Saia Burgess Controls PCD7.D412DTPF, PCD7.D412DT5F, PCD7.D457VT5F, PCD7.D410VT5F User Manual

Manual

I/O-modules

PCD7.D412DTPF standard SVGA MB Panel and

PCD7.D4xxxT5F programmable pWeb Panel

Document 27-620 | Release ENG07 | 2019-06-20

for PCD1 / PCD2 series

and for PCD3 series

Saia-Burgess Controls AG

0 Content

0 Content

0.1 Document versions ............................................................................... 0-4

0.3 Brands and trademarks ........................................................................ 0-4

1 Quickstart

1.1 Introduction ........................................................................................... 1-1

1.2 Denition of the connectors ................................................................... 1-1

1.3 Voltage supply of the panel ................................................................... 1-2

1.4 Dimensions and cut-out (in mm) ........................................................... 1-3

1.4.1 12.1" panel ............................................................................................ 1-3

1.4.2 10.4" panel ............................................................................................ 1-3

1.4.3 5.7" panel .............................................................................................. 1-3

1.5 Installation of the panels ....................................................................... 1-4

1.5.1 Installation in control cabinet ................................................................. 1-4

1.5.2 Drywall mounting set for MB panels ...................................................... 1-5

1.6 Operation and handling of the touchscreen .......................................... 1-5

1.7 Setting up communications for displaying a website ............................. 1-6

1.7.1 HTTP Direct over ethernet RJ-45 connector ......................................... 1-6

1.7.2 USB port as Service port ....................................................................... 1-7

1.7.3

Getting started with the Web Editor on the MicroBrowser panel PCD7.D4xx 1-7

Content

Content

0

2 Technical data for the two panel types

2.1 Technical data of the SVGA MicroBrowser panel .................................. 2-1

2.2 Technical data for the pWeb panels ...................................................... 2-2

2.2.1 Overview ............................................................................................... 2-2

2.2.2 Product-related presentation ................................................................. 2-2

2.2.2 Battery of the pWeb panel ..................................................................... 2-3

3 Logic controller of the programmable pWeb panel

3.1 Communications interfaces ................................................................... 3-4

3.1.1 On-board RS-485 .................................................................................. 3-4

3.1.2 Additional communications ports using slot A (Port no. 1) .................... 3-5

3.1.2.1 PCD7.F110S Serial Interface Module RS-485/RS-422 ........................ 3-7

3.1.2.2 PCD7.F121S Serial interface module RS-232

suitable for modem connection ............................................................. 3-8

3.1.2.3 PCD7.F150S Serial Interface Module RS-485 with Electrical Isolation 3-9

3.1.2.4 PCD7.F180S Serial Interface Module Belimo MP-Bus ........................ 3-10

3.2 Conguration of the hardware settings in PG5 ..................................... 3-11

3.2.1 General information ............................................................................... 3-11

3.2.2 Running the device congurator ........................................................... 3-12

3.3 Firmware version ................................................................................... 3-13

3.4 Downloading the program and backup ................................................. 3-14

3.4.1 Downloading the user program with PG5 ............................................. 3-14

3.4.2 Backing up and restoring the user program .......................................... 3-15

3.5 LED and operating status (12" pWeb panel, only) ................................ 3-16

3.6 Software Watchdog ............................................................................... 3-17

3.7 RIOs ...................................................................................................... 3-17

Manual PCD7.D412DTPF & PCD7.D4xxxT5F │ Document 27-620 – Release ENG07 │ 2019-06-20

0-1

Saia-Burgess Controls AG

4 Using the Setup menu

on the SVGA MB panels and pWeb panels

4.1 Opening the Setup menu ...................................................................... 4-1

4.2 Customising the start screen ................................................................. 4-2

4.3 Changing the password ........................................................................ 4-2

4.4 Saving and exiting ................................................................................. 4-3

5 Structure and description of the Setup menu

5.1 Network ................................................................................................. 5-2

5.1.1 DCHP On .............................................................................................. 5-2

5.1.2 TCP/IP address ..................................................................................... 5-2

5.1.3 Subnet Mask ......................................................................................... 5-2

5.1.4 Default Gateway .................................................................................... 5-2

5.1.5 Primary DNS Server .............................................................................. 5-2

5.1.6 Secondary DNS Server ......................................................................... 5-2

5.2 Logic Controller (pWeb panels, only) .................................................... 5-3

5.2.1 Program Name ...................................................................................... 5-3

5.2.2 Status: RUN or HALT ............................................................................ 5-3

5.2.3 S-BUS ................................................................................................... 5-3

5.3 Web Connection .................................................................................... 5-5

5.3.1 Connection ............................................................................................ 5-5

5.3.2 Type (no selection for pWeb) ................................................................ 5-5

5.3.3 Start page .............................................................................................. 5-5

5.3.4 Remote Host IP ..................................................................................... 5-5

5.3.5 Remote Port .......................................................................................... 5-5

5.3.6 Connection List ..................................................................................... 5-5

5.4 System .................................................................................................. 5-6

5.4.1 Production data ..................................................................................... 5-6

5.4.2 Info ........................................................................................................ 5-6

5.4.3 Settings ................................................................................................. 5-7

5.4.4 Special Settings .................................................................................... 5-8

5.4.5 Log ........................................................................................................ 5-8

5.4.6 Restart ................................................................................................... 5-8

5.5 Display .................................................................................................. 5-9

5.5.1 Brightness ............................................................................................. 5-9

5.5.2 Backlight [min] ....................................................................................... 5-9

5.5.3 Rotation ................................................................................................. 5-9

5.5.4 Calibrate Touchscreen ........................................................................... 5-9

5.6 Keyboard ............................................................................................... 5-9

5.6.1 SIP (Virtual Keyboard) ........................................................................... 5-9

5.6.2 Name of the rst keyboard .................................................................... 5-9

5.6.3 Width of the Focus (in Pixels) ............................................................... 5-9

5.7 Password .............................................................................................. 5-10

5.8 Language .............................................................................................. 5-10

Content

Content

0

Manual PCD7.D412DTPF & PCD7.D4xxxT5F │ Document 27-620 – Release ENG07 │ 2019-06-20

