Page 1

Plan Master

Height Adjustable Drafting Table

an LDI Spaces Company

Minneapolis, MN 55428

www.safcoproducts.com

PRODUCT WARRANTY REGISTRATION is available online at: www.safcoproducts.com

Tools required: Phillips screwdriver, hammer

(nail or pointed tool may be used to help start holes)

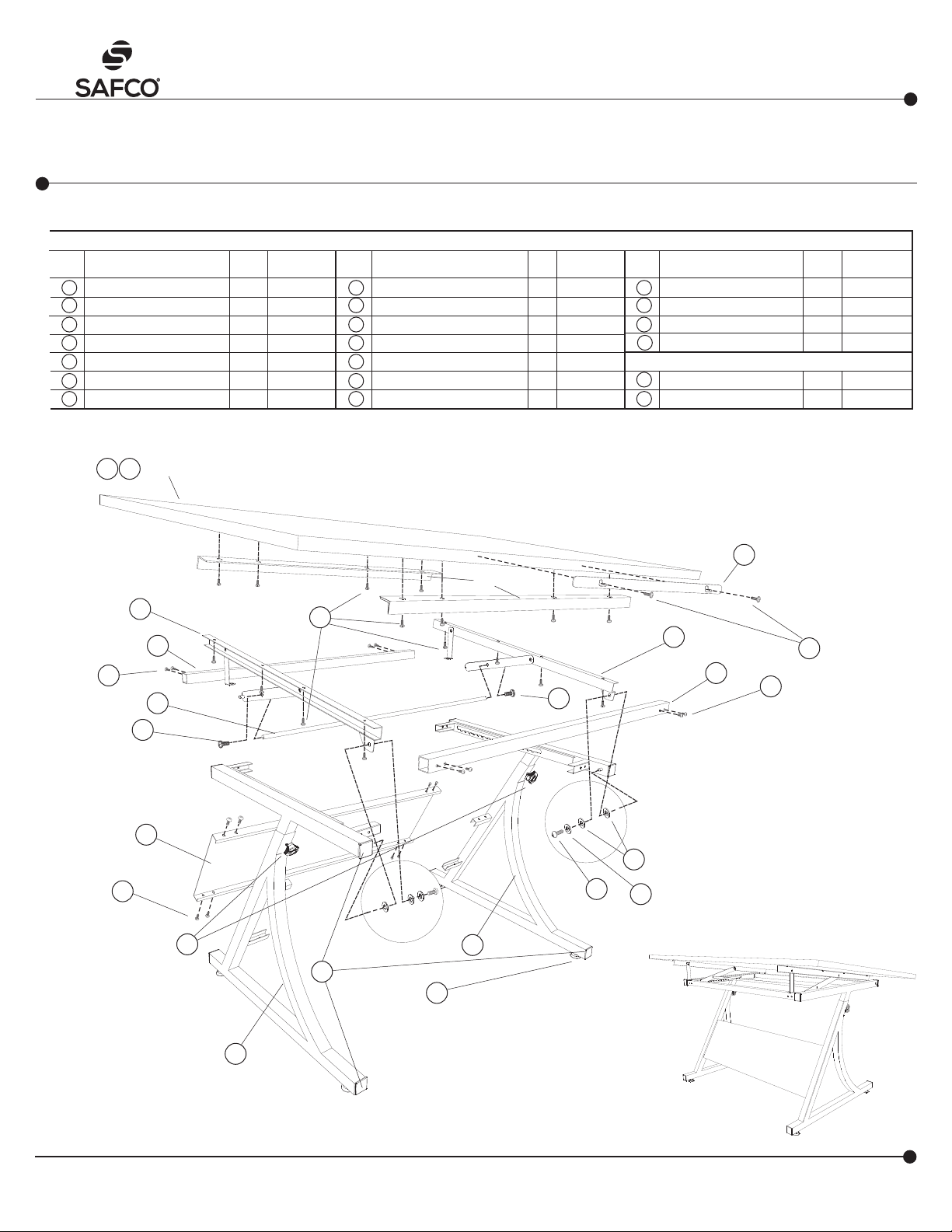

LETTER

CODE

A

Left Frame Assembly 1 3957-51BL

B

Right Frame Assembly 1 3957-52BL

C

Back Panel 1 3957-53BL

D

Horizontal Tube 2 3957-54BL

E

Lift Bar 1 3957-55BL

F

Left Support Channel 1 3957-60BL

G

Right Support Channel 1 3957-61BL

S

DESCRIPTION

TABLE TOP (SOLD SEPARATELY)

T

READ THESE INSTRUCTIONS BEFORE STARTING! FOLLOW THE ASSEMBLY PROCEDURES CAREFULLY.

PART NO.

QTY.

ASSEMBLY INSTRUCTIONS

PARTS LIST

LETTER

CODE

H

I

J

K

L

M

N

DESCRIPTION

Tube Plug

Large Flat Head Machine Screw

Long Pan Head Machine Screw

Pan Head Hi-Grip Screw

Nylon Spacer

Washer

Adjustment Knob, Black

8 3957-76BL

18 3957-79NC

4 3957-82NC

2 3957-71NC

2 3957-73BL

PART NO.

