Page 1

4900 Industry Drive

Central Point, OR 97502

Visit us on the web:

www.ergoindemand.com

TASK MASTER® INDUSTRIAL CHAIR

(17” - 35” Range)

ASAS

AS

ASAS

TOOLS REQUIRED: 1/2" CRESCENT OR SOCKET WRENCH; SCREWDRIVER; RUBBER MALLET

SEMBLSEMBL

SEMBL

SEMBLSEMBL

Y Y

Y

Y Y

INSTRUCTIONSINSTRUCTIONS

INSTRUCTIONS

INSTRUCTIONSINSTRUCTIONS

5120

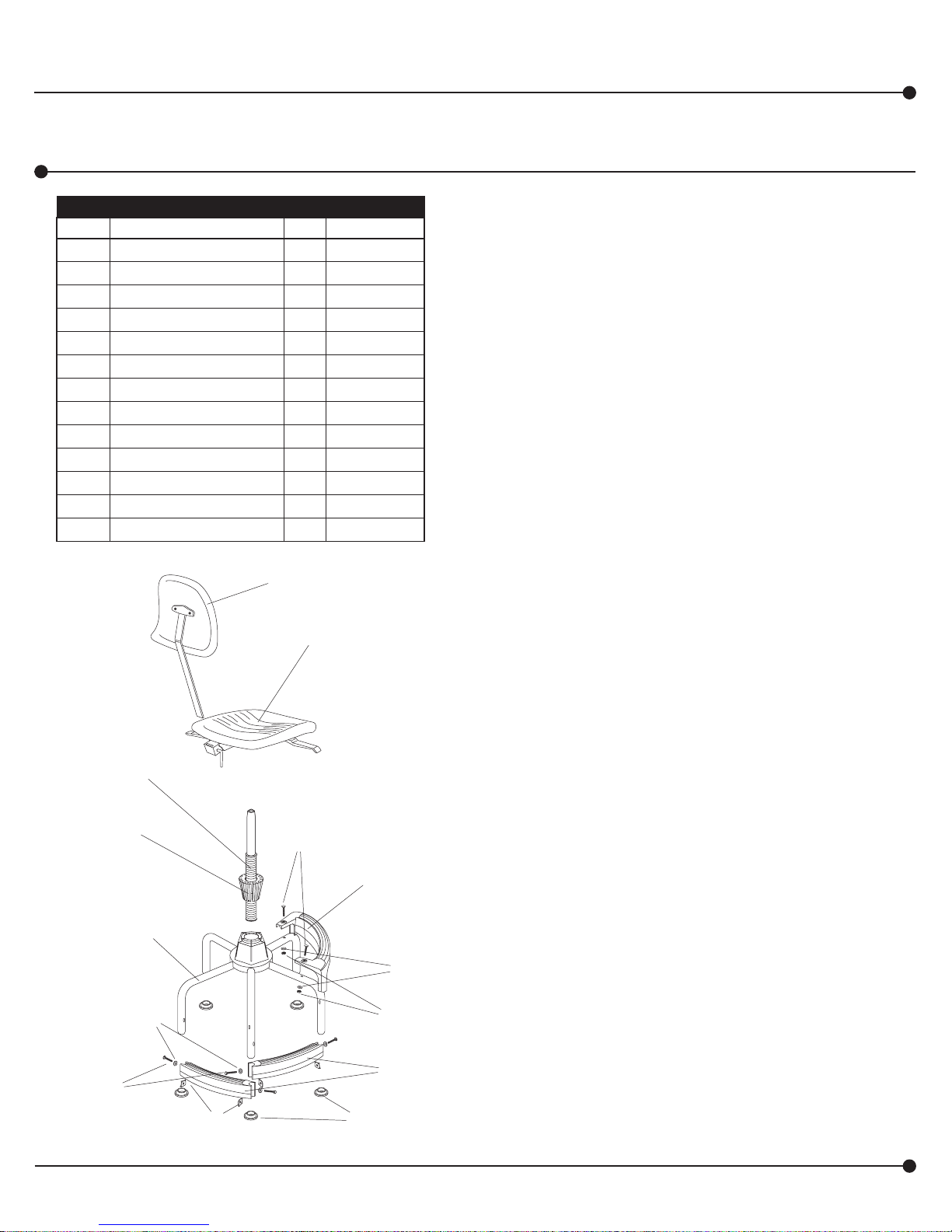

PARTS LISTPARTS LIST

PARTS LIST

PARTS LISTPARTS LIST

CODE

Base 1 5101-04

A

Q

Lower Footrest 2 5101-06

B

Q

Footrest Nut 4 5101-24

C

Q

Flat Washer 6 5147-31

D

Q

Hex Bolt 4 5101-23

E

Q

Glide 5 5101-25

F

Q

Upper Footrest 1 5118-06

G

Q

Carriage Bolt (Black) 2 5118-23

H

Q

Locking Nut 2 5118-24

I

Q

Tapered Bushing (on K) 1 5101-05

J

Q

Wavetube Assembly 1 5101-11

K

Q

Seat Assembly 1 5113-01BL

L

Q

Back Assembly 1 5113-02BL

M

Q

DESCRIPTION

M

QQ

Q

QQ

QTY.

