Page 1

SAGEM-LINK F

Microwave Radio Links

7 GHz – 38 GHz

Installation and Operation Manual

288 055 571-04

Issue 04 : July 2005

Page 2

SAGEM-LINK F 288055571-04

Installation and Operation Manual

Page 2/142

Issue 04 : July 2005

Reproduction and communication prohibited without the written permission of Sagem Communication

No reproduction without the written consent of Sagem Communication.

Sagem Communication reserves the right to change the specifications for improvement.

All trademarks are registrated by their owners.

Page 3

SAGEM-LINK F 288055571-04

Installation and Operation Manual

Page 3/142

Issue 04 : July 2005

Reproduction and communication prohibited without the written permission of Sagem Communication

HANDBOOK CHANGE LIST

(Each new edition supersedes the previous edition)

No. Issue

(No., date)

Change

Description

Changed

Pages

(Volume 1)

01 July 2004 Creation of document

02 September 2004 All pages

03 November 2004 All pages

04 July 2005 All pages

Page 4

SAGEM-LINK F 288055571-04

Installation and Operation Manual

Page 4/142

Issue 04 : July 2005

Reproduction and communication prohibited without the written permission of Sagem Communication

SAGEM-LINK F

INSTALLATION AND OPERATION MANUAL

Table of Contents

CHAPTER 1 - INSTALLATION ............................................................................................. 7

1.1 - Overview................................................................................................................... 7

1.2 - Unpacking the Equipment ........................................................................................ 7

1.3 - IDU Installation ......................................................................................................... 8

1.4 - Antenna Installation .................................................................................................. 8

1.4.1- Antenna Mount ................................................................................................... 9

1.4.2 - Typical Antenna Installation ............................................................................ 10

1.5 - Installing the ODU(s) .............................................................................................. 10

1.6 - Installing the IDU to ODU Coaxial Cable(s) ........................................................... 16

1.7 - Powering Up the System ........................................................................................18

1.8 - Aligning the Antennas............................................................................................. 20

1.9 - Connecting IDU to External Equipments ................................................................ 23

1.9.1 - IDU Front Panel Access Description ............................................................... 23

1.9.2 - IDU Rear Panel Access Description ............................................................... 24

1.9.3 - Connectors Pinout Description........................................................................ 24

CHAPTER 2 - COMMISSIONING ....................................................................................... 36

2.1 - Overview................................................................................................................. 36

2.2 - Preliminary Verifications ......................................................................................... 36

2.3 - Frequency Scan...................................................................................................... 37

2.4 - Receive Signal Level .............................................................................................. 37

2.5 - Tributary Tests........................................................................................................ 38

2.6 - Engineering Order Wire Test (optional).................................................................. 39

2.7 - Alarm Relays and I/O Dry Loops Test (optional).................................................... 39

2.7.1 - Simulating an IDU Alarm ................................................................................. 39

2.7.2 - Simulating an ODU Alarm ............................................................................... 39

2.7.3 - Simulating a Tributary Alarm ........................................................................... 39

2.7.4 - Simulating a RSL Alarm .................................................................................. 39

2.7.5 - Simulating a Custom Alarm............................................................................. 40

2.7.6 - Testing Input Dry Loops .................................................................................. 40

2.7.7 - Testing Alarm Relays ...................................................................................... 40

2.8 - 1+1 Verification (optional)....................................................................................... 41

2.9 - BER Measurement ................................................................................................. 43

2.10 - Recording Configuration Information.................................................................... 44

CHAPTER 3 - SAGEM-LINK F PILOT DESCRIPTION ...................................................... 48

3.1 - Overview................................................................................................................. 48

3.2 - SAGEM LINK F Pilot : Main Operations to Configure a Link ................................. 49

3.2.1 - Installing the SAGEM – LINK F Pilot Software................................................ 49

3.2.2 - Connecting the Laptop to SAGEM – LINK F IDU............................................ 49

3.2.3 - Link Preliminary Configuration ........................................................................ 50

3.2.4 - Completing Link Configuration ........................................................................ 55

3.3 - SAGEM-LINK F Pilot : Menus Description ............................................................. 64

3.3.1 - Configuration Menu .........................................................................................64

3.3.2 - Alarms Menu ................................................................................................... 66

3.3.3 - Monitoring Menu.............................................................................................. 71

3.3.4 - Parameters Menu ............................................................................................ 77

3.3.5 - Downloads Menu............................................................................................. 81

3.3.6 - NMI Menu ........................................................................................................ 82

3.3.7 - Tools Menu...................................................................................................... 88

3.3.8 – Changing an IDU Configuration...................................................................... 95

Page 5

SAGEM-LINK F 288055571-04

Installation and Operation Manual

Page 5/142

Issue 04 : July 2005

Reproduction and communication prohibited without the written permission of Sagem Communication

CHAPTER 4 - TROUBLESHOOTING................................................................................. 97

4.1 - Overview................................................................................................................. 97

4.2 – Visual Inspection.................................................................................................... 97

4.3 – Troubleshooting Steps........................................................................................... 98

4.3.1 – Define the symptom........................................................................................ 98

4.3.2 – Isolate the problem .........................................................................................98

4.3.3 – Fix the problem ............................................................................................... 98

4.4 – Alarms and Status Indication LED ......................................................................... 98

4.5 - SAGEM-LINK F Pilot Alarm Menus ........................................................................ 99

4.5.1 – Alarms Screen ................................................................................................ 99

4.5.2 – Direct and Indirect Alarms ............................................................................ 101

4.5.3 – Equipment Log ............................................................................................. 101

4.6 – Typical SAGEM-LINK F Pilot Screens................................................................. 102

4.6.1 – No connection to the IDU from the Pilot software ........................................ 102

4.6.2 – No Local equipment...................................................................................... 102

4.6.3 – No Remote Radio .........................................................................................103

4.6.4 – RSL Alarms .................................................................................................. 103

4.6.5 – Transmit Power alarm .................................................................................. 103

4.6.6 – Minor alarms ................................................................................................. 104

4.6.7 – No alarm .......................................................................................................104

4.7 – Replacing an ODU ............................................................................................... 105

4.8 – Replacing a Cable Interface module.................................................................... 105

4.9 – Replacing an IDU................................................................................................. 105

CHAPTER 5 - SYSTEM DESCRIPTION........................................................................... 106

5.1 - Overview............................................................................................................... 106

5.2 – System Composition............................................................................................ 106

5.2.1 - IDU Versions ................................................................................................. 108

5.2.2 – Cable Interface Module Versions ................................................................. 108

5.2.3 – ODU Versions............................................................................................... 108

5.3 – SAGEM-LINK F Block Diagram ........................................................................... 110

5.4 – IDU Description.................................................................................................... 111

5.5 – Cable Interface Module Description..................................................................... 112

5.6 – Outdoor Unit Description ..................................................................................... 112

5.7 – Protected Configurations ..................................................................................... 113

5.7.1 – 1+1 Mute Hot Standby (MHSB).................................................................... 113

5.7.2 – 1+1 Space Diversity...................................................................................... 113

5.7.3 – 1+1 Frequency Diversity............................................................................... 114

CHAPTER 6 - ETHERNET OPTION ................................................................................. 115

6.1 - Overview............................................................................................................... 115

6.2 - Ethernet and E1 Combinations Description ......................................................... 115

6.3 - Ethernet Features Description.............................................................................. 119

6.3.1 - Ethernet Bridging........................................................................................... 119

6.3.2 – Bandwidth Allocation .................................................................................... 120

6.3.3 – Ethernet Interface Configurations................................................................. 121

6.4 - Ethernet Configuration.......................................................................................... 122

6.5 - Ethernet Alarms .................................................................................................... 122

6.5.1 - Ethernet RJ45 LEDs...................................................................................... 122

6.5.2 – Sagem Link F Pilot Ethernet Alarm .............................................................. 123

6.6 - Ethernet Troubleshooting ..................................................................................... 124

APPENDIX 1 - SAGEM-LINK F SPECIFICATIONS ......................................................... 125

General .........................................................................................................................125

Transmitter.................................................................................................................... 126

Receiver........................................................................................................................ 127

Tributaries ..................................................................................................................... 128

Auxiliary Channels and Management Interfaces .......................................................... 128

Mechanical.................................................................................................................... 128

Consumption................................................................................................................. 129

Page 6

SAGEM-LINK F 288055571-04

Installation and Operation Manual

Page 6/142

Issue 04 : July 2005

Reproduction and communication prohibited without the written permission of Sagem Communication

Environmental ............................................................................................................... 129

APPENDIX 2 - SAGEM-LINK F PART NUMBERS .......................................................... 130

Link Composition .......................................................................................................... 130

SAGEM LINK F Modules Part Numbers....................................................................... 131

SAGEM LINK F ODU Part Numbers ............................................................................ 132

APPENDIX 3 - MISCELLANEOUS ................................................................................... 136

Changing 8 GHz ODU T/R Spacing Procedure........................................................... 136

Using Pilot software with an Ethernet Connection........................................................ 138

Upgrading a 2x2/4x2 Mbit/s IDU................................................................................... 139

Page 7

SAGEM-LINK F 288055571-04

Installation and Operation Manual

Page 7/142

Issue 04 : July 2005

Reproduction and communication prohibited without the written permission of Sagem Communication

Chapter 1

Installation

1.1 - Overview

This chapter explains how to install and set up SAGEM LINK F radio links. The main topics covered are :

• Unpacking the Equipment

• IDU installation

• Antenna installation

• ODU installation

• IDU to ODU Coaxial cable installation

• Powering up the system

• Antenna alignment

• Connecting IDU to external equipments

1.2 - Unpacking the Equipment

Verify that the items received are compliant with the packing list.

If any part of the equipment is damaged, contact Sagem representative for repair or replacement

instructions.

The IDU and ODU are packaged in two separate boxes. In addition, the optional items are

packaged in a separate container.

The IDU box contains, the IDU with cable interface module (one for 1+0 systems, two for 1+1

systems), the DC Power supply cable and a CDROM including the user manual and the SAGEM

LINK F Pilot software.

The ODU box contains only one ODU.

Save case and shipping material, in case the equipment has to be returned.

Page 8

SAGEM-LINK F 288055571-04

Installation and Operation Manual

Page 8/142

Issue 04 : July 2005

Reproduction and communication prohibited without the written permission of Sagem Communication

1.3 - IDU Installation

To install the IDU in a 19-inch rack :

• Attach the IDU in the 19-inch rack using four 6x12 stainless steel hex screws and washers into the

corresponding rack cage nuts. This attachment grounds the IDU to the earth.

Maint

Mux

Tribs

Cust

S

On

Off

Call

PC

POWER

EOW

Mgr 100bT

EastWest

TRIB 1- 4 TRIB 5- 8

TRIB 9-12 TRIB 13-16

ODU

POWER

Faston Male Plug

Figure 1.1 - IDU installation

• An additional grounding is possible by the use of a Faston plug (left side of the IDU). Use a 6

mm2 section cable (minimum length required).

NOTE: When more than one IDU are to be mounted in the rack, it is recommended to keep a gap of 1

unit between two IDUs.

1.4 - Antenna Installation

Three types of antenna with several diameters are available for SAGEM LINK F radios.

• Integrated antenna with Sagem Link F ODU interface (0.3m, 0.6m, 0.9m, 1.2m or 1.8m

diameter). With these antennas, the ODU is directly attached on the antenna. In some protected

configuration using a coupler, the coupler is attached to the antenna, and the ODU are attached

on the coupler.

• External antenna with standard rectangular waveguide flange, which is connected to the

SAGEM LINK F ODU with a flex guide.

• External antenna with two access (dual polarized antenna) connected by two flex guides to the

ODUs.