0-2

Saia-Burgess Controls AG

6 Localles/localserver

6.1 Connecting via FTP access ................................................................... 6-1

6.2 INTFLASH/WEBPAGES ........................................................................ 6-2

7 Updating and special settings

7.1 Firmware update ................................................................................... 7-1

7.1.1 Additional information on downloading FW ........................................... 7-1

7.1.2 Safe Firmware Download via USB ........................................................ 7-1

7.2 Reset / Resetting the device to factory settings .................................... 7-2

7.3 Backlight ................................................................................................ 7-2

7.4 Typefaces supported by MB panel PCD7.D4xx .................................... 7-3

7.5 Special Unicode fonts ........................................................................... 7-5

7.5.1 General information ............................................................................... 7-5

7.5.2 Multi-languages: Example ..................................................................... 7-7

7.5.3 Analysing incorrect fonts, font sizes or format templates ...................... 7-9

7.5.4 Web Editor ............................................................................................. 7-9

7.6 Internal special functions ....................................................................... 7-10

7.6.1 Container variable for SVGA MB panel ................................................. 7-10

7.6.2 uBT_BackLight Containerdiagramm ..................................................... 7-15

7.6.3 Additional uBTerminal container for "Save logs to File” function ........... 7-15

7.7 List of message box messages ............................................................. 7-16

Content

Content

0

8 Handling: precautionary measures

8.1 Glass touchscreen ................................................................................ 8-1

8.2 Information on the LCDs of the MB panel display ................................. 8-1

8.3 Care ...................................................................................................... 8-1

9 General recommendations for the Web Editor

9.1 In the "Project congurations" ............................................................... 9-1

9.2 In the Web Editor project (general information) ..................................... 9-1

9.3 Denition of an object in the Web Editor ............................................... 9-2

9.4 Handling ................................................................................................ 9-2

9.5 Some rules regarding gif images .......................................................... 9-2

9.5.1 Decompression in the video cache at startup using the Gif list ............. 9-3

9.5.2 Decompression of Gif les in the video cache at startup

using a dummy start screen .................................................................. 9-4

9.5.3 Decompression of Gif les: analysis/calculation ................................... 9-4

9.6 Expanded error messages for the SVGA panel .................................... 9-5

9.7 Extended alarm macros ........................................................................ 9-5

9.8 Trend macros for MB panels with "save logs to les" ........................... 9-5

A Appendix

A.1 Icons ...................................................................................................... A-1

A.2 Safety information ................................................................................. A-2

A.3 Waste of Electrical and Electronic Equipment (WEEE) disposal .......... A-3

A.4 Contact .................................................................................................. A-4

Manual PCD7.D412DTPF & PCD7.D4xxxT5F │ Document 27-620 – Release ENG07 │ 2019-06-20

