Panel Saw/Router

Owner’s Manual

SR5, SR5U, SR5A, SR5UA, 3400 & TR2

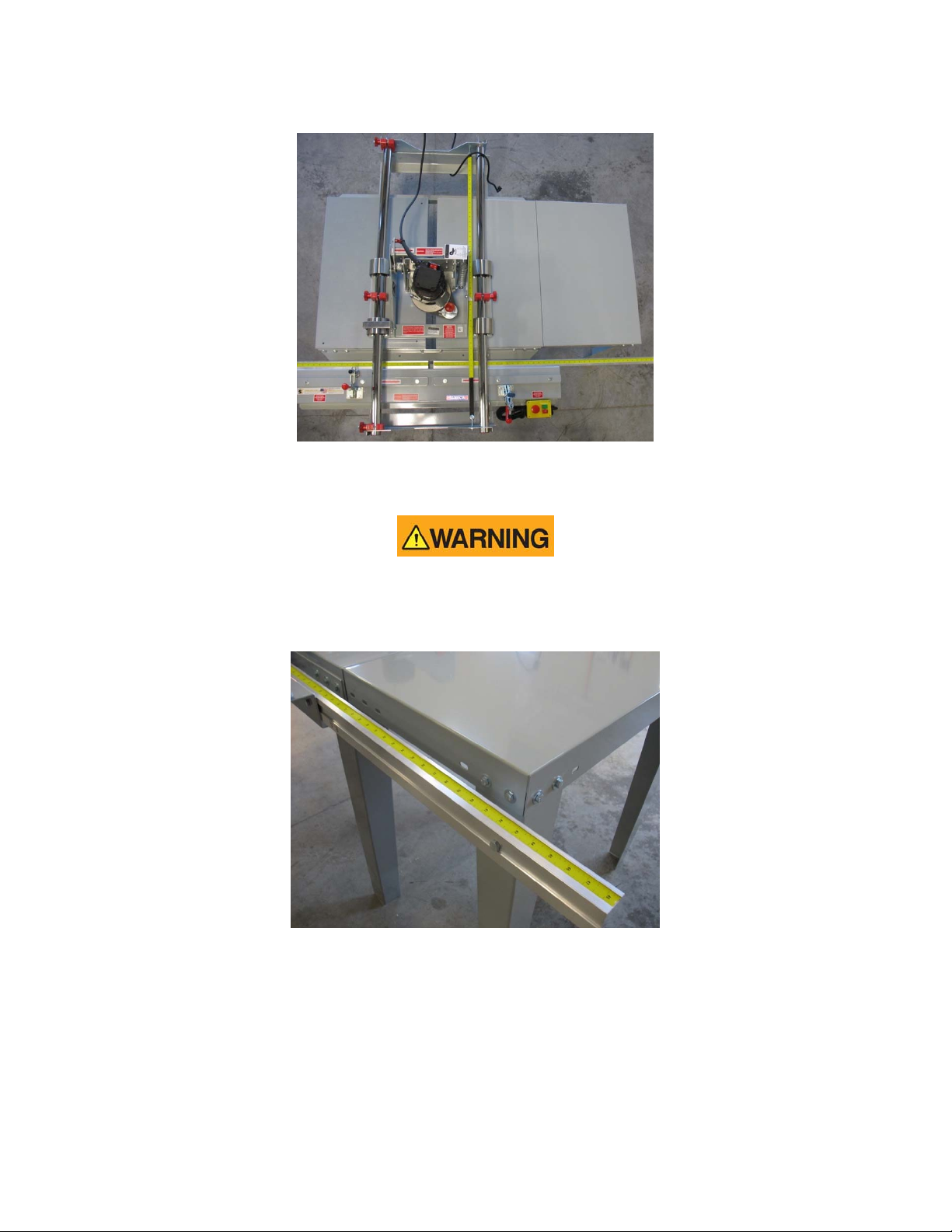

SR5U vertical panel saw/router with TR2 horizontal router with optional accessories

optional accessories

Proudly made in the USA

www.SafetySpeed.com

Read and understand this manual before operating this tool. Failure to follow the safety precautions and

instructions can result in serious injury or death. Keep this manual in an accessible and safe location for

future reference.

A message from all of us at SAFETY SPEED MANUFACTURING:

Thank you for purchasing a Safety Speed Manufacturing (SSM) vertical panel saw/router or horizontal router. We

take pride in building these fine products in the U.S.A.

Each SSM product is designed to give years of dependable service. Your new panel saw and/or router was built

from the finest components available, and every machine is individually assembled by craftsmen - some of whom

have been building these products for more than 25 years. We appreciate you choosing SSM products for your

facility.

Team Safety Speed

Ham Lake, Minnesota

Safety Speed Manufacturing (SSM) warrants the parts and workmanshi p of this tool, except for the electric

motor(s), for one year from the date of purchase. SSM will repair or replace, at our discretion, any

component that is determined to be defective. Repair or replacement is limited to providing replacement

parts from the factory. SSM assumes no responsibility for making repairs on site. Parts returned to the

factory must be returned freight prepaid and include a Return Authorization (R.A.) number. Please call

SSM 763-755-1600 for a R.A. number.

Limited Warranty

All motors are warranted directly by the motor manufacturer. See local repair and maintenance centers

for warranty claims for motors.

Safety Speed Manufacturing assumes no responsibility for any damage or accidents resulting from the

misuse of this tool, its misapplication, or failure to follow precautionary safety measures. SSM assumes

no responsibility for any consequential damage or loss of production. SSM will not be responsible for

claims made for machines that are not used or maintained in the normal course of business, used for

applications not intended, or modified in any way. This warranty gives you specific legal rights, and you

may also have other rights which vary from state to state. SSM # 763-755-1600.

This manual applies to the following SSM panel saw and router models:

SR5 SR5A 3400

SR5U SR5UA TR2

Enter your model number and serial number for quick and easy reference when ordering accessories, supplies or

parts.

Note: The Model and Serial Number label of the SR5 variations and the 3400 can be found on the upper, left side

of the frame, when facing the vertical saw/router (Fig. 1). The Model and Serial Number label of the TR2 (horizontal

router) can be found on the top, front left side of the frame (Pg. 5, Fig. 3).

Model No:_____________________________

Serial & Model

Label

Serial No: _____________________________

Safety Speed Mfg.

13943 LINCOLN ST. NE

HAM LAKE, MN 55304

763-755-1600

Figure 1: Serial & Model label (SR5U

shown)

2

CONTENTS

Safety….………………………………………………………………. 4

Safety & Warning Label Placement………....………………………………… 4

Safety & Warning Labels Identified.………....………………………………… 5

Safety Procedures.……………………………………………………………... 7

Electrical Safety….……………………………………………………………... 11

Extension Cords…………………...………....………………………………… 12

Short-Circuit Protection…………...………....………………………………… 12

Vertical Panel Saw Components………………………………………….…. 12

Horizontal Router Components………………………………………………. 14

Router Carriage Components………………………………………………… 14

Installation/Set Up ..................................................................... 16

Tools Required for Installation ................................................................... 16

Operating Environment ............................................................................. 16

Inventory…...…………………………………………………………………... 17

Unpacking (SR5-3400) .............................................................................. 17

Unpacking/Machine Assembly (TR2) ........................................................ 19

Machine Assembly (SR5-3400)……………………………………………… 22

Operation ................................................................................... 33

Capacities of the Tool ................................................................................ 34

Selecting a Router Bit ................................................................................ 35

Selecting a Saw Blade .............................................................................. 36

Basic Operating Functions/Saws .............................................................. 37

General Operating Tips ............................................................................. 42

Operating Procedure: Crosscutting .......................................................... 43

Operating Procedure: Rip cutting ............................................................. 45

Basic Operating Functions/Routers………………… ………………………. 48

Maintenance .............................................................................. 51

General Maintenance ................................................................................ 51

Cleaning .................................................................................................... 52

Maintaining the Motor ................................................................................ 52

Lubricating the Guides .............................................................................. 52

Service ....................................................................................... 53

Repairs ...................................................................................................... 53

Replacement Parts .................................................................................... 53

Alignment ................................................................................................... 53

Accessories ............................................................................... 58

Tools Required for Installation……………………………………………….. 58

Frame Wheels ........................................................................................... 58

Frame Stand .............................................................................................. 59

Table Extensions………………………………………………………………. 61

Frame Extensions ...................................................................................... 62

Dust Collection Kits ................................................................................... 62

Stop Bar ..................................................................................................... 65

Quick Stop ................................................................................................. 66

Midway Fence ........................................................................................... 68

Hold-Down Bar .......................................................................................... 70

Air Clamping Package………..………………………………………………. 72

Accessory List…………………………………………………………………. 73

Specifications ............................................................................ 73

3

SAFETY

Read and understand this manual before operating this tool. Failure to follow the safety

precautions and instructions can result in serious injury or death. Keep this manual in an

accessible and safe location for future reference. Electronic copies of this manual are available

at www.safetyspeed.com. Printed copies are available by calling SSM 763-755-1600.