Antennas models depend on the frequency bands :

• 7 GHz → 7.1 - 7.7 GHz

• 8 GHz → 8.025 - 8.5 GHz

• 13 GHz → 12.75 - 13.25 GHz

Page 9

SAGEM-LINK F 288055571-04

Installation and Operation Manual

Page 9/142

Issue 04 : July 2005

Reproduction and communication prohibited without the written permission of Sagem Communication

• 15 GHz → 14.4 - 15.35 GHz

• 18 GHz → 17.7 - 19.7 GHz

• 23 GHz → 21.2 - 23.6 GHz

• 26 GHz → 24.5 - 26.5 GHz

• 38 GHz → 37 - 39.5 GHz

Alternative antennas to those specified by Sagem may be used, but they must meet the following

requirements

• Minimum gain to achieve adequate link margin,

• Radiation Pattern Envelope compliant to the network and country regulations

• Mechanical characteristics to meet specific site requirements (wind and frost resistance)

NOTE: With some antennas, the manufacturer’s guarantee applies only if the antenna feed is

pressurized. Therefore, it is essential to observe the recommendations relative to the selected

antenna type. Provision must therefore be made for:

y

installation and connection of a pressurizing system if the antenna is connected to the ODU

with a waveguide;

y

use pressurization windows and seals to protect waveguide connections.

1.4.1- Antenna Mount

In most cases, the antenna mounts provided by antenna manufacturers fit on tubular poles

(diameter 88.9 to 114 mm).

If the antenna is installed on towers using another type of structure (e.g., square-section tower),

special mounting kits must be used for this support.

The following precautions must always be taken :

- Allow enough clearance (± 10°) about the alignment axis. Leave also adequate space

around the ODU to allow easy mounting.

- make sure that nothing may obstruct the link, even partially, especially in the near field of

view,

- keep enough room for access to the antenna and ODU (for set-up and maintenance

measurements),

- install proper lightning rod and earthing,

Note: If there is an existing lightning rod, make sure that the ODU installation site is covered by

the lightning protection cone.

- misalignment under extreme weather conditions must not exceed ± 20 min angle in elevation

and azimuth.

The antenna mount may be secured in different ways depending on the antenna installation site

type and environment :

- mounting pole secured to the HEA section with a back-plate or clips,

- mounting pole secured to a square-shaped base plate with threaded rods. The base plate is

set on top of a resilient plate which may be installed on the terrace of a building without

affecting water-tightness,

- wall-mounted staff on the building front,

Page 10

SAGEM-LINK F 288055571-04

Installation and Operation Manual

Page 10/142

Issue 04 : July 2005

Reproduction and communication prohibited without the written permission of Sagem Communication

- antenna mount secured directly to a tower tube (diameter 88.9 or 114 mm),

- antenna support secured to a square-section tower tube with adapters.

1.4.2 - Typical Antenna Installation

Refer to the antenna manufacturer procedures.

1.5 - Installing the ODU(s)

Depending on the configuration, and on the antenna type, there are several ODU mounting

possibilities :

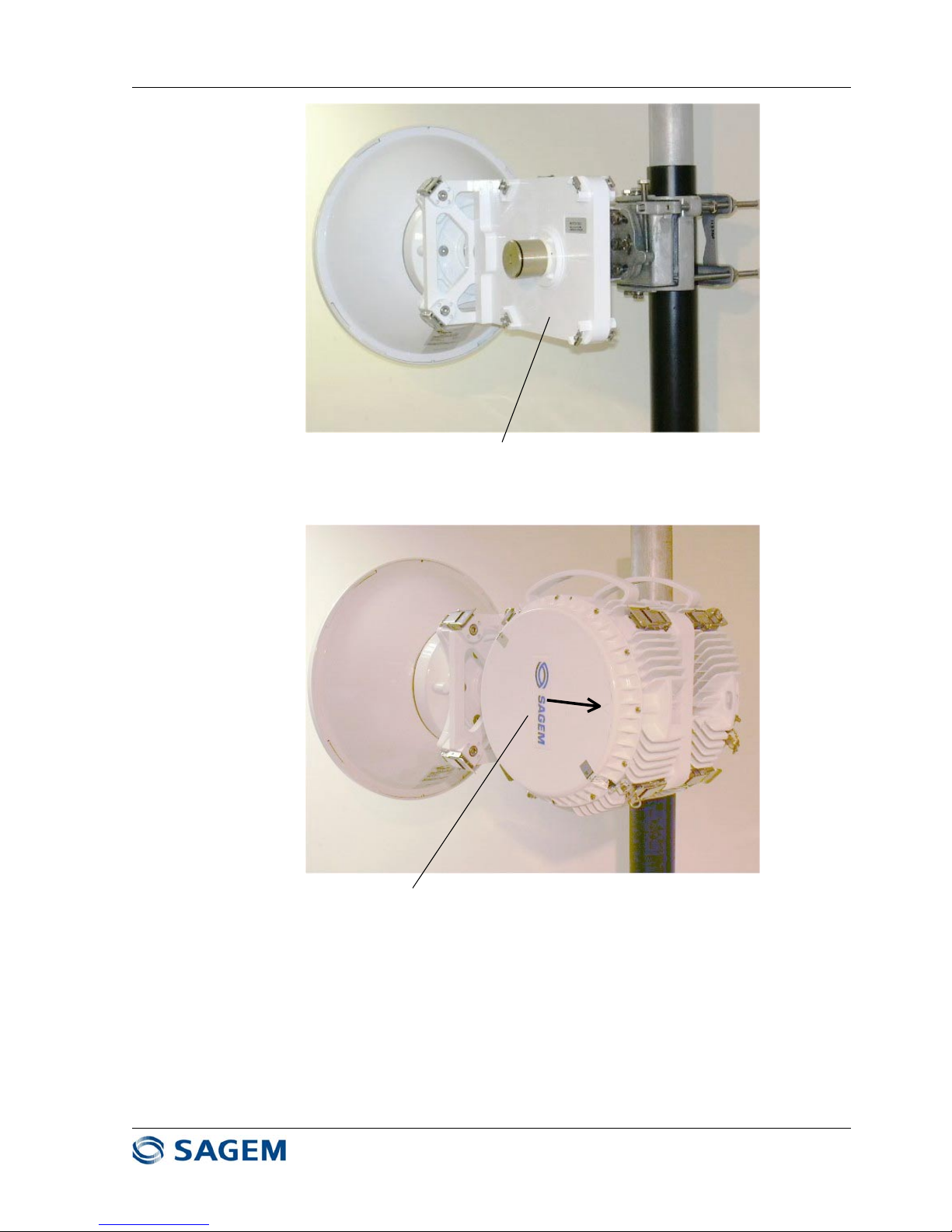

• 1+0 Configuration with integrated antenna : (or 1+1 configuration with two antennas)

The ODU is directly attached on an integrated antenna with four latches. It is connected to the

IDU by a single coaxial cable terminated with N male connectors.

Figure 1.2 - SAGEM LINK F ODU with an Integrated Antenna

Setting the Polarization :

If antenna has a circular waveguide interface (7 GHz, 8 GHz or 38 GHz), polarization depends

only on the ODU position. For vertical polarization, make sure that the arrow on the ODU cover is

vertical, for horizontal polarization, turn the ODU from 90 degrees.

Page 11

SAGEM-LINK F 288055571-04

Installation and Operation Manual

Page 11/142

Issue 04 : July 2005

Reproduction and communication prohibited without the written permission of Sagem Communication

Horizontal PolarizationVertical Polarization

Figure 1.3 – Polarization Setting for the ODU

If antenna has a rectangular waveguide interface (13 GHz, 15 GHz, 18 GHz, 23 GHz and 26

GHz), then polarization depends on the antenna source position.

Note that ODU waveguide output must always be in the same position compared to antenna

waveguide input.

For vertical polarization, turn antenna source in order to have the large side of the waveguide in

horizontal position according to antenna manufacturer procedure. Install the ODU accordingly

For horizontal polarization turn antenna source to have the large side of the waveguide in vertical

position. Turn also the ODU in order to have coincidence between ODU and antenna

waveguides.

• 1+0 Configuration with remote mount and standard antenna :

In case of the use of a standard antenna (i.e. large antenna without SAGEM LINK F ODU

interface), the ODU is mounted on a pole with a remote mount and connected to the antenna with

a standard rectangular flex guide.

Polarization depends on the antenna source position (vertical polarization is obtained when the

big side of the antenna waveguide flange is horizontal).

Figure 1.4 - SAGEM LINK F ODU Remote mount

Page 12

SAGEM-LINK F 288055571-04

Installation and Operation Manual

Page 12/142

Issue 04 : July 2005

Reproduction and communication prohibited without the written permission of Sagem Communication

• 1+1 Configuration with a Coupler and an Integrated Antenna :

The coupler is attached on the integrated antenna with four bolts. Two ODUs are mounted

vertically on the coupler with four latches. Each ODU is connected to its modem by a coaxial

cable.

As in most cases the coupler is not symmetrical, it is important to identify which ODU is

connected to the main position, and which ODU is connected to protection (standby) position.

The main and standby ODU positions are indicated on the coupler.

Whatever the polarization is, 1+1 the coupler is always mounted in the same position. There are

two types of coupler :

- Andrew coupler : for this type of coupler the arrow on the ODU cover must be vertical

- Filtel coupler : for this type of coupler, the arrow on the ODU cover must be horizontal.

Page 13

SAGEM-LINK F 288055571-04

Installation and Operation Manual

Page 13/142

Issue 04 : July 2005

Reproduction and communication prohibited without the written permission of Sagem Communication

A

ndrew Coupler

ODU arrow is in vertical

position (Andrew coupler)

Standb

y

ODU

Main ODU

Figure 1.5a - SAGEM LINK F 1+1 Configuration with integrated antenna and Andrew

coupler

Page 14

SAGEM-LINK F 288055571-04

Installation and Operation Manual

Page 14/142

Issue 04 : July 2005

Reproduction and communication prohibited without the written permission of Sagem Communication

Filtel Coupler

ODU with Filtel coupler

Horizontal arrow

Figure 1.5b – SAGEM LINK F 1+1 Configuration with integrated antenna and Filtel coupler

On the coupler there is a label or a marking indicating the position of main and stand by ODUs.

Page 15

SAGEM-LINK F 288055571-04

Installation and Operation Manual

Page 15/142

Issue 04 : July 2005

Reproduction and communication prohibited without the written permission of Sagem Communication

Polarization setting :

- Coupler : ODUs are mounted vertically on the coupler. Depending on the coupler type the

arrow on the ODU cover must be horizontal (Filtel) or vertical (Andrew).

- The polarization can be adjusted from turning the coupler polarizer from 90 degrees

(Andrew) or by replacing polarizer (Filtel). Refer to coupler supplier instructions.

- Antenna : If the antenna has a rectangular waveguide interface, rotate antenna source to

have the wanted polarization. Make sure that polarizations are the same for the antenna

and for the coupler.

Vertical Polarization Horizontal Polarization

Figure 1.6 – Setting the Polarization for Andrew Coupler

Vertical Polarization Horizontal Polarization

Figure 1.7 – Setting the Polarization for Filtel Coupler

• 1+1 Configuration with a Coupler Remote Mounted and a Standard Antenna :

The coupler is attached on the remote mount and connected to the standard antenna by a flex

guide.

The two ODUs are vertically mounted on the coupler, with the arrows in vertical (Andrew) or

horizontal position (Filtel). Each ODU is connected to the IDU with a coaxial cable.

Page 16

SAGEM-LINK F 288055571-04

Installation and Operation Manual

Page 16/142

Issue 04 : July 2005

Reproduction and communication prohibited without the written permission of Sagem Communication

Polarization setting is done by turning antenna source.

As coupler is not symmetrical in most cases, it is important to identify main position (lowest

insertion loss) and standby position.

It is also necessary to identify ODU cables (main or standby) with a label.

• 1+1 Frequency Diversity Configuration with Remote Mounts and a Dual Polarized Antenna :

In this configuration each ODU is remote mounted on a pole, and is connected to an antenna

access with a flex guide.

It is important to identify ODU cables for the one which is on vertical polarization (main), and the

one which is horizontal polarization (standby).

1.6 - Installing the IDU to ODU Coaxial Cable(s)

Recommended cables coaxial cables are Belden 9914 and Andrew LDF4-50A. If an other type of

cable is used, make sure it is compatible with outdoor use. This cable should be double or triple

shielded. Cable impedance is 50 Ohm, and is terminated by two N male connectors.

N connectors must be compatible with the cable, and connector mounting procedure must follow

connector manufacturer recommendations.

Install one cable in a 1+0 system or two cables in a 1+1 system.

It is very important to protect N connectors against water : wrap Isolation tape (15 cm) over the

coax cover. Start winding from coax cover with one half overlap with each winding in order to

protect completely connection from rain action. Press with fingers the tape and make sure the

protection is correct.

