Page 1

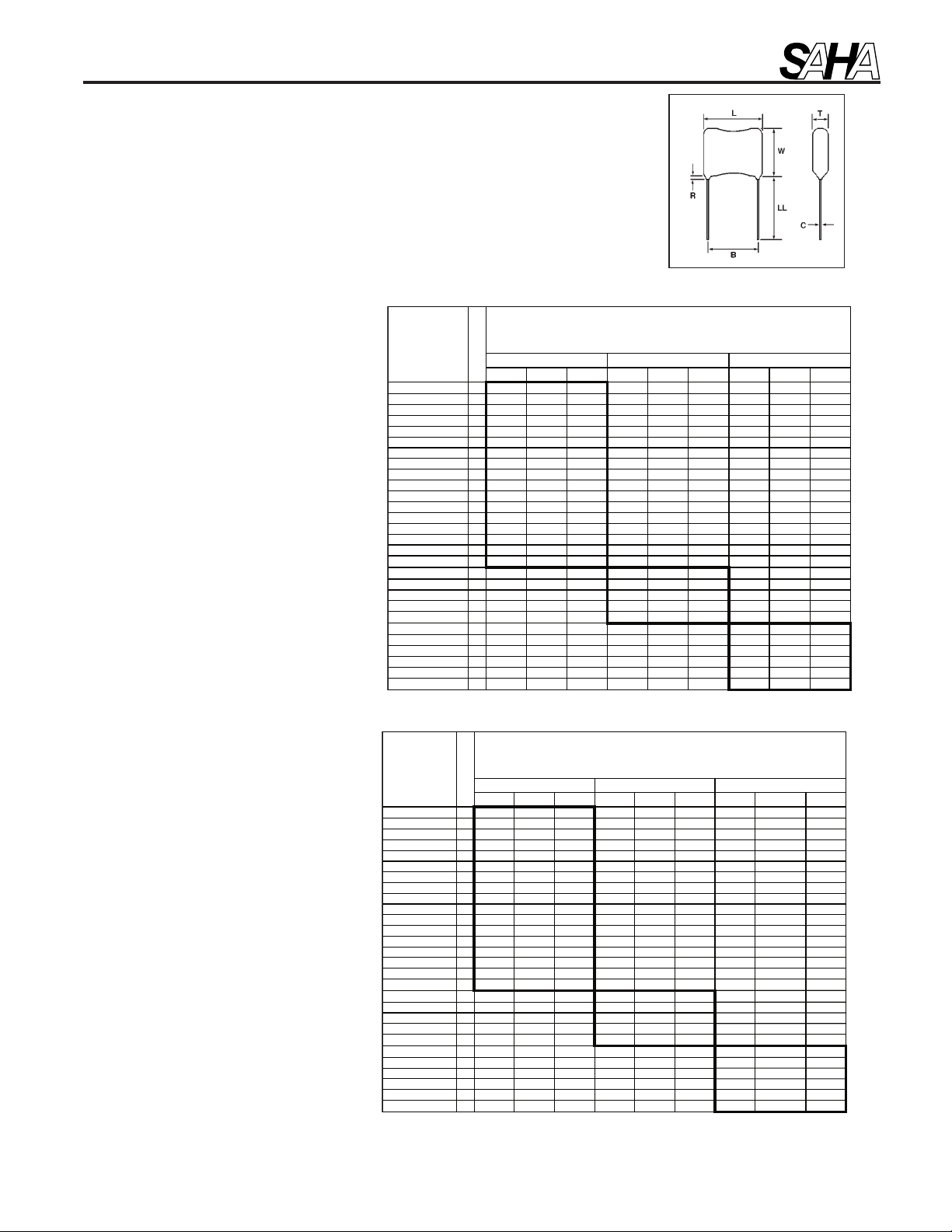

SAHA DESIGNATION DM 05 DM 10 DM 12 DM 15

MIL STYLE - Discontinued - CM 04 - CM 05

CAPACITANCE RANGE pF 1 to 390 1 to 390 1 to 2500 1 to 1200

MAXIMUM 50 V DC 390 820 - 2500

CAPACITANCE 100 V DC 200 390 2500 2000

IN pF IN THE 300 V DC 120 360 820 2000

RATED 500 V DC - 250 430 750

VOLTAGE 1000 V DC* - - - -

INDICATED

MAXIMUM L 0.270 0.390 0.413 0.490

NOMINAL W 0.250 0.380 0.433 0.420

DIMENSIONS IN T 0.190 0.220 0.220 0.240

INCHES B 0.120 0.141 0.200 0.234

MAXIMUM L 6.86 9.91 10.49 12.45

NOMINAL W 6.35 9.65 11.00 10.67

DIMENSIONS IN T 4.83 5.59 5.59 6.10

mm B 3.05 3.58 5.08 5.94

SAHA DESIGNATION DM 19 DM 20 DM 30 DM 42

MIL STYLE - Discontinued CM 06 - CM 07 -

CAPACITANCE RANGE pF 1 to 8200 680 to 12,000 5100 to 20,000 16000 to 82000

MAXIMUM 50 V DC - - - -

CAPACITANCE 100 V DC 8200 12000 - 82000

IN pF IN THE 300 V DC 6800 12000 20000 68000

RATED 500 V DC 5100 10000 20000 51000

VOLTAGE 1000 V DC* 4700 - 12000 30000

INDICATED

MAXIMUM L 0.710 0.820 0.830 1.470

NOMINAL W 0.590 0.630 0.920 0.920

DIMENSIONS IN T 0.370 0.450 0.450 0.450

INCHES B 0.344 0.438 0.438 1.063

MAXIMUM L 18.03 20.83 21.08 37.34

NOMINAL W 14.99 16.00 23.37 23.37

DIMENSIONS IN T 9.40 11.43 11.43 11.43

mm B 8.74 11.13 11.13 27.00

SAHA

Designation M - 6 M - 12

Capacitance

Range in pF 22 - 68 82 - 220

Maximum

Capacitance in 68 220

the rated voltage

350 VDC

SAHA

Designation M - 37 M - 50

Capacitance

Range in pF 270 - 560 680 - 10000

Maximum

Capacitance in 560 10000

the rated voltage

350 VDC

SAHA Designation MMR B - 1 MMR B - 2 MMR L - 1 MMR E - 1 MMR E - 2

Capacitance Range (pF) 4 - 1,500 750 - 2,500 4 - 1,500 4 - 6,000 4,001 - 10,000

Maximum 100 V DC 1,500 1,500 1,500 6,000 10,000

Capacitance in 350 V DC 750 1,500 750 4,000 7,500

the rated voltage 750 V DC - - - - -

SAHA Designation MMR A - 1 MMR A - 2 MMR A - 3 MMR A - 4 MMR S - 1

Capacitance Range (pF) 4 - 7,500 4 - 15,000 2,001 - 27,000 3,501 - 40,000 4 - 60,000

Maximum 100 V DC 7,500 15,000 27,000 40,000 60,000

Capacitance in 350 V DC 5,000 10,000 15,000 20,000 50,000

the rated voltage 750 V DC 1,000 2,000 3,500 5,000 -

SAHA Designation MMA 10 MMA 15 MMA 20 MMA 30

Capacitance Range (pF) 10 - 5,100 10 - 1,000 10 - 2,700 560 - 43,000

Maximum 300 V DC 5,100 - - 43,000

Capacitance in 500 V DC 380 1,000 2,700 30,000

the rated voltage - - - -

查询DM05供应商

MICA CAPACITORS

MICA CAPACITORS

Quick Reference Guide

DM Series General Specifications by Case Size

330 - 430

M Series

General Specifications

(Formerly Sold as

RS Components 124-XXX series)

1

SUSCO Engineers & Buyers Guide - Mica Section Tel: 516-981-6690 Fax: 516-981-6867

MMR & MMA Series General Specifications

MMR Series (Equivalent to: ASHCROFT (GB) and JAHRE (D) Molded Radial)

MMA Series (Equivalent to: ASHCROFT (GB) and JAHRE (D) Molded Axial)

* Available as special part.

Page 2

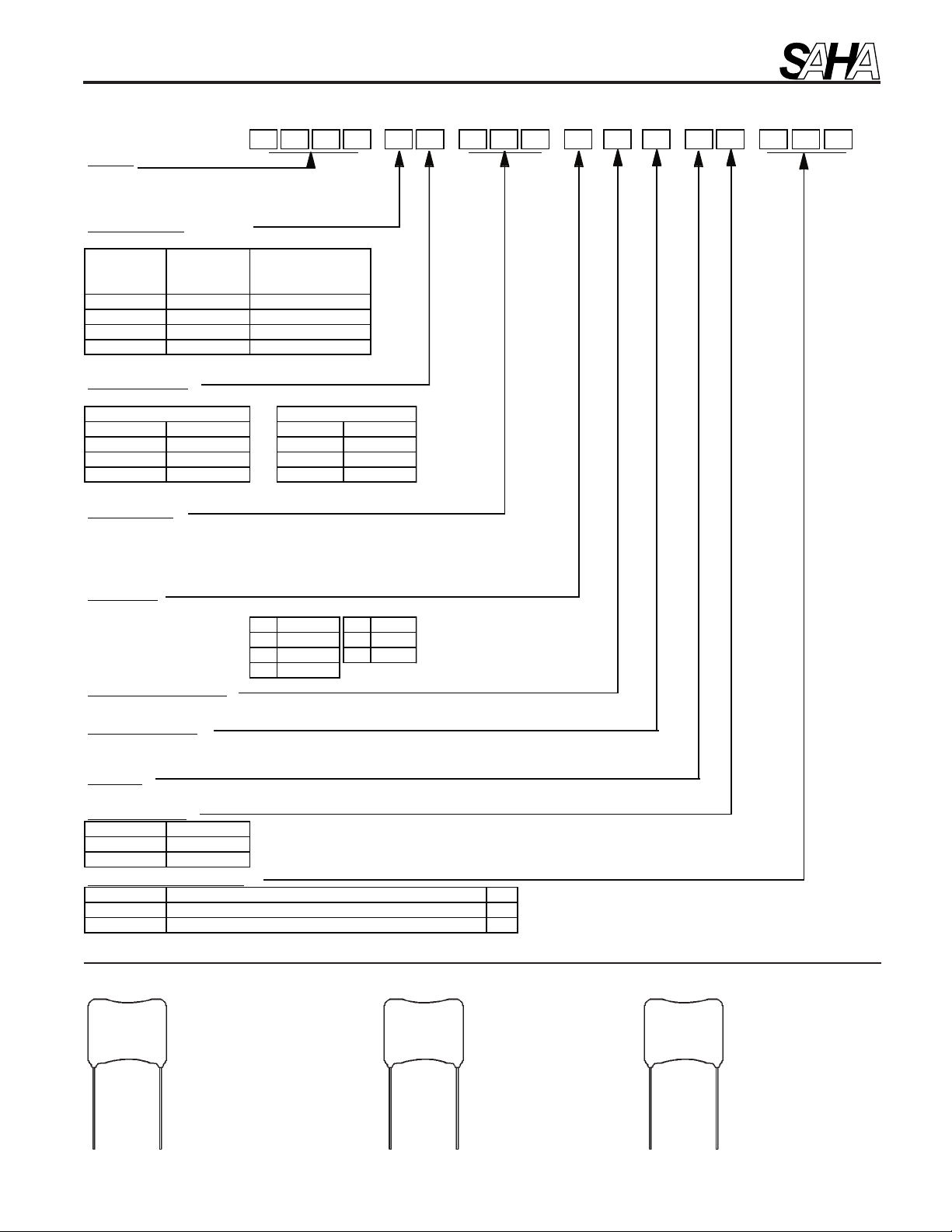

MICA CAPACITOR - PART NUMBERING SYSTEM

Sample Part Number: DM05FA151J-CA Description: DM05 Series, 150pF, 100 Volt, 5% in Ammo Pack, Inside Crimped.