0-3

Saia-Burgess Controls AG

Content

Document versions | Brands and trademarks

0.1 Documentversions

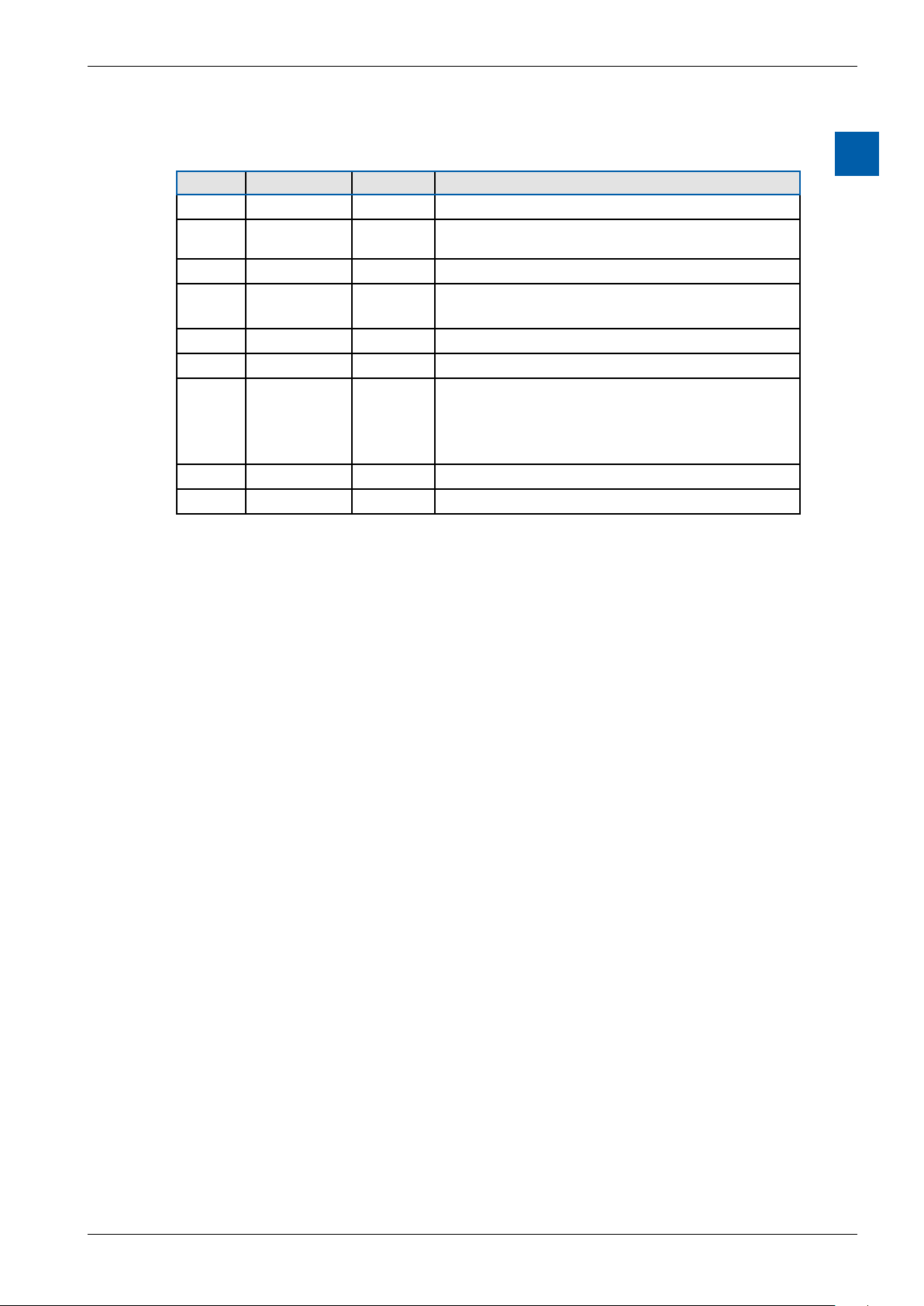

Version Published Redactor Remarks

EN01 2012-10-10 ErDa First version of manual

EN02 2012-11-28 HaMa

EN03 2013-12-18 ErDa Chapter 7.6.2 Container variables removed

EN04 2013-05-31 HaMa Chapter 3.1.2 Description oft the communica-

EN05 2014-01-20 HaMa New logo and new company name

ENG06 2016-01-27 HaMa New xation set

ENG07 2019-06-20 HaMa - Added the crossed bin logo for “Waste of

0

■ Ch1.2 Connection SD » D and /SD » D

■ Ch3.1.1 Picture RS-485-Network replaced

tion modules PCD7.F1xxS for Slot A

Electrical and Electronic Equipment (WEEE)”

disposal

- copied from Word to InDesign

0.3 Brands and trademarks

Saia PCD® and Saia PG5®

are registered trademarks of Saia-Burgess Controls AG.

Technical modications are based on the current state-of-the-art technology.

Saia-Burgess Controls AG, 2012. © All rights reserved.

Published in Switzerland

Manual PCD7.D412DTPF & PCD7.D4xxxT5F │ Document 27-620 – Release ENG07 │ 2019-06-20

0-4

Saia-Burgess Controls AG

1 Quickstart

Quickstart

Introduction | Denition of the connectors

1.1 Introduction

This manual covers the technical aspects of the PCD7.D412DTPF SVGA MB panel and the PCD7.D4xxxT5F programmable pWeb panel. The aim of the Quickstart

chapter is to facilitate the rapid installation of components of the PCD7.D4xxxT5F.

The following are discussed:

■ Denition of the connectors

■ Power supply and consumption

■ Dimensions

■ Possible communications modes

In other chapters, more details can be found about:

■ Hardware

■ Software (Setup menu step-by-step and conguration)

■ Usage, rmware update, etc.

■ Maintenance

Complementary manuals:

■ PG5 2.0 User guide | 26-732

■ File System and FTP Server | 26-855

■ Ethernet TCP/IP | 26-766

■ Smart RIO PCD3.T665 | 26-892

■ PCD3 series (conguration of the communications interfaces) | 26-789

1

1.2 Denitionoftheconnectors

PROTECTIVE EARTH MUST BE CONNECTED!

Manual PCD7.D412DTPF & PCD7.D4xxxT5F │ Document 27-620 – Release ENG07 │ 2019-06-20

1-1

Saia-Burgess Controls AG

Connections

Power Supply PCD7.F1xxS

Connector

pins

RS 485

Connector

pins

Signal

1 24 V (+)

2 GND (-)

Signal

1 GND

2 NC

3 /D

4 D

Quickstart

Denition of the connectors | Voltage supply of the panel

Connector

pins

0 GND GND

1 TXD232 SD

2 RXD232 /SD

3 RTS232

4 CTS232

5 GND GND

6 DTR232

7 DSR232

8 COM232

9 DCD232

Signal

RS 232

Signal

RS 485

1

Power supply

Communications

Reset button

Earth (-) / 24V (+) Connector, 2-pole

2× Ethernet (switch !) 2× RJ-45 with LED indicator

USB Standard USB slave

Pushbutton

1.3 Voltage supply of the panel

Pin Signal

1 24V (+)

2 Earth (-)

Current supply:

→ 24 VDC +30% / –20%

or

→ 19 VAC ±15% current supply with full-wave rectier

Current consumption Power output without back-

PCD7.D412DT5F

PCD7.D410VT5F

PCD7.D457VT5F

PCD7.D412DTPF Max 600 mA 5 W

Max 600 mA

Max 600 mA

max 500 mA

light

5 W

5 W

5 W

Current supply with jack plug for cable of max. 1.5 mm2.

Manual PCD7.D412DTPF & PCD7.D4xxxT5F │ Document 27-620 – Release ENG07 │ 2019-06-20

1-2

Saia-Burgess Controls AG

1.4 Dimensions and cut-out (in mm)

1.4.1 12.1" panel

62 6

Quickstart

Dimensions and cut-out (in mm)

1

Front panel W × H, 319 × 264

Display W × H, 245 × 185

1.4.2 10.4" panel

Front panel W × H, 281 × 221

Display W × H, 211 × 150

1.4.3 5.7" panel

Cut-out W × H, 300 × 244

62 6

Cut-out W × H, 262 × 202

50 6

Front panel W × H, 202 × 156

Display 5.7" W × H, 117 × 88

Manual PCD7.D412DTPF & PCD7.D4xxxT5F │ Document 27-620 – Release ENG07 │ 2019-06-20

Cut-out W × H, 189 × 142

1-3

Saia-Burgess Controls AG

1.5 Installation of the panels

1.5.1 Installation in control cabinet

■ The installation position is horizontal. Slide the unit into the installation cut-out.

