Installation and Operation Manual

CBX/CB Series

Fixed Frame Top Mount Trailer Air Suspension

For Disc and Drum Brake Applications

XL-AS11406OM-en-US Rev E

Contents

Contents Page

Introduction ......................................................................... 3

Warranty .............................................................................. 3

Notes, Cautions, and Warnings ............................................. 3

Section 1 – General Safety Instructions ................................ 4

Section 2 – Standard Decal Requirements ............................ 5

Section 3 – CBX Fusion Model Identification ....................... 6

Section 4 – CBX Fusion Model Nomenclature ....................... 6

Section 5 – CBX Model Identification ................................... 7

Section 6 – CBX Model Nomenclature .................................. 7

Section 7 – CB-2300 Model Identification ........................... 8

Introduction

This manual provides information necessary for the installation

and operation of the SAF-HOLLAND® CBX/CB fixed frame top

mount trailer air suspension. Although the images throughout

this manual depict the CBX23 Fusion, there is no difference in

fit or function between the models in the CBX/CB Series.

The CBX/CB suspensions include premium 5.75" diameter

axles, the CB suspensions include 5" diameter axles. For axle

end and/or brake servicing information or component

replacements, refer to Drum Brake Manual XL-TA10006OM-en-US,

Disc Brake Manual XL-SA10059OM-en-US or contact Customer

Service at 888-396-6501.

Contents Page

Section 8 – CB-2300 Model Nomenclature ........................... 8

Section 9 – Welding Standards ............................................. 9

Section 10 – Standard Air Control System Installation ........ 10

Section 11 – Suspension Assembly Installation ................... 11

Section 12 – Ride Height Adjustment ................................. 12

Section 13 – SwingAlign™ Axle Alignment .......................... 14

Section 14 – Brake Adjustment Instructions ........................ 14

Section 15 – Pre-Operation Information ............................. 15

Section 16 – Maintenance and Service Schedule................. 16

Section 17 – Torque Specifications ..................................... 17

Warranty

Refer to the complete warranty for the country in which

the product will be used. A copy of the written warranty is

included with the product or available on the internet at

www.safholland.com.

Notes, Cautions, and Warnings

Before starting any work on the unit, read and understand all

the safety procedures presented in this manual. This manual

contains the terms “NOTE”, “IMPORTANT”, “CAUTION”, and

“WARNING” followed by important product information. These

terms are defined as follows:

This suspension uses air drawn from the tractor air system to

pressurize the air springs. The height control valve (HCV) regulates

the air pressure required for varying loads while maintaining the

design ride height. This suspension can provide a cushioned ride

throughout the load range, from empty to fully loaded.

The suspension also provides excellent side-to-side and

axle-to-axle loading which helps equalize and control braking.

Read this manual before using or servicing this product and

keep it in a safe location for future reference. Updates to this

manual, which are published as necessary, are available on

the internet at www.safholland.us.

When replacement parts are required, SAF-HOLLAND

highly recommends the use of only SAF-HOLLAND Original

Parts. A list of technical support locations that supply

SAF-HOLLAND Original Parts and an Aftermarket Parts Catalog

are available on the internet at www.safholland.us

or contact Customer Service at 888-396-6501.

NOTE: Includes additional information to enable accurate

and easy performance of procedures.

IMPORTANT: Includes additional information that

if not followed could lead to hindered

product performance.

Used without the safety alert symbol,

indicates a potentially hazardous

situation which, if not avoided, could

result in property damage.

Indicates a potentially hazardous

situation which, if not avoided, could

result in minor or moderate injury.

Indicates a potentially hazardous

situation which, if not avoided, could

result in death or serious injury.

XL-AS11406OM-en-US Rev E · 2018-04-17 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

3

General Safety Instructions

1. Safety Instructions

General and Servicing Safety Instructions

Read and observe all Warning and Caution hazard alert

messages. The alerts provide information that can help prevent

serious personal injury, damage to components, or both.

Failure to follow the instructions and

safety precautions in this manual could

result in improper servicing or operation

leading to component failure which, if not

avoided, could result in death or serious injury.

All maintenance should be performed by a properly

technician using proper/special tools, and safe procedures.

NOTE: In the United States, workshop safety requirements

are defined by federal and/or state Occupational

Safety and Health Act (OSHA). Equivalent laws may

exist in other countries. This manual is written based

on the assumption that OSHA or other applicable

employee safety regulations are followed by the

location where work is performed.

Properly support and secure the vehicle from unexpected

movement when servicing the unit.

Failure to properly support and secure the

vehicle and axles prior to commencing work

could create a crush hazard which, if not

avoided, could result in death or serious injury.

If possible, unload the trailer before performing any

service procedures.

After re-positioning the brake chamber, slack adjuster and/

or ABS system as instructed in this manual, always consult

the manufacturer’s manual for proper operation.

Service both roadside and curbside of an axle. Worn parts

should be replaced in sets. Key components on each axle’s

braking system, such as friction material, rotors and drums

will normally wear over time.

Follow all manufacturer’s instructions on spring pressure

and/or air pressure controls.

Failure to follow manufacturer’s instructions

regarding spring pressure or air pressure

control could allow unexpected release of

energy which, if not avoided, could result

in death or serious injury.

DO NOT paint the wheel contact surfaces between the wheel

and hub.

IMPORTANT: The wheel contact surfaces MUST be clean,

smooth and free from grease.

Failure to keep wheel and hub contact surfaces

clean and clear of foreign material could

allow wheel/hub separations which, if not

avoided, could result in death or serious injury.

Only the wheel and tire sizes approved by the trailer builder

can be used.

trained

Operational and Road Safety Instructions

Before operating vehicle, ensure that the maximum permissible

axle load is NOT exceeded and that the load is distributed

equally and uniformly.

Make sure that the brakes are NOT overheated from

continuous operation.

Failure to minimize the use of brakes during

overheating conditions could result in

deterioration of brake efficiency which,

if not avoided, could result in death or

serious injury.

The parking brake MUST NOT be immediately applied when

the brakes are overheated.

If the parking brake is immediately applied

to the brakes when overheated, the brake

drums or discs could be damaged by different

stress fields during cooling.

