Saft SUN+ 405, SUN+ 250, SUN+ 305, SUN+ 355, SUN+ 455 Installation And Operating Instructions Manual

...

Sunica.plus Ni-Cd batteries

Installation and operating instructions

December 2013

Important recommendations

■ Never allow an exposed flame or spark

near the batteries particularly while

charging.

■ Never smoke while performing any

operation on the battery.

■ For protection, wear rubber gloves, long

sleeves, and appropriate splash goggles

or face shield.

■ The electrolyte is harmful to skin and

eyes. In the event of contact with skin

or eyes, wash immediately with plenty

of water. If eyes are affected, flush

with water, and obtain immediate

medical attention.

■ Remove all rings, watches and other

items with metal parts before working

on the battery.

■ Use insulated tools.

■

Avoid static electricity and take measures

for protection against electric shocks.

■ Discharge any possible static electricity

from clothing and/or tools by touching

an earth-connected part "ground" before

working on the battery.

1. Receiving the shipment

Do not overturn the package. Check the

packages and cells for transport damage.

The cells are shipped filled and charged, and

is ready for immediate use.

Transport seals are located under the lid of

each vent, they must be removed prior to

mounting.

The cells must never be charged with the

plastic transport seals in place as this is

dangerous and can cause permanent

damage.

2. Storage

Store the cells indoors in a dry, clean, cool

location (0°C to +30°C / +32°F to +86°F)

and well ventilated space on open shelves.

Storage of filled cells at temperatures above

+30°C (+86°F) can result in loss of capacity.

This can be as much as 5% per 10°C

(18°F) above +30°C (+86°F) per year.

Do not store in direct sunlight or expose to

excessive heat.

Sunica.plus batteries are supplied filled with

electrolyte and charged, they can be stored

in this condition for maximum 2 years

from date of shipment.

Never drain the electrolyte from the cells.

3. Installation

3.1. Location

Install the battery in a dry and clean room.

Avoid direct sunlight and heat. The battery

will give the best performance and maximum

service life when the ambient temperature is

between +10°C to +30°C / +50°F to +86°F

3.2. Ventilation

During the last part of charging, the battery

is emitting gases (oxygen and hydrogen

mixture). At normal float charge, the gas

evolution is very small but some ventilation

is necessary.

Note that special regulations for

ventilation may be valid in your area

depending on the application.

3.3. Mounting

Verify that cells are correctly interconnected

with the appropriate polarity. The battery

connection to load should be with nickel

plated cable lugs.

Recommended torques for terminal

bolts are:

• M6 = 11 ± 1.1 N.m (97.4 ± 9.8 lbf.in)

• M8 = 20 ± 2 N.m (177.0 ± 17.7 lbf.in)

• M10 = 30 ± 3 N.m (265.0 ± 26.6 lbf.in)

The connectors and terminals should be

corrosion-protected by coating with a thin

layer of anti-corrosion oil.

Remove the transport seals and close the

vent caps.

If a central water filling system is used as an

option, refer to the corresponding

installation and operating instructions sheet.

3.4 Electrolyte

When checking the electrolyte levels,

a fluctuation in level between cells is not

abnormal and is due to the different

amounts of gas held in the separators

of each cell. The level should be at least

15 mm above the minimum level mark

and there is normally no need to adjust it.

Do not top-up prior to initial charge.

After commissioning, when the level is

stabilized, it should be not less than

5 mm below the maximum level mark.

4. Commissioning

Verify that the transport seals are removed

and the ventilation is adequate during the

operation.

A good commissioning is important.

Charge at constant current is preferable.

If the current limit is lower than indicated

in the table A, charge for a proportionally

longer time.

.

4.1. Cells stored up to 6 months:

A commissioning charge is normally not

required and the cells are ready for immediate

use. If full performances are necessary

immediately, a commissioning charge as

mentioned in section 5.4. is recommended.

4.2. Cells stored more than 6 months

and up to 2 years:

A commissioning charge is necessary.

• Commissioning at ambient temperature

between +10°C to +30°C

(+50°F to +86°F)

- Constant current charge:

20 h at 0.1 C

(see table A)

Note: At the end of the charge, the cell

voltage will reach the level of 1.75V/cell,

thus the charger shall be able to supply

such voltage.

When the charger maximum voltage

setting is too low to supply constant

current charging, divide the battery in two

parts to be charged individually.

- Constant potential charge: 1.55 V/cell

for a minimum of 24 hours with current

limited to 0.1 C

Table A).

• Commissioning at ambient temperature

above +30°C (+50°F)

- Only constant current charge:

20 h at 0.1 C

The electrolyte temperature is to be

monitored during charge. If the

temperature exceeds +45°C (+113°F)

during charging, then it must be stopped to

reduce the temperature. The charging can

be resumed when electrolyte temperature

drops below +40°C (+104°F).

