Page 1

an LDI Spaces Company

Minneapolis, MN 55428

www.safcoproducts.com

TASK MASTER® INDUSTRIAL CHAIR

(19” - 27” Range)

5113

ASSEMBLY INSTRUCTIONS

TOOLS REQUIRED: Standard Screwdriver

PRODUCT WARRANTY CARD is available online at: www.safcoproducts.com

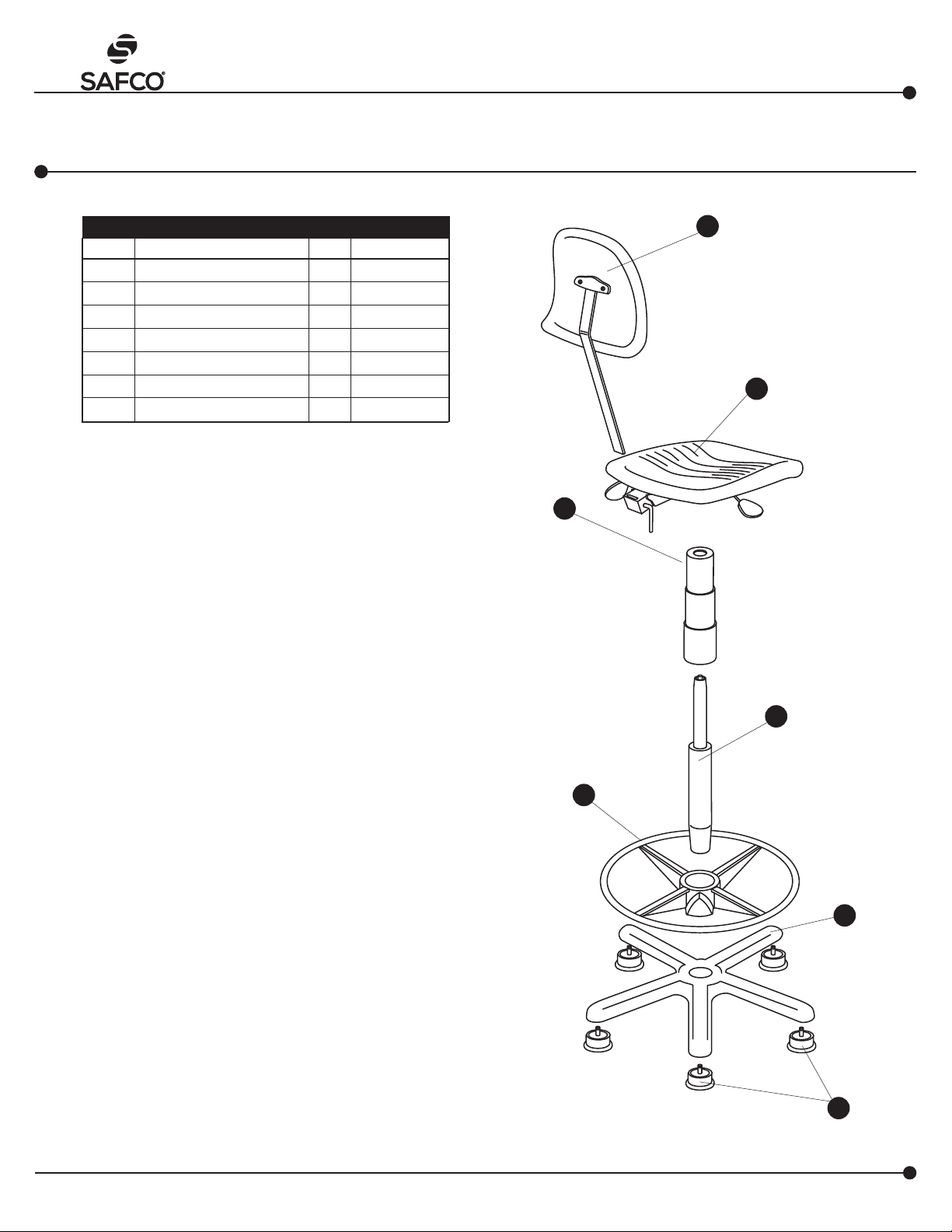

PARTS LIST

CODE DESCRIPTION

A

Glide 5 5110-75

B

Base 1 5105-04BL

C

Cylinder 1 5110-61

D

Foot Ring 1 5110-56

E

Dust Cover (3 pc set) 1 5110-64

F

Seat Assembly 1 5113-51BL

G

Back Assembly 1 5113-52BL

Check all parts against Parts List before beginning assembly. Allow all parts to warm to room

temperature prior to assembly.

Install a (A) Glide into each of the legs of the (B)

1

Base. Press fi rmly into place. Be sure the glide is

inserted completely into leg for proper stability.

Insert the (C) Cylinder into the base, tapered end

2

down. Secure the cylinder by applying a little downward pressure (CAUTION: When applying downward pressure, avoid plastic button at top of cylinder,

as pressure will release pneumatic lift)

QTY.

PART NO.

G

F

E

Slide (D) Foot Ring on to cylinder (ring side up), po-

3

sition at desired height. Turn knob to secure. Place

(E) Dust Cover over exposed cylinder.

Install the (F) Seat Assembly by aligning the hole

4

on the underside with the shaft of the cylinder; push

down fi rmly on seat.

Insert the stem of the (G) Back Assembly into the

5

slot at the back of the seat. Use a screwdriver to

depress the push button at the bottom of the stem

and slide until the stem goes all the way through the

slot and sticks out the other side about 2". It may

be necessary to rotate the lever at the back of seat

assembly clockwise so stem will slide all the way

through the slot. Rotate the lever counterclockwise to

lock the stem.

Make the fi nal chair adjustments following the instruc-

6

tions on the reverse side.

C

D

B

A

Registered U.S. Patent D381,823

100511337: 1 of 6; Rev A;

Rev Date 19-SEP-2016

For questions or concerns, please call the Safco Consumer Hot Line 1-800-664-0042

available Monday-Friday 7:30 AM to 5:00 PM (Central Time) (English-speaking operators)