Observe the operating recommendation of the trailer

manufacturer for off-road operation of the installed axles.

IMPORTANT: The definition of OFF-ROAD means driving

on non-asphalt/non-concrete routes, e.g.

gravel roads, agricultural and forestry tracks,

on construction sites and in gravel pits.

IMPORTANT: Off-road operation of axles beyond

the approved application design could

result in damage and impair suspension

system performance.

Follow the recommended routine maintenance and inspections

described in this manual. These procedures are designed so

that optimum performance and operational safety are achieved.

In the event of suspension air pressure loss, quickly reduce

speed as safely as possible and remove the vehicle from

traffic. If unable to remove vehicle from traffic, follow DOT

safety requirements regarding emergency situations.

Contact a qualified towing and/or service company to assist

in repairing the vehicle or to move it to a qualified repair facility.

DO NOT operate the vehicle in the absence of suspension

air pressure; however in the event of an air system failure

while in service, an internal rubber bumper built into the

air spring will make it possible to temporarily operate the

vehicle at reduced speed determined by road conditions.

Operating the vehicle without proper air

pressure can cause tire failure, fire, or loss

of vehicle control which, if not avoided,

could result in death or serious injury.

4

XL-AS11406OM-en-US Rev E · 2018-04-17 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

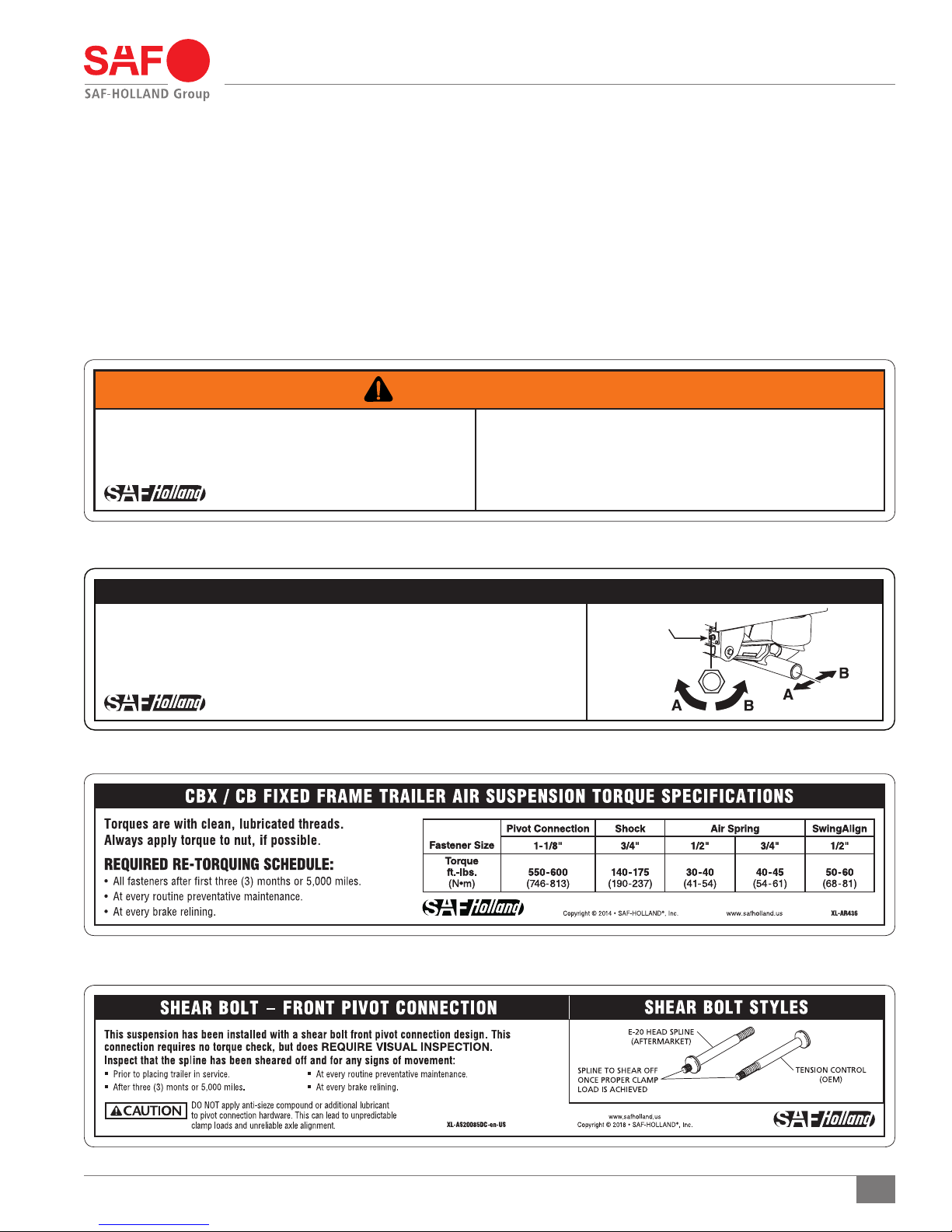

2. Standard Decal Requirements

Decal Requirements

The following three (3) decals MUST be properly installed on

the trailer prior to putting it in service:

It is the responsibility of the end user to periodically inspect

all decals and ensure that they are clean and completely legible.

If any decals are missing, loose, damaged or difficult to read,

Tire Clearance Warning Decal: XL-AR356-01 (Figure 1).

SwingAlign Axle Alignment Decal: XL-AR435 (Figure 2).

Torque Decal: XL-AR436 (Figure 3).

Shear Bolt Decal: XL-AS20085DC-en-US (Figure 4).

contact SAF-HOLLAND Customer Service at 888-396-6501

to order replacements immediately.

Figure 1

WARNING

Minimum tire clearance MUST be maintained between tires and

nearest point of contact on the suspension or vehicle. Premature

tire wear, fire or loss of vehicle control could result from contact

with the tires if clearances are not maintained.

Copyright © 2011 • SAF-HOLLAND, Inc.

www.safholland.us

XL-AR356-01

Figure 2

SWING ALIGN® NON-WELDED AXLE ALIGNMENT PROCEDURES

ALIGNMENT BOLT IS ON THE FRONT OF THE ROADSIDE FRAME BRACKET:

STEP 1. To properly align the suspension, the trailer should be pulled in a straight line for a sufficient distance

to insure there are no binds in the suspension.