NOTE: Cables must be installed in compliance with national and local regulations and meet the

specific requirements of the installation site.

Some precautions are necessary when installing the equipment on unprotected places (e.g.,

antenna towers, building terraces, etc.) to prevent equipment from damage by lightning.

In a 1+1 system when two cables are installed, it is very important to identify main cable and

standby cable. If the cables are not labeled, it is necessary to perform a resistance check to

identify each cable.

Disconnect N connectors from IDU, and short circuit one of the N connector on the ODU side

(while the other one is open), and measure cable resistance on the IDU side. The lowest

resistance corresponds to the short circuited cable.

Put labels on both sides of the cables.

Remove the short circuit, make sure connectors are clean and dry, and connect proper cable to

each ODU.

Cable Grounding

It is necessary to ground properly ODU to IDU cable for a good lightning protection. For this

purpose, a cable grounding kit is provided as an option.

Page 17

SAGEM-LINK F 288055571-04

Installation and Operation Manual

Page 17/142

Issue 04 : July 2005

Reproduction and communication prohibited without the written permission of Sagem Communication

Figure 1.9 : SAGEM-LINK F Grounding Kit

The number of necessary grounding points depends on the site, and on the cable length.

Normally, a good protection is achieved with :

• A grounding kit on the cable close to the ODU

• A grounding kit on the cable at the building entrance

• A grounding kit on the cable at the bottom of the pylon

• A grounding kit each 50 meters for long cables.

Page 18

SAGEM-LINK F 288055571-04

Installation and Operation Manual

Page 18/142

Issue 04 : July 2005

Reproduction and communication prohibited without the written permission of Sagem Communication

1.7 - Powering Up the System

Before powering up the Sagem Link F terminal, check that :

IDU and ODU and cables are properly grounded

IDU and ODU are connected together with right coaxial cable(s). in 1+1 operation, main and

standby cables have been previously identified and connected to the main and standby IDU

cable interfaces

To Main

ODU

DC Power In

To Standby

ODU

Main Channel

On/Off Switch

Standby Channel

On/Off Switch

Green LED

"Power"

Maint

Mux

Tribs

Cust

Call

S

On

Off

POWER

S

On

Off

POWER

Main Cable Interface Standby Cable Int erface

Figure 1.10 – SAGEM LINK F 1+1 IDU

Input DC Power Voltage is within specified range : - 36 VDC to –59 VDC (-48 VDC nominal).

Measure DC voltage (polarity and amplitude) on the cable plug before connection into the

IDU. Negative voltage must be used only. DC Connector Pinout is given in Figure 1.11.

Maint

mux

Tribs

Cust

-48VDC

GROUND

(0 VDC)

GROUND

Figure 1.11 : IDU DC Input Connector

Page 19

SAGEM-LINK F 288055571-04

Installation and Operation Manual

Page 19/142

Issue 04 : July 2005

Reproduction and communication prohibited without the written permission of Sagem Communication

Plug DC connector into IDU connector. If the terminal is a 1+0 system, switch on the terminal

with the switch in front panel. If the terminal is a 1+1 system, switch on both switches.

The green LED(s) labeled "Power" should be lit.

Connect a PC on IDU front panel DB9 connector Labeled "PC" and run the Sagem Link F Pilot

software

Verify and change if necessary, terminal local parameters (refer to Sagem Link Pilot

description in chapter 4) :

- Transmit frequency,

- capacity,

- modulation,

- transmit power

- Link ID Code

- ATPC must be in the "Off" position at that time

Unless the link is already operating (remote parameters are displayed on the right side of the

main screen of the Pilot software), make sure local terminal parameters are in accordance

with far end terminal parameters. (Frequency, capacity, modulation, and Link ID Code must

match)

If remote terminal parameters are good and if the main screen displays a "No Remote Radio"

message, it means antennas are not properly aligned.

Page 20

SAGEM-LINK F 288055571-04

Installation and Operation Manual

Page 20/142

Issue 04 : July 2005

Reproduction and communication prohibited without the written permission of Sagem Communication

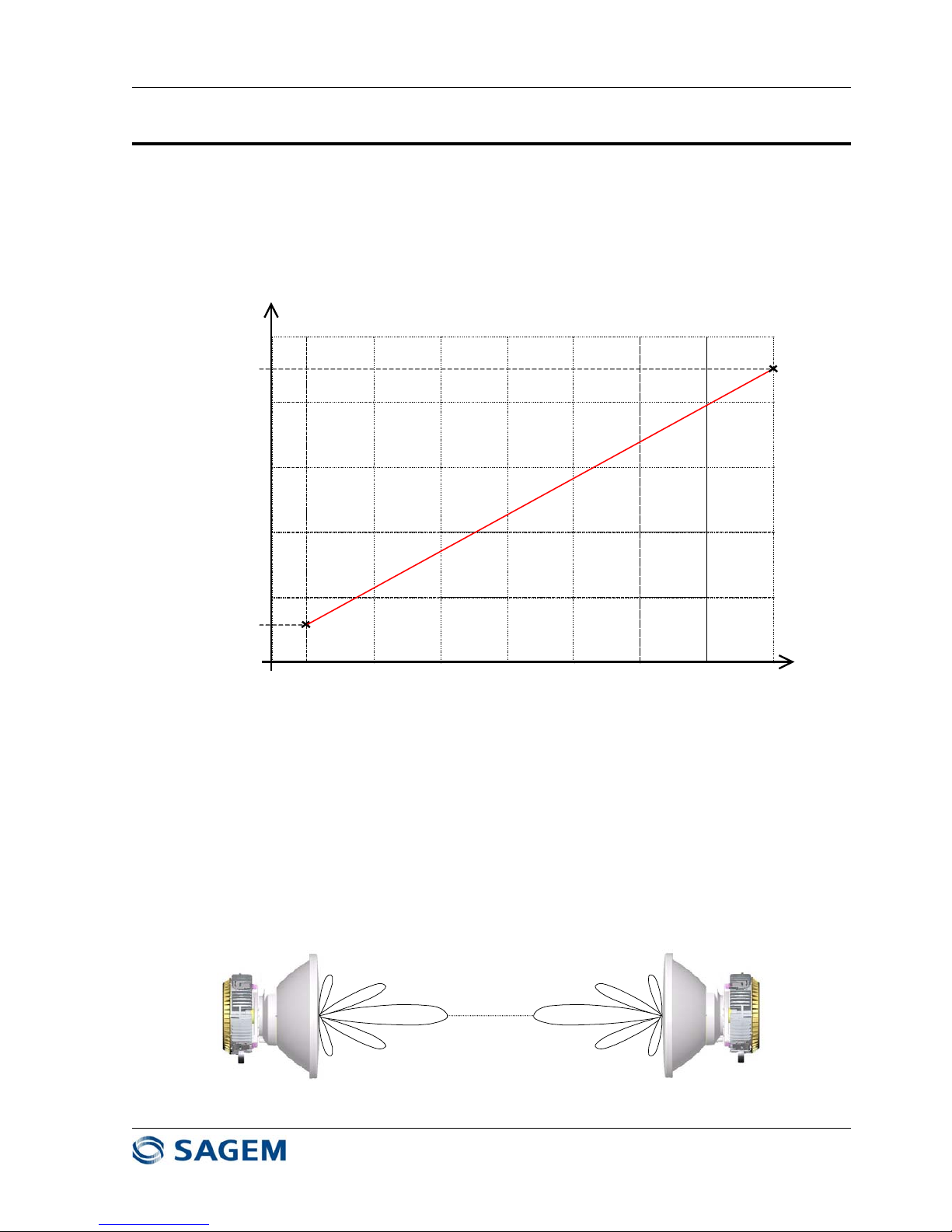

1.8 - Aligning the Antennas

Antenna alignment is performed with both terminals operating, in normal weather conditions. The

receive signal level (RSL) voltage is available on the ODU BNC connector.

A typical RSL curve at ODU access is given on Figure 1.12 The highest the RSL voltage is, the

highest is the receive signal level.

-90 dBm

1 V

2 V

3 V

4 V

5 V

RSL Voltage

RSL at ODU Input

-80 dBm -70 dBm

-60 dBm

-50 dBm -40 dBm -30 dBm -20 dBm

0.5 V

4.5 V

Figure 1.12 : Typical SAGEM LINK F Receive Signal Level Voltage

Note : RSL is measured at ODU antenna port. In some 1+1 systems involving a coupler or a

remote mount antenna, it is necessary to take in account branching losses to know the actual

power at antenna access.

Optimal performance is done when main antenna lobe is aligned with the center of the remote

end antenna.

It is important to identify main lobe antenna, by rotating the antenna to have the maximum RSL

voltage. Note there is around 25 dB difference between side lobes and main lobes (1.5 V).

Good Alignment

Page 21

SAGEM-LINK F 288055571-04

Installation and Operation Manual

Page 21/142

Issue 04 : July 2005

Reproduction and communication prohibited without the written permission of Sagem Communication

Bad Alignment

Figure 1.13 : Antenna Alignment

The expected receive signal level has previously being determined and depends on frequency,

remote transmit power, local and remote antenna gains, and length hop.

Use the following procedure successively on both ends of the link to align the antenna :

1- Make sure remote transmit power is set in order to avoid overload at receive input (i.e. RSL

less than –20 dBm).

2- Verify that remote terminal is operational

3- Remove the cap on the local ODU BNC connector and connect a voltmeter.

4- Rotate slowly the antenna in the azimuth direction (horizontal) and find the maximum voltage.

If the voltage is around 4.5V (-20 dBm), then diminish the remote transmit power in order to

be in a more linear region.

5- Rotate slowly the antenna in the elevation direction (vertical) until the voltage is maximum.

Record the measured voltage.

6- When maximum voltage has been found, tighten all fasteners, verify that the voltage has not

changed. Replace protective cap on the BNC connector.

7- Compare expected receive level with current receive level. If the difference between expected

and actual receive is more than 5 dB, then it should be necessary to optimize again antenna

alignment, or to check again if polarization is the same on both ends of the link.

Connect a laptop computer to the PC connector and run the Sagem Link F Pilot software.

Normally, the link should be established (no "NO REMOTE RADIO" message displayed). The

main screen should be like that :

Page 22

SAGEM-LINK F 288055571-04

Installation and Operation Manual

Page 22/142

Issue 04 : July 2005

Reproduction and communication prohibited without the written permission of Sagem Communication