L

QQ

Q

QQ

PART NO.

Check all parts against Parts List before beginning assembly.

Allow all parts to warm to room temperature prior to assembly.

Locate the HIGHER set of mounting holes on the side of the legs

1

of the (A) Base. From the bottom, slide a (B) Lower Footrest (with

the curved front facing out) up between those legs until the holes

in the footrest line up with those in the legs. Place a (C) Footrest

Nut inside the footrest, with the cupped side matching the curve

of the footrest end. Insert a (D) Flat Washer on to (E) Hex Bolt

through the hole in the base leg and the footrest, and thread it into

the footrest nut. Attach the other end of the footrest the same

way. Now tighten bolts alernately with a wrench, until both sides

are evenly tight. Do not overtighten.

Mount the second (B) Lower Footrest into the LOWER set of

2

mounting holes on the legs, using the same procedure as before.

Install a (F) Glide onto each of the legs of the base. The glides

3

should fit snugly, so place a glide under a leg and tap the leg into

it with a rubber mallet. Be sure the leg is inserted completely into

the glide for proper stability. (HINT: Glides are easier to install if

they are slightly expanded. Use a blow dryer or warm water,

drying thoroughly, to expand glides.)

Position the (G) Upper Footrest over the holes on the tops of two

4

of the base legs. Insert a (H) Carriage Bolt (Black) through each of

the footrest holes and through the legs. Add (D) Flat Washer and

fasten with (I) Locking Nuts on the underside of the legs; tighten

alternately with a wrench, until both sides are evenly tight. Do not

overtighten.

K

QQ

Q

QQ

J

QQ

Q

QQ

A

QQ

Q

QQ

D

QQ

Q

QQ

E

QQ

Q

QQ

C

QQ

Q

QQ

Registered U.S. Patents 5,836,555; D381,823

5120-37MP: 1 of 6;

Rev. 4: 11/06 (8004.04)

H

QQ

Q

QQ

The (J) Tapered Bushing should come preassembled on (K)

5

Wavetube (contact Ergo if it is not). Spread the tapered bushing

slightly (it has a split side) and slide to about halfway down

wavetube. Insert the wavetube assembly, wave surface first, into

the central hub of the base; slide it down until the tapered bushing

pops inside the hub and nests securely.

G

QQ

Q

QQ

D

QQ

Q

QQ

I

QQ

Q

QQ

B

QQ

Q

QQ

F

QQ

Q

QQ

For questions or concerns, please call

available Monday-Friday 8:00 AM to 4:30 PM (Central Time) (English-speaking operators)

