Safety Isolation System User Manual

Safety Isolation System

ElectroGuard Overview . . . . . . . . . . . . . . . . . . . . . . 12-2

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-2

Non Combination Systems (for North America). . . 12-4

Non Combination Systems

(Outside North America) . . . . . . . . . . . . . . . . . . . . 12-5

Combination Systems with Fusible Disconnect

(for North America). . . . . . . . . . . . . . . . . . . . . . . . . 12-6

Combination Systems with Fusible Disconnect

(Outside North America) . . . . . . . . . . . . . . . . . . . . 12-7

Combination Systems with Thermal-magnetic

Circuit Break er (for North America) . . . . . . . . . . 12-10

Combination Systems with Thermal-magnetic Circuit

Breaker (Outside North America). . . . . . . . . . . . . . 12-12

Optional Features . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-15

Typical Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . 12-18

Wire Length Considerations. . . . . . . . . . . . . . . . . . .12-18

Ordering Instructions . . . . . . . . . . . . . . . . . . . . . . . 12-19

Safety Isolation System

ElectroGuard

Overview

The ElectroGuard Safety Isolation System is used in place of a

disconnect switch for Lockout and Tagout (LOTO). It uses power

contactors and Remote Lockout Stations to accomplish LOTO.

Isolating the electrical energy usually involves calling an electrician to

turn “Off” the main disconnecting means. The electrician would

then perform LOTO of the disconnecting means operating handle.

This same procedure is required to perform cleaning, maintenance,

setup, lubrication or adjustment. Machines or processes with

multiple access points may require operator/maintenance

intervention several times a shift (perhaps as often as 60 times per

shift).

To perform these activities, the operator/maintenance person may

be required to place part of his or her body into an area not accessed

during normal operati on. This may cause serious or fatal injury if

LOTO procedures are not followed.

The ElectroGuard Safety Isolation System allows the machine

operator to safely and quickly accomplish LOTO with dramatically

reduced downti me.

Provides Energy Isolation

• Power isolation accomplished by means of contactors rather than

disconnect switches.

• Uses redundant, independent and self-monitoring circ uits to

detect a system fault.

• Prevents accumulation of faults in order to maintain the integrity

of the safety system.

• Tamper-resistant design.

Convenient Remote Lockout Station

• Allows remote isolation of the electrical power to the machine or

process—machine operator simply turns “Off” a Remote

Lockout Station.

• A light on the Remote Lockout Station indicates that the threephase power source to the machine or process has been isolated.

No Light Means No Entry.

• If a fault occurs in the Safety Isolation System, the “System

Isolated” light on the Remote Lockout Stations will not

illuminate.

•Easy Lockout/Tagout.

Certified by TUV to meet requirements of Category 4

• Certified by TUV to meet Category 4, the most stringent safety

category defined within International Standard EN 954-1/ISO

13849-1.

• Subjected by TUV to rigorous third party testing and verification

of the Failure Mode & Effect Analysis (FMEA).

Status Communication Capability to a Remote PLC

• Optional Remote I/O via Flex modules. Communication can be

via the DeviceNet communication platform or the Remote I/O

communication platform.

Available from 23-1200 Amperes.

Specifications

Approvals

Standards

Estimated Component Life

Remote Lockout Station 250,000 operations

Power Contactors 23A - 85A : 2,000,000 operations

(Isolation & Grounding) 110A-1200A: 1,000,000 op e ra tions

Environmental

Storage Temperature -10°C...+60°C (14°F...140°F)

Operating Temperature 0°C...+40°C (32°F...104°F) (Ambient )

Relative Humidity,

Non condensing

Power Panel Construction Tamper-resistant Control Module

Remote Lockout Station

Construction

Expansion Module

Construction

Safety Iso lation Sys. Inputs

Standard Inputs from Remote Lockout Stations

Optional Inputs from

Rockwell Automation

Safety Products

System Operational Limits +10%, -15% o f the line voltage

➊ Use of any of these input devices will not meet Lockout/Tagout (LOTO)

requirements.

Listed Industrial Control Panel;

CULUS

TUV Rheinland certified; CE marked

for all applicable directi ves

IEC/EN 60204-1; IEC/EN 60439-1;

Category 4 to International Standard

EN 954-1/ISO 13849 -1; 98/ 37/ E C

Machinery Directive; 89/336/EC EMC

Directive; 73/23/EC Low Voltage

Directive; Fulfils the function of an

energy isolating device in accordance

with the conditions set forth in the

FedOSHA letter of interpretation

pertaining to Sec tio n 1910.147(b);

Cal/OSHA 3314.

