Page 1

FP5/GP5

efesotomasyon.com - Control Techniques,emerson,saftronics -ac drive-servo motor

TECHNICAL MANUAL

Page 2

efesotomasyon.com - Control Techniques,emerson,saftronics -ac drive-servo motor

Page 3

PREFACE

•

•

•

efesotomasyon.com - Control Techniques,emerson,saftronics -ac drive-servo motor

Saftronics’ FP5/GP5 is the world’s first optimized Inverter specifically designed for general-purpose applications. This manual describes

installation, maintenance and inspection, troubleshooting, and specifications of the FP5/GP5. Read this manual thoroughly before operation.

General Precautions

Some drawings in this manual are shown with the protective cover or shields removed, in

order to describe detail with more clarity. Make sure all covers and shields are replaced

before operating this product.

This manual may be modified when necessary because of improvement of the product,

modification, or changes in specifications. Such modifications are denoted by a revision

number.

• To order a copy of this manual, contact your Saftronics representative.

Saftronics is not responsible for any modification of the product made by the user, since that

will void your warranty.

Page 4

PREFACE

•

efesotomasyon.com - Control Techniques,emerson,saftronics -ac drive-servo motor

Notes for Safe Operation

Read this manual thoroughly before installation, operation, maintenance or inspection of the FP5/GP5. In this manual, notes for safe

operation are classified as followed:

WARNING

CAUTION

Even items described in CAUTION may result in a fatal accident in some situations. In either case, follow these important notes.

Take the following steps to ensure proper operation.

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury

to personnel.

Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury

to personnel and damage to equipment. It may also be used to alert against unsafe practices.

§ Receiving

CAUTION

Do not install or operate any Inverter that is damaged or has missing parts. Failure to observe this may

result in personal injury or equipment damage.

§ Installation

CAUTION

• When moving the unit, lift the cabinet by the base, never lift by the front cover. Otherwise, the main unit

may be dropped causing damage to the unit.

• Mount the Inverter on nonflammable material (i.e., metal). Failure to observe this can result in a fire.

• When mounting units in an enclosure, install a fan or other cooling device to keep the intake air

temperature below 45°C. Overheating may cause a fire or damage the unit.

Page

2

Page

6

6

6

§ Wiring

WARNING

• Only commence wiring after verifying that the power supply is turned OFF. Failure to observe this

warning can result in an electrical shock or fire.

• Wiring should be performed only by qualified personnel. Failure to observe this warning can result in an

electrical shock or fire.

• When wiring the emergency stop circuit, check the wiring thoroughly before operation. Failure to

observe this warning can result in personal injury.

• Make sure to ground the ground terminal ( ). (Ground resistance 200V class: 100Ω or less, 400V

class: 10Ω or less.) Failure to observe this warning can result in an electrical shock or fire.

Firmware – S2011 and S3012

Revision: 1 (9/98) ii © Saftronics, Inc.

Page

10

10

10

11

Page 5

PREFACE

efesotomasyon.com - Control Techniques,emerson,saftronics -ac drive-servo motor

CAUTION

• Verify that the Inverter rated voltage coincides with the AC power supply voltage. Failure to observe this

can result in personal injury or fire.

• Do not perform a withstand voltage test on the Inverter. It may cause semi-conductor elements to be

damaged.

• To connect a Braking Resistor, Braking Resistor Unit or Braking Unit, follow the procedures described in

Chapter 11. Improper connection may cause a fire.

• Tighten terminal screws to the specified tightening torque. Failure to observe this can result in a fire.

• Never connect the AC main circuit power supply to output Terminals T1, T2, and T3 (U, V, and W). The

Inverter will be damaged and invalidate the warranty.

§ Operation

WARNING

• Only turn ON the input power supply after replacing the front cover. Do not remove the cover while

current is flowing. Failure to observe this can result in an electrical shock.

• When the retry function (n057) is selected, do not approach the Inverter or the load, since it may restart

suddenly after being stopped. (Construct machine system, so as to assure safety for personnel, even if

the Inverter should restart.) Failure to observe this can result in personal injury.

• Since the stop button can be disabled by a function setting, install a separate emergency stop switch.

Failure to observe this can result in personal injury.

Page

10

10

10

10

11

Page

24

24

24

CAUTION

• Never touch the heatsink or discharging resistor since the temperature is very high. Failure to observe

this can result in harmful burns to the body.

• Since it is easy to change operation speed from low to high speed, verify the safe working range of the

motor and machine before operation. Failure to observe this can result in personal injury and machine

damage.

• Install a holding brake separately, if necessary. Failure to observe this can result in personal injury.

• Do not change signals during operation. The machine or the Inverter may be damaged.

• All the constants of the Inverter have been preset at the factory. Do not change the settings

unnecessarily. The Inverter may be damaged. For supply voltage, follow Paragraph 4.3 of Chapter 4.

Page

24

24

24

24

24

Firmware – S2011 and S3012

Revision: 1 (9/98) iii © Saftronics, Inc.

Page 6

PREFACE

•

efesotomasyon.com - Control Techniques,emerson,saftronics -ac drive-servo motor

§ Maintenance and Inspection

WARNING

• Never touch high-voltage terminals in the Inverter. Failure to observe this can result in an electrical

shock.

• Replace all protective covers before powering up the Inverter. To remove the cover, make sure to shut

OFF the Molded Case Circuit Breaker. Failure to observe this can result in an electrical shock.

• Perform maintenance or inspection only after verifying that the CHARGE LED goes OFF, after main

circuit power supply is turned OFF. The capacitors are still charged and can be dangerous.

• Only authorized personnel should be permitted to perform maintenance, inspections or parts

replacement. (Remove all metal objects (watches, bracelets, etc.) before operation. Use tools that are

insulated against electrical shock.) Failure to observe this can result in an electrical shock.

CAUTION

• The control PC board employs CMOS ICs. Do not touch the CMOS elements. They are easily damaged

by static electricity.

• Do not connect or disconnect wires or connectors while power is applied to the circuit. Failure to observe

this can result in personal injury.

Page

64

64

64

64

Page

64

64

§ Others

WARNING

Never modify the product. Failure to observe this can result in an electrical shock or personal injury and

will invalidate the warranty.

Firmware – S2011 and S3012

Revision: 1 (9/98) iv © Saftronics, Inc.

Page 7

Table of Contents

efesotomasyon.com - Control Techniques,emerson,saftronics -ac drive-servo motor

1 Receiving .............................................................................................. 1

1.1 Inspection Checkpoints.................................................................................. 2

1.2 Identifying the Parts....................................................................................... 2

2 Installation ............................................................................................ 5

2.1 Removing and Replacing the Digital Operator................................................ 6

2.2 Removing and Replacing the Front Cover...................................................... 7

2.3 Choosing a Location to Mount the Inverter..................................................... 7

2.4 Clearances .................................................................................................... 8

3 Wiring .................................................................................................... 9

3.1 Connection Diagram...................................................................................... 10

1.1.1 Receiving Checkpoints........................................................................................................ 2

1.1.2 Checking the Nameplate Data............................................................................................ 2

2.1.1 Removing the Digital Operator .......................................................................................... 6

2.1.2 Replacing the Digital Operator............................................................................................ 6

3.2 Wiring the Main Circuit................................................................................... 11

3.2.1 Wiring Precautions for Main Circuit Point ........................................................................... 11

3.2.2 Wiring Precautions for Main Circuit Output........................................................................ 12

3.2.3 Grounding............................................................................................................................ 12

3.2.4 Functions of Main Circuit Terminals................................................................................... 13

3.2.5 Main Circuit Configuration................................................................................................... 15

3.2.6 Parts Required for Wiring.................................................................................................... 17

3.3 Wiring the Control Circuit............................................................................... 21

3.3.1 Functions of Control Circuit Terminals ............................................................................... 21

3.3.2 Wiring the Control Circuit Terminals................................................................................... 22

3.3.3 Precautions on Control Circuit Wiring................................................................................. 22

3.4 Wiring Inspection........................................................................................... 22

4 Operation .......................................................................................... 23

4.1 Operation Mode Selection.............................................................................. 25

4.2 Test Run Checkpoints.................................................................................... 26

4.3 Setting the Line Voltage Using Jumper (For 400V Class 18.5kW and Above). 26

4.4 Test Run........................................................................................................ 27

4.4.1 Digital Operator Display at Power-Up................................................................................. 27

4.4.2 Operation Check Points...................................................................................................... 28

4.4.3 Example of Basic Operation ............................................................................................... 28

5 Simple Data Setting.............................................................................. 31

5.1 Digital Operator Key Description.................................................................... 32

5.2 LED Description............................................................................................. 32

6 Programming Features ........................................................................ 35

6.1 Constant Set-Up and Initialization.................................................................. 36

6.1.1 Constant Selection/Initialization (n001).............................................................................. 36

6.2 V/f Pattern Setting.......................................................................................... 36

6.2.1 Preset V/f Pattern................................................................................................................ 37

6.2.2 Custom V/f Pattern.............................................................................................................. 38

6.3 Setting Operation Conditions ......................................................................... 38

Firmware – S2011 and S3012

Revision: 1 (9/98) v © Saftronics, Inc.