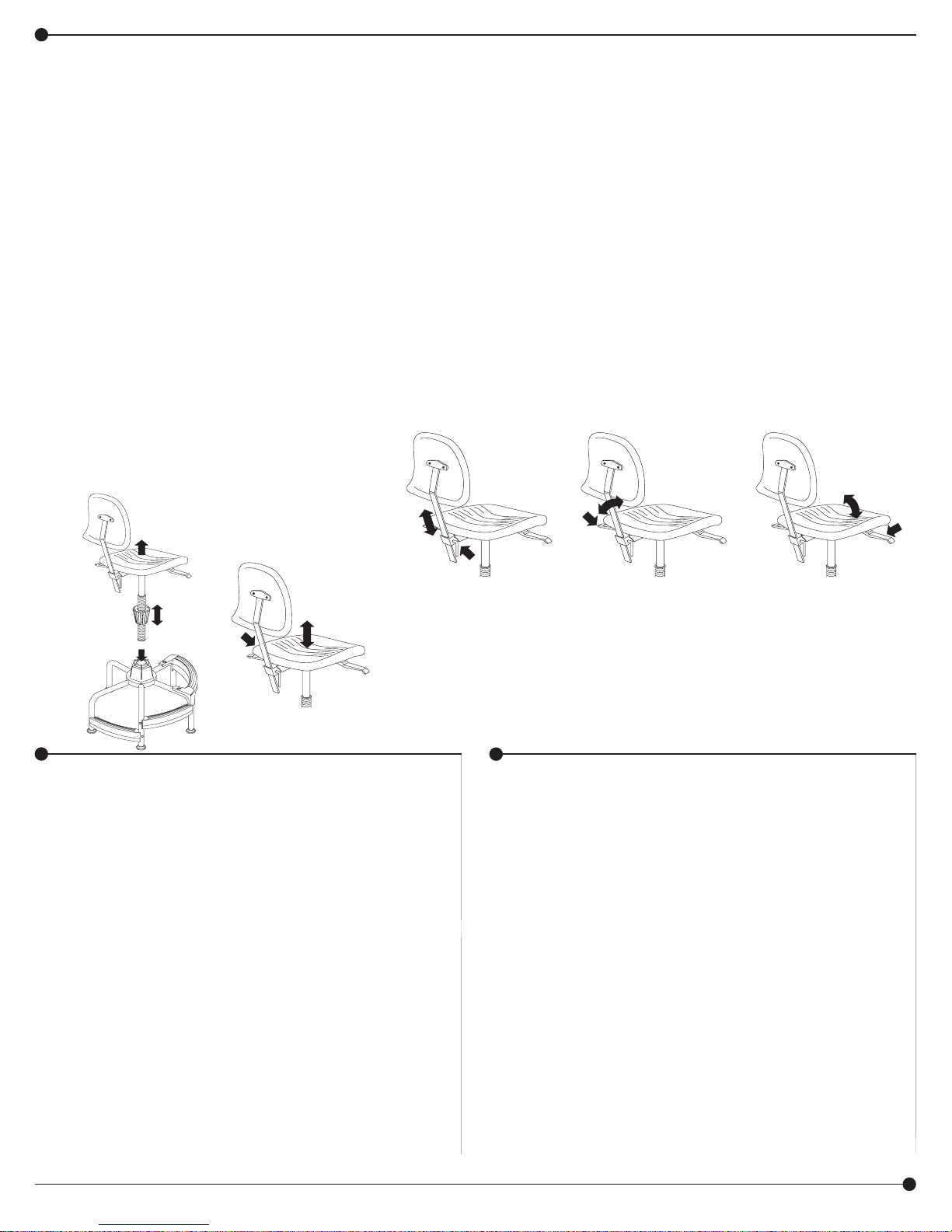

Install the (L) Seat Assembly by aligning the hole on the underside

6

with the shaft of the wavetube assembly; push down firmly on seat.

Insert the stem of the (M) Back Assembly into the slot at the back

7

of the seat. Use a screwdriver to depress the push button at the

bottom of the stem and slide until the stem goes all the way

through the slot and sticks out the other side about 2". It may be

necessary to rotate the lever at the back of seat assembly

clockwise so stem will slide all the way through the slot. Rotate

the lever counterclockwise to lock the stem.

Make the final chair adjustments following the instructions on the

8

reverse side.

Ergo In Demand at 1-800-888-6024

Page 2

CHAIR ADJUSTMENT INSTRUCTIONS

To maximize the ergonomic benefits of this chair, it is essential to understand how the controls function and how they affect your posture.

ADJUST THE

HEIGHT RANGE:

The wavetube gives the

chair an extra 10" of height

adjustment, providing a total

seat height range of 17" to

35". Determine the

appropriate range for the

task or tasks at hand. Place

a foot on the chair base and

lift the seat with a sharp

pull. The upper chair

assembly will disconnect

from the base. Spread the

tapered bushing and move

it along the wavetube to the

desired position (toward the

seat for lower height range,

toward the open end for

higher ranges). Do not let

any part of the bushing

extend beyond either end

of the wavetube.

ADJUST THE

FINAL HEIGHT:

The front lever under the

seat on the left side

pneumatically adjusts the

height of the seat over a

range of about 8". The

proper height should be

determined by a

combination of variables:

the height of the work

surface, the task to be

performed and your body

size. Typically, the chair

should be high enough so

your arms form a 90o angle

at the elbow or slightly

greater. This allows for

better circulation in the

shoulders and neck area

and also reduces the

amount of fatigue in the

forearms and hands. The

feet should lie flat on the

ground or footrest. To help

insure good posture,

maintain a 90o angle at the

bend of the knees.

ADJUST THE

BACK HEIGHT:

The backrest height

adjustment lever is behind

and below the seat. By

sliding the backrest

assembly up or down, you

adjust the height of the back,

which has a lumbar support

curve to it. Sit centered on

the seat. The curve in the

backrest should fit into the

small of your back. This will

reduce the pressure on the

spinal discs, especially in

the lumbar area.

ADJUST THE

BACK ANGLE:

The back angle adjustment

lever is the rear one on the

left side, under the seat.

The 22o angle adjustment

of the backrest is especially

critical for work tasks that

require leaning forward. Lift

the lever and allow the

surface of the backrest to

support the upper body

weight by positioning it to

the natural curve of the

spine. Press down on the

lever to lock into place. The

backrest hinge should tilt

freely, to help prevent

twisting of the spine.

