- Industrial interface

TECHNICAL NOTE

VS1000: Evaluation Kit EVBA_2.0

EVBA_2.0 – is a “plug and play” Evalu ation Kit for Safran Colibrys VS1000 accelerometers line.

To facilitate the integrat ion in user environment and easil y verify the excellent performanc es of VS1000 sensors,

EVBA_2.0 integrates a VS1000 sensor with the user specified range, an ultra-low-noise, high-accuracy 3.3V voltage

reference, the decoupling capacitors and output buffers.

Features:

- Low noise power supply management converting +5V to 3.3V

- Output signal conditioning:

buffers to enable the use of long lines between the sensor and the user electronic

low-pass filters with a cutting frequency

- Easy integration into system: 4 fixing holes

Contents

1 EVBA_2.0 description: ......................................................................................................................................... 2

2 Evaluation board function .................................................................................................................................... 4

3 Operation ............................................................................................................................................................. 7

4 Ordering Information ............................................................................................................................................ 9

5 Disclaimer ............................................................................................................................................................ 9

VS1000: Evaluation Kit EVBA_2.0

Document number 30N.EVBA_2.0.A

Document revision V1.0

Date of revision 06 September 2016

Note Safran Colibrys reserves the right to change these data without notice

Safran Colibrys reserves the right to change these data without notice

by electrostatic discharge (ESD). Handle with appropriate precautions and

Pin Nr

Pin name

Connector

Description

1

VTemp_f

J1

Temperature sensor analog output (buffered)

2

VDD_s

J1

+3.3 VDC reference voltage sens e output (not buffered)

3

OUTN_f

J1

Negative differential output (buffered)

4

V

MID

J1

Internal ASIC reference voltage. For decoupling capacitors only

5

OUTP_f

J1

Positive differential output (buffered)

6

VSS (0 V)

J1

Must be connected to ground plane (GND)

7

Vout_SE

J1

Single output acceleration (Vout_SE = OUTP - OUTN) (buffered)

8

Vp (+5V)

J1

Power supply 5.0VDC – 5.5VDC

9

VSS (0 V)

J1

Must be connected to ground plane (GND)

10

VSS (0 V)

J1

Must be connected to ground plane (GND)

11

ERR

J1

Error signal (output, active high)

12

ST

J1

Self-test activation (input, active high)

13

POR

J1

Power-on Reset signal (output, active high)

14

RESET

J1

System reset signal (input, active low)