6.3.1 Reverse Run Prohibit (n006) .............................................................................................. 38

6.3.2 Multi-Step Speed Selection................................................................................................. 38

6.3.3 Operation at Low Speed ..................................................................................................... 39

6.3.4 Adjusting Frequency Setting Signal.................................................................................... 40

6.3.5 Adjusting Frequency Upper and Lower Limits ................................................................... 41

Page 8

6.3.6 Using Two Accel/Decel Times............................................................................................ 41

efesotomasyon.com - Control Techniques,emerson,saftronics -ac drive-servo motor

6.3.7 Automatic Restart after Momentary Power Loss (n051) ................................................... 42

6.3.8 Soft-Start Characteristics (n023)........................................................................................ 42

6.3.9 Torque Detection................................................................................................................. 43

6.3.10 Frequency Detection (n073)............................................................................................... 44

6.3.11 Jump Frequencies (n058 to n060) ..................................................................................... 44

6.3.12 Continuing Operation by Automatic Fault Reset (n056).................................................... 45

6.3.13 Operating Coasting Motor without Trip .............................................................................. 45

6.3.14 Using Frequency Meter of Ammeter (n048)....................................................................... 46

6.3.15 Calibrating Frequency Meter of Ammeter (n049) .............................................................. 46

6.3.16 Reducing Motor Noise or Leakage Current (n050)............................................................ 47

6.4 Selecting Stopping Method ............................................................................. 48

6.4.1 Selecting Stopping Method (n004)..................................................................................... 48

6.4.2 Coast to Stop with Timer 1 (n004=2) ................................................................................. 49

6.4.3 Applying DC Injection Braking Current (n064)................................................................... 49

6.5 Building Interface Circuits with External Devices............................................. 50

6.5.1 Using Sequence Input Signals (n035 to n039).................................................................. 50

6.5.2 Using Analog Input Signals (n042 to n045) ....................................................................... 53

6.5.3 Using Output Signals (n040, n041).................................................................................... 55

6.6 Setting Operation Conditions.......................................................................... 56

6.6.1 Torque Compensation Gain (n067).................................................................................... 56

6.7 Motor Protection ............................................................................................. 57

6.7.1 Motor Overload Detection................................................................................................... 57

6.8 PID Control .................................................................................................... 58

6.8.1 Intended Value Setting........................................................................................................ 58

6.8.2 Detected Value Setting....................................................................................................... 58

6.9 Energy Saving Control ................................................................................... 59

6.9.1 Energy Saving Gain K2 (n096)........................................................................................... 59

6.9.2 Energy Saving Tuning......................................................................................................... 59

6.10 MEMOBUS Control........................................................................................ 60

6.10.1 Communication Specifications ........................................................................................... 60

6.10.2 Data to be Sent/Received by Communication................................................................... 60

7 Maintenance and Inspection................................................................ 63

7.1 Periodic Inspector .......................................................................................... 64

7.2 Parts Replacement Schedule (Guidelines)...................................................... 64

8 Troubleshooting.................................................................................... 65

8.1 Fault Diagnosis and Corrective Actions .......................................................... 66

8.2 Alarm Display and Explanation....................................................................... 69

8.3 Motor Faults and Corrective Actions............................................................... 70

9 Specifications........................................................................................ 71

9.1 Standard Specifications .................................................................................. 72

10 Dimensions............................................................................................ 75

10.1 Dimensions .................................................................................................... 76

11 Typical Connection Diagram................................................................ 79

11.1 Braking Resistor Unit...................................................................................... 80

11.2 Braking Unit and Braking Resistor Unit........................................................... 81

12 Constant List .........................................................................................83

12.1 Constant List.................................................................................................. 84

13 Digital Operator Monitor Display ......................................................... 91

13.1 Digital Operator Monitor Display..................................................................... 92

INDEX................................................................................................................ 95

Firmware – S2011 and S3012

Revision: 1 (9/98) vi © Saftronics, Inc.

Page 9

1

efesotomasyon.com - Control Techniques,emerson,saftronics -ac drive-servo motor

Receiving

This chapter describes how to inspect the inverter after delivery to the user.

1.1 Inspection Checkpoints.................................................. 2

1.1.1 Receiving Checkpoints....................................................................................... 2

1.1.2 Checking the Nameplate Data ........................................................................... 2

1.2 Identifying the Parts........................................................ 2

Page 10

Chapter 1: Receiving

•

efesotomasyon.com - Control Techniques,emerson,saftronics -ac drive-servo motor

CAUTION

Do not install or operate any Inverter which is damaged or has missing parts. Failure to observe this may result in personal injury or

equipment damage.

1.1 Inspections Checkpoints

1.1.1 Receiving Checkpoints

Table 1 Checkpoints

Does the Inverter model number correspond with the purchase

order?

Are any parts damaged?

Is hardware properly seated and securely tightened?

Was an instruction manual received? FP5/GP5 Instruction Manual

If any of the above checkpoints are not satisfactory, contact your Saftronics representative.

1.1.2 Checking the Nameplate Data

§ Nameplate Data

Checkpoints Description

Check the model number on the nameplate on the side of the

FP5/GP5. (See below.)

Visually check the exterior and verify that there was no

damage during transport.

Remove Inverter front cover. Check all visible hardware with

appropriate tools.

§ Model Designation

Figure 1 Nameplate Data

Figure 2 Model Designation

Firmware – S2011 and S3012

Revision: 1 (9/98) 2 © Saftronics, Inc.

Page 11

§ Specification Designation

efesotomasyon.com - Control Techniques,emerson,saftronics -ac drive-servo motor

∗ For special specifications, a spec sheet number appears on the nameplate.

1.2 Identifying the Parts

Chapter 1: Receiving

Figure 3 Specification Designation

Figure 4 Configuration of FP5/GP5

Firmware – S2011 and S3012

Revision: 1 (9/98) 3 © Saftronics, Inc.

Page 12

Chapter 1: Receiving

efesotomasyon.com - Control Techniques,emerson,saftronics -ac drive-servo motor

NOTES:

Firmware – S2011 and S3012

Revision: 1 (9/98) 4 © Saftronics, Inc.

Page 13

2

efesotomasyon.com - Control Techniques,emerson,saftronics -ac drive-servo motor

Installation

This chapter describes configuration, location and clearances when mounting the FP5/GP5.

2.1 Removing and Replacing the Digital Operator............. 6

2.1.1 Removing the Digital Operator........................................................................... 6

2.1.2 Replacing the Digital Operator........................................................................... 6

2.2 Removing and Replacing the Front Cover.................... 7

2.3 Choosing a Location to Mount the Inverter.................. 7

2.4 Clearances....................................................................... 8

Page 14

Chapter 2: Installation

•

efesotomasyon.com - Control Techniques,emerson,saftronics -ac drive-servo motor

CAUTION

When moving the unit, lift the cabinet by the base, never lift by the front cover. Otherwise, the main unit may be dropped causing

damage to the unit.

• Mount the Inverter on nonflammable material, (i.e., metal). Failure to observe this can result in a fire.

• When mounting units in an enclosure, install a fan or other cooling device to keep the intake air temperature below 45°C. Overheating

may cause a fire or damage to the unit.

2.1 Removing and Replacing the Digital Operator

Remove and replace the Digital Operator as follows:

2.1.1 Removing the Digital Operator

To remove the Digital Operator from the front cover,

push the Digital Operator lever in the direction

shown by arrow 1 and lift the Digital Operator in the

direction shown by arrow 2.

Figure 5 Removing the Digital Operator

2.1.2 Replacing the Digital Operator

Engage the Digital Operator on claws A in the

direction shown by arrow 1 and then on claws B in

the direction shown by arrow 2 to lock the Digital

Operator.

Figure 6 Replacing the Digital Operator

NOTE: Never fit the Digital Operator in any other direction or by any other method. The Digital Operator will not be connected to the

Inverter.

Firmware – S2011 and S3012

Revision: 1 (9/98) 6 © Saftronics, Inc.

Page 15

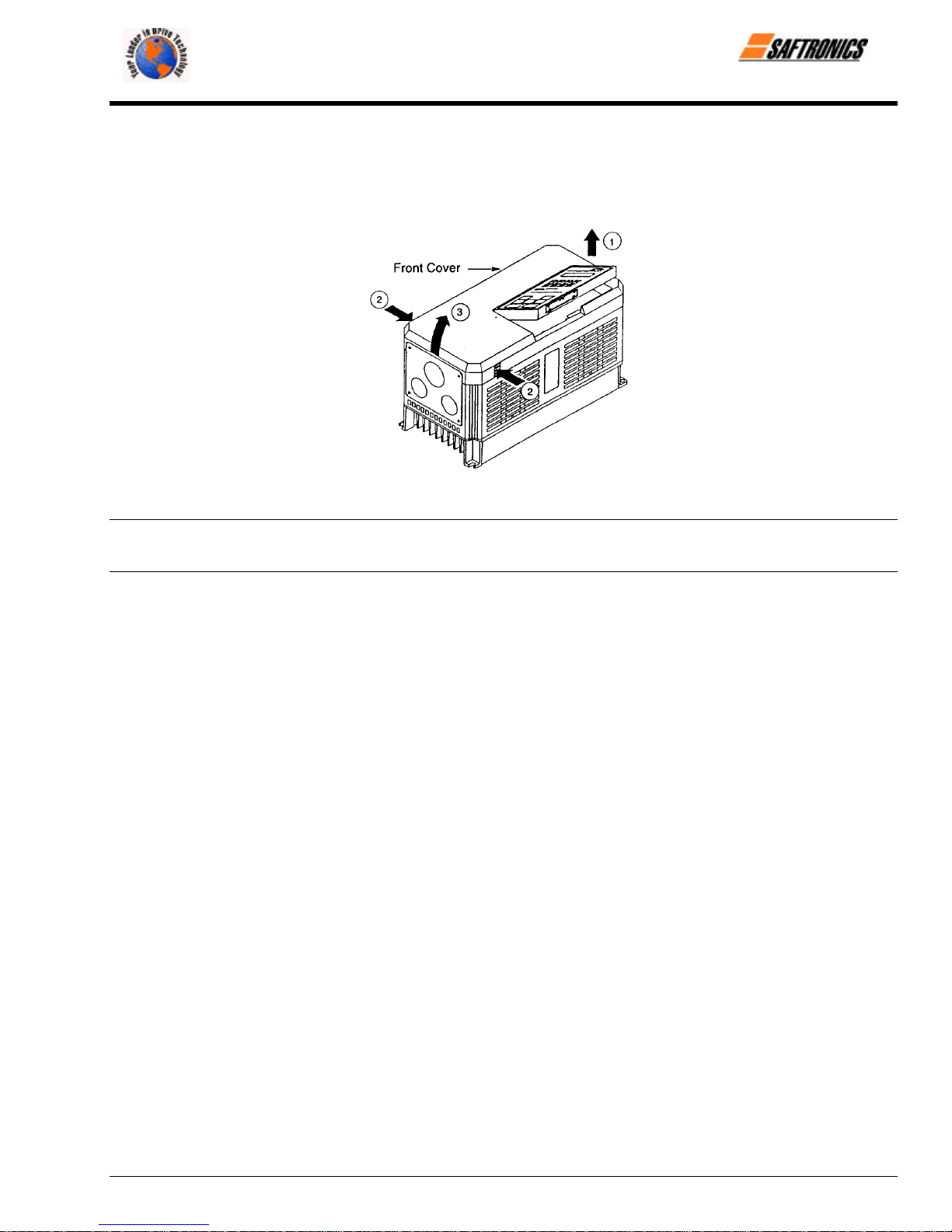

2.2 Removing and Replacing the Front Cover

efesotomasyon.com - Control Techniques,emerson,saftronics -ac drive-servo motor

To remove the front cover, first move the Digital Operator in the direction shown by arrow 1. (Figure 5). Then squeeze the cover in

the direction shown by arrows 2 on both sides and lift in the direction shown by arrow 3.