90% Relative Humidity

23A-85A systems support up to 4

Remote Lockout Stations without an

Expansion Module

110A-1200A systems support up to 6

Remote Lockout Stations without an

Expansion Module

Control Module with vie win g window

for visual check of status indicator lights

Top and bottom 25.4mm (1.0in)

conduit entry (removable plug in

bottom conduit hole)

Sealing provision for tamper-resist ance

Operating handle accepts up to 3

padlocks

4 port—supports up to 4 lockout

stations

• allows the sy st e ms to

accommod ate up to 24 Remote

Lockout St ations

10 port—supports up to 10 lockout

stations

• allows the sy st e ms to

accommod ate up to 60 Remote

Lockout St ations

Window for viewing status indicator

lights; Sealed for tamper-resistance

Safety Mats, ➊

Light Curtains, ➊

E-Stop Stations, ➊

Proximity Switches, ➊

Photo Switches ➊

12-2

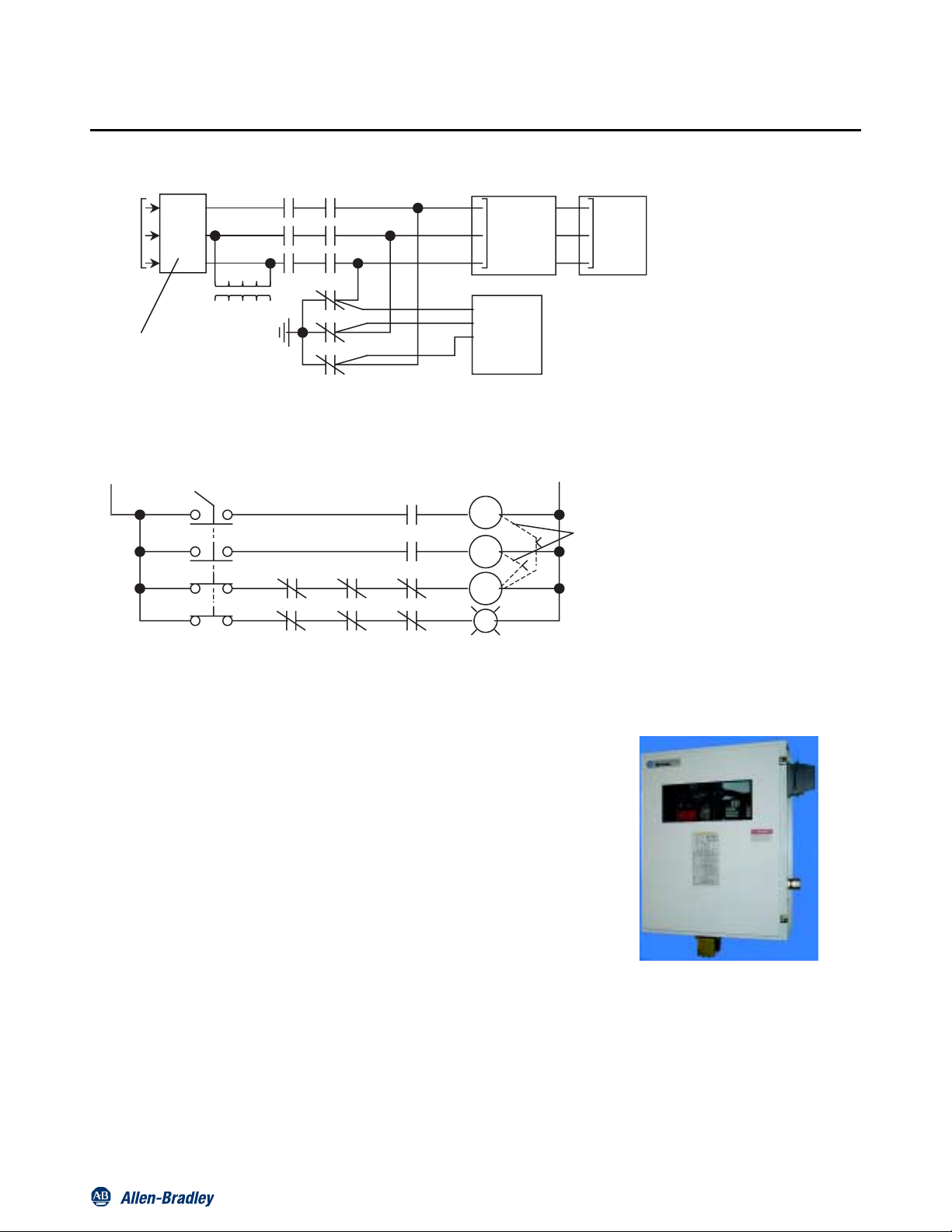

Principle of Operation

Incoming

3 Phase

Power

Control Power

Disconnecting

Means/Branch

Circuit Protection ➊

H2H1

Grd

Power Circuit

Trans.

X2X1

2IC1IC

GC

To M oto r

Controllers

Voltage

Decay

Relays

(VDR)

To Loads

Safety Isolation System

ElectroGuard

Overview

After using the nor mal stopping

method of the machine or process,

the machine operator turns a

Remote Lockout Station handle

from the “On” to “Off ” position.

The station signals the isolation