ADJUST THE

SEAT ANGLE:

The seat angle adjustment

lever is the one on the right

side, under the seat. The

seat tilt is important for work

tasks that require leaning

forward. The 10o tilt allows

you to lean forward without

extra pressure under the

thighs. Lift the lever and

shift your weight forward

until you find a

comfortable position, then

release the lever to lock

into place.

MAINTENANCE

The pneumatic lift in the Cylinder is

permanently lubricated at the factory and

needs no further lubrication. NEVER

LUBRICATE THE PNEUMATIC LIFT. Do not

remove clip from bottom of Cylinder. Contact

Ergo immediately if clip is missing or

damaged. Clean polyurethane seat and back

with soap and water. To repair small cuts in

polyurethane, apply a few drops of quickdrying glue into the cut and press the sides

together until the glue sets.

5120-37MP: 2 of 6; Rev. 4: 11/06 (8004.04)

GENERAL SAFETY INSTRUCTIONS

Do not stand on seat.

Chair must be on level surface to ensure proper

stability.

Only use chair when fully assembled.

Never use chair if it does not perform according

to this sheet or warranty may be void.

Immediately report any problems to Ergo and

always give the manufacturer's date code

information from the label under the seat.

CAUTION: Allow for optimum support. Never try

to position Tapered Bushing below the retaining

ring at the bottom of the Wavetube. Always leave

at least 1/2" clearance between the bottom of the

Wavetube and the floor.

Ergo In Demand, Inc., Central Point, OR 97502

Page 3

4900 Industry Drive

Central Point, OR 97502

S’il vous plaît visiter-nous sur l’Internet :

www.ergoindemand.com

TASK MASTER® CHAISE INDUSTRIELLE

(GAMME DE HAUTEURS DE 43 À 89 CM [17 À 35 PO])

INSTRUCTIONS DE MONTINSTRUCTIONS DE MONT

INSTRUCTIONS DE MONT

INSTRUCTIONS DE MONTINSTRUCTIONS DE MONT

OUTILS REQUIS : CLÉ À DOUILLE OU À MOLETTE 1/2 PO ; TOURNEVIS; MAILLET À TÊTE EN CAOUTCHOUC.

5120

AGEAGE

AGE

AGEAGE

CODE

ALPHABÉTIQUE

A Base 1 5101-04

Q

B Repose-pieds bas 1 5101-06

Q

C Écrou de repose-pieds 2 5101-24

Q

D Rondelle plate 4 5147-31

Q

E Boulon hexagonal 2 5101-23

Q

F Glissière 5 5101-25

Q

G Repose-pieds haut 1 5118-06

Q

H Boulon de carrosserie (noir) 2 5118-23

Q

I Contre-écrou 2 5118-24

Q

J

Q

Q

Q

Q

Brevet américain enregistré 5,836,555 ; D381,823

Manchon conique

K Ensemble de tube à filets ondulés 1 5101-11

L Ensemble de siège 1 5120-01BL

M Ensemble de dossier 1 5113-02BL

K

J

A

E

LISTE DES PIÈCES

DESCRIPTION

D

C

(sur K)

M

QTÉ.

1 5101-05

L

H

No DE PIÈCE

G

D

I

B

F

Avant de commencer le montage, vérifier toutes les pièces à l’aide

de la liste des pièces. Permettre à toutes les pièces d’atteindre la

température de la pièce avant de faire le montage.

Repérer la série HAUTE des trous de montage qui se trouvent sur les

1

côtés des pieds de la base (A) . En commençant par le bas, glisser un

repose-pieds bas (B) (avec la partie courbe vers l’avant) entre deux

pieds et le soulever jusqu’à ce que les trous du repose-pieds soient

alignés avec les trous des pieds. Mettre un écrou de repose-pieds (C)

à l’intérieur du repose-pieds, de sorte que la partie courbe de l’écrou

épouse la partie courbe de l’extrémité du repose-pieds. Glisser une

rondelle plate (D) sur le boulon hexagonal (E) , insérer le boulon dans

le trou du pied de la base et dans le trou du repose-pied, puis le visser

dans l’écrou du repose-pieds. Fixer l’autre extrémité du repose-pieds

de la même manière. Serrer les boulons peu à peu à l’aide d’une clé,

en passant de l’un à l’autre successivement jusqu’à ce qu’ils soient

bloqués également. Ne pas serrer les boulons trop fort.

Monter le deuxième repose-pieds bas (B) sur la série BASSE des trous

2

de montage qui se trouvent sur les pieds, en suivant le procédé décrit cidessus.