Indicates a hazardous situation which, if not avoided, will result in death or serious injury.

Indicates a hazardous situation which, if not avoided, could result in death or serious

injury.

Indicates a potentially hazardous situation, which if not avoided, could result in minor or

moderate injury.

Safety & Warning Label Placement (Saw)

Pinch Point

Motor

Specifications

DO NOT Place Hands

Under Carriage or

Near Blade

DO NOT Operate In

Wet Conditions

Blade Size &

Rotation

Prevent Kickback

Figure 2: Safety & Warning Label locations, SR5U with

saw shown

DO NOT Place Hands

Under Carriage or Near

Blade

Indexing Pins

Horizontal Cutting

Direction

DO NOT Operate Without

Guards in Place

Disconnect Power

Before Changing Motors

DO NOT Operate Saw If

Label Can Be Read

(Under blade guard on saw

foot)

Safety & Warning Label Placement (Router)

4

Nose Cone Adjustment

g

(behind Carriage)

Read & Understand

Manual

DO NOT Place Hands Under

Carriage or near Blade

(one behind Carriage)

DO NOT Place Hands Under

Carria

Nose Cone Adjustment

Horizontal Cutting

Direction

Serial & Model #

DO NOT Operate Without

Guards in Place

Pinch Point

e or near Blade

Safety Warning Labels Identified

Read And Understand Owner’s Manual

Horizontal Cutting Direction

DO NOT Operate in Wet

Conditions

DO NOT Place Hands Under

Carriage or near Blade

Remote ON/OFF Switch

Figure 3: Safety & Warning Label locations, TR2 shown

Do NOT Place Hands Under Saw/Router

Feed Stock In Direction Of Arrows

Remote ON/OFF Switch

Adjust Nose Cone Before Routing

Do Not Place Hands

Under Saw/Router

5

Adjust Nose Cone Before Routing

Do Not Use Without Guards

6

When using electric tools, always follow basic safety precautions to reduce the risk of fire,

electric shock, and personal injury.

READ AND SAVE ALL INSTRUCTIONS FOR FUTURE USE. Before use, be sure everyone using this machine

reads and understands this manual as well as any labels packaged with or attached to the machine.

1. KNOW YOUR POWER TOOL. Read this manual carefully to learn your power tool’s applications and limitations

as well as potential hazards associated with this type of tool.

2. DO NOT ALLOW UNQUALIFIED PEOPLE TO OPERATE the tool.

3. AVOID DANGEROUS ENVIRONMENTS. Do not use your power tool in rain, damp or wet locations, or in the

presence of explosive atmospheres (gaseous fumes, dust, or flammable materials). Remove materials or

debris that may be ignited by sparks.

4. KEEP WORK AREA CLEAN AND WELL LIT. Cluttered, dark work areas invite accidents. Provide at least 200

watts of lighting at the front work area of the tool. Eliminate all shadows that could interfere with clear viewing

of the work area.

5. DRESS PROPERLY. Do not wear loose-fitting clothing or jewelry. Wear a protective hair covering to contain

long hair, as it may be caught in moving parts. When working outdoors, wear rubber gloves and insulated,

nonskid footwear. Keep hands and gloves away from moving parts.

6. USE SAFETY EQUIPMENT. Everyone in the work area should wear safety goggles or glasses with side

shields that comply with current safety standards. Wear hearing protection during extended use and a dust

mask for dusty operations. Hard hats, face shields, safety shoes, etc. should be used when specified or

necessary. Keep a fire extinguisher nearby.

7. KEEP BYSTANDERS AWAY. Keep children and bystanders at a safe distance from the work area to avoid

distracting the operator and contacting the tool or extension cord.

8. MAKE THE WORKSHOP CHILD PROOF with padlocks, master switches, etc.

9. NEVER LEAVE THE TOOL RUNNING UNATTENDED. Turn the power OFF. Do not leave the tool until it

comes to a complete stop.

10. PROTECT OTHERS IN THE WORK AREA from debris such as chips and sparks. Provide barriers or shields

as needed.

11. SECURE THE WORK. Use a clamp, vise, or other practical means to hold your work securely, freeing both

hands to control the tool.

12. USE THE RIGHT TOOL. Do not use a tool or attachment to do a job for which it is not recommended. For

example, do not use a circular saw to cut tree limbs or logs. Do not alter the tool, remove guards, or operate

the saw or router when removed from the carriage and frame.

13. USE PROPER ACCESSORIES. Using non-recommended accessories may be hazardous. Be sure

accessories are properly installed and maintained. Do not defeat a guard o r other safety device when install ing

an accessory or attachment.

14. CHECK FOR DAMAGED PARTS. Inspect guards an d other parts before use. Check for misal ignment, binding

of moving parts, improper mounting, broken parts, and any other conditions that may affect operation. If

abnormal noise or vibration occurs, turn the tool off immediately and have the problem corrected before further

use. Do not use a damaged tool. Tag damaged tools “DO NOT USE” until repaired. Repair or replace a

damaged guard or other part. For all repairs, insist on identical replacement parts or factory certified

conversions.

15. REMOVE ALL ADJUSTING WRENCHES AND TOOLS from the tool before turning it on. Make this a habit.

16. GROUND YOUR TOOL. See “Electrical Safety,” page 11.

7

17. AVOID ACCIDENTAL STARTING. Be sure your tool is turned off before plugging it in. Do not use the tool if

the power switch does not turn it on and off. Observe correct Lockout/Tagout procedures when performing

maintenance on the tool.

18. DO NOT FORCE THE TOOL. Your tool will perform best at the rate for which it was designed. Excessive force

only causes operator fatigue, increased wear, increased risk of binding or sudden breakage, and reduced

control.

19. KEEP HANDS AWAY FROM ALL CUTTING EDGES, MOVING PARTS AND PINCH POINTS.

20. DO NOT ABUSE THE CORD. Never unplug the cord by yanking it from the outlet. Pull the plug rather than

the cord to reduce the risk of damage. Keep the cord away from heat, oil, sharp objects, cutting edges, and

moving parts.

21. DO NOT OVERREACH. MAINTAIN CONTROL. Keep proper footing and balance at all times. Mai ntain a firm

grip.

22. STAY ALERT. Watch what you are doing, and use common sense. Do not use a tool when you are tired,

distracted, or under the influence of drugs, alcohol, or any medication causing decreased cont rol.

23. UNPLUG THE TOOL when it is not in use, before changing items such as blades or bits, and before performing

recommended maintenance. Observe appropriate Lockout/Tagout procedures.

24. MAINTAIN TOOLS CAREFULLY. Keep handles dry, clean, and free from oil and grease. Keep cutting edges

sharp and clean. Follow instructions for lubricating and changing accessories. Periodically inspect tool cords

and extension cords for damage. Have damaged parts repaired or replaced.

25. MAINTAIN LABELS AND NAMEPLATES. These carry important information. If unreadable or missing, contact

Safety Speed for a free replacement.

26. AVOID KICKBACK. Kickback is a violent reaction to a pinched or binding blade/bit. It throws the saw upward

when crosscutting and a router back when through cross routing and throws the work piece out when ripping

with a saw or router. Firm control, proper support of the work piece, and con centration on the j ob are essential

to reduce the risk of injury from kickback:

a. KEEP SAW BLADE/ROUTER BITS CLEAN AND SHARP. A dull or improperly sharpened blade/bit

produces a narrow kerf and is likely to be pinched by the work piece. Any blade with a small set, even

though sharp, may be likely to kick back. A dull blade/bit encourages you to force the saw/router,

causing reduced control and binding. The excessive friction generated can cause the blade/bit to warp

or bind. Use only blades/bits that are recommended for use with your tool. Do not use blades with

mounting holes that are not the correct size or shape. Do not use bits with a damaged/worn shank or of

the wrong size. Never use defective or incorrect blade flanges or bolts. Be sure the blade bolt/arbor is

tight. Select the proper blade/bit for the application. Blade/bit speed specifications must be at least as

high as the nameplate RPM.

b. DO NOT FORCE THE MACHINE. Let the saw/router do the work. A saw/router is more easily controlled

and will do a better job when used in the manner for which it was designed.

8

c. SECURE WORK PROPERLY. If a piece is supported on both sides of the cut in such a way that it allows

the material to bow and pinch the blade/bit, it may produce kickback. Do not cut/rout pieces smaller than

the carriage. Support large panels properly. Use clamps when applicable.

d. IF THE BLADE/BIT BINDS, TURN MACHINE OFF! The saw/router or work piece may kick back. Keep

hands, body, and bystanders out of the path of the blade/bit and material.

e. STAY ALERT. Watch what you are doing and use common sense. Do not allow yourself to be

distracted. Do not operate the tool when you are tired or under the influence of drugs or alcohol. Hold

the tool and material firmly and exercise control at all times. Position yourself and co-workers out of the

kickback path. Repetitive cuts that lull you into careless movements can also cause kickback. A brief

“stretch” may be all that is necessary to avoid a problem.

f. RESTARTING IN MID-CUT. If the saw/router is stopped in mid-cut, TURN SAW/ROUTER OFF! Allow

the blade/bit to stop. Then back up the saw/router (if crosscutting) or the board/panel (if rip cutting)

before restarting.

g. IF THE BLADE/BIT STALLS, TURN SAW/ROUTER OFF! DO NOT TURN THE SWITCH ON AND OFF.