contactors (1IC and 2IC) to drop

out and isolate the supply voltage

from the loads (see Control

Circuit).

When system residual voltage

decays to pre-determined levels,

the grounding contactor (GC) is

energized, connecting the load to

ground (see Power Circuit). The

grounding contactor (GC) is

electrically and mechanically

interlocked with the isolation

contactors (1IC and 2IC).

Control Circuit

Remote Lockout Station

Off

➊ Available factory installed within the ElectroGuard as an option.

On

GC

GC

2IC1ICVDR

2IC1ICGC

1IC

2IC

GC

System Isolated (*)

(*) = “On” when the Remote

Lockout Stat io n switch is “Off”

Optional Features

• Four (4) or ten (10) port Expansion Modules to permit additional Remote

Lockout Stations to be used (see page 12-16 for details).

• Pneumatic Isolation Module to isolate pneumatic energy (see page 12-15 for

details).

• Status communication to a remote PLC (see page 12-17 for details).

• Fusible disconnect switch (Bulletin 2032) or therm al-magnetic circuit breaker

(Bulletin 2033) to provide branch circuit protection.

Mechanically

Interlocked

1IC, 2I C, &

GC are

mechanically

and electrically

interlocked

The “System Isolated” Light will

now illuminate on the Remote

Lockout Station to indicate the

system is isolated. The machine

operator then Locks-Out and

Tags-Out the station in the “O ff”

position.

