password must be entered, and then conrmed with OK.

→ For information on entering passwords, see “5.7 Password” on page 5-10

Manual PCD7.D412DTPF & PCD7.D4xxxT5F │ Document 27-620 – Release ENG07 │ 2019-06-20

4-2

Saia-Burgess Controls AG

4.4 Savingandexiting

Using the Setup menu

Saving and exiting

4

If you have changed one or more parameters, you must conrm if you want to

save the changes, to save & reboot, or to reset the new parameters without sav-

ing.

Manual PCD7.D412DTPF & PCD7.D4xxxT5F │ Document 27-620 – Release ENG07 │ 2019-06-20

4-3

Saia-Burgess Controls AG

Structure and description of the Setup menu

5 Structure and description of the Setup menu

The Setup screen is the rst screen which is displayed when the Setup menu is

accessed.

5

Network MB panel settings See section 5.1

1

Logic Controller Congure the internal logic controller

2

(pWeb panels, only)

Web Connection Congure the web connection See section 5.3

3

System Info/Settings/Special Settings/FW download &

4

Reboot

Display Display settings See section 5.5

5

Keyboard Virtual keyboard See section 5.6

6

Password Enter a password See section 5.7

7

Language Selection of the language (E, G, F, I and Dutch) See section 5.8

8

Back to application Back to application

9

See section 5.2

See section 5.4

Manual PCD7.D412DTPF & PCD7.D4xxxT5F │ Document 27-620 – Release ENG07 │ 2019-06-20

5-1

Saia-Burgess Controls AG

5.1 Network

This is where you can congure the network settings for the panel. Depending

on the network, the connection may also work without setting a gateway or DNS

server. You can exit the menu using the Setup button.

On pWeb panels, the network conguration is generally performed using the PG5 device congurator. If the Device Conguration is updated via PG5, the data set in Setup is overwritten. If you

want this data to be carried over to the PG5, the conguration requires the conguration le to be

uploaded into the PG5 project.

5.1.1 DCHP On

If DCHP is o, an IP must be set by the user. Otherwise all the necessary settings

are acquired by the DCHP server.

Structure and description of the Setup menu

Network

5

5.1.2 TCP/IP address

IP address of the panel.

5.1.3 Subnet Mask

Subnet mask of the network on which the panel is located.

5.1.4 Default Gateway

IP of the standard gateway.

5.1.5 PrimaryDNSServer

IP of the primary DNS server.

5.1.6 SecondaryDNSServer

IP of the secondary DNS server.

Manual PCD7.D412DTPF & PCD7.D4xxxT5F │ Document 27-620 – Release ENG07 │ 2019-06-20

5-2

Saia-Burgess Controls AG

5.2 Logic Controller (pWeb panels, only)

Settings of the programmable logic controller in pWeb panels. The settings congured here can also be made in the PG5 Device congurator.

If the Device Conguration is updated via PG5, the data set in Setup is overwritten. If you want this

data to be carried over to the PG5, the conguration requires the conguration le to be uploaded

into the PG5 project.

5.2.1 Program Name

Displays the name of the loaded PG5 project.

Structure and description of the Setup menu

Logic Controller (pWeb panels, only)

5

5.2.2 Status: RUN or HALT

Displays the status of the logic controller.

5.2.3 S-BUS

Conguration of the S-bus of the internal logic controller.

Î S-Bus Station

S-bus station of the logic controller

Î Serial

Settings for the serial S-bus connection

● Active

Activates the serial connection

● PGU

When PGU is activated, the panel can be programmed via the serial inter-

face

● Port

For setting the S-bus port

● Mode

Data or parity

● Baud reate

Speed of the S-bus

● TS Delay

Sets a transmission delay. Setting 0 causes the default values to be used

● TN Delay

Sets a transmission delay. Setting 0 causes the default values to be used

Manual PCD7.D412DTPF & PCD7.D4xxxT5F │ Document 27-620 – Release ENG07 │ 2019-06-20

5-3

Saia-Burgess Controls AG

Î Serial Master Gateway

Settings for the master gateways

● Active

Activates or deactivates the master gateway

● Port

Port of the master gateways

● Mode

Data or parity mode

● Baud rate

Sets the baud speed of the serial S-bus

● Start address

First S-Bus station on gateway

● End address

Last S-Bus station on gateway

● Speed

Speed of connection

Î IP

For setting the IP address

● Active

Activates S-bus via IP

● PGU

If PGU is activated, the panel can be programmed via this interface.

