Safeplace T500 C, M800 C, T800 C, M500 C, T300 C Technical Manual & Handheld Unit Manual

...

TQM Technical Manual

Handheld Unit Manual

For models: M800 - C,C4,SL,W,MS,E

&

T800 - C,C4,SL,W,MS,E

M500 - C,C4,SL,W,MS,E

T500 - C,C4,SL,W,MS,E

T300 - C,C4,SL,W,MS,E

Q300 - C,C4,SL,W,MS,E

M300 - C,C4,SL,W,MS,E

IMPACT - C,C4,SL,W,MS,E

590.1060.001

Version 05 – 2.09

2

Registration Form

Please fill in this form and fax it to the

following number: +972 8 85 73 962

or email to sales@safeplace.co.il

Property name:__________________________________

Chain/Group:___________________________________

Address:__________________________________________________________

_________________________________________________________________

_________________________________________________________________

Contact persons:____________________________________________________

_________________________________________________________________

Telephone number:______________________________

Fax number:___________________________________

Email:________________________________________

Safe model________________ Quantity __________________

Color_________________________________________

3

4

Table of Contents

1 General Description and Guidelines Page 7

2 Safety Instructions Page 8

3 Safe Models Page 10

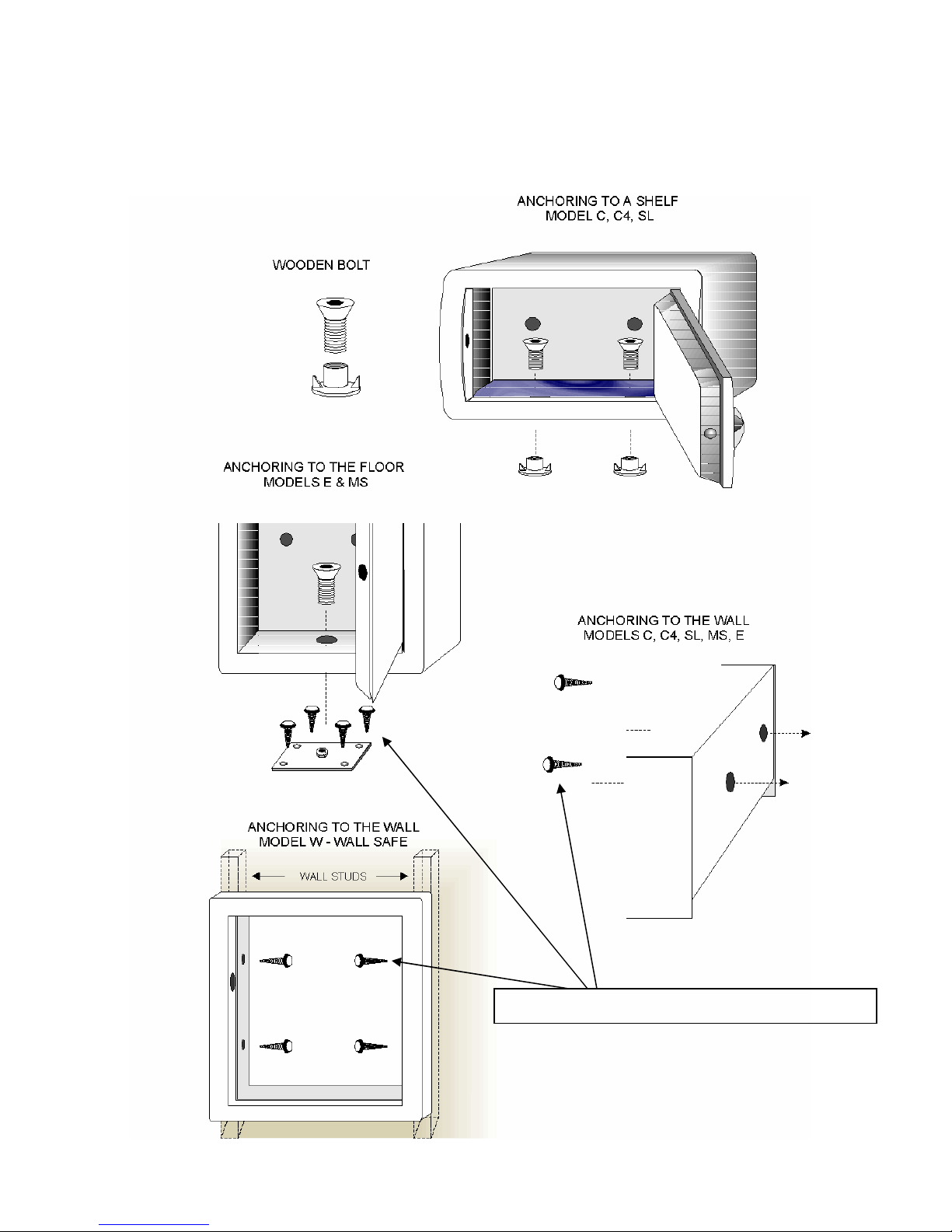

4 Anchoring the Safe Page 11

5 Emergency Opening Procedure Page 12

Page 13Emergency Opening with EOT 3005a

Page 14Emergency Opening with BiMax Handheld Unit5b

Page 15Emergency with Master Key/Card5c

6 Mechanical Emergency Opening for C, C4, SL, W Page 16

7 Mechanical Emergency Opening for E4, MS4 Page 17

8 Trouble-Shooting Page 18

Page 21Trouble-Shooting for Magna 500

9 Battery Replacement Page 22

10 Parts Replacement Page 23

10a Electronic Board Page 24

10b Battery Housing Page 25

Page 26Lock Assembly10c

Page 28Panel Assembly10d

Page 30Door Replacement10e

11 Safe Place Components

11a C, C4, SL, W Page 31

11b E4, MS4 Page 32

11c Assembled Door C, C4, SL Page 33

11d Assembled Door E4, MS4 Page 34

5

6

General Description

And Guidelines

Dear Customer,

You have just received new safes. In the following manual, you will find