D M 0 5 F A 1 5 1 J O 3 - S A - R 0 2

Series

Enter Series Code: (up to 4 Characters)

Series included: DM05, DM10, DM12, DM15,

DM19, DM20, DM30, DM42.

Characteristic

Enter characteristic code: ( 1 Character)

Temperature

Characteristic Coefficient Capacitance

Letter PPM/C Drift

C -200 to +200 ± (0.5% + 0.1pF)

D -100 to +100 ± (0.3% + 0.1pF)

E -20 to +100 ± (0.1% + 0.1pF)

F 0 to +70 ± (0.05% + 0.1pF)

see catalog for individual part characteristic code

Rated Voltage

Enter voltage code: (1 character)

Rated Voltage Code Rated Voltage Code

Letter Code Volts DCW Letter Code Volts DCW

Y 50 E 350

A 100 D 500

C 300 F* 1000*

* Note: Not for use in snubber applications

Capacitance

Enter EIA Capacitance Code: (3 Digits)

First Two Digits represents significant figures of capacitance in Picofarads.

Third Digit indicates number of zeros to follow.

Example: 10pF = 100, 100pF = 101, 1000pF = 102

Tolerance

Enter Capacitance Tolerance Code: ( 1 Character)

Tolerance Code D ± 0.5pF H ± 3 %

E ± 0.5 % J ± 5 %

F ± 1 % K ± 10 %

G ± 2 %

Temperature Range

Code O = -55 to +125 C

Vibration Grade

Standard Grade = 3

(see catalog for details)

Marking

S = Saha

Package Type

Bulk < Blank >

Ammo Pack A

Tape & Reel T

Special Specifications

C Cut followed by 2 Digit specification code 01 -99

R Crimped followed by 2 Digit specification code 01 -99

P Cut & Crimped followed by 2 Digit specification code 01 -99

Examples: C 0 2 = cut leads to 0.175 mm P 0 2 = cut leads to 0.175 mm and inside crimp

(See Special Specifications Sheet) Rev D - 2/99

MICA CAPACITORS

Part Marking

TYPE 1- Capacitance in pF,

150 ± 5%

500V

SAHA

tolerance in percentage or +/pF and voltage(Vdc) are indicated in numbers along with

the brand marking. Brand

marking of “SAHA”, “S” or

“KEC” are common. Parts are

also supplied with no brand

TYPE 1

marking in some cases based

on product availability and

customer requirements.

Tel: 516-981-6690 Fax: 516-981-6867 SUSCO Engineers & Buyers Guide - Mica Section 2

CM 05 FD

151JO3

SAHA

TYPE 2

TYPE 2 - Formerly for

Military certified Capacitors.

The CM series code has

been discontinued.

151J or

150 pF

+/- 5%

TYPE 3

TYPE 3 - Capacitance in

EIA capacitance code

(as in Type 2) and tolerance with tolerance code

or capacitance value in

pF with tolerance in +/% or +/- pF are marked

on the capacitors.

Voltage is not marked on

the part. Brand marking

is optional.

Page 3

MICA CAPACITORS

PERFORMANCE CHARACTERISTICS

GENERAL SPECIFICATIONS FOR SAHA MICA CAPACITORS

The SAHA Mica capacitors meet the required commercial specifications and the EIA

requirements. The CMO series capacitors also meet the military specifications MIL-C-5. The

actual specifications and dimensions of the capacitors are mentioned under each series in

the catalog.

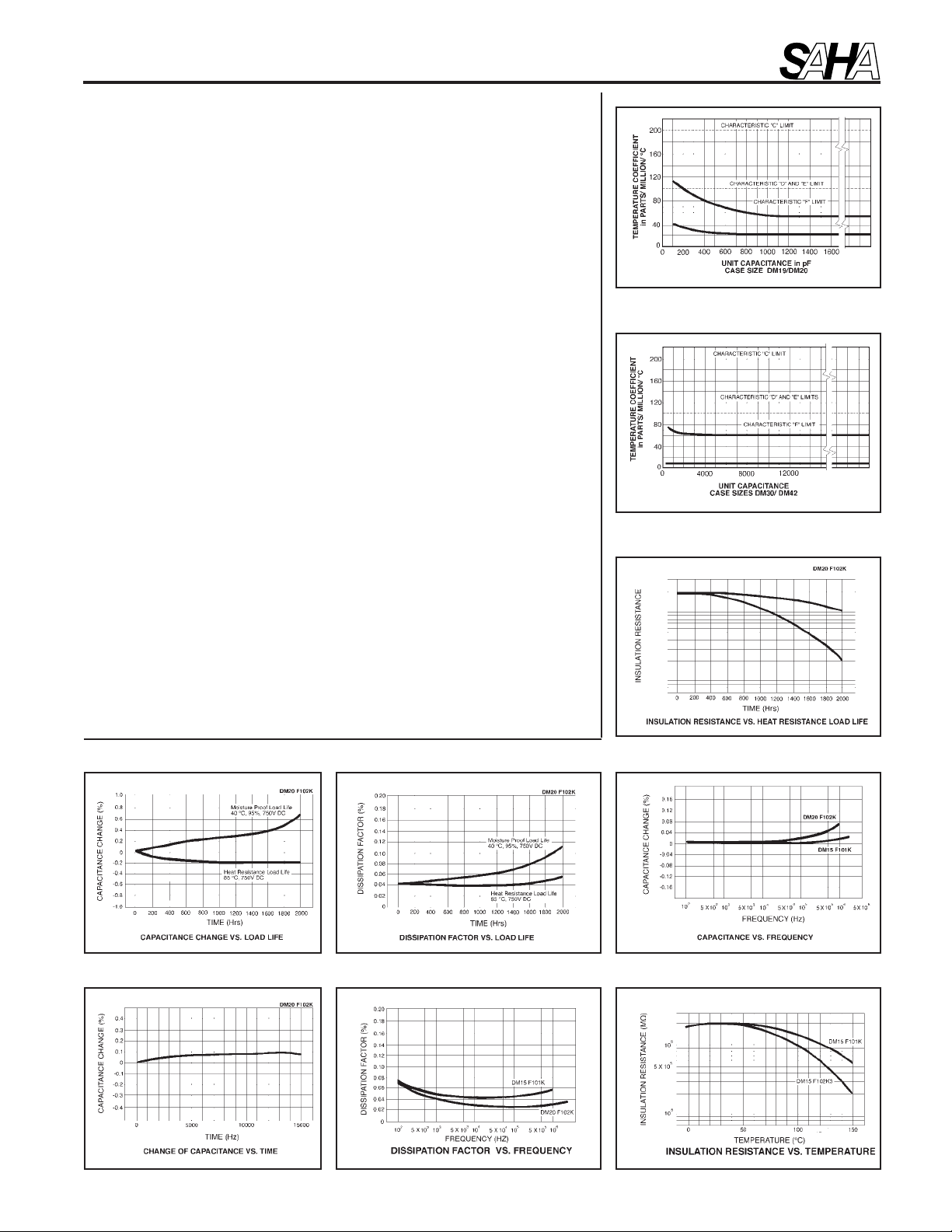

CAPACITANCE

The capacitance of mica capacitors is measured at 1 M Hz ±10% for capacitance values up

to 1000 pF and at 1 K Hz ±10% for capacitance values above 1000 pF. The capacitance

value when measured at 25 °C shall be with in the tolerance specified.

DISSIPATION FACTOR

The dissipation factor for mica capacitors are measured at 1MHz for values up to 1000 pF

and at 1 KHz for values above 1000 pF. The values shall remain within the specified values.

The variation pattern of dissipation factor for different values of capacitance are also shown

in the Figure 3.

INSULATION RESISTANCE

The insulation resistance is measured at 50 ±5 V for capacitors with rated voltage of 50 V

DC and at 100 ±10 V for capacitors with higher voltage rating. The insulation resistance thus

measured at 25 °C shall meet the specified limits. The variation of insulation resistance for

different capacitance values at 25 °C is shown in Figure 1. After certain tests listed below

the insulation resistance value changes and these values are plotted in Figure 2. Figure 4

indicates the variation pattern of insulation resistance with capacitance value at different

temperature conditions.

WITHSTANDING VOLTAGE

The mica capacitors are designed to withstand higher voltage than the rated voltage for

limited time. These capacitors shall withstand 200% of the rated voltage for 1 to 5 seconds

when applied with a limiting surge current value of 50 mA.

VIBRATION GRADE

The capacitors shall be subjected to a harmonic motion having an amplitude of 1.5 mm and

the frequency which is varied between the limits of 10 and 55 Hz. The entire frequency

range from 10 to 55 Hz and then back to 10 Hz shall be traversed in approximately 1 minute

and the motion shall be applied for a period of 1hour in each of the three mutually

perpendicular directions. After testing, when the electrical measurements are performed:

1. The insulation resistance shall be more than 30000 M Ohms for capacitance value up to

10000 pF. Please refer to Figure 2 for acceptable variation pattern for Insulation

Resistance for values above 10000 pF.

2. The dissipation factor shall be within the original specified limits. Please also refer to

Figure 3 for variation pattern of dissipation factor with respect to capacitance value.

