Saeco Phedra Evo D.A. 5P2015, Phedra Evo D.A. 5P2015T, Phedra Evo D.A. 5P2015A, Phedra Evo D.A. 5P2015AT Operation And Maintenance

Page 1

Vending Machine

UK

WARNING: This instruction manual is intended exclusively for specialized personnel.

OPERATION AND MAINTENANCE

Page 2

English

2

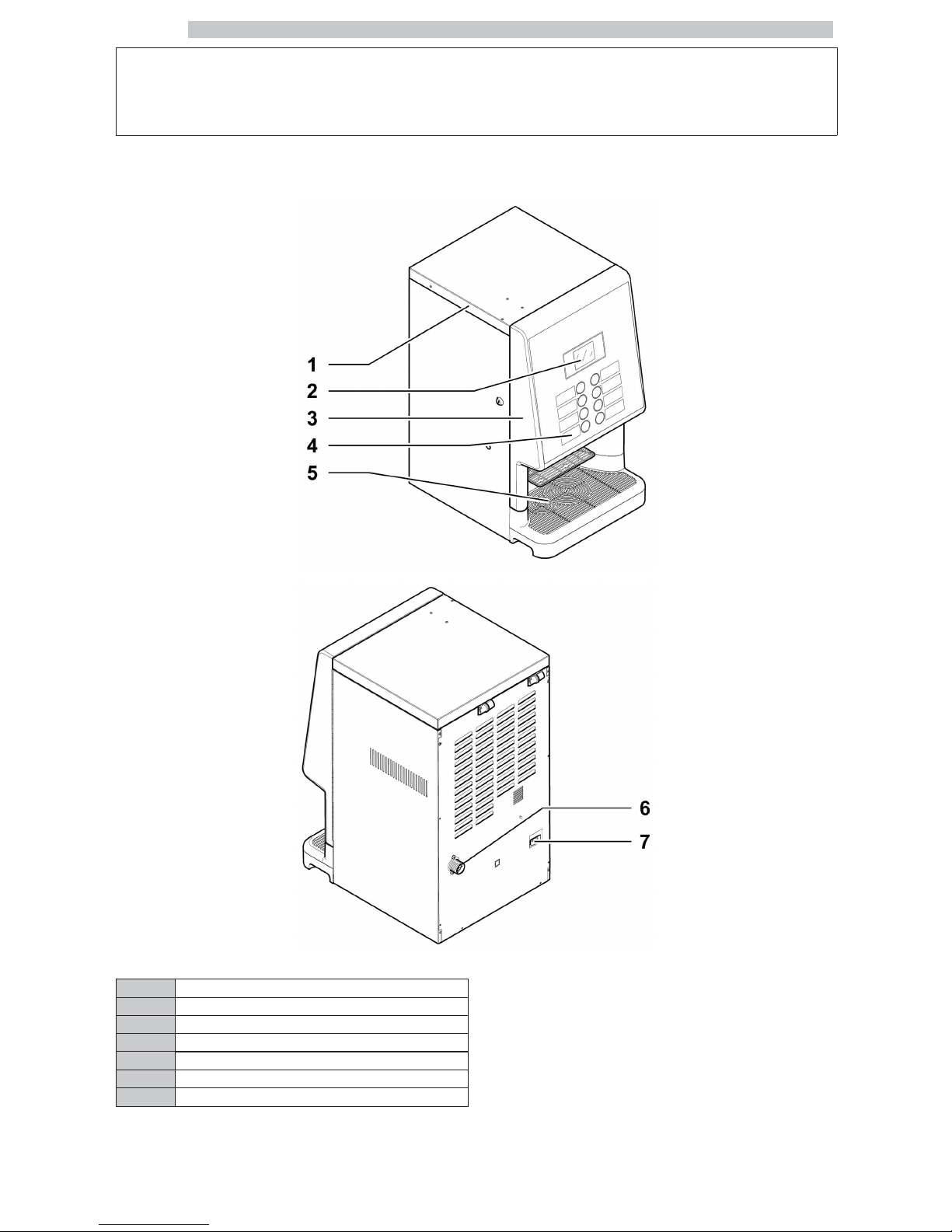

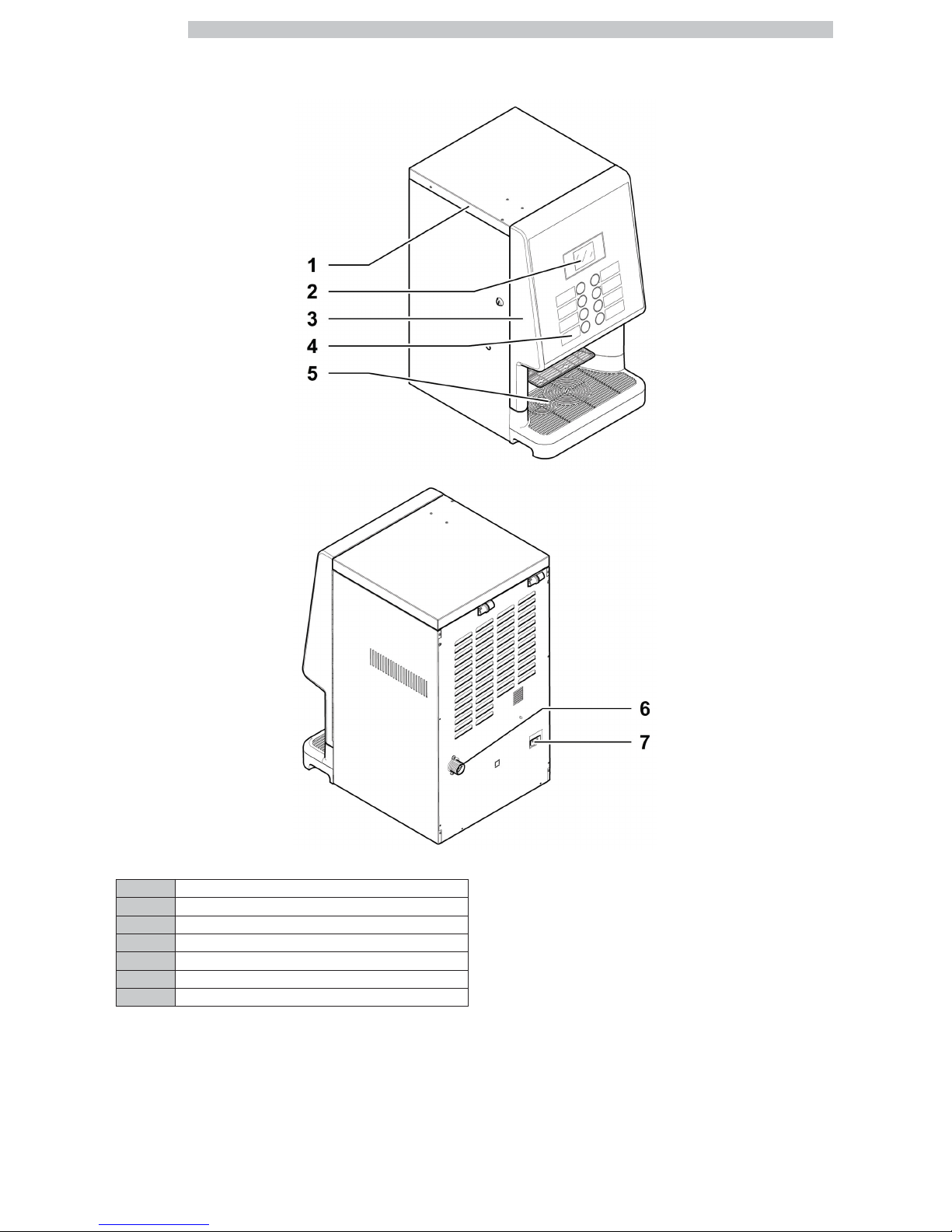

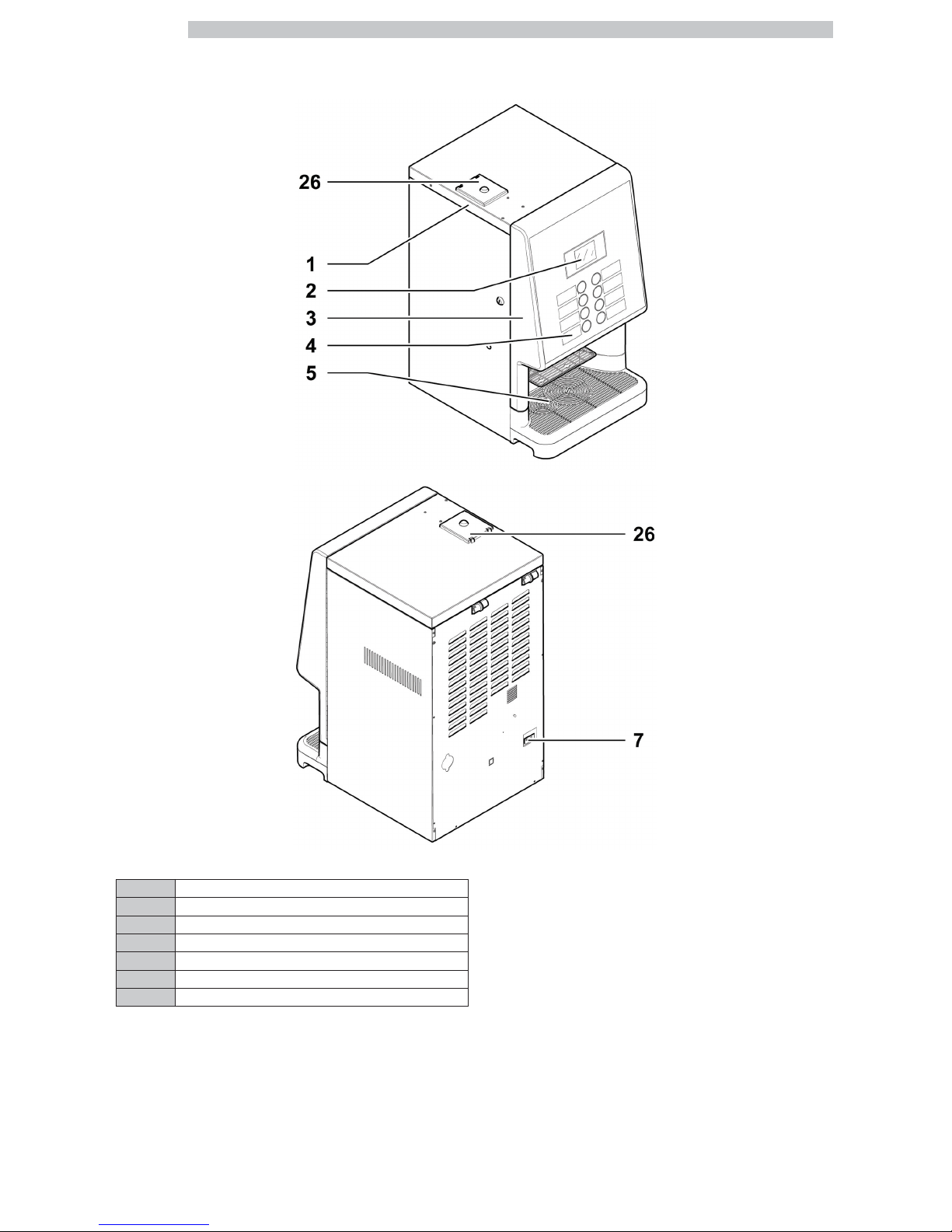

MAIN PARTS

MAIN PARTS - ESPRESSO VERSION