Page 2

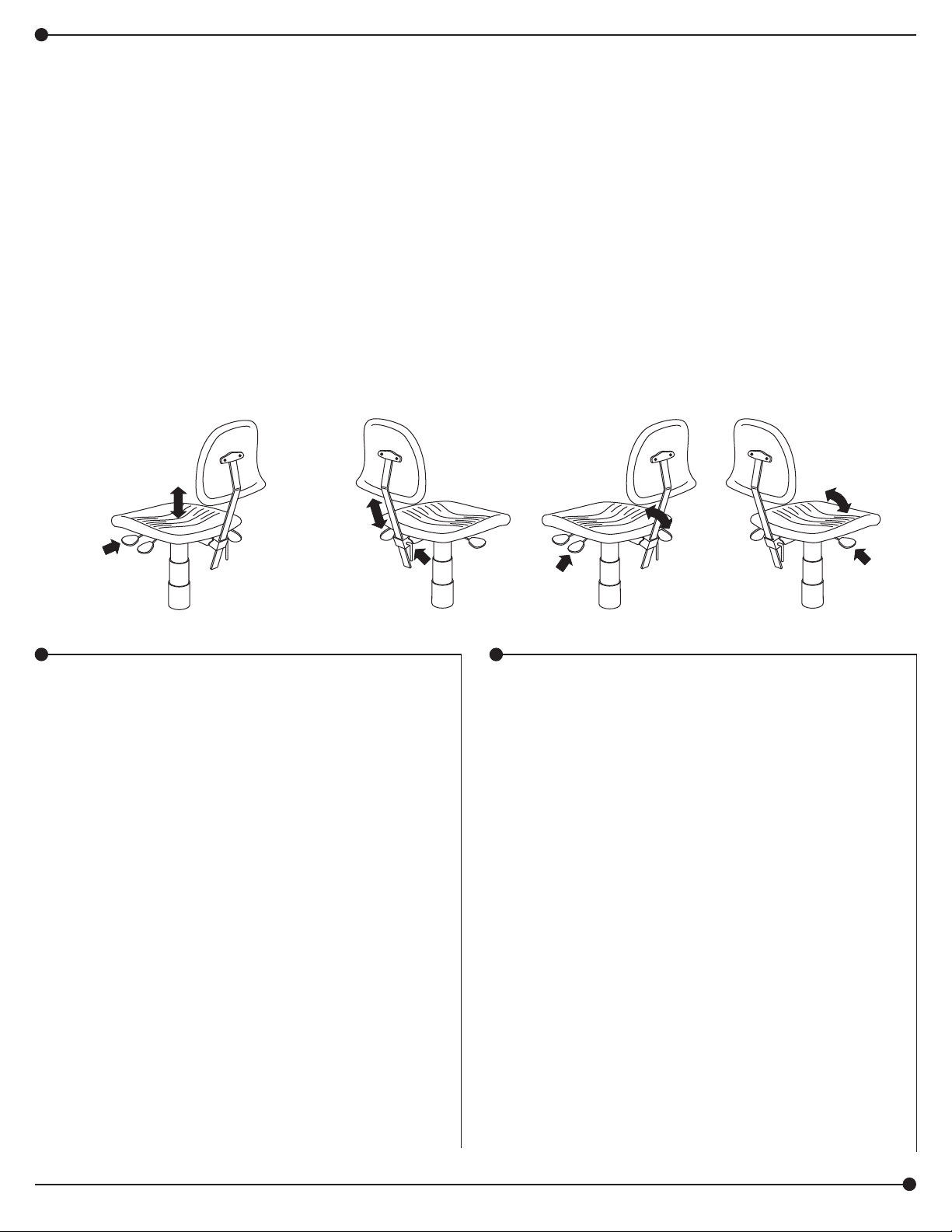

CHAIR ADJUSTMENT INSTRUCTIONS

To maximize the ergonomic benefi ts of this chair, it is essential to understand how the controls function and how they affect your posture.

ADJUST THE

HEIGHT RANGE:

The front lever under the seat on the left side

pneumatically adjusts the height of the seat over a

range of about 8". The proper height should

be determined by a combination of variables:

the height of the work surface, the task to be

performed and your body size. Typically, the chair

should be high enough so your arms form

o

angle at the elbow or slightly greater.

a 90

This allows for better circulation in the shoulders

and neck area and also reduces the amount of

fatigue in the forearms and hands. The feet should

lie fl at on the ground or footring. To help insure

good posture, maintain a 90o angle at the bend of

the knees.

ADJUST THE

BACK HEIGHT:

The backrest height

adjustment lever is behind

and below the seat. By sliding

the backrest assembly up or

down, you adjust the height

of the back, which has a

lumbar support curve to it.

Sit centered on the seat. The

curve in the backrest should

fi t into the small of your back.

This will reduce the pressure

on the spinal discs, especially

in the lumbar area.

ADJUST THE

BACK ANGLE:

The back angle adjustment

lever is the rear one on the

left side, under the seat. The

22o angle adjustment of the

backrest is especially critical

for work tasks that require

leaning forward. Pull up on

the lever and allow the surface

of the backrest to support

the upper body weight by

positioning it to

the natural curve of the spine.

Press down on the lever to

lock into place. The backrest

hinge should tilt freely, to help

prevent twisting of the spine.

ADJUST THE

SEAT ANGLE:

The seat angle adjustment

lever is the one on the right

side, under the seat. The

seat tilt is important for work

tasks that require leaning

foward. The 10o tilt allows you

to lean foward without extra

pressure under the thighs.

Lift the lever and shift your

weight forward until you fi nd

a comfortable position, then

release the lever to lock into

place.