3. The capacitance change shall not exceed ±1% or ±1 pF whichever is greater.

FIGURE 1

FIGURE 2

FIGURE 3

FIGURE 4

SOLDERING HEAT RESISTANCE

Both leads of the capacitors shall be immersed in molten solder at a temperature of 270

°C for 3 to 4 seconds. After the test the capacitors shall meet the initial requirements of the

Withstanding voltage and the Capacitance change shall not exceed ± 0.55 or ±1 pF.

MOISTURE RESISTANCE

Capacitors shall be subjected to a temperature of 40 ±2 °C at 90 to 95 % relative humidity

for 240 ±8 Hours. After the test:

1. The samples shall meet the after test requirement of Insulation resistance values as

furnished in Figure 2.

2. The dissipation factor shall be within 1.5 times the original specified limits. Please also

refer to Figure 3 for variation pattern of dissipation factor with respect to capacitance

value for original limits.

3. The capacitance change shall not exceed ±3% or ±1 pF whichever is greater.

MOISTURE RESISTANCE LOADING

Capacitors shall be subjected to a temperature of 40±2 °C at 90 to 95% relative humidity

with rated voltage for 500 Hours. After the test the samples are maintained at normal

temperature and relative humidity for a period of 4 to 24 hours. When tested after this;

1. The capacitor samples shall be free of cracks, or other mechanical damages and the

marking shall remain legible

2. The samples shall meet the original requirement of the Withstanding voltage

3. The samples shall meet the after test requirement of Insulation resistance as furnished in

Figure 2

4. The dissipation factor shall be within 2 times the original limits

5. The capacitance change shall not exceed ±5% or ±1 pF

3

SUSCO Engineers & Buyers Guide - Mica Section Tel: 516-981-6690 Fax: 516-981-6867

FIGURE 5

Page 4

MICA CAPACITORS

MOISTURE RESISTANCE LOADING

Capacitors shall be subjected to a temperature of 40±2 °C at 90 to 95% relative humidity

with rated voltage for 500 Hours. After the test the samples are maintained at normal

temperature and relative humidity for a period of 4 to 24 hours. When tested after this;

1. The capacitor samples shall be free of cracks, or other mechanical damages and the

marking shall remain legible

2. The samples shall meet the original requirement of the Withstanding voltage

3. The samples shall meet the after test requirement of Insulation resistance as furnished in

Figure 2

4. The dissipation factor shall be within 2 times the original limits

5. The capacitance change shall not exceed ±5% or ±1 pF

LIFE TEST

The capacitor samples shall be subjected to a temperature of 125 °C with 150% of rated

voltage for 2000 hours.

After the test :

1. The capacitor samples shall be free of cracks, or other mechanical damages and the

marking shall remain legible

2. The samples shall meet the original requirement of the Withstanding voltage

3. The samples shall meet the original requirements of Insulation resistance as furnished in

Figure 1.

4. The dissipation factor shall be within 1.5 times the original limits

5. The capacitance change shall not exceed ±3% or ±1 pF(whichever is greater) for

characteristic "C" and ±2.5 ±1pF (whichever is greater) for characteristic D, E and F.)

OTHER TYPICAL VARIATION PATTERNS

Some typical variation patterns for selected values during heat resistance load life test and

moisture proof load life tests as listed below are illustrated in Figures 8 through 10.

1. Insulation resistance Vs. time for heat resistance load life test and moisture proof load life

tests (Figure 8).

2. Capacitance change in percentage Vs. time (Figure 9).

3. Dissipation factor Vs. time (Figure 10).

FIGURE 6

FIGURE 7

FIGURE 8

Other variation patterns and characteristic for selected values as listed below are furnished

as Figures 11 through 14

1. Capacitance change Vs. frequency (Figure 11)

2. Capacitance change Vs. time(Figure 12)

3. Dissipation factor change Vs. frequency(Figure 13)

4. Insulation resistance Vs. temperature (Figure 14)

FIGURE 9

FIGURE 10

FIGURE 11

FIGURE 12 FIGURE 13 FIGURE 14

Tel: 516-981-6690 Fax: 516-981-6867 SUSCO Engineers & Buyers Guide - Mica Section

4

Page 5

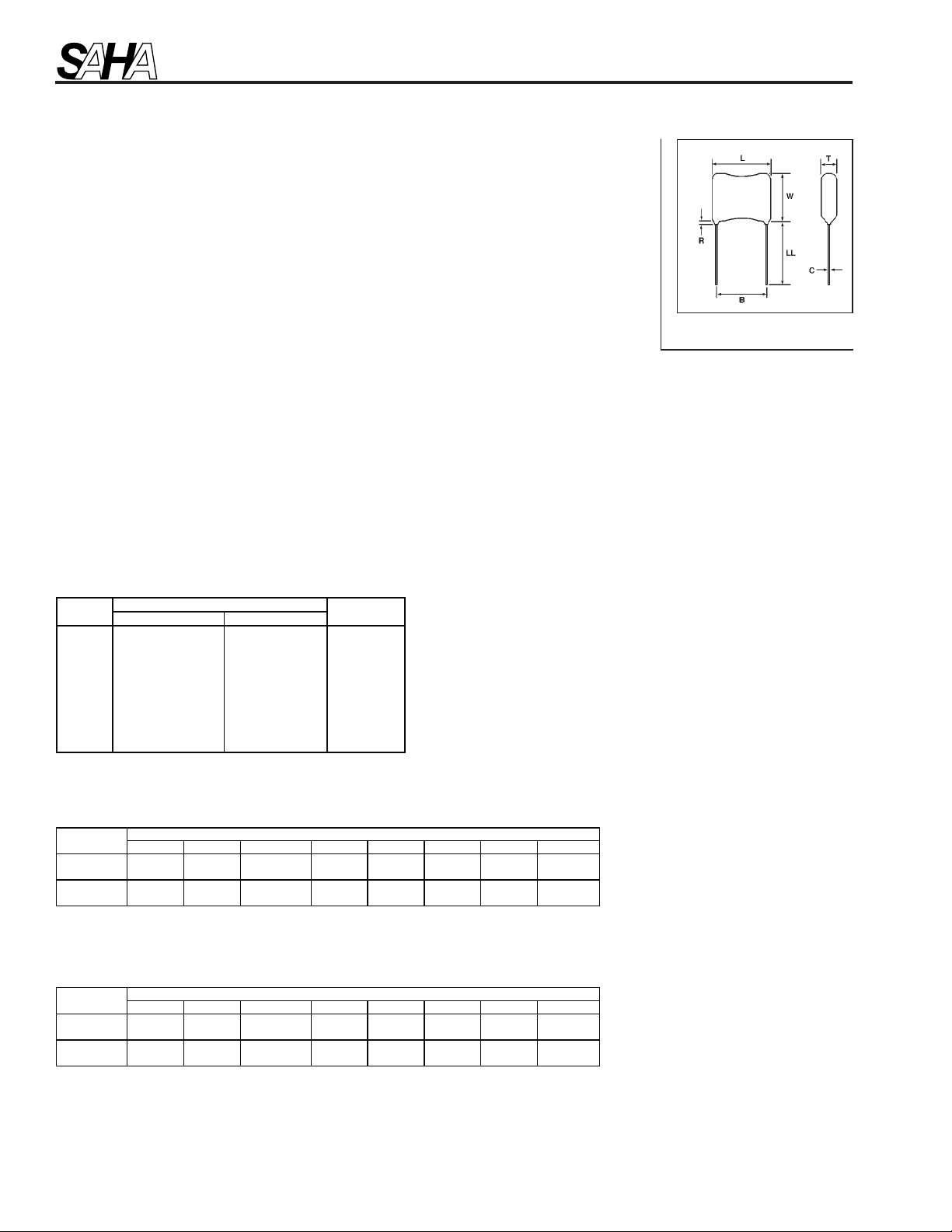

MICA CAPACITORS

Dimension CASE CODE

DM05 DM10 DM12 DM15 DM19 DM20 DM30 DM42

B 3.05 3.57 5.00 5.95 8.73 11.11 11.11 26.99

± 0.8 ± 0.8 ± 0.8 ± 0.8 ± 0.8 ± 0.8 ± 0.8 ± 0.8

C 0.40 0.40 0.50 0.60 0.80 0.80 1.00 1.00

Dimension CASE CODE

DM05 DM10 DM12 DM15 DM19 DM20 DM30 DM42

B 0.120 0.141 0.197 0.234 0.344 0.438 0.438 1.063

± 0.031 ± 0.031 ± 0.031 ± 0.031 ± 0.031 ± 0.031 ± 0.031 ± 0.031

C 0.016 0.016 0.020 0.025 0.032 0.032 0.04 0.04

#26 #26 #24 #22 #20 #20 #18 #18

Case Capacitance Range in pF Equivalent

Size Standard MIL MIL Series

DM05 1 to 390 - None

DM10 1 to 820 1 to 390 CM 04

DM12 1 to 2,500 - None

DM15 1 to 2,500 1 to 390 CM 05

DM19 100 to 8,200 430 to 4,700 CM 06

DM20 680 to 12,000 - None

DM30 5,100 to 20,000 5,100 to 20,000 CM 07

DM42 16,000 to 82,000 - None

DMSERIES

INTRODUCTION

SAHA Mica capacitors have been designed to meet the exacting physical, electrical and environmental

requirements of the MIL-C-5 and RS-153 specifications. Careful selection of raw materials, starting with the

finest available grade of India Ruby Mica, and the constant monitoring of all equipment and processes,

provides an overall uniform level of quality consistent with today's most sophisticated electronic equipment.

Ideal for Tuning, Timing, Filtering and Coupling Circuits.

FEATURES

Low loss and high stability

•

Available in very close tolerances

•

Suitable for precision applications

•

Wide range of operating temperature

•

GENERAL SPECIFICATIONS

CAPACITANCE RANGE: 1 pF to 82,000 pF VOLTAGE RATING: 50 V DC to 500 V DC (Higher voltage capacitors can also be custom

made) TEMPERATE RATING: - 40 to + 150 °C CASE SIZES: DM 05 to DM 42 INSULATION RESISTANCE: 100,000 M Ohms minimum at

25°C for capacitance up to 10,000 pF. Please refer to characteristic curve for values above the range. DISSIPATION FACTOR <0.1% at

1 M Hz for values between 100 to 1,000 pF <0.2 at 1K Hz for values above 1,000 pF. Please refer to characteristic curve for values above

the range.