Optional Pneumatic Isolation Module

12-3

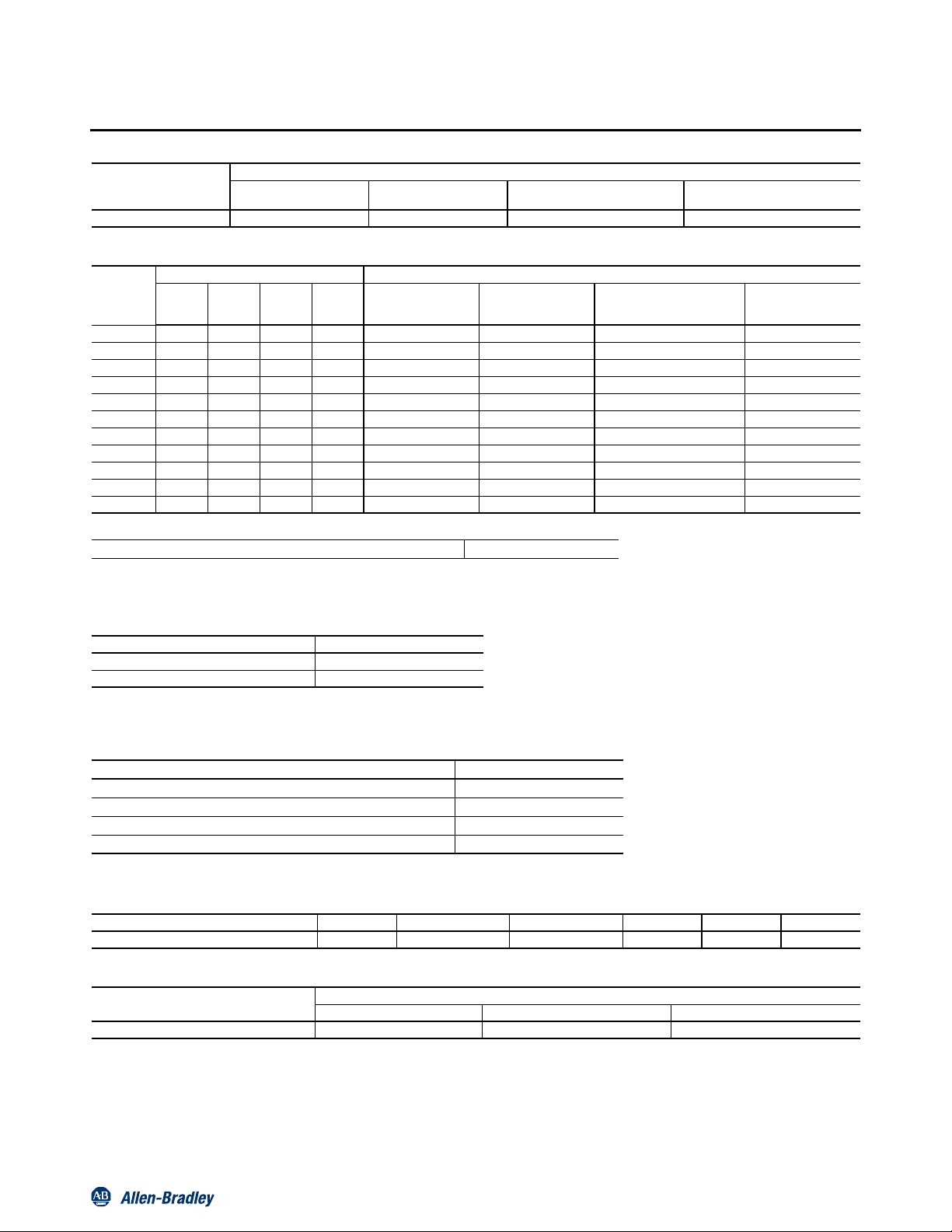

Safety Isolation System

ElectroGuard

Non Combination Systems

+

Power Panel

One or More Remote Lockout Stations

(conduit hub not included)