all the necessary information for operating and maintaining the

safes, including:

1. Safety instructions.

2. Anchoring - The different options for anchoring the safes.

3. Emergency opening.

4. Parts replacement - How to replace the main components of the

safe.

5. Safe Place components - All the safe components you may

need to purchase in the future. Please note which size safe

(C, SL, MS, E & W) you have, and choose the component.

6. Trouble-shooting - safe feedback that will identify the problem in

a malfunctioning safe.

Service and Warranty Guidelines:

We provide a 2 year limited warranty for parts. You received

spare parts to enable you to replace any defective part. We ask

you to please send us any defective parts for later replacement.

If you have any questions or need assistance, please call your

local distributor. If for any reason you cannot reach your local

distributor, you can always contact us at fax number: ++972-88573962, or e-mail: service@safeplace.co.il

7

Safety Instructions

For safes with power outlet (recharge socket)

The safe model you have purchased is equipped with a 220V or

110V power (USA Rating : 110V 5A 60Hz) outlet for laptop

recharging. Please follow the safety instructions carefully before

hooking up the power outlet.

1. Only a certified electrician should handle this equipment.

2. Unplug the receptacle from the wall outlet before performing

maintenance.

3. If no plug is connected to the electrical wire – connect as follows:

U.S.A:

Black wire to terminal marked L

White wire to terminal N

Green wire to terminal E or GR

:Europe

Brown wire to terminal marked L or

Blue wire to terminal marked N

Green & yellow wire to terminal marked E or

4. The receptacle must be protected by a 6 Amp fuse.

5. Do not plug it in if for any reason, the power supply cord or plug

is damaged or frayed.

6. Do not allow anything to rest on the power cord.

8

Safety Instructions

For safes with AC power hook-up (Adaptor)

Adaptor specifications AC-DC:

Output – 9V DC, 500mA max. built in thermal fuse.

1. Only a certified electrician should handle this equipment.

2. Pay attention to wire marks (+ / -) and assemble them

properly.