● Port

Port of the IP connection

Î IP Master Gateway

● Active

For setting the master gateway

● Timeout

Timeout for a expected response which should be received (Standard 0)

● Start address

First S-Bus station on gateway

● End address

Last S-Bus station on gateway

Structure and description of the Setup menu

Logic Controller (pWeb panels, only)

5

Manual PCD7.D412DTPF & PCD7.D4xxxT5F │ Document 27-620 – Release ENG07 │ 2019-06-20

5-4

Saia-Burgess Controls AG

5.3 Web Connection

This is where you can set the data for the device from which the website is to be

loaded and displayed. On programmable pWeb panels, this is usually the internal

controller, and so the Local Host IP Address 127.0.0.1 must be set.

Structure and description of the Setup menu

Web Connection

5.3.1 Connection

Name of the connection.

5.3.2 Type (no selection for pWeb)

Local Only for SVGA MB panel

No connection with any PCD

Connection is made with the local IP address 127.0.0.1

HTTP Direct Direct connection (Ethernet, only)

5.3.3 Start page

Name of the start page for this connection.

5.3.4 Remote Host IP

IP address of the connected PCD.

5.3.5 Remote Port

5

Remote port (default: 80).

5.3.6 Connection List

We advise you to establish one or more connections (up to x16) from the “List of

Connections”. Edit the connection or connections and select the connection which

you would like to use for your project. Each connection can be edited at any time.

The names for the connections are required as the URL jump target in the Web

Editor:

Examples: the connection in the list is called conn2_http, and the start page of the

project Start.html

Manual PCD7.D412DTPF & PCD7.D4xxxT5F │ Document 27-620 – Release ENG07 │ 2019-06-20

5-5

Saia-Burgess Controls AG

5.4 System

5.4.1 Production data

Display of the most important production data, such as serial number and ASN.

Î ASN

SBC product number (order number)

Î Serial number

Serial number of the device

Î MAC Address

MAC address of the device

Î HW Version

Hardware version of the device

Î Production Date

Month in which the device was produced

Î Display Type

Type of display (internal designation)

Î HW LCD Rotation

Rotation of the display

Structure and description of the Setup menu

System

5

5.4.2 Info

System info, such as Firmware Version, Booter Version, etc.

Î Firmware Version

Î Booter Version

Î M1 Expansion Info

Î Video Cache Permanent

Î Erasable Video Cache

Firmware version currently installed on the panel

Booter version currently installed on the panel

Indicates if an M1 memory expansion is present (or a F1xxS module on the

pWeb panel)

Info: permanent video cache used

Info: cache is used for images. Dependent upon the size and number of gif les

in the cache

Manual PCD7.D412DTPF & PCD7.D4xxxT5F │ Document 27-620 – Release ENG07 │ 2019-06-20

5-6

Saia-Burgess Controls AG

5.4.3 Settings

General settings for the panel.

Î Buzzer

Buzzer which sounds when buttons are operated or certain actions are performed

● BuzzerOn/O

Buzzer signal when buttons are operated On / O

● Buzzer frequency

Pitch of the buzzer

Î File Search Order

Local / remote les

● Nolocallesearch

“No local le search” means les (teq, .gif, etc.) are not searched for on the

local server of the MB panel.

● Local before remote

“Local before remote” means les (.teq,.gif, etc.) are searched for rst on the

local server, before the PCD server is searched. Files are searched for rst

in INTFLASH/Webpages

● Remote before local

“Remote before local” means le (.teq,.gif, etc.) are searched for on the re-

mote server, before the local server on the MB panel is searched.

Î Start Delay [s]

Start delay for restart (min. 1 sec., max. 15 sec.)

Î Start screen

Enter the greeting & modify the welcome screen

● Startup text

Freely-denable greeting (max. 64 characters)

● X-position of the text

Value between 0 and 639

● Y-position of the text

Value between 0 and 479

● Nameofthegraphicle

gif graphic le: INTFLASH/WEBPAGES/…

● X-position of the graphic

Value between 0 and 639

● Y-position of the graphic

Value between 0 and 479

Î FileCacheActive

During normal operation, the le cache should be active.

The le cache can be activated and deactivated. Deactivation is used, for ex-

ample during project handling, because changes to cached les are trackable.