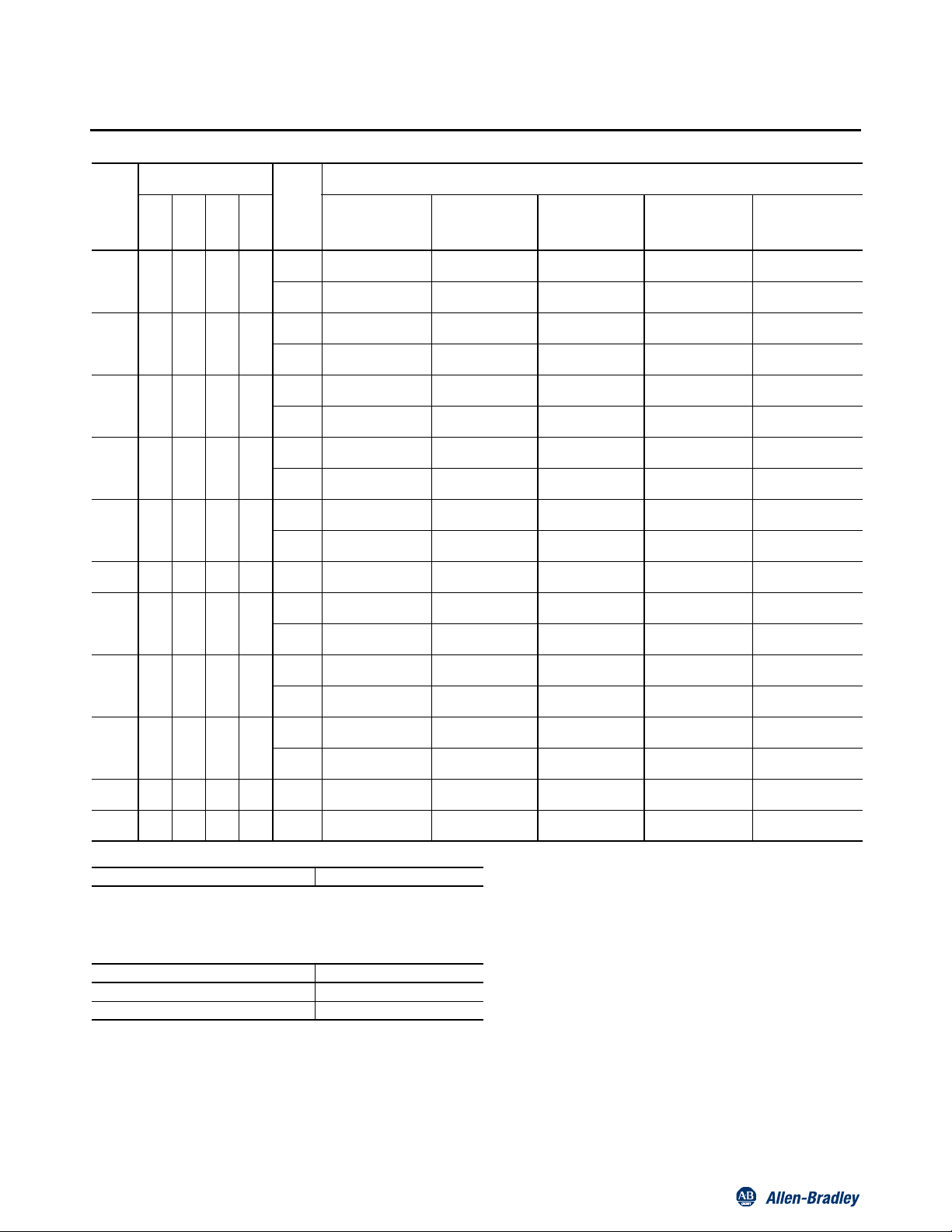

Product Selection: For North America (see page 12-19 for Ordering Instructions)

3-Phase Max. Hp Rating (60Hz) Catalogue Number

Ampere

Rating

(AC-3)

110 40 40 75 100

180 50 60 150 150

210 60 75 - 200

300 100 125 250 300

420 150 175 350 400

630 200 250 500 600

860 250 300 600 700

1200 450 450 900 900

200V 230V 460V 575V

23 5 7.5 15 15

43 10 15 30 30

85 25 30 60 60

Type 1 General

Purpose

Enclosure

2031-A0023A⊗ 2031-A0023J⊗ 2031-!0023J⊗ 2031-A0023F⊗ 2031-A0023C⊗

2031-A0043A⊗ 2031-A0043J⊗ 2031-!0043J⊗ 2031-A0043F⊗ 2031-A0043C⊗

2031-A0085A⊗ 2031-A0085J⊗ 2031-!0085J⊗ 2031-A0085F⊗ 2031-A0085C⊗

2031-A0110A⊗ 2031-A0110J⊗ 2031-!0110J⊗ 2031-A0110F⊗ 2031-A0110C⊗

2031-A0180A⊗ 2031-A0180J⊗ 2031-!0180J⊗ 2031-A0180F⊗ 2031-A0180C⊗

2031-A0210A⊗ 2031-A0210J⊗ 2031-!0210J⊗ 2031-A0210F⊗ 2031-A0210C⊗

2031-A0300A⊗ 2031-A0300J⊗ 2031-!0300J⊗ 2031-A0300F⊗ 2031-A0300C⊗

2031-A0420A⊗ 2031-A0420J⊗ 2031-!0420J⊗ 2031-A0420F⊗ 2031-A0420C⊗

2031*-A0630A⊗ 2031*-A0630J⊗ 2031-!0630J⊗ 2031*-A0630F⊗ 2031*-A0630C⊗

2031*-A0860A⊗ 2031*-A0860J⊗ 2031-!0860J⊗ 2031*-A0860F⊗ 2031*-A0860C⊗

2031*-A1200A⊗ 2031*-A1200J⊗ 2031-!1200J⊗ 2031*-A1200F⊗ 2031*-A1200C⊗

Type 12

Dust tight

Enclosure

Type 1 2 M oto r

Control Centre

Typ e E ncl os ure

(with bussing)

To order the Time D ela y f eatur e, add th e following Catalogue String to the end of the Catalo gue Num ber sho w n in the

table:

Factory set 30 second time delay feature: -1TD

Example: Catalogue Number 2031-A0180A ⊗ b ecomes Catalogue Number 2031-A0180A⊗-1TD to include the time delay feature.

* Input Power Feed Catalogue Number Code

The Catalogue Number as listed is incomplete. Select an Input Power Feed Code from the table below.