3. Disconnect the adaptor from the main power before replacing

the electronic board.

4. Check the adaptor specifications before plugging into main

power (see above).

9

Safe Models

Biometric

Digital Safes

Magna 800

Magna 500

Magna 300

Impact

Combination

Titan 500

Card Safe

Titan 800

Smart Key

Quantor 300

Tiara-M Top Open

C - Small

SL – Super Laptop

MS – Medium

C4 - Laptop

W – Wall

E – Floor

10

Anchoring The Safe

Anchoring Bolts should be - 10*1”

11

Emergency Opening Procedure

In case the safe is locked and

the guest is unable to open it,

observe the following procedure:

1. Perform the override procedure with the BiMax

Handheld Unit or Emergency Opening Tool T300 (see

details on following pages). If the safe does not open,

go to step 2.

2. Make sure your HHU/EOT and Master Card/iButton

are working properly. Test them on another safe.

3. If the above does not help, perform mechanical

opening.

Before performing the mechanical opening, we highly

recommend contacting your local service

representative for assistance.

12

Override Procedure With EOT 300

(Emergency Override Tool)

1. Plug-in the EOT – The

green led will light up.

2. Place the Master (red)

iButton on the rounded

reader within 6 seconds.

3. If you have an error (red

light) press Clear button

and try again.

A green light will blink and

the safe will open!

13

Override Procedure

With BiMax Handheld Unit

Please Also See Page 7 of Override and Audit Handheld Unit Manual in this

Booklet

1. Turn the Handheld on by

pressing the ON button, enter

your password and put your

finger on the reader.

2. Select Override Safe

and press ENTER.

3. Connect Safe And Press

Enter appears on the

display. Connect the

Handheld plug to the

underside of the safe keypad

and press ENTER.

4. Attach iButton appears on

the display. Attach the

master iButton.

The safe will open!

14

Override Procedure

With Master Key/Card

Titan 300/800/500 models:

Slide the Master card from

left to right with

magnetic stripe up.

The safe will open!

Quantor 300 model:

Place the Master (red)

iButton on the iButton

reader.

A green light will blink

and safe will open!

15

Mechanical Emergency Opening

For C, C4, SL & W Models

THE DRILLING PROCEDURE IS THE LAST OPTION FOR OPENING THE SAFE.

PLEASE MAKE SURE YOU TRY ALL OTHER OPTIONS BEFORE DRILLING!

1. Place the drilling template on the left

bottom corner of the safe door.

1a. For Titan Models, forcibly remove the

panel to place the drilling plate.

1b. For left hand doors, place the template

at the upper right corner.

1 c. For W left hand doors, forcibly remove

the panel and place the template at the

upper right corner.

2. Drill 3 holes with a 4 mm drill through the

template.

3. Remove the template and enlarge the

holes to 8 mm.

4. Drill through the head of the screws all the

way until the the lock assembly moves

backward.

The safe will open!

16

Mechanical Emergency Opening

For E4 & MS4 Models

THE DRILLING PROCEDURE IS THE LAST OPTION FOR OPENING THE SAFE.

PLEASE MAKE SURE YOU TRY ALL OTHER OPTIONS BEFORE DRILLING!

1. Place the drilling template on the left

bottom corner of the safe door.

2. Drill a 4 mm hole through the template.

3. Remove the template and enlarge the

holes to 8 mm.

4. Drill through the head of the screws all the

way until the lock assembly moves

backward.

The safe will open!

17

Trouble-Shooting 1

Check Microswitch. Close door.

Check Microswitch. Close door.

For Magna 800, Titan 800 and Titan 500 Models:

Safe series 500 and 800 have a built in diagnostic system which

shows error numbers on the display if there is any problem

with the safe.

The following list is available in the Tools Menu of the HHU.

Display Problem Description Operation Instructions

Common Operational Problems

Code Wrong code Enter code again. Try another code.

Batt Low Batteries Replace batteries

Er00 Clock is not set Set Safe Clock

Er01 Card error Slide card again or replace card

Er02 Bolt cannot lock Push door. Release bolt.