Î Setup Call With Delay

Activates or deactivates the delay.

Structure and description of the Setup menu

System

5

Manual PCD7.D412DTPF & PCD7.D4xxxT5F │ Document 27-620 – Release ENG07 │ 2019-06-20

5-7

Saia-Burgess Controls AG

5.4.4 Special Settings

Special system settings.

Î Reset All Parameters

This command resets all parameters to the default values.

Î FormatIntash

Extended function with request for conrmation: “Do you really want to format

INFLASH?” This command wipes the ash memory and recreates the le system from scratch. After the Formatting OK message, the device returns to the

System menu.

Î Time

Real Time Clock (RTC)

● Time

Real Time Clock (RTC): enter time (container: uBT_RtcTime)

● Date

RTC: enter date (container: uBT_RtcDate)

● TimeServerActive

Activates/deactivates the time server

Î Memory

Only in problem cases!

Outside of the permissible memory range Heap 1, 2, 3 and LR.

Î Show Runtime Info

Extended command on the run time

Structure and description of the Setup menu

System

5

5.4.5 Log

Clicking the button scrolls further through the list. This allows you to check, for

example, if typefaces are found. The last screen gives info on error messages.

Access to log.txt via FTP: uBT_FS/LOG.TXT

5.4.6 Restart

Restarts the system.

Manual PCD7.D412DTPF & PCD7.D4xxxT5F │ Document 27-620 – Release ENG07 │ 2019-06-20

5-8

Saia-Burgess Controls AG

5.5 Display

5.5.1 Brightness

Can be adjusted in a range between 0 and 20.

5.5.2 Backlight [min]

Structure and description of the Setup menu

Display | Keyboard

The touchscreen or buttons are not selected during this period, the backlight is

switched o. You can activate it again by touching the screen or a button. Can be

adjusted in a range between 0 and 5000.

5.5.3 Rotation

Landscape / Portrait

5.5.4 Calibrate Touchscreen

Carefully, using the stylus

5.6 Keyboard

5.6.1 SIP (Virtual Keyboard)

5

Activates/deactivates SIP (Soft Input Panel).

Virtual Keyboard

5.6.2 Nameoftherstkeyboard

You can choose from: Alphapad.teq (alphanumeric) or keypad.teq (numeric) as the

rst keyboard to open.

5.6.3 Width of the Focus (in Pixels)

You can select a value from 0 to 6 pixels. A frame identies the selected area or

edit eld. The entry denes the frame width in pixels. At a width of 0, no frame is

displayed. This is advisable if you are working only with the touchscreen.

Manual PCD7.D412DTPF & PCD7.D4xxxT5F │ Document 27-620 – Release ENG07 │ 2019-06-20

5-9

Saia-Burgess Controls AG

5.7 Password

You can enter an alphabetic, numeric or alphanumeric password (maximum number of characters = 32, incl. spaces). You must conrm the password after entering

it.

When you enter a new password, you have to conrm it. If the characters entered

in the conrmation eld do not match the new password, the old password is re-

tained.

If you would like to disable password protection, press the Enter key and conrm

without inputting any characters.

Forgot your password? Delete the le inash/cong/passwd.dat (FTP connection). This will

resolve your problem.

Structure and description of the Setup menu

Password | Language

5

5.8 Language

You can select one of the precongured languages for the Setup process.

Manual PCD7.D412DTPF & PCD7.D4xxxT5F │ Document 27-620 – Release ENG07 │ 2019-06-20

5-10

Saia-Burgess Controls AG

6 Localles/localserver

6.1 ConnectingviaFTPaccess

The internal structure can be accessed only via FTP: SBC le system (FTP access: user name and password). ftp:// IP address

FILE CACHE: Contains the cache memory

INTFLASH: Contains:

● INTFLASH/CONFIG/

KEYMAP.DAT Congure keyboard - only MB with buttons (F-keys).

Does not apply to this MB panel.

PASSWD.DAT Only displayed if a password has been creased (Forgot your

password? Delete this le.)

TSPOINTS.DAT For internal use

● INTFLASH/WEBPAGES Directory for all project les which you want to save

"LOCALLY” (teq,gifles,etc.)

● INFLASH/FONT FONT directory must be created by the user. It contains all

the special or additional .bft les containing typefaces.