LIFE TEST DETAILS:

Capacitors shall withstand 1.5 times the rated DC voltage at 125 °C for 2000 hours. After the test:

1. Capacitance change shall not exceed 1% of the initial value or 1 pF, which ever is greater.

2. Dissipation Factor shall be within 1.5 times the original limits.

3. Insulation Resistance shall meet the initial specified requirements.

4. There shall be no remarkable change in the appearance and the marking shall remain legible.

DIMENSIONS:

LL = 31.75 mm (1.25”) min.

CASE SIZE Vs. CAPACITANCE RANGE

LEAD DIMENSIONS IN MILLIMETERS

LL" = 30 mm min.

Dimension "R" = 2.0 mm max. for DM 05 TO DM 15 and 3.2 mm max. for DM 19 to DM 42

LEAD DIMENSIONS IN INCHES

LL" = 1.25" min.

Dimension "R" = 0.078" max. for DM 05 TO DM 15 and 0.125"max. for DM 19 to DM 42

5

SUSCO Engineers & Buyers Guide - Mica Section Tel: 516-981-6690 Fax: 516-981-6867

Page 6

CAPACITANCE VOLTAGE

VALUE in pF 300 V DC 100 V DC 50 V DC

Lmax. W max. T max Lmax. W max. T max Lmax. W max. T max

1 - 12 C 6.86 4.83 2.79

15 C 6.86 4.83 3.05

18 - 20 C 6.86 5.08 3.05

22 - 24 C 6.86 5.08 3.05 6.86 4.83 3.05

27 E 6.86 5.08 3.30 6.86 4.83 3.05

30 - 33 E 6.86 5.08 3.30 6.86 5.08 3.05

36 E 6.86 5.33 3.30 6.86 5.08 3.05

39 E 6.86 5.33 3.30 6.86 5.08 3.05 6.86 4.83 3.05

43 E 6.86 5.33 3.56 6.86 5.08 3.05 6.86 4.83 3.05

47-51 E 6.86 5.33 3.56 6.86 5.08 3.30 6.86 4.83 3.05

56 E 6.86 5.59 3.81 6.86 5.08 3.30 6.86 4.83 3.05

62 E 6.86 5.59 3.81 6.86 5.33 3.30 6.86 5.08 3.05

68 E 6.86 5.59 3.81 6.86 5.33 3.56 6.86 5.08 3.05

75 - 82 E 6.86 5.84 4.06 6.86 5.33 3.56 6.86 5.08 3.05

91 F 6.86 5.84 4.32 6.86 5.33 3.56 6.86 5.08 3.30

100 - 110 F 6.86 6.10 4.57 6.86 5.59 3.81 6.86 5.08 3.30

120 F 6.86 6.35 4.83 6.86 5.59 4.06 6.86 5.08 3.30

130 F 6.86 5.84 4.06 6.86 5.33 3.30

150 F 6.86 5.84 4.32 6.86 5.33 3.56

160 F 6.86 5.84 4.32 6.86 5.33 3.56

170 - 180 F 6.86 6.10 4.57 6.86 5.33 3.56

200 F 6.86 6.35 4.83 6.86 5.59 3.81

220 F 6.86 5.59 3.81

240 F 6.86 5.59 4.06

270 F 6.86 5.84 4.06

300 F 6.86 5.84 4.32

330 - 360 F 6.86 6.10 4.57

390 F 6.86 6.35 4.83

Characteristics

CAPACITANCE

VOLTAGE

VALUE in pF 300 V DC 100 V DC 50 V DC

Lmax. W max. T max Lmax. W max. T max Lmax. W max. T max

1 - 12 C 0.270 0.190 0.110

15 C 0.270 0.190 0.120

18 - 20 C 0.270 0.200 0.120

22 - 24 C 0.270 0.200 0.120 0.270 0.190 0.120

27 E 0.270 0.200 0.130 0.270 0.190 0.120

30 - 33 E 0.270 0.200 0.130 0.270 0.200 0.120

36 E 0.270 0.210 0.130 0.270 0.200 0.120

39 E 0.270 0.210 0.130 0.270 0.200 0.120 0.270 0.190 0.120

43 E 0.270 0.210 0.140 0.270 0.200 0.120 0.270 0.190 0.120

47-51 E 0.270 0.210 0.140 0.270 0.200 0.130 0.270 0.190 0.120

56 E 0.270 0.220 0.150 0.270 0.200 0.130 0.270 0.190 0.120

62 E 0.270 0.220 0.150 0.270 0.210 0.130 0.270 0.200 0.120

68 E 0.270 0.220 0.150 0.270 0.210 0.140 0.270 0.200 0.120

75 - 82 E 0.270 0.230 0.160 0.270 0.210 0.140 0.270 0.200 0.120

91 F 0.270 0.230 0.170 0.270 0.210 0.140 0.270 0.200 0.130

100 - 110 F 0.270 0.240 0.180 0.270 0.220 0.150 0.270 0.200 0.130

120 F 0.270 0.250 0.190 0.270 0.220 0.160 0.270 0.200 0.130

130 F 0.270 0.230 0.160 0.270 0.210 0.130

150 F 0.270 0.230 0.170 0.270 0.210 0.140

160 F 0.270 0.230 0.170 0.270 0.210 0.140

170 - 180 F 0.270 0.240 0.180 0.270 0.210 0.140

200 F 0.270 0.250 0.190 0.270 0.220 0.150

220 F 0.270 0.220 0.150

240 F 0.270 0.220 0.160

270 F 0.270 0.230 0.160

300 F 0.270 0.230 0.170

330 - 360 F 0.270 0.240 0.180

390 F 0.270 0.250 0.190

Characteristics

DM 05 Mica Capacitors

MICA CAPACITORS

DIMENSIONS:

LL = 31.75 mm (1.25”) min.

DM05

Case

Dimensions

in Millimeters

Lead Spacing:

3.05 ± 0.8mm

DM05

Tel: 516-981-6690 Fax: 516-981-6867 SUSCO Engineers & Buyers Guide - Mica Section

Dimensions

Lead Spacing:

0.120 ± 0.031”

Case

in Inches

6

Page 7

MICA CAPACITORS

CAPACITANCE VOLTAGE

VALUE in pF 300 V DC 100 V DC 50 V DC

Lmax. W max. T max Lmax. W max. T max Lmax. W max. T max

1 - 12 C 6.35 4.06 2.29

15 - 20 C 6.35 4.32 2.54 6.35 4.06 2.29

22 C 6.35 4.32 2.54 6.35 4.06 2.54 6.35 4.06 2.29

24 C 6.35 4.32 2.54 6.35 4.32 2.54 6.35 4.06 2.29

27 - 36 E 6.35 4.32 2.79 6.35 4.32 2.54 6.35 4.06 2.29

39 E 6.35 4.57 2.79 6.35 4.32 2.54 6.35 4.06 2.29

43 E 6.35 4.57 3.05 6.35 4.32 2.54 6.35 4.32 2.54

47 - 51 E 6.35 4.57 3.05 6.35 4.32 2.79 6.35 4.32 2.54

56 - 62 E 6.35 4.57 3.30 6.35 4.32 2.79 6.35 4.32 2.54

68 E 6.35 4.83 3.30 6.35 4.57 2.79 6.35 4.32 2.54

75 - 82 E 6.35 4.83 3.56 6.35 4.57 3.05 6.35 4.32 2.54

91 F 6.35 4.83 3.81 6.35 4.57 3.05 6.35 4.32 2.79

100 F 6.35 5.08 4.06 6.35 4.57 3.30 6.35 4.32 2.79

110 F 6.35 5.08 4.06 6.35 4.83 3.30 6.35 4.32 2.79

120 F 6.35 5.33 4.32 6.35 4.83 3.56 6.35 4.32 2.79

130 F 6.35 4.83 3.56 6.35 4.32 2.79

150 F 6.35 4.83 3.81 6.35 4.57 3.05

160 F 6.35 5.08 3.81 6.35 4.57 3.05

170 - 180 F 6.35 5.08 4.06 6.35 4.57 3.05

200 F 6.35 5.33 4.32 6.35 4.57 3.30

220 F 6.35 4.83 3.30

240 - 270 F 6.35 4.83 3.56

300 F 6.35 4.83 3.81

330 - 360 F 6.35 5.08 4.06

390 F 6.35 5.33 4.32

Characteristics

CAPACITANCE

VOLTAGE

VALUE in pF 300 V DC 100 V DC 50 V DC

Lmax. W max. T max Lmax. W max. T max Lmax. W max. T max

1 - 12 C 0.250 0.160 0.090

15 - 20 C 0.250 0.170 0.100 0.250 0.160 0.090

22 C 0.250 0.170 0.100 0.250 0.160 0.100 0.250 0.160 0.090

24 C 0.250 0.170 0.100 0.250 0.170 0.100 0.250 0.160 0.090

27 - 36 E 0.250 0.170 0.110 0.250 0.170 0.100 0.250 0.160 0.090

39 E 0.250 0.180 0.110 0.250 0.170 0.100 0.250 0.160 0.090

43 E 0.250 0.180 0.120 0.250 0.170 0.100 0.250 0.170 0.100

47 - 51 E 0.250 0.180 0.120 0.250 0.170 0.110 0.250 0.170 0.100

56 - 62 E 0.250 0.180 0.130 0.250 0.170 0.110 0.250 0.170 0.100

68 E 0.250 0.190 0.130 0.250 0.180 0.110 0.250 0.170 0.100

75 - 82 E 0.250 0.190 0.140 0.250 0.180 0.120 0.250 0.170 0.100

91 F 0.250 0.190 0.150 0.250 0.180 0.120 0.250 0.170 0.110

100 F 0.250 0.200 0.160 0.250 0.180 0.130 0.250 0.170 0.110

110 F 0.250 0.200 0.160 0.250 0.190 0.130 0.250 0.170 0.110

120 F 0.250 0.210 0.170 0.250 0.190 0.140 0.250 0.170 0.110

130 F 0.250 0.190 0.140 0.250 0.170 0.110

150 F 0.250 0.190 0.150 0.250 0.180 0.120

160 F 0.250 0.200 0.150 0.250 0.180 0.120

170 - 180 F 0.250 0.200 0.160 0.250 0.180 0.120

200 F 0.250 0.210 0.170 0.250 0.180 0.130

220 F 0.250 0.190 0.130

240 - 270 F 0.250 0.190 0.140

300 F 0.250 0.190 0.150

330 - 360 F 0.250 0.200 0.160

390 F 0.250 0.210 0.170

Characteristics

SCDM 05Mica Capacitors

SCDM05

Case

Dimensions

in Millimeters

Lead Spacing:

3.05 ± 0.8mm

DIMENSIONS:

LL = 31.75 mm (1.25”) min.