STEP 2. Check to verify trailer is empty and emergency brakes are NOT engaged.

STEP 3. Rotate bolt CLOCKWISE to move axle forward (A arrows); COUNTERCLOCKWISE to move axle rearward (B arrows).

Copyright © 2011 • SAF-HOLLAND, Inc.

www.safholland.us

TIRE CLEARANCE REQUIREMENTS

• 1 INCH (25.4 mm) MINIMUM VERTICAL tire clearance is required between the top of the tire

and the nearest point of contact above the tire when the air pressure is completely exhausted

from the air suspension or when the axle is fully lifted if equipped with a suspension lift feature.

• 2 INCH (50.8 mm) MINIMUM LATERAL tire clearance is required between the sides of the

tire and the nearest point of contact through total travel of the air suspension. This includes

when the wheels are fully turned in either direction if equipped with an SAF Self Steer Axle.

XL-AR435 Rev. B

ALIGNMENT BOLT HEAD

NOTE:

1/2 turn of

free play in either

direction (A or B)

is acceptable.

A = axle forward

B = axle rearward

Figure 3

Figure 4

XL-AS11406OM-en-US Rev E · 2018-04-17 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

5

Model Identification and Nomenclature

24.50"

31.70"

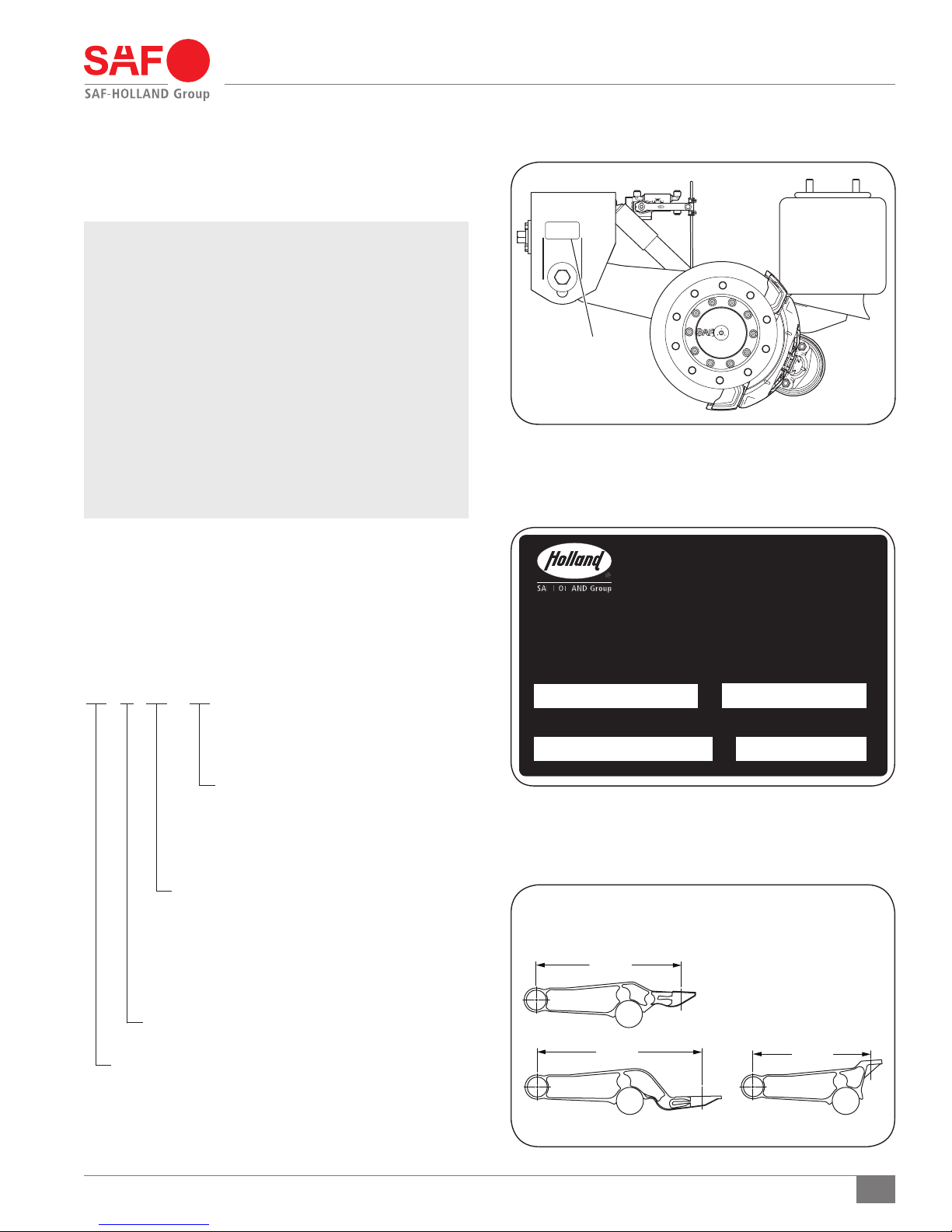

3. CBX Fusion Model Identification

The CBX Fusion suspension serial tag is located on the frame

bracket (Figure 4).

NOTE: This manual applies to the suspension models

listed on the front cover. However, determine the

specific model number, write that information

below and refer to it when obtaining information

or replacement parts (Figure 5).

NOTE: If the suspension serial tag is NOT legible or is

NOT available, it can identified by the appearance

of the equalizing beam (Figure 6). The CBX

Fusion model will have a cast beam with a lower

air spring mounting plate welded to it mounted on

a 5.75" round axle (Figure 6).

NOTE: The CBX Fusion models come in four (4) different

beam lengths. Equalizing beam lengths are

measured from the centerline of the pivot to

the centerline of the air spring mounting plate

(Figure 6).

4. CBX Fusion Model Nomenclature

Figure 4

TAG LOCATED ON

THE FRAME BRACKET

Figure 5

The sample tag illustrated will help interpret the information

on the SAF-HOLLAND, Inc. serial number tag. The part

number is on the first line. The model number along with the

suspension capacity are on the second line. The third line

contains the serial number (Figure 5).