QTY.

2 3957-77NC

16 3957-78NC

LETTER

CODE

O

*Table Tops below sold & shipped separately

Drawing Board – 60" 1 3948*

Drawing Board – 48" 1 3951*

Leveler

P

Drawing Board Support Bar

Q

Pencil Bar

R

Short Pan Head Machine Screw

S

T

3957

DESCRIPTION QTY.

4 3957-75NC

2 3957-65BL

1 3957-83BL

2 3957-74NC

PART NO.

F

D

J

E

I

C

J

N

Adjustment Knob AT-

TENTION!

Do NOT loosen

until instruction num-

ber 9.

Q

P

K

G

K

D

I

J

L

R

M

B

H

O

A

100395737: 1 of 4; Rev A; Rev Date

05-JUL-2016

ASSEMBLED

UNIT

For questions or concerns, please call the Safco Consumer Hot Line 1-800-664-0042

available Monday-Friday 7:30 AM to 5:00 PM (Central Time) (English-speaking operators)

Page 2

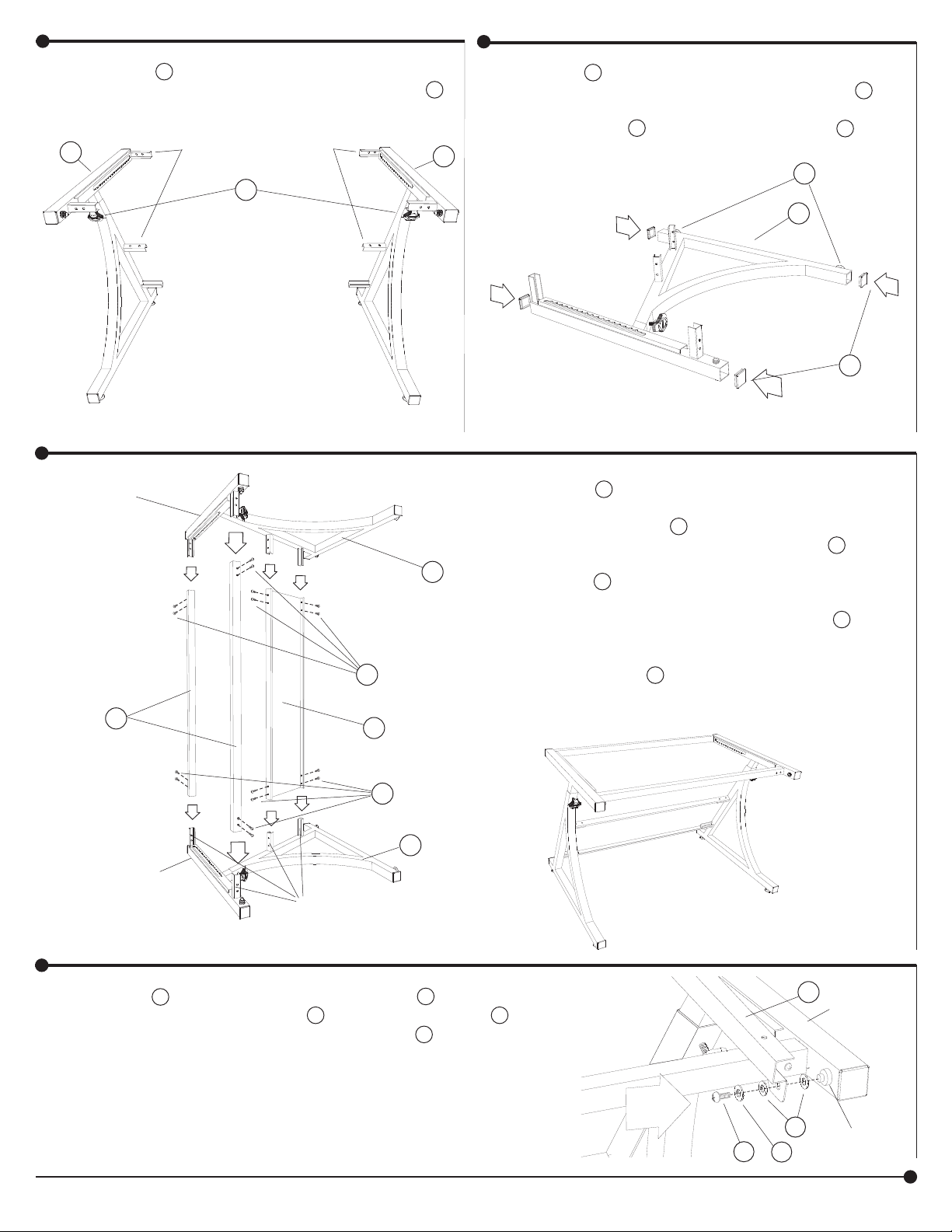

Locate the A Left Frame Assembly (the short chan-

1

nels will be on the right side of the frame), and the B

Right Frame Assembly (the short channels will be on

the left side of the frame).

A

SHORT CHANNELS

N

ATTENTION!