A dull blade/bit or excess pressure may cause stalling. TURN OFF the switch immediately if the

blade/bit binds or the saw/router stalls, and remove the saw/router from the cut.

h. AVOID CUTTING NAILS OR OTHER FASTENERS. Inspect for and remove all metal fasteners before

cutting.

i. SUPPORT THIN MATERIAL. Large sheets such as paneling, Formica, etc., tend to warp or sag and

must be well supported over their entire length to avoid pinching the blade. Optional hold down bar

recommended for this application. Use clamps when applicable.

27. HANDLE THE COUNTERWEIGHT WITH CARE. The counterweight cable is u nder tension. See page 22. Do

not pull on the cable by hand or attempt to disassemble or repair the counterweight. Replacement

counterweights can be purchased directly from Safety Speed, or an authorized dealer.

28. DO NOT USE PUSH STICKS.

29. CROSSCUTTING & CROSSROUTING (VERTICAL CUTTING/ROUTING) MUST ALWAYS BE DONE FROM

THE TOP DOWN. Raise the saw/router carriage to the uppermost position on the guides and lock it into position

with the carriage lock whenever the tool is not in use. See “Operating Procedure: Crosscutting”, for more

information.

30. RIPPING (HORIZONTAL CUTTING/ROUTING) MUST ALWAYS BE DONE WITH THE DIRECTION OF THE

ARROW (on Warning Label). Raise the saw/router carriage to the top of the guides and lock it into position

with the carriage lock whenever the tool is not in use. See “Operating Procedure: Rip cutting”, for more

information.

31. ALWAYS WAIT FOR THE BLADE/BIT TO STOP COMPLETELY BEFORE CHANGING POSITIONS. Unplug

the tool before transporting or moving it.

32. DO NOT PLACE YOUR HANDS ON OR UNDER THE SAW CARRIAGE OR IN THE PATH OF THE BLADE

OR BIT. Do not try to retrieve a piece of cut material while the blade is rotating. This symbol is to remind you:

33. DO NOT DEFEAT THE GUARDS OR OPERATE THE TOOL WITHOUT THE GUARDS IN PLACE. Do not

remove the saw/router motor from the plate.

9

34. NEVER STAND ON THE TOOL. Serious injury could occur if the tool is tipped or if you unintentionally contact

the cutting tool.

35. DIRECTION OF FEED. Always feed work into the blade or cutter against the direction of the rotation of the

blade or cutter.

36. HOME CENTERS AND COMMERCIAL LOCATIONS should check with their local electrical contractor to be

sure the proper amount of electrical power (volts/amps) will be available for this machine during all operating

hours and conditions. Be aware of any special electrical safety requirements for this machine (examples: key

lock offs, timers, coded security, touch pads, disconnects, or time lockouts) required by local codes.

37. DISCONNECT AND LOCK THE POWER OFF before changing saw blades/bits or making any adjustments.

38. BEFORE CONNECTING THE SAW/ROUTER MOTOR TO THE POWER SUPPLY BE SURE THE MOTOR

SWITCH IS IN THE OFF POSITION.

39. KEEP THE CARRIAGE LOCK SECURELY TIGHTENED when the machine is not in use.

40. DO NOT PLACE HANDS UNDER CARRIAGE OR IN LINE WITH CARRIAGE TRAVEL. Be aware of potential

pinch points at top of saw/router carriage. Only hold or operate saw/router with designated handles. Do not

place hands under carriage or in-line with carriage travel.

41. REFER TO PAGES 5 & 6 FOR WARNING LABEL IDENTIFICATION.

Please Read Before Operating the Saw/Router

Some dust created by power sanding, sawing, grinding, drilling, and other construction activities

contains chemicals known to cause cancer, birth defects or other reproductive harm. Some examples

of these chemicals are:

• Lead from lead-based paint

• Crystalline silica from bricks and cement and other masonry products, and

• Arsenic and chromium from chemically treated lumber.

10

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your

exposure to these chemicals: work in a well ventilated area, and work with approved safety equipment, such as

those dust masks that are specifically designed to filter out microscopic particles.

Electrical Safety

Improperly connecting the grounding wire can result in the risk of electric shock. Check

with a qualified electrician if you are not sure that the outlet is properly grounded. Do not

modify the plug provided with the tool. Never remove the grounding prong from the plug.

Do not use the tool if the cord or plug is damaged. If damaged, have it repaired by a

qualified electrician before use. If the plug will not fit the outlet, have a proper outlet

installed by a qualified electrician.

Some machines are equipped with a polarized plug (one blade is wider than the other). This plug will fit in

a polarized outlet only one way. If the plug does not fit fully in the outlet, reverse the plug. If it still does

not fit, contact a qualified electrician to install a polarized outlet. Do not change the plug in any way.

Double insulation eliminates the need for the three wire grounded power supply system mentioned above.

Do not expose machine to rain or wet conditions. Water entering a power tool will increase the risk of

electric shock.

For best performance and to prevent damage use a dedicated electrical circuit for all SSM machines.

The plug must be connected to a properly grounded outlet (Fig. 4) If the tool should electrically malfunction or break

down, grounding provides a low-resistance path to carry electricity away from you, reducing the risk of electric

shock.

Figure 4: Grounded Plug and Outlet

The grounding prong on the plug is connected through the green wire inside the cord to the grounding system in

the tool. The green wire in the cord must be the only wire connected to the tool’s grounding system and m ust never

be attached to an electrically “live” terminal.

Your tool must be plugged into an appropriate outlet, properly installed and grounded in accordance with all codes

and ordinances. The plug and outlet should look like those in Figure 4.

Figure 5 illustrates a temporary adapter available for connecting grounded plugs. The green rigid ear or lug

extending from the adapter must be connected to a permanent ground such as a properly grounded outlet box or

receptacle. Simply remove the center screw from the outlet, insert the adapter and reattach the screw through the

green grounding ear to the outlet. If in doubt of proper grounding, call a qualified electrician. A temporary adapter

should only be used until a qualified electrician can install a properly grounded outlet. The Canadian Electrical

Code prohibits the use of temporary adapters.

11

Figure 5: Temporary Grounding Adapter

Extension Cords

Extension cords are not recommended. If an extension cord is used, please adhere to the following suggestions.

Grounded tools require a three-wire extension cord. As the distance from the supply outlet increases a heaviergauge extension cord must be used. Extension cords with ina dequately sized wire causes a serious drop i n voltage,

resulting in loss of power and possible motor damage. Refer to Table I below to determine the required minimum

wire size.

Table I: Recommended Minimum Wire Gauge for Extension Cords

Nameplate Amps

< 5

5 - 8

8 - 12

12 - 15

15 - 20

25’(7.6m) 50’(15m) 75’(23m) 100’(31m) 150’(46m) 200’(61m)

* Based on limiting the line voltage drop to 5V at 150% of rated amperes.

Not recommended

The smaller the gauge number of the wire, the greater the ampacity (capacity) of the cord. For example, a 14gauge cord can carry a higher current than a 16-gauge cord.

Extension Cord Length*

16 16 16 14 12 12

16 16 14 12 10

14 14 12 10

12 12 10 10

10 10 10

Guidelines for Using Extension Cords

For longest motor life and optimum performance extensions cords are not recommended.

If you are using an extension cord outdoors, be sure it is marked with the suffix “W-A” (“W” in Canada) to indicate

that it is acceptable for outdoor use.

Be sure your extension cord is properly wired and in good el ectrical condition. Always replace a damaged extension

cord or have it repaired by a qualified person before using it.

Protect extension cords from sharp objects, excessive heat, and damp or wet areas.

Short-Circuit Protection

This machine must only be plugged into a dedicated circuit that has a short-circuit protection device which is locate d

ahead of the equipment in the circuit, in accordance with local codes.

General guidelines are as follows:

120 volt: 20 amp protection.

These models can include: SR5, SR5U, SR5A, SR5UA, 3400 & TR2

220 volt: 10 amp protection.

These models can include: SR5, SR5U, SR5A, SR5UA, 3400 & TR2

12

Reference your motor label and your local codes before installation.

Electrical Connections

Connect the power cord from the panel saw/router to a dedicated circuit that m eets the requirement of the m achine

and local codes. Connect the power cord from the dust collector to a circuit that meets the requirement of the dust

collector.

