WSK INTELLIGENT TEMPERATURE AND

CONTROLLER

USER

MANUAL

HUMIDITY

WSK INTELLIGENT TEMPERATURE AND HUMIDITY CONTROLLER

USER MANUAL v 1.0

Thanks for choosing the Intelligent temperature and humidity controller

of our company. In order to convenient you to buy and use the controller

with safety, please read this manual carefully and note the following points.

CAUTION

1. The device must be installed and maintained by professional personnel

2. The signal and power supply must be cut off before any operations to the

internal or external part of the controller

The following conditions will cause damage or abnormality to the controller

1. Auxiliary power source voltage over range

2. Distribute system frequence over range

3. Current, voltage input poles incorrect

4. With electric pull out communication plug

5. No according requirement to connect terminal

Warning

1. Wiring warning

If the equipment failure or error occurs, can cause system fault, installation

of external protection circuit to prevent such incidents

In order to prevent the equipment damage or failure, choose the appropriate

fuse protection to prevent the power cord and input, output, strong current shock

2. Power supply

In order to prevent the equipment damage or failure, please use the rated

power

To prevent electric shock, or equipment failure, all wiring complete rear can

supply

3. Prohibited to use in the vicinity of flammable gas

As fire, explosion or equipment damage, banned in flammable, explosive

gas, venting occasion use

4. It is forbidden to touch the instrument inside

To prevent electric shock or burn, it is forbidden to touch the instrument

inside, only the company service engineer can check the internal wiring or

replacement parts. Instrument with

high pressure and high temperature parts. Very dangerous.

5. It is forbidden to change instrument

In order to prevent accidents or equipment failure, it is forbidden to change

equipment

6. Maintenance

Scrapped to prevent electric shock, instrument or fails, only the company's

service engineer can be replacement parts

In order to ensure the instrument is continuous and safe use, should be

regular maintenance. Instrument internal some parts may be damaged with

longer duration of use

WSK INTELLIGENT TEMPERATURE AND HUMIDITY CONTROLLER

CATALOG

1. Introduction…………………………

2.Technical Data………………………………2

3.Definition and Specification Matching………3

4. Outline、 installation hole and wiring………4

5.PanelExplain and Each function………………5

6. Operation Process…………………………6-12

………1

WSK INTELLIGENT TEMPERATURE AND HUMIDITY CONTROLLER

INTRODUCTION

1. Temperature and humidity controller uses a dedicated microprocessor, SMT

SMT technology and high precision temperature and humidity sensor. Make

the product delicate and cabinet, reliable performance, high precision

measurement and control temperature and humidity, strong anti-jamming

capability control mode is simple. Can be widely used in industry, agriculture,

medical, chemical warehouse where the temperature and humidity

measurement and control.

2. Alarm function, this controller has the temperature, humidity process heater

disconnection quotation function, communication function, get more extensive

application in the field of automation control

Remark:

Process alarm output contact and disconnection alarm for the same.

WSK INTELLIGENT TEMPERATURE AND HUMIDITY CONTROLLER

Main Technical Data

Supply voltage

AC: Switching power supply 85V~265V, 50~60Hz

AC: Transformer 110V, 220V, 380V, 50~60Hz

DC: 24V, 36V, 48V, 110V, 220V

Accuracy class

Temperature: ±0.5°C

Humidity: 5%±RH

Resolving power: 14 Bit

Cycle of sampling: 0.5 Sec

Measurement range

Temperature: -40~100°C

Humidity: 0~100%RH

Display

Measured values and set values by LED

Output condition and alarming condition by LED lights

Way of operating

Controlling by two-step (settable turn difference)

Control output

Relay output: Contact capability 250VAC 3A (Resistive load)

Voltage pulse output: 0~12 (Suitable for solid relay SSR)

Output contact

Electrical endurance: 1×10 times

Mechanical durability: 1×10 times

Installation

Panel type and embedded

Others

Insulation resistance: >50MΩ (500VDC)