Example: Catalogue Number 2031*-A0630J ⊗ becomes Catalogue Number 2031T-A0630J⊗ for a “Top Feed” input power requirement.

➊

Typ e 4

Watertight

Painted Steel

Enclosure

Typ e 4 X

Watertight

Stainless Steel

Enclosure

Input Power Feed Catalogue Number Code

Top Feed T

Bottom Feed B

! Bussing Designation

The Catalogue Number as listed is incomplete. Select a Bussing Designation Code from the table below.

Example: Catalogue Number 2031-!0085J⊗ becomes Catalogue Number 2031-M0085J⊗ for “600A Line Side Incomin g Bus and Outgoing Power Cables”

bussing designation.

Typ e of B u s si n g ➋ Catalogue Number Code

600A Line Side Incoming Bu s and Outgoing Power Cables M

1200A Line Side Incoming Bus and Outgoing Power Cables S

Line Side Incoming Power Cables and 600A Load Sid e Ou tgoing Bus F

Line Side Incoming Power Cables and 1200A Load Side O utgo ing Bus B

Input Line Voltage Code

⊗

The Catalogue Number as listed is incomp lete. Select an Input Line Voltage Code from the table below.

Example: Catalogue Numb er 2031-A0085J⊗ becomes Catalogue Number 2031-A0085JB for a 480V 60Hz Input Line Voltage application.

Input Line Voltage 208V 60Hz 240V 60Hz 480V 60Hz 600V 60Hz

Voltage Code for Catalogue Number HA B C

➊ Optional Time Delay Feature. The Safety Isolation System may be ordered with a factory set time delay featur e (30 seconds) in order to allow time for the machine

operator to shut-down drives or other equipment that requires a controlled stop, after the operating handle on a Remote Lockout Station has been moved to the “Off”

position. Consult your local Rockwell Automation sales office for other time settings.

➋ Bus Type: Copper with tin plating. Consult factory for other types of bussing.

12-4

Safety Isolation System

ElectroGuard

Non Combination Systems

Product Selection: Remote Lockout Station ➊

Catalo gue Number

“System Isolated”

Light Colour

White 2030-RLSAW 2030-RLSJW 2030-RLSFW 2030-RLSCW

Product Selection: For Outside of North America (see page 12-19 for Ordering Instructions)

3-Phase Max. kW Rati ng (50Hz) Catalogue N umber

Ampere

Rating

(AC-3)

23 7.5 11 11 11

43 13 22 22 22

85 25 45 45 45

110 32 55 63 100

180 55 90 110 160

210 63 110 150 200

300 90 160 200 300

420 132 220 300 425

630 200 355 450 500

860 250 500 560 600

1200 391 710 888 1043

To order the Time Delay feature, add the following Cat. String to the end of the Cat. No. shown in the table:

Factory set 30 second time delay feature: -1TD

Example: Catalogue Number 2031-C0180 H⊗becomes Catalogue Number 2031-C0180H⊗-1TD to include the time delay feature.

* Input Power Feed Catalogue Number Code

The Catalogue Number as listed is incomplete. Select an Input Power Feed Code from the table below.

Example: Catalogue Numb er 2031*-C0630H⊗ becomes Catalogue Number 2031T-C0630H⊗ for a “To p Feed” input power requirement.

