MOVING WASH 1200 (PF09014)

Moving head projector

USER’ S MANUAL release 1.0

This manual must be considered an integral part of the projector.

1

BEFORE CONNECTING AND USING THE PROJECTOR, IT IS IMPORTANT TO READ CAREFULLY ALL THE

INSTRUCTIONS IN THIS MANUAL.

QUALIFIED PERSONNEL ONLY, IN COMPLIANCE WITH ALL THE SECURITY LAWS, CAN DO THE

INSTALLATION, THE MAINTENANCE AND THE UTILISATION OF THIS PROJECTOR.

BEFORE CONNECTING THE PROJECTOR, MAKE SURE THAT THE FREQUENCY AND THE VOLTAGE

VALUES ARE SUITABLE AS SPECIFIED ON THE PROJECTOR.

FOR ANY DOUBT, CONTACT YOUR SUPPLIER OR SEND AN E-MAIL TO:

tech@lamposrl.it

INDEX

GENERAL DESCRIPTION ---------------------------------------------------------------------------- page 2

START-UP PROCEDURES -------------------------------------------------------------------------- page 2

SPECIAL FUNCTIONS -------------------------------------------------------------------------------- page 5

DMX CHANNEL ASSIGNMENT -------------------------------------------------------------------- page 5

OPTICAL SYSTEM ------------------------------------------------------------------------------------ page 7

MAINTENANCE ---------------------------------------------------------------------------------------- page 8