■ Make sure that the ventilation slots are not covered, to allow air circulation and

the device does not overheat.

■ Install 4 mounting clamps for 5.7" (2 on top and 2 on the bottom), 6 clamps for

10.4" (2 on top, 2 on the bottom and 2 on the sides) and 8 clamps for the 12.1"

(3 on top, 3 on the bottom and 2 on the sides). Refer to the photos below.

Quickstart

Installation of the panels

1

Mounting parts of 12.1" panels

Mounting parts of 10.4" panels

Mounting parts of 5.7" panels

Note:

■ It is helpful to have somebody hold the unit from the front side of the panel

while the brackets are being installed.

■ The bolts require a 2.5 mm Allen key.

■ Screw the bolts into the brackets up to the point when you can still clip them

onto the MicroBrowser without being obstructed by the plate.

■ Clip them onto the unit then tighten the bolts until they touch the plate.

■ The required torque to seal the gasket is 20 cNm. To avoid breaking the clamp,

do not exceed 30 cNm.

How to ensure spray water protection according to IP65:

The device must be mounted on a at surface or wall. Tighten the bolts until the

front plate of the PCD7.D4xx is just touching the mounting surface/wall.

Manual PCD7.D412DTPF & PCD7.D4xxxT5F │ Document 27-620 – Release ENG07 │ 2019-06-20

1-4

Saia-Burgess Controls AG

1.5.2 Drywall mounting set for MB panels

The MicroBrowser panels are not just for mounting in the control cabinet; They

also look very good in the oce or living room, or mounted on a wall. This is why

we provide wall mounting kits for solid and cavity wall mounting.

Quickstart

Installation of the panels | Operation and handling

1

In-wall

Mounting kit for the 5.7” MB panel PCD7.D457-IWS2 PCD7.D457-OWS2

Mounting kit for the 10.4” MB panel PCD7.D410-IWS PCD7.D410-OWS

Mounting kit for the 12.1” MB panel PCD7.D412-IWS PCD7.D412-OWS

On-wall

In-wall(cavitywalls) On-wall (solid walls)

1.6 Operation and handling of the touchscreen

To operate the touchscreen, use only your nger, the stylus or a soft nger stylus.

Do not use sharp tools (e.g., sharp metallic objects, paperclips or a screwdriver,

etc.).

Manual PCD7.D412DTPF & PCD7.D4xxxT5F │ Document 27-620 – Release ENG07 │ 2019-06-20

1-5

Saia-Burgess Controls AG

Setting up communications for displaying a website

1.7 Setting up communications for displaying a website

1.7.1 HTTPDirectoverethernetRJ-45connector

The quickest communications port is the ethernet port via RJ-45, with the HTTP

Direct protocol selected. The speed is either 10 MBit/s or 100 MBit/s after an autonegotiation protocol with the connected device.

Internal connection for programmed pWeb panels

The programmed panels are connected internally directly to the programmable

logic controller, via an ethernet connection. It therefore suces, in this case, to

simply set the local host IP address 127.0.0.1 and HTTP Direct connection in the

Setup menu under Web connection. The programmable pWeb panels are obviously also capable of displaying websites from controllers located within the network.

The procedure for this is the same as with the standard 12” SVGA panel.

Connectingtoexternaldevices

If an ethernet connection to an Automation Server exists, the HTTP connection

can be established between our PCD7.D4xx and any SBC controller. In the case

of the programmable panels, the panel is generally connected to the internal con-

troller.

Quickstart

1

Ethernet http direct

Quick test of the SVGA panel

■ First the Saia PCD must have a web program loaded which was created with

the Web Editor (see 26-838_Manual_Web-Editor). You can ask the SBC Support Team for some examples. They will also soon be available on our website.

■ Using a CAT5 cable, you can connect our PCD7.D4xx terminal to the SBC

device. The current controllers support auto-crossing; a crossover cable is thus

no longer required.

■ Using PG5, dene the HW settings of the Saia PCD device: S-bus support

must be selected together with the TCP/IP channel where a valid IP address is

entered.

Manual PCD7.D412DTPF & PCD7.D4xxxT5F │ Document 27-620 – Release ENG07 │ 2019-06-20

1-6

Saia-Burgess Controls AG

Setup settings of the SVGA panel:

Congure the SVGA panel by opening the Setup menu (refer to chapter 5):

Quickstart

Setting up communications for displaying a website

Î First, be sure that you are on the same network subnet. For example, if the

Saia PCD has the IP address 192.168.12.92, give your terminal (in the Network

menu) an IP address like 192.168.12.90, as normally the subnet mask is set to

255.255.255.0.

Î In the Conguration menu, enter the Address of the start page that corre-

sponds to the IP address of the Saia PCD, and also enter its HTML start page

name.

Your MB panel should now be connected to the Saia PCD and the start page selection should be displayed on the screen. You can now navigate your web pages.

1.7.2 USBportasServiceport

The USB port on the programmable panels is used mainly to download the user

program onto the controller with PG5.

On SVGA standard MB panels, this port is generally used as a Service port. It is

used mainly to download new rmware programs onto the device.

The USB port meets the USB 1.1 specication. Maximum speed: 12 MBit/s.