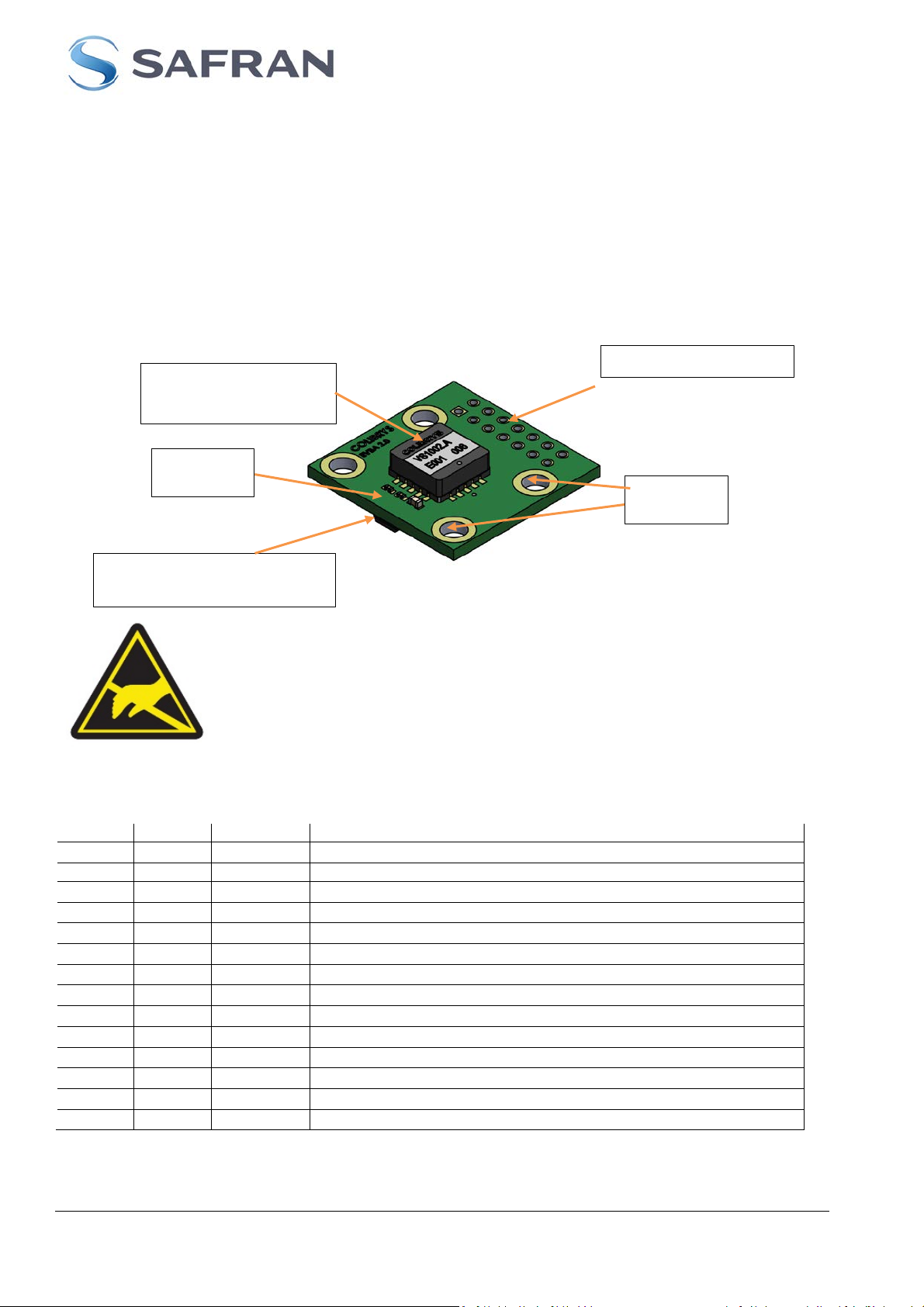

Accelerometer VS1000

Decoupling

capacitors

Connecting holes “J1”

Ø3.4mm

fixing hole

Proximity electronics, with

TECHNICAL NOTE

1 EVBA_2.0 description:

1.1 General overview

The EVBA_2.0 is a Kit containing 3 components:

- 1 analog evaluatio n board with soldered V S1000 of c orrespond ing G range. Evaluation board contains

electronic circuits to achieve a preliminary signal conditioning

- 1 * header connector “J1” with 14 pins (to be soldered onto the EVBA dedicated pads)

- 1 * mating connector (14 pins) including 13 cm length signal cable ribbon

The EVBA_2.0 is protected from outside atmospheric condition effects (temperature, humidity) by a vacuum

sealed electrostatic conductive plastic bag

power supply and buffers

Note: MEMS accelerom eter and electro nic cir cuits on t he EVB A can be dam aged

placement should be done in accordance with strict ESD control

Please check the integrity of the plastic bag and report if any damage or if the bag

is open on arrival.

1.2 Interface Pinout

The Table 1 below describes the pin name and interface for the connecting pads J1:

(1)

Note 1: this pin should be left unconnected.

Table 1: Interface Pinout

Safran Colibrys SA

Av. des Sciences 13 – 1400 Yverdon-les-Bains - Switzerland T +41 58 100 5000

www.safran-colibrys.com page 2 F +41 58 100 5001

30N.EVBA V2.10.16

1 2 13

14

TECHNICAL NOTE

1.3 Electrical connections

It is the user choice to mount Header connector (Figure 1) on J1 connecting pads or to solder the signal wires

directly on the EVBA board. The size of the soldering hole are of 0.8mm, so wires up to a conductor area of

0.5mm2 or AWG21 are suitable. The wires or the Mating connector (Figure 2) will ideally be hand soldered

using a PB free solder with the appropriate flux.