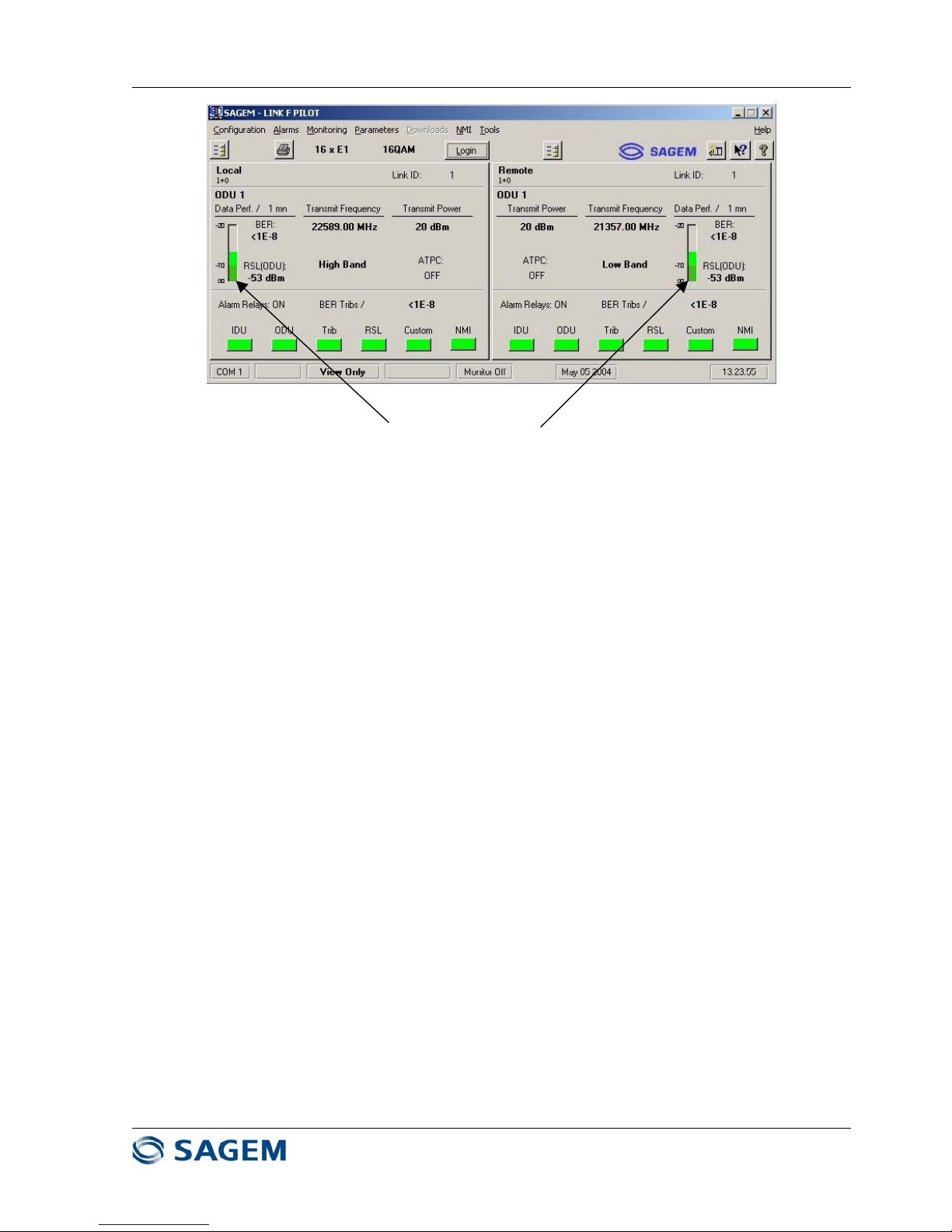

Receive Signal Levels should be similar on both ends

If there is more than 5 dB difference (with the same

transmit output power), check antenna alignment, ODUs,

IDUs, and antennas.

Figure 1.14 : Main Sagem Link F Pilot Screen

Page 23

SAGEM-LINK F 288055571-04

Installation and Operation Manual

Page 23/142

Issue 04 : July 2005

Reproduction and communication prohibited without the written permission of Sagem Communication

1.9 - Connecting IDU to External Equipments

1.9.1 - IDU Front Panel Access Description

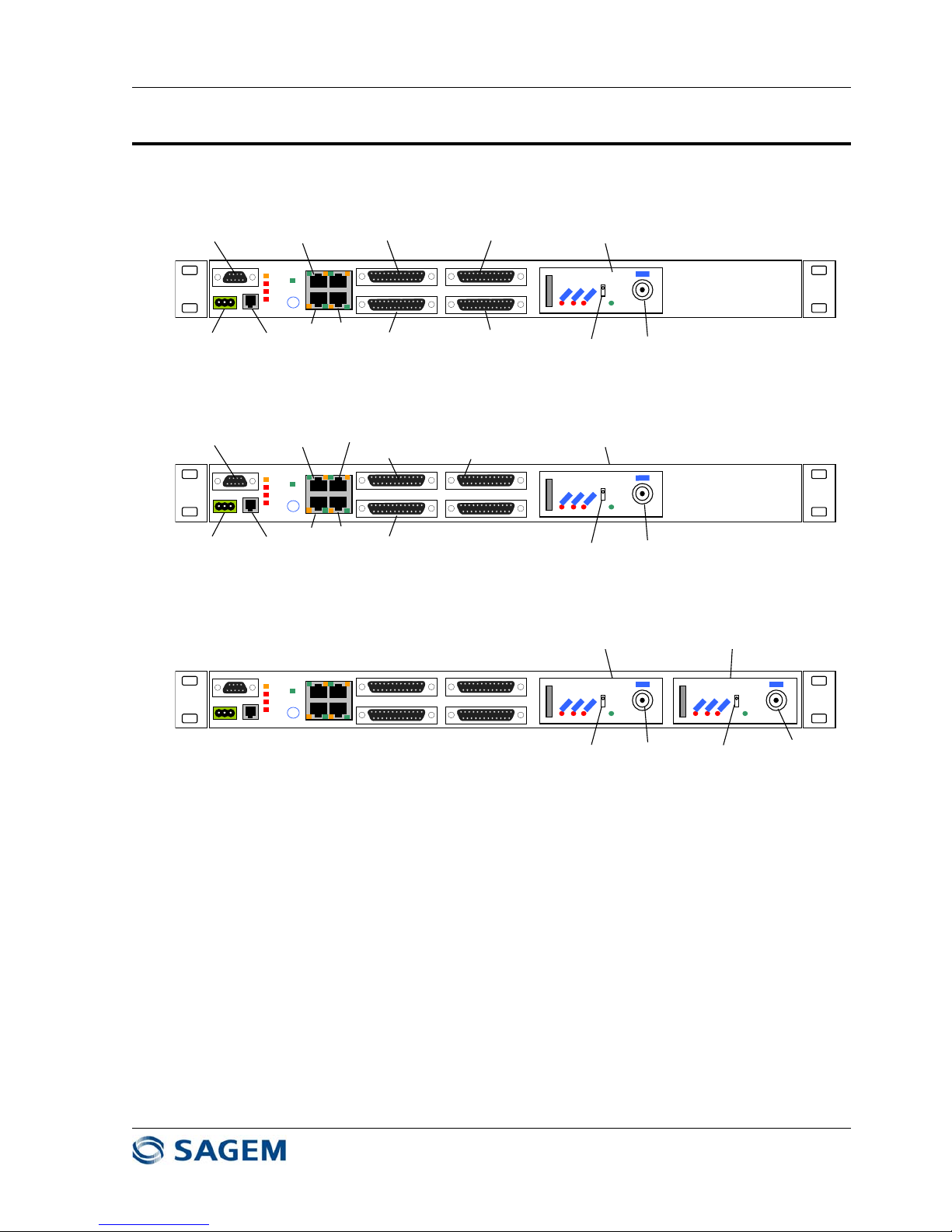

The following access are available at the IDU Front panel (See Figure 1.15) :

To Main

ODU

To Standby

ODU

Main Channel

On/Off Switch

Standby Channel

On/Off Switch

Cable Interface Module

(Main)

Cable Interface Module

(Standby)

IDU for 1+1 System

To ODU

DC Power In

On/Off Switch

To PC serial Port

EOW

Handset

SNMP

Manager

West

East

Tribs 1-4

Tribs 9-12

Tribs 5-8

Tribs 13-16

Cable Interface Module

IDU for 1+0 System (16 E1 version)

Maint

Mux

Tribs

Cust

Call

S

On

Off

POWER

To ODU

DC Power In

On/Off Switch

To PC serial Port

EOW

Handset

SNMP

Manager

100BaseT

West

East

Tribs 1-4

Tribs 5-8

Extra Trib

Cable Interface Module

IDU for 1+0 System (Ethernet version)

Maint

Mux

Tribs

Cust

Call

S

On

Off

POWER

Maint

Mux

Tribs

Cust

Call

S

On

Off

POWER

S

On

Off

POWER

Figure 1.15 – SAGEM LINK F IDU Front Panel for 1+0 and 1+1 Systems

• a power connection from a negatively biased DC source of between –36 VDC and -59 VDC,

labeled "Power",

• a point-to-point Engineering Order Wire RJ11 connection labeled "EOW",

• a PC port to connect a local craft terminal, via a DB 9 connector,

• Four Ethernet ports (RJ 45 connectors):

- 3 x 10 baseT Ports dedicated to Network Management Interface "Mgr", "West", "East"

(Ethernet hub),

- 1 x 100 baseT Port "100bT" (option)

• 16 x G703 2 Mbit/s tributary ports (4 tributaries per DB25 connector) in unbalanced 75 Ω mode, or

in balanced 120 Ω mode, the selection between modes is controlled by software :

Page 24

SAGEM-LINK F 288055571-04

Installation and Operation Manual

Page 24/142

Issue 04 : July 2005

Reproduction and communication prohibited without the written permission of Sagem Communication

- 16 E1 version : "Tribs 1-4", "Tribs 5-8", "Tribs 9-12", "Tribs 13-16".

- Ethernet version : : "Tribs 1-4", "Tribs 5-8", "Extra Trib",

Warning : the connector corresponding to tributaries 5 to 8 is not the same fo

r

16 E1 and Ethernet versions.

• One N connector per ODU connection "ODU".

• One ground connection ("Faston" connector).

1.9.2 - IDU Rear Panel Access Description

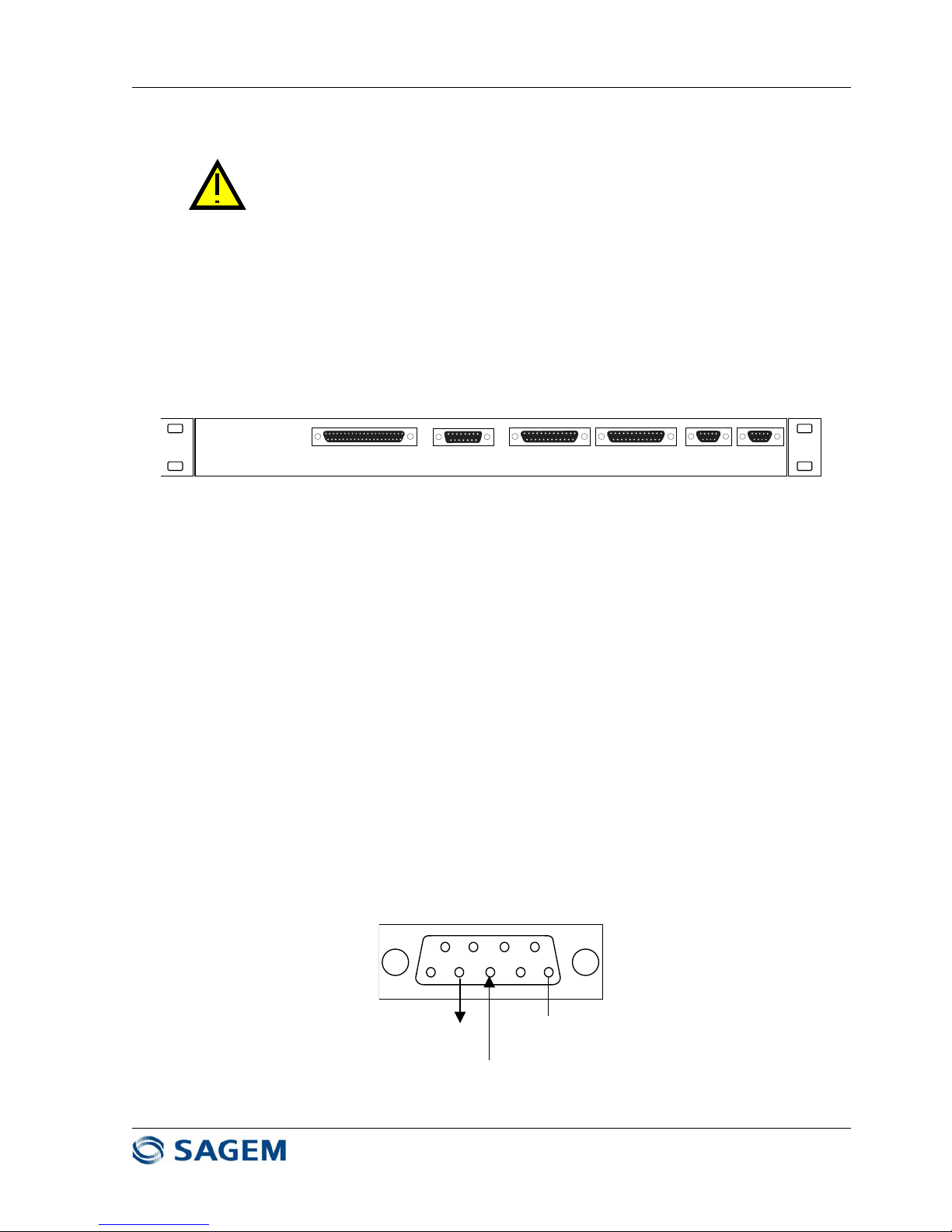

The following access are available at the IDU Rear panel (See Figure 1.16)

MGMT2

Aux2

Aux1

MGMT1

AUX3

ALARM RELAYS & DRY LOOPS

Figure 1.16 – SAGEM LINK F IDU Rear Panel

The IDU rear panel provides the following interfaces :

• a DB37 connector labeled "ALARM RELAYS & DRY LOOPS" including terminal alarm relays, and

4 input output dry loops.