Figure 7 Removing and Replacing the Front Cover

Chapter 2: Installation

NOTE: Do not replace the front cover with the Digital Operator connected. The Digital Operator will not be connected to the Inverter.

Replace the front cover first and then install the Digital Operator on the cover. See Figure 6 for replacing the Digital Operator.

2.3 Choosing a Location to Mount the Inverter

To ensure proper performance and long operating life, follow the recommendations below when choosing a location for installing the

FP5/GP5. Make sure the Inverter is protected from the following conditions:

o Extreme cold and heat. Use only within ambient temperature range: −10°C to + 40°C.

o Rain, moisture. (For enclosed wall-mounted type.)

o Oil sprays, splashes.

o Salt spray.

o Direct sunlight. (Avoid using outdoors.)

o Corrosive gases or liquids.

o Dust or metallic particles in the air. (For enclosed wall-mounted type.)

o Physical shock, vibration.

o Magnetic noise. (Example: welding machines, power devices, etc.)

o High humidity.

o Radioactive materials.

o Combustibles: thinners, solvents, etc.

Firmware – S2011 and S3012

Revision: 1 (9/98) 7 © Saftronics, Inc.

Page 16

Chapter 2: Installation

efesotomasyon.com - Control Techniques,emerson,saftronics -ac drive-servo motor

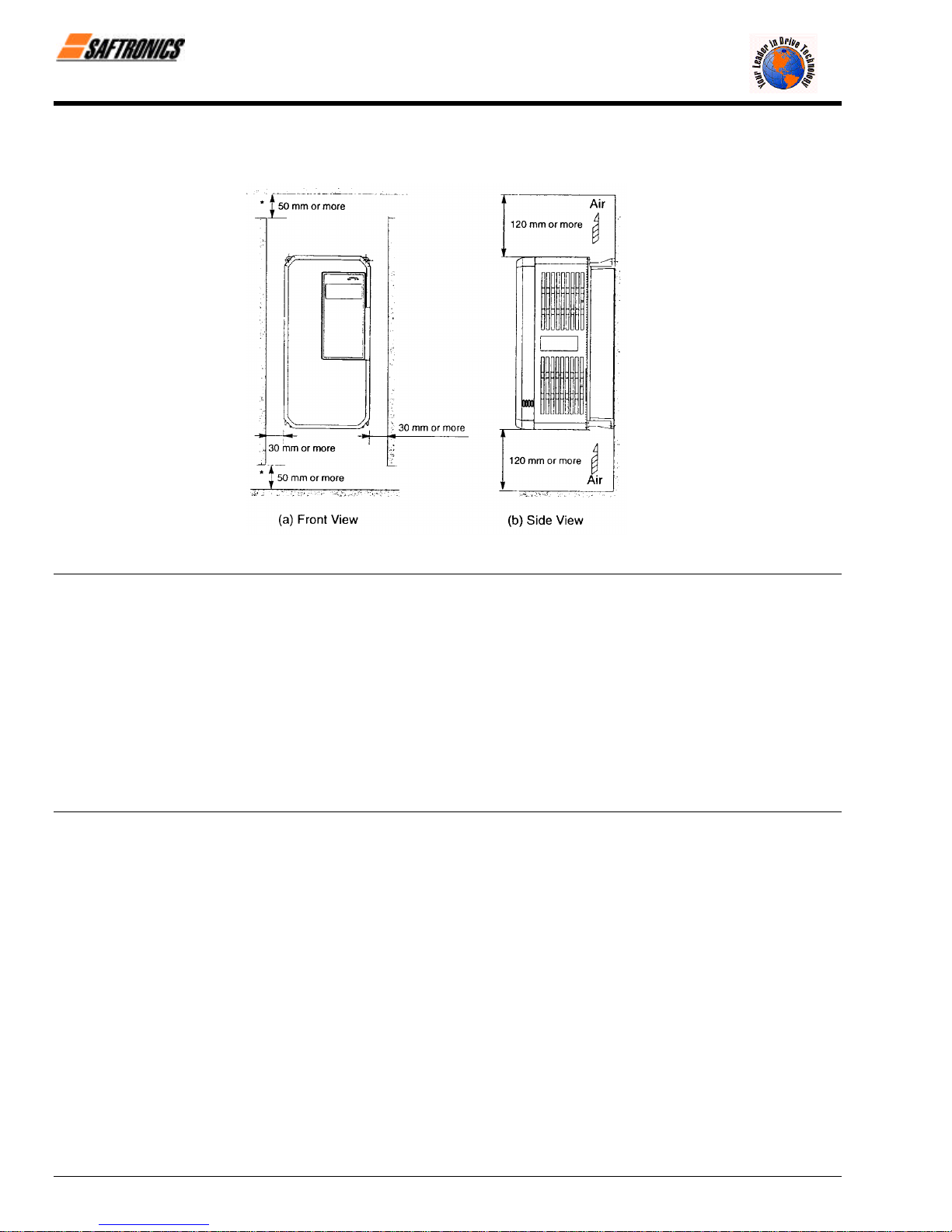

2.4 Clearances

Install the FP5/GP5 vertically and allow sufficient clearances for effective cooling as shown below.

Figure 8 Clearances

NOTE: 1. The clearances required at the top and bottom and both sides are common in open chassis type (IP00) and enclosed

wall-mounted type (NEMA1/IP20).

2. Remove the top and bottom covers to use the open chassis type of 200V/400V 15kW or less.

3. When installing the models of 200V/400V 30kW or more equipped with eyebolts, extra spacing will be required on either

side. For detailed dimensions, contact your Saftronics representative.

4. For the external dimensions and mounting dimensions, refer to Chapter 10 Dimensions.

5. Allowable intake air temperature to the Inverter:

• Open chassis type (IP00) : - 10°C to 45°C

• Enclosed wall-mounted type : - 10°C to 40°C (NEMA 1/IP20)

6. Ensure sufficient space for the sections at the upper and lower parts marked with [ in order to permit the flow of

intake/exhaust air to/from the Inverter.

Firmware – S2011 and S3012

Revision: 1 (9/98) 8 © Saftronics, Inc.

Page 17

3

efesotomasyon.com - Control Techniques,emerson,saftronics -ac drive-servo motor

Wiring

This chapter describes the main circuit wiring and the control circuit wiring of the FP5/GP5.

3.1 Connection Diagram....................................................... 10

3.2 Wiring the Main Circuit................................................... 11

3.2.1 Wiring Precautions for Main Circuit Input .......................................................... 11

3.2.2 Wiring Precautions for Main Circuit Output........................................................ 12

3.2.3 Grounding ........................................................................................................... 12

3.2.4 Functions of Main Circuit Terminals................................................................... 13

3.2.5 Main Circuit Configuration.................................................................................. 15

3.2.6 Parts Required for Wiring................................................................................... 17

3.3 Wiring the Control Circuit .............................................. 21

3.3.1 Functions of Control Circuit Terminals............................................................... 21

3.3.2 Wiring the Control Circuit Terminals.................................................................. 22

3.3.3 Precautions on Control Circuit Wiring................................................................ 22

3.4 Wiring Inspection............................................................ 22

Page 18

Chapter 3: Wiring

•

•

•

efesotomasyon.com - Control Techniques,emerson,saftronics -ac drive-servo motor

WARNING

Only commence wiring after verifying that the power supply is turned OFF. Failure to observe this can result in an electrical shock or

fire.

• Wiring should be performed only by qualified personnel. Failure to observe this can result in an electrical shock or fire.

When wiring the emergency stop circuit, check the wiring thoroughly before operation. Failure to observe this can result in personal

injury.

CAUTION

• Verify that the Inverter rated voltage coincides with the AC power supply voltage. Failure to observe this can result in personal injury

or fire.

• Do not perform a withstand voltage test of the Inverter. It may cause semi-conductor elements to be damaged.

To connect a Braking Resistor, Braking Resistor Unit or Braking Unit, follow the procedures described in Chapter 11. Improper

connection may cause fire.

• Tighten terminal screws to the specified tightening torque. Failure to observe this can result in a fire.

3.1 Connection Diagram

Below is a connection diagram of the main circuit and control circuit. Using the Digital Operator, the motor can be operated by

wiring the main circuit only.

Figure 9 FP5/GP5 Connection Diagram

Firmware – S2011 and S3012

Revision: 1 (9/98) 10 © Saftronics, Inc.

Page 19

Chapter 3: Wiring

•

•

efesotomasyon.com - Control Techniques,emerson,saftronics -ac drive-servo motor

NOTE:

1.

2. Voltage or current input for the master frequency reference can be selected by constant n042. Voltage reference input is

preset at the factory (FV).

3. Control circuit Terminal FS of + 15V has a maximum output current capacity of 20 mA.

4. Multi-function analog output should be used for monitoring meters (e.g., output frequency meter) and should not be used

for feedback control system.

3.2 Wiring the Main Circuit

Make sure to ground the ground terminal ( ). (Ground resistance 200V class: 100Ω or less, 400V class: 10× or less.)

Failure to observe this can result in an electrical shock or a fire.

Never connect the AC main circuit power supply to output Terminals T1, T2, and T3 (U, V and W). The Inverter will be

damaged and invalidate the warranty.

3.2.1 Wiring Precautions for Main Circuit Input

§ Installation of Molded Case Circuit Breaker (MCCB)

Make sure to connect Molded Case Circuit Breakers (MCCB) or fuses between AC main circuit power supply and

FP5/GP5 input Terminals L1, L2 and L3 (R, S, and T) to protect wiring.