Insulation capability: 1500VAC per minute

Power consumption: <10VA

Environment: 0~50°C, 30~85%RH no corrosive gas

Weight: About 0.5Kg (The power supply of product is the

switching power supply)

WSK INTELLIGENT TEMPERATU+RE AND HUMIDITY CONTROLLERWSK INTELLIGENT TEMPERATU+RE AND HUMIDITY CONTROLLER

WSK INTELLIGENT TEMPERATURE AND HUMIDITY CONTROLLER

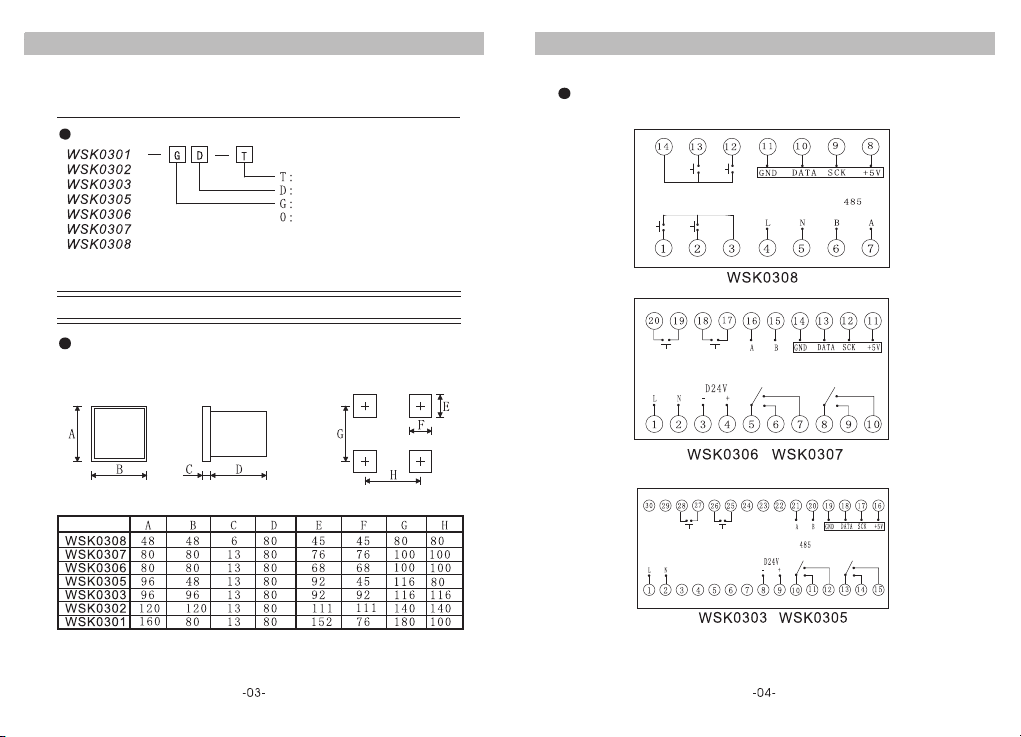

Definition of

Model No. and Specification Matching

Model identification

WSK INTELLIGENT TEMPERATURE AND HUMIDITY CONTROLLER

WSK INTELLIGENT TEMPERATU+RE AND HUMIDITY CONTROLLER

WSK INTELLIGENT TEMPERATU+RE AND HUMIDITY CONTROLLER

The wiring diagram(subject to the product itself the wiring diagram)