MAINTENANCE

The pneumatic lift in the Cylinder is permanently

lubricated at the factory and needs no further

lubrication. NEVER LUBRICATE THE

PNEUMATIC LIFT. Do not remove clip from

bottom of Cylinder. Contact Safco immediately if

clip is missing or damaged. Clean polyurethane

seat and back with soap and water. To repair

small cuts in polyurethane, apply a few drops of

quick drying glue into the cut and press the sides

together until the glue sets.

GENERAL SAFETY INSTRUCTIONS

Do not stand on seat.

Chair must be on level surface to ensure proper

stability.

Only use chair when fully assembled.

Never use chair if it does not perform according

to this sheet or warranty may be void.

Immediately report any problems to Safco

and always give the manufacturer's date code

information from the label under the seat.

100511337: 2 of 6; Rev A; Rev Date 19-SEP-2016

Safco Products Company, New Hope, MN 55428

Page 3

TASK MASTER® CHAISE INDUSTRIELLE

(GAMME DE HAUTEURS DE 48 À 68 CM [19 À 27 PO])

an LDI Spaces Company

Minneapolis, MN 55428

www.safcoproducts.com

LISTE DES PIÈCES

CODE

ALPHABÉTIQUE

A

Glissière 5 5110-75

B

Base 1 5105-04BL

C

Cylindre 1 5110-61

D

Tube anti-poussière (3 pièces) 1 5110-56

E

Dust Cover (3 pc set) 1 5110-64

F

Ensemble de siège 1 5113-51BL

G

Ensemble de dossier 1 5113-52BL

Avant de commencer le montage, vérifier toutes les pièces à l’aide de la

liste des pièces. Permettre à toutes les pièces d’atteindre la température

de la pièce avant de faire le montage.

DESCRIPTION

INSTRUCTIONS DE MONTAGE

OUTILS REQUIS : Tournevis standard

Le formulaire d’inscription de garantie du produit est disponible à : www.safcoproducts.com

QTÉ.

No DE PIÈCE

5113

G

F

Installer une glissière (A) dans chacun des pieds de la base (B)

1

. Pousser la glissière pour la rentrer solidement en place. Vérifi er

que la glissière est insérée complètement dans le pied, pour assurer une bonne stabilité.

Insérer le cylindre (C) dans la base, avec le bout conique vers le

2

bas. Rentrer le cylindre dans la base en exerçant une légère pression vers le bas. (AVERTISSEMENT: En exerçant une pression

vers le bas, ne pas toucher le bouton en plastique sur le haut du

cylindre, car une pression sur le bouton déclenchera l’élévateur

pneumatique.)

Glisser l’anneau repose-pieds (D) sur le cylindre, avec l’anneau

3

vers le haut, et le positionner à la hauteur voulue. Tourner le bouton pour bloquer l’anneau. Glisser le tube anti-poussière (E) sur

le cylindre.

Installer l’ensemble de siège (F) en alignant le trou sur le des-

4

sous avec l’arbre de l’ensemble de cylindre. Pousser le siège

fermement vers le bas.

Insérer la tige de l’assemblée arrière (G) dans la rainure au dos

5

du siège. Utiliser un tournevis déprimer le bouton de la poussée

à fond de tige et le glisser jusqu’à la tige traverse complètement

la rainure et étend à travers l’autre côté approximativement 5 cm

2 (po). Ce peut être nécessaire de tourner le levier au dos de

l’assemblée du siège comme les aiguilles d’une montre afi n que

la tige glisse complètement à travers la rainure. Tourner le levier

pour fi xer la tige dans le sens inverse des aiguilles d'une montre.

E

C

D

B

Faire les derniers règlements de la chaise en suivant les instruc-

6

tions au verso.