● INFLASH/TRENDLOGS TRENDLOGS directory is created automatically

when logs are stored. The .CSV les with the logs are saved to this location

automatically (this uses Web Editor MB Macro S2F).

● PLC_SYS Internal use, no access (conguration sett., uBT_containers, etc.)

● BUBT_FS UBT_FS/LOG.TXT List of the startup process + Error info (read,

only)

● WEB For internal use.

● SLOFLASH Created automatically when an SD memory card is use with the

SD card interface.

Local les / local server

Connecting via FTP access

6

Manual PCD7.D412DTPF & PCD7.D4xxxT5F │ Document 27-620 – Release ENG07 │ 2019-06-20

6-1

Saia-Burgess Controls AG

xxxxxxxxxxx.TEQ

xxxxxx.ITQ

6.2 INTFLASH/WEBPAGES

Caution:thedirectoryname"M1_Flash”usedintheSBClesystemonthe

current QVGA and VGA MB panel no longer exists on this panel. The direc-

torynameoftherootlevelis"INTFLASH”

xxxxxxx.TEQ

xxxxxxxx.GIF

Local les / local server

INTFLASH/WEBPAGES

6

1) Recommended simplest method: Copy all shared les (.teq, .gif, etc.) to INTFLASH/WEBPAGES.

N.B.: If you have copy .teq or .gif les (or even .itq, .csv and .html les) when using a local server,

then you must always create at least one .tcr with all the PPO data (Web Builder).

Caution: Switch the Setup option from "No local le search" to "Local le search

before remote"!

2) Copy all associated les (.teq + .gif ) to the corresponding subdirectories of INTFLASH/WEBPAGES/. Each associated station has its own subdirectory. The names of the subdirectories correspond to the communication method:

HTTP direct communication IP address of the station with an underscore instead of a dot

e.g. IP address 192.168.12.90 becomes 192_168_12_90)

Copy les to INTFLASH/WEBPAGES/192_168_12_90

xxxxxxxxxxx.TEQ

xxxxxxxxxx.GIF

xxxxxxxx.HTML

Manual PCD7.D412DTPF & PCD7.D4xxxT5F │ Document 27-620 – Release ENG07 │ 2019-06-20

!!! File names: max. 24 ASCII characters without spaces, including le extension.

N.B.: If you have copy .teq or .gif les (or even .itq, .csv and .html les) when using a

local server, then you must always create at least one .tcr (Web Builder), as it

contains all the PPO data. Do not forget to switch the Setup option from "No local

le search" to "Local le search before remote”.

6-2

Saia-Burgess Controls AG

7 Updating and special settings

7.1 Firmware update

7.1.1 Additional information on downloading FW

If problems occur while downloading via a USB connection, try the following

solution:

Restart the MB panel with the USB cable REMOVED. Press the Download button

and the MB panel’s Download mode is activated. Next, connect the USB cable to

the MB panel and press Start in the FW Download Service Program.

If problems occur while downloading via a USB or ethernet connection, try the

following solution:

Updating and special settings

Firmware update

If communications are interrupted during the download process, no notication

appears on screen. This is because the FW ash memory is erased at the start of

the process.

7.1.2 SafeFirmwareDownloadviaUSB

The safe method for downloading rmware is always via USB.

a) Switch o the MB panel

b) At the top of the back cover os a hole of 3 mm in diameter. It contains a button.

Take a narrow-tipped pen or a small screwdriver (any cylindrical object with a

diameter of 3 mm is suitable) and use it to hold down the button for short while.

You can see the location of the Reset button in the gure:

7

c) Switch on the MB panel with ON at the same time. Wait 3-4 sec. until the LED

starts to ash.

Then download the FW using the SBC FW Service Program.

CAUTION: The *.blk le type is used for a complete FW le. Use only those

les intended for the PCD7.D4xx panel and which were supplied

by Saia Burgess Controls.

Manual PCD7.D412DTPF & PCD7.D4xxxT5F │ Document 27-620 – Release ENG07 │ 2019-06-20

7-1

Saia-Burgess Controls AG

7.2 Reset/Resettingthedevicetofactorysettings

In a number of particular cases, the Reset button can be used to fully reset the MB

panel and restore the factory default settings.

When could this function be of use?