1 Top door

2 Display

3 Front door

4 Keypad

5 Dispensing outlet (beverage dispensing)

6 Water connection coupling

7 Power cord socket

Page 3

English

3

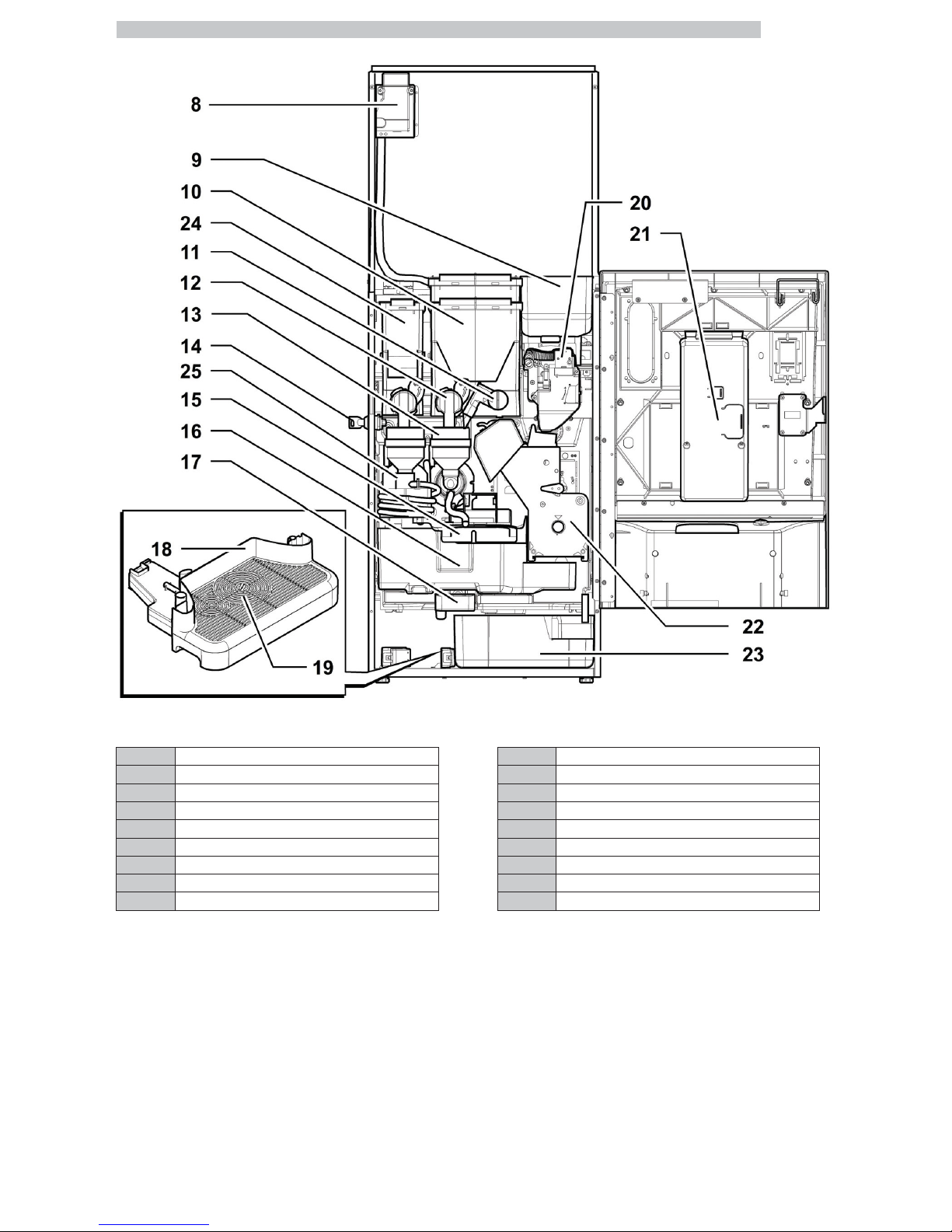

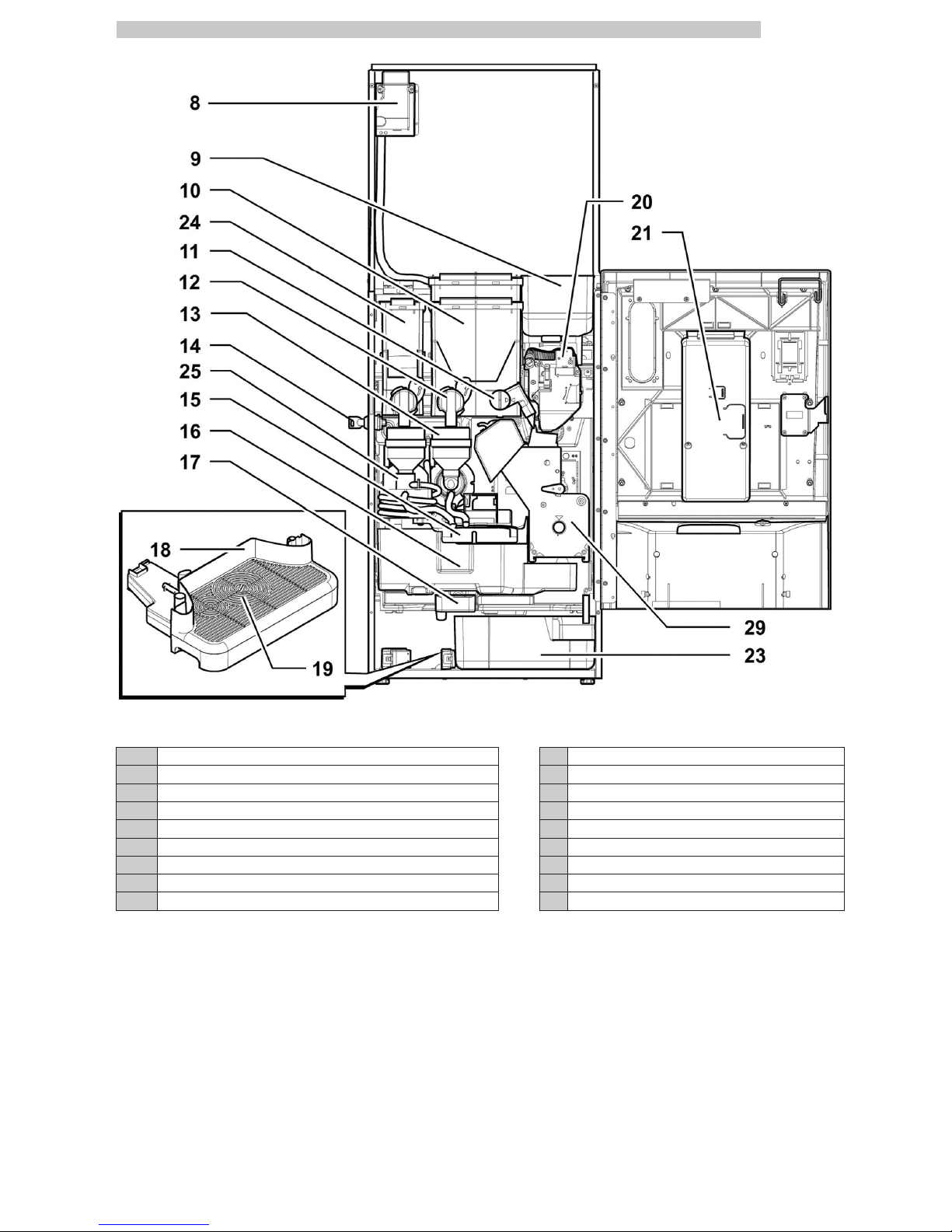