P

indicates twisted-pair shielded wires.indicates shielded wires and

WARNING

CAUTION

§ Installation of Ground Fault Interrupter

When connecting a ground fault interrupter to input Terminals L1, L2 and L3 (R, S, and T), select one that is not

affected by high frequency.

Examples: NV series by Mitsubishi Electric Co., Ltd. (manufactured in or after 1988), EG, SG series by Fuji Electric

Co., Ltd. (manufactured in or after 1984).

§ Installation of Magnetic Contactor

Inverters can be used without a Magnetic Contactor (MC) installed at the power supply side. When the main circuit

power supply is shut OFF in the sequence, a MC can be used instead of a MCCB. However, when a MC is switched

OFF at the primary side, regenerative braking does not function and the motor coasts to a stop.

• The load can be operated/stopped by opening/closing the MC at the primary side. However, frequent switching

may cause the Inverter to malfunction.

• When using a Braking Resistor Unit, use a sequencer to break power supply side on overload relay trip contact.

If the Inverter malfunctions, the Braking Resistor Unit may be damaged.

§ Terminal Block Connection Sequence

Input power supply phases can be connected to any terminal regardless of the order of L1, L2 and L3 (R, S, and T)

on the terminal block.

§ Installation of AC Reactor

When connecting an Inverter (200V/400V 15kW or less) to a large capacity power supply transformer (600k VA or

more), or when switching a phase advancing capacitor, excessive peak current flows in the input power supply

circuit, which may damage the converter section. In such cases, install a DC Reactor (optional) between Inverter ¾

1 and ¾ 2 terminals or an AC Reactor (optional) on the input side. Installation of a reactor is effective for

improvement of power factor on the power supply side.

Firmware – S2011 and S3012

Revision: 1 (9/98) 11 © Saftronics, Inc.

Page 20

Chapter 3: Wiring

efesotomasyon.com - Control Techniques,emerson,saftronics -ac drive-servo motor

§ Installation of Surge Suppressor

§ Prohibition of Installation of Phase Advancing Capacitor

3.2.2 Wiring Precautions for Main Circuit Output

§ Connection of Terminal Block and Load

§ Strict Prohibition of Connection of Input Power Supply to Output Terminals

§ Strict Prohibition of Short Circuiting or Grounding of Output Circuit

For inductive loads (magnetic contactors, magnetic relays, magnetic valves, solenoids, magnetic brakes, etc.)

connected near the Inverter, use a surge suppressor simultaneously.

If a Phase Advancing Capacitor or Surge Suppressor is connected in order to improve the power factor, it may

become overheated and damaged by Inverter high harmonic components. Also, the Inverter may malfunction

because of overcurrent.

Connect output Terminals T1, T2, and T3 (U, V, and W) to motor lead wires T1, T2, and T3 (U, V, and W). Verify

that the motor rotates in the forward direction (CCW: counterclockwise when viewed from the motor load side) with

the forward RUN command. If the motor rotation is incorrect, exchange any two of output Terminals T1, T2, and T3

(U, V, and W).

Never connect the input power supply to output Terminals T1, T2, and T3 (U, V, and W).

Never touch the output circuit directly or put the output line in contact with the Inverter case. Otherwise, it may cause

an electrical shock or grounding. In addition, never short-circuit the output line.

§ Prohibition of Connection of Phase Advancing Capacitor or LC/RC Noise Filter

Never connect a Phase Advancing Capacitor or LC/RC noise filter to the output circuit.

§ Avoidance of Installation of Magnetic Starter

Do not connect a Magnetic Starter or MC to the output circuit. If the load is connected while the Inverter is running,

the Inverter overcurrent protective circuit operates because of inrush current.

§ Installation of Thermal Overload Relay

An electronic overload protective function is incorporated into the Inverter. However, connect a Thermal Overload

Relay when driving several motors with one Inverter or when using a multi-pole motor. When using a Thermal

Overload Relay, set Inverter constant n033 to 0 (motor overload protection selection: no protection). Additionally, for

Thermal Overload Relay at 50Hz, set the same rated current value as that described on the motor nameplate, or at

60Hz 1.1 times larger than the rated current value described on the motor nameplate.

§ Wiring Distance between Inverter and Motor

If the total wiring distance between Inverter and motor is excessively long and the Inverter carrier frequency (main

transistor switching frequency) is high, harmonic leakage current from the cable will adversely affect the Inverter and

peripheral devices.

If the wiring distance between Inverter and motor is long, reduce the Inverter carrier frequency as described below.

Carrier frequency can be set by constant n050.

Table 2 Wiring Distance between Inverter and Motor

Wiring Distance between Inverter and Motor

Carrier Frequency

(Set value of constant n050)

Up to 164ft

(50m)

15kHz or less

(6)

Up to 328ft

(100m)

10kHz or less

(4)

More than 328ft

(100m)

5kHz or less

(2)

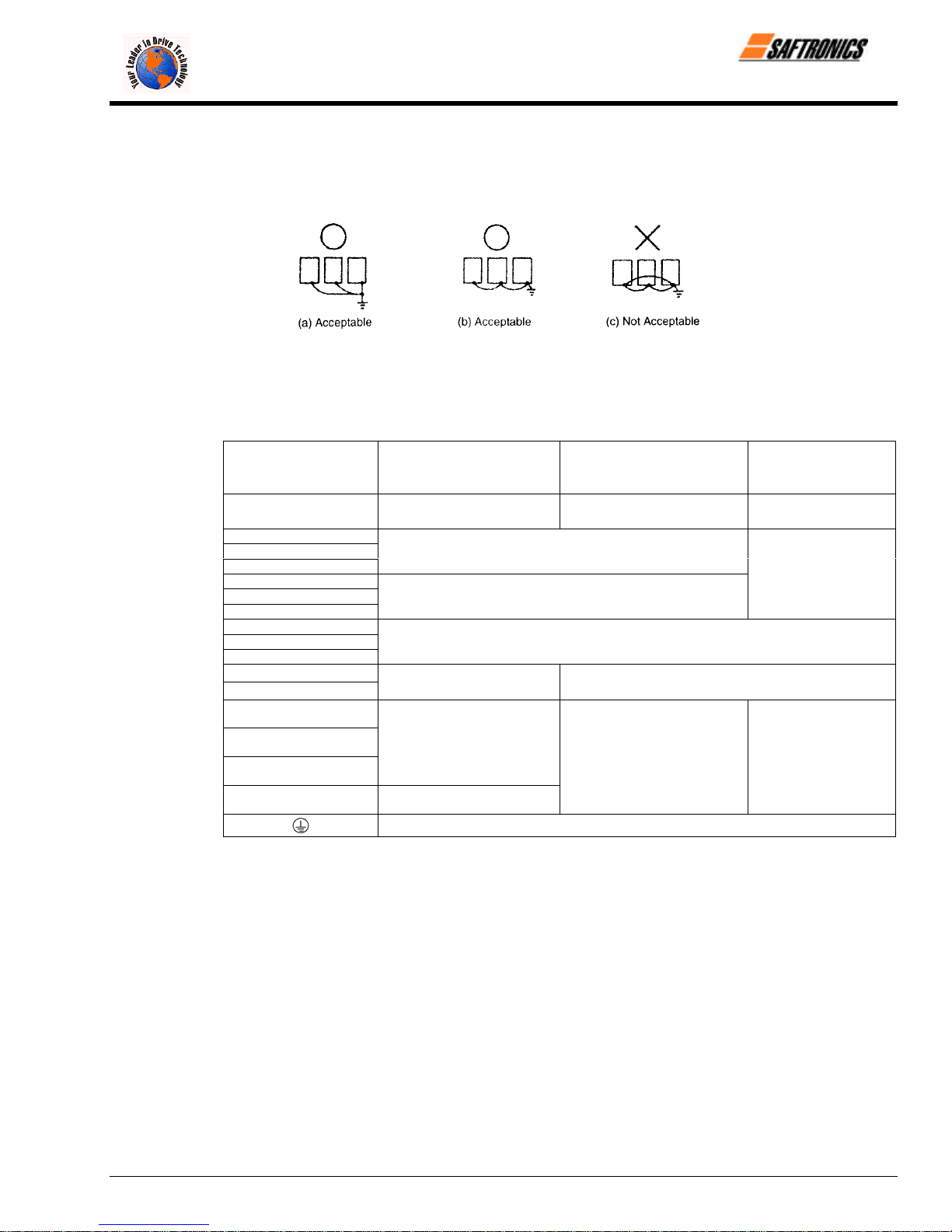

3.2.3 Grounding

• Ground resistance

• 200 V class: 100 Ω or less, 400 V class: 10 Ω or less

• Never ground the Inverter in common with welding machines, motors, or other large-current electrical equipment.

Run all the ground wires in a conduit separate from wires for large-current electrical equipment.

Firmware – S2011 and S3012

Revision: 1 (9/98) 12 © Saftronics, Inc.

Page 21

• Use the ground wires described in Tables 5 or 6 and keep the length as short as possible.

efesotomasyon.com - Control Techniques,emerson,saftronics -ac drive-servo motor

• When using several Inverter units side by side, ground the units as shown in Figure 10, (a) or (b). Do not loop the

ground wires as shown in (c).