SCDM05

Case

Dimensions

in Inches

7

Lead Spacing:

0.120 ± 0.031”

SUSCO Engineers & Buyers Guide - Mica Sections Tel: 516-981-6690 Fax: 516-981-6867

Note: Bold Outlined Sections indicate SUSCO Standard items.

Page 8

CAPACITANCE VOLTAGE

VALUE in pF 500 V DC 300 V DC 100 V DC

Lmax. W max. T max Lmax. W max. T max Lmax. W max. T max

1 - 18 C 9.14 8.38 4.83

20 - 24 E 9.14 8.38 4.83

27 E 9.40 8.38 4.83

30 - 36 E 9.40 8.64 4.83

39 E 9.40 8.64 4.83 9.40 8.64 4.83 9.14 8.38 4.83

43 E 9.40 8.64 4.83 9.40 8.64 4.83 9.40 8.38 4.83

47 - 68 E 9.40 8.64 4.83 9.40 8.64 4.83 9.40 8.64 4.83

75 E 9.40 8.64 5.08 9.40 8.64 4.83 9.40 8.64 4.83

82 E 9.40 8.89 5.08 9.40 8.64 4.83 9.40 8.64 4.83

91 - 100 F 9.40 8.89 5.08 9.40 8.89 5.08 9.40 8.64 4.83

110 F 9.65 8.89 5.08 9.40 8.89 5.08 9.40 8.64 4.83

120 F 9.65 8.89 5.08 9.40 8.89 5.08 9.40 8.64 5.08

130 F 9.65 9.14 5.08 9.65 8.89 5.08 9.40 8.89 5.08

150 F 9.65 9.14 5.33 9.65 8.89 5.08 9.40 8.89 5.08

160 F 9.65 9.14 5.33 9.65 9.14 5.08 9.40 8.89 5.08

180 F 9.91 9.40 5.33 9.65 9.14 5.33 9.65 8.89 5.08

200 F 9.91 9.40 5.59 9.65 9.14 5.33 9.65 8.89 5.08

220 F 9.91 9.40 5.59 9.91 9.40 5.33 9.65 9.14 5.33

240 - 250 F 9.91 9.65 5.59 9.91 9.40 5.59 9.65 9.14 5.33

270 F 9.91 9.65 5.59 9.65 9.40 5.33

300 F 9.91 9.65 5.59 9.91 9.40 5.33

330 F 10.16 9.91 5.84 9.91 9.40 5.59

360 F 10.16 9.91 5.84 9.91 9.65 5.59

390 - 400 F 9.91 9.65 5.59

430 - 680 F 10.16 9.91 5.84

750 - 820* F 10.16 9.91 5.84

Characteristics

CAPACITANCE

VOLTAGE

VALUE in pF 500 V DC 300 V DC 100 V DC

Lmax. W max. T max Lmax. W max. T max Lmax. W max. T max

1 - 18 C 0.360 0.330 0.190

20 - 24 E 0.360 0.330 0.190

27 E 0.370 0.330 0.190

30 - 36 E 0.370 0.340 0.190

39 E 0.370 0.340 0.190 0.370 0.340 0.190 0.360 0.330 0.190

43 E 0.370 0.340 0.190 0.370 0.340 0.190 0.370 0.330 0.190

47 - 68 E 0.370 0.340 0.190 0.370 0.340 0.190 0.370 0.340 0.190

75 E 0.370 0.340 0.200 0.370 0.340 0.190 0.370 0.340 0.190

82 E 0.370 0.350 0.200 0.370 0.340 0.190 0.370 0.340 0.190

91 - 100 F 0.370 0.350 0.200 0.370 0.350 0.200 0.370 0.340 0.190

110 F 0.380 0.350 0.200 0.370 0.350 0.200 0.370 0.340 0.190

120 F 0.380 0.350 0.200 0.370 0.350 0.200 0.370 0.340 0.200

130 F 0.380 0.360 0.200 0.380 0.350 0.200 0.370 0.350 0.200

150 F 0.380 0.360 0.210 0.380 0.350 0.200 0.370 0.350 0.200

160 F 0.380 0.360 0.210 0.380 0.360 0.200 0.370 0.350 0.200

180 F 0.390 0.370 0.210 0.380 0.360 0.210 0.380 0.350 0.200

200 F 0.390 0.370 0.220 0.380 0.360 0.210 0.380 0.350 0.200

220 F 0.390 0.370 0.220 0.390 0.370 0.210 0.380 0.360 0.210

240 - 250 F 0.390 0.380 0.220 0.390 0.370 0.220 0.380 0.360 0.210

270 F 0.390 0.380 0.220 0.380 0.370 0.210

300 F 0.390 0.380 0.220 0.390 0.370 0.210

330 F 0.400 0.390 0.230 0.390 0.370 0.220

360 F 0.400 0.390 0.230 0.390 0.380 0.220

390 - 400 F 0.390 0.380 0.220

430 - 680 F 0.400 0.390 0.230

750 - 820* F 0.400 0.390 0.230

Characteristics

DM 10 / CM04 Mica Capacitors

DM10

CM04

Case

Dimensions

in Millimeters

MICA CAPACITORS

DIMENSIONS:

LL = 31.75 mm (1.25”) min.

Lead Spacing:

3.57 ± 0.8mm

DM10

CM04

Dimensions

Lead Spacing:

0.141 ± 0.031”

Tel: 516-981-6690 Fax: 516-981-6867 SUSCO Engineers & Buyers Guide - Mica Sections

Case

in Inches

* Available only in 50 V rating. Note: Values above 390 pF - available on special order only

Note: Bold Outlined Sections indicate SUSCO Standard items.

8

Page 9

MICA CAPACITORS

CAPACITANCE VOLTAGE

VALUE in pF 500 V DC 300 V DC 100 V DC

Lmax. W max. T max Lmax. W max. T max Lmax. W max. T max

1 - 18 C 9.50 10.01 4.50

20 - 82 E 9.50 10.01 4.50

91 - 430 F 9.50 10.01 4.50

470 F 10.01 10.49 5.08

510 F 10.01 10.49 5.08

560 F 10.01 10.49 5.08

620 F 10.01 10.49 5.08

680 F 10.01 10.49 5.08

750 F 10.49 11.00 5.59

820 F 10.49 11.00 5.59

910 F 10.49 11.00 5.59

1,000 F 10.49 11.00 5.59

1,100 F 11.00 11.51 6.10

1,200 F 11.00 11.51 6.10

1,300 - 2,500 F 11.00 11.51 6.10

Characteristics

CAPACITANCE VOLTAGE

VALUE in pF 500 V DC 300 V DC 100 V DC

Lmax. W max. T max Lmax. W max. T max Lmax. W max. T max

1 - 18 C 0.374 0.394 0.177

20 - 82 E 0.374 0.394 0.177

91 - 430 F 0.374 0.394 0.177

470 F 0.394 0.413 0.200

510 F 0.394 0.413 0.200

560 F 0.394 0.413 0.200

620 F 0.394 0.413 0.200

680 F 0.394 0.413 0.200

750 F 0.413 0.433 0.220

820 F 0.413 0.433 0.220

910 F 0.413 0.433 0.220

1,000 F 0.413 0.433 0.220

1,100 F 0.433 0.453 0.240

1,200 F 0.433 0.453 0.240

1,300 - 2,500 F 0.433 0.453 0.240

Characteristics

CAPACITANCE VOLTAGE

VALUE in pF 500 V DC 300 V DC 100 V DC

Lmax. W max. T max Lmax. W max. T max Lmax. W max. T max

1 - 18 C 7.87 5.84 3.05

20 - 56 E 7.87 5.84 3.05

62 - 68 E 8.13 5.84 3.30 7.87 5.84 3.05

75 - 82 E 8.13 5.84 3.30 8.13 5.84 3.30 7.87 5.84 3.05

91 F 8.13 5.84 3.30 8.13 5.84 3.30 7.87 5.84 3.05

100 F 8.13 5.84 3.30 8.13 5.84 3.30 8.13 5.84 3.30

110 - 120 F 8.13 6.10 3.56 8.13 5.84 3.30 8.13 5.84 3.30

130 - 160 F 8.13 6.10 3.56 8.13 6.10 3.56 8.13 5.84 3.30

180 F 8.38 6.10 3.81 8.13 6.10 3.56 8.13 6.10 3.56

200 F 8.38 6.10 3.81 8.38 6.10 3.81 8.13 6.10 3.56

220 - 240 F 8.64 6.35 4.06 8.38 6.10 3.81 8.13 6.10 3.56

250 F 8.64 6.35 4.06 8.64 6.35 4.06 8.13 6.10 3.56

270 - 300 F 8.64 6.35 4.06 8.38 6.10 3.81

330 F 8.89 6.60 4.32 8.38 6.10 3.81

360 F 8.89 6.60 4.32 8.64 6.35 4.06

390 - 400 F 8.64 6.35 4.06

430 - 470 F 8.89 6.60 4.32

750 - 820* F 8.89 6.60 4.32

Characteristics

CAPACITANCE

VOLTAGE

VALUE in pF 500 V DC 300 V DC 100 V DC

Lmax. W max. T max Lmax. W max. T max Lmax. W max. T max

1 - 18 C 0.310 0.230 0.120

20 - 56 E 0.310 0.230 0.120

62 - 68 E 0.320 0.230 0.130 0.310 0.230 0.120

75 - 82 E 0.320 0.230 0.130 0.320 0.230 0.130 0.310 0.230 0.120

91 F 0.320 0.230 0.130 0.320 0.230 0.130 0.310 0.230 0.120

100 F 0.320 0.230 0.130 0.320 0.230 0.130 0.320 0.230 0.130

110 - 120 F 0.320 0.240 0.140 0.320 0.230 0.130 0.320 0.230 0.130

130 - 160 F 0.320 0.240 0.140 0.320 0.240 0.140 0.320 0.230 0.130

180 F 0.330 0.240 0.150 0.320 0.240 0.140 0.320 0.240 0.140

200 F 0.330 0.240 0.150 0.330 0.240 0.150 0.320 0.240 0.140

220 - 240 F 0.340 0.250 0.160 0.330 0.240 0.150 0.320 0.240 0.140

250 F 0.340 0.250 0.160 0.340 0.250 0.160 0.320 0.240 0.140

270 - 300 F 0.340 0.250 0.160 0.330 0.240 0.150

330 F 0.350 0.260 0.170 0.330 0.240 0.150

360 F 0.350 0.260 0.170 0.340 0.250 0.160

390 - 400 F 0.340 0.250 0.160

430 - 470 F 0.350 0.260 0.170

750 - 820* F 0.350 0.260 0.170

Characteristics

SCDM 10 Mica Capacitors

DIMENSIONS:

LL = 31.75 mm (1.25”) min.