READ AND SAVE ALL INSTRUCTIONS FOR FUTURE REFERENCE

Vertical Panel Saw/Router Components

Cord Keeper

Counterweight

Pulley

hose)

(behind

(Router)

Plate

Dado Stop (2)

Counterweight Canister

& Counterweight (behind frame)

Handle

Frame Stand

Wheels

Figure 6: Vertical Panel Saw/Router reference guide, SR5U shown with accessories

Stop Block

Faceplate

Guide

Tubes

Carriage

Lock (2)

Carriage

Clamps

(2 or 4)

(Saw) Plate

Blade Guard

(aka Dust Bonnet)

Rulers (4)

Midway Fence

Material Rollers

(behind Faceplate)

13

Guide Tubes (2)

Horizontal Router Components

Cord Keeper

Dado Stop (2)

Nose Cone Adjustment

Knob (behind carriage)

Carriage Lock (2)

Router Plunge Lever

Handle

Clamps (2)

Serial & Model

# Label

Dado Stop (2)

Figure 7: Horizontal Router reference guide,

TR2 shown with accessories

ON/OFF Switch Router

Router Assist Lift Spring

Carriage Lock (2)

Carriage

Dust Collection Port

Rulers (2), Horizontal

& Vertical

Fence

Remote ON/OFF

Switch Router

Router Carriage Components

Dust Port

Carriage Lock (2)

ON/OFF Switch

Depth Adjusting Ring

Router Carriage Components (cont.)

Handle

Carriage

Carriage Lock (2)

Router Base Lock Knob

Router Plunge Handle

Figure 8: 3400 & TR2 Carriage (3400 show n)

14

Installation Handle

Dust Port

Carriage Lock (2)

ON/OFF Switch

Depth Adjustment Knob

(Router Bit Depth)

Router Plunge Handle

Figure 9: SR5 and SR5A Router Carriage

Knurled Knobs

Carriage

Router Plate

Router Base

Flip Lock

Carriage Lock (2)

Handle (2)

Installation Handle

Carriage Lock (2)

Dust Port

ON/OFF Switch

Router Plunge Handle

Figure 10: SR5U and SR5UA Router Carriage

Knurled Knobs

Handle

Carriage

Router Plate

Carriage Lock (2)

Depth Adjusting Ring

15

INSTALLATION/SET UP

Your Safety Speed saw/router comes from the factory assembled and aligned. You will only have to mount the

following parts before you can run these tools:

Router Motor: SR5*, SR5A*, SR5U, SR5UA, 3400 & T R2

Saw or Router Plate: SR5, SR5A, SR5U & SR5UA

Cord keeper, all models

* The router motor may be installed on some configurations.

If you ordered any optional accessories, (e.g. Frame Stand, Frame Wheels, Dust Kit, Vacuum, etc.), you will find

assembly instructions packed with that item and repeated at the end of this manual, (page 58).

Tools Required for Installation

NOTE: Additional tools may be required for installing accessories or making adjustments.

5/16 or 3/8” wrench or nut driver

1/2” wrench (TR2)

9/16” wrench (all models)

3/4” wrench (SR5, SR5A, SR5U & SR5UA)

Collet wrenches (router) included:

- 1-1/8” (2) SR5 & SR5A

- 1-1/16” (2) SR5U, SR5UA, 3400 & TR2

Blade wrench (saw) included:

- 1/2” wrench (SR5 & SR5A)

- 6mm Hex wrench (SR5U & SR5UA)

Operating Environment

For safe operation, install the machine in an area that is well lit. Eliminate all shadows that could interfere with clear

viewing of the work area.

Do not locate the machine in a damp or wet location, or a location where it may be exposed to rain.

If the machine will be operated in an enclosed area, SSM recommends installing the optional Dust Kit and Vacuum.

(see pg. 62).

Avoid explosive atmospheres (gaseous fumes, dust, or flammable materials).

Secure the area so that children and bystanders are kept a safe distance from the work area. Provide barri ers and

shields as needed.

NOTE: The average noise level of SSM saws/routers is less than 80 dB.

16

Inventory

Each model incudes the frame, motor(s) and counterweight, except TR2. These items may be installed on the

saw/router or packaged in separate boxes. The SR5 Series saws/routers include a separate box for the saw and

router motor, and dust cover (Fig. 11, SR5U shown). The 3400 and TR2 include packaging for the router motors.

Accessories may be packaged and included with saw/router frame or shipped separately. Carefully remove and

inspect all items before assembly and operation.

NOTE: The SR5 and SR5A with Milwaukee routers include a second collet for ¼” bits. All router models

come equipped with the standard ½” collet, which is the best choice for large router bits.

Saw & Router

Motors and Plates

Figure 11: Packaged saw/router and boxes (SR5U shown)

Unpacking

SR5, SR5U, SR5A, SR5UA & 3400

1. Removing plastic sheeting, protective cardboard, and wood crating. NOTE: Uncrating methods vary by model

and accessories.

Caution: Have a helper hold saw/router frame for the next steps.

2. Remove wood crate by cutting (a reciprocating saw is used as an example) the wood frame along the

outside/back corners (Fig. 12) being careful not to damage panel saw/router. Cut around base. NOTE: Do

not cut through (across) crate base (Fig.13).

NOTE: Cut between block of wood and base of wood crate, supporting counter weight in back. This will ease

removal of wood block supporting counterweight (Fig. 15).

17

Figure 12: Cutting back of wood crate

Figure 13: Cutting along base of wood crate, do not cut through (across) base

3. Cut top of crate near saw frame, to release crate, Fig. 14. Remove back side of crate as it should be loose

from saw/router and crate. Make sure helper is holding the frame.

Figure 14: Cutting top (back) of wood crate

18

Figure 15: Counterweight support block

4. Make sure helper is holding the frame. NOTE: If you purchased an optional stand, install it before removing

saw/router from crate. Refer to stand installation instructions.

5. Push sides of crate away from frame to release and remove saw/router and set out of crate and place in the

desired and secure position.

6. One or more boxes of parts are attached to the frame. The cord keeper is attached to the carriage. Remove

these items for later installation.

NOTE: When assembling any version of the SR5 or 3400 skip ahead to page 22 for Assembly

instructions.

Unpacking/Assembly

TR2

Caution: Have a helper hold/lift router frame for the next steps.

Figure 16: TR2 back (open side) of crate

19

1. With the assistance of a helper lay crate flat on floor with back (open side, Fig. 16) of crate down and cardbo ard

side up (Fig.17).

Figure 17: TR2 crate positioned flat for unpacking

2. Removing plastic sheeting, protective cardboard, and wood crating. NOTE: Uncrating methods vary by model

and accessories.

3. Remove wood crate by prying off boards on top of cardboard. Remove cardboard.

4. Remove boxes and loose parts from crate.

5. Cut away or pry away sides of crate.

6. Remove two wood cross pieces from inside of crate. Cutting or prying may be necessary to remove these cross

pieces (if sides of crate have not been fully removed). Being careful not to damage router or frame during this

step.

7. With the assistance of a helper, lift TR2 from crate.

8. With the assistance of a helper, install four legs on the inside corners of the base, using four 3/8” hex bolts

through each corner and leg. Finger tighten.

9. After placing TR2 in position, tighten all sixteen bolts through legs.

10. Install two Ruler Support Angles (Pg. 14. Fig. 7) with Scales (rulers, right and left) by bolting to frame. Each

Ruler Support Angle should have the yellow Scale facing “up” with the zero mark near the center of the table.

The back or side of the Angle will bolt to the side of the tube of the fence. Two bolts are used on each Ruler

Support Angle and can be adjusted slightly by loosening the nuts and moving the Scale and retightening.

11. Install accessories (Air Clamps, Dust Vacuum Kit, etc.) at this time.

Note: instructions for attaching accessories are included with the accessory and many are duplicated in the

back of this manual starting on page 58.

Mounting the Router Motor into Router Base on Router Plate: TR2

Do not use router motor for applications not intended. Do not use router motor removed from

the carriage, plate or base for any application. The router motors are engineered for SSM and

built specifically for the intended use as a horizontal router.

20

Make certain the router is unplugged when mounting into base, adjusting or changing bits.

Observe appropriate Lockout/Tagout procedures to insure the tool cannot accidentally be

powered.

8. Install router motor into base by loosening router base lock-knob (do not remove). Place router motor into base

and twist to position motor until motor is seated in base but collet is not touching acrylic sub-base. Tighten

router base lock-knob. This will secure router motor in base.

9. Install cord keeper into end of guide tubes by squeezing ends and pushing into end of tubes (Fig. 18).

Figure 18: Installing Cord Keeper TR2

10. Place router cord through rubber guide and into cord keeper. Cord should never drag onto work surface or

under carriage. Readjust if necessary.

11. Plug router cord into remote ON/OFF switch located at front of machine.

Unplug Router before adjusting.

Observe appropriate Lockout/Tagout procedures to insure the tool cannot accidentally be powered.

Figure 19: Installed Cord Keeper and cord TR2

21

Machine Assembly

SR5, SR5U, SR5A, SR5UA & 3400

To reduce the risk of injury or damage to components, do not attempt to disassemble or

repair the Counterweight without proper technical instructions from SSM.

When unpacking, loosen 2 Carriage Locks (Pg. 13, Fig. 6), move Carriage to center. Remove wood support block

from bottom, center of Counterweight Canister (Pg.19, Fig.15).

Counterweight Canister

Figure 20: Counterweight System

Do not remove the bolt and nut from the Counterweight cable.