2

GENERAL DESCRIPTION

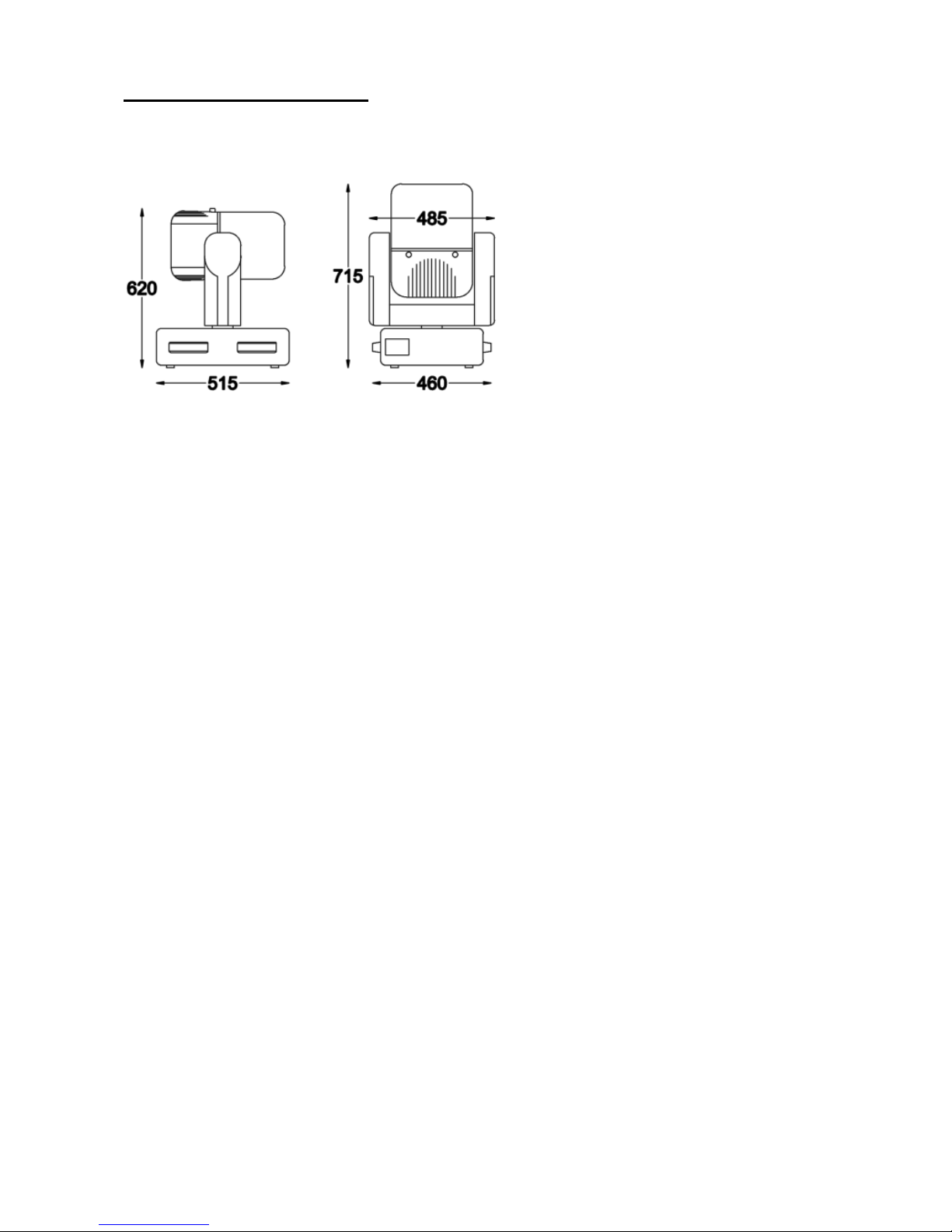

Technical Features and Dimensions

Voltage rating 230 V

Rated current 7,4 A

Frequency 50 Hz

Maximum surface temperature 70º C

Distance from inflammable surfaces 2 mt

Weight 52,5 Kg

Protection rate IP20

HMI 1200/S short discharge lamp, socket SFc 10-4

CAUTION

The projector cannot be mounted on inflammable surfaces.

Norms applied to construction:

EN 60 598-1 EN 60 598-2-17 EN 294 EN 50 082-1

EN 55 015 EN 60 555-2 EN 61 000-3-2

Working Position

Moving Wash 1200 can work in all positions.

Admissible Environmental Conditions

The projector was engineered and produced to function in covered, dry areas with an air temperature ranging

between 5° and 35° C, and with a humidity level between 30 and 90%.Sharp changes in room temperature may

generate condensation inside the projector, which can harm the projector. Therefore, switch on the projector only

after it has undergone a period of gradual adaptation to the room temperature.

Storage

The projector, in its original packing, must be kept in covered, dry areas with a temperature between -10° C and

+50° C.

Mechanical Safety Guards

A bipolar cut-off switch is located between the lamp compartment and the cooling unit. This safety switch cuts off

the power to the projector if the top lid is opened.

Noise Level

After the projector has been powered up and the initial configuration takes place, the noise produced by the

projector is primarily due to its cooling system. The noise level is much lower than the limit of 70 dB permitted by

law.

Handling

The projector, with or without packing, must be handled with care. Lifting and handling must be carried out with

special equipment. Do not expose the projector, with or without its packing, to brusque accelerated or decelerated

movements, knocks, dragging, or other stress caused by unsuitable handling methods.

3

START-UP PROCEDURES

Positioning and Installation

Follow these steps for opening the package and installing the projector on its working position:

· Place the projector near the place it will be installed.

· Open the package and remove anchoring elements and accessories.

· Carefully read the instructions in the manual.

· Prepare suitable hooks for the anchoring brackets and auxiliary support.

· Using suitable lifting equipment, place the projector up against the hooks.

· Attach the auxiliary support element and make sure it is tightly fastened.

· Make sure all adjustable parts are locked firmly in place in the desired position.

IMPORTANT

The projector has PAN and TILT Lock and Release Mechanism. Un-lock the mechanism before switching on the projector.

CAUTION

You must verify the stability of the anchoring elements when the projector is in working condition. In compliance

with the laws in force, the anchoring support must withstand a load of 525 kg. Screws, hooks, and hardware must

be inserted correctly and installed to prevent them from accidentally loosening.

IMPORTANT

Do not install the projector where there are objects located at a distance of less than 20 centimetres from the

cooling system.

Lamp installation

• Loosen the knobs on the top lid and remove it.

• Remove the lamp from the packing and carefully read the

manufacturer’s instructions.

• LAMP HMI/S 1200W short, double ended: Loosen the two

ring nuts at both end of the lamp (socket SFc10-4).

Place the lamp in its socket. Make sure the protuberance of the

central bulb is facing downwards to avoid creating shadows in

the projection. Tighten the two ring nuts on the lamp.

• Replace the lid and firmly tight the knobs.

CAUTION

During lamp installation and substitution, the operator must take care to avoid any contact between the lamp bulb

and the condenser lens. (The condenser lens is a special tempered glass, very resistant to the high temperature

but very fragile in case of contact with quartz glass)

Power Supply

The projector absorbs 1600W at 230V. Makes sure the projector does not pull the cable in all different working

positions.

Connect the fixture to the mains with the enclosed power cord. See the table for the colours of the connectioncable.