SCDM10

Case

Dimensions

in Millimeters

Lead Spacing:

3.57 ± 0.8mm

SCDM10

Case

Dimensions

in Inches

Lead Spacing:

0.141 ± 0.031”

* Available only in 50 V rating.

Note: Bold Outlined Sections indicate

SUSCO Standard items.

DM 12 Mica Capacitors

DM12

Case

Dimensions

in Millimeters

Lead Spacing:

5.0 ± 0.8mm

DM12

9

Note: Bold Outlined Sections indicate

SUSCO Engineers & Buyers Guide - Mica Sections Tel: 516-981-6690 Fax: 516-981-6867

Case

Dimensions

in Inches

Lead Spacing:

0.197 ± 0.031

SUSCO Standard items.

Page 10

CAPACITANCE VOLTAGE

VALUE in pF 500 V DC 300 V DC 100 V DC

Lmax. W max. T max Lmax. W max. T max Lmax. W max. T max

1 - 18 C 11.43 9.14 4.32

20 - 68 E 11.43 9.14 4.32

75 - 82 E 11.43 9.14 4.57

91 - 100 F 11.68 9.14 4.57

110 - 130 F 11.68 9.40 4.57

150 - 180 F 11.68 9.40 4.83

200 F 11.68 9.65 4.83

220 - 240 F 11.68 9.65 5.08

270 - 390 F 11.94 9.91 5.33

430 F 11.94 9.91 5.33 11.68 9.65 5.08

470 - 510 F 11.94 10.16 5.59 11.68 9.65 5.08

560 - 620 F 12.19 10.41 5.84 11.68 9.65 5.08

680 F 12.45 10.67 6.10 11.94 9.91 5.33

750 F 12.70 10.92 6.35 11.94 9.91 5.33

820 F 11.94 9.91 5.33 11.94 9.91 5.33

910 F 11.94 10.16 5.59 11.94 10.16 5.59

1,000 F 12.19 10.16 5.84 12.19 10.16 5.84

1,100 F 12.45 10.67 6.10 12.19 10.16 5.84

1,200 - 2,000 F 12.70 10.92 6.35 12.45 10.67 6.10

2,200 - 2,500* F 12.45 10.67 6.10

Characteristics

DM 15 / CM05 Mica Capacitors

CAPACITANCE

VOLTAGE

VALUE in pF 500 V DC 300 V DC 100 V DC

Lmax. W max. T max Lmax. W max. T max Lmax. W max. T max

1 - 18 C 0.450 0.360 0.170

20 - 68 E 0.450 0.360 0.170

75 - 82 E 0.450 0.360 0.180

91 - 100 F 0.460 0.360 0.180

110 - 130 F 0.460 0.370 0.180

150 - 180 F 0.460 0.370 0.190

200 F 0.460 0.380 0.190

220 - 240 F 0.460 0.380 0.200

270 - 390 F 0.470 0.390 0.210

430 F 0.470 0.390 0.210 0.460 0.380 0.200

470 - 510 F 0.470 0.400 0.220 0.460 0.380 0.200

560 - 620 F 0.480 0.410 0.230 0.460 0.380 0.200

680 F 0.490 0.420 0.240 0.470 0.390 0.210

750 F 0.500 0.430 0.250 0.470 0.390 0.210

820 F 0.470 0.390 0.210 0.470 0.390 0.210

910 F 0.470 0.400 0.220 0.470 0.400 0.220

1,000 F 0.480 0.400 0.230 0.480 0.400 0.230

1,100 F 0.490 0.420 0.240 0.480 0.400 0.230

1,200 - 2,000 F 0.500 0.430 0.250 0.490 0.420 0.240

2,200 - 2,500* F 0.490 0.420 0.240

Characteristics

DM15

CM05

Case

Dimensions

in Millimeters

MICA CAPACITORS

DIMENSIONS:

LL = 31.75 mm (1.25”) min.

Lead Spacing:

5.95 ± 0.8mm

DM15

CM05

Case

Dimensions

in Inches

Lead Spacing:

0.234 ± 0.031

Tel: 516-981-6690 Fax: 516-981-6867 SUSCO Engineers & Buyers Guide - Mica Section

* Available only in 50 V rating.

Note: Bold Outlined Sections indicate SUSCO Standard items.

10

Page 11

MICA CAPACITORS

CAPACITANCE VOLTAGE

VALUE in pF 500 V DC 300 V DC 100 V DC

Lmax. W max. T max Lmax. W max. T max Lmax. W max. T max

1 - 18 C 10.92 7.11 3.56

20 - 68 E 10.92 7.11 3.56

75 - 100 F 10.92 7.11 3.81

110 - 160 F 11.18 7.37 3.81

180 - 200 F 11.18 7.37 4.06

220 - 270 F 11.18 7.62 4.06

300 - 390 F 11.43 7.87 4.06

430 - 470 F 11.43 7.87 4.32 11.18 7.37 3.81

510 F 11.43 7.87 4.57 11.18 7.37 3.81

560 F 11.43 7.87 4.57 11.18 7.62 4.06

620 F 11.43 8.13 4.83 11.18 7.62 4.06

680 F 11.68 8.13 5.08 11.43 7.62 4.06

750 F 11.68 8.13 5.33 11.43 7.62 4.06

820 F 11.43 7.87 4.32 11.43 7.87 4.06

910 F 11.43 7.87 4.57 11.43 7.87 4.32

1,000 F 11.43 8.13 4.83 11.43 7.87 4.32

1,100 F 11.68 8.13 5.08 11.43 7.87 4.57

1,200 - 2,000 F 11.68 8.13 5.33 11.43 8.13 4.83

2,200 - 2,500* F 11.43 8.13 4.83

Characteristics

CAPACITANCE

VOLTAGE

VALUE in pF 500 V DC 300 V DC 100 V DC

Lmax. W max. T max Lmax. W max. T max Lmax. W max. T max

1 - 18 C 0.430 0.280 0.140

20 - 68 E 0.430 0.280 0.140

75 - 100 F 0.430 0.280 0.150

110 - 160 F 0.440 0.290 0.150

180 - 200 F 0.440 0.290 0.160

220 - 270 F 0.440 0.300 0.160

300 - 390 F 0.450 0.310 0.160

430 - 470 F 0.450 0.310 0.170 0.440 0.290 0.150

510 F 0.450 0.310 0.180 0.440 0.290 0.150

560 F 0.450 0.310 0.180 0.440 0.300 0.160

620 F 0.450 0.320 0.190 0.440 0.300 0.160

680 F 0.460 0.320 0.200 0.450 0.300 0.160

750 F 0.460 0.320 0.210 0.450 0.300 0.160

820 F 0.450 0.310 0.170 0.450 0.310 0.160

910 F 0.450 0.310 0.180 0.450 0.310 0.170

1,000 F 0.450 0.320 0.190 0.450 0.310 0.170

1,100 F 0.460 0.320 0.200 0.450 0.310 0.180

1,200 - 2,000 F 0.460 0.320 0.210 0.450 0.320 0.190

2,200 - 2,500* F 0.450 0.320 0.190

Characteristics

SCDM 15 Mica Capacitors

SCDM15

Case

Dimensions

in Millimeters

DIMENSIONS:

LL = 31.75 mm (1.25”) min.

Lead Spacing:

5.95 ± 0.8mm

SCDM15

Case

Dimensions

in Inches

11

Lead Spacing:

0.234 ± 0.031”

* Available only in 50 V rating.

Note: Bold Outlined Sections indicate SUSCO Standard items.

SUSCO Engineers & Buyers Guide - Mica Section Tel: 516-981-6690 Fax: 516-981-6867

Page 12

CAPACITANCE VOLTAGE

VALUE in pF 500 V DC 300 V DC 100 V DC

Lmax. W max. T max Lmax. W max. T max Lmax. W max. T max

100 - 330 F 16.26 12.70 4.83

360 - 470 F 16.26 12.95 5.08

510 - 620 F 16.51 12.95 5.08

680 - 910 F 16.51 12.95 5.33

1,000 - 1,100 F 16.51 13.21 5.59

1,200 - 1,300 F 16.76 13.21 5.59

1,500 F 16.76 13.21 5.84

1,600 F 16.76 13.46 5.84

1,800 - 2,000 F 17.02 13.46 6.10

2,200 F 17.02 13.46 6.35

2,400 F 17.02 13.72 6.60

2,700 F 17.27 13.72 6.86

3,000 F 17.27 13.97 7.11

3,300 F 17.27 13.97 7.37 17.02 13.72 6.60

3,600 F 17.27 14.22 7.62 17.27 13.72 6.86

3,900 F 17.53 14.22 7.87 17.27 13.72 6.86

4,300 F 17.53 14.48 8.38 17.27 13.97 7.11

4,700 F 17.78 14.73 8.89 17.27 13.97 7.37

5,100 F 18.03 14.99 9.40 ---

5,600 F 17.27 14.22 7.87

6,200 F 17.53 14.22 8.13 17.53 14.22 7.87

6,800 F 17.53 14.48 8.38 17.53 14.48 8.13

7,500 F 17.78 14.48 8.64

8,200 F 17.78 14.73 8.89

Characteristics

CAPACITANCE

VOLTAGE

VALUE in pF 500 V DC 300 V DC 100 V DC

Lmax. W max. T max Lmax. W max. T max Lmax. W max. T max

100 - 330 F 0.640 0.500 0.190

360 - 470 F 0.640 0.510 0.200

510 - 620 F 0.650 0.510 0.200

680 - 910 F 0.650 0.510 0.210

1,000 - 1,100 F 0.650 0.520 0.220

1,200 - 1,300 F 0.660 0.520 0.220

1,500 F 0.660 0.520 0.230

1,600 F 0.660 0.530 0.230

1,800 - 2,000 F 0.670 0.530 0.240

2,200 F 0.670 0.530 0.250

2,400 F 0.670 0.540 0.260

2,700 F 0.680 0.540 0.270

3,000 F 0.680 0.550 0.280

3,300 F 0.680 0.550 0.290 0.670 0.540 0.260

3,600 F 0.680 0.560 0.300 0.680 0.540 0.270

3,900 F 0.690 0.560 0.310 0.680 0.540 0.270

4,300 F 0.690 0.570 0.330 0.680 0.550 0.280

4,700 F 0.700 0.580 0.350 0.680 0.550 0.290

5,100 F 0.710 0.590 0.370 ---

5,600 F 0.680 0.560 0.310

6,200 F 0.690 0.560 0.320 0.690 0.560 0.310

6,800 F 0.690 0.570 0.330 0.690 0.570 0.320

7,500 F 0.700 0.570 0.340

8,200 F 0.700 0.580 0.350

Characteristics

DM 19 / CM06 Mica Capacitors

DM19

CM06

Case

Dimensions

in Millimeters

MICA CAPACITORS

DIMENSIONS:

LL = 31.75 mm (1.25”) min.