CB X 23 - 14

Ride Height

14" (356 mm)

15" (381 mm)

16" (406 mm)

17" (432 mm)

Axle Capacity

Suspension Series

20 – 20,000

23 – 23,000

25 – 25,000

25/30 – 25,000/30,000*

*30,000 at creep speed

5.75" Diameter Premium Axle

Cast Beam Suspension

Figure 6

CBX FUSION BEAM LENGTH OPTIONS

33.80"

26.50"

6

XL-AS11406OM-en-US Rev E · 2018-04-17 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

Model Identification and Nomenclature

31.70"

5. CBX Model Identification

The CBX suspension serial tag is located on the frame bracket

(Figure 7).

NOTE: This manual applies to the suspension models

listed on the front cover. However, we urge you to

determine your specific model number, write that

information below and refer to it when obtaining

information or replacement parts (Figure 8).

NOTE: If the suspension serial tag is NOT legible or

is NOT available, it can be identified by the

appearance of the equalizing beam. The CBX

model will have a full cast beam mounted to a

5.75" round axle (Figure 9).

NOTE: The CBX models come in three (3) different beam

lengths. Equalizing beam lengths are measured

from the centerline of the pivot to the centerline

of the air spring mounting plate (Figure 9).

6. CBX Model Nomenclature

The sample tag illustrated will help interpret the information

on the SAF-HOLLAND, Inc. serial number tag. The model number

is on the first line along with the suspension capacity. The

second line contains the part number and the serial number

(Figure 8).

CB X 23 - 14

Figure 7

TAG LOCATED ON

THE FRAME BRACKET

Figure 8

MODEL NO.

SAF-HOLLAND, INC.

CAPACITY (LBS)

Axle Capacity

Suspension Series

20 – 20,000

23 – 23,000

25 – 25,000

25/30 – 25,000/30,000*

*30,000 at creep speed

5.75" Diameter Premium Axle

Cast Beam Suspension

Ride Height

14" (356 mm)

15" (381 mm)

16" (406 mm)

17" (432 mm)

PART NO.

CONSULT SPECIFICATION FOR CAPACITY AND RECOMMENDED APPLICATION.

SERIAL NO.

Figure 9

CBX BEAM LENGTH OPTIONS

33.80"

26.50"

XL-AS11406OM-en-US Rev E · 2018-04-17 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

7

Model Identification and Nomenclature

7. CB-2300 Model Identification

The CB-2300 suspension serial tag is located on the frame

bracket (Figure 10).

NOTE: If the suspension serial tag is NOT legible or is NOT

available, you can identify your suspension model

by the appearance of the equalizing beam. The

CB-2300 model will have a full cast beam with

a 5" round axle (Figure 10).

NOTE: This manual applies to the suspension models

listed on the front cover. However, determine the

specific model number, write that information

below and refer to it when obtaining information

or replacement parts (Figure 11).

8. CB-2300 Model Nomenclature

The sample tag illustrated will help interpret the information

on the SAF-HOLLAND, Inc. serial number tag. The model number

is on the first line along with the suspension capacity. The

second line contains the part number and the serial number

(Figure 11).

Figure 10

TAG LOCATED ON

THE FRAME BRACKET

Figure 11

SAF-HOLLAND, INC.

CB 2300 - 14

Axle Capacity

Suspension Series

23,000 lbs.

Cast Beam Suspension

Ride Height

14" (356mm)

15" (381mm)

16" (406mm)

17" (432mm)

MODEL NO.

PART NO.

CONSULT SPECIFICATION FOR CAPACITY AND RECOMMENDED APPLICATION.

CAPACITY (LBS)

SERIAL NO.

8

XL-AS11406OM-en-US Rev E · 2018-04-17 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

9. Welding Standards

9.1 Scope

When welding is required for the suspension repairs, observe

the requirements below. This specification applies to all

components supplied by SAF-HOLLAND, and its products.

The customer assumes all responsibility for weld integrity if

weld material and procedure differ from those listed below.

Welding Standards

The recommended welding gas for gas metal arc welding

(GMAW) is 90% Argon / 10% CO2. If a different gas is used,

welds must comply with penetration requirements illustrated

(Figure 12). Where the installation drawing specifies

different than above, the drawing shall prevail.

9.2 Workmanship

All welding on SAF-HOLLAND products MUST be performed by

a welder qualified according to the appropriate AWS standard

for the weld being made or an equivalent standard. It is the

responsibility of the customer to provide good workmanship

when welding on SAF-HOLLAND products.

9.3 Material

Items to be welded that are made from low carbon or high-strength

alloy steel are to be welded with AWS filler metal specification

AWS A5.18, filler metal classification ER-70S-3, ER-70S-6 or

equivalent unless specified on the installation drawing.

NOTE: Any substitution for filler material from the above

standard must comply, as a minimum, with the

following mechanical properties:

Tensile Strength - 72k psi (496 MPa)

Yield Strength - 60k psi (414 MPa)

Charpy V Notch - 20 ft.-lbs. (27 N•m) at 0o F (-17.7o C)

% Elongation - 22%

9.4 Procedures

Tack welds used for positioning components are to be

located in the center of the final weld, where practical. Tack

weld should be completely fused to the finish weld. DO NOT

break arc at the end of the weld. Back up all finish welds

at least 1/2" (12.7 mm) or a sufficient amount to prevent

craters at the end of the weld. Where weld is illustrated to go

around corners, it is assumed the corner represents a stress

concentration area. DO NOT start or stop weld within 1" (25.4 mm)

of the corner. Particular care should be taken to prevent

undercutting in this area.

9.5 Weld Size

If weld size is NOT specified, the effective throat of the weld

MUST be no smaller than the thinnest material being welded

(Figure 12).

Figure 12

LACK OF FUSION OF

ANY KIND IN THIS AREA

IS NOT ACCEPTABLE AT

ANY TIME

XL-AS11406OM-en-US Rev E · 2018-04-17 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

PENETRATION AS MEASURED

THROUGH SEAM

TARGET PENETRATION TO BE

10% OF THINNEST MATERIAL

FROM INTERSECTION OF FILLET

AS ILLUSTRATED

TARGET PENETRATION

9

Installation Instructions

10. Standard Air Control

System Installation

The following is a typical air system installation and should

be plumbed as illustrated (Figure 13). Optional air control

systems are available. Contact SAF-HOLLAND applications

department to discuss your particular needs.