• a DB15 connector labeled "AUX3" corresponding to a 64 kbit/s auxiliary data channel with a V11

electrical interface, that can be configured in either co-directional or contra-directional mode,

• two "MGMT1" and "MGMT2" DB25 connectors: management ports, MGMT1 configurable in

synchronous V11 or asynchronous V28 mode and MGMT2 used in synchronous V11 mode

• two 9600 bit/s (max.) asynchronous digital auxiliary data channels "AUX1" and "AUX2" (DB9

connectors), with V11 or V28 electrical interface configurable by software.

1.9.3 - Connectors Pinout Description

Local Craft Terminal Connection

Local Craft Terminal connection is made via a serial access (DB9 connector). Connector Pinout is given

in Figure 1.17.

This is a DCE, V28 interface, compliant to EIA 574 standard.

1

5

96

Output Data

2

3

Input Data

Ground

Figure 1.17 - DB9 PC connector Pinout

Page 25

SAGEM-LINK F 288055571-04

Installation and Operation Manual

Page 25/142

Issue 04 : July 2005

Reproduction and communication prohibited without the written permission of Sagem Communication

Engineering Order Wire

The IDU female connector "EOW " (RJ11) provides connection to a telephone handset.

Pin Description

1 Microphone (input)

2 Earpiece (ground)

3 Earpiece (output)

4 Microphone (ground)

Figure 1.18 - Engineering Orderwire Connector Pinout

Note : Handset is provided as an option

Ethernet Ports

Four RJ45 Ethernet Ports are available : three of them are use for Network Management operation, the

fourth is dedicated to an optional 100 baseT transmission.

The ports "Mgr", "East" and "West" are part of an internal 10 baseT Ethernet hub, and can be connected

to other IDUs or to a SNMP manager. Note that in a network, it is necessary to limit the number of

cascaded hubs to 4.

The pinout of Ethernet Ports are given in Figure 1.19

10 base T (SNMP)

"West"

1 1

11

8

8

88

10 base T (SNMP)

"East"

10 base T (SNMP)

Manager

100 BaseT

(Ethernet Option only)

PIN No Signal name Description

1 TX_ETH_P Ethernet output (+)

2 TX_ETH_N Ethernet output (-)

3 RX_ETH_P Ethernet input (+)

4-NC

5-NC

6 RX_ETH_N Ethernet input (-)

7-NC

8-NC

Figure 1.19 – Ethernet Ports Pinout

Page 26

SAGEM-LINK F 288055571-04

Installation and Operation Manual

Page 26/142

Issue 04 : July 2005

Reproduction and communication prohibited without the written permission of Sagem Communication

E1 Tributaries Connections

The four DB25 connectors in IDU front panel correspond to four x 4 Input/output 2 Mbit/s access (E1).

When Ethernet option is installed, additional E1 tributaries can be used along with Ethernet interface.

Refer to chapter 6 for more information. Depending on configuration, up to 8 E1 tributaries can be

combined with Ethernet transmission.

If the configuration with Ethernet option corresponds to a 28 MHz channel in QPSK mode, or to a 14

MHz in 16QAM mode, then an extra E1 tributary is available. Note that this particular tributary is not

available for all other cases.

Tributary access are available in 120 Ω balanced mode, or in 75 Ω unbalanced mode. Impedance mode

is controlled by the Pilot software.

It is possible to have one connector configured in balanced mode, while the others are configured in

unbalanced mode.

It is not possible to have on the same DB25 connector two tributaries in a different mode.

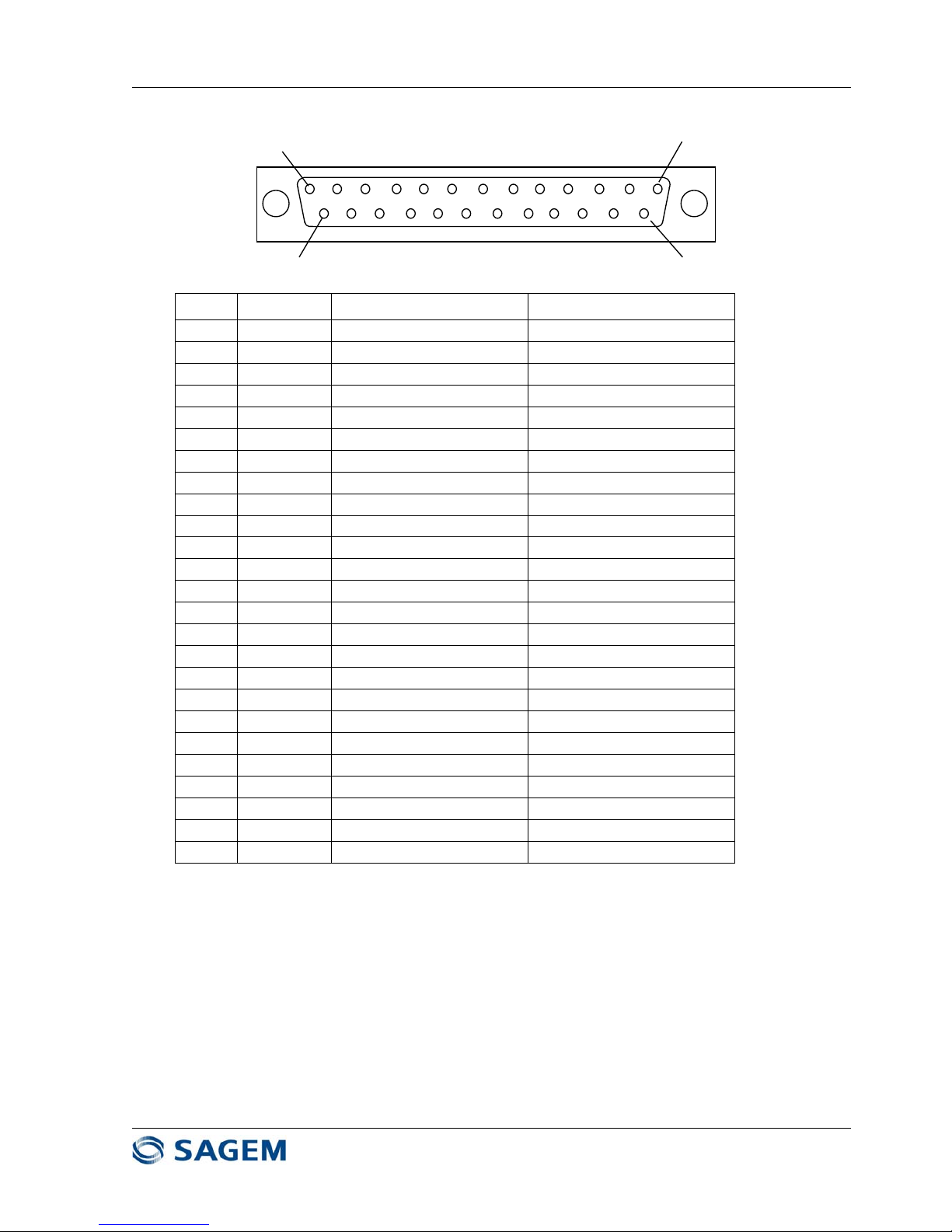

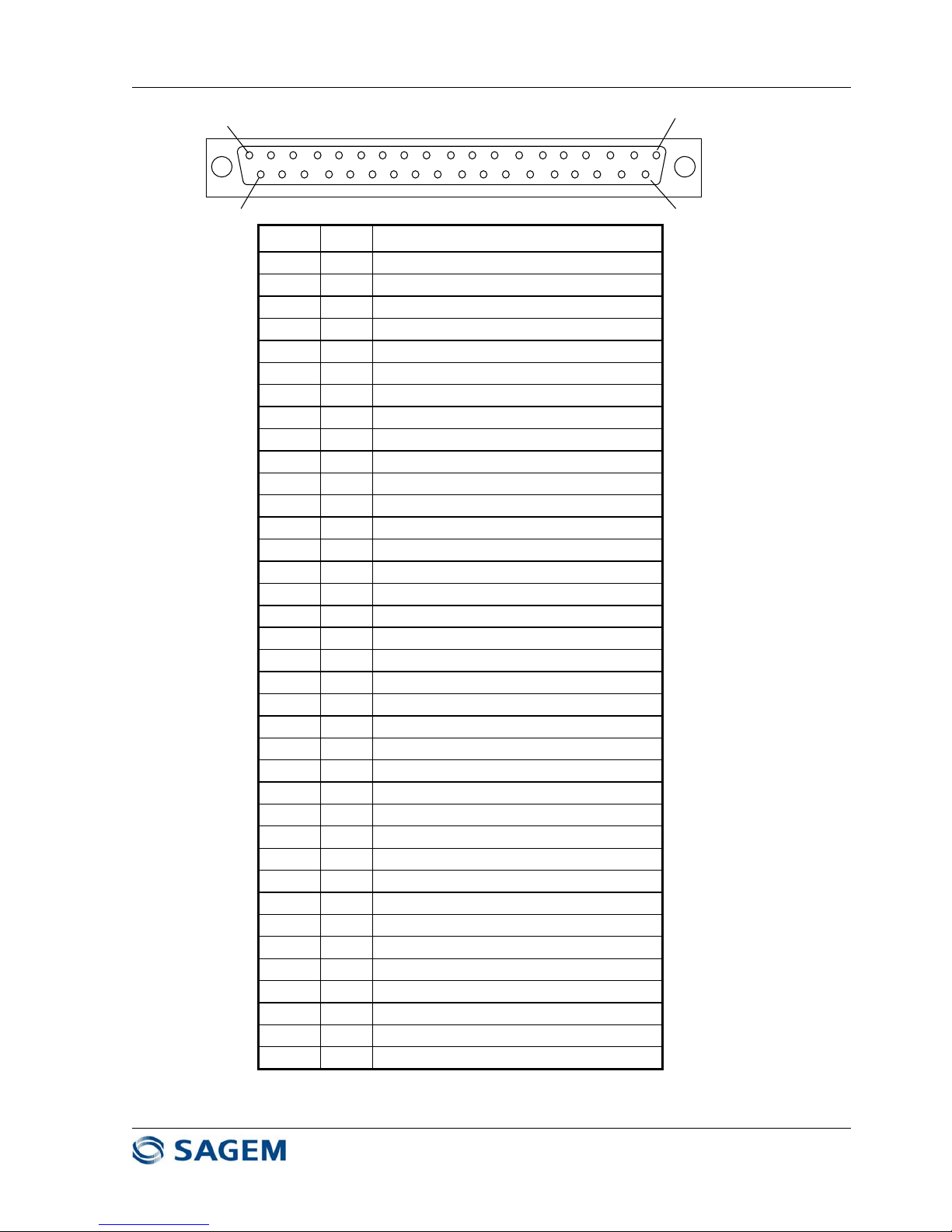

Tributary connector pinout corresponding to tributaries 1 to 4 is given in Figure 1.20. The other tributary

connectors have the same pinout.