100511337: 3 of 6; Rev A;

Rev Date 19-SEP-2016

Brevet américain enregistré D381,823

A

Pour toute question ou tout problème, veuillez communiquer avec l’Assistance téléphonique à la clientèle

Safco au 1-800-664-0042 du lundi au vendredi, de 7H30 à 17H00 (Heure centrale) (Opérateurs de langue anglaise)

Page 4

INSTRUCTIONS DE RÉGLAGE DE LA CHAISE

Pour profi ter au maximum des avantages ergonomiques de cette chaise, il est indispensable de savoir comment les commandes fonctionnent

et comment elles infl uencent votre posture.

POUR RÉGLER LA GAMME

DES HAUTEURS :

Le levier de devant sous le siège sur le

côté gauche ajuste la hauteur du siège

sur une gamme d’environ 20 cm (8 po).

Il faut déterminer la hauteur appropriée

du siège en tenant compte de plusieurs

variables: la hauteur de la surface de

travail, la tâche à exécuter et la grandeur

de votre corps. Normalement, la chaise

devrait se trouver à une hauteur telle que

vos bras forment un angle de 90 degrés

ou un peu plus au coude. Cette posture

assure une meilleure circulation aux

épaules et au cou, et réduit la fatigue des

avant-bras et des mains.

Les pieds devraient être plantés solidement sur le sol. Pour assurer une bonne

posture, maintenir un angle de 90 degrés

aux genoux.

POUR RÉGLER LA HAUTEUR

DU DOSSIER :

Le levier de réglage de la hauteur du dossier se trouve derrière

le siège et en dessous. On peut

glisser l’ensemble de dossier

vers le haut ou vers le bas pour

régler la hauteur du dossier, qui

est courbe pour assurer un support lombaire. Pour régler la hauteur du dossier, il faut s’asseoir

avec le corps bien centré sur

le siège. La courbe du dossier

devrait épouser le creux des

reins pour réduire la pression sur

les disques vertébraux, surtout

au niveau de la région lombaire.

POUR RÉGLER L’ANGLE

DU DOSSIER :

Le levier de l’ajustement de l’angle

du dos est l’arrière on sur le côté

gauche, en dessous le siège.

Le 22o ajustement de l’angle du

dossier-lit est particulièrement critique pour tâches du travail

qui exigent la tendance en avant.

Soulever le levier et permettre

à la surface du dossier-lit de supporter le poids du corps supérieur en

le plaçant à la

courbe naturelle de la colonne vertébrale. Presser le levier pour fi xer

dans position vers le bas.

La charnière de dossier-lit devrait

incliner librement, aider préviennent

tordre de la colonne vertébrale.

POUR RÉGLER L’ANGLE

DU SIÈGE :

Le levier du réglage pour

l’angle du siège est localisé

le côté à droite, au-dessous

du siège. L’inclinaison du

siège est un facteur important

dans l’exécution des tâches

qui obligent une personne

à se pencher vers l’avant.

L’inclinaison de 10 degrés permet de se pencher vers l’avant

sans augmenter la pression

sous les cuisses. Soulever le

levier et déplacer le poids du

corps vers l’avant pour trouver

une posture confortable, puis

lâcher le levier pour bloquer le

siège.

ENTRETIEN

L’élévateur pneumatique du cylindre a reçu un

graissage permanent à l’usine, et n’a pas besoin d’être graissé. NE JAMAIS GRAISSER

L’ÉLÉVATEUR PNEUMATIQUE. Ne pas enlever

la bague sur le dessous du cylindre, et communiquer avec Safco immédiatement si la bague

manque ou est endommagée. Nettoyer le siège

et le dossier en polyuréthanne avec du savon

et de l’eau. Pour réparer les petites coupures

dans le polyuréthanne, mettre quelques gouttes

d’une colle à séchage rapide dans la coupure,

puis presser les côtés ensemble jusqu’à la colle

prenne.

CONSIGNES GÉNÉRALES DE SÉCURITÉ

Ne pas se mettre debout sur le siège.

La chaise doit se trouver sur une surface

plane, pour assurer une bonne stabilité.

N’utiliser la chaise que lorsqu’elle est complètement montée.