Figure 10 Grounding of Three Inverter Units

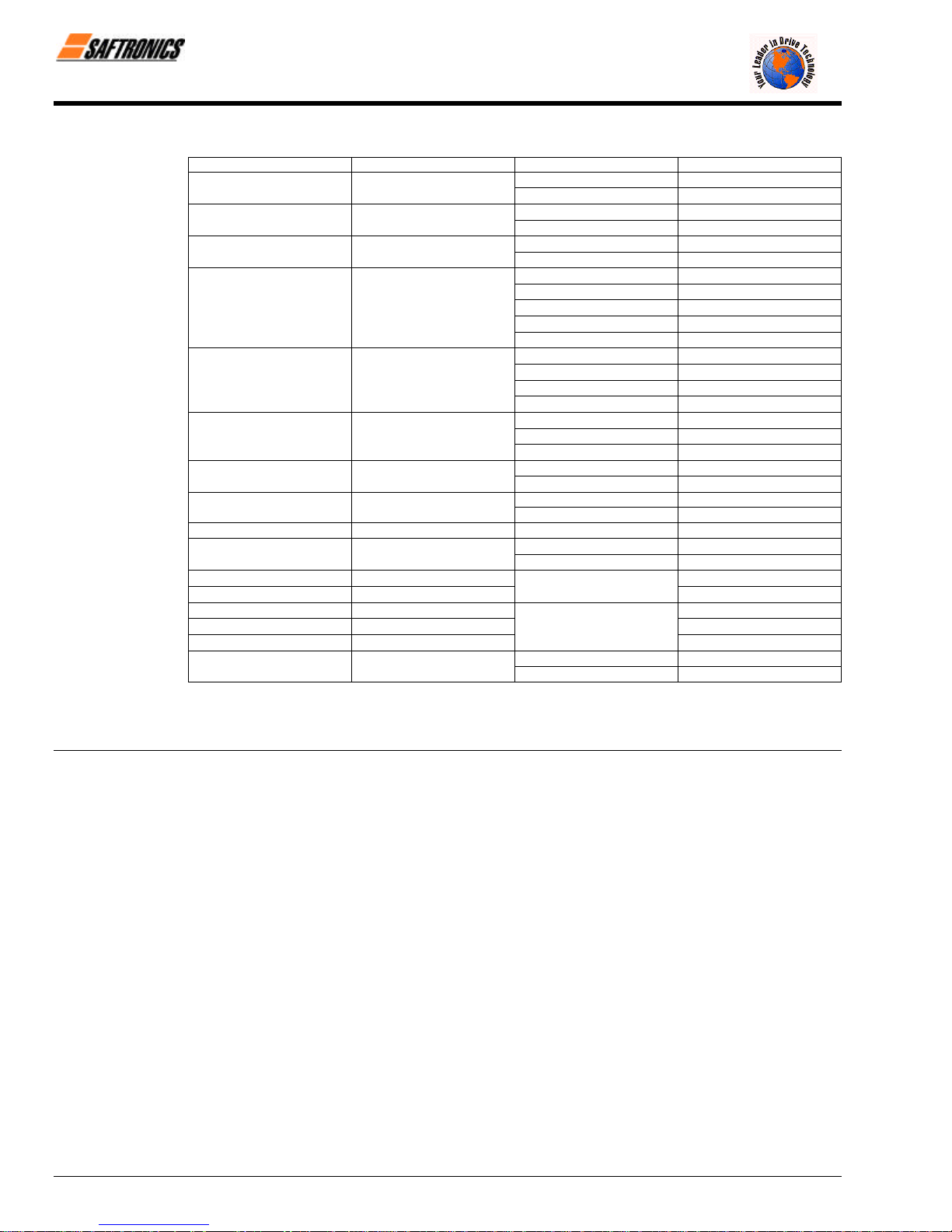

3.2.4 Functions of Main Circuit Terminals

The following table outlines the functions of the main circuit terminals. Wire according to each terminal function.

Table 3 200 V Class Terminal Functions

Chapter 3: Wiring

Models

FP5/GP5

Max Applicable Motor

Output

L1 (R)

L2 (S)

L3 (T)

L11 (R1)

L21 (S1)

L31 (T1)

T1 (U)

T2 (V)

T3 (W)

B1

B2

Ö

¾ 1

¾ 2

¾ 3

23P7 to 27P5 2011 to 2015 2018 to 2075

3.7 to 7.5 kW 11 to 15 kW 18.5 to 75 kW

Main circuit input power supply

Inverter output

Braking Resistor Unit

• DC Reactor (¾1 − ¾2)

• DC bus terminals (¾1 − ¾2

Ground terminal (Ground resistance: 100 Ω or less)

• DC Reactor (¾1 − ¾2)

• DC bus terminals (¾1 − ¾2

• Braking Unit (¾3 − Ö)

Main circuit input

power supply

Firmware – S2011 and S3012

Revision: 1 (9/98) 13 © Saftronics, Inc.

Page 22

Chapter 3: Wiring

efesotomasyon.com - Control Techniques,emerson,saftronics -ac drive-servo motor

Table 4 400 V Class Terminal Functions

Models

FP5/GP5

Max Applicable Motor

Output

L1 (R)

L2 (S)

L3 (T)

L11 (R1)

L21 (S1)

L31 (T1)

T1 (U)

T2 (V)

T3 (W)

B1

B2

Ö

¾ 1

¾ 2

¾ 3

r (l 1)

s 200 (l 2 200)

s 400 (l 2 400)

40P4 to 4015 4018 to 4045 4055 to 4160 4185 to 4300

0.4 to 15 kW 18.5 to 45 kW 55 to 160 kW 185 to 300 kW

Main circuit input

power supply

Braking Resistor Unit

• DC Reactor

(¾1 − ¾2

• DC bus terminals

(¾1 − Ö)

Main circuit input power supply

Inverter output

Ground terminal (Ground resistance: 10Ω or less)

• Braking Unit (¾ 3 − Ö)

• Braking Unit (¾ 3 − Ö)

Cooling fan power supply

(Control power supply

r (l 1) − s 200 (l 2 200):

200 to 230 VAC input

r (l 1) − s 400 (l 2 400):

380 to 460 VAC input

Main circuit input

power supply

Firmware – S2011 and S3012

Revision: 1 (9/98) 14 © Saftronics, Inc.

Page 23

3.2.5 Main Circuit Configuration

efesotomasyon.com - Control Techniques,emerson,saftronics -ac drive-servo motor

200V Class

FP5/GP523P7 to FP5/GP527P5 FP5/GP52011 to FP5/GP52015

FP5/GP52018 to FP5/GP52022 FP5/GP52030 to FP5/GP52075

Chapter 3: Wiring

= The wiring has been completed at the factory prior to shipping.

‡ When installing a DC Reactor (option) on models of 15kW or below, remove the short-circuit bar between

¾ 1 and ¾2 terminals and connect a DC Reactor with the terminals.

Firmware – S2011 and S3012

Revision: 1 (9/98) 15 © Saftronics, Inc.

Page 24

Chapter 3: Wiring

efesotomasyon.com - Control Techniques,emerson,saftronics -ac drive-servo motor

400V Class

FP5/GP540P4 to FP5/GP541P5 FP5/GP542P2 to FP5/GP54015

FP5/GP54018 to FP5/GP54045 FP5/GP54055 to FP5/GP54160

FP5/GP54185 to FP5/GP54300

= The wiring has been completed at the factory prior to shipping.

‡ When installing a DC Reactor (option) on models of 15kW or below, remove the short-circuit bar between

¾ 1 and ¾ 2 terminals and connect a DC Reactor with the terminals.

Firmware – S2011 and S3012

Revision: 1 (9/98) 16 © Saftronics, Inc.

Page 25

3.2.6 Parts Required for Wiring

efesotomasyon.com - Control Techniques,emerson,saftronics -ac drive-servo motor

Select wires or Closed-Loop Connectors to be used for wiring from Tables 5, 6 and 7.

Circuit

Model

FP5/GP5

Table 5 200 V Class Wire Size

Terminal Symbol

Terminal

Screw

Wire Size

=

AWG mm

Chapter 3: Wiring

2

Wire Type

Main

Control

23P7 M4 10 5.5

25P5 M5

(U, V, W)

L1, L2, L3, (R, S, T) Ö, ¾ 1, ¾ 2, B1, B2, T1, T2, T3

(U, V, W)

8 8

10-8 5.5 − 8

L1, L2, L3, (R, S, T) Ö, ¾ 1, ¾ 2, B1, B2, T1, T2, T3

27P5 M5

(U, V, W)

L1, L2, L3, (R, S, T) Ö, ¾ 1, ¾ 2, B1, B2, T1, T2, T3

8 8

10-8

2011 M6

V, W)

L1, L2, L3, (R, S, T) Ö, ¾ 1, ¾ 2, ¾ 3, T1, T2, T3 (U,

4 22

8 8

2015

L1, L2, L3, (R, S, T) Ö, ¾ 1, ¾ 2, ¾ 3, T1, T2, T3 (U,

V, W)

M8 3 30

M6 8 8

L1,L2, L3, (R, S, T) L11, L21, L31, (R1, S1, T1), T1,

2018 M8

T2, (U, V, W)

3 30

6 14

L1,L2, L3, (R, S, T), L11, L21, L31, (R1, S1, T1), T1,

2022 M8

T2, T3 (U, V, W)

2 38

6 14

2030

L1,L2, L3, (R, S, T), L11, L21, L31, T1, T2, T3, (U, V,

W)

M10 4/0 100

M8 4 22

2037

L1,L2, L3, (R, S, T), L11, L21, L31, T1, T2, T3, (U, V,

W)

M10 1/0 x 2P 60 5 2P

M8 4 22

2045

L1,L2, L3, (R, S, T), L11, L21, L31, T1, T2, T3, (U, V,

W)

M10 1/0 x 2P 60 5 2P

M8 4 22

2055

L1,L2, L3, (R, S, T), L11, L21, L31, T1, T2, T3, (U, V,

W)

M10 1/0 x 2P 60 5 2P

M8 3 30

2075

L1,L2, L3, (R, S, T), L11, L21, L31, T1, T2, T3, (U, V,

W)

M12 4/0 x 2P 100 5 2P

M8 1 50

S1, S2, S3, S4, S5, S6, SC,

Common to

all models

FV, FI, FS, FC,

AM, AC, M1, M2, MA, MB, MC

20-16

G M3.5 20-14

5.5 − 8

Stranded

0.5 − 1.25

Solid

0.5 − 1.25

0.5 − 2

Power cable:

600V vinyl

sheathed wire

or equivalent

Twisted

shielded wire

= Where size is determined using 75°C temperature-rated copper wire.

Firmware – S2011 and S3012

Revision: 1 (9/98) 17 © Saftronics, Inc.