Counterweight Pulley

Counterweight Cable

Standing Up the Tool

Do not attempt to lift machine without help of an assistant.

1. With the help of an assistant, position machine in its intended operating location.

2. If the tool is to be mounted to the floor, a wall or post, it must be securely attached to prevent injury from tipping.

Position the frame with a 10 – 15 degree angle of back-lean for optimum performance (does not apply to TR2).

3. If installing the optional Fixed Frame Stand follow the mounting instructions packed with the stand (and repeated

at the end of this manual). The stand will correctly support the tool under normal operating conditions.

A freestanding saw/router must be located away from areas where it could be accidentally

tipped over.

22

Mounting the Router Motor and Router Plate on the Carriage

Models: SR5, SR5U, SR5A, SR5UA & 3400

Do not use panel saw or router motor for applications not intended. Do not use saw or router

motor removed from the carriage, plate or base for any application. The saw and router motors are

engineered for SSM and built specifically for the intended use as a vertical panel saw/router or

horizontal router.

The router motor is inside the box marked “Router Motor”. Remove packaging. Mounting the router motor to the

router base which is affixed to the router plate and attaching the plate to the carriage creates the “Router Carriage”.

1. Install router motor into base by loosening router base lock-knob (do not remove) (Pg. 14, Fig. 8) or opening

flip-clamp (Pg. 15, Fig. 9) (depending on model). Place router motor into base and twist clockwise to position

motor until motor is seated in base but collet is not touching acrylic sub-base. Tighten router base lock-knob or

close flip-clamp (depending on model). This will secure router motor in base.

2. Loosen the two carriage locks and lower the carriage to a comfortable worki ng height. Then tighten the carriage

locks securely.

3. Mount the router motor plate to the carriage by setting the bottom of the plate into the carriage and tipping up

and back to seat the plate by centering the alignment pin into the corresponding guide hole. Secure plate to

carriage using the two knurled knobs and tighten securely.

NOTE: Knurled Knobs are offset to reduce chance of becoming loose, but should be checked as

part of normal maintenance and operation.

4. Make sure router is turned OFF! Plug router cord into machine cord attached to cord keeper.

5. Loosen carriage locks and move carriage to top of guide tubes.

Carriage

Router Plate

Carriage Lock (1 of 2)

Alignment Pin

Knurled Knob (1 of 2)

Depth Adjustment Knob

(Router Bit Depth)

Router Plunge Lever

Figure 21: Mounting (Router) Plate to Carriage, SR5 shown

23

Changing Bits (Routers)

Confirm the router is unplugged when mounting into base, adjusting or changing bits.

Observe appropriate Lockout/Tagout procedures to insure the tool cannot accidentally be

powered.

1. Observe appropriate Lockout/Tagout procedures to insure the tool cannot accidentally be powered

2. Move Carriage to a comfortable working height.

3. Tighten a Carriage Lock.

4. Loosen the clamp/release or flip-clamp (depending on model) o f the router base.

5. Rotate the router motor counterclockwise and pull to remove the motor from base.

6. Using the provided wrench kit, loosen the collet and remove bit.

7. Install new bit and tighten collect.

Confirm router bit is properly seated in collet when tightening.

8. Place router motor into base and twist clockwise to position until motor is seated in base but collet or bit is not

touching acrylic sub-base. Tighten router base clamp or close flip-clamp (depending on model).

9. Loosen Carriage Lock and move Carriage to top of guide tubes.

Mounting the Saw Plate on the Carriage

Models: SR5, SR5U, SR5A & SR5UA

Do not use panel saw or router motor for applications not intended. Do not use saw or router

motor removed from the carriage, plate or base for any application. The saw and router motors are

engineered for SSM and built specifically for the intended use as a vertical panel saw/router or

horizontal router.

The saw motor and plate are in a separate box marked “saw motor”. Mounting the saw motor plate to the carriage

creates the “Saw Carriage”.

1. Loosen the two carriage locks and lower the carriage to a comfortable worki ng height. Then tighten the carriage

locks securely.

24

Knurled Knob stud

(

(1 of 2)

Alignment Pin

Knurled Knob stud

2 of 2)

Carriage Lock

Figure 22: Mounting Saw Plate to Carriage, SR5U shown

Carriage Lock

2. Mount the saw motor plate to the carriage by setting the bottom of the plate into the carria ge and tipping up and

back to seat plate by centering the alignment pin into the corresponding guide hole. Secure plate to carriage

using the two knurled knobs and tighten securely.

NOTE: Knurled Knobs are offset to reduce chance of becoming loose, but should be checked as

part of normal maintenance and operation.

3. Make sure saw is turned OFF! Plug saw cord into machine cord attached to cord keeper. This is a Twist-Lock

connection (Fig. 23 & 24). Match prongs on plug and twist to secure. Twist in reverse before separating halves.

Figure 23: Twist Lock connections

Figure 24: Twist Lock connected

25

4. Loosen carriage locks and move carriage to top of guide tubes.

Installing a Blade SR5 & SR5

1. Observe appropriate Lockout/Tagout procedures to insure the tool cannot accidentally be powered.

2. Select the correct blade for your needs. Refer to “Selecting a Blade”, page 36.

IMPORTANT: Because the saw blade must be carefully matched to the materials being cut, Safety Speed does

not supply a blade as standard equipment on the saw. Improper blade selection can result in reduced tool life,

inaccurate, poor quality cuts, and safety risks. Consult with your machinery dealer or with our customer service

department (763-755-1600) to determine the best blade for your cutting needs.

NOTE: It is a good idea to have spare blades available to prevent downtime.

3. Tighten a Carriage Lock. While holding the spindle lock “in” (Fig. 25, #16) (located on the bottom side of the

motor) remove the blade bolt (#12), using the included 6mm hex wrench, (supplied with the machine) from the

saw motor spindle by turning it counterclockwise. Remove the outer blade flange (#13), but leave the inner

blade flange (#14) on the spindle.

14 16

15

12

13

Figure 25: Installing a Saw Blade (SR5 & SR5A)

26

4. Install the blade with the arrow pointing counterclockwise as shown Fig. 25, #15.

5. Reinstall the outer blade flange (#13) and hand-tighten the arbor bolt (#12). To keep the spindle from turnin g

while you tighten the bolt hold “in” the spindle lock button (#16) Use the 6mm hex wrench provided with the

machine (stored in motor housing) to securely tighten the bolt clockwise.

6. Install Blade Guard before operating (Page 28).

To reduce the risk of injury, do not operate the tool without the blade guard in place.

7. Loosen the carriage lock and allow the saw carriage to return to the top of the guides.

Installing a Blade SR5U & SR5UA

1. Observe appropriate Lockout/Tagout procedures to insure the tool cannot accidentally be powered.

2. Select the correct blade for your needs. Refer to “Selecting a Blade” page 36.

IMPORTANT: Because the saw blade must be carefully matched to the materials being cut, Safety Speed does

not supply a blade as standard equipment on the saw. Improper bl ade sele ction can re sult in redu ce d tool l ife,

inaccurate and poor quality cuts, and safety risks. Consult with your machinery dealer, or with our customer

service department (763-755-1600) to determine the best blade for your cutting needs.

NOTE: It is a good idea to have spare blades available to prevent downtime.

14 15

13

12

16

Figure 26: Installing a Saw Blade (SR5U & SR5UA)

3. First tighten the carriage lock, then while holding the spindle lock “in” (Fig. 26, #16) (located on the bottom side

of the motor) remove the blade bolt by turning it clockwise, using the included ½” wrench. Remove the outer

blade flange (#13), but leave the inner blade flange (#14) on the spindle.

4. Install the blade with the arrow pointing clockwise as shown (Fig. 26, #15).

27

5. Reinstall the outer blade flange (#13) and hand-tighten the arbor bolt (#12). To keep the spindle from turning

while you tighten the bolt hold “in” the spindle lock button (#16). Use the ½” wrench provided with the

machine to securely tighten the bolt clockwise.

6. Install Blade Guard before operating (Page 28, below).

To reduce the risk of injury, do not operate the tool without the blade guard in place.

7. Loosen the carriage lock and allow the saw carriage to return to the top of the guide tubes.

NOTE: It is a good idea to have spare blades available to prevent downtime.

Installing the Blade Guard (aka Dust Bonnet)

The blade guard (Fig. 27) for SR5 & SR5A is in the box marked “Saw Motor.”

NOTE: The blade guard for SR5U & SR5UA is factory installed.

Always install the blade guard before operating the saw.

The guard is shipped with two (SR5U & SR5UA, Fig. 27) or three (SR5 & SR5A, Fig. 28) torque knobs (#22)

installed, depending on the model. Remove the knobs to install the guard. Be sure to leave the rubber washers on

the torque knobs, as they prevent the knobs from slipping.

Attach the guard (Fig. 27 & 28, #21) to the carriage by reinstalling the torque knobs as shown (Fig. 27 & 28, #22).

Return the carriage to the top of the guide tubes and tighten the carriage lock.