Note: Connector J1 is a 14 Positions Header, Shrouded Connector 0.100" (2.54mm) Through Hole, Right Angle

This connector is delivered unsoldered to the evaluation board. The user is free to use it or to solder any

connection directly on the board.

Figure 1: Connector J1 Figure 2: Mating connector (14 pins)

1.4 Mechanical dimensions

The mechanical layout of the evaluation board is shown in Figure 3. All components are soldered on the top

and bottom surface and the board can be mounted using the 4 x Ø3.40 mm through holes:

Note: This is for the VS1002, other range looks like same

Figure 3: Mechanical Dimensions [mm] showing a VS1002

Safran Colibrys SA

Av. des Sciences 13 – 1400 Yverdon-les-Bains - Switzerland T +41 58 100 5000

www.safran-colibrys.com page 3 F +41 58 100 5001

30N.EVBA V2.10.16

TECHNICAL NOTE

2 Evaluation board function

To fac ilitate the integration in an user environment a nd easily verify the excel lent performances of the Safran

Colibrys VS1000 s er ie sensors, the p lu g a nd pl a y board EVBA_2.0 integrates one VS1 000 s ensor with the user

specified range, an ultra-low-noise, high-accur ac y 3.3V voltage reference, the dec oupling ca pacit ors and out put

buffers as shown in Figure 4. The board will powered by a single +5V

2.1 Normal operation (recommended)

Optimal acceleration m easurem ents are ach ieved by using the diff erential buff ered signal outputs OUTP_f and

OUTN_f.

2.2 Optional operation

If user application requires a unipolar signal, a single-ended buffered output Vout_SE is provided as well.

2.3 Block Diagram

The Block diagram of the EVBA2.0 is given below. The sensor implemented is represented by the green marked

zone. The VS1000 sensor signal outputs are linked to a unity gain buffer via a 1

The Output of the unity gain buffer is then connected to the dedicated pins of J1. The board +5.0V power supply

is connected to VP and an Ultra-Low-N oise, High-Accuracy 3.3V Volt age Reference generates the necessary

+3.30 VDD voltage. The capacitors C1, C2 and C3 forms the decoupling elements for the ASIC reference voltage

Vmid. Note that this voltage level is also linked to J1. That pin must be left open for normal operation.

The single ended output signal Vout_SE expresses the relation described at §2.8

power supply.

DC

st

order low pass filter (fc=16kHz).

Figure 4: Functional Diagram EVBA2.0

Safran Colibrys SA

Av. des Sciences 13 – 1400 Yverdon-les-Bains - Switzerland T +41 58 100 5000

www.safran-colibrys.com page 4 F +41 58 100 5001

30N.EVBA V2.10.16

2.4 Electrical Schema

The corresponding detailed electrical schema is given below.

TECHNICAL NOTE

Figure 5: EVBA Elect ro n ic c ir c uit

2.5 Power Supply

The EVBA power supply is set for +5.0V

(pin8 of J1) and the 0VDC must be connected to all VSS pins of J1 (pin

DC

6, pin 9, pin10).

The VS1000 series accelerometers require a +3.30VDC power supply named Vdd. The sensor outputs are

ratiometric to that Vdd voltage level. This could directly impact the acceleromet er bias, scale factor, noise or

thermal perform ance. Therefore, a low-noise, high-stability and lo w-thermal drift Vdd po wer supply has been

implemented on the board using an Ultra-Low-Noise, High-Accuracy 3.3V Voltage Reference type ADR4533.

The Sensor Vdd line (+3.30V

) is als o connec ted to PIN 2 of the J1 a nd can be then used as an out put si gnal

DC

(VDD_S) in order to compens ate any variatio n on the power suppl y voltage that may im pact the accelerometer

signal (ratiometric output).

The voltage Vmid sets to a le vel of 0. 5 x Vdd and is a voltage required b y the ASI C of the sensor. F or a norm al

operation of the sensor th is line should be left op en. Checking the level sha ll be only reserved and lim ited for

debug purposes. Any impedance c onnec ted to that line c ould dir ectl y im pac t the st abilit y, bias, s cale f actor an d

noise figure of the VS1000 series sensors.