Top Feed T

Bottom Feed B

230V 400V 500V 600V IP 30 Enclosure IP 54 Enclosure

Input Power Feed Catalogue Number Code

Type 1 General

Purpose Enclosure

Type 12 Dust tight

Enclosure

2031-C0023P⊗ 2031-C0023H⊗ 2031-!0023H⊗ 2031-C0023W⊗

2031-C0043P⊗ 2031-C0043H⊗ 2031-!0043H⊗ 2031-C0043W⊗

2031-C0085P⊗ 2031-C0085H⊗ 2031-!0085H⊗ 2031-C0085W⊗

2031-C0110P⊗ 2031-C0110H⊗ 2031-!0110H⊗ 2031-C0110W⊗

2031-C0180P⊗ 2031-C0180H⊗ 2031-!0180H⊗ 2031-C0180W⊗

2031-C0210P⊗ 2031-C0210H⊗ 2031-!0210H⊗ 2031-C0210W⊗

2031-C0300P⊗ 2031-C0300H⊗ 2031-!0300H⊗ 2031-C0300W⊗

2031-C0420P⊗ 2031-C0420H⊗ 2031-!0420H⊗ 2031-C0420W⊗

2031*-C0630P⊗ 2031*-C0630H⊗ 2031-!0630H⊗ 2031*-C0630W⊗

2031*-C0860P⊗ 2031*-C0860H⊗ 2031-!0860H⊗ 2031*-C0860W⊗

2031*-C1200P⊗ 2031*-C1200H⊗ 2031-!1200H⊗ 2031*-C1200W⊗

Type 4 Watertight Painted

Steel Enclosure

IP 54 Motor Control

Centre Type Enclosure

(w/bussing) IP 65 Enclosure

Type 4X Watertight Stainless

Steel Enclosure

➋

! Bussing Designation

The Catalogue Number as listed is incomplete. Select a Bussing Designat ion Code from the table.

Example: Catalogue Numb er 2031-!0085H⊗ becomes Catalogue Number 2031-E0085H⊗ for “600A Line Side Incoming Bus and Outgoing Power Cables”

bussing designation.

Typ e of B u s si n g ➌ Catalogue Number Code

600A Line Side Incoming Bu s and Outgoing Power Cables E

1200A Line Side Incoming Bus and Outgoing Power Cables D

Line Side Incoming Power Cables and 600A Load Sid e Ou tgoing Bus H

Line Side Incoming Power Cables and 1200A Load Side O utgo ing Bus R

Input Line Voltage Code

⊗

The Catalogue Number as listed is incomp lete. Select an Input Line Voltage Code from the table below.

Example: Catalogue Number 2031-C0085P⊗ becomes Catalogue Number 20 31- C 00 85PN for a 380V 50Hz Input Line Voltage application.

Input Line Voltage 220V 50HZ 380-400V 50Hz 400-415V 50Hz 440V 50Hz 500V 50Hz 550V 50Hz

Voltage Code for Catalogue Number A N G B M C

Product Selection: Remote Lockout Station ➊

Catalogue Number

“System Isolated” Light Colour

Green 2030-RLSPG 2030-RLSHG 2030-RLSWG

➊ Safety Isolation Systems rated up through 85A can support a maximum of four (4) Remote Lockout Stations (RLS).

Systems rated from 110A - 1200A can support a maximum of six (6) RLS. If additional RLS are required, order the optional Expansion Module(s) (see page 12-16).

➋ Optional Time Delay Feature. The Safety Isolation System may be ordered with a factory set time delay featur e (30 seconds) in order to allow time for the machine

operator to shut-down drives or other equipment that requires a controlled stop, after the operating handle on a Remote Lockout Station has been moved to the “Off”

position. Consult your local Rockwell Automation sales office for other time settings.

➌ Bus Type: Copper with tin plating. Consult factory for other types of bussing.

IP 30 Enclosure IP 54 Enclosure IP 65 Enclosure

12-5

Safety Isolation System

ElectroGuard

Combination Systems with Fusible Disconnect Switch

Product Selection: For North America (see page 12-19 for Ordering Instructions)

3-Phase Max. Hp

Rating (60Hz)

Fuse

Amp.

Rating

200V230V460V575

(AC-3)