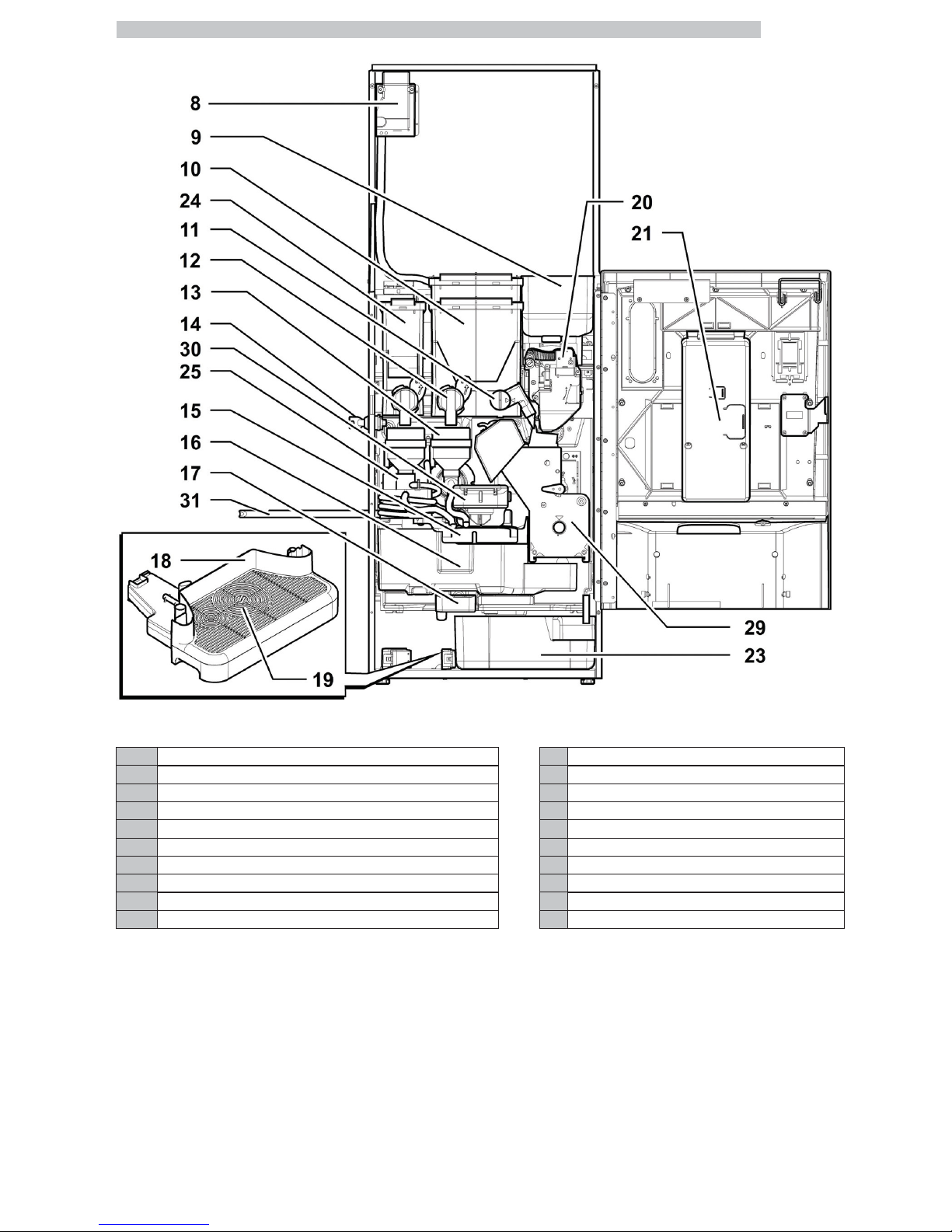

8 Safety switch 17 Drain conveyor

9 Coffee bean hopper 18 Drip Tray

10 Container 2/3 (instant products) 19 Grill

11 Adjustable powder dispensing channel 20 Coffee grinder