21

Blade Guard

21

22

22

Figure 27: Installing the Blade Guard (SR5 & SR5A)

28

22

(smaller knob)

Figure 28: Installing the Blade Guard (SR5U & SR5UA)

21

22

Blade Guard

Rip and Crosscut Rulers (Scales): SR5, SR5A, SR5U, SR5UA & 3400

The saw/router has one rip ruler mounted vertically and a second rip ruler if the Mid-Way Fence is installed. The

rip ruler is set at the factory, for right-to-left cuts using a blade with a 1/8” kerf (1/8” width). The ruler can be adjusted

to accommodate other blade widths or kerfs. To adjust the rip rulers, refer to page 41 “Adjusting the Rip Rulers” in

the Operation section.

The saw/router has two crosscut rulers, one attached to the frame on each side of the carriage and two more

crosscut rulers if the Mid-Way Fence is installed. To adjust the crosscut rulers, refer to page 42 “Adjusting the

Crosscut Rulers” in the Operation section.

NOTE: After the saw is completely assembled, make a test cut to verify that the rulers are

lined up correctly. Readjust if necessary.

Installing the Cord Keeper: SR5, SR5A, SR5U, SR5UA & 3400

The Cord Keeper holds the cord away from the blade/bit and away from your work piece.

1. Pinch the ends of the Cord Keeper together as shown in figure 29, page 30, while slowly sliding the ends into

the guide tubes. Seat the ends securely, (Fig. 30).

29

Rubber Stopper

Figure 29: Installing the Cord Keeper

Cord Keeper

Figure 30: Cord keeper installed (SR5U)

2. Remove the rubber stopper from the ring in the Cord Keeper. See figure 30. Uncoil the cord, and place the

plug end through the ring as shown, (Fig. 30). Connect the loose cord to the cord from the saw/router by

inserting the plug and twisting to lock (if equipped with a twist-lock).

30

Cord Keeper

Rubber Stopper

Cord

Figure 31: Cord keeper installed with cord

3. Loosen the two carriage locks and lower the carriage to the bottom of the guide tubes (the farthest that the

cord will have to be extended). Lock a carriage lock in this lowered position.

4. Pull the Cord Keeper down so it is approximately parallel to the floor as shown. Pull the cord up to remove any

slack in it. Then open the rubber stopper and pull it over the cord with the small end of the taper on the bottom.

Press the rubber stopper into the ring on the cord holder, (Fig. 31 & 32).

Rubber Stopper

Pull cord keeper

so it is parallel

to the floor.

No slack in cord.

Carriage (at the

bottom of the guides)

Figure 32: Installing the Cord Keeper

5. Loosen the carriage lock. Allow the carriage to return to the top of the guid e tubes and then lock a carriage lock.

NOTE: If there is too much or not enough slack in the cord, readjust if necessary.

Installing the Hold-Down Clamps:

All models (SR5 variations, 3400 & TR2) include two “Lower” Hold-Down Clamps and models that include the

Mid-Way Fence include two “Upper” Hold-Down Clamps to be used when Vertical (cross) Routing and some

crosscutting applications. The clamps are typically packed with the saw motor, but can be in a different box(es),

depending on machine configuration.

NOTE: If you purchased the optional Pneumatic Hold-Down Clamps for the 3400 or TR2 see

instructions at the back of this manual and packed with clamps to attach now.

31

“Lower” Hold-Down Clamps:

Figure 33: “Lower” Hold-Down Clamp

1. Remove nut, washer and spacer from clamp.

2. Slide clamp stud into hole of faceplate and align spacer between face plate and frame (Fig. 33).

3. Attach washer and nut to stud, behind frame.

4. Tighten nut while holding clamp parallel to guide tube.

5. Adjust clamp for various thickness material by loosening nuts on pad and tightening so pad locks o n material

when clamp is tightened.

“Upper” Hold-Down Clamps on Mid-Way Fence:

Figure 34: “Upper” Hold-Down Clamp installed

1. Remove “L” stud, washer and locking knob.

2. Slide clamp onto horizontal frame member (Fig. 35). Position one clamp on each side of guide tubes to

securely hold stock when routing or sawing when using the Mid-Way Fence.

Figure 35: Installing “Upper” Hold-Down Clamp

3. Slide “L” stud through two holes in clamp, attach washer and Lock Knob.

32

4. Hand Tighten Lock Knob.

5. Remove Upper Clamps if not using Mid-Way Fence by reversing above procedure.

Backer Board

The Backer Board (Fig. 36) is used when crosscutting thin sheet goods such as plastics or when trimming flexible

material as it gives support at the cut. It can also reduce chipping and tearing. It is standard equipment for the

SR5A and SR5UA and is factory installed. It is located in the space between the two upright frame columns on

each side of the saw blade. It is held in place with magnets and should be removed when ripping or making

through cuts with a router.

NOTE: The kerf mark in the backer board can be used as an alignment aid when positioning stock

for crosscutting. Align the cut mark with the kerf in the backer board for quick

positioning of material.

Backer Board

Figure 36: Backer Board Installed, SR5U shown

OPERATION

(All Models)

The following are suggestions that give you a general idea of how a panel saw/router is

intended to be operated. No instructions can replace common sense and experience. Be

sure you and all operators have enough time and material to become familiar with the

general operating characteristics of this tool, and have FULLY READ AND UNDERSTOOD

all general operating and safety instructions.

33

Capacities of the Tool

Small Work pieces

Do not cut/rout pieces that are so small that your hand must be behind the carriage to hold the piece in

place. Use a tool better suited to these applications, such as a table saw, radial arm saw, chop saw, band saw or

router table.

Work piece Height (Vertical Crosscutting, Cross Routing)

SSM saw/router crosscut/cross rout capacity as shown in Table II below.

Table II: Maximum work piece height (stock width) for Crosscu tting & Cross Routing

Model Max. Height

SR5 62 in.(1575mm)

SR5U 62 in.(1575mm)

SR5A 62 in.(1575mm)

SR5UA 62 in.(1575mm)

3400 62 in.(1575mm)

TR2 36 in.(910mm)

Work piece Thickness

Maximum thickness of a work piece to be cut with SSM saws and routers is:

1-3/4” (45mm) on all models*.

SSC recommends using the optional Hold-Down Bar for frequent cutting of materials thinner than 1/2” (13 mm).

*2” (50mm) thick cutting is available as an option with many models when ordering a new panel saw/router.

Crosscutting/Cross Routing Capacities of vertical machines

When crosscutting/cross routing (vertical cuts & routing), the work piece must be supported on at least two rollers

(Page 44, Fig. 45) for safe operation and accurate cutting/routing. When you use the optional Midway Fence, the

work piece must extend at least 4” (100mm) beyond the carriage on both sides (Page 45, Fig. 46).

Do not crosscut/cross rout work pieces that extend more than 5 feet (1520mm) beyond the outermost roller. To

increase available capacity for these larger panels, SSM recommends using the optional Frame Extensions (Page

62, Fig. 66).

NOTE: Included with all Router models are two (Blind or Stopped) Dado Stops.

These can be located on the right or left Guide Tubes, when facing the saw/router

(Pg. 13 & 14, Fig. 6 & 7). They can be used to limit Carriage travel in

either direction for Blind Dados or Stopped cuts.

NOTE: The lower Dado Stop may need to be removed for certain cuts with the

34

saw or router for the blade or bit to complete the cut.

Rip Cutting and Ploughing (grooving) Capacities of vertical machines

Always use both Carriage Locks when Ploughing or Grooving with a Router!

The minimum length recommended for rip (horizontal) cuts/routing is 2-1/2 feet (760mm), so the work piece will be

supported on at least four rollers. Pieces shorter than 4 feet (1220mm) can be rotated 90 and be crosscut/cross

routed. This size limitation also applies when using the optional Midway Fence. See page 46, Fig. 47 & 48.

There is no limit to the length of stock that can be rip cut or routed. However, you must insure that the stock is

properly supported at all times. For regular rip cutting or routing of long pieces, SSM recommends using optional

Frame Extensions or Extension Tables.

Selecting a Router Bit

The router bit must be carefully matched to the materials being routed. Improper bit selection can result in

reduced tool life, inaccurate and poor quality cuts and safety risks. Call your dealer or SSM for Specialty Router

Bits or for help in choosing the correct router bits. SSM #763-755-1600.

NOTE: The SR5 and SR5A with Milwaukee routers include a second collet for ¼” bits. All router models

come equipped with the standard ½” collet, which is the best choice for large router bits.

35

Selecting a Saw Blade

The saw blade must be carefully matched to the materials bei ng cut. Improper blade selection can result in reduced

tool life, inaccurate and poor quality cuts, and safety risks.

NOTE: The following table lists some recommended blades for certain applications.

If in doubt, consult with your machinery dealer, or with our customer service department (763-755-1600), to

determine the best blade for your cutting needs.

NOTE: It is a good idea to have replacement blades on hand to prevent unnecessary downtime.