4

When in doubt, consult a qualified electrician.

Be careful with your operations. With a high voltage you can suffer a dangerous electric shock when touching the

wires! Inside the projector, the ignitor circuit have very high voltage, over 5Kv.

The User must ensure that the power supply is provided with a highly sensitive differential circuit breaker 30m/A to

protect the projector from indirect contacts, and that the grounding system PE is working properly.

Do not power the projector with a dimmer circuit

Control Unit

The projector can be controlled by all types of controllers on the market that can execute the standard DMX 512

protocol. Controller-projector and projector-projector connections require a two-core screened cable provided with

CANNON XLR 3 pin, plugs and sockets. The ground braid on the screened cable must be connected to just one

end of the cable. The projector and cables must not be installed near overhead ducts for electrical cables or

intense magnetic fields.

Projector Address

The DMX BASE CHANNEL (DMX starting address) is the identity of the projector when in function. The projector

execute the information contained in the DMX starting channel exactly from the BASE CHANNEL (included). In

example if a projector is setted on the DMX starting address 57, it will performs its features following the

information contained in the channel 57, 58, 59 and so on.

HOW TO SET the correct DMX starting address:

Setting the rotative switches, you can read the DMX BASE CHANNEL on the display.

5

SPECIAL FUNCTIONS

Dip-switch Function

1 –

2 –

3 –

4 OFF = PAN/TILT 8/ bit resolution

ON = PAN/TILT 16 bit fine resolution

5 OFF = Standard configuration of PAN direction

ON = Invert PAN direction

6 OFF = Standard configuration of TILT direction

ON = Invert TILT direction

7 –

8 OFF = Standard configuration of 3chromie

ON = Invert the configuration of 3chromie

9 –

10 OFF = Display orientation for ground installation

ON = Display orientation for ceiling installation

DMX CHANNEL ASSIGNMENT

Ch. Function

1 CYAN

2 MAGENTA

3 YELLOW

4 SHUTTER / STROBE

5 PAN

6 TILT

7 COLOURS WHEEL

8 OVALIZER

9 Multi Step Zoom

10 CTO correction filter

11 DIMMER

12 13 PAN fine 16bit

14 TILT fine 16bit

6

CHANNEL 1 = CYAN

WHITE = 0

PROPORTIONAL 1 > 85

CYAN 86 > 100

PROPORTIONAL 101 > 254

WHITE = 255

CHANNEL 2 = MAGENTA

WHITE = 0

PROPORTIONAL 1 > 85

MAGENTA 86 > 100

PROPORTIONAL 101 > 254

WHITE = 255

CHANNEL 3 = YELLOW

WHITE = 0

PROPORTIONAL 1 > 85

YELLOW 86 > 100

PROPORTIONAL 101 > 254

WHITE = 255

Option to channel 1, 2 and 3: dip-switch 8 in ON position, invert the channels functioning

CHANNEL 4 = SHUTTER / STROBE

CLOSED 0 > 25

STROBE EFFECT MIN SPEED = 26

STROBE EFFECT MAX SPEED = 230

OPEN 231 > 255

CHANNEL 5 = PAN

Horizontal movement from 0 to 255, 450°

Dip-switch 5 in ON position, invert the PAN direction

CHANNEL 6 = TILT

Vertical movement from 0 to 255, 252°

Dip-switch 6 in ON position, invert the TILT direction

CHANNEL 7 = COLOURS WHEEL

WHITE 0 > 42

RED 43 > 85

YELLOW 86 > 128

MAGENTA 129 > 171

GREEN 172 > 214

BLUE 215 > 255

7

CHANNEL 8 = OVALIZER

NO OVALIZER = 0

PROPORTIONAL, from 0° to 360° 1 > 254

360° OVALIZER = 255

CHANNEL 9 = ZOOM

NARROW BEAM 0 > 63 19,3°

LIGHT FROST 64 > 127 24,8°

MEDIUM FROST 128 > 191 27°

HEAVY FROST 192 > 255 30°

CHANNEL 10 = CTO correction warm filter

6000K day-light = 0

PROPORTIONAL 0 > 255

3200K warm light = 255

CHANNEL 11 = DIMMER

BLACK-OUT = 0

INCREASING DIMMER LEVEL 0 > 255

OPEN = 255

CHANNEL 12 = AUX. CHANNEL

NOT USED

CHANNEL 13 = PAN fine

(16 bit HIGH DEFINITION DMX with dip-switch n° 04 in position ON)

CHANNEL 14 = TILT fine

(16 bit HIGH DEFINITION DMX with dip-switch n° 04 in position ON)

OPTICAL SYSTEM

MOVING WASH 1200 is provided with a high-efficiency lighting system made of parabolic reflector, Fresnel 200mm

lens, IR mirror and quality CYM disks. This system lets MOVING HEAD to project an extremely powerful and

homogenous light beam. The Multi Step Zoom allows the operator to perform different angles of the projection

beams perfectly focused.