The air control system of the CBX/CB suspensions use air drawn

from the tractor air system to pressurize the suspension’s air

springs. The suspension, working with the air control system,

provides optimum suspension performance only when all air

control system components are installed and operating properly.

IMPORTANT: Make certain that all air lines and valves

are free from obstruction through the full

operational range of the suspension.

IMPORTANT: A pressure protection valve (PPV) MUST

be attached to the air reservoir in order to

maintain proper air pressure (Figure 13).

Figure 13

STANDARD AIR CONTROL SYSTEM

AIR RESERVOIR

IMPORTANT: The air pressure protection valve maintains

safe brake pressure. Approximately 85 psig

(5.9 bars) opens the valve, and 65 psig

(4.5 bars) closes the valve.

NOTE: When installing the pressure protection valve,

use a drop of oil or Loctite® to lubricate threaded

connections. DO NOT use a pipe compound or

teflon tape as they may clog the valve.

A height control valve (HCV) is used to regulate the air

pressure required for varying load capacities (Figure 13).

TO AIR SPRINGS

TO AIR SPRINGS

PRESSURE PROTECTION

VALVE (PPV)

TO HEIGHT CONTROL

VALVE (HCV)

AIR SPRING

AIR SPRING

TO AIR SUPPLY

CONTROL ARM

(NEUTRAL POSITION)

AIR SPRING

HEIGHT CONTROL

VALVE (HCV)

AIR SPRING

10

XL-AS11406OM-en-US Rev E · 2018-04-17 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

Installation Instructions

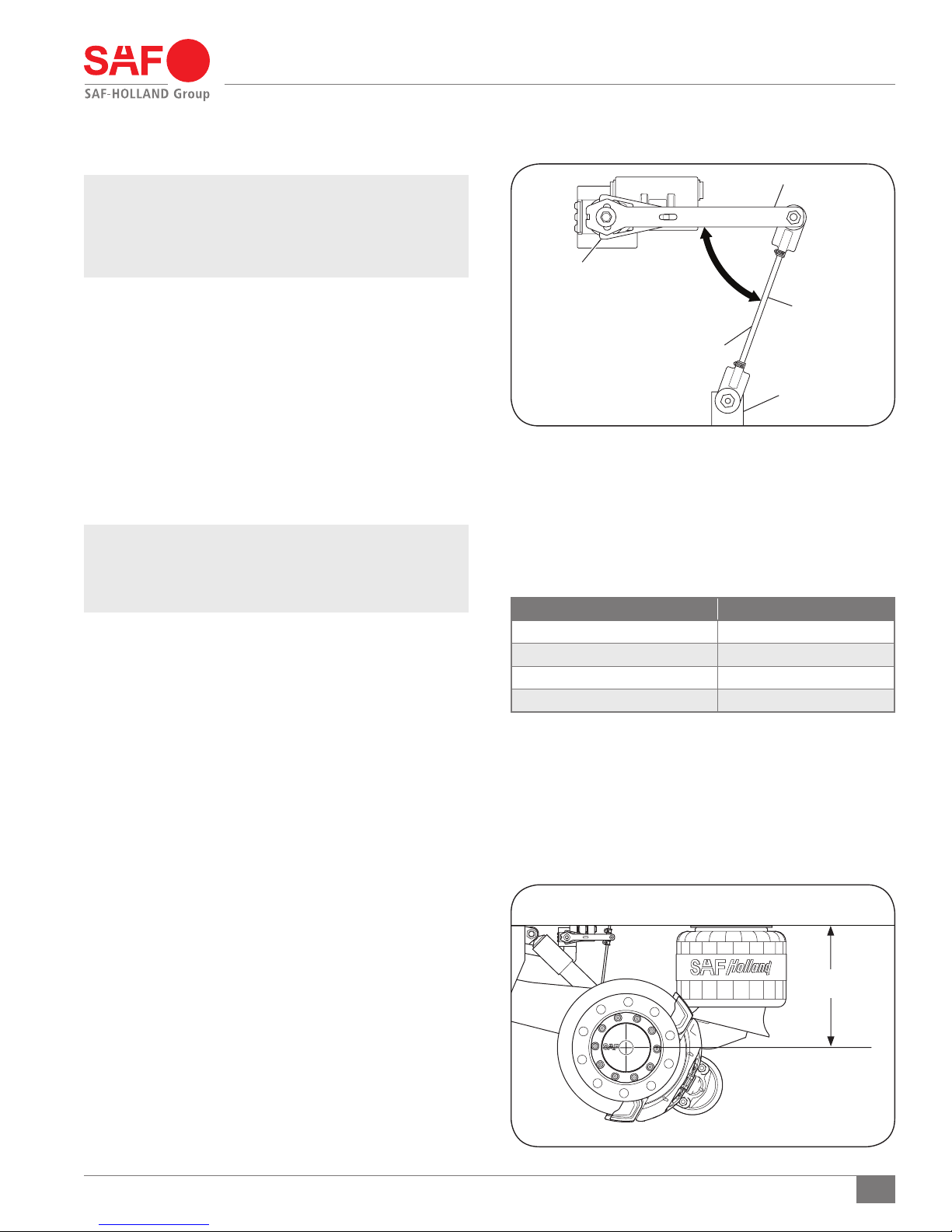

11. Suspension Assembly Installation

NOTE: Locate the suspension on the trailer frame. Refer

to your model’s specific installation drawing for

the proper weld patterns and locations. To obtain a

copy of your specific installation drawing, contact

SAF-HOLLAND Customer Service at 888-396-6501.

1. Once the suspension is correctly positioned, weld the

suspension in place as outlined in Section 9.

2. Ensure the linkage assembled to the height control valve

(HCV) and suspension is installed properly (Figure 14).

3. Install the service and emergency lines to the suspension

and allow the suspension to air up.

6. Measure the ride height of the suspension with a tape

measure (Figure 15).

7. Compare the measured suspension ride height value to

the appropriate value (Table 1). Ensure the measured

ride height value is within ± 1/4" (6 mm).