12 Instants opening 21 CPU card

13 Mixer 22 Brew group

14 Door lock 23 Coffee grounds drawer

15 Dispensing arm 24 Container 1 (instant products)

16 Coffee grounds drawer 25 Spiral mixer

Page 4

English

4

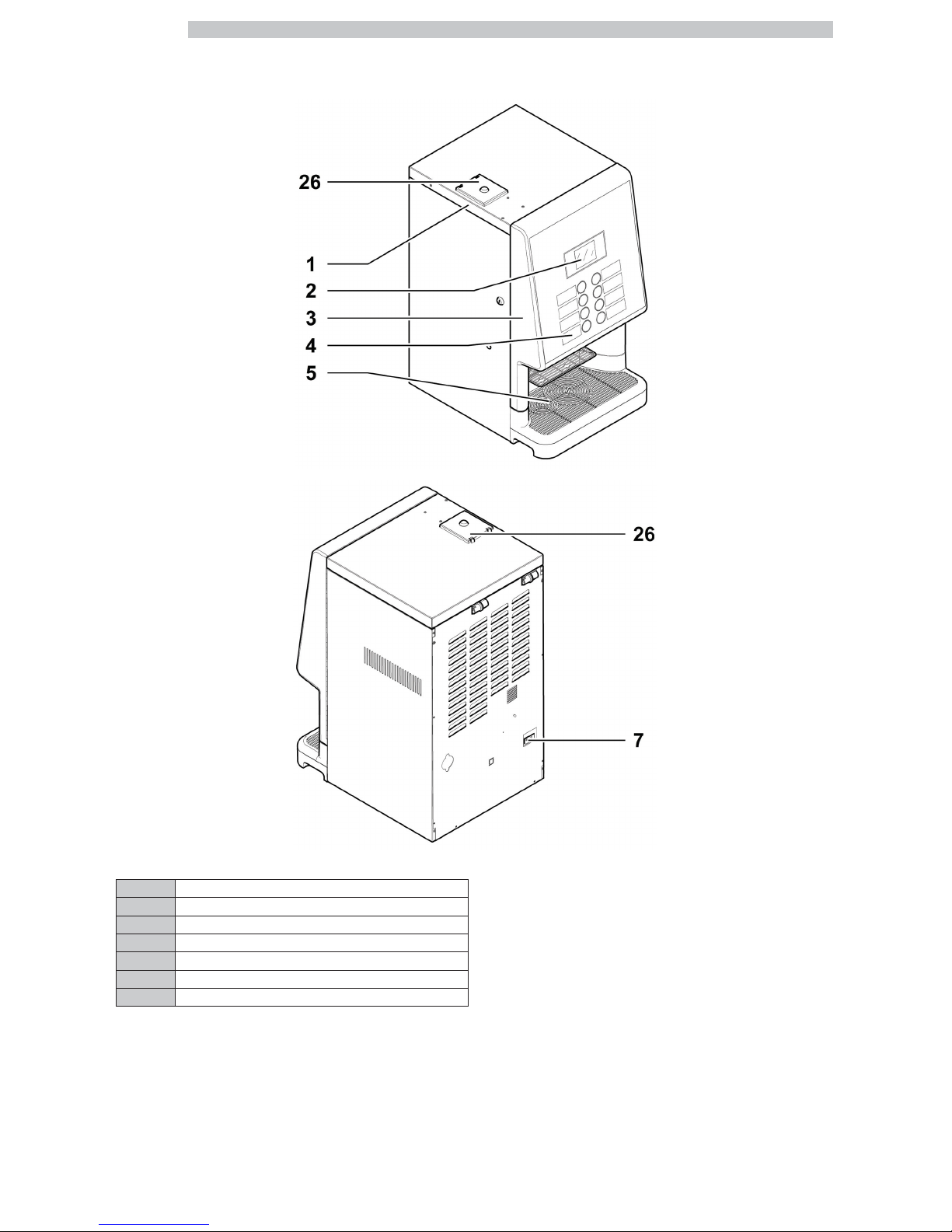

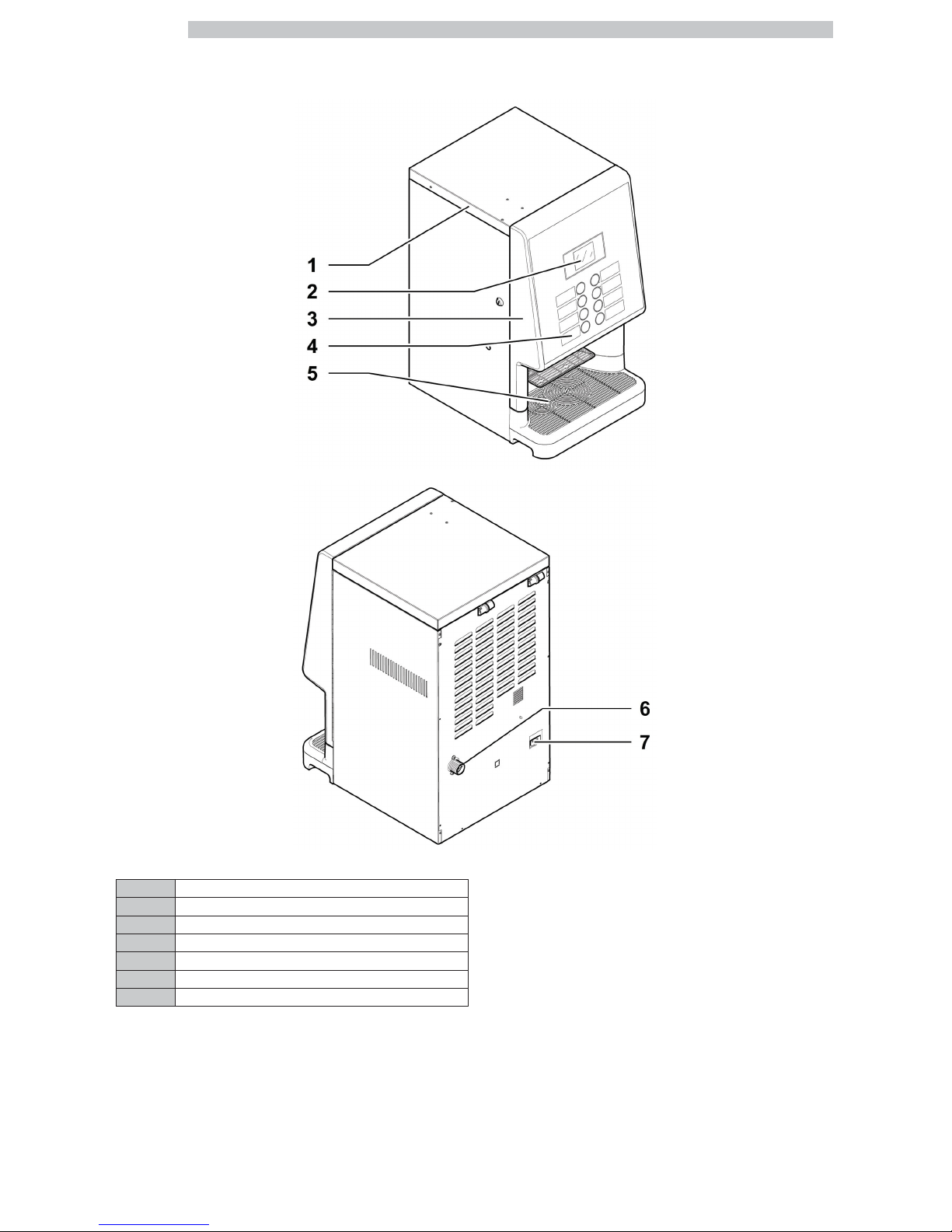

MAIN PARTS - ESPRESSO WATER TANK VERSION

1 Top door

2 Display

3 Front door

4 Keypad

5 Dispensing outlet (beverage dispensing)

7 Power cord socket