1.7.3

Getting started with the Web Editor on the MicroBrowser panel PCD7.D4xx

1

Detailed documentation can be downloaded from our website. See manual 26-838

Manual Web Editor. To get started with programming the MB panel, some particular features must be observed:

■ If no assistance is available from the Wizard when creating a new project, the

project must be set up as follows:

● Using the virtual keyboard with SVGA MB panels

● See Chapter 5.6 Keyboard

● If you want to use the le Background.teq or foreground.teq, you rst need

to generate these les. Why is this? Before objects or text and elds can appear, these les must rst be positioned on each page.

● Once the project is ready to download, enter the desired HTML le name

and generate a Build Project. Then make a Webserver Build in the Saia PG5

Project Manager, so that all the les are held in the PCD. If you just want to

access the PCD with MB panel PCD7.D4xx and not with a PC browser, you

can reduce the amount of data by deleting the .jar les, as they are already

included on the panel.

Manual PCD7.D412DTPF & PCD7.D4xxxT5F │ Document 27-620 – Release ENG07 │ 2019-06-20

1-7

Saia-Burgess Controls AG

Technical data of the SVGA MicroBrowser panel

2 Technical data for the two panel types

The hardware of the SVGA MicroBrowser panels and the programmable pWeb

panels is dierentiated in several areas by the Programmable Logic Controller on

the pWeb panels. These are described in the following sections:

2.1 Technical data of the SVGA MicroBrowser panel

Display

Display size 12.1" TFT

Resolution SVGA 800 × 600

Backlight LED

Colours 65,536

Contrast adjustment Ye s

On Board File System 128 MByte

Operating system

Internetservices

Interfaces

Ethernet 10 / 100 M 2× RJ45 (switch)

Current consumption

Voltage supply

Protection class (front)

Temperature

Relativehumidity

Processor

Real Time Clock (RTC)

Saia PCD COSinuS with SBC MicroBrowser expansion

Automation Server, SBC MicroBrowser

Max 600 mA

24 VDC±20 %

IP65

Operation: 0 … 50°C

Storage: –25 … +70°C

Operation: 10 … 80%

Storage: 10 … 98% (non-condensing)

Coldre CF5373L, 240 MHz

Yes, with Supercap

Technical data

2

Manual PCD7.D412DTPF & PCD7.D4xxxT5F │ Document 27-620 – Release ENG07 │ 2019-06-20

2-1

Saia-Burgess Controls AG

Technical data of the SVGA MicroBrowser panel

2.2 Technical data for the pWeb panels

2.2.1 Overview

Logic controller

User program, ROM /DB/text 1 MByte

RAM/DB/text 1 Mbyte

Media 14,336 ags / 16,384 registers

Backup for user User program is saved to the integrated micro SD card

File system for user 128 MBytes, on-board

Program cycle time 10 cycles / sec maximum

Protocolsoneldlevel

Internetservices

Interfaces

Ethernet 10 / 100 M 2× RJ45 (switch)

USB (1.1 / 2.0) 1× client

Serial interfaces RS-485 & socket for PCD7.F1xxS communications module

Temperature range

Relativehumidity

Processor

Real Time Clock (RTC)

Battery

Serial-S-bus, Ether-S-bus, Ether-S-I/O, Modbus RTU,

TCP or M-bus

SBC MicroBrowser, Automation Server

Operation: 0 … 50°C

Storage: –25 … +70°C

Operation: 10 … 80%

Storage: 10 … 98% (non-condensing)

Coldre CF5373L, 240 MHz

Yes, with battery back-up

Lithium Renata CR 2032 (lifetime 1-3 years)