Installer une glissière (F) sur chacun des pieds de la base. Les

3

glissières devraient s’ajuster solidement aux pieds. Pour l’installation,

mettre une glissière au-dessous d’un pied, puis rentrer le pied dans la

glissière en le tapant avec un maillet à tête en caoutchouc. Vérifier que

le pied est inséré complètement dans la glissière, pour assurer une

bonne stabilité. (CONSEIL : Les glissières sont plus faciles à installer si

elles sont légèrement dilatées. Pour dilater les glissières, les chauffer à

l’aide d’un séchoir à air chaud, ou bien les tremper dans de l’eau

chaude, puis les essuyer avec soin.)

Positionner le repose-pieds haut (G) vis-à-vis des trous qui se trouvent

4

sur le haut de deux pieds de la base. Passer un boulon de carrosserie

(H) (noir) à travers chacun des trous du repose-pieds et à travers les

trous des pieds. Ajouter une rondelle plate (D) et attacher le reposepieds sur le dessous des pieds à l’aide des contre-écrous (I) . Serrer

les deux boulons de carrosserie peu à peu à l’aide d’une clé, en

passant de l’un à l’autre successivement jusqu’à ce qu’ils soient

bloqués également des deux côtés. Ne pas serrer les boulons trop fort.

Le manchon conique (J) devrait être déjà monté sur le tube à filets

5

ondulés (K) (communiquer avec Ergo si ce n’est pas le cas). Écarter

légèrement le manchon conique (il a une fente sur un côté), puis le

glisser à peu près au milieu de la partie ondulée du tube. Insérer

l’ensemble du tube et du manchon dans le moyeu central de la base,

avec la surface ondulée du manchon vers le bas. Glisser le manchon

vers le bas jusqu’à ce que le manchon conique rentre dans le moyeu et

s’y loge solidement.

Installer l’ensemble de siège (L) en alignant le trou du dessous avec

6

l’arbre de l’ensemble de tube à filets ondulés. Appuyer vigoureusement

sur le siège.

Insérer la tige de l’assemblée arrière (M) dans la rainure au dos du

7

siège. Utiliser un tournevis déprimer le bouton de la poussée à fond de

tige et le glisser jusqu’à la tige traverse complètement la rainure et

étend à travers l’autre côté approximativement 5 cm 2 (po). Ce peut être

nécessaire de tourner le levier au dos de l’assemblée du siège comme

les aiguilles d’une montre afin que la tige glisse complètement à

travers la rainure. Tourner le levier pour fixer la tige dans le sens

inverse des aiguilles d'une montre.

Faire les derniers règlements de la chaise en suivant les instructions au

8

verso.

5120-37MP: 3 of 6;

Rev. 4: 11/06 (8004.04)

Pour toute question ou tout problème, veuillez communiquer avec l’Assistance téléphonique à la clientèle

Ergo au 1-800-888-6024 du lundi au vendredi, de 8H00 à 16H30 (Heure du Pacifique) (Opérateurs de langue anglaise)

Page 4

INSTRUCTIONS DE RÉGLAGE DE LA CHAISE

Pour profiter au maximum des avantages ergonomiques de cette chaise, il est indispensable de savoir comment les commandes

fonctionnent et comment elles influencent votre posture.

POUR RÉGLER LA

GAMME DES

HAUTEURS :

Le tube à filets ondulés

permet un réglage

supplémentaire de la

hauteur de 25 cm (10 po).

La gamme complète des

hauteurs du siège est donc

de 43 à 89 cm (17 à 35

po). Déterminer la gamme

qui convient à la tâche ou

aux tâches à exécuter.

Mettre un pied sur la base

du tabouret, puis soulever

le siège en le tirant

brusquement vers le haut.

L’ensemble supérieur du

tabouret se détachera de

la base. Écarter le

manchon conique et le

déplacer sur le tube à filets

ondulés jusqu’à l’endroit

voulu (rapprocher le

manchon du siège pour

une gamme de hauteurs

plus basse, et de

l’extrémité ouverte pour les

gammes plus élevées). Ne

pas permettre à une partie

quelconque du manchon

de dépasser une extrémité

du tube à filets ondulés.

POUR RÉGLER LE SIÈGE

À LA HAUTEUR

DÉFINITIVE :

Le levier de devant sous

le siège sur le côté

gauche ajuste la hauteur

du siège sur une gamme

d’environ 20 cm (8 po). Il

faut déterminer la hauteur

appropriée du siège en

tenant compte de

plusieurs variables : la

hauteur de la surface de

travail, la tâche à

exécuter et la grandeur

de votre corps.

Normalement, la chaise

devrait se trouver à une

hauteur telle que vos bras

forment un angle de 90

degrés ou un peu plus au

coude. Cette posture

assure une meilleure

circulation aux épaules et

au cou, et réduit la fatigue

des avant-bras et des

mains. Les pieds

devraient être plantés

solidement sur le sol ou

sur le repose-pieds. Pour

assurer une bonne

posture, maintenir un

angle de 90 degrés aux

genoux.