26 Tank funnel door

Page 5

English

5

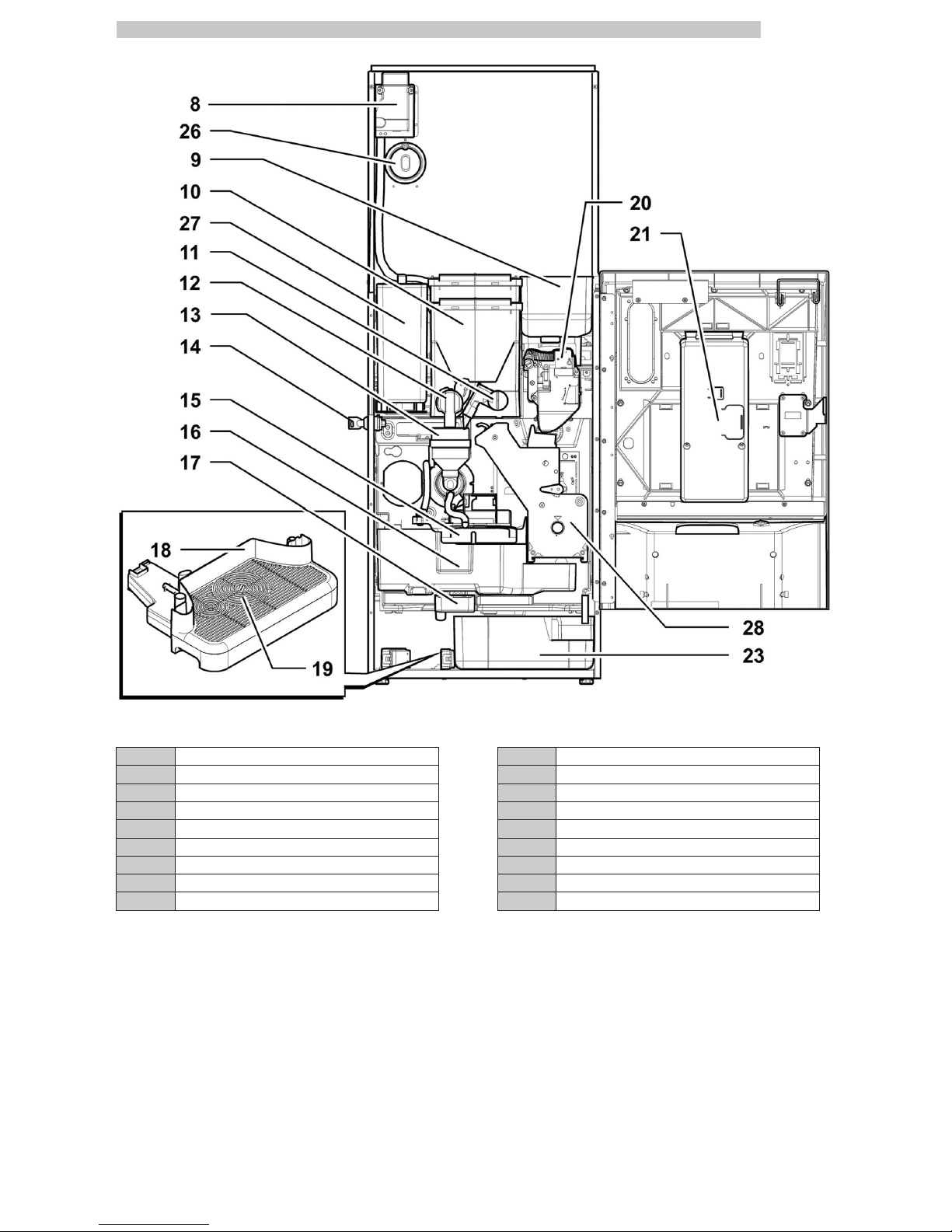

8 Safety switch 17 Drain conveyor

9 Coffee bean hopper 18 Drip Tray

10 Container 2/3 (instant products) 19 Grill

11 Adjustable powder dispensing channel 20 Coffee grinder

12 Instants opening 21 CPU card

13 Mixer 23 Coffee grounds drawer

14 Door lock 26 Tank funnel door

15 Dispensing arm 27 Water tank

16 Coffee grounds drawer 28 Brew group Gusto

Page 6

English

6