Table III: Recommended SSM Blades for Certain Applications

Material 8200HG 840ATB 860ATBL 860ATB 864NRATB 860NRTCG 860TCG 860TCGS 880ATBL 880TCGL

Aluminum composite

Aluminum plate

Chipboard

Double-face panels

Duraply

Gatorfoam

Hardwood

Laminated panels

Masonite

Melamine

Particle board

Plexiglas up to 1/2”

Plywood

Polycarb. (Lexan)

Polyester

Printed grain lamin.

Solid wood

Veneer

Vinyl

Always keep blades clean and sharp for the best performance. A dull or dirty blade can bind and pinch, resulting

in kickback and poor quality cuts. If in doubt, replace it with a new/sharp blade.

The blade diameters specified for SSM panel saws are 8” (200mm), with an arbor of 5/8” (16mm). Minimum

blade kerf for the saw blade is .10” (2.5mm).

X X X

X

X X X X X

X X X X

X X

X X

X X X X

X X X

X X X X

X X X

X X X X X

X X

X X X X X

X X

X X X

X X

X X X X X

X X X

X X X

Riving knife thickness is .08” (1.98mm), blades thinner than this kerf should NOT be used!

Only blades made in conformity to BS EN 847-1:2013 should be used on SSM machines.

36

Basic Operating Controls and Functions of Saws

)

Refer to figure 37 & 38 for the location of operator controls on each model saw.

Handle

Carriage Lock

Index Pins

Figure 37: Basic SAW Operating Controls and Components (SR5 & SR5A)

Dado Stop (2)

ON/OFF Switch

Spindle Lock

Blade Guard

Carriage Lock

Tension Lock Knob

(Hold Down Bar)

Knurled Knob(2

ON/OFF Switch

Handle

Spindle Lock

Index Pins

Blade Guard

Carriage Lock

Carriage Lock

Figure 38: Basic SAW Operating Controls and Components (SR5U & SR5UA)

Removing and Reinstalling the Blade Guard (Dust Bonnet)

Unplug Saw before adjusting.

Observe appropriate Lockout/Tagout procedures to insure the tool cannot accidentally be powered.

The Blade Guard (Dust Bonnet) (Fig. 39 & 40, #21) is attached to the carriage with torque knobs (Fig. 39 & 40,

#22). Remove the torque knobs to remove the guard. Be sure to leave the rubber washers on the torque knobs to

prevent the knobs from slipping.

37

Always install the blade guard before operating the saw (Fig. 39 & 40, #21).

21

Blade Guard

21

22

22

Figure 39: Removing/Installing the Blade Guard (Models SR5 & SR5A)

22

(smaller knob)

21

22

Figure 40: Removing/Installing the Blade Guard (Models SR5U & SR5UA)

Blade Guard

Changing the Blade

38

Unplug Saw/Router before adjusting.

Observe appropriate Lockout/Tagout procedures to insure the tool cannot accidentally be powered.

1. Observe appropriate Lockout/Tagout procedures to insure the tool cannot accidentally be powered.

2. Move Carriage to a comfortable working height. Tighten a Carriage Lock.

3. Remove the blade guard, see “Removing and Installing the Blade Guard” and (Fig. 39 & 40, #21).

4. To keep the spindle from turning while you loosen the arbor bolt (SR5 & SR5A Fig. 41, #12) or (SR5U &

SR5UA Fig. 42, #12) push the spindle lock (#16) located on the under-side of the saw motor Fig. 42 (SR5U &

SR5UA) or on top of the motor housing Fig. 41 (SR5 & SR5A).

5. Use the 6mm hex wrench (SR5 & SR5A) or ½” wrench (SR5U & SR5UA) provided with the saw to loosen and

remove the spindle bolt (Fig. 41, #12, counterclockwise SR5 & SR5A) or (Fig. 42, #12 clockwise SR5U &

SR5UA), while holding the spindle lock.

6. Remove the outer blade flange (Fig. 41 or 42, #13), blade (#15), and inner blade flange (#14).

7. Clean the spindle, flanges, bolt, and blade to remove built-up dust and debris.

8. Reinstall the inner flange, slide on the new blade with the arrow pointing counterclockwise (SR5 & SR5A),

hand-tighten the bolt clockwise. On the (SR5U & SR5UA) models the arrow should be pointing clockwise

and you loosen the bolt turning clockwise and tighten the bolt turning counterclockwise.

9. Use the 6mm hex wrench or ½” wrench to tighten the bolt while pushing the spindle lock.

10. Reinstall the blade guard.

Always install the blade guard before operating the saw/router.

11. Loosen the carriage lock and allow the saw carriage to return to the top of the guides.

12. Reconnect the power.

NOTE: You may have to readjust the rip and crosscut rulers after changing blades or installing a resharpened blade. See “Adjusting the Crosscut Rulers”.

14 16

15

12

13

Figure 41: Installing a Saw Blade (SR5 & SR5A)

39

14 15

13

12

16

Figure 42: Installing a Saw Blade (SR5U & SR5UA)

Starting and Stopping the Motors

SR5 & SR5A Saws: Start the saw motor by lifting on the paddle switch (ON) (Pg. 37, Fig. 37), located under the

saw handle. Stop the motor by pressing the switch down (OFF).

SR5U & SR5UA Saws: Start the saw motor by rotating the start-stop switch ON (Pg. 37, Fig. 38). Stop the motor

by turning the switch OFF.

SR5, SR5U, SR5A, SR5UA & 3400 Routers: Start the router motor by de pressing the rocker switch O N. Stop the

motor by depressing the switch OFF (Pg. 15, Fig. 9 & 10).

TR2 Routers: Start the router motor by pushing the ON button at the remote ON/OFF switch. Stop the motor by

pushing the OFF button on the remote ON/OFF switch (Pg. 14, Fig. 7).

Note 1: The router switch on the router should be at the ON position to use the remote ON/OFF switch.

Note 2: The remote router switch includes an EMERGENCY STOP button, which should only be used in

an emergency.

Rotating the Turntable on the Carriage

All saw models. Pull out both of the Index Pins (Pg. 37, Fig. 37 & 38), and pivot the turntable until they snap into

the appropriate holes.

Moving the Carriage Up or Down (back & forth, TR2)

SR5 & SR5A Saws: Use the handle attached to the motor body (Pg. 37, Fig. 37).

SR5 & SR5A Routers: Use the handles mounted to the router carriage (Pg. 15, Fig. 9).

SR5U & SR5UA Saws: Use the handle in front of the right guide tube, attached to the carriage in the far upper

right hand corner (page 37, Fig. 38).

SR5U, SR5UA, 3400 & TR2 Routers: Use the handle in front of the right guide tube, attached to the carriage in

the far upper right hand corner (Pg. 15, Fig. 10).

40

Locking the Carriage

Lock the carriage by tightening the 2 Carriage Locks, (page 37, Fig. 37 & 38):

One Lock on each of the two Guide Tubes, all models.

Use both Carriage Locks when ploughing or cross routing.

Rip and Crosscut Rulers (Scales): SR5, SR5A, SR5U, SR5UA & 3400

The saw/router has one rip ruler mounted vertically. The rip ruler is set at the factory, for right-to-left cuts using a

blade with a 1/8” kerf (1/8” width). The ruler can be adjusted to accommodate other blade widths or kerfs.

The saw/router has two crosscut rulers, one attached to the frame on each side of the carriage and two more

crosscut rulers if the Mid-Way Fence is installed.

Adjusting the Rip Rulers

Unplug Saw/Router before adjusting.

Observe appropriate Lockout/Tagout procedures to insure the tool cannot accidentally be powered.

Be sure the blade is installed before following these steps:

1. Remove the blade guard (Pg. 37, Fig. 39 & 40) so the blade is exposed.

2. Loosen the carriage lock and lower the carriage to a comfortable working height, as shown in figure 43.

3. Rotate saw, if necessary, to horizontal or ripping configuration.

4. Use a square at least 14” long and place across rollers.

5. Move carriage down to square, with bottom edge of blade or tooth to a measurement. Tighten carriage lock.

6. Adjust ruler, if necessary by loosening hex nut holding indicator and slide indicator to match measurement from

square.

7. Install blade guard.

Always install the blade guard before operating the saw/router.

8. Make a test cut to verify that the ruler is lined up correctly. Readjust if necessary.

Adjusting the Crosscut Rulers

The saw/router has two crosscut rulers, one attached to the frame on each side of the saw/router. The two crosscut

rulers, or four rulers with Mid-Way Fence must be adjusted to the specific blade that is mounted in the saw.

Unplug Saw/Router before adjusting.

Observe appropriate Lockout/Tagout procedures to insure the tool cannot accidentally be powered.

41

Be sure the blade is installed before following these steps:

1. Remove the blade guard (Pg. 37, Fig. 39 & 40) so the blade is exposed.

2. Loosen the carriage lock and lower the carriage to a comfortable working height, as shown in figure 43.

Figure 43: Adjusting the Crosscut Rulers

3. Rotate saw, if necessary, to vertical (crosscut) configuration.

4. Use a square (Fig. 43, #17) that measures at least 14” (356mm) on one side. Line up one edge of the square

with the tips of the saw blade, and the other edge of the square with the crosscut (horizontal) ruler. Slide the

ruler (#19) so that its measure matches the measure on the square. A magnet holds the ruler in place and

allows the ruler to be adjusted to various blade types. To prevent unauthorized adjustment, clear tape can be

wrapped around the ruler and frame.