Ne jamais utiliser la chaise si elle ne fonctionne

pas selon les indications de la présente feuille;

autrement, la garantie risque d’être nulle et

sans effet.

Rapporter tout problème à Safco immédiatement, en citant toujours le code de date du

fabricant, qui fi gure sur l’étiquette au-dessous

du siège.

100511337: 5 of 6; Rev A;

Rev Date 19-SEP-2016

Para dudas o preguntas, favor de llamar a Línea directa para el cliente de Safco 1-800-664-0042

Disponible lunes-viernes de 7:30 AM a 5:00 PM (Hora Central) (Operadores que hablan inglés)

Page 5

TASK MASTER® SILLA INDUSTRIAL

(RANGO DE ALTURA DE 48 A 68 CM [19-27"])

an LDI Spaces Company

Minneapolis, MN 55428

www.safcoproducts.com

LISTA DE PIEZAS

CLAVE

ALFABÉTICA

A

Deslizador 5 5110-75

B

Base 1 5105-04BL

C

Cilindro 1 5110-61

D

Anillo de apoyo para los pies 1 5110-56

E

Forro antipolvo (juego de 3 piezas) 1 5110-64

F

Asiento 1 5113-51BL

G

Respaldo 1 5113-52BL

Antes de empezar a ensamblar, por favor verifi que que

estén incluidas todas las piezas de la lista. Antes de ensamblar, permita que la temperatura de las piezas alcance la

temperatura ambiente.

DESCRIPCIÓN

INSTRUCCIONES DE ENSAMBLAJE

HERRAMIENTAS REQUERIDAS: El Destornillador Standard

El formulario de Registro de Garantía de Productos está disponible a: www.safcoproducts.com

CANT.

NO. DE PIEZA

5113

G

F

Instale los deslizadores, (A) , en cada una de las patas de la

1

base, (B) , y presione fi rmemente. Para que la silla se mantenga

estable, asegúrese de que los deslizadores queden insertados

completamente en las patas.

Inserte en la base el extremo cónico del cilindro, (C) . Asegúre-

2

lo presionando ligeramente hacia abajo. (PRECAUCIÓN:

Cuando presione hacia abajo evite tocar el botón de plástico

que se encuentra en la parte superior del cilindro, ya que esto

accionaría el elevador neumático).

Deslice el anillo de apoyo para los pies, (D) , en el cilindro (con

3

el anillo hacia arriba), colóquelo a la altura deseada y fíjelo

girando la perilla. Cubra el cilindro con el forro antipolvo, (E) .

Para instalar el asiento, (F) , alinee el orifi cio de la parte inferior

4

del asiento con el extremo superior del cilindro y empuje fi rme-

mente el asiento hacia abajo.

Inserte el tallo de la asamblea trasera (G) en la ranura al tra-

5

sero del asiento. Use un destornillador para deprimir el botón

al fondo de tallo y resbalarlo hasta el tallo pasa completamente

por la ranura y se extiende a través del otro lado aproximadamente 5 cm (2"). Puede ser necesario rodar a la izquierda la

palanca al trasero de la asamblea del asiento para que el tallo

resbalara completamente a través de la ranura. Ruede a la

derecha la palanca afi anzar el tallo.

E

C

D

B

Para hacer los ajustes fi nales, siga las instrucciones que se

6

encuentran al reverso de esta hoja.

100511337: 5 of 6; Rev A;

Rev Date 19-SEP-2016

A

Patente D381,823 registrade en EE.UU.

Para dudas o preguntas, favor de llamar a Línea directa para el cliente de Safco 1-800-664-0042

Disponible lunes-viernes de 7:30 AM a 5:00 PM (Hora Central) (Operadores que hablan inglés)

Page 6

INSTRUCCIONES PARA AJUSTAR LA SILLA

Para aumentar al máximo los benefi cios ergonómicos de esta silla, es muy importante que entienda el funcionamiento de los controles y la

manera en que afectan su postura.