POUR RÉGLER

LA HAUTEUR DU

DOSSIER :

Le levier de réglage de la

hauteur du dossier se

trouve derrière le siège et

en dessous. On peut

glisser l’ensemble de

dossier vers le haut ou

vers le bas pour régler la

hauteur du dossier, qui

est courbe pour assurer

un support lombaire. Pour

régler la hauteur du

dossier, il faut s’asseoir

avec le corps bien centré

sur le siège. La courbe du

dossier devrait épouser le

creux des reins pour

réduire la pression sur les

disques vertébraux,

surtout au niveau de la

région lombaire.

POUR RÉGLER L’ANGLE

DU DOSSIER :

Le levier de l’ajustement

de l’angle du dos est

l’arrière on sur le côté

gauche, en dessous le

siège. Le 22o ajustement

de l’angle du dossier-lit est

particulièrement critique

pour tâches du travail qui

exigent la tendance en

avant. Soulever le levier

et permettre à la surface

du dossier-lit de supporter

le poids du corps

supérieur en le plaçant à

la courbe naturelle de la

colonne vertébrale.

Presser le levier pour fixer

dans position vers le bas.

La charnière de dossier-lit

devrait incliner librement,

aider préviennent tordre

de la colonne vertébrale.

POUR RÉGLER

L’ANGLE DU SIÈGE :

Le levier du réglage pour

l’angle du siège est

localisé le côté à droite,

au-dessous du siège.

L’inclinaison du siège est

un facteur important

dans l’exécution des

tâches qui obligent une

personne à se pencher

vers l’avant. L’inclinaison

de 10 degrés permet de

se pencher vers l’avant

sans augmenter la

pression sous les

cuisses. Soulever le

levier et déplacer le

poids du corps vers

l’avant pour trouver une

posture confortable,

puis lâcher le levier pour

bloquer le siège.

ENTRETIEN

L’élévateur pneumatique du cylindre a reçu un graissage

permanent à l’usine, et n’a pas besoin d’être graissé. NE

JAMAIS GRAISSER L’ÉLÉVATEUR PNEUMATIQUE. Ne

pas enlever la bague sur le dessous du cylindre, et

communiquer avec Ergo immédiatement si la bague

manque ou est endommagée. Nettoyer le siège et le

dossier en polyuréthanne avec du savon et de l’eau. Pour

réparer les petites coupures dans le polyuréthanne, mettre

quelques gouttes d’une colle à séchage rapide dans la

coupure, puis presser les côtés ensemble jusqu’à la colle

prenne.

5120-37MP: 4 of 6; Rev. 4: 11/06 (8004.04)

CONSIGNES GÉNÉRALES DE SÉCURITÉ

Ne pas se mettre debout sur le siège.

Le tabouret doit se trouver sur une surface plane, pour

assurer une bonne stabilité.

N’utiliser le tabouret que lorsqu’il est complètement monté.

Vérifier les dispositifs d’attache de temps en temps, et les

bloquer solidement au besoin.

Ne jamais utiliser la chaise si elle ne fonctionne pas selon

les indications de la présente feuille; autrement, la garantie

risque d’être nulle et sans effet.

Rapporter tout problème à Ergo immédiatement, en citant

toujours le code de date du fabricant, qui figure sur

l’étiquette au-dessous du siège.

AVERTISSEMENT : Assurer un soutien optimal. Ne

jamais essayer de positionner le manchon conique audessous de la bague de maintien qui se trouve sur le

bas du tube à filets ondulés. Laisser toujours un

écartement d’au moins 1,2 cm (1/2 po) entre le bas du

tube à filets ondulés et le plancher.

Ergo In Demand, Inc., Central Point, OR 97502

Page 5

4900 Industry Drive

Central Point, OR 97502

Por favor visítenos en la

Internet:

www.ergoindemand.com

TASK MASTER® SILLA INDUSTRIAL

(RANGO DE ALTURA DE 48 A 68 CM [19-27"])

INSTRUCCIONES DE ENSAMBLAJEINSTRUCCIONES DE ENSAMBLAJE

INSTRUCCIONES DE ENSAMBLAJE

INSTRUCCIONES DE ENSAMBLAJEINSTRUCCIONES DE ENSAMBLAJE

HERRAMIENTAS REQUERIDAS: LLAVE DE TUERCAS DE BOCA TUBULAR O DE MEDIA LUNA DE 1/2"; DESTORNILLADOR; MAZO DE GOMA

5120

CLAVE

ALFABÉTICA

A Base 1 5101-04

Q

B

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Patente 5,836,555; D381,823 registrade en EE.UU.