Technical data

2

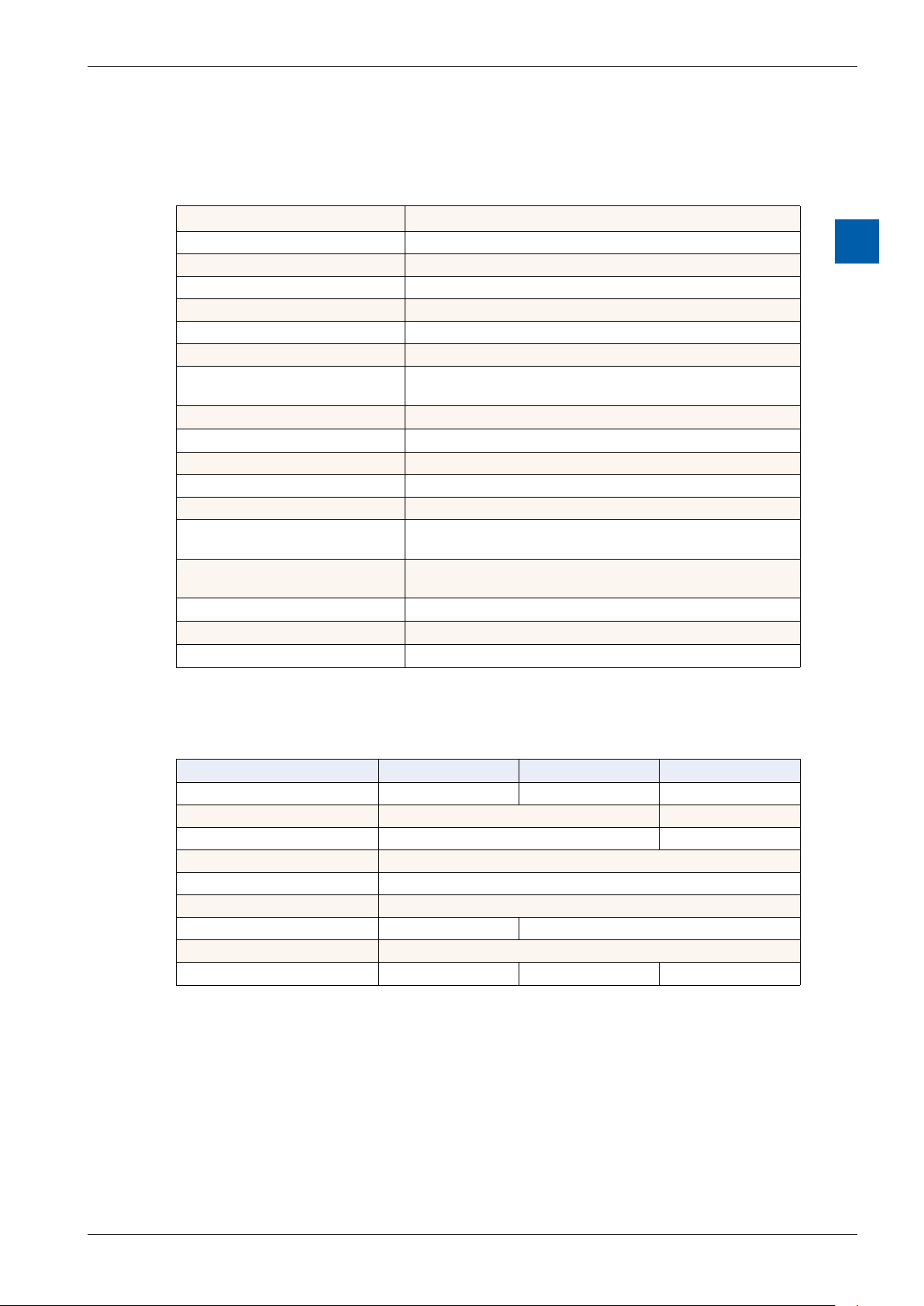

2.2.2 Product-related presentation

Technical data PCD7.D457VT5F PCD7.D410VT5F PCD7.D412DT5F

Display size 5.7 TFT 10.4 TFT 12.1 TFT

Resolution/Pixels VGA 640 × 480 SVGA 800 × 600

Touchscreen Resistive four-wire Resistive ve-wire

Contrast adjustment yes

Backlight LED

Voltage supply 18 - 32V

Current consumption Max. 500 mA Max. 600 mA

Protection class (front) IP 65

Front status LED No No Yes

Manual PCD7.D412DTPF & PCD7.D4xxxT5F │ Document 27-620 – Release ENG07 │ 2019-06-20

2-2

Saia-Burgess Controls AG

2.2.2 Battery of the pWeb panel

The hardware components are maintenance-free, with the exception of the CPUs

for the pWeb panel, whose battery requires occasional replacement.

Technical data

Technical data of the SVGA MicroBrowser panel

The components do not contain any user-replaceable parts. If hardware problems

occur, please return the components to Saia-Burgess Controls.

The resources (register, ags, timer, counters, etc.) and the character strings/DBs

are stored in the RAM. In order to prevent these from being lost, and to enable

the hardware clock to carry on running during a power failure, the devices are

equipped with a back-up battery:

CPU model Buer Buertime

PCD7.D4xxx Renata CR 2032 lithium battery 1-3 years

1)

Depending on the ambient temperature: The higher the temperature, the shorter the buer time.

1)

New controllers include batteries in the scope of delivery, and these must be

inserted during commissioning. Pay attention to the polarity of the batteries.

CPUs with lithium batteries are not maintenance-free. The battery voltage is monitored by the CPU. The status LED lights up (12” pWeb panel only) and XOB 2 is

called if:

■ the battery voltage is lower than 2.4 V;

■ the battery is missing.

2

In order to avoid data-loss, we recommend changing the batteries while the panel

is connected to the power supply.

■ Disconnect from the voltage supply.

■ Remove the cover of the pWeb panel.

■ To prevent data loss while changing the battery 119B, reconnect to the voltage

supply.

■ Push the terminal holder back slightly (see arrow in gure).

■ Remove the battery.

■ Insert a Renata CR 2032 button battery so that the positive terminal is in con-

tact with the terminal holder.

■ Disconnect from the voltage supply and reattach the back wall of the panel.

Manual PCD7.D412DTPF & PCD7.D4xxxT5F │ Document 27-620 – Release ENG07 │ 2019-06-20

2-3

Saia-Burgess Controls AG

Communications interfaces

3 Logic controller of the programmable pWeb panel

3.1 Communications interfaces

Various communications interfaces are integrated into the programmable logic

controller. These can also be expanded by installing an additional module.