In the case of remote areas, where

the only charger available is the photovoltaic

array, the battery should be connected to the

system with no connected load and no

voltage limit. The battery should then be

charged in good sunshine conditions. During

this operation, the Ah charged shall be in the

magnitude of 1.6 time the rated capacity,

and, in order to limit the risk of electrolyte

overflow, it is recommended not to exceed

the charge current value specified

in the Table A.

A recommended

5

A (see the current in

5

recommended.

5

Sunica.plus Ni-Cd batteries

4.3. Cell electrolyte after prolonged float

charge:

Check the electrolyte level and adjust it to the

upper level mark by adding distilled or

deionized water.

Note: When full battery performance is

required for capacity test purposes, the

battery has to be charged in accordance

with IEC 62259 section 7 (7.1 & 7.2).

5. Charging in service

The photovoltaic array converts solar

irradiance into DC electrical power at a predetermined range of voltages whenever

sufficient solar radiation is available. Unlike a

main connected system, the output from a

photovoltaic array is variable and, to obtain

the best efficiency from the system, it is quite

normal to have some form of charge control.

Two main techniques for charging the

batteries are generally used in photovoltaic

systems.

These are those which have a constant

voltage limitation based on the PWM technics

and those with several voltage steps charging

where the battery, by switching means, is

charging up to a high pre-set voltage (boost

or float threshold), then drops to a lower

voltage level (battery reconnect threshold)

and then back to the high pre-set voltage

and so on.

Recommended charging voltages for a typical

photovoltaic application sized for

5 days or more back up time:

a) case of constant voltage limitation (PWM

regulator system or similar)

• float: 1.50 V/cell

• boost (not mandatory): 1.65 V/cell

b) case of regulators based on the switching

principle:

• boost threshold (not mandatory):

1.65 V/cell

• float threshold: 1.55 V/cell

• battery reconnect threshold:

1.45 V/cell

For lower back-up time, the values have to be

increased depending of the load requirement.

Consult the manufacturer.

For use in warm areas, a temperature

compensation on the charge voltage is not

recommended.

For use in cold areas, a temperature

compensation is recommended to increase

the charge acceptance.

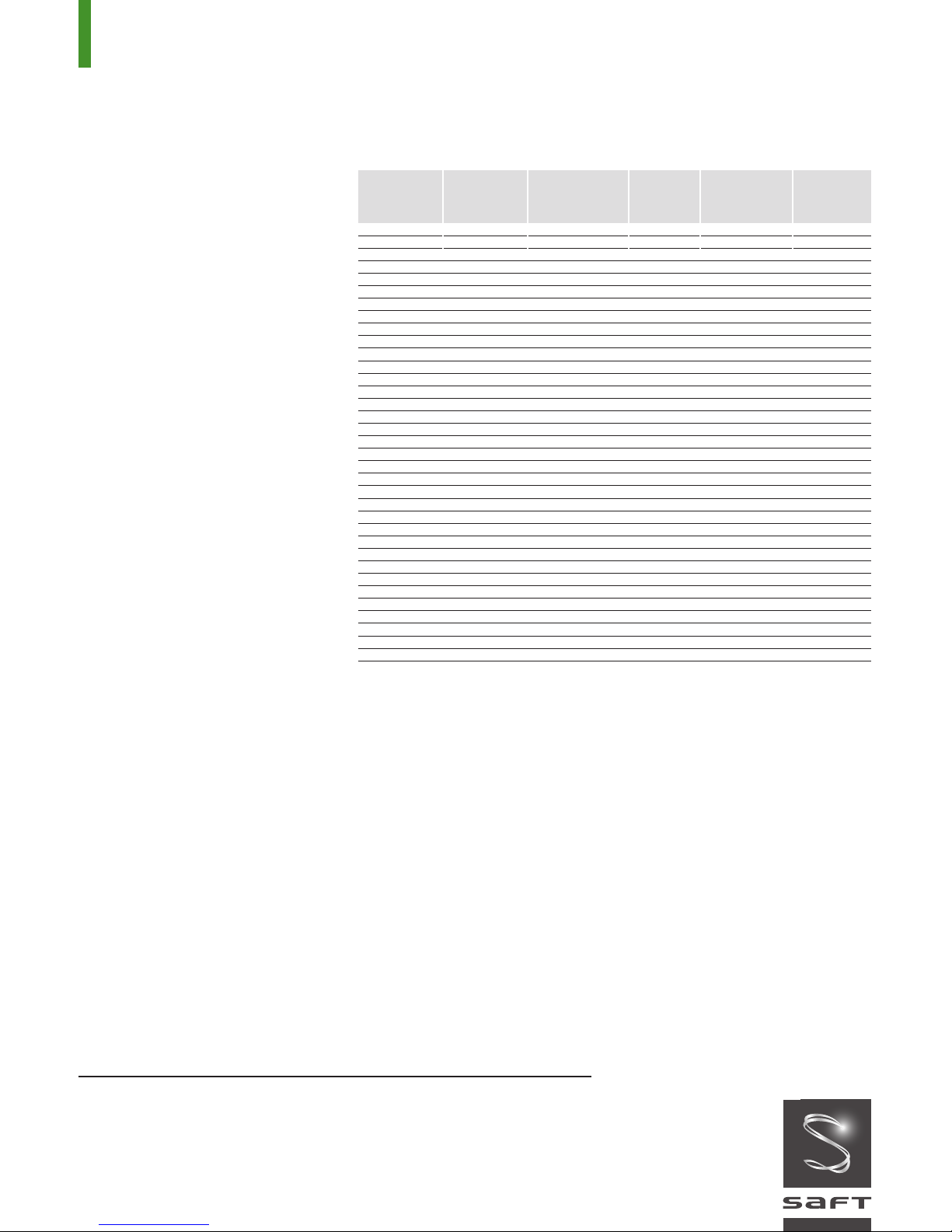

Table A:

Rated Nominal Capacity Charging Max. quantity Cell

Cell type

SUN+ 100 95 100 9,5 280 M8

SUN+ 150 140 150 14,0 380 M10

SUN+ 200 185 200 19,0 500 M10

SUN+ 250 235 250 24,0 590 M10

SUN+ 305 280 305 28,0 700 M10

SUN+ 355 325 355 33,0 880 2xM10

SUN+ 405 375 405 38,0 1000 2xM10

SUN+ 455 420 455 42,0 1100 2xM10

SUN+ 505 470 505 47,0 1200 2xM10

SUN+ 555 515 555 52,0 1300 2xM10

SUN+ 610 560 610 56,0 1400 2xM10

SUN+ 660 610 660 61,0 1600 3xM10

SUN+ 710 650 710 65,0 1700 3xM10

SUN+ 760 700 760 70,0 1800 3xM10

SUN+ 810 750 810 75,0 1900 3xM10

SUN+ 860 800 860 80,0 2000 3xM10

SUN+ 910 840 910 84,0 2100 3xM10

SUN+ 960 890 960 89,0 2300 4xM10

SUN+ 1015 940 1015 94,0 2400 4xM10

SUN+ 1065 980 1065 98,0 2500 4xM10

SUN+ 1115 1030 1115 103 2600 4xM10

SUN+ 1170 1080 1170 108 2700 4xM10

SUN+ 1215 1120 1215 112 2800 4xM10

SUN+ 1270 1170 1270 117 3000 5xM10

SUN+ 1320 1220 1320 122 3100 5xM10

SUN+ 1370 1260 1370 126 3200 5xM10

SUN+ 1420 1300 1420 130 3300 5xM10

SUN+ 1470 1350 1470 135 3400 5xM10

SUN+ 1520 1400 1520 140 3500 5xM10

SUN+ 1570 1450 1570 145 3700 5xM10

SUN+ 1620 1500 1620 150 3800 6xM10

SUN+ 1670 1550 1670 155 3900 6xM10

SUN+ 1720 1600 1720 160 4000 6xM10

SUN+ 1775 1650 1775 165 4100 6xM10

SUN+ 1830 1700 1830 170 4200 6xM10

The recommended value is:

–3.0 mV/°C/cell (–1.68 mV/°F/cell)

starting from +20°C (+68°F).

6. Periodic Maintenance

■ In a correctly designed standby

application, Sunica.plus requires the

minimum of attention.

However, it is good practice with any system

to carry out an inspection of the system once

per year or at the recommended topping-up

interval period to ensure that the charging

system, the battery and the ancillary

electronics are all functioning correctly.

■ When this system service is carried out,

it is recommended that the following

actions should be taken:

• Keep the battery clean using only water.

Do not use a wire brush or solvents of

any kind. Vent plugs can be rinsed in

clean water if necessary.

• Check visually the electrolyte level.

Never let the level fall below the minimum

Capacity 5 h - 120 h - 1.00 V Current of water connection

C

h 1,00 V Ah C

5

(Ah) (Ah) (A) in cc per pole

Ah 0.1 C5A to be added bolt

120

level mark. Use only distilled or deionized

water to top-up (see Table A for the

quantity of water per cell). Topping up of

the Sunica.Plus battery shall be carried

out when battery is fully charged.

Experience will tell the time interval

between topping-up.

Note: There is no need to check the

electrolyte density periodically.

Interpretation of density measurements is

difficult and could be misleading.

• Check every two years that all

connectors are tight.

• The connectors and terminal bolts should

be corrosion-protected by coating with a

thin layer of anti-corrosion oil.

•

High water consumption is usually caused

by improper voltage setting of the charger.

7. Environment

To protect the environment all used batteries

must be recycled. Contact your local Saft

representative for further information.

Saft

Industrial Battery Group

12, rue Sadi Carnot

93170 Bagnolet - France

Tel: +33 1 49 93 19 18

Fax: +33 1 49 93 19 64

www.saftbatteries.com

Doc N° 21885-2-1213

Data in this document is subject to change without

notice and becomes contractual only after written

confirmation.

Société par Actions Simplifiée

au capital de 31 944 000

RCS Bobigny B 383 703 873

Le Révérend Imprimeur - Printed in France - 1k

€

Loading...

Loading...