AJUSTE DEL RANGO DE ALTURA:

La palanca que se encuentra bajo el

asiento, del lado izquierdo (es la que

está más alejada del respaldo), ajusta

neumáticamente la altura en un rango de

aproxima damente 20 cm (8"). La altura

adecuada se debe determinar usando una

serie de variables tales como la altura de

la superfi cie de trabajo, la tarea a realizar y

el tamaño de su cuerpo. Normalmente,

la silla se debe colocar a una altura que

permita que sus brazos se doblen en un

ángulo de 90° o un poco mayor. Esto permite una mejor circulación de la sangre en

los hombros y el cuello y reduce la fatiga

en los antebrazos y las manos. Los pies

deben descansar apoyados sobre el piso

o sobre el anillo de apoyo. Para ayudar a

asegurar una buena postura, mantenga las

rodillas dobladas en un ángulo de 90°.

AJUSTE DE LA ALTURA

DEL RESPALDO:

La palanca para ajustar la altura

del respaldo se encuentra

bajo la parte posterior del

asiento. Ajuste la altura del respaldo deslizándolo hacia arriba

o hacia abajo. El respaldo tiene

una curva que sirve de soporte

para la región lumbar. Siéntese

en el centro de la silla de manera

que la curva coincida con la

parte inferior de su espalda. Esto

reducirá la presión en los discos

vertebrales, especialmente los

lumbares.

AJUSTE DEL ÁNGULO

DEL RESPALDO:

La palanca para ajustar el ángulo del

respaldo se encuentra bajo

el asiento, del lado izquierdo.

Es la que está más cercana al respaldo. El respaldo se puede ajustar

a un ángulo de 22°; esto

es especialmente importante si se

trabaja inclinado hacia adelante.

Jale la palanca hacia arriba para

liberar el respaldo de manera que

su superfi cie siga la curva natural de

la columna vertebral y apoye

el peso de la parte superior del cuerpo. Para mantener esta posición,

empuje la palanca hacia abajo. La

bisagra del respaldo se debe inclinar

libremente para ayudar a evitar

torceduras de la columna.

AJUSTE DEL ÁNGULO

DEL ASIENTO:

La palanca para ajustar

el ángulo del asiento se encuentra bajo el asiento,

del lado derecho. Es la que

está más alejada del respaldo.

La inclinación del asiento es

importante cuando se llevan

a cabo tareas que requieren

que el cuerpo se incline hacia

adelante. Inclinar el asiento

a 10° permite moverse hacia

adelante sin ejercer presión

adicional debajo de los muslos.

Jale la palanca hacia arriba e

inclínese hacia adelante hasta

que quede en una posición

cómoda. Suelte

la palanca para

mantener esta

posición.

MANTENIMIENTO

El elevador neumático del cilindro viene con

lubricación permanente desde la fábrica y no

requiere lubricación adicional. NUNCA LU-

BRIQUE EL ELEVADOR NEUMÁTICO. No

retire la pinza del extremo inferior del cilindro.

Si falta o se daña esta pinza, comuníquese

con Safco inmediatamente. Limpie el asiento

de poliuretano con agua y jabón. Para reparar pequeñas rasgaduras en el poliuretano,

aplique unas cuantas gotas de pegamento

de secado rápido en la rasgadura y junte las

orillas hasta que seque el pegamento.

INSTRUCCIONES GENERALES DE SEGU-

RIDAD

No se pare en el asiento.

La silla debe estar sobre una superfi cie nivelada

para proporcionar la estabilidad adecuada.

Utilice la silla sólo cuando esté completamente

ensamblada.

Nunca utilice la silla si no funciona de acuerdo

con las indicaciones contenidas en esta hoja o

se podría anular la garantía.

Informe inmediatamente a Safco acerca de cualquier problema y siempre proporcione la información del código de fecha del fabricante que

se encuentra en la etiqueta bajo el asiento.

100511337: 6 of 6; Rev A; Rev Date 19-SEP-2016

Safco Products Company, New Hope, MN 55428

Loading...

Loading...