Page 26

Chapter 3: Wiring

efesotomasyon.com - Control Techniques,emerson,saftronics -ac drive-servo motor

Circuit

Model

FP5/GP5

Table 6 400 V Class Wire Size

Terminal Symbol

Terminal

Screw

Wire Size

=

AWG mm

2

Wire Type

Main

40P4 M4 2 − 5.5

(U, V, W)

L1, L2, L3 (R, S, T), Ö, ¾ 1, ¾ 2, B1, B2, T1, T2, T3

L1, L2, L3, (R, S, T), Ö, ¾ 1, ¾ 2, B1, B2, T1, T2, T3

40P7 M4

(U, V, W)

2 − 5.5

L1, L2, L3, (R, S, T), Ö, ¾ 1, ¾ 2, B1, B2, T1, T2, T3

41P5 M4

(U, V, W)

2 − 5.5

L1, L2, L3 (R, S, T), Ö, ¾ 1, ¾ 2, B1, B2, T1, T2, T3

42P2 M4

(U, V, W)

L1, L2, L3 (R, S, T), Ö, ¾ 1, ¾ 2, B1, B2, T1, T2, T3

43P7 M4

(U, V, W)

14-10

12-10

2 − 5.5

2 − 5.5

3.5 − 5.5

L1, L2, L3 (R, S, T), Ö, ¾ 1, ¾ 2, B1, B2, T1, T2, T3

44P0 M4

(U, V, W)

2 − 5.5

L1, L2, L3 (R, S, T), Ö, ¾ 1, ¾ 2, B1, B2, T1, T2, T3

45P5 M4 12-10 3.5 − 5.5

(U, V, W)

Power cable:

600V vinyl

sheathed wire

or equivalent

47P5 M5 8-6 5.5

4011

(U, V, W)

L1, L2, L3, (R, S, T), Ö, ¾ 1, ¾ 2, B1, B2, T1, T2, T3

(U, V, W)

M5 8-6

M6 8 8

L1, L2, L3 (R, S, T), Ö, ¾ 1, ¾ 2, B1, B2, T1, T2, T3

4015

L1, L2, L3 (R, S, T), Ö, ¾ 1, ¾ 2, B1, B2, T1, T2, T3

(U, V, W)

M5 8-6

M6 8 8

4018

L1, L2, L3 (R, S, T), L11, L21, L31 (R1, S1, T11), T1,

T2, T3 (U, V, W)

M6 6 14

M8 8 8

4022

L1, L2, L3 (R, S, T), L11, L21, L31 (R1, S1, T11), T1,

T2, T3 (U, V, W)

M6 4 22

M8 8 8

L1, L2, L3 (R, S, T), L11, L21, L31 (R1, S1, T11), T1,

4030 M8

T2, T3 (U, V, W)

= Where size is determined using 75°C temperature-rated copper wire.

8 − 14

8 − 14

4 22

8 8

Firmware – S2011 and S3012

Revision: 1 (9/98) 18 © Saftronics, Inc.

Page 27

Table 6 400 V Class Wire Size (Continued)

efesotomasyon.com - Control Techniques,emerson,saftronics -ac drive-servo motor

Circuit

Model

FP5/GP5

Terminal Symbol

L1, L2, L3 (R, S, T), L11, L21, L31 (R1, S1, T11), T1,

4037 M8

T2, T3 (U, V, W)

L1, L2, L3 (R, S, T), L11, L21, L31 (R1, S1, T11), T1,

4045 M8

T2, T3 (U, V, W)

L1, L2, L3 (R, S, T), L11, L21, L31 (R1, S1, T11), T1,

4055

T2, T3 (U, V, W)

L1, L2, L3 (R, S, T), L11, L21, L31 (R1, S1, T11), T1,

4075

T2, T3 (U, V, W)

L1, L2, L3 (R, S, T), L11, L21, L31 (R1, S1, T11), T1,

4110

Main

4160

T2, T3 (U, V, W)

L1, L2, L3 (R, S, T), L11, L21, L31 (R1, S1, T11), T1,

T2, T3 (U, V, W)

L1, L2, L3 (R, S, T), Ö, ¾ 1, ¾ 3, T1, T2, T3 (U, V, W)

4185

r (l1), s 200 (l2 200), s 400 (l

L1, L2, L3 (R, S, T), Ö, ¾ 1, ¾ 3, T1, T2, T3 (U, V, W)

400)

2

4220

r (l1), s 200 (l2 200), s 400 (l

L1, L2, L3 (R, S, T), Ö, ¾ 1, ¾ 3, T1, T2, T3 (U, V, W)

400)

2

4300

Control

Common to

all models

r (l1), s 200 (l2 200), s 400 (l

S1, S2, S3, S4, S5, S6, SC,

FV, FI, FS, FC,

AM, AC, M1, M2, MA, MB, MC

G M3.5 20-14

400)

2

= Where size is determined using 75°C temperature-rated copper wire.

Terminal

Screw

Wire Size

AWG mm

3 30

6 14

1 50

6 14

M10 4/0 100

M8 4 22

M10 1/0 x 2P 60 x 2P

M8 4 22

M10 1/0 x 2P 60 x 2P

M8 3 30

M12 4/0 x 2P 100 x 2P

M8 1 50

M16

M8 1 50

M4 20-10

M16

M8 1/0 60

M4 20-10

M16

M8 1/0 60

M4 20-10

650MCM

x 2P

650MCM

x 2P

650MCM

x 2P

20-16

325 x 2P

0.5 − 5.5

325 x 2P

0.5 − 5.5

325 x 2P

0.5 − 5.5

Stranded

0.5 − 1.25

0.5 − 1.25

0.5 − 2

Chapter 3: Wiring

=

2

Solid

Wire Type

Power cable:

600V vinyl

sheathed wire

or equivalent

Twisted

shielded wire

Firmware – S2011 and S3012

Revision: 1 (9/98) 19 © Saftronics, Inc.

Page 28

Chapter 3: Wiring

efesotomasyon.com - Control Techniques,emerson,saftronics -ac drive-servo motor

Table 7 Closed-Loop Connectors

AWG Size Wire Size mm

2

20 0.5

18 0.75

16 1.25

14 2

12-10 3.5 / 5.5

8 8

6 14

4 22

3-2 30 / 38 M8

1-1/0 50 / 60

3/0 80

4/0 100

4/0 100

300MCM 150

400MCM 200

650MCM 325

Terminal Screw Closed-Loop Connectors

M3.5

M4

M3.5

M4

M3.5

M4

M3.5

M4

M5

M6

M8

M4

M5

M6

M8

M5

M6

M8

M6

M8

1.25 − 3.5

1.25 − 4

1.25 − 3.5

1.25 − 4

1.25 − 3.5

1.25 − 4

2 − 3.5

2 − 4

2 − 5

2 − 6

2 − 8

5.5 − 4

5.5 − 5

5.5 − 6

5.5 − 8

8 − 5

8 − 6

8 − 8

14 − 6

14 − 8

M6 14 - 6

M8 14 - 8

38 − 8

M8

M10

M10

60 − 8

60 − 10

80 − 10

100 − 10

100 − 12

M12

150 − 12

200 − 12

M12 x 2

M16

325 − 12

325 − 16

NOTE: When determining wire size, consider voltage drop. Select a wire size so that voltage drop will be less than 2% of the normal

rated voltage. Voltage drop is calculated by the following equation:

Phase-to-phase voltage drop (V) = /3 5 wire resistance (Ω/km) 5 wiring distance (m) 5 current (A) 5 10

−3

Firmware – S2011 and S3012

Revision: 1 (9/98) 20 © Saftronics, Inc.

Page 29

3.3 Wiring the Control Circuit

efesotomasyon.com - Control Techniques,emerson,saftronics -ac drive-servo motor

The following table outlines the functions of the control circuit terminals. Wire according to each terminal function.

3.3.1 Functions of Control Circuit Terminals

Classification

Terminal Signal Function Description Signal Level

S1 Forward run/stop Forward run when closed, stop when open

Chapter 3: Wiring

Table 8 Control Circuit Terminals

S2 Reverse run/stop

S3 External fault input

S4 Fault reset input Reset when closed

S5 Multi-step speed reference 1 Effective when closed

Sequence Input Signal

Analog Input Signal

S6 Multi-step speed reference 2 Effective when closed

SC

FS

FV

FI

FC

G

M1

M2

Sequence control input

common terminal

+ 15 V

Power supply output

Frequency reference input

(voltage)

Frequency reference input

(current)

Common terminal for control

circuit

Connection to shield sheath

of signal lead

During running (NO contact) Closed when running

Reverse run when closed,

stop when open

Fault when closed,

normal state when open

Multi-function contact

inputs (n035 to n039)

For analog command + 15 V power supply

0 to + 10 V/100% 0 to + 10 V (20 kΩ)

4 to 20 mA/100%

0 V

n042 = 0 : FV

effective

n042 = 1 : FI

effective

Multi-function

contact output

(n041)

Photo-coupler insulation

Input: + 24 VDC 8 mA

+ 15 V

(Allowable current 20 mA

maximum)

4 to 20mA (250Ω)

Dry contact

Contact capacity:

250 VAC 1 A or less

30 VDC 1 A or less

MA

MB

Sequence Output Signal

Analog Output

G

Firmware – S2011 and S3012

Revision: 1 (9/98) 21 © Saftronics, Inc.

MC

AM Frequency meter output

Signal

AC Common

S1 S2 S3 SC SC S4 S5 S6 FV FI FS FC AM AC M1 M2 MA MB MC

Fault contact output (NO/NC

contact)

Figure 11 Control Circuit Terminal Arrangement

Fault when closed between

Terminals MA and MC.

Fault when open between

Terminals MB and MC.

0 to + 10 V/100% frequency

Multi-function

contact output

(n040)

Multi-function

analog monitor 1

(n048)

Dry contact

Contact capacity:

250 VAC 1 A or less

30 VDC 1 A or less

0 to + 10 V 2 mA or less

Page 30

Chapter 3: Wiring

efesotomasyon.com - Control Techniques,emerson,saftronics -ac drive-servo motor

3.3.2 Wiring the Control Circuit Terminals

Insert the wire into the lower part of the terminal block and connect it tightly with a screwdriver. Wire sheath strip length

must be 7 mm (approximately ¼ inch).

3.3.3 Precautions on Control Circuit Wiring

• Separate control circuit wires from main circuit wires and other power cables to prevent erroneous operation caused

by noise interference.