Additional communication function

Additional circuit alarm

Additional process alarm

No function above mentioned

Attention: If DC:24V output is needed, please note

that when placing order

Frame Size and Installation Hole Size and Wiring

Frame Size and Hole Size

Frame Size

Hole Size

Public

Terminal

Temp

Controlling

Temp

Alarming

Power Supply

Power Supply

Temp

Alarming

Temp

Alarming

Humidity

Controlling

Humidity

Alarm+ing

Humidity

Alarm+ing

Humidity

Alarming

Public

Terminal

Temp and Humidity Sensor

Power Supply

485

Communication

Humidity

Controlling

Communication

Communication

Temp and Humidity Sensor

Temp

Controlling

Temp and Humidity Sensor

Temp

Humidity

Controlling

Controlling

WSK INTELLIGENT TEMPERATURE AND HUMIDITY CONTROLLER

WSK INTELLIGENT TEMPERATU+RE AND HUMIDITY CONTROLLERWSK INTELLIGENT TEMPERATU+RE AND HUMIDITY CONTROLLER

WSK INTELLIGENT TEMPERATURE AND HUMIDITY CONTROLLER

WSK INTELLIGENT TEMPERATU+RE AND HUMIDITY CONTROLLER

WSK INTELLIGENT TEMPERATU+RE AND HUMIDITY CONTROLLER

Panel Explaination and Each Function

Panel show

Content description

Temp Measuring

Humidity Measuring

Temperature control output indicator light

Humidity control output indicator light

Temperature process alarm indicator lights

Humidity process alarm indicator lights

Temperature disconnection alarm indicator lights

Humidity disconnection alarm indicator lights

The communications light

Instrument power light work

Increasing Key

Decreasing Key

Displacement Key Mode Key

Confirm Key

Display value model

Mode content parameter values

Up Key

Down Key

Quit Key

Operation Process

Boot Up Process

Open the Power

Self-checking of LED device

Automatic

Transfomation)

Displaying the current temperature and humidity

Automatic

Transfomation)

Set the mode and modify the parameter

In normal display mode of ℃/%RH, press the “SET” button to enter the

temperature and humidity controlling and alarming settings. Press the “SET”

button for more than 3 seconds to enter the setting mode condition.

Shift Key for more than 3 seconds

“SET”

To press “SET” shift key again to enter the condition of modifying the content and parameter

“SET”Shift Key

To modify the parameter content

Confirm Key to save the changes

Confirm Key to return

All LEDS light up

Measuring the current

temperature and humidity

Displaying current temperature

and humidity

WSK INTELLIGENT TEMPERATURE AND HUMIDITY CONTROLLER

At this time the parameter can be modified by pressing the shift key “SET”,

Increasing key “ ”, reducing key “ ”. Click the confirm button “ ”

to save the data after modification. If you need continue to modify other

parameter, press the increasing key “ ” and reducing key “ ” selection

need to modify the pattern. In setting mode, if modified, and then click the

confirm button “ ” to return to normal state

Attention

This controller has automatic returning function. When the operator set parameter modification

operation and forget to return to the main display mode, the instrument after 30 seconds

etc

automatically return to the main display mode

Before using the controller or modifying the parameter of the controller, please read the

following instructions carefully.

.