Er03 Bolt cannot open Push door. Release bolt.

Er04 Not enough digits Enter 4 digits

Er05 Activator needed Plug Activator

Er06 Wrong Override Change override unit

Er07 Bolt in middle position Override safe. Check lock assembly.

Er08 Illegal card Use another card

Er10 Door Microswitch open

Er11 Card error Slide card again. Replace card.

Er12 Button Error Re-attach button. Replace button.

Er13 Wrong Operation Enter 4 digits to open

Er14 Door Microswitch Open

Er16 Wrong Master Use different master

Er17 Common code Enter non-common Code

Er18 Common code Enter non-common Code

Er20 Comm. Failure Check HHU connection. Try again

Er21 Comm. Failure Check HHU connection. Try again

Er22 Comm. Failure Check HHU connection. Try again

Er23 Comm. Failure Try again

Er24 Comm. Failure Try again

Er25 Override failed Start override process again

Er26 Illegal operation Start override process again

Er27 Wrong IR key Use card or press CLR button

Er28 Wrong IR key Use iButton or press CLR button

Communication Problems

18

Trouble-Shooting 2

Display Problem Description Operation Instructions

Override Problems

Er30 Unit disabled Use different type of override

Er31 Master disabled Use override unit or code

Er32 Wrong master Use iButton or code

Er35 Wrong master Use card or code

Er36 Master disabled Use different type of override

Er37 Memory problem Replace main PCB

Er38 Master defin. Err. Factory Error

Er39 Memory problem Try process again.

Operational Problems in Dual Safes

Er40 Wrong key Open with code or card

Er41 Button disabled Use code or card

Er42 No Code Entered Enter code and lock

Er43 Wrong key Open with code or iButton

Er44 Wrong key Open with card or iButton

Er45 Illegal Operat. Use code or iButton

Er46 Illegal Card Use different card

Er47 Illegal Button Use different iButton

Er48 Keypad disabled Use card or iButton

Er50 Keypad disabled Use card or iButton

Manufacturer Problems

Er64 No master defined Factory Error

Er66 Master defin. Err. Factory Error

Er67 Master defin. Err. Factory Error

Er68 Master defin. Err. Factory Error

Er70 Software error.

Er71 Illegal Time Check designated operation time

Er73 Card Unauthorized Try to close with a different card

Er74 Can't Add Card Card already registered

Er75 Can't Add Card Illegal user card

Er76 Can't Delete Card Not a registered card user

Er77 Factory Error Factory Error

Er78 Can't Add Card Memory full

Er79 Add/Del Time Ended Start process again

Er80 Bad Card Can't register this card

Er81 Factory Error Factory Error

Er82 Factory Error Factory Error

Er83 Can't Close with This Card Illegal user card

Er84 Memory problem Replace main PCB

Er85 Memory problem Replace main PCB

19

Trouble-Shooting 3

Anti-Tamper Problems

Er90 Motor tampered Override safe. Check lock assembly.

Er91 Motor tampered Override safe. Check lock assembly.

Er92 Motor tampered Override safe. Check lock assembly.

Er93 Motor tampered Override safe. Check lock assembly.

Er94 Motor tampered Override safe. Check lock assembly.

Er95 Motor tampered Override safe. Check lock assembly.

Er96 Audit Tampered Read from safe. Initiate Safe Data.

Er101 Motor tampered. Override safe. Check lock assembly.

20

Trouble-Shooting for Magna 500

• Safe clock is not initialized. Use the Handheld

Unit to initialize it. (INIT. SAFE DATA)

• The locking bolt won’t eject all the way to lock.

Make sure the door is properly closed and

nothing stops the bolt from moving smoothly.

Check the lock assembly. Check connection of

lock assembly to the electronic board.

• The locking bolt won’t reject all the way to open.

Press the door to release any pressure on the

bolt.

• Not enough digits were entered for locking.

Enter a complete number. If this happens

during override procedure, it means the safe

does not recognize the override unit. Check the

connectors with the unit.