Logic Controller

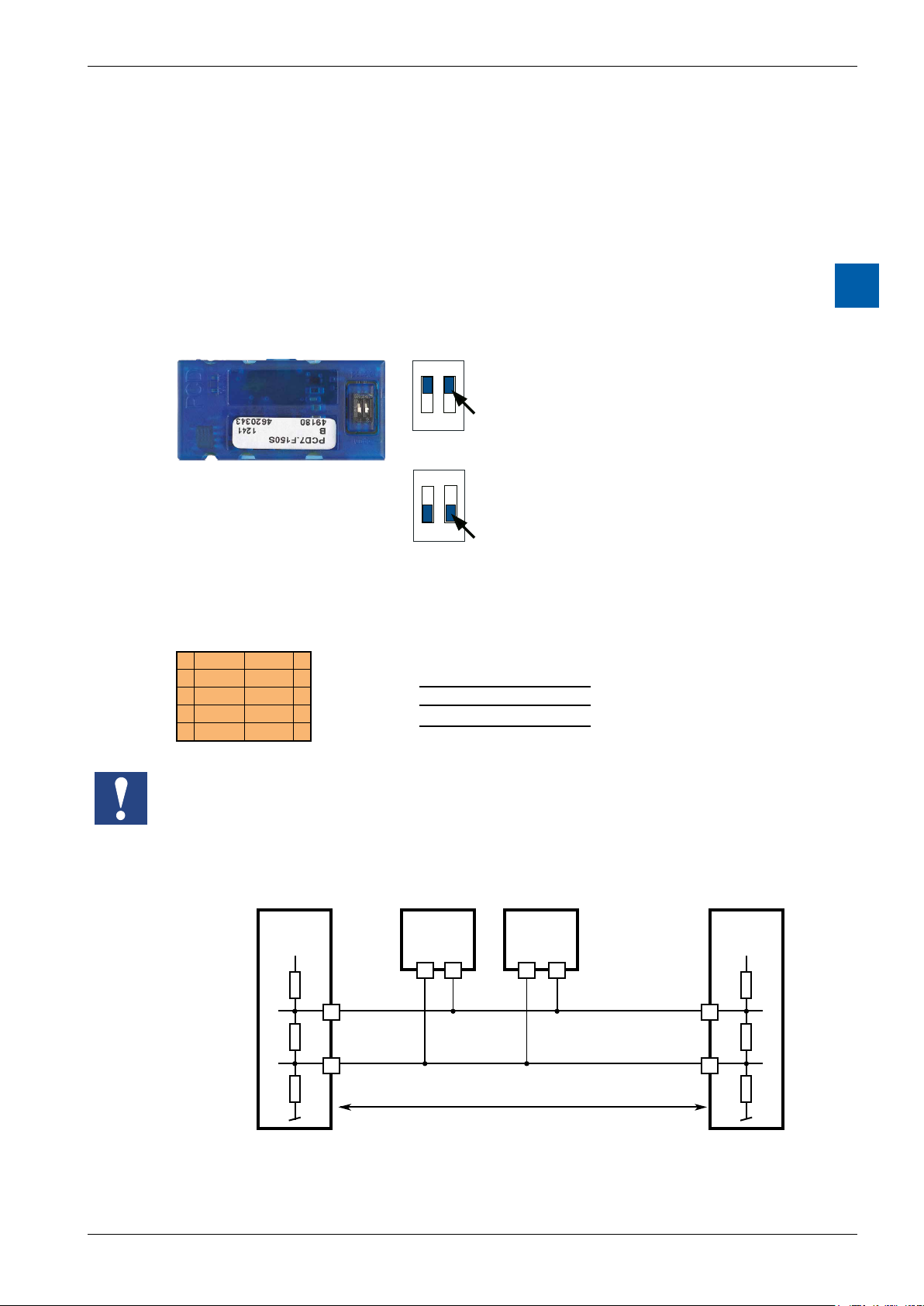

3.1.1 On-board RS-485

PCD4.DxxxT5F PCD3.Mxxxx PCD2.M5xxx PCD1.M2xxx

GND

/D

D

The pin nos of the connected PCD are explained in the respective manual.

Make sure that the terminators are properly terminated.

In the example below, you can see a possible connection between the terminals

and PCDs. In order to avoid reection on the communications channel, the network should be terminated with termination resistors. The PCD7.D4xx has a switch

for this:

3

RS-485-Network

Pull up

330 Ohm

Termination

Resistor

150 Ohm

Pull down

330 Ohm

First station Middle stations

PCD1.M2_

Port #1

+5 V

/n

n n

PCD1.M2_

PCD2.M5_

n n

Bus RS485

Segment length max. 1200 m

PCD3.Mxxxx

max. 32 stations

End station

PCD7.D457VT5F

PCD7.D410VT5F

PCD7.D412DT5F

+5 V

/n/n

/RX - /TX

RX - TX

/n

Manual PCD7.D412DTPF & PCD7.D4xxxT5F │ Document 27-620 – Release ENG07 │ 2019-06-20

3-4

Saia-Burgess Controls AG

Thefollowinggureshowsyouwhereitislocated.

Î If the switch is in the top position, the network is closed.

Î If the switch is in the bottom position, the network is open.

Conguration can either be performed directly, via the Setup menu on the pWeb

panel, or indirectly, via the Hardware conguration on the PG5. Overwrite the

current conguration the same as when making a change.

Logic Controller

Communications interfaces

3

3.1.2 Additional communications ports using slot A (Port no. 1)

Slot A on the pWeb panels allows you to plug in optional modules for communications interfaces. Only modules of the PCD7.F1xxS series are supported.

Installation - PCD7-D412DT5F

Earth 2 × Ethernet

(switch)

USB Reset

Switch

PCD7.F1xxS RS-485 Power Supply

Multi-colored front LED

Manual PCD7.D412DTPF & PCD7.D4xxxT5F │ Document 27-620 – Release ENG07 │ 2019-06-20

3-5

Saia-Burgess Controls AG

Installation - PCD7.D410VT5F

Logic Controller

Communications interfaces

Earth 2 × Ethernet

(switch)

Installation - PCD7.D457VT5F

Earth 2 × Ethernet

(switch)

USB Reset

Switch

USB Reset

Switch

PCD7.F1xxS RS-485 Power Supply

3

PCD7.F1xxS RS-485 Power Supply

Connections

PCD7.F1xxS

Connector

pins

0 GND GND

1 TXD D

2 RXD /D

3 RTS

4 CTS

5 GND GND

6 DTR

7 DSR

8 COM

9 DCD

Signal

RS-232

Signal

RS-485

RS-485

Connector

pins

1 GND

2 NC

3 /D

4 D

Power Supply

Connector

pins

1 24 V (+)

2 GND (-)

Signal

Signal

Manual PCD7.D412DTPF & PCD7.D4xxxT5F │ Document 27-620 – Release ENG07 │ 2019-06-20

3-6

Saia-Burgess Controls AG

3.1.2.1 PCD7.F110S Serial Interface Module RS-485/RS-422

Termination resistors can be connected (CLOSED) or disconnected (OPEN) with

slide switchs.