When Ethernet option is present and when the data rate corresponds to a 28 MHz channel in QPSK

mode, or to a 14 MHz in 16QAM mode, the extra tributary is available on the third connector (Pinout

equivalent as trib #1, the other pins are not connected)

Page 27

SAGEM-LINK F 288055571-04

Installation and Operation Manual

Page 27/142

Issue 04 : July 2005

Reproduction and communication prohibited without the written permission of Sagem Communication

Pin Signal 120 Ohm balanced 75 Ohm unbalanced

1 GND Ground Ground

14 TXHDB3P1 Transmit trib #1 - P Transmit trib #1

2 GND Ground Ground

15 TXHDB3N1 Transmit trib #1 - N

Grounded by the cable

3 RXHDB3P1 Receive trib #1 - P Receive trib #1

16 GND Ground Ground

4 RXHDB3N1 Receive trib #1 - N

Grounded by the cable

17 TXHDB3P2 Transmit trib #2 - P Transmit trib #2

5 GND Ground Ground

18 TXHDB3N2 Transmit trib #2 - N

Grounded by the cable

6 RXHDB3P2 Receive trib #2 - P Receive trib #2

19 GND Ground Ground

7 RXHDB3N2 Receive trib #2 - N

Grounded by the cable

20 TXHDB3P3 Transmit trib #3 - P Transmit trib #3

8 GND Ground Ground

21 TXHDB3N3 Transmit trib #3 - N

Grounded by the cable

9 RXHDB3P3 Receive trib #3 - P Receive trib #3

22 GND Ground Ground

10 RXHDB3N3 Receive trib #3 - N

Grounded by the cable

23 TXHDB3P4 Transmit trib #4 - P Transmit trib #4

11 GND Ground Ground

24 TXHDB3N4 Transmit trib #4 - N

Grounded by the cable

12 RXHDB3P4 Receive trib #4 - P Receive trib #4

25 GND Ground Ground

13 RXHDB3N4 Receive trib #4 - N

Grounded by the cable

Figure 1.20 – DB25 Tributary Connector Pinout

1

25

14

13

Page 28

SAGEM-LINK F 288055571-04

Installation and Operation Manual

Page 28/142

Issue 04 : July 2005

Reproduction and communication prohibited without the written permission of Sagem Communication

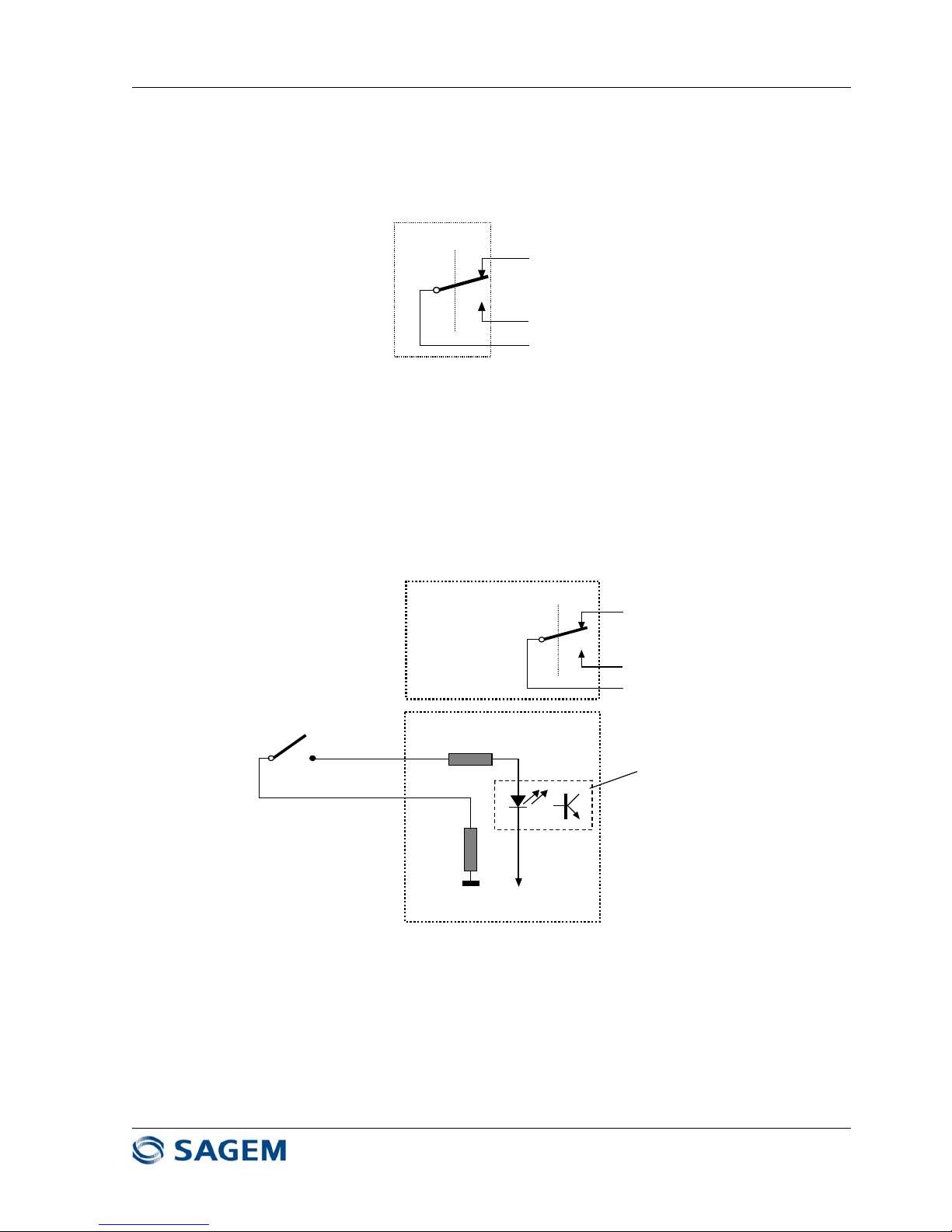

Alarm Relays and I/O Dry Loops

The rear panel DB37 connector includes

• 5 alarm relays : these alarms are managed by SAGEM LINK Pilot software. The electrical

interfaces for each alarm is given in Figure 1.21 :

Normally Open

Normally Closed

Common

Figure 1.21 – Alarm relay electrical interface

The alarm condition correspond to normally closed state of the relay.

NC= Normally Closed

NO= Normally Open

• 4 Inputs / Outputs dry loops: the electrical interface for each loop is given in Figure 1.20 :

LOOP INPUT_A

5 k

Ω

Photocoupler

-48V

5 k

Ω

LOOP INPUT_B

LOOP OUTPUT NO

LOOP OUTPUT NC

COMMON LOOP OUTPUT

SAGEM LINK

IINPUTS OUTPUTS

Figure 1.22 – I/O Dry Loop electrical interface

The pinout of DB37 connector is given in Figure 1.23

Page 29

SAGEM-LINK F 288055571-04

Installation and Operation Manual

Page 29/142

Issue 04 : July 2005

Reproduction and communication prohibited without the written permission of Sagem Communication

1

37

20

19

PIN # I/O Signal

1 - GROUND

20 I LOOP INPUT #1 – A

2 I LOOP INPUT #1 – B

21 I LOOP INPUT #2 – A

3 I LOOP INPUT #2 – B

22 I LOOP INPUT #3 – A

4 I LOOP INPUT #3 – B

23 I LOOP INPUT #4 – A

5 I LOOP INPUT #4 – B

24 O LOOP OUTPUT #1 NC

6 O COMMON LOOP OUTPUT #1

25 O LOOP OUTPUT #1 NO

7 O LOOP OUTPUT #2 NC

26 O COMMON LOOP OUTPUT #2

8 O LOOP OUTPUT #2 NO

27 O LOOP OUTPUT #3 NC

9 O COMMON LOOP OUTPUT #3

28 O LOOP OUTPUT #3 NO

10 O LOOP OUTPUT #4 NC

29 O COMMON LOOP OUTPUT #4

11 O LOOP OUTPUT #4 NO

30 O ALARM RELAY #1 NC

12 O COMMON ALARM RELAY #1

31 O ALARM RELAY #1 NO

13 O ALARM RELAY #2 NC

32 O COMMON ALARM RELAY #2

14 O ALARM RELAY #2 NO

33 O ALARM RELAY #3 NC

15 O COMMON ALARM RELAY #3

34 O ALARM RELAY #3 NO

16 O ALARM RELAY #4 NC

35 O COMMON ALARM RELAY #4

17 O ALARM RELAY #4 NO

36 O ALARM RELAY #5 NC

18 O COMMON ALARM RELAY #5

37 O ALARM RELAY #5 NO

19 - GROUND

Figure 1.23 – Alarm relays and I/O Dry Loop Connector Pinout

Page 30

SAGEM-LINK F 288055571-04

Installation and Operation Manual

Page 30/142

Issue 04 : July 2005

Reproduction and communication prohibited without the written permission of Sagem Communication

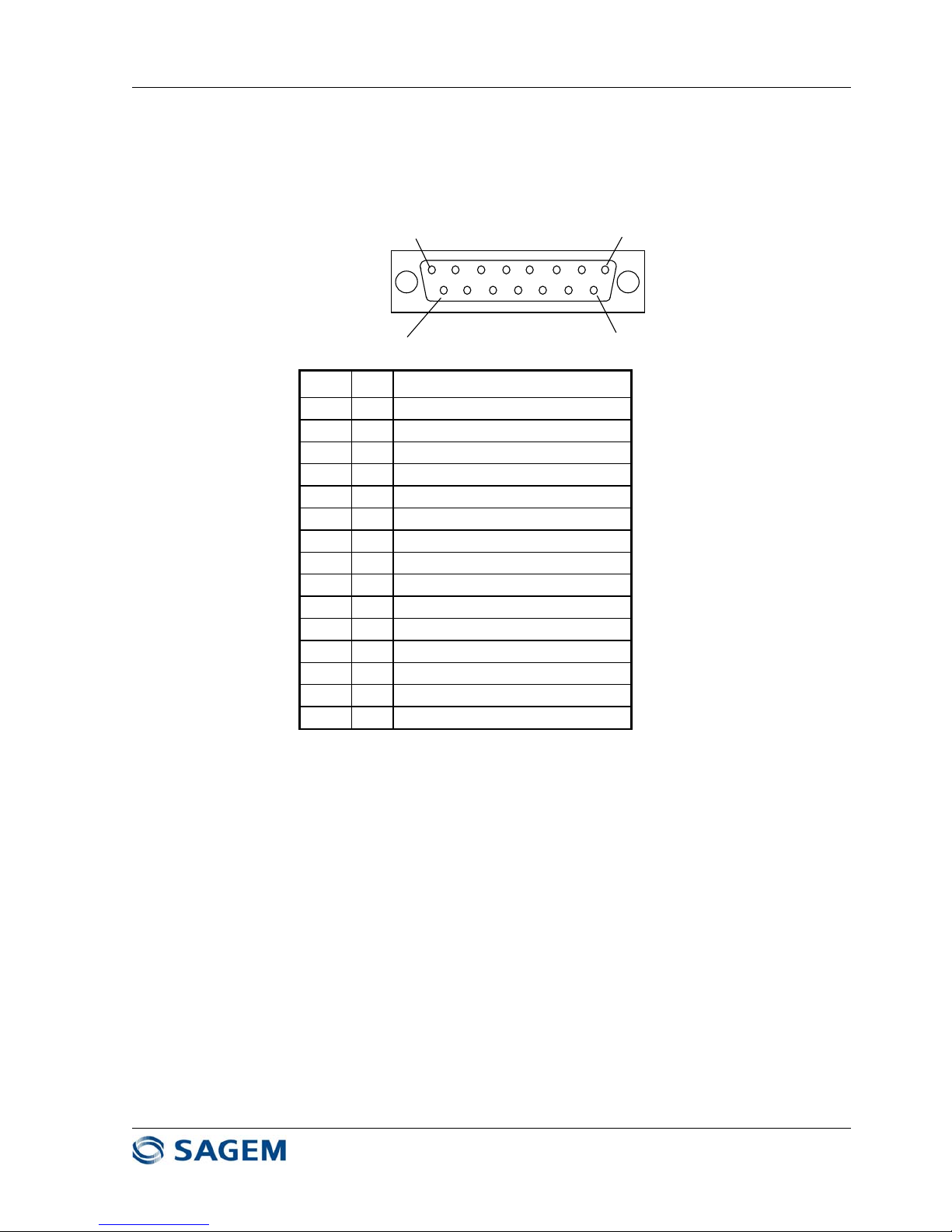

64 kbit/s Auxiliary Data Channel (AUX3)

The 64 kbit/s auxiliary data channel connector "AUX3" is available in a DB 15 connector on the rear

panel.