Beam angle from 10% to 10% of light beam:

19,3° 15000Lux at 5m

24,8° 10800Lux at 5m

27° 8400Lux at 5m

30° 6900Lux at 5m

8

MAINTENANCE

CAUTION

Safety guards, lenses, and filters must be replaced if they are visibly damaged to the point that they become

ineffective (for example, if they have deep slashes or cuts).

The lamp must be replaced if damaged, cracked, or deformed by the heat.

PLANNED MAINTENANCE

at user’s charge and responsibility

OPERATION FREQUENCY ACTION

Lamp replacement 750 hours (verify) M1

Surface temperature test Quarterly M3

Cleaning Two months M4

Testing of safety breaker circuit on general

electric system

Monthly Check life-saving safety device pressing “T” button

Check damage to cables due to mobile use

of projector

Once a year

Replace cables if

damaged

NOTE: To ensure the correct functioning of the unit, a general service check of the projector must be made, twice a

year, from an authorized technician

ATTENTION

Always use original spare parts to ensure safe and proper functioning of the projector.

Do not make changes to the projector. A modified projector requires a new CE marking.

M1 - LAMP REPLACEMENT

The lamp must be replaced with the same type of lamp and according to the same frequency. A less efficient lamp jeopardizes

projector performance. Replace the lamp as follows:

- When the projector is cold, turn off the ON/OFF switch to cut the electricity and open the top lid to access the lamp

compartment.

- Remove the lamp from the lamp holder.

- Remove the new lamp from its packing and carefully read the Manufacturer’s instructions.

LAMP HMI 1200W/S Short Double Ended: Loosen the two ring nuts at both ends of the lamp. Place the lamp in its socket inside

the projector. Make sure the protuberance of the central bulb is facing downwards to avoid creating shadows in the projection.

Tighten the two ring nuts on the lamp.

- Replace the top lid and firmly tighten the knobs.

- Switch on the projector to make sure the lamp is working correctly.

ATTENTION

During lamp installation and lamp substitution, the operator must take care to avoid any contact between the lamp bulb and the

reflector.

M3 - SURFACE TEMPERATURE TEST

Before you check the temperature, make sure the projector is in the full operating mode (wait about 20 minutes after switching

on the projector). Use a contact probe to measure the surface temperature on the projector’s metal case and determine the

hottest area (Top lid near to the lamp). The temperature must be less than 70°. Otherwise, check the cooling system.

9

M4 - CLEANING

ATTENTION

Cleaning must be carried out when the projector is cool, disconnected from the power supply, with the general power switch

turned off, and the ON/OFF switch on the rear panel switched OFF.

Frequency

It is recommended to clean the projector every two months to ensure efficiency and performances. If the projector is used in

particularly smoky or dusty areas, clean the projector more frequently.

1. Open the top lid by unscrewing the knob and removing it from its seat.

2. Use a vacuum cleaner to remove dust.

3. Use a soft cloth (non-fabric) and pH neutral (pH7) liquid detergent to clean mirror and lens surfaces. Make sure you remove

all residual traces. Never touch the lamp directly with your hands or materials that can leave greasy traces.

4. Follow the same steps to clean the other internal parts of the projector.

5. Make sure the cleaning procedure did not damage any internal part or modified their correct position.

6. Make sure no cleaning materials or tools remain inside the projector.

7. Replace the top lid and firmly tighten the knob.

Life span and disposal

If the projector is operated in ordinary working conditions and the user follows the planned maintenance operations established

by the Manufacturer, it should last for three years. When the projector is discarded, it must be disposed of according to recycling

laws.

The improper use of this projector, cancel the guarantee and our responsibility. All the information have been

written and driven with extreme care; however, we do not engage us any responsibility for contingent errors or

omissions. We reserve the right to modify and/ or improve our product as we retain necessary, without subsequent

warning or notice. It is forbidden any complete or partial reproduction of this handbook, if not expressly authorized.

Loading...

Loading...