23 5 7.5 15 15

43 10 15 30 30

85 25 30 60 60

110 40 40 75 100

180 50 60 125 150

210 60 75 150 200

300 75 125 250 300

420 150 175 350 400

630 200 250 500 600

860 250 300 600 700

1200 450 450 900 900

V

Clip

Rating/

Typ e ➊

30A

Class J

60A

Class J

60A

Class J

100A

Class J

100A

Class J

200A

Class J

200A

Class J

400A

Class J

200A

Class J

400A

Class J

400A

Class J

400A

Class J

600A

Class J

600A

Class J

800A

Class L

800A

Class L

2000A

Class L

2000A

Class L

2000A

Class L

Typ e 1 G enera l

Purpose

Enclosure

2032-A0023A⊗-24J 2032-A0023J⊗-24J 2032-!0023J⊗-24J 2032-A0023F⊗-24J 2032-A0023C⊗-24J

2032-A0023A⊗-25J 2032-A0023J⊗-25J 2032-!0023J⊗-25J 2032-A0023F⊗-25J 2032-A0023C⊗-25J

2032-A0043A⊗-25J 2032-A0043J⊗-25J 2032-!0043J⊗-25J 2032-A0043F⊗-25J 2032-A0043C⊗-25J

2032-A0043A⊗-26J 2032-A0043J⊗-26J 2032-!0043J⊗-26J 2032-A0043F⊗-26J 2032-A0043C⊗-26J

2032-A0085A⊗-26J 2032-A0085J⊗-26J 2032-!0085J⊗-26J 2032-A0085F⊗-26J 2032-A0085C⊗-26J

2032-A0085A⊗-27J 2032-A0085J⊗-27J 2032-!0085J⊗-27J 2032-A0085F⊗-27J 2032-A0085C⊗-27J

2032-A0110A⊗-27J 2032-A0110J⊗-27J 2032-!0110J⊗-27J 2032-A0110F⊗-27J 2032-A0110C⊗-27J

2032-A0110A⊗-28J 2032-A0110J⊗-28J 2032-!0110J⊗-28J 2032-A0110F⊗-28J 2032-A0110C⊗-28J

2032-A0180A⊗-27J 2032-A0180J⊗-27J 2032-!0180J⊗-27J 2032-A0180F⊗-27J 2032-A0180C⊗-27J

2032-A0180A⊗-28J 2032-A0180J⊗-28J 2032-!0180J⊗-28J 2032-A0180F⊗-28J 2032-A0180C⊗-28J

2032-A0210A⊗-28J 2032-A0210J⊗-28J 2032-!0210J⊗-28J 2032-A0210F⊗-28J 2032-A0210C⊗-28J

2032-A0300A⊗-28J 2032-A0300J⊗-28J 2032-!0300J⊗-28J 2032-A0300F⊗-28J 2032-A0300C⊗-28J

2032-A0300A⊗-29J 2032-A0300J⊗-29J 2032-!0300J⊗-29J 2032-A0300F⊗-29J 2032-A0300C⊗-29J

2032-A0420A⊗-29J 2032-A0420J⊗-29J 2032-!0420J⊗-29J 2032-A0420F⊗-29J 2032-A0420C⊗-29J

2032-A0420A⊗-30L 2032-A0420J⊗-30L 2032-!0420J⊗-30L 2032-A0420F⊗-30L 2032-A0420C⊗-30L

2032*-A0630A⊗-30L 2032*-A0630J⊗-30L 2032-!0630J⊗-30L 2032*-A0630F⊗-30L 2032*-A0630C⊗-30L

2032*-A0630A⊗-34L 2032*-A0630J⊗-34L 2032-!0630J⊗-34L 2032*-A0630F⊗-34L 2032*-A0630C⊗-34L

2032*-A0860A⊗-34L 2032*-A0860J⊗-34L 2032-!0860J⊗-34L 2032*-A0860F⊗-34L 2032*-A0860C⊗-34L

2032*-A1200A⊗-34L 2032*-A1200J⊗-34L 2032-!1200J⊗-34L 2032*-A1200F⊗-34L 2032*-A1200C⊗-34L

Type 12 Dust

tight Enclosure

To order the Time De lay feature, add the following Catalogue String to the end of the Cat. No. shown in the table:

Factory set 30 second time delay feature: -1TD

Example: Catalogue Number 2032-A0180A⊗-27J becomes Catalogue Numbe r 2032-A0180A⊗-27J-1TD to include the time delay feature.

* Input Power Feed Catalogue Number Code

The Catalogue Number as listed is incomplete. Select an Input Power Feed Code from the table below.

Example: Catalogue Number 2032*-A0630J⊗-30L becomes C a t a lo gu e Number 2032T-A0630J⊗-30L for a “Top Feed” input power requirement.

Input Power Feed Catalogue Number Code

Top Feed T

Bottom Feed B

➊ Power fuses are not included with the disconnect switch. Select power fuses in accordance wi th applicable local codes.

➋ Optional Time Delay Fea ture. The Safety Isolation System ma y be ord ered wit h a factory set time delay feat ure (3 0 seconds) in order to allow time for t he mach ine operator

to shut-down drives or other equipment that requires a controlled stop, after the operating handle on a Remote Lockout Station has been moved to the “Off” position.

Consult your local Rockwell Automation sales office for other time settings.

Catalogue Number ➋

Type 12 Motor

Control Centre

Type Enclosure

(with bussing)

Typ e 4

Watertight

Painted Steel

Enclosure

Typ e 4 X

Watertight

Stainless Steel

Enclosure

12-6

Loading...

Loading...