5. Repeat the above steps to adjust the crosscut ruler on the other side (#20) of the tool.

6. Install blade guard.

Always install the blade guard before operating the saw/router.

6. Make a test cut to verify that the ruler is lined up correctly. Readjust if necessary.

General Operating Tips

For smooth, clean, chip-free cuts, you must use industrial carbide saw blades and bits that are sharp. Dull or

improperly sharpened blades/bits will cause chipping, unclean cuts, chatter, and motor overloading. If you are

not sure that a blade/bit is sharp, replace it with a new/sharp one.

When feeding material through the tool horizontally, or moving the carriage over the material vertically, do it

slowly, smoothly, and (whenever possible) without stopping and in the direction of the arrows on the

carriage labels. Overfeeding results in poor-quality cuts, shortened blade/bit life and motor overloading.

Be careful when setting material onto the rollers. Do not drop heavy material onto the rollers or damage to

the rollers may result.

For best results when sawing/routing, place the work piece onto the tool with its backside facing you (unless

routing the face only. This provides the smoothest possible cut on the face side of the panel.

Panels being cut horizontally or vertically must always be fed against the rotation of the saw blade/bit.

42

Vertical panel saws/routers are intended for cutting large panels down to size. As the overall panel size

becomes smaller and smaller consider the “Midway fence” page 68 or other types of sawing/routing tools as

they become more convenient and safer to use.

When routing on a vertical router, if most panels are narrow, the optional Midway Fence will bring the work

surface to a comfortable height.

When routing window openings, start the plunge cut in an upper corner. This allows the drop piece to fall

downward and away from the bit when the final cut of the opening is completed.

Refer to the Maintenance section for regular maintenance procedures.

Operating Procedure: Crosscutting

A crosscut or cross routing is a vertical cut that must always be done from the top to the bottom of a work piece as

shown on page 44, Fig. 44 and 45. (See also “General Operating Tips” above and “Capacities of the Tool”.)

To reduce the risk of injury, do not place your hands on or under the carriage or in the

path of the saw blade/bit.

1. Position the saw motor in the crosscutting position with the blade oriented vertically. See “Rotating the

Turntable”.

2. Loosen the carriage lock and move the carriage to the top of the guides.

3. Place the work piece on top of the rollers. Be careful not to drop the material on the rollers.

4. Slide the work piece to the desired position, using the crosscut rulers or optional gauging systems (Stop Bar or

Quick Stop) as measures.

5. Make certain that the work piece is adequately supported and stable in the machine. Refer also to “Capacities

of the Tool”. The work piece can be held with one hand.

6. Do not hold the work piece so that your hand is anywhere behind the carriage or guides or in the path

of the saw blade/bit!

7. Start the motor (see “Starting and Stopping the Motor”), and allow it to reach full speed before beginning the

cut.

8. When the motor has reached full speed, slowly and smoothly pull the carriage down so the blade/bit runs

through the work piece. Keep one hand on the handle at all times and the other hand clear of saw

carriage/router carriage. Be careful not to force the saw through the work piece, to avoid binding.

9. If the blade binds in the work piece, or the work piece shifts during the cut, stop the motor, carefully

move the carriage to the top of the guides, restart the motor, and begin the cut again.

10. Support and remove the cut-off piece as the saw completes its cut.

11. Once the cut is complete, turn OFF the motor and wait for the blade/bit to come to a full stop. Move the work

pieces away from the blade/bit. Return the carriage to the top of the guides, and tighten a carriage lock.

43

12. When making saw cuts that are less than 1” (25mm), the chatter preventer (guard) (located inside the blade

guard) must be resting on the work piece, not on the cut-off piece. See page 47 & 48, Fig. 50 & 51. If it is not

positioned this way, it will jam the work piece and prevent the carriage from continuing through the cut. If the

saw jams, turn the saw OFF and wait for the blade to stop. Then back the saw out of the cut.

NOTE: A coasting saw blade/bit could mar the edge of a freshly cut work piece.

Figure 44: Crosscut motor position (SR5U shown)

Figure 45: Crosscutting (work supported on at least two rollers)

44

Figure 46: Crosscutting using optional Midway Fence Kit

(work extends at least 4” (100mm) beyond saw carriage)

Operating Procedure: Rip cutting

A rip cut is a horizontal cut that can be done either from the left to the right or from the right to the left, as shown on

page 46, Fig. 47. Rip cuts must always be done by moving the work piece in the direction of the arrow on

the saw carriage. (See also “General Operating Tips” above and “Capacities of the Tool.”)

To reduce the risk of injury, ripping must always be done with the direction of the arrow

on the saw/router.

1. Before you begin, be sure there is enough space on both sides of the saw to completely load the work piece

on the saw frame, move it past the saw, and completely off-load it.

2. Select the ripping direction, from right or from left, based on preference. Then rotate the turntable to the ripping

position as shown. See “Rotating the Turntable”. The rip measurement is set at the factory for cutting right

to left. The measurement indicator will need to be adjusted for left to right.

3. Select the height of the saw blade above the rollers. Raise or lower the carriage until the height index tab is

aligned with the corresponding dimension on the vertically mounted ruler. Lock the carriage securely to the

guides in this position.

4. Start the motor (see “Starting and Stopping the Motor”) and allow it to reach full speed before beginning the

cut.

5. Position the material on the side of the machine indicated by the arrows on the carriage that show direction of

cut. Place the work piece on top of the rollers. Be careful not to drop the material onto the rollers.

45

6. When the motor has reached full speed, slowly and smoothly push the work piece through the saw, in the

direction of the feed arrow on the saw. Warning: Avoid placing your hand s, cl othing, or body parts under

the carriage or in the cutting path of the saw blade. Do not look directly down the line of cut because

dust and debris are generated during this operation.

Be careful not to force the work piece through the saw, to avoid binding.

If the saw blade binds in the work piece, or the work piece shifts during the cut, stop the saw motor,

carefully back the work piece out of the saw, reposition the work piece, restart the motor, and begin

the cut again.

7. As the work piece passes across the machine, move to the other side and complete the cut by pulling the work

piece past the saw blade. Support the upper piece to keep it from pinching the blade or the kerf protector, or

falling away from the machine.

8. Once the cut is complete, turn off the motor and wait for the blade to come to a full stop. Remove the work

pieces from the machine.

9. Rotate the turntable back to the vertical position and return the carriage to the top of the guides. Lock the

carriage in this position.

Figure 47: Saw Motor in Rip cutting Position

Figure 48: Rip cutting From the Right Using Optional Midway Fence

(work must extend beyond saw carriage at least 4” (100mm))

46

Feed stock with arrows

Figure 49: Rip cutting motor position (SR5U shown)

10. When making cuts that are less than 1 inch, the chatter preventer (guard) (located inside the blade guard) must

be resting on the work piece, not on the cut-off piece. See Fig. 50 & 51. If it is not positioned this way, it will

jam the work piece and prevent the carriage from continuing through the cut. If the saw jams, turn the saw

OFF and wait for the blade to stop. Then back the saw out of the cut before continuing with the cut.

Figure 50: Chatter Preventer (guard) in position for crosscutting (SR5 shown)

47

Basic Operating Controls and Functions of Routers

Router Plunge Lever

Carriage Lock

Handle

Flip Stops

Chatter Preventer (guard)

Figure 51: Chatter Preventer (guard) in position

for crosscutting (SR5U shown)

Nose Cone

Adjustment Knobs

Router ON/OFF Switch

Carriage Lock

Hold-Down Clamp

Fence

Hold-Down Clamp

Remote Router

Dado Stop (2)

Figure 52: Basic Router Operating Controls, TR2 shown

ON/OFF Switch

Operating Procedure: Routing (3400, SR5 series & TR2)

Routing is accomplished with the Router Carriage and a router bit for the proper cut. This can be accomplished

using either a vertical router (e.g. SR5 or 3400) or horizontal router (e.g. TR2). The router can be pulled across

stock for vertical cuts or the router can be locked in place and stock fed through for horizontal routing.

To reduce the risk of injury, do not place your hands on or under the carriage or in the

path of the saw blade/bit.

Unplug Router before adjusting.

Observe appropriate Lockout/Tagout procedures to insure the tool cannot accidentally be

powered.

48

1. With bit installed, (see Changing Bits page 24), set proper depth of cut.

2. Adjust bit depth by loosening motor clamp or flipping open lever clamp (depends on model).

3. Rotate depth collar or depth knob (depends on model) to extend bit past nose cone to desired depth of cut.

4. Tighten/Lock clamp for router base and motor.

5. Adjust router to working position by lowering Plunge Lever and locking in place by pushing down firmly.

Nose Cone Adjustment

Plunge Lever

(Raised Position)

Knob

Carriage Lock

Carriage Lock

Nose Cone Locking