This data channel can be configured in a V11 co-directional mode (transmit clock given by the

external equipment) or in a V11 contra-directional mode (transmit clock given by SAGEM LINK F) :

Aux3 Connector pinout is given in Figure 1.24

1

8

9

15

Pin # I/O Signal

1 I Byte Timing Input (-)

9 I Transmit Data Input (-)

2 I Byte Timing Input (+)

10 I/O Transmit Clock (-)

3 O Byte Timing Output (-)

11 I/O Transmit Clock (+)

4 O Receive Data (+)

12 O Receive Clock (+)

5 O Receive Data (-)

13 O Receive Clock (-)

6 O Byte Timing Output (+)

14 - Ground

7 - Ground

15 - NC

8 I Transmit Data Input (+)

Figure 1.24 – Aux3 Data Channel Connector Pinout

Page 31

SAGEM-LINK F 288055571-04

Installation and Operation Manual

Page 31/142

Issue 04 : July 2005

Reproduction and communication prohibited without the written permission of Sagem Communication

9600 bit/s Auxiliary Data Channel (AUX1 & Aux2)

The 9600 bit/s auxiliary data channels "AUX1" and AUX2 are connected to two DB 9 connectors on

the rear panel.

This data channels can be configured either in a DCE V11 interface, or V28 interface (compliant to

EIA 574 standard). Depending on the interface, connector pinout is given on Figure 1.25

15

96

Pin # V11 Interface V28 Interface

1 Ground Ground

6NC NC

2 Output Data – (+) Output Data

7 Output Data – (-) NC

3 Input Data – (+) Input Data

8 Input Data – (-) NC

4NC NC

9NC NC

5 Ground Ground

Figure 1.25 – Aux1 or Aux2 Data Channel Connector Pinout

Serial Management Interface Ports MGMT1 and MGMT2

Serial management interface ports MGMT1 and MGMT2 are available in two DB25 connectors located

on the rear panel.

Data rate available : 9600 bit/s up to 115200 bit/s.

MGMT1 port can be configured in two modes :

- V11 synchronous mode (EIA 530)

- V28 asynchronous mode (ISO 2110)

MGMT1 port can be connected to a modem (RTS, CTS, DTR, DSR and DCD available).

MGMT2 port is not configurable, and is only available in V11 synchronous mode and X24/V11. When it

is used in X24 mode, this interface is a DCE type (terminal mode).

Connector pinout is given in Figure 1.26

Page 32

SAGEM-LINK F 288055571-04

Installation and Operation Manual

Page 32/142

Issue 04 : July 2005

Reproduction and communication prohibited without the written permission of Sagem Communication

1

25

14

13

Pin # V11 Mode V28 Mode (MGMT1 only)

1 Ground Ground

14 Transmit Data – (-) NC

2 Transmit Data – (+) Transmit Data

15 Transmit Clock – (-) NC

3 Receive Data – (+) Receive Data

16 Receive Data – (-) NC

4 NC Request to Send

17 Receive Clock (+) NC

5 NC Clear to Send

18 NC NC

6 NC DCE Ready

19 NC NC

7 Ground Ground

20 NC DTE Ready

8NC NC

21 NC NC

9 Receive Clock (-) NC

22 NC NC

10 NC NC

23 NC NC

11 NC NC

24 NC NC

12 Transmit Clock (-) NC

25 NC NC

13 NC NC

Figure 1.26 – MGMT1 and MGMT2 Management Ports Connector Pinout

Page 33

SAGEM-LINK F 288055571-04

Installation and Operation Manual

Page 33/142

Issue 04 : July 2005

Reproduction and communication prohibited without the written permission of Sagem Communication

Cable References for SAGEM LINK F

The cables which can be connected to the IDU front panel are shown in Figure 1.27.

To Other IDU

Ethernet straight or crossed cables

To PC /LT

To ODU

or

IDU to ODU c able

(Balanced or Unbalanced )

2 Mbit/s In/Out Cable

To Distribution Panel

Ethernet straight or crossed cable

To Network

Manager

(Network Management)

Telephone Handset

To DC Power

Source

Straight cable

Crossed cable

To modem

12 21

20

13

9

5 24 30

21

20

On

Of

f

POWER

Figure 1.27 – Cables for a Terminal Station – Front Panel

The cables which can be connected to the IDU rear panel are shown in Figure 1.28.

AUX3 Data Channel Cable

To Distribution

Panel

14

6

37

7

MGMT2

Aux2

Aux1

MGMT1

AUX3

ALARM RELAYS & DRY LOOPS

OR

To PC

15

T

o Distribution

Panel

Alarm Relays & Dry Loops Cable

To Distribution

Panel

O

R

To EOW 300

Figure 1.28 – Cables for a Terminal Station – Rear Panel

In a relay station IDU are connected "back to back". Typical connection is given on Figures 1.29 and 1.30

Page 34

SAGEM-LINK F 288055571-04

Installation and Operation Manual

Page 34/142

Issue 04 : July 2005

Reproduction and communication prohibited without the written permission of Sagem Communication

Transfer 2 Mbit/s In/Out Cable

36

Relay statio n Ethernet Cable

21

s

s

Figure 1.29 – Cables for a relay station – Front Panel

MGMT1-MGMT2 Trans fer Cable

19

Aux1/Aux2 Dat a ChannelTransf er Cable

8

Aux3 Data Channel Transfer Cable

18

Figure 1.30 – Cables for a relay station – Rear Panel

Table 1.1 indicates Sagem Part Number for all cables for this IDU (terminal or relay modes).

Figure

item

Drawing # Designation Length SAGEM P/N

2.5 m 55670225

9 55050152EA - DC Power cable 5 m 55670226

12 m 55670227

25 m 55670228

2.5 m 55670182

5 55050138EA

- 2 Mbit/s tributary 120 Ω In/Out cable

5 m 55670183

12 m 55670184

24.8 m 55670185

55670563EA

- 2 Mbit/s tributary 75 Ω In/Out cable

2.5 m 55670563-2M5

30 DB25 – 8 BNC-F 5 m 55670563-5M0

12 m 55670563-12M

25 m 55670563-25M

60 m 251043775

55670405EA

- 2 Mbit/s tributary 75 Ω In/Out cable

2.5 m 55670405-2M5

24 DB25 – 8 BNC-M 5 m 55670405-5M0

12 m 55670405-12M

25 m 55670405-25M

12 55050156EA

- PC/LT connection cable

1.5 m 55670223

3 m 55670224

13 55050184EA - Modem connection cable 1.5 m 55670340

3 m 55670341

2.5 m 55670342

14 55050185EA

- Aux3 data channel cable to disc. Panel

5 m 55670343

12 m 55670344

25 m 55670345

6 55050149EA - Aux3 - EOW 300 channel cable 1.5 m 55670221

3 m 55670222

Page 35

SAGEM-LINK F 288055571-04

Installation and Operation Manual

Page 35/142

Issue 04 : July 2005

Reproduction and communication prohibited without the written permission of Sagem Communication

Figure

item

Drawing # Designation Length SAGEM P/N

18 55050189EA - AUX3 data channel transfer cable 1.5 m 55670352

3 m 55670022

36 - Crossed 2 Mbit/s tributary transfer cable 2.5 m 251027429

2.5 m 55670215

7 55050150EA - Aux1/Aux2 - Data channel cable 5 m 55670216

to distribution panel 12 m 55670217

25 m 55670218

15 55670420EA - Aux1/Aux2 - PC connection cable 1.5 m 55670420-1M5

3 m 55670420-3M0

8 55050151EA - AUX1/AUX2 data channel transfer cable 1.5 m 55670219

3 m 55670220

2.5 m 251378024

37 251389233EA - Alarm relays and dry loops cable to 5 m 251378037

Distribution panel (DB37) 12 m 251378045

24.8 m 251378058

20 - Straight ETHERNET cable (NMI/NMI 1.5 m 55670421

transfer or to manager) 3 m 55670422

21 - Crossed ETHERNET cable (NMI/NMI 1.5 m 55670423

transfer or to manager) 3 m 55670424

19 55050190EA - MGMT1 - MGMT2 transfer cable 1.5 m 55670354

3 m 55670355

Table 1.1 – Cables Part Numbers

Page 36

SAGEM-LINK F 288055571-04

Installation and Operation Manual

Page 36/142

Issue 04 : July 2005

Reproduction and communication prohibited without the written permission of Sagem Communication

Chapter 2

Commissioning

2.1 - Overview

This chapter explains how to verify Sagem Link F correct operation after installation. Testing

procedures are given in order to check radio system is operating according to the specifications.

The tests performed are :

• Frequency Scan

• Receive Signal Level

• Tributary Tests

• Engineering Order Wire (optional)

• Alarm Relays and I/O Dry Loops Test (optional)

• 1+1 Verification (optional)

• BER measurement

Required test equipment

• Laptop Computer with a serial interface

• Sagem Link F Pilot software

• 2 Mbit/s Bit Error Rate Analyzer

• Digital voltmeter

Sagem Link F Field Commissioning Form

A field commissioning form is provided in order to record all measurement data and remarks during

commissioning operation.

Note

The Bit Error Rate tests are made only with the 2 Mbit/s signals. For IDU using Ethernet option, it will

be necessary to choose a configuration with at least one 2 Mbit/s tributary available. Refer to Chapter

6 for more details.

2.2 - Preliminary Verifications

Before beginning commissioning tests, it is necessary to check the following :

• Verify all equipment for damage occurred during installation

• Verify that all equipments are properly mounted

• Verify antenna polarization

• Check ODU, cable and IDU groundings

• Measure DC Input Voltage on each terminal and record it on the commissioning form

• Connect laptop computer to the PC DB9 connector on the IDU front panel, and run the Sagem

Link F Pilot software. Be sure to be logged in super user mode (Default password = 2345). On

the main screen verify and change if necessary :

- Local and Remote terminal transmit frequency

- Modulation type and Capacity

- Local and Remote terminal nominal transmit power, ATPC should be in “OFF” position

- Tributary Impedance

Page 37

SAGEM-LINK F 288055571-04

Installation and Operation Manual

Page 37/142

Issue 04 : July 2005

Reproduction and communication prohibited without the written permission of Sagem Communication

- Link ID Code

- If there is a tributary alarm, verify tributary inputs configuration and connections.

- If there are other alarms, or if the link does not work, refer to the troubleshooting section

in this manual

Note any discrepancy in the field commissioning form.

2.3 - Frequency Scan

A special function of the Pilot software is to measure and to record automatically the receive spectrum

around receive frequency. This operation is done on the local terminal only. During frequency scan

process, local transmitter is in mute position, so the link is not operating.

This measurement allows the user to measure interferer levels around receive frequency and to

display it graphically. A record of this measurement is stored in the flash memory, and can be

consulted after installation. In order to check interferer level at receive frequency, it could be

necessary to mute the remote transmitter.

Refer to frequency scan procedure in chapter 3 section 3.3.7.6.

Frequency scan is to be done separately on each end of the link.

Note in the commissioning form the presence of interferers close to the receive signal (adjacent and

second adjacent)

2.4 - Receive Signal Level

In normal weather conditions, the receive signal level depends on :

• Remote Transmit Power (tolerance : ± 2 dB)

• Remote and Local antenna gains (tolerance : ± 1 dB each)

• Free Space Path Attenuation

• Coupler Losses for a 1+1 Hot Stand By system, or flex guide losses for a remote mount system

Compare the actual receive signal level displayed on the main screen of the Pilot software, with the

expected signal level.

As the tolerances are:

• ± 2 dB for the transmit power

• ± 1 dB for the antenna gain (per antenna)

• ± 3 dB for the receive level measurement

• ± 0.5 dB for 1+1 coupler losses

If we want to compare the receive level displayed with the expected calculated receive level, it is

necessary to take in account the tolerances for each parameter :

For a 1+0 system, the worst case for this comparison is within ±7 dB (±2 ±1 ±1 ± 3). For most of the

cases, a typical tolerance is ±5 dB.

So, if the receive level displayed by the Pilot software is less than 5 dB compared to the calculated

receive level, it should be necessary to check again antenna alignment, a propagation problem or a

wrong polarization first. If there is still a problem on the receive level, replace ODU, then IDU, and if

necessary the antenna.

Record the measured receive signal level at each end of the link for each receiver.

Page 38

SAGEM-LINK F 288055571-04

Installation and Operation Manual

Page 38/142

Issue 04 : July 2005

Reproduction and communication prohibited without the written permission of Sagem Communication

2.5 - Tributary Tests

These tests are to be done on both ends of the link.

Using a BER analyzer with G821 capability, test all used 2 Mbit/s access.

BER Analyzer Settings :

• Transmit to Receive test

• 2 Mbit/s

• Internal Clock

• PRBS : 2

15

-1.