PCD7.F110S RS-485 terminator

Slider

O

C

21

Open not terminated

(factory setting)

Logic Controller

Communications interfaces

3

Slider

O

C

21

Closed terminated

RS-422 connection

Port x.1 - 10 pin spring-loaded terminal block

RS-422

0 PGND Tx 1

2 /Tx Rx 3

4 /Rx PGND 5

6 RTS /RTS 7

8 CTS /CTS 9

Terminal

Pin

PGND 10

TX 11

/TX 12

RX 13

/RX 14

PGND 15

RTS 16

/RTS 17

CTS 18

/CTS 19

RS-422

Peripherie-

device

PGND

TX

/TX

RX

/RX

SGND

RTS

/RTS

CTS

/CTS

RS 485 connection (Electrically connected RS-485 interface)

Port x.1 - 10 pin spring-loaded terminal block

RS-485

0 PGND Rx-Tx 1

2 /Rx-/Tx 3

4 PGND 5

6 7

8 (SGD) 9

PCD Modul

RX - TX

/RX - /TX

Terminal

x0

x1

x2

RS-485

GND

RS-485

RS-485

Peripherie-

device

PGNDPGND

RX - TX

/RX - /TX

For more details, see Manual 26-740, section "Installation components for RS-485

Networks."

Manual PCD7.D412DTPF & PCD7.D4xxxT5F │ Document 27-620 – Release ENG07 │ 2019-06-20

3-7

Saia-Burgess Controls AG

3.1.2.2 PCD7.F121S Serial interface module RS-232 suitable for modem connection

PCD7.F121S

RS-232 connection

Port x.1

RS-485

0 PGND TxD 1

2 RxD RTS 3

4 CTS PGND 5

6 DTR DSR 7

8 COM DCD 9

10 pin spring-loaded terminal block

Logic Controller

Communications interfaces

3

RS-232 connection to DTE RS-232 connection to DCE

cable

External modem

(ETCD) DCE

PGND

TX

RX

RTS

CTS

SGND

DTR

DSR

DCD

0 PGND

1 TXD

2 RXD

3 RTS

4 CTS

5 PGND

6 DTR

7 DSR

8 Reserve

9 DCD

cable

Peripherie

device (DTE)

PGND

TX

RX

RTS

CTS

SGND

DTR

DSR

DCD

0 PGND

1 TXD

2 RXD

3 RTS

4 CTS

5 PGND

6 DTR

7 DSR

8 Reserve

9 DCD

Manual PCD7.D412DTPF & PCD7.D4xxxT5F │ Document 27-620 – Release ENG07 │ 2019-06-20

3-8

Saia-Burgess Controls AG

Communications interfaces

3.1.2.3 PCD7.F150S Serial Interface Module RS-485 with Electrical Isolation

Electrical isolation is achieved with three optocouplers and a DC/DC converter.

Data signals are protected against overvoltage with an anti-surge diode (10 V).

Electrical isolation is achieved using three optical couplers and a DC/DC converter.

The data signals are protected against excess voltages by a suppressor diode

(10 V).

The line terminator for port x.1 is integrated into the module and can be activated

using the silde switch on the module.

PCD7.F150S RS-485 terminator

ON

C

O

1 2

ON

C

O

1 2

Closed terminated

Slider

Open not terminated

(factory setting)

Logic Controller

3

Slider

RS 485 connection - 10 pin spring-loaded terminal block

Port x.1

RS-485

0 PGND Rx-Tx 1

2 /Rx-/Tx 3

4 PGND 5

6 7

8 (SGD) 9

PCD Modul

RX - TX

/RX - /TX

Terminal

x0

x1

x2

RS-485

GND

RS-485

RS-485

Peripherie-

device

PGNDPGND

RX - TX

/RX - /TX

When using this module, the permitted ambient temperature for the control unit is

reduced by 5°C.

Line terminator:

First station Middle stations End station

+5 V

/n

Pull up

330 Ohm

Termination

Resistor

150 Ohm

Pull down

330 Ohm

+5 V

n n

28

Bus RS-485

29 n

Segment length max. 1200 m

max. 32 stations

/n/n

/RX - /TX

RX - TX

More details are available in the manual 26-740 “Installation components for

RS-485 networks”.

Manual PCD7.D412DTPF & PCD7.D4xxxT5F │ Document 27-620 – Release ENG07 │ 2019-06-20

3-9

Saia-Burgess Controls AG

3.1.2.4 PCD7.F180S Serial Interface Module Belimo MP-Bus

Up to 8 actuators and sensors can be connected.

PCD7.F180S

Belimo connection

Port x.1

Belimo MP-Bus

0 PGND MP 1

2 ‘MFT’ ‘IN’ 3

4 PGND 5

6 7

8 (SGD) 9

10 pin spring-loaded terminal block

Logic Controller

Communications interfaces

3

MP-Bus cabling

0 PGND Earth connection, MP line

1 MP Multi-point

The MP-Bus is the Belimo master slave

bus. Up to 8 slaves can be connected to

a master device.

These are:

■ MFT(2) ap drives

■ MFT(2) valve drives

■ MFT re damper drives

■ VAV NMV-D2M compact controller

2 ‘MFT’ MFT programming unit (internal MP-Bus)

3 ‘IN’ detection of MFT programming unit

(input 10 kΩ, Z5V1)

5 PGND Earth connection, MFT programming unit

Manual PCD7.D412DTPF & PCD7.D4xxxT5F │ Document 27-620 – Release ENG07 │ 2019-06-20

3-10

Loading...

Loading...