Safran Colibrys SA

Av. des Sciences 13 – 1400 Yverdon-les-Bains - Switzerland T +41 58 100 5000

www.safran-colibrys.com page 5 F +41 58 100 5001

30N.EVBA V2.10.16

TECHNICAL NOTE

2.6 Accelerom eter sen so r

The sensor block is composed of the VS1000 accelerometer and three capacitors C1 (10 µF), C2 (1 µF) and C3

(1 µF). These capacitors are required as decoupling capacitors and for a proper sensor startup. They are

mandatory for the pr oper operation and full perf ormance of the accelerometer. T hey are located as close as

possible to the VS1000 package on the printed circuit board.

2.7 Output signal conditioning

The analog acceler at ion s ignal ou tput lines (OutN, O ut P) req uir e a h igh impedance load in or der not to degrade

the signal characteristic. To drive long signal lines between the EVBA and the user electronic, buffers have been

implemented on the EVBA. Additionally the Temperature analog output signal is also buffered.

The buffers are implem ented using a Zero-Drif t, Single-Sup ply, Rail-to-R ail Input/Output Operatio nal Amp lifiers

type AD8574.

The operational am plifiers U3A, U3B and U3C are configured as vo ltage f ollower (gain =1) and are prec eded by

low-pass filters R8/C8, R7/C7 and R6/C6 respectively introducing a cutting frequency of 16 kHz. The attenuation

at 1500Hz is less than 0.5%, allowing the use of the full bandwidth of the sensor.

The resistors R15, R14 an d R13 (all of 100 Ω) are connected t o the buf fer output reduc e the lo op phas e shif t at

high frequency when driving a capacitive load (ie the cable link between the EVBA and the Electronic system).

2.8 Differential to Single Output

Safran Colibrys’s VS1000 series provide a differential output for the sensed acceleration. The EVBA implements

a differential to single en ded m ode c onverter built arou nd the four th O P am plifier of the AD8574 ( U3D). A s et of

matched resistances is used to divide the voltages and add an offset to avoid saturation of the amplifier:

−

_

=

_

_

2

Note:

- The scale factor of the single ended output is only half that of the differential output.

- The common mode noise is not canceled when using a single ended output.

2.9 Temperature sensing

Each Safran Colibrys VS1000 accelerometer integrate an internal temperature sensor. The output voltage

Vtemp_f buffer ed by OPAMP U3B (u nity gain) to PIN1 of J 1 gives a voltage pro portional to t he internal sensor

temperature and can be u sed to achieve additional com pensation of the measured acceleration to ob tain the

optimum readouts.

The temperature is then given by the function

= 1.23 − 0.004 ( −

+

2

)

Safran Colibrys SA

Av. des Sciences 13 – 1400 Yverdon-les-Bains - Switzerland T +41 58 100 5000

www.safran-colibrys.com page 6 F +41 58 100 5001

30N.EVBA V2.10.16

TECHNICAL NOTE

2.10 Bill of material (BOM)

The following table lists all components used for the presented design:

Component Value Function

U1 VS1000 Safran Colibrys Accelerometer

U2 ADR4533 3V3 Voltage Reference – Analog Devices ADR4533BRZ

U3 AD8574 Quad Operational Amplifier – Analog Devices AD8574ARZ

R1, R2, R3, R4 10 kΩ Voltage divider – 0402 resistor

R5 20 kΩ Voltage divider – 0402 resistor

R6, R7, R8 100 kΩ Low pass filter – 0402 resistor

R9, R10 5 kΩ Voltage divider – 0402 resistor

R11, R12 40 kΩ Voltage divider – 0603 resistor

R13, R14, R15, R16 100 Ω Output load – 0402 resistor

C1 10 µF Decoupling – 0603 capacitor

C2, C3, C4 1 µF Decoupling – 0402 capacitor

C5 100 nF Decoupling – 0402 capacitor

C6, C7, C8 100 pF Low pass filter – 0402 capacitor

J1 HEADER 7X2 Connector (if required*)

*The wires may also be soldered directly on the board.