• Use twisted shielded or twisted-pair shielded wire for the control circuit line and connect the shielded sheath to the

Inverter Terminal G. See Figure 12.

3.4 Wiring Inspection

After completing installation and wiring, check for the following items. Never use control circuit megger check.

o Wiring is proper.

o Wire clippings or screws are not left in the unit.

o Screws are securely tightened.

o Bare wire in the terminal does not contact other terminals.

Figure 12 Shielded Wire Termination

Firmware – S2011 and S3012

Revision: 1 (9/98) 22 © Saftronics, Inc.

Page 31

4

efesotomasyon.com - Control Techniques,emerson,saftronics -ac drive-servo motor

Operation

This chapter describes the basic operation procedures of the FP5/GP5.

4.1 Operation Mode Selection......................................... 25

4.2 Test Run Checkpoints............................................... 26

4.3 Setting the Line Voltage Using Jumper

(For 400V Class 18.5kW and Above) ........................ 26

4.4 Test Run...................................................................... 27

4.4.1 Digital Operator Display at Power-Up....................................................... 27

4.4.2 Operation Check Points............................................................................. 2/

4.4.3 Example of Basic Operation...................................................................... 28

Page 32

Chapter 4: Operation

•

•

•

•

•

•

efesotomasyon.com - Control Techniques,emerson,saftronics -ac drive-servo motor

WARNING

Only turn ON the input power supply after replacing the front cover. Do not remove the cover while current is flowing. Failure to

observe this can result in an electrical shock.

When the retry function (n057) is selected, do not approach the Inverter or the load, since it may restart suddenly after being

stopped. (Construct machine system, so as to assure safety for personnel, even if the Inverter should restart.) Failure to observe

this can result in personal injury.

Since the stop button can be disabled by a function setting, install a separate emergency stop switch. Failure to observe this can

result in personal injury.

CAUTION

Never touch the heatsink or discharging resistor since the temperature is very high. Failure to observe this can result in harmful

burns to the body.

Since it is easy to change operation speed from low to high speed, verify the safe working range of the motor and machine before

operation. Failure to observe this can result in personal injury and machine damage.

• Install a holding brake separately if necessary. Failure to observe this caution can result in personal injury.

• Do not change signals during operation. The machine or the Inverter may be damaged.

All the constants of the Inverter have been preset at the factory. Do not change the settings unnecessarily. The Inverter may be

damaged. For supply voltage, follow Paragraph 4.3 of Chapter 4.

Firmware – S2011 and S3012

Revision: 1 (9/98) 24 © Saftronics, Inc.

Page 33

4.1 Operation Mode Selection

efesotomasyon.com - Control Techniques,emerson,saftronics -ac drive-servo motor

The FP5/GP5 has two operation modes, LOCAL and REMOTE, as described in Table 9. These two modes can be selected by

the Digital Operator LOCAL/REMOTE key only while the operation is stopped. The selected Operation mode can be verified by

observing the Digital Operator SEQ and REF LED’s as shown below. The Operation mode is set to REMOTE (run by control

circuit Terminals FV and FI frequency reference and RUN command from a control circuit terminal) prior to shipment. Multifunction contact inputs from control circuit Terminals S3 to S6 are enabled in both Operation modes LOCAL/REMOTE.

• LOCAL : Both frequency reference and RUN command are set by the Digital Operator. SEQ and REF LED’s go OFF.

• REMOTE : Master frequency reference and RUN command can be selected as described in Table 9.

Table 9 Reference Selection in REMOTE Mode (n002: Operation Method Selection)

Chapter 4: Operation

Setting Operation Method Selection

0 Operation by RUN command from Digital Operator OFF Master frequency reference from Digital Operator OFF

Operation by RUN command from control circuit

1

terminal

2 Operation by RUN command from Digital Operator OFF

Operation by RUN command from control circuit

3

terminal

4 Operation by RUN command from Digital Operator OFF

Operation by RUN command from control circuit

5

terminal

Operation by RUN command from serial

6

communication

Operation by RUN command from serial

7

communication

Operation by RUN command from serial

8

communication

SEQ

LED

ON Master frequency reference from Digital Operator OFF

Master frequency reference from control circuit

Terminals FV and FI

Master frequency reference from control circuit

ON

Terminals FV and FI

Master frequency reference set by serial

communication

Master frequency reference set by serial

ON

communication

Master frequency reference set by serial

ON

communication

ON Master frequency reference from Digital Operator OFF

Master frequency reference from control circuit

ON

Terminals FV and FI

Reference Selection

REF

LED

ON

ON

ON

ON

ON

ON

Firmware – S2011 and S3012

Revision: 1 (9/98) 25 © Saftronics, Inc.

Page 34

Chapter 4: Operation

efesotomasyon.com - Control Techniques,emerson,saftronics -ac drive-servo motor

4.2 Test Run Checkpoints

To assure safety, prior to initial operation, disconnect the machine coupling so that the motor is isolated from the machine. If

initial operation must be performed while the motor is still coupled to the machine, use great care to avoid potentially hazardous

conditions. Check the following items before a test run.

o Wiring and terminal connections are correct.

o No short-circuit caused by wire clippings.

o Screw-type terminals are securely tightened.

o Motor is securely mounted

o All items are correctly earthed (grounded).

4.3 Setting the Line Voltage Using Jumper (For 400V Class 18.5kW and Above)

Set the line voltage jumper according to the main circuit power supply. (See Figure 13.) Insert the jumper at the appropriate

location corresponding to the input line voltage. It has been preset at the factory to 440V.

Figure 13 Line Voltage Jumper (For 400V Class 18.5kW to 45kW)

Firmware – S2011 and S3012

Revision: 1 (9/98) 26 © Saftronics, Inc.

Page 35

4.4 Test Run

efesotomasyon.com - Control Techniques,emerson,saftronics -ac drive-servo motor

4.4.1 Digital Operator Display at Power-up

When the system is ready for operation, turn ON the power supply. Verify that the Inverter powers up properly. If any

problems are found, turn OFF the power supply immediately. The Digital Operator display illuminates as shown below

when turning the power supply ON.

Chapter 4: Operation

Figure 14 Digital Operator Display at Power-Up

Firmware – S2011 and S3012

Revision: 1 (9/98) 27 © Saftronics, Inc.

Page 36

Chapter 4: Operation

efesotomasyon.com - Control Techniques,emerson,saftronics -ac drive-servo motor

4.4.2 Operation Check Points

Check the following items during operation.

o Motor rotates smoothly.

o Motor rotates in the correct direction.

o Motor does not have abnormal vibration or noise.

o Acceleration and deceleration are smooth.

o Current matches the load flow.

o Status indicator LED’s and Digital Operator display are correct.

4.4.3 Example of Basic Operation.

§ Operation by Digital Operator

The diagram below shows a typical operation pattern using the Digital Operator.

Figure 15 Operation Sequence by Digital Operator

Table 10 Typical Operation by Digital Operator

Description Key Sequence Digital Operator Display LED Display

¬ Power ON

• Display frequency reference value. 0.0

Operation Condition Setting REMOTE LED (SEQ. REF) OFF

Frequency Setting Change the value

-

• Select LOCAL mode.

• Change reference value.

• Write-in set value.

by pressing

\ /

15.0

/ \

15.0

• Select output frequency monitor display.

0.0

® Forward Run

• Forward run (15 Hz) 15.0

RUN LED ON

Fref

Fref

Fref

Fout

Fout

Firmware – S2011 and S3012

Revision: 1 (9/98) 28 © Saftronics, Inc.

Page 37

¯ Frequency Reference Value Change

efesotomasyon.com - Control Techniques,emerson,saftronics -ac drive-servo motor

(15 Hz to 60 Hz)

• Select frequency reference value

display.

Table 10 Typical Operation by Digital Operator (continued)

Press 7 times

15.0

Chapter 4: Operation

Fref

Reverse Run

°

• Change set value.

• Write-in set value.

• Select output frequency monitor display.

• Select reverse run.

• Write-in set value.

Change the value

by pressing

Press 3 times

Switch to “rev”

by pressing

\ /

60.0

/ \

60.0

60.0

fo

\ /

eu

/ \

eu

Fref

Fref

Fref

F/R

F/R

F/R

• Select output frequency monitor display.

Press 5 times

60.0

Stop

±

• Decelerates to a stop.

RUN LED OFF STOP LED ON

0.0

Fout

Fout

§ Operation by Control Circuit Terminal Signal

The diagram below shows a typical operation pattern using the control circuit terminal signals.

Figure 16 Operation Sequence by Control Circuit Terminal Signal

Firmware – S2011 and S3012

Revision: 1 (9/98) 29 © Saftronics, Inc.

Page 38

Chapter 4: Operation

efesotomasyon.com - Control Techniques,emerson,saftronics -ac drive-servo motor

Description Key Sequence Digital Operator Display LED Display

Power ON

¬

Frequency Setting

-

Output Frequency Display

Forward Run

®

Stop

¯

• Display frequency reference value. 0.0

REMOTE mode is preset at the factory REMOTE LED (SEQ, REF) ON

• Input frequency reference voltage 60.0

(current) by control circuit Terminal FV For reference voltage 10V

or FI and verify the input value by the

Digital Operator.

• Select output frequency monitor display.

• Close between control circuit Terminals 60.0

SI and SC to perform forward run. RUN LED ON

• Open between control circuit Terminals

SI and SC to stop operation.

Table 11 Typical Operation by Control Circuit Terminal Signal

STOP LED ON

(RUN LED blinking

during deceleration)

0.0

0.0

Fref

Fref

Fout

Fout

Fout

Firmware – S2011 and S3012

Revision: 1 (9/98) 30 © Saftronics, Inc.

Page 39

5

efesotomasyon.com - Control Techniques,emerson,saftronics -ac drive-servo motor

Simple Data Setting

This chapter describes simple data setting.

5.1 Digital Operator Key Description................................... 32

5.2 LED Description.............................................................. 32

Page 40

Chapter 5: Simple Data Setting

efesotomasyon.com - Control Techniques,emerson,saftronics -ac drive-servo motor

5.1 Digital Operator Key Description

Mode Indicator LED’s (Remote Mode)

Lights when selecting Input mode from the control circuit terminal or

serial communication.