Lead Spacing:

8.73 ± 0.8mm

DM19

CM06

Case

Dimensions

in Inches

Tel: 516-981-6690 Fax: 516-981-6867 SUSCO Engineers & Buyers Guide - Mica Section

Lead Spacing:

0.344 ± 0.031”

Note: Bold Outlined Sections indicate SUSCO Standard items.

12

Page 13

MICA CAPACITORS

CAPACITANCE VOLTAGE

VALUE in pF 500 V DC 300 V DC 100 V DC

Lmax. W max. T max Lmax. W max. T max Lmax. W max. T max

100 - 240 F 15.49 11.43 3.30

270 - 560 F 15.49 11.43 3.56

620 - 820 F 15.49 11.68 3.81

910 - 1,100 F 15.75 11.68 4.06

1,200 - 1,500 F 15.75 11.68 4.32

1,600 - 1,800 F 15.75 11.68 4.57

2,000 - 2,200 F 16.00 11.68 4.83

2,400 F 16.00 11.94 5.33

2,700 F 16.00 11.94 5.59

3,000 F 16.00 11.94 5.84

3,300 F 16.00 12.19 6.10 16.00 10.67 5.33

3,600 F 16.26 12.19 6.35 16.00 11.94 5.33

3,900 F 16.26 12.19 6.60 16.00 11.94 5.33

4,300 F 16.51 12.45 7.11 16.00 11.94 5.59

4,700 F 16.51 12.45 7.62 16.00 11.94 5.84

5,100 F 16.76 12.70 8.13 16.00 12.19 6.10

5,600 F 16.26 12.19 6.35

6,200 F 16.26 12.19 6.60 16.26 12.19 6.35

6,800 F 16.26 12.45 6.86 16.26 12.19 6.60

7,500 F 16.51 12.45 7.11

8,200 F 16.51 12.45 7.62

Characteristics

CAPACITANCE

VOLTAGE

VALUE in pF 500 V DC 300 V DC 100 V DC

Lmax. W max. T max Lmax. W max. T max Lmax. W max. T max

100 - 240 F 0.610 0.450 0.130

270 - 560 F 0.610 0.450 0.140

620 - 820 F 0.610 0.460 0.150

910 - 1,100 F 0.620 0.460 0.160

1,200 - 1,500 F 0.620 0.460 0.170

1,600 - 1,800 F 0.620 0.460 0.180

2,000 - 2,200 F 0.630 0.460 0.190

2,400 F 0.630 0.470 0.210

2,700 F 0.630 0.470 0.220

3,000 F 0.630 0.470 0.230

3,300 F 0.630 0.480 0.240 0.630 0.420 0.210

3,600 F 0.640 0.480 0.250 0.630 0.470 0.210

3,900 F 0.640 0.480 0.260 0.630 0.470 0.210

4,300 F 0.650 0.490 0.280 0.630 0.470 0.220

4,700 F 0.650 0.490 0.300 0.630 0.470 0.230

5,100 F 0.660 0.500 0.320 0.630 0.480 0.240

5,600 F 0.640 0.480 0.250

6,200 F 0.640 0.480 0.260 0.640 0.480 0.250

6,800 F 0.640 0.490 0.270 0.640 0.480 0.260

7,500 F 0.650 0.490 0.280

8,200 F 0.650 0.490 0.300

Characteristics

Characteristics

SCDM 19 Mica Capacitors

SCDM19

Case

Dimensions

in Millimeters

DIMENSIONS:

LL = 31.75 mm (1.25”) min.

Lead Spacing:

8.73 ± 0.8mm

SCDM19

Case

Dimensions

in Inches

13

Lead Spacing:

0.344 ± 0.031”

SUSCO Engineers & Buyers Guide - Mica Section Tel: 516-981-6690 Fax: 516-981-6867

Note: Bold Outlined Sections indicate SUSCO Standard items.

Page 14

CAPACITANCE

VOLTAGE

VALUE in pF 500 V DC 300 V DC 100 V DC

Lmax. W max. T max Lmax. W max. T max Lmax. W max. T max

680 - 1,200 F 0.750 0.510 0.200

1,300 - 1,600 F 0.750 0.510 0.210

1,800 - 2,200 F 0.760 0.520 0.220

2,400 F 0.770 0.530 0.250

2,700 F 0.770 0.540 0.260

3,000 F 0.770 0.540 0.270

3,300 F 0.780 0.550 0.280

3,600 F 0.780 0.550 0.290

3,900 F 0.780 0.560 0.300

4,300 F 0.780 0.560 0.310 0.770 0.540 0.270

4,700 F 0.790 0.560 0.320 0.770 0.540 0.270

5,100 F 0.790 0.570 0.330 0.780 0.550 0.280

5,600 F 0.790 0.570 0.340 0.780 0.550 0.290

6,200 F 0.790 0.580 0.350 0.780 0.560 0.300 0.780 0.550 0.290

6,800 F 0.800 0.590 0.370 0.790 0.560 0.320 0.780 0.560 0.300

7,500 F 0.800 0.600 0.390 0.790 0.570 0.330 0.780 0.560 0.300

8,200 F 0.810 0.610 0.410 0.790 0.570 0.340 0.780 0.560 0.310

9,100 F 0.810 0.620 0.430 0.800 0.580 0.360 0.790 0.570 0.330

10,000 F 0.820 0.630 0.450 0.800 0.590 0.370 0.790 0.570 0.340

11,000 F 0.800 0.590 0.380 0.790 0.580 0.350

12,000 F 0.810 0.600 0.400 0.800 0.580 0.360

Characteristics

CAPACITANCE VOLTAGE

VALUE in pF 500 V DC 300 V DC 100 V DC

Lmax. W max. T max Lmax. W max. T max Lmax. W max. T max

680 - 1,200 F 19.05 12.95 5.08

1,300 - 1,600 F 19.05 12.95 5.33

1,800 - 2,200 F 19.30 13.21 5.59

2,400 F 19.56 13.46 6.35

2,700 F 19.56 13.72 6.60

3,000 F 19.56 13.72 6.86

3,300 F 19.81 13.97 7.11

3,600 F 19.81 13.97 7.37

3,900 F 19.81 14.22 7.62

4,300 F 19.81 14.22 7.87 19.56 13.72 6.86

4,700 F 20.07 14.22 8.13 19.56 13.72 6.86

5,100 F 20.07 14.48 8.38 19.81 13.97 7.11

5,600 F 20.07 14.48 8.64 19.81 13.97 7.37

6,200 F 20.07 14.73 8.89 19.81 14.22 7.62 19.81 13.97 7.37

6,800 F 20.32 14.99 9.40 20.07 14.22 8.13 19.81 14.22 7.62

7,500 F 20.32 15.24 9.91 20.07 14.48 8.38 19.81 14.22 7.62

8,200 F 20.57 15.49 10.41 20.07 14.48 8.64 19.81 14.22 7.87

9,100 F 20.57 15.75 10.92 20.32 14.73 9.14 20.07 14.48 8.38

10,000 F 20.83 16.00 11.43 20.32 14.99 9.40 20.07 14.48 8.64

11,000 F 20.32 14.99 9.65 20.07 14.73 8.89

12,000 F 20.57 15.24 10.16 20.32 14.73 9.14

Characteristics

DM 20 Mica Capacitors

DM20

Case

Dimensions

in Millimeters

MICA CAPACITORS

DIMENSIONS:

LL = 31.75 mm (1.25”) min.

Lead Spacing:

11.11 ± 0.8mm

DM20

Case

Dimensions

in Inches

Lead Spacing:

0.438 ±0.031”

Tel: 516-981-6690 Fax: 516-981-6867 SUSCO Engineers & Buyers Guide - Mica Section

Note: Bold Outlined Sections indicate SUSCO Standard items.

14

Page 15

MICA CAPACITORS

CAPACITANCE VOLTAGE

VALUE in pF 500 V DC 300 V DC 100 V DC

Lmax. W max. T max Lmax. W max. T max Lmax. W max. T max

1 - 100 F 17.78 11.43 3.05

200 - 620 F 17.78 11.43 3.30

750 - 1,200 F 17.78 11.43 3.56

1,200 - 1,600 F 17.78 11.68 3.81

1,800 F 18.03 11.68 3.81

2,000 - 2,200 F 18.03 11.68 4.06

2,400 - 2,700 F 18.03 11.68 5.08

3,300 - 3,300 F 18.29 11.94 5.59

3,600 F 18.29 11.94 5.84

3,900 F 18.29 12.19 6.10

4,300 F 18.29 12.19 6.35 18.29 11.94 5.33

4,700 F 18.54 12.19 6.60 18.29 11.94 5.59

5,100 F 18.54 12.45 6.86 18.29 11.94 5.84

5,600 F 18.54 12.45 7.11 18.29 12.19 6.10

6,200 F 18.80 12.45 7.62 18.29 12.19 6.35 18.29 11.94 5.59

6,800 F 18.80 12.70 8.13 18.54 12.19 6.60 18.29 11.94 5.84

7,500 F 19.05 12.70 8.64 18.54 12.45 6.86 18.29 12.19 6.10

8,200 F 19.05 12.95 9.14 18.54 12.45 7.11 18.29 12.19 6.35

9,100 F 19.30 13.21 9.65 18.80 12.45 7.37 18.54 12.19 6.60

10,000 F 19.30 13.46 10.16 18.80 12.45 7.62 18.54 12.45 6.86

11,000 F 18.80 12.70 8.13 18.54 12.45 7.11

12,000 F 19.05 12.70 8.64 18.80 12.45 7.37

Characteristics

CAPACITANCE

VOLTAGE

VALUE in pF 500 V DC 300 V DC 100 V DC

Lmax. W max. T max Lmax. W max. T max Lmax. W max. T max

1 - 100 F 0.700 0.450 0.120

200 - 620 F 0.700 0.450 0.130

750 - 1,200 F 0.700 0.450 0.140

1,200 - 1,600 F 0.700 0.460 0.150

1,800 F 0.710 0.460 0.150

2,000 - 2,200 F 0.710 0.460 0.160

2,400 - 2,700 F 0.710 0.460 0.200

3,300 - 3,300 F 0.720 0.470 0.220

3,600 F 0.720 0.470 0.230

3,900 F 0.720 0.480 0.240

4,300 F 0.720 0.480 0.250 0.720 0.470 0.210

4,700 F 0.730 0.480 0.260 0.720 0.470 0.220

5,100 F 0.730 0.490 0.270 0.720 0.470 0.230

5,600 F 0.730 0.490 0.280 0.720 0.480 0.240

6,200 F 0.740 0.490 0.300 0.720 0.480 0.250 0.720 0.470 0.220

6,800 F 0.740 0.500 0.320 0.730 0.480 0.260 0.720 0.470 0.230

7,500 F 0.750 0.500 0.340 0.730 0.490 0.270 0.720 0.480 0.240

8,200 F 0.750 0.510 0.360 0.730 0.490 0.280 0.720 0.480 0.250

9,100 F 0.760 0.520 0.380 0.740 0.490 0.290 0.730 0.480 0.260

10,000 F 0.760 0.530 0.400 0.740 0.490 0.300 0.730 0.490 0.270

11,000 F 0.740 0.500 0.320 0.730 0.490 0.280

12,000 F 0.750 0.500 0.340 0.740 0.490 0.290

Characteristics

SCDM 20 Mica Capacitors

SCDM20

Case

Dimensions

in Millimeters

DIMENSIONS:

LL = 31.75 mm (1.25”) min.