Do NOT

unscrew the

ADJUSTMENT

KNOBS

until the fi nal

instruction.

Place the A Left Frame Assembly on a protected

2

surface with the short channels upward. Insert the

H Tube Plugs if they are not already installed on the

tube ends. Insert the O Levelers. Repeat with the B

B

Right Frame Assembly.

O

A

H

3

OF RIGHT

ASSEMBLY

UPPER

END

FRAME

D

UPPER

END

OF LEFT

FRAME

ASSEMBLY

SHORT

CHANNELS

Insert the D Horizontal Tubes onto each of the short

channels along the upper end of the Left Frame Assembly. Attach using two J Long Pan Head Machine

Screws for each tube. Insert one end of the C Back

B

J

C

J

A

Panel onto the two lower short channels and attach

using four J Long Pan Head Machine Screws.

With the help of an assistant, carefully lift the B Right

Frame Assembly up and insert the short channels into

the open ends of the tube and back panel. Loosely

fasten using eight J Long Pan Head Machine Screws.

Carefully turn the assembled base upright.

Place one L Nylon Spacer on the pin. Insert the G Support

4

Channel onto the pin. Place one L Nylon Spacer and one M

Washer on the pin and fasten securely using one R Short Pan

Head Machine Screw. Repeat for the other support channel

and frame.

100395737: 2 of 4; Rev A; Rev Date 05-JUL-2016

G

Do Not

Overtighten.

L

M

R

Safco Products Company, New Hope, MN 55428

FRAME

HINGE

PIN

Page 3

5

Raise the G Right Support Channel and insert the channel pin into

the notched channel in the frame.

Repeat this procedure for the

F Left Support Channel.

CHANNEL

PIN

NOTCHED

CHANNEL

6

G

Attach the E Lift Bar to each channel arm through the countersunk holes using one I Large Flat Head Machine Screw at

each end.

F

E

G

I

CHANNEL

ARM

7

Prepare the Drawing Board.

Carefully open the Drawing Board

carton. Keep the Drawing Board in the

carton. Two people are required to lift

the assembled base onto the S or T

Drawing Board. Position the F and G

support channel assemblies located

on the base onto the drawing board.

Carefully center the frame from sideto-side and front-to-back. Fasten the

support channels to the drawing board

using K Pan Head Hi-Grip Screws

through each channel. Attach the Q

Pencil Bar to the front edge of the

drawing board using two K Pan Head

Hi-Grip Screws.

I

F

G

K

NOTE: if it is too diffi cult to get

the screws into the board, position

the base and use a hammer and nail

to carefully tap starter holes using the

channel holes as a guide. Then, fi nish

fastening the screws to the board.

Position the P Support Bars in between the left

8

and right support channels. The Support Bars must

be placed at least 8" in from the long edges. Attach

to the Drawing Board using four K Pan Head HiGrip Screws for each Support Bar.

When the frame is securely fastened to the

Drawing Board, turn the entire assembly upright.

100395737: 3 of 4; Rev A; Rev Date 05-JUL-2016

S or

T

Safco Products Company, New Hope, MN 55428

Q

K

P

Page 4

Lower the Drawing Board to the fl at

9

position by raising the E Lift Bar

upward with one hand while

easing the board downward

with the other hand. (see inset)

Loosen the N Adjustment Knobs

on both frames.

(ATTENTION: NEVER COMPLETELY

UNSCREW THE KNOBS!)

Standing at the FRONT of the table

(hinge pivot side), place your hands in

the center of the drawing board approximately 30 inches apart and press down

and away several times to insure proper

alignment of the telescoping tubes

within the end frames. When the movement is satisfactory, lock the drawing

board in its lowest position by tightening the knobs.

Finish tightening the eight machine

screws on the back panel, and the eight

screws that attach the D Horizontal

Tubes to the frame.

END

FRAME

HINGE

PIVOT

(FRONT)

N

INSET

LIFT BAR

OPERATING INSTRUCTIONS

Position the table in the location where

it is to be used and adjust the levelers

up or down to compensate for unlevel

fl oors.

TILT ADJUSTMENT

Automatic stops are built into the support channels for a minimum

7 degree tilt angle of the drawing

board. If a 7 degree tilt is desired,

simply lift the drawing board up

about 5". The stops will

automatically swing down into

position and rest on the frame.

If a fl at position is desired, each

stop can be swiveled off of the frame

towards the rear of the table. Be sure to

hold the drawing board up so you won’t

injure your fi ngers. (see inset in step 9)

Increase the tilt angle on the drawing

board by raising the Lift Bar and moving the pins at the ends of the channel

arms into the notched slots on the end

frames.

HEIGHT ADJUSTMENT

To elevate the entire work surface,

loosen the adjustment knobs, lift drawing board by its front edge to desired

height, then re-tighten the knobs (see

CHANNEL

ARM

NOTCHED

CHANNEL

LEVELERS

LIFT BAR

100395737: 4 of 4; Rev A; Rev Date 05-JUL-2016

Safco Products Company, New Hope, MN 55428

Loading...

Loading...