IMPORTANT: If the measured ride height value is NOT

within ± 1/4" (6 mm), follow the Ride

Height Adjustment procedures described

in Section 12.

4. Visually check all air control system fittings for air leaks

by applying a soapy water solution and checking for

bubbles at all air connections and fittings.

Figure 14

HEIGHT

CONTROL

VALVE

Table 1

CONTROL ARM

90° OR LESS

AT RIDE

HEIGHT

LINKAGE

LOWER AXLE

MOUNTING

BRACKET

MODEL “A” RIDE HEIGHT

CBX/CB-14 14"

CBX/CB-15 15"

CBX/CB-16 16"

CBX/CB-17 17"

XL-AS11406OM-en-US Rev E · 2018-04-17 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

Figure 15

(CBX23 FUSION ILLUSTRATED)

“A”

RIDE HEIGHT

11

Ride Height Adjustment

12. Ride Height Adjustment

IMPORTANT: Trailer MUST be unloaded before

beginning any service procedures.

1. On a level surface, support the front of the trailer with

either a kingpin stand, landing gear, or while coupled to

a tractor (Figure 16).

2. Raise the trailer frame approximately 2" (51 mm) above

the suspension’s specified ride height (Figure 17).

3. Place multiple jack stands at the suspension’s specified ride

height (Table 2) under the vehicle frame at OEM specified

locations, then lower the trailer onto the jack stands.

NOTE: It could be necessary to shim the jack stands to

achieve specified ride height.

Failure to properly support the suspension

during maintenance could create a crush

hazard which, if not avoided, could result

in death or serious injury.

Table 2

MODEL “A” RIDE HEIGHT

CBX/CB-14 14"

CBX/CB-15 15"

CBX/CB-16 16"

CBX/CB-17 17"

Figure 16

FIFTH WHEEL

OPERATING HEIGHT

Figure 17

(CBX23 FUSION ILLUSTRATED)

“A” RIDE

HEIGHT

SUPPORT AT KINGPIN

“A”

RIDE HEIGHT

4. Exhaust all air from the suspension, set the parking

brakes, and chock the wheels.

Failure to exhaust the suspension air

and chock the tires prior to beginning

maintenance could allow vehicle

movement which, if not avoided, could

result in death or serious injury.

5. Disconnect the linkage from the control arm and lower

the axle mounting bracket (Figure 18).

6. Pin the height control valve so that the valve arm is in

the center or neutral position (Figure 18).

Figure 18

HEIGHT

CONTROL

VALVE

CONTROL ARM

90° OR LESS AT

RIDE HEIGHT

LINKAGE

LOWER AXLE

MOUNTING

BRACKET

12

XL-AS11406OM-en-US Rev E · 2018-04-17 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

Ride Height Adjustment

7. Measure distance “B” between the valve arm and mounting

bracket holes to determine linkage length (Figure 19).

8. Adjust the linkage to required length and install the hardware

into the upper and lower connections (Figure 19). Torque

hardware to 30-40 in.-lbs. (3-5 N•m).

NOTE: It could be necessary to cut linkage rod to achieve

proper length. Be sure to de-burr rod to prevent

link end damage.

9. Raise the trailer approximately 2" (50 mm) above the

ride height and remove the jack stands.

10. Slowly lower the trailer so that the trailer suspension is

fully collapsed.

11. Pull the pin and apply air to the trailer allowing the

suspension to return to ride height.

12. With the suspension at rest, measure the ride height.

Ride height MUST be within 1/4" (6 mm) of the

suspensions specified ride height.

13. Spray a soapy water mix on all air line connections to

check for air leaks and verify fittings are tight.

IMPORTANT: It is the responsibility of the air system

installer to secure all air lines and check

for air leaks. If air leaks are detected,

repair as required.

Figure 19

HEIGHT

CONTROL

VALVE

CONTROL ARM

LINKAGE

B

LOWER AXLE

MOUNTING

BRACKET

Failure to eliminate air leaks could

compromise the suspension performance

which, if not avoided, could result in

component or property damage.

14. Remove the wheel chocks.

XL-AS11406OM-en-US Rev E · 2018-04-17 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

13

A

A=B ± 1/8" (3 mm)

C=D ± 1/16" (1 mm)

KINGPIN

B

D

C

Installation Instructions

13. SwingAlign Axle Alignment

13.1 Alignment Preparation

1. Pull the trailer in a straight line for a sufficient distance

to ensure that there are no binds in the suspension.

2. Disengage the trailer parking brakes and make sure the

trailer is empty.

3. Manually measure or use an optical device specifically

designed for alignment measuring to determine the following:

a. Measure the distance from the king pin to the centerline

of the front axle spindles. It is recommended that the

spindle extensions be utilized.

b. Dimensions A and B (Figure 20) MUST be equal to

within 1/8" (3 mm).

c. Measure the distance from the centerline of the front axle

spindles to the centerline of the rear axle spindles.

d. Dimensions C and D (Figure 20) MUST be equal to

within 1/16" (1 mm).

13.2 Alignment Instructions

1. Using the measurements per Section 13.1 Step 3, align

each axle. Align by rotating the alignment bolt head

using a 1-3/8" socket wrench on the front face of the

road-side frame bracket clockwise to move axle forward

(A arrows); counterclockwise to move axle rearward

(B arrows) (Figure 21). Approximately 250 ft.-lbs.

(339 N•m) will be required.

Figure 20

Figure 21

ALIGNMENT

BOLT

WASHER

IMPORTANT: DO NOT loosen the pivot bolts.

IMPORTANT: Two (2) scribe lines on the side of the frame

bracket indicate maximum adjustment for axle

alignment. If the edge of the visible washer

touches either scribe line, the SwingAlign

axle alignment adjustment is “out of stroke.”

Inspect and repair trailer components as

necessary and realign (Figure 22).

IMPORTANT: The SwingAlign design maintains proper

alignment without welding or without

loosening of the pivot connection. DO NOT

weld alignment bolt or pivot bolts

14. Brake Adjustment Instructions

Brakes should be adjusted per axle and brake manufacturer’s

specifications.

For CBX/CB Suspensions with Drum Brake Systems refer to

SAF-HOLLAND Drum Brake Service Manual, XL-TA10006OM.