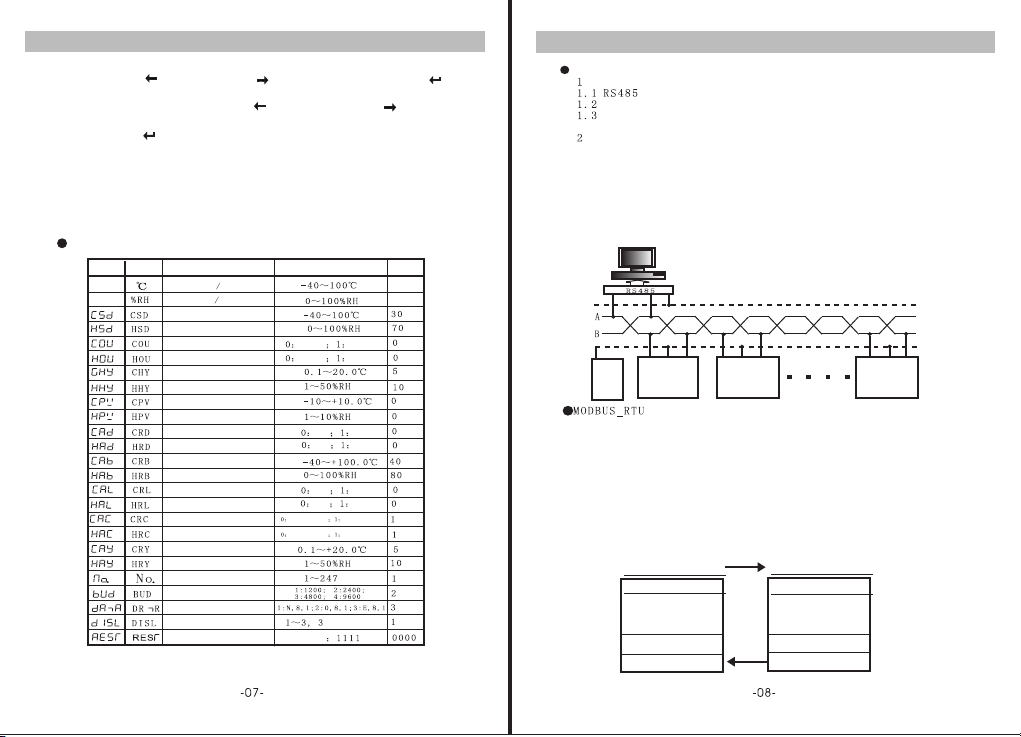

Mode content and parameter list

Display

Instruction

Name

Temperature measured values

Mode display values

Humidity measured values

Mode display values

Temperature controlling setting values

Humidity controlling setting values

Temperature controlling alternative mode

Humidity controlling alternative mode

Temperature controlling hysteresis error setting

Humidity controlling hysteresis error setting

Temperature measurement value correction

Humidity measurement value correction

Temperature heater disconnection alarming condition

Humidity heater disconnection alarming condition

Temperature process alarming setting values

Humidity process alarming setting values

Temperature process alarming condition

Humidity process alarming condition

Temperature process alarming mode alternative setting

Humidity process alarming mode alternative setting

Temperature process alarming hysteresis error setting

Humidity process alarming hysteresis error setting

Communication address range of controller

Communication velocity of controller

Data format of controller

LED display brightness of controller

Back to the factory default setting

Setting range

Heat up

Humidification

OFF

OFF

OFF

OFF

Lower deviation alarming

Lower deviation alarming

is the lightest brightness

Password

Default

setting

Actual measured

values

Actual measured

values

Cool

Dehumidification

ON

ON

ON

ON

Higher deviation alarming

Higher deviation alarming

WSK INTELLIGENT TEMPERATURE AND HUMIDITY CONTROLLER

Communication agreement

The physical layer

communication interface, the asynchronous half-duplex mode

Communications speed can be set to 1200-9600 BPS, the factory default 2400 BPS

Byte transfer formats: one start bit, 8 data bits, parity (N81, E81, 081) optional,

factory default E81

Digital communication protocol:

The controller provides asynchronous duplex RS485 serial communication interface and

adopts the MODBUS-RTU protocol, all kinds of data information can be transmitted on the

communications lines. One route can connect to 32 network controller at the same time,

each controller can be set different mailing Address (the Address No.), different series

controller communication terminal number is different, the communication connection is

shielded twisted-pair cable should be used with copper net, wire diameter is not less than

0.55 mm. Wiring should keep communication lines from high voltage cable, or other strong

electric field environment, T type is recommended for the network connection

(see figure 1), but does not recommend a star or other contact way

FIG 1

power

temperature and

humidity controller

supply

The MODBUS-RTU communication protocol uses the master-slave communication

response mode connections on a communication line. First of all, the main computer

of the signal only address addressing to a terminal equipment (machine), and then,

the response signal from the terminal to transmit to host in the opposite direction, i.e.,

in a single communication line signal transmission instead of two direction all

communication data flow (half duplex working mode). MODBUS protocol is

only allowed on the host (PC, PLC, etc.) and the communication between the

terminal equipment (see chart 2), and does not allow independent data exchange

between terminal equipment, so that each terminal equipment not occupy the

communication line when they are initialized again, but only in response to the

native query signal

communication protocol:

Master device

query information

Device address

Function code

The database

Error checkingError checking

temperature and

humidity controller

Device address

Function code

The database

Error checking

In response to the

information of the equipment

temperature and

humidity controller

FIG 2

WSK INTELLIGENT TEMPERATURE AND HUMIDITY CONTROLLER

WSK INTELLIGENT TEMPERATURE AND HUMIDITY CONTROLLER

The host query:

Query message frames includes device address, function code, data, information, check code. Address

code informs the machine that is selected to perform the destined function equipment, such as functional

code 3 or 4 is for registering the data which is read from the device and return their content; Contains data

from the device to perform functions other additional information, such as reading command, data

segment additional information start from how to register and number of registers to read; Check code is

used to test the correctness of the a frame information, provides from the device with a validation

message content is the right approach, it adopts CRC16 calibration rule

If from the device to produce a normal response, in response to the message from the machine address

code, function code, code and data information CRC16 check code. Data information code, including the

data collected from the device, such as register values or state. If there are errors, we agreed from the

machine does not respond. Transport refers to a data frame in a series of separate data structure and used

for the transmission of data limited rules, defines the RTU mode compatible with MODBUS agreement

under the mode of transmission. Each byte: a start bit, 8 data bits, parity bit (,), 1 stop bit (a parity bit) or

1 stop bit (and white parity bits).

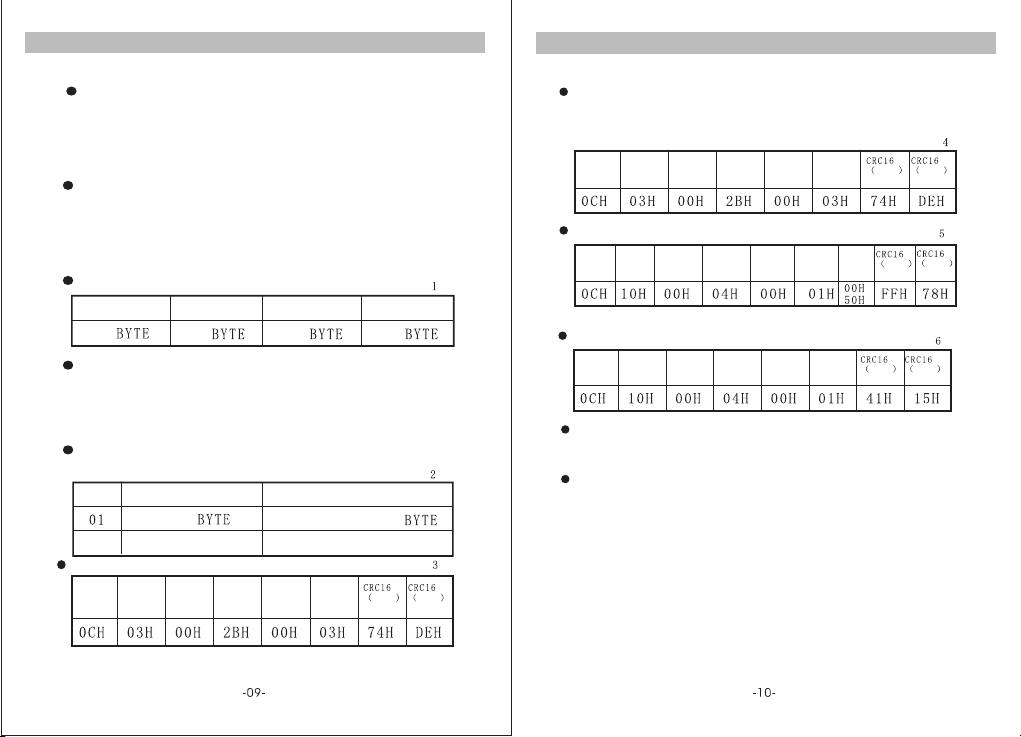

The structure of the data frame:(Message format) Table 1

Address Code

ONE

Address Code

At the beginning of a frame by a byte (eight binary code), the decimal is 0-255, only use the 1-247 in our

system, the other address. These bits indicate the address specified by the user terminal equipment, the

device will accept data from the connected to the host. Each terminal equipment address must be unique,

only by addressing to the terminal response contains the address of the query. When the terminal sends

back a response, in the response from the machine address data and tell the host which terminal is to

communicate with them.