SEQ: Lights when selecting RUN command from control circuit

terminal or serial communication.

REF: Lights when selecting frequency reference from control

circuit Terminals FV and FI or serial communication.

Display

Displays set values of each function or monitoring values such as

frequency and output current. (4 Digits)

Quick-Start LED’s

LED Description

Fref Frequency reference setting/monitoring Enable

Fout Output frequency monitor Enable

Iout Output current monitor Enable

kWout Output power monitor Enable

F/R FWD/REV RUN command selection Enable

Montr Monitor selection Enable

Accel Acceleration time Enable

Decel Deceleration time Enable

Vmtr Motor rated voltage Disable

V/F V/f pattern selection Disable

Fgain Frequency reference gain Disable

Fbias Frequency reference bias Disable

FLA Motor rated current Disable

PID PID selection Disable

kWsav Energy Saving selection Disable

PRGM Constant number/data Disable

Set/Read

During

Run

5.2 LED Description

By using the Quick-Start LED’s on the Digital Operator, simple operation of the Inverter is possible. Each Quick-Start LED is

selected each time DSPL key is pressed. Following is a table describing Quick-Start LED selection.

(Example of model FP5/GP5)

Enter Key

Displays each constant set value. By pressing this key again, the

set value is written in.

Number Change Keys

Changes set values or constant numbers.

∧ : Increment key

∨ : Decrement key

Operation Command Keys

Operation command keys operate the Inverter.

*STOP/RESET : Red LED lights by pressing STOP.

(Resets operation at faults. Reset is disabled

while a RUN command is ON.)

RUN : Red LED lights by pressing RUN.

Operation Mode Selection Key

The Operation mode is alternated between REMOTE and LOCAL

(Digital Operator).

Display Selection Key

Selects the contents of Quick-Start LED’s. (See Page 33)

Figure 17 Digital Operator Key Description

Firmware – S2011 and S3012

Revision: 1 (9/98) 32 © Saftronics, Inc.

Page 41

LED

efesotomasyon.com - Control Techniques,emerson,saftronics -ac drive-servo motor

Display

Chapter 5: Simple Data Setting

Table 12 LED Description

Description Key Sequence Digital Operator Display Remarks

Power ON

Fref Frequency reference setting/monitoring

Fout Output frequency monitor

Iout Output current monitor

kWout Output power monitor

F/R FWD/REV RUN command selection

Montr Monitor selection

Accel Acceleration time

Decel Deceleration time

(During run)

Vmtr Motor rated voltage

0.0

0.0

0.0

0.0

Press ENTER key to

display the monitor value.

Fo

U – 01

10.0

10.0

200.0

V/F V/f pattern selection

Fgain Frequency reference gain

Fbias Frequency reference bias

FLA Motor rated current

PID PID selection

kWsav Energy saving selection

PRGM Constant number/data

Firmware – S2011 and S3012

Revision: 1 (9/98) 33 © Saftronics, Inc.

1

100

0

14.0

0

0

002

Set/read is enabled only

during stop.

Press ENTER key to

display the data.

Page 42

Chapter 5: Simple Data Setting

efesotomasyon.com - Control Techniques,emerson,saftronics -ac drive-servo motor

NOTES:

Firmware – S2011 and S3012

Revision: 1 (9/98) 34 © Saftronics, Inc.

Page 43

6

efesotomasyon.com - Control Techniques,emerson,saftronics -ac drive-servo motor

Programming Features

This chapter describes programming features.

6.1 Constant Set-Up and Initialization................................. 36

6.1.1 Constant Selection/Initialization (n001) ............................................................. 36

6.2 V/f Pattern Setting........................................................... 36

6.2.1 Preset V/f Pattern ............................................................................................... 37

6.2.2 Custom V/f Pattern ............................................................................................. 38

6.3 Setting Operation Conditions ........................................ 38

6.3.1 Reverse Run Prohibit (n006).............................................................................. 38

6.3.2 Multi-Step Speed Selection................................................................................ 38

6.3.3 Operation at Low Speed..................................................................................... 39

6.3.4 Adjusting Frequency Setting Signal................................................................... 40

6.3.5 Adjusting Frequency Upper and Lower Limits................................................... 41

6.3.6 Using Two Accel/Decel Times ........................................................................... 41

6.3.7 Automatic Restart after Momentary Power Loss (n051)................................... 42

6.3.8 Soft-Start Characteristics (n023)........................................................................ 42

6.3.9 Torque Detection................................................................................................ 43

6.3.10 Frequency Detection (n073)............................................................................... 44

6.3.11 Jump Frequencies (n058 to n060)..................................................................... 44

6.3.12 Continuing Operation by Automatic Fault Reset (n056).................................... 45

6.3.13 Operating Coasting Motor without Trip.............................................................. 45

6.3.14 Using Frequency Meter of Ammeter (n048) ...................................................... 46

6.3.15 Calibrating Frequency Meter of Ammeter (n049).............................................. 46

6.3.16 Reducing Motor Noise or Leakage Current (n050) ........................................... 47

6.4 Selecting Stopping Method............................................ 48

6.4.1 Selecting Stopping Method (n004)..................................................................... 48

6.4.2 Coast to Stop with Timer 1 (n004=2)................................................................. 49

6.4.3 Applying DC Injection Braking Current (n064)................................................... 49

6.5 Building Interface Circuits with External Devices........ 50

6.5.1 Using Sequence Input Signals (n035 to n039) .................................................. 50

6.5.2 Using Analog Input Signals (n042 to n045)....................................................... 53

6.5.3 Using Output Signals (n040, n041).................................................................... 55

6.6 Setting Operation Conditions ........................................ 56

6.6.1 Torque Compensation Gain (n067) ................................................................... 56

6.7 Motor Protection ............................................................. 57

6.7.1 Motor Overload Detection .................................................................................. 57

6.8 PID Control ...................................................................... 58

6.8.1 Intended Value Setting....................................................................................... 58

6.8.2 Detected Value Setting....................................................................................... 58

6.9 Energy Saving Control ................................................... 59

6.9.1 Energy Saving Gain K2 (n096) .......................................................................... 59

6.9.2 Energy Saving Tuning........................................................................................ 59

6.10 MEMOBUS Control.......................................................... 60

6.10.1 Communication Specifications........................................................................... 60

6.10.2 Data to be Sent/Received by Communication................................................... 60

Page 44

Chapter 6: Programming Features

efesotomasyon.com - Control Techniques,emerson,saftronics -ac drive-servo motor

6.1 Constant Set-up and Initialization

6.1.1. Constant Selection/Initialization (n001)

The following table describes the data which can be set or read when n001 is selected.

Setting Constant that can be set Constant that can be read

0

(Constant write disable)

1

(Factory setting)

2 n001 to n049 n001 to n108

3 n001 to n108 n001 to n108

4, 5 Not used (disabled)

8 Initialize: 2-wire sequence

9 Initialize: 3-wire sequence

[ Refer to Page 50.

6.2 V/f Pattern Setting

V/f pattern can be set by constant n010.

Set value 0 to E: Preset V/f pattern can be selected.

F : Custom V/f pattern can be set.

n001 n001 to n108

n001 to n034 n001 to n108

[

Firmware – S2011 and S3012

Revision: 1 (9/98) 36 © Saftronics, Inc.

Page 45

Chapter 6: Programming Features

efesotomasyon.com - Control Techniques,emerson,saftronics -ac drive-servo motor

6.2.1. Preset V/f Pattern

The following shows the preset V/f patterns. (The voltages are for 200V class. For 400V class, the value is twice that of

200V class.)

Table 13 Preset V/f Pattern (n010 = 0 to E)

Specifications n010 V/f Pattern *1 Specifications n010 V/f Patterns *1

Low

Starting

Torque

50 Hz 0 50 Hz

High

Starting

Torque

8

9

60 Hz

Saturation

60 Hz

General-Purpose

50 Hz

60 Hz

Variable Torque Characteristics

50 Hz

Saturation

72 Hz 3 90 Hz C

Variable

Torque 1

Variable

Torque 2

Variable

Torque 3

Variable

Torque 4

1

F

2

4

5

6

7

High Starting Torque *2

60 Hz

High Speed Operation

Low

Starting

Torque

High

Starting

Torque

120 Hz D

180 Hz E

A

B

∗ 1 Consider the following items as the conditions for selecting a V/f pattern. They must be suitable for:

• The voltage and frequency characteristics of motor.

• The maximum rotation speed of motor.

∗ 2 Select high starting torque only in the following conditions. Normally, this selection is not required.

• The wiring distance is long (150 meters (492 feet) and above).

• Voltage drop at startup is large.

• AC Reactor is inserted in the input or output of the Inverter.

• A motor smaller than the nominal output of the Inverter is used.

∗ 3 Voltages when the models of 200V, 55kW or above, or 400V, 55kW or above are selected.

Firmware – S2011 and S3012

Revision: 1 (9/98) 37 © Saftronics, Inc.

Page 46

Chapter 6: Programming Features

efesotomasyon.com - Control Techniques,emerson,saftronics -ac drive-servo motor

6.2.2. Custom V/f Pattern

Set each pattern when using a special motor (high-speed motor, etc.) or when requiring special torque adjustment of

machine.

Make sure to satisfy the following

conditions for setting of constants

n012 to n018.

n017 < n015 < n014 < n012

Constant No. Name Unit Setting Range Factory Setting

n012 Maximum output frequency 0.1 Hz

n013 Maximum voltage 0.1 V

n014

n015 Middle output frequency 0.1 Hz

n016

n017 Minimum output frequency 0.1 Hz

n018

Maximum voltage output

frequency (base frequency)

Middle output frequency

voltage

Minimum output frequency

voltage

Figure 18 Custom V/f Pattern Setting

50.0 − 400.0 Hz

0.1 − 255.0 V

0.1 Hz 0.2 − 400.0 Hz 60.0 Hz

0.1 −399.9 Hz

0.1 V 0.1 − 255.0 V

0.1 − 10.0 Hz

0.1 V 0.1 − 50.0 V

[

[

[

60.0 Hz

200.0 V

15.0 V