For CBX Suspension with Disc Brake Systems refer to

SAF-HOLLAND Disc Brake Service Manual, XL-SA10059OM.

14

XL-AS11406OM-en-US Rev E · 2018-04-17 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

(Figure 22).

“A” ARROWS - AXLE FORWARD

“B” ARROWS - AXLE REARWARD

NOTE: 1/2 TURN OF FREE PLAY

IS ACCEPTABLE

Figure 22

ALIGNMENT BOLT ASSEMBLY

ALIGNMENT BOLT

SCRIBE

LINES

WASHER

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

PIVOT BOLT

ALIGNMENT PLATES

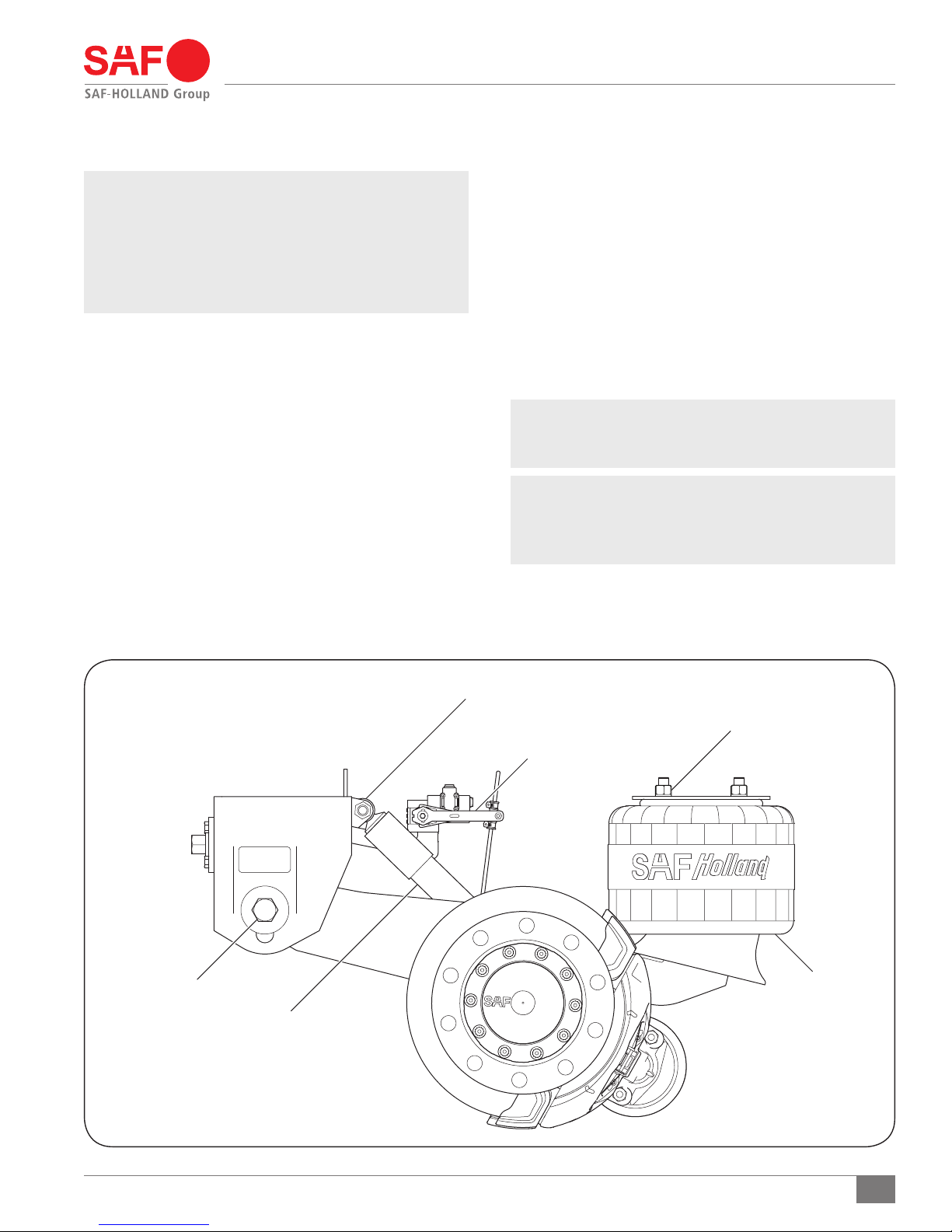

15. Pre-Operation

Pre-Operation Information

NOTE: In the United States, workshop safety requirements

are defined by federal and/or state Occupational

Safety and Health Act. Equivalent laws may exist

in other countries. This manual is written based

on the assumption that OSHA or other applicable

employee safety regulations are followed by the

location where work is performed.

1. With the vehicle on a level surface, bring air system to

operating pressure (above 85 psig/5.9 bars).

2. Shut off the vehicle and visually check all air control system

fittings for air leaks by applying a soapy water solution and

checking for bubbles at all air connections and fittings.

Examine the air springs (Figure 23) for equal firmness.

3. Check the shock absorbers for proper installation and make

sure that the upper and lower 3/4" shock absorber nuts

are torqued to 140-175 ft.-lbs. (190-237 N•m) (Figure 23).

4. Verify that the 1/2" air spring mounting nuts are torqued

to 30-40 ft.-lbs. (41-54 N•m), and the 3/4" air spring

mounting nuts are torqued to 40-45 ft.-lbs. (54-61 N•m)

(Figure 23).

5. With the suspension at full capacity, check that there is a

1" (25 mm) minimum clearance around the air springs.

6. The suspension’s ride height should be within ±1/4" (6 mm)

of the recommended design height. For proper ride height,

refer to Section 12.

7. Determine which pivot bolt style is installed (Figure 23).

If 1-1/8" hex head bolt, verify torque on the nut is

550-600 ft.-lbs. (746-813 N•m).

If 7/8" pan head shear bolt, verify spline has been

sheared off.

IMPORTANT: The SwingAlign design maintains proper

alignment under correct torque without

welding; DO NOT weld.

NOTE: SwingAlign pivot connections are on roadside and

fixed alignment pivot connections are on curbside.

For SwingAlign Connection Axle Alignment

procedure, refer to Section 13.