If, for example, you have copied the local le required for an FTP connection

with the local server into the wrong directory or have unintentionally deleted data

which is necessary for displaying the Setup menu. The most common error is

the appearance of the message "uBTerminal not found”, while the content on

screen remains unchanged. In such a case, proceed as follows:

1) A. Switch o the MB panel with OFF

2) Activate the Reset button, at the top of the device’s rear cover, by holding down

the button.

3) Switch on the MB panel at the same time. After approx. 5 sec., the buzzer is

activated with increasing frequency.

4) Once the pitch (or the frequency) of the buzzer has stabilised (after approx.

10 sec.), release the Reset button and wait.

5) You may have to wait to 1 to 2 minutes. During this time, the FW is reconstructing the whole organisation of the memory and recreating all the les which are

required for the default settings. Finally, the MB panel reboots automatically,

and you will be asked to recalibrate the touchscreen. Once you have calibrated

it, the system has been fully restored.

Updating and special settings

Reset / Resetting | Backlight

7

7.3 Backlight

The period for which the backlight remains on can be set manually. This function

helps to save energy. If the backlight is deactivated, you will save approx. 3/4

watts, which is a non-negligible value. This will also extend the servicelife of the

backlight.

Servicelifeofthebacklight

The normal service life of the backlight (at 25°C) is dened as approx. 50 Kh. This

corresponds to 5 years of continuous use. However, this value is quickly reduced

(to half or less) if the operating temperature is 10°C or less. It makes sense for

the user to take this into account and to adapt the standby period of the backlight

accordingly.

Manual PCD7.D412DTPF & PCD7.D4xxxT5F │ Document 27-620 – Release ENG07 │ 2019-06-20

7-2

Saia-Burgess Controls AG

Typefaces supported by MB panel PCD7.D4xx

7.4 Typefaces supported by MB panel PCD7.D4xx

Default fonts available for the VGA MB panel

FONT SIZE

Fonts and formats 10 12 14 16 20 24 36

Arial × × × × × ×

Arial Bold × × × ×

Courier New × × ×

Courier New Bold × ×

Tahoma × × × ×

Tahoma Bold × × ×

Calculatingthegivenamountofplayfor:

Single text eld, multi-line text eld, edit eld for text eld, and button with text.

Updating and special settings

7

Denitions:

Font size: Character size (font size in pixels)

Y-dimension: Size of the graphical symbol (in pixels)

X-dimension: Width of a character

Text length: Length of a single-line piece of text.

Text eld: Length of the painter

General recommendations for textelds (you can nd info in the online help for

the rst version of Web Editor)

We recommend using text elds exceeding the size displayed in the Editor by up

to 20%. To determine the text eld length, you can also consult the following table

of the min. and max. X-dimension.

General recommendations for the Y-dimension in proportion to the font size and

format

Basic rule: The text should be INSIDE the contours.

For buttons and edit elds, a shadow of 2 pixels is added (to the inside of the

button contours and to the outside of the edit elds).

If the text is too large for the edit eld, it is overlaid by the border and the 3D

shadow.

Manual PCD7.D412DTPF & PCD7.D4xxxT5F │ Document 27-620 – Release ENG07 │ 2019-06-20

7-3

Saia-Burgess Controls AG

Updating and special settings

Typefaces supported by MB panel PCD7.D4xx

The following borders must be planned for:

● Single text elds and such with multiple lines: 2 × border width + 1

● Buttons: 2 × border width + 5

● Edit elds 2 × border width + 5

Font size y Size min x Size max x Size

Arial 36 41 7 36

Arial 24 28 7 24

Arial 20 23 6 20

Arial 16 19 3 16

Arial 12 15 3 12

Arial 10 12 3 10

Arial Bold 36 41 9 35

Arial Bold 24 28 7 23

Arial Bold 20 23 6 20

Arial Bold 14 16 4 15

CourierNew 20 23 12 12

CourierNew 16 19 10 10

CourierNew 12 14 7 7

CourierNew 10 12 6 6

CourierNew Bold 20 23 12 12

CourierNew Bold 14 17 8 8

Tahoma 24 29 5 24

Tahoma 20 25 4 20

Tahoma 16 20 4 16

Tahoma 12 15 4 12

Tahoma 10 13 3 10

Tahoma Bold 24 29 7 29

Tahoma Bold 20 25 6 24

Tahoma B

old 14 17 4 17

7

Manual PCD7.D412DTPF & PCD7.D4xxxT5F │ Document 27-620 – Release ENG07 │ 2019-06-20

7-4

Saia-Burgess Controls AG

7.5 Special Unicode fonts

7.5.1 General information

The user can add additional fonts, for example, which are required for some

languages or special fonts/formats/sizes, which are not provided for by default on

the MB panel.