Apoyo para los pies inferior

C Tuerca para el apoyo para los pies 2 5101-24

D Roldana plana 4 5147-31

E Perno hexagonal 2 5101-23

F Deslizador 5 5101-25

G

Apoyo para los pies superior

H Tornillo de carruaje (negro) 2 5118-23

I Tuerca de seguridad 2 5118-24

J Casquillo cónico (colocado en K) 1 5101-05

K Tubo ondulado 1 5101-11

L Asiento 1 5120-01BL

M Respaldo 1 5113-02BL

K

J

A

E

LISTA DE PIEZAS

DESCRIPCIÓN

D

CANT.

NO. DE PIEZA

1 5101-06

1 5118-06

M

L

H

G

D

I

B

C

F

Antes de empezar a ensamblar, por favor verifique que estén

incluidas todas las piezas en la lista. Antes de ensamblar,

permita que la temperatura de las piezas alcance la temperatura

ambiente.

Localice los orificios de montaje SUPERIORES de las patas de la

1

base, (A) . Desde abajo, deslice el primer apoyo para los pies

inferior, (B) , (con la curva hacia afuera) entre esas patas hasta que

los orificios del apoyo para los pies queden alineados con los

orificios de las patas. Coloque una tuerca, (C) , en el interior del

apoyo para los pies con el lado curvo hacia la curva. Inserte una

roldana plana, (D) , en el perno hexagonal, (E) . Colóquelo a través

del orificio de la pata y del apoyo para los pies y atorníllelo en la

tuerca. Fije el otro extremo del apoyo para los pies de la misma

manera. Ahora apriete los pernos con la llave alternando entre

ellos hasta que queden igual de apretados. No apriete demasiado.

Instale el segundo apoyo para los pies inferior, (B) , en los orificios

2

de montaje INFERIORES de las patas siguiendo las instrucciones

arriba mencionadas.

Coloque un deslizador, (F) , en cada una de las patas de la base.

3

Los deslizadores deben quedar ajustados, por lo que será

necesario colocar un deslizador bajo cada una de las patas y

golpear suavemente con el mazo de goma. Para que la silla se

mantenga estable, asegúrese de que los deslizadores queden

bien insertados en las patas. (SUGERENCIA: Es más fácil colocar

los deslizadores cuando se encuentran un tanto expandidos. Para

expandirlos, utilice una secadora de pelo o agua tibia y seque

completamente).

Coloque el apoyo para los pies superior, (G) , sobre los orificios

4

localizados en la parte superior de dos de las patas. Inserte un

perno de carroza, (H) , (negro) en cada orificio atravesando el

apoyo y la pata. Coloque la roldana plana, (D) , y atornille las

tuercas de seguridad, (I) , por la parte inferior de las patas. Apriete

con la llave alternando entre los pernos hasta que queden al

mismo nivel. No apriete demasiado.

El casquillo cónico, (J) , debe venir instalado desde la fábrica en el

5

tubo ondulado, (K) , (de no ser así, comuníquese con Ergo). Abra

ligeramente el casquillo (tiene un corte vertical) y deslícelo hasta

aproximadamente la mitad del tubo ondulado. Inserte el tubo por el

extremo de las ondulaciones en el orificio central de la base y

deslícelo hacia abajo hasta que el casquillo cónico quede

insertado en forma segura dentro del orificio central.

Instale el asiento, (L) , alineando el orificio de su cara inferior con

6

el tubo ondulado y empujando firmemente el asiento hacia abajo.

Inserte el tallo de la asamblea trasera (M) en la ranura al trasero

7

del asiento. Use un destornillador para deprimir el botón al fondo

de tallo y resbalarlo hasta el tallo pasa completamente por la

ranura y se extiende a través del otro lado aproximadamente 5 cm

(2"). Puede ser necesario rodar a la izquierda la palanca al trasero

de la asamblea del asiento para que el tallo resbalara

completamente a través de la ranura. Ruede a la derecha la

palanca afianzar el tallo.

8

Para hacer los ajustes finales, siga las instrucciones que se

encuentran al reverso de esta hoja.

5120-37MP: 5 of 6;

Rev. 4: 11/06 (8004.04)

Para dudas o preguntas, favor de llamar a Línea directa para el cliente de Ergo 1-800-888-6024

Disponible lunes-viernes de 8:00 AM a 4:30 PM (Operadores que hablan inglés)

Page 6

INSTRUCCIONES PARA AJUSTAR LA SILLA

Para aumentar al máximo los beneficios ergonómicos de esta silla, es muy importante que entienda el funcionamiento de los controles y

la manera en que afectan su postura.

AJUSTE DEL RANGO

DE ALTURA:

El tubo ondulado aumenta

el rango de altura de la

silla 25 cm (10"), lo que

ofrece un rango de altura

total de 43 a 89 cm (17-35").