Lead Spacing:

11.11 ± 0.8mm

SCDM20

Case

Dimensions

in Inches

15

Lead Spacing:

0.438 ± 0.031”

SUSCO Engineers & Buyers Guide - Mica Section Tel: 516-981-6690 Fax: 516-981-6867

Note: Bold Outlined Sections indicate SUSCO Standard items.

Page 16

CAPACITANCE VOLTAGE

VALUE in pF 500 V DC 300 V DC

Lmax. W max. T max Lmax. W max. T max

5,100 F 19.81 21.84 7.11

5,600 - 6,200 F 19.81 22.10 7.37

6,800 F 19.81 22.10 7.62

7,500 F 20.07 22.35 7.87 19.81 21.84 6.86

8,200 F 20.07 22.35 8.13 19.81 21.84 7.11

9,100 F 20.07 22.35 8.38 19.81 22.10 7.11

10,000 F 20.32 22.61 8.64 19.81 22.10 7.37

11,000 F 20.32 22.61 8.89 19.81 22.10 7.62

12,000 F 20.32 22.61 9.14 20.07 22.35 7.87

13,000 F 20.57 22.61 9.40 20.07 22.35 7.87

15,000 F 20.57 22.86 9.91 20.07 22.35 8.38

16,000 F 20.83 22.86 10.41 20.32 22.61 8.64

18,000 F 20.83 23.11 10.92 20.32 22.61 9.14

20,000 F 21.08 23.37 11.43 20.57 22.61 9.40

Characteristics

CAPACITANCE

VOLTAGE

VALUE in pF 500 V DC 300 V DC

Lmax. W max. T max Lmax. W max. T max

5,100 F 0.780 0.860 0.280

5,600 - 6,200 F 0.780 0.870 0.290

6,800 F 0.780 0.870 0.300

7,500 F 0.790 0.880 0.310 0.780 0.860 0.270

8,200 F 0.790 0.880 0.320 0.780 0.860 0.280

9,100 F 0.790 0.880 0.330 0.780 0.870 0.280

10,000 F 0.800 0.890 0.340 0.780 0.870 0.290

11,000 F 0.800 0.890 0.350 0.780 0.870 0.300

12,000 F 0.800 0.890 0.360 0.790 0.880 0.310

13,000 F 0.810 0.890 0.370 0.790 0.880 0.310

15,000 F 0.810 0.900 0.390 0.790 0.880 0.330

16,000 F 0.820 0.900 0.410 0.800 0.890 0.340

18,000 F 0.820 0.910 0.430 0.800 0.890 0.360

20,000 F 0.830 0.920 0.450 0.810 0.890 0.370

Characteristics

DM 30 / CM07 Mica Capacitors

CAPACITANCE VOLTAGE

VALUE in pF 500 V DC 300 V DC 100 V DC

Lmax. W max. T max Lmax. W max. T max Lmax. W max. T max

16,000 F 35.81 22.10 7.11

18,000 F 35.81 22.10 7.37

20,000 F 36.07 22.10 7.62

22,000 F 36.07 22.35 7.87 36.07 22.10 7.37

24,000 F 36.32 22.35 8.13 36.07 22.10 7.62

27,000 F 36.32 22.35 8.38 36.07 22.35 7.87 35.81 22.10 7.11

30,000 F 36.58 22.61 8.89 36.32 22.35 8.13 35.81 22.10 7.37

33,000 F 36.58 22.61 9.14 36.32 22.35 8.64 36.07 22.10 7.62

36,000 F 36.83 22.86 9.65 36.58 22.61 8.89 36.07 22.35 7.87

39,000 F 36.83 22.86 10.16 36.58 22.61 9.14 36.32 22.35 8.13

43,000 F 37.08 23.11 10.67 36.83 22.86 9.40 36.32 22.35 8.38

47,000 F 37.34 23.11 11.43 36.83 22.86 9.91 36.32 22.61 8.64

51,000 F 37.59 23.37 11.94 37.08 22.86 10.16 36.58 22.61 9.14

56,000 F 37.08 23.11 10.67 36.58 22.86 9.40

62,000 F 37.34 23.37 11.43 36.83 22.86 9.91

68,000 F 37.59 23.37 11.94 37.08 22.86 10.41

75,000 F 37.34 23.11 11.18

82,000 F 37.59 23.37 11.68

Characteristics

CAPACITANCE

VOLTAGE

VALUE in pF 500 V DC 300 V DC 100 V DC

Lmax. W max. T max Lmax. W max. T max Lmax. W max. T max

16,000 F 1.410 0.870 0.280

18,000 F 1.410 0.870 0.290

20,000 F 1.420 0.870 0.300

22,000 F 1.420 0.880 0.310 1.420 0.870 0.290

24,000 F 1.430 0.880 0.320 1.420 0.870 0.300

27,000 F 1.430 0.880 0.330 1.420 0.880 0.310 1.410 0.870 0.280

30,000 F 1.440 0.890 0.350 1.430 0.880 0.320 1.410 0.870 0.290

33,000 F 1.440 0.890 0.360 1.430 0.880 0.340 1.420 0.870 0.300

36,000 F 1.450 0.900 0.380 1.440 0.890 0.350 1.420 0.880 0.310

39,000 F 1.450 0.900 0.400 1.440 0.890 0.360 1.430 0.880 0.320

43,000 F 1.460 0.910 0.420 1.450 0.900 0.370 1.430 0.880 0.330

47,000 F 1.470 0.910 0.450 1.450 0.900 0.390 1.430 0.890 0.340

51,000 F 1.480 0.920 0.470 1.460 0.900 0.400 1.440 0.890 0.360

56,000 F 1.460 0.910 0.420 1.440 0.900 0.370

62,000 F 1.470 0.920 0.450 1.450 0.900 0.390

68,000 F 1.480 0.920 0.470 1.460 0.900 0.410

75,000 F 1.470 0.910 0.440

82,000 F 1.480 0.920 0.460

Characteristics

DIMENSIONS:

LL = 31.75 mm (1.25”) min.

MICA CAPACITORS

DM30

CM07

Case

Dimensions

in Millimeters

Lead Spacing:

11.11 ± 0.8mm

DM30

CM07

Case

Dimensions

in Inches

Note: Bold Outlined Sections indicate

SUSCO Standard items.

DM 42 Mica Capacitors

DM42

Dimensions

in Millimeters

Lead Spacing:

26.99 ± 0.8mm

Lead Spacing:

0.438 ± 0.031”

Case

DM42

Note: Bold Outlined Sections indicate

SUSCO Standard items.

Dimensions

Lead Spacing:

1.063 ± 0.031”

Tel: 516-981-6690 Fax: 516-981-6867 SUSCO Engineers & Buyers Guide - Mica Section

Case

in Inches

16

Page 17

MICA CAPACITORS

ITEM Symbol Specifications (mm) Specifications (inches)

Value Tol. Value Tol.

Body width L L max. L max.

Body height W W max. W max.

Body thickness T T max. T max.

Lead-wire diameter d 0.5 ±0.05 0.020 ±0.002

Pitch of components P 12.7 ±1.0 0.500 ±0.039

Sprocket hole pitch P O 12.7 ±0.3 0.500 ±0.12

Lead location P 1 3.85 ±0.7 0.152 ±0.028

Hole center to component center P 2 6.35 ±1.3 0.250 ±0.051

Component lead spacing F 5 +0.6 to -0.2 0.197 +0.024 to -0.008

Deflection h 0 ±2.0 0.000 ±0.079

Carrier tape width W t 18 ±1.0 to -.05 0.709 ±0.039 to -0.002

Hold down tape width W O 12.5 min. 0.492 min.

Sprocket hole location W 1 9 ± 0.5 0.354 ±0.020

Adhesive tape border W 2 3 max. 0.118 max.

Length of scating plans H 1 16 ±0.5 0.630 ±0.020

Lead-wire protrusion L P 2 max. 0.079 max.

Sprocket hole diameter D O 4 ±0.2 0.157 ±0.008

Overall tape thickness t 0.7 ±0.2 0.028 ±0.008

Cut out length H 2 11 max. 0.433 max.

Series Quantity per Reel (min.)

DM12 1K pcs.

DM15 1K pcs.

Series Quantity per Reel (min.)

DM12 1K pcs.

DM15 1K pcs.

Product Std. Quantity

DM Series Single Coat per Bag

DM05 SCDM05 500 pcs.

DM10 SCDM10 500 pcs.

DM12 SCDM12 500 pcs.

DM15 SCDM15 500 pcs.

DM19 SCDM19 250 pcs.

DM20 SCDM20 250 pcs.

DM30 100 pcs.

DM42 50 pcs.

Tape/Reel & Packaging Specifications

Taping Specifications Reel and Ammo Specifications

Taping Dimensions

Bulk Pack Quantity

17

SUSCO Engineers & Buyers Guide - Mica - Section Tel: 516-981-6690 Fax: 516-981-6867

Reel Pack Quantity

Ammo Pack Quantity

All Dipped Mica capacitors are

shipped in bulk packing. Tape

and Reel format available for

DM12 and DM15 capacitors

upon request and meet EIA

standards.

Dipped Mica capacitors are

also available with various

lead forming and trimming

options. Please provide

specific requirements

Loading...

Loading...