• Wrong master card. Locate the correct card.

• Locking bolt is in middle position. Perform

override procedure.

• Override procedure was not completed. Start

from the beginning.

• Safe has performed an illegal operation. Check

the safe motor and then perform override

procedure.

21

Battery Replacement

C, C4, SL

W, Special Sizes

E, MS

1. Unscrew the cover bolts and remove the door

cover.

2. Remove the old batteries and install the new

batteries. Make sure the batteries point in the

right direction.

3. For safes with Audit function – you must set safe

clock by using the HHU after replacing batteries.

4. Batteries should be replaced every two years.

5. Use only Alkaline Batteries!

22

Parts Replacement

After trouble-shooting the safe, the next step is replacing the

defective part. The safe mechanism is made up of four

components:

Electronic Board

Battery Housing

Lock Assembly

Panel Assembly

The Elimination Method

If you are still not sure where the safe problem lies after the

trouble-shooting process, you should replace the four

components, one after the other, until you discover the

defective component. When performing this process, make

sure that your spare parts are in working order and the

connectors are properly connected. Replace one component

at a time. If the problem is not solved, put the component

back in the same order and then continue to the next

component.

23

Electronic Board Replacement

1. Unscrew the 3 electronic

board screws.

2. Carefully disconnect all

the connectors from the

panel assembly, locking

assembly, and battery

housing assembly.

C, C4, SL

W, Special Sizes

3. Replace the new board

carefully, and connect it

in the same order. After

checking that the door is

functioning properly,

reconnect the screws

(Safes with audit function

should be initialized

before use).

E, MS

24

Battery Housing Replacement

1. Disconnect the

battery housing

connector.

2. Unscrew the two

battery housing

screws.

3. Replace the new

battery housing.

C, C4, SL

W, Special Sizes

4. Replace the plastic

base.

5. The Universal Kit

used in W & special

size safes has builtin battery housing.

Replace the entire

kit.

E, MS

25

Lock Assembly Replacement

C, C4, SL

E, MS

1. For MS & E - remove the electronic board & the battery housing.

2. Unscrew the 4 (E4) or 6 (MS4) nuts.

3. For C, C4, & SL - unplug the lock assembly connector from the

electronic board.

4. Remove the 5 star rings (They cannot be reused.)

26

Lock Assembly Replacement

Universal Kit - W, Special Sizes

1. Remove the

electronic board.

2. Unscrew the 4

nuts which attach

the Universal Kit.

3. Unscrew the 3

bolts which attach

the motor base to

the Universal Kit

(from the back).

4. Make sure the

spring that pulls

back the motor

base is in place

when you

unscrew the

bolts.

27

Panel Assembly Replacement

1. Remove the electronic

board.

2. Unscrew the 4 keypad

panel screws.

3. Replace the new panel

carefully. Make sure

the flat cable runs

freely from the panel

into the door and is

connected to the

electronic board

properly. After

checking that the safe

is working properly,

screw back the panel

and electronic board

screws.

E, MS

E, MS

E, MSE, MS

C, C4, SL

C, C4, SL

C, C4, SLC, C4, SL

28

Panel Assembly Replacement

Universal Kit - W, Special Sizes

1. Remove the electronic

board.

2. Unscrew the 4 nuts

which connect the

Universal Kit to the

door.

3. Unscrew the 4 keypad

panel screws.

4. Replace the new panel

carefully. Make sure

the flat cable runs freely

from the panel into the

door and is connected

to the electronic board

properly. After

checking that the safe

is working properly,

screw back the panel

and electronic board

screws.

29

Door Replacement

2 3

1

Replacing the Door:

1. Unscrew the two screws.

2. Extract the two hinges from the hinge housing.

3. Keep the washers from the bottom connection in a safe place.

4. Replace the defective door with a new one.

5. Insert the top hinge through the top hinge housing and through

the hole in the top frame. Then tighten the top screw.