Table 2: Bill of material

3 Operation

Handle with appropriate precautions and be done in accordance with strict ESD control.

It is the user choice to use the connector provided or to solder the signal wire lines

directly on the board. In both situation please follow the proper soldering process. Hand

soldering is recommended.

3.1 Power Up

Once the cabling done the EVBA can be powered up by applying the VP voltage level. The current consumption

and the reference voltage V

Parameter Designation [unit] Typical

Sensor +3.30V power supply VDD [VDC]

Board current consumption IP [mADC]

shall be:

DD

3.30

7.14

Safran Colibrys SA

Av. des Sciences 13 – 1400 Yverdon-les-Bains - Switzerland T +41 58 100 5000

www.safran-colibrys.com page 7 F +41 58 100 5001

30N.EVBA V2.10.16

Single-ended

VOUT_SE

J1 / Pin#

Signal

Designation

12

ST

Self-test activation, active high

14

RESET

System reset signal, active low

TECHNICAL NOTE

3.2 Outputs

With the EVBA board placed horizontal in a quite environment will expose the sensor to an acceleration of 1g.

The corresponding level of the signals OUTP_f, OUTN_f and Vout_SE settles proportional to the range and

scale factor of the VS1000 mounted. The available ranges are ± 2g, 5g, 10g, 30g, 100g and 200g.

The typical readouts are at 1g acceleration:

Parameter

OUTP OUTP [VDC]

OUTN OUTN [VDC]

output

With the EVBA operated in an ambient temperature of +25°C ± 3°C the Vtemp-f signal on J1/1 shall read:

Designation

[unit]

[VDC]

2g 5g 10g 30g 50g 100g 200g

2.325 1.920 1.785 1.695 1.677 1.663 1.657

0.975 1.380 1.515 1.605 1.623 1.636 1.643

2.325 1.920 1.785 1.695 1.677 1.663 1.657

Parameter Designation [unit] Typical

Typical

Vtemp buffered Vtemp_f [VDC]

The VS1000 accelerometer provides logic output signals:

1.210

Parameter Designation [unit] Typical

Error signal (flag) ERR [VDC]

Power-on Reset signal (flag) POR [VDC]

Vss

Vdd

3.3 Logic signals

Some functionalities can be controlled by applied logical signals according to the Table 3.

They all are referenced to the VS1000 Vdd (+3.3V

) voltage level and proper

DC

interfacing is required. A Logic HIGH level corres ponds to the Vd d voltage level and a

logic LOW level to the Vss voltage level.

Table 3

For the detailed function and effects of these signals please refer to the Datasheet of the VS1000 sensor.

Safran Colibrys SA

Av. des Sciences 13 – 1400 Yverdon-les-Bains - Switzerland T +41 58 100 5000

www.safran-colibrys.com page 8 F +41 58 100 5001

30N.EVBA V2.10.16

Range [g]

Designation

Part Number

±2

EVBA_2.0_VS1002.A

37628071

±5

EVBA_2.0_VS1005.A

37623081

±10

EVBA_2.0_VS1010.A

37625033

±30

EVBA_2.0_VS1030.A

37628084

±50

EVBA_2.0_VS1050.A

37629043

±100

EVBA_2.0_VS1100.A

37629061

±200

EVBA_2.0_VS1200.A

37629081

TECHNICAL NOTE

4 Ordering Information

The user will have to select the appropriate sensor range for his application (see VS1000 family data sheet) and

then order the corr esponding EVB A version. Table 4 sho ws the range, Designat ion and Part num ber for each

available EVBAs.:

Table 4: EVBA ordering number

5 Disclaimer

EVBA_2.0_VS1000 evaluation kit is only intended for device evaluation, not for production purposes.

Safran Colibrys SA

Av. des Sciences 13 – 1400 Yverdon-les-Bains - Switzerland T +41 58 100 5000

www.safran-colibrys.com page 9 F +41 58 100 5001

30N.EVBA V2.10.16

Loading...

Loading...