• 120 Ohm balanced, or 75 Ohm unbalanced depending on IDU configuration.

All used tributaries are to be tested one by one :

• Click on the button

(top left of the toolbar on main screen) or use the menu : "Tools /

Tributaries". The tributary screen appears.

• Verify that the tributary under test is configured in normal mode (N), with active service

(A), and no loopback (blank button).

• All other tributaries should be unconnected and configured as inverted (I)

• Normally there should be a local tributary alarm.

• Connect a 2 Mbit/s BER analyzer on the tributary input. Be sure to use a cable in the same

impedance (refer to "Interface" indication). The tributary alarm should be now cleared.

• Click on the loopback button to have access to loopback configuration screen, and select a

remote loopback for the tributary under test. (For loopback procedure refer to Chapter 3,

section 3.2.4).

• Verify on the BER analyzer that there is no error occurred during one minute

• Once the test has been done, disconnect the cable, and change Data alarm in invert mode

(I), and remove remote loopback for this tributary.

• Repeat this test for all used tributaries.

Page 39

SAGEM-LINK F 288055571-04

Installation and Operation Manual

Page 39/142

Issue 04 : July 2005

Reproduction and communication prohibited without the written permission of Sagem Communication

2.6 - Engineering Order Wire Test (optional)

If the handsets have been ordered, the following test is made to verify EOW proper operation. This

test requires the presence of people in local and in remote station. Connect handset in each IDU of

the link (RJ11 connector)

• From the local terminal press on the call button (PRESS). At the remote end the green led

corresponding to the EOW flashes. Verify that audio communication is operating properly

• Make the same test from the remote terminal.

2.7 - Alarm Relays and I/O Dry Loops Test (optional)

When alarm relays and I/O dry loops are used in the site, perform the following tests to verify proper

alarm operation.

This test is to be done on each end of the link.

Before starting the test verify that there is no alarm displayed in the equipment.

It is not possible to simulate all possible alarms without opening equipment : for instance, simulating a

Tx frequency alarm would require to open the ODU and to disturb externally the synthesizer phase

lock loop. However some alarms can be simulated with simple operations :

2.7.1 - Simulating an IDU Alarm

An IDU alarm could be easily simulated by entering a wrong Link ID code in the local terminal. This

wrong ID Code generates an IDU alarm, but does not affect modem or radio operation. To simulate an

IDU alarm :

• Remove DC Power on the local terminal, and disconnect IDU to ODU cable

• Power up the IDU, and change local ID Code.

• Switch off again DC power and connect IDU to ODU cable

• Switch on the IDU. Once the IDU is properly initialized, there should be an IDU alarm

displayed.

•

Once the test has been done, do not forget to write the right Link ID code using the same procedure.

2.7.2 - Simulating an ODU Alarm

An ODU alarm can be obtained by removing IDU to ODU cable. Prior to removing ODU cable, it is

necessary to switch off the cable interface module.

2.7.3 - Simulating a Tributary Alarm

A tributary alarm is obtained by changing the status of one tributary from normal (N) to invert (I), or

from invert to normal.

Once the test has been done, do not forget to restore the previous configuration.

2.7.4 - Simulating a RSL Alarm

To simulate a RSL Alarm, it should be necessary to diminish remote transmit power and to increase

RSL alarm threshold. (ATPC off).

Change the RSL alarm threshold to -60 dBm.

Page 40

SAGEM-LINK F 288055571-04

Installation and Operation Manual

Page 40/142

Issue 04 : July 2005

Reproduction and communication prohibited without the written permission of Sagem Communication

Decrease slowly remote transmit power in order to have a receive level below –60 dBm. Take care to

avoid to break the link, because in this case, it will not be possible to establish again communication

from the local terminal.

Once the test has been done, do not forget to restore previous settings.

2.7.5 - Simulating a Custom Alarm

To simulate a Custom alarm, configure " Local Aux1 Alarm" on the "Custom relay" (use the menu

Alarms / Config / Local, and select the IDU tab).

Then short circuit pins 2 and 20 of the DB37 connector (LOOP INPUT #1 – A and LOOP INPUT #1 –

B).

The alarm is displayed in the screen Alarm/View/Local - ALL tab. Verify that the alarm is cleared

when the loop is in open position.

2.7.6 - Testing Input Dry Loops

Affect " Local Aux1 Alarm", " Local Aux2 Alarm", " Local Aux3 Alarm" and " Local Aux4 Alarm" on the

Custom relay, and verify the alarm changes by short-circuiting or opening the loops.

2.7.7 - Testing Alarm Relays

For this test, it is necessary to use a multimeter to check continuity between contacts.

The three contacts of each relay are available in the DB 37 connector (see Figure 2.1) :

Normally Open (NO)

Normally Closed (NC)

Common

Figure 2.1 : Relay Contacts

When the IDU is not powered, the NC is connected to the Common, while the NO is in open position.

When the IDU is powered and when there is no alarm :

• NO is connected to Common

• NC is not connected to Common

When there is an alarm on the relay under test (use the above procedure to simulate alarms) :

• NC is connected to Common

• NO is not connected to Common

Simulate various alarms, and test the corresponding relays upon this procedure.

Page 41

SAGEM-LINK F 288055571-04

Installation and Operation Manual

Page 41/142

Issue 04 : July 2005

Reproduction and communication prohibited without the written permission of Sagem Communication

2.8 - 1+1 Verification (optional)

1+1 systems require additional tests compared to unprotected systems. These tests are made to verify

main and stand by units, and switches proper operation.

These tests are made on both sides of the link. As a remote switch control is not available for security

reasons, this test may require the presence of people on both sides of the link.

In hot standby mode, only one transmitter is active at a time. For a 1+1 system in frequency diversity

mode, both transmitter are active, and only receiver switchings are to be made.

In normal operation with revertive switching on, and without any alarms, the active transmitters and

receivers are the main units.

Du to the use of an asymmetrical coupler, the transmit power at antenna access and the receive

signal level at ODU access depend on the switches positions. For a 6 dB coupler, the difference

between the main and standby unit is around 5 dB.

In the figures below, active transmitter and receiver are written in bold characters.

Tx Main (L)

Rx Main (L)

Tx Standby (L)

Rx Standb y (L)

Tx Main (R)

Rx Main (R)

Tx Standby (R)

Rx Standby (R)

Figure 2.2 : Main local transmitter and receiver active

From the local terminal, connect a BER analyzer on a 2 Mbit/s tributary and make a remote loopback

for this tributary. There should not be any error during one minute.

From the local terminal in super user mode, select the menu "Tools/Diagnostic Tools/Equipment

Forcing" to access to the manual switching mode (refer to Chapter 3 section 3.3.7.2).

Select standby receiver by clicking on the Rx2 case, and validate.

Tx Main (L)

Rx Main (L)

Tx Standby (L)

Rx Standby (L)

Tx Main (R)

Rx Main (R)

Tx Standby (R)

Rx Standby (R)

Figure 2.3 : Main local transmitter and standby local receiver active

This switching should be error free. Wait one minute to verify the transmission is error free.

From the local terminal, in the same menu, select standby transmitter by clicking on the case "Tx2".

This switching causes errors. However the switching time should be less than 2 seconds (less than 2 x

10

6

errors).

Page 42

SAGEM-LINK F 288055571-04

Installation and Operation Manual

Page 42/142

Issue 04 : July 2005

Reproduction and communication prohibited without the written permission of Sagem Communication

Tx Main (L)

Rx Main (L)

Tx Standby (L)

Rx Standby (L)

Tx Main (R)

Rx Main (R)

Tx Standby (R)

Rx Standby (R)

Figure 2.4 : Standby local transmitter and receiver active

Clear the counter, and verify there is no error occurred during one minute.

If a revertive switch is used, from the local terminal select "Auto" for both transmitter and receiver.

Main local ODU should be now active.

If there is no revertive switch selected, select Rx1 and Tx1 in manual mode and validate. Then click on

the "Auto" cases.

The system is now in automatic mode, and the maintenance LED should be off.

Note : During transmitter switch from standby to main, errors are also generated.

Use the same procedure from the remote end of the link.

Page 43

SAGEM-LINK F 288055571-04

Installation and Operation Manual

Page 43/142

Issue 04 : July 2005

Reproduction and communication prohibited without the written permission of Sagem Communication

2.9 - BER Measurement

This test is to be done from one side of the link with all tributaries linked with a daisy chain

arrangement as described in Figure 2.5 and Figure 2.6.

In case of a problem due to an interferer, it should be necessary to measure the two directions

separately and to proceed to a frequency scan.

For a 1+1 system, as the verification of the different units have already been made, the quality test

shall be performed only with main channels (automatic mode).

A BER test using G821 parameters shall be performed for a duration depending on the network :

• 30 minutes for low capacity links (GSM, Wifi,…)

• 24 hours for medium and high capacity links

An other amount of time could be used for this test, but this will require Sagem approval.

Figure 2.5 : Link Quality Measurement

.

Page 44

SAGEM-LINK F 288055571-04

Installation and Operation Manual

Page 44/142

Issue 04 : July 2005

Reproduction and communication prohibited without the written permission of Sagem Communication

Figure 2.6 : Tributary daisy chain connections

The BER tester shall be configured as follows :

• 2 Mbit/s data rate, HDB3, with a 2

15

-1 sequence, using the same impedance than selected

in the IDU.

• Run the test for the required amount of time

• Depending on the BER tester used, results could be transferred electronically to the PC via

a serial port in a file. If it is not possible, the results shall be printed on paper.

Once all these tests have been completed, do not forget to remove tributary daisy chain arrangement.

The system is now ready to operate with traffic connected. If any test have failed to meet specifications,

consult the troubleshooting chapter in this manual.

2.10 - Recording Configuration Information

This procedure explain how to get all necessary information from SAGEM LINK F equipment to be

attached with Sagem Link F Field Commissioning Form.

Connect the computer to the local IDU and run the Sagem Link F Pilot software in super user mode

(default password : "2345")

Link Configuration Information :

From the main screen, open the menu "Configuration/Print", this screen appears :

Check all cases

Select File

Validate

Save the file in the PC using a name including site names :

Page 45

SAGEM-LINK F 288055571-04

Installation and Operation Manual

Page 45/142

Issue 04 : July 2005

Reproduction and communication prohibited without the written permission of Sagem Communication

"Name of local site – Name of Remote site.txt".

This file is a text file describing local and remote configuration, with information regarding hardware

and software involved (part numbers, manufacturing date, versions…).

Saving Local and Remote Configuration

Local and remote configurations can be saved in data files. In case of a replacement of a unit,

previous configuration can be restored easily.

To save local or remote configuration use the menu, :

"Configuration/Save as/Local or Remote". Chose a name for the configuration files like :

"Name of local site – Name of Remote site.slf", for the local terminal and

"Name of Remote site – Name of Local site.slf", for the remote terminal.

Page 46

SAGEM-LINK F 288055571-04

Installation and Operation Manual

Page 46/142

Issue 04 : July 2005

Reproduction and communication prohibited without the written permission of Sagem Communication

S

SAGEM LINK F

Field Commissioning Form

Page 1/2

Customer Information :

Link Name :

Date :

Terminal Configuration :

1+0 1+1 HSB 1+1 SD 1+1 FD

Capacity / Modulation :

2xE1 / QPSK 4xE1 / QPSK 8xE1 / QPSK

16xE1 / QPSK 8xE1 / 16QAM 16xE1 / 16QAM

Local Site Remote Site

Name : Name :

Antenna Type : Antenna Type :

IDU to ODU Cable Length : IDU to ODU Cable Length :

Transmit Frequency : Transmit Frequency :

TEST DATA

Local Site Remote Site

Input DC Voltage : VDC Input DC Voltage : VDC

RSL at ODU access (dBm) RSL at ODU access (dBm)

Measured Expected Difference Measured Expected Difference

Main Main

Standby Standby

Tributary Tests : Pass Fail Tributary Tests : Pass Fail

E.O.W. * : Pass Fail E.O.W. * : Pass Fail

Alarms & Loops* : Pass Fail Alarms & Loops* : Pass Fail

1+1 Operation* : Pass Fail 1+1 Operation* : Pass Fail

Bit Error Tests Bit Error Tests

Test Duration :

Number of Errors :

Pass Fail

* Note : Optional

Page 47

SAGEM-LINK F 288055571-04