Such languages include: Russian, Greek, Chinese, Japanese, Korean.

Such fonts include: Comic sans MS, Charleworth, Book Antica, Century,

Trebuchet, Verdana.

Dierent sizes, such as 10,12,14, etc., or formats such as plain (or normal), bold,

etc., can be used on all these fonts.

Updating and special settings

Special Unicode fonts

Fonts and Unicode fonts: http://www.sbc-support.ch Product Info

HMI Web-Panel PCD7.D4xxx Additional information for Sales Companies

(restricted Area).

Files containing typefaces for specic languages or fonts/formats/sizes not

appearing in the list can also be installed on an MB panel. If you want to do so,

please contact SBC Support.

To ensure that all characters are supported, we recommended using the Arial

typeface. This is particularly the case for languages with a large number of

characters, such as Chinese.

This means using Unicode les with typefaces (.bft) generated and made available

by Saia Burgess Controls. The rmware searches the following locations for

typefaces:

INTFLASH/FONT

A le with typefaces contains the data for a continuous string of characters. If, for

example, Greek and Cyrillic are required, two les must be loaded: one with the

Greek alphabet and another containing the Cyrillic characters.

The size of such a font le must not exceed 128 KBytes.

7

(Chinese requires many les with dierent font sizes to cover all the characters.)

Manual PCD7.D412DTPF & PCD7.D4xxxT5F │ Document 27-620 – Release ENG07 │ 2019-06-20

7-5

Saia-Burgess Controls AG

If a font le is found, it is registered. A maximum of 65 dierent les can be

registered. When a character is required, the front le is opened and the data for

the characters is called up. The data is intended for subsequent use.

Updating and special settings

Special Unicode fonts

Î Name of the font les: max. 24 ASCII characters without spaces (including le

extension)

Î To install font les: copy the les to the FTP server of the MB panel via an FTP

connection.

Î Chinese fonts: 12 is the smallest legible font size.

7

Manual PCD7.D412DTPF & PCD7.D4xxxT5F │ Document 27-620 – Release ENG07 │ 2019-06-20

7-6

Saia-Burgess Controls AG

7.5.2 Multi-languages: Example

Î Switch to a dierent language with the button (set the variable with the mouse

button held down).

Examples: Translate "Happy Birthday" to Czech using the "HTML TAG” type.

The Czech requires an expansion of the European characters, which can be

downloaded by logging into the SBC Support site.

Procedure:

● The Unicode font .bft le(s) with expanded European character set must be

copied into INTFLASH /FONT (see section 13.1).

● Web Editor: create the static text "Happy Birthday” and select "HTML TAG” as

the source type.

● Under the "Text Positions Advanced” tab for position settings: if you are using

exotic characters (such as Katakana, Chinese, etc.), we recommend sticking

with the default settings for the text position (not centred or justied).

● In some typefaces, it is not possible to represent all Unicode characters. We

recommend using the "Arial Unicode MS" or "MS Sans Serif" typefaces, as they

are well suited to use with Unicode characters.

Updating and special settings

Special Unicode fonts

7

DonotedittheCSVleintheS-WebEditordirectly, because the text window

of the S-Web Editor will save the CSV le in ASCII mode. You could, for example,

use Notepad to edit your CSV les (or another text editor, which allows you to

save the les in Unicode format). In the Notepad "Save As" dialog box, you can

select the "Unicode” entry in the dropdown menu under "Encoding". In MS Excel,

use the format "Unicode Text”.

Once you have saved your CSV les in the Unicode format and selected a

typeface in the HMI which can be used to display Unicode characters, then the

Unicode strings should be displayed properly. If you want to use Unicode, you do

not need to make any further settings in the S-Web Editor.

Manual PCD7.D412DTPF & PCD7.D4xxxT5F │ Document 27-620 – Release ENG07 │ 2019-06-20

7-7

Saia-Burgess Controls AG

Web Editor: Create a button with the following action parameters "Actions Set Variables":

The type is the "Container”, the name is "@LANGUAGE” and then the Unicode

.csv le.