6. Insert the bottom hinge through the bottom hinge housing.

Insert the washers back into place, and insert the hinge

through the washers and through the hole in the bottom frame.

7. Tighten the bottom screw.

8. Check that the door fits into the frame.

30

Safe Place Components

Models C, C4, SL, W

Please Specify Safe Color When Ordering Parts

NO.

Part Name Catalog Number

Right Hand Left Hand

1 Painted Box C 314.0030.250 314.0040.250

2 Painted Box C4 314.0030.400 314.0040.400

3 Painted Box SL 315.0030.380 315.0032.380

4 Painted Box W 316.1010.002 316.1020.002

M800 M500 M300 T800 T300 T500 Impact Q300

5 Assembled Door C, C4214.2800.001 214.1101.001 214.2300.001 214.3800.001 214.3300.001 214.3500.001 214.7000.001 214.1300.001

6 Assembled Door SL 215.2800.001 215.1101.001 215.2300.001 215.3800.001 215.3300.001 215.3500.001 215.7000.001 215.1300.001

7 Assembled Door W 213.2800.001 213.1101.001 213.2300.001 213.3800.001 213.3300.001 213.3500.001 213.7000.001 213.1300.001

8 Door Cover C, C4 523.1100.007

9 Door Cover SL 523.1100.016

10 Door Cover W 523.1100.015

11 Floor Carpet 570.1100.002

12 Nuts M10 535.3120.002

13 Bolts

#M10*20/M10*25

535.2020.120

/125

31

Safe Place Components

Models MS, E

Please Specify Safe Color When Ordering Parts

NO.

Part Name Catalog Number

Right Hand

1 Painted Box E 311.0050.010

2 Painted Box MS 312.0050.010

M800 M500 M300 T800 T300 T500 Impact Q300

3 Assembled Door E 211.2800.001 211.1101.001 211.2300.001 211.3800.001 211.3300.001 211.3500.001 211.7000.001 211.1300.001

4 Assembled Door MS 212.2800.001 212.1101.001 212.2300.001 212.3800.001 212.3300.001 212.3500.001 212.7000.001 212.1300.001

5 Door Cover E 523.1100.006

6 Door Cover MS 523.1100.010

7 Floor Carpet 570.1100.002

9 Anchoring Bolt #

M12*30

535.2020.230

341.2300.001Anchoring Plate10

32

Safe Place Components

Assembled Door C,C4,SL

Please Specify Safe Color When Ordering Parts

No Part Name Catalog Number

1 Painted Door C, C4 333.1300.020 333.1300.020

2 Painted Door SL 333.1300.030 333.1300.030

3 Painted Door W 335.1010.002 335.1020.002

4a Panel M800 370.2800.001 7 Battery Housing 556.0400.010

4b Panel M500 370.1101.001 8a Electronic Board M800 550.8002.001

4c Panel M300 370.2300.001 8b Electronic Board M500 550.3350.001

4d Panel T800 370.3800.001 8c Electronic Board M300 550.6002.001

4e Panel T300 370.3300.001 8d Electronic Board T800 550.8002.001

4f Panel T500 370.3500.001 8e Electronic Board T300 550.6002.001

4g Impact 370.7000.001 8f Electronic Board T500 550.8002.001

4h Panel Q300 370.1300.001 8g Electronic Board Impact 550.8002.001

6

Lock Assembly W/Universal

Kit

Right Hand Left Hand

550.6002.001Electronic Board Q3008h363.1000.050Lock Assembly C, C4, SL5

522.2100.001Door Hinge9363.1000.050

33

Safe Place Components

Assembled Door MS, E

Please Specify Safe Color When Ordering Parts

No. Part Name Catalog Number

1 Painted Door E 331.0010.033

2 Painted Door MS 331.0010.023

3 Lock Assembly MS 362.1000.003

4 Lock Assembly E 362.1000.005

5 Battery Housing 556.0400.010

6 Door Hinge 522.2100.001

7 Nut #M 6 535.3120.007

8 Panels See Previous Page

See Previous PageElectronic Boards9

34

Loading...

Loading...