Determine la altura

adecuada para la tarea a

realizar. Coloque un pie

sobre la base de la silla y

levante el asiento tirando

rápida y fuertemente para

desprender la parte

superior de la silla. Abra el

casquillo cónico y

deslícelo sobre el tubo

ondulado hasta llegar a la

altura deseada (hacia el

asiento si se desea más

bajo o hacia el extremo

abierto si se desea más

alto). El casquillo no debe

sobrepasar los extremos

del tubo ondulado.

AJUSTE DE LA ALTURA

FINAL DESEADA:

La palanca que se

encuentra bajo el asiento,

del lado izquierdo (es la

que está más alejada del

respaldo), ajusta

neumáticamente la altura

en un rango de aproximadamente 20 cm (8"). La

altura adecuada se debe

determinar usando una

serie de variables tales

como la altura de la

superficie de trabajo, la

tarea a realizar y el

tamaño de su cuerpo.

Normalmente, la silla se

debe colocar a una altura

que permita que sus

brazos se doblen en un

ángulo de 90° o un poco

mayor. Esto permite una

mejor circulación de la

sangre en los hombros y

el cuello y reduce la fatiga

en los antebrazos y las

manos. Los pies deben

descansar sobre el

apoyo para los pies o el

piso. Para una buena

postura, mantenga las

rodillas dobladas en un

ángulo de 90°.

AJUSTE DE LA ALTURA

DEL RESPALDO:

La palanca para ajustar la

altura del respaldo se

encuentra bajo la parte

posterior del asiento.

Ajuste la altura del

respaldo deslizándolo

hacia arriba o hacia

abajo. El respaldo tiene

una curva que sirve de

soporte para la región

lumbar. Siéntese en el

centro de la silla de

manera que la curva

coincida con la parte

inferior de su espalda.

Esto reducirá la presión

en los discos vertebrales,

especialmente los

lumbares.

AJUSTE DEL ÁNGULO

DEL RESPALDO:

La palanca para ajustar el

ángulo del respaldo se

encuentra bajo el asiento,

del lado izquierdo. Es la

que está más cercana al

respaldo. El respaldo se

puede ajustar a un ángulo

de 22°; esto es

especialmente importante

si se trabaja inclinado

hacia adelante. Jale la

palanca hacia arriba para

liberar el respaldo de

manera que su superficie

siga la curva natural de la

columna vertebral y apoye

el peso de la parte

superior del cuerpo . Para

mantener esta posición,

empuje la palanca hacia

abajo. La bisagra del

respaldo se debe inclinar

libremente para ayudar a

evitar torceduras de la

columna.

AJUSTE DEL ÁNGULO

DEL ASIENTO:

La palanca para ajustar

el ángulo del asiento se

encuentra bajo el

asiento, del lado

derecho. La inclinación

del asiento es importante

cuando se llevan a cabo

tareas que requieren

que el cuerpo se incline

hacia adelante. Inclinar

el asiento a 10° permite

moverse hacia adelante

sin ejercer presión

adicional debajo de los

muslos. Jale la palanca

hacia arriba e inclínese

hacia adelante hasta

que quede en una

posición cómoda. Suelte

la palanca para

mantener esta posición.

MANTENIMIENTO

El elevador neumático del cilindro viene con lubricación

permanente desde la fábrica y no requiere lubricación

adicional. NUNCA LUBRIQUE EL ELEVADOR

NEUMÁTICO. No retire la pinza del extremo inferior del

cilindro. Si falta o se daña esta pinza, comuníquese con

Ergo inmediatamente. Limpie el asiento de poliuretano

con agua y jabón. Para reparar pequeñas rasgaduras

en el poliuretano, aplique unas cuantas gotas de

pegamento de secado rápido en la rasgadura y junte

las orillas hasta que seque el pegamento.

INSTRUCCIONES GENERALES DE SEGURIDAD

No se pare en el asiento.

La silla debe estar sobre una superficie nivelada para

proporcionar la estabilidad adecuada.

Utilice la silla sólo cuando esté completamente

ensamblada.

Revise periódicamente todos los tornillos y apriételos

nuevamente si es necesario.

Nunca utilice la silla si no funciona de acuerdo con las

indicaciones contenidas en esta hoja o se podría anular

la garantía.

Informe inmediatamente a Ergo acerca de cualquier

problema y siempre proporcione la información del

código de fecha del fabricante que se encuentra en la

etiqueta bajo el asiento.

PRECAUCIÓN: Obtenga el mayor soporte. Nunca trate

de colocar el casquillo cónico a un nivel más bajo

que el anillo de retención que se encuentra en el

extremo inferior del tubo ondulado. Siempre deje

por lo menos 1.2 cm (1/2") de espacio entre la parte

inferior del tubo ondulado y el piso.

5120-37MP: 6 of 6; Rev. 4: 11/06 (8004.04)

Ergo In Demand, Inc., Central Point, OR 97502

Loading...

Loading...