Function Code: (Table 2)

Tell what is addressing to the terminal to perform the function. Listed in the following table shows the

supported code function, and their meaning and function

CODE

Function Code

ONE

Meaning Behavior

ONE

Query data frame (main machine) ( Table 3)

Address

Command

The starting

register

address

(high)

The starting

register

address

(low)

Data Code Check Code

ONE

TWO

Quantity of

Quantity of

register

register

(high)

(low)

Table

TWO

Table

Table

low

high

The response data (from the machine frame) (see table 4)

This function allows the user to change the contents of a register, is written to the data to be

highlighted as writable attribute, the number of address range is not more than, this example

is written communication

The starting

The starting

Quantity of

Address

Command

register

address

(high)

register

address

(low)

register

(high)

Quantity of

register

(low)

Query data frame (the host machine) (see table 5)

The starting

The starting

Quantity of

Quantity of

Address

Command

register

address

(high)

register

address

(low)

register

(high)

register

(low)

Record

the data

Response data (from the machine frame), indicating that the data has been written. (table 6)

The starting

The starting

Quantity of

register

Address

Command

Check code:

Error check (CRC) domain are two bytes, containing a 16-bit binary values. CRC value is calculated

by the transport equipment, and then attached to a data frame, the receiving device to recalculate the CRC

value when receiving data, and then compared with acceptance to the CRC in the domain of value, if the

two values are not equal, an error has occurred. As shown in figure 3

Communication message example

Read data (functional code: 3) : this function can users get the terminal equipment acquisition \

recorded data, as well as the system parameters. Host a request there is no limit to the number of data

collected, but not beyond the definition of address range

address

(high)

register

address

(low)

register

(high)

Quantity of

register

(low)

low

low

Table

high

Table

low

Table

high

high

TEMPE

T

I

GEN

LL

E

T

N

K I

WS

Correspondence address (see table 7)

Address

Project

Description

The basic setting information

Sensor for real-time detecting temperature values

Sensor for real-time detecting humidity values

Temperature controlling setting

Humidity controlling setting

Temperature control mode

Humidity control mode

RA

TUR

E A

Next

End of the frame

U

ND H

Start

or

moves to the right one

carry

End

Data

format

M

TY

DI

I

Length of

the data

C

ON

or

Read and

write

L

O

R

T

The actual measured value

The actual measured value

R

E

L

FIG3

Instruction

Heat Up

Humidification

Table

Cool

Dehumidification

Address

NTELLI

SK I

W

Project

Description

The basic setting information

Temperature controlling hysteresis error

Humidity controlling hysteresis error

Temperature measurement value

Humidity measurement value

Temperature heater disconnection alarming setting

Humidity heater disconnection alarming setting

Temperature process alarming setting

Humidity process alarming setting

Temperature process alarming state

Humidity process alarming state

Temperature process alarming mode

Humidity process alarming mode

Temperature process alarming

hysteresis error setting

Humidity process alarming

hysteresis error setting

controller communication address range

controller communication velocity

the controller data format

the lED display brightness

LLER

RO

NT

Y

CO

IT

D

D HUMI

AN

E

UR

T

A

PER

EM

T

T

N

E

G

Length of

The data

format

the data

Read and

write

Instruction

OFF

OFF

OFF

OFF

OFF

Lower deviation alarming

Higher deviation alarming

Lower deviation alarming

Higher deviation alarming

3 is the highest

brightness

ON

ON

ON

ON

2

Loading...

Loading...