Figure 23

PIVOT BOLT

UPPER SHOCK ABSORBER NUT

AIR SPRING MOUNTING NUT

HEIGHT CONTROL VALVE

AIR SPRING

SHOCK ABSORBER

XL-AS11406OM-en-US Rev E · 2018-04-17 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

15

Maintenance and Service Schedule

16. Routine Maintenance and

Daily Inspection

16.3 Visual Inspection Procedure

1. Daily or before each trip, check the suspension to ensure

it is fully operational.

2. Inspect all decals to ensure they are clearly legible and

intact. Clean with a terry cloth towel, soap and water.

3. Visually inspect air springs for sufficient inflation and

that the suspension is at proper ride height. For ride

height details and measurements, refer to Section 12

of this manual.

16.1 Initial Three (3) Months or 5,000 Mile

(8,000 km) Service Inspection

1. Suspension ride height (underside of frame to centerline

of axle) MUST be within ± 1/4" (6 mm) of recommended

design height. For instructions on measuring ride height,

refer to Section 11.

An improperly set ride height could result

in suspension component damage and/or

poor vehicle ride performance.

2. After first three (3) months or 5,000 miles (8,000 km)

of service, whichever comes first, inspect bolts and nuts

at the pivot connections to ensure there are no signs

of movement. Check all other nuts and bolts for proper

torque, refer to the specifications listed in Section 17. Retorque as necessary thereafter.

3. With the vehicle on a level surface and air pressure above

85 psig (5.9 bars), verify that all the air springs are of

sufficient and equal firmness.

IMPORTANT: A schedule for physical and visual inspections

should be established by the operator

based on severity of operation or damage

to the vehicle could occur.

IMPORTANT: During each pretrip and safety inspection

of the vehicle, a visual inspection of the

suspension should be done or damage to

the vehicle could occur.

Visually check for:

Loose, broken or missing fasteners. Repair or replace

as needed.

Loose, damaged, or missing fasteners

can cause loss of vehicle control which,

if not avoided, could result in death or

serious injury.

Air springs – clearances, wear damage, and proper inflation.

Shock absorbers – leaking or damaged.

Cracked parts or welds.

NOTE: Check all air control system fittings for air leaks,

by applying a soapy water solution and checking

for bubbles at all air connections and fittings.

16.2 Routine Physical Inspections

Every 100,000 Miles (160,000 km) or one (1) year, whichever

comes first.

Check all other suspension components for any sign of damage,

looseness, torque loss, wear or cracks. Repair, tighten or

replace damaged part(s) to prevent equipment breakdown.

16

XL-AS11406OM-en-US Rev E · 2018-04-17 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

17. Torque Specifications

Torque Specifications

Table 3

COMPONENT TORQUE VALUE

Shock Absorber

Pivot Connection, Hex Head Bolt

* Pivot Connection,

Pan Head Shear Bolt

Lower Air Spring Nut

Upper Air Spring Nut

SwingAlign Mounting Fasteners

Only - NOT Pivot Bolt

Height Control Valve Lower Linkage

All torque specifications are ± 5%.

Torques specified are for clean, lubricated threads.

Always Apply torque to nut if possible.

Required re-torquing at every brake re-lining.

* If equipped with 7/8" pan head shear bolt, ensure that the spline is

sheared off and that there are no signs of movement.

140-175 ft.-lbs.

190-237 N•m

550-600 ft.-lbs.

746-813 N•m

Visual Inspection 7/8"

30-40 ft.-lbs.

40-54 N•m

40-45 ft.-lbs.

54-61 N•m

50-60 ft.-lbs.

68-81 N•m

30-40 In.-lbs.

3-5 N•m

FASTENER

SIZE

3/4"

1-1/8"

1/2"

3/4"

1/2"

1/4"

Figure 24

BOLT IDENTIFICATION

GRADE 5 GRADE 8

LOCK NUT IDENTIFICATION

LOCK NUT

GRADE B

7/8" PAN HEAD

SHEAR BOLT

LOCK NUT

GRADE C

6 DOTS3 DOTS

NOTE: Torque specifications listed above are with

clean lubricated / coated threads (Table 3).

All new SAF-HOLLAND fasteners come precoated

from the factory. For bolt and lock nut grade

markings refer to Figure 24.

IMPORTANT: The use of special lubricants with friction

modifiers, such as Anti-Seize or Never-Seez®,

without written approval from SAF-HOLLAND

engineering, will void warranty and could

lead to over torquing of fasteners or other

component issues.

General Information

1. The torque specifications are applied to the nut and NOT

the bolt.

Failure to use the proper fasteners when

servicing the suspension could cause

component failure which, if not avoided,

could result in death or serious injury.

Failure to properly torque all fasteners

could result in component failure which,

if not avoided, could result in death or

serious injury.

XL-AS11406OM-en-US Rev E · 2018-04-17 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

17

Notes

18

XL-AS11406OM-en-US Rev E · 2018-04-17 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

Notes

XL-AS11406OM-en-US Rev E · 2018-04-17 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

19

From fifth wheel rebuild kits to suspension bushing repair kits,

SAF-HOLLAND Original Parts are the same quality components used

in the original component assembly.

SAF-HOLLAND Original Parts are tested and designed to provide

maximum performance and durability. Will-fits, look-alikes or, worse

yet, counterfeit parts will only limit the performance potential and

could possibly void SAF-HOLLAND’s warranty. Always be sure to spec

SAF-HOLLAND Original Parts when servicing your

SAF-HOLLAND product.

SAF-HOLLAND USA

www.safholland.us

SAF-HOLLAND CANADA

WESTERN CANADA

www.safholland.ca

SAF-HOLLAND MEXICO

www.safholland.com.mx

info@safholland.com

SAF-HOLLAND INC.

1950 Industrial Blvd., Muskegon, MI 49442

www.safholland.com

888.396.6501

·

519.537.3494

·

604.574.7491

·

52.55.5362.8743

·

Fax 800.356.3929

·

Fax 800.565.7753

·

Fax 604.574.0244

·

Fax 52.55.5362.8743

·

XL-AS11406OM-en-US Rev E · 2018-04-17 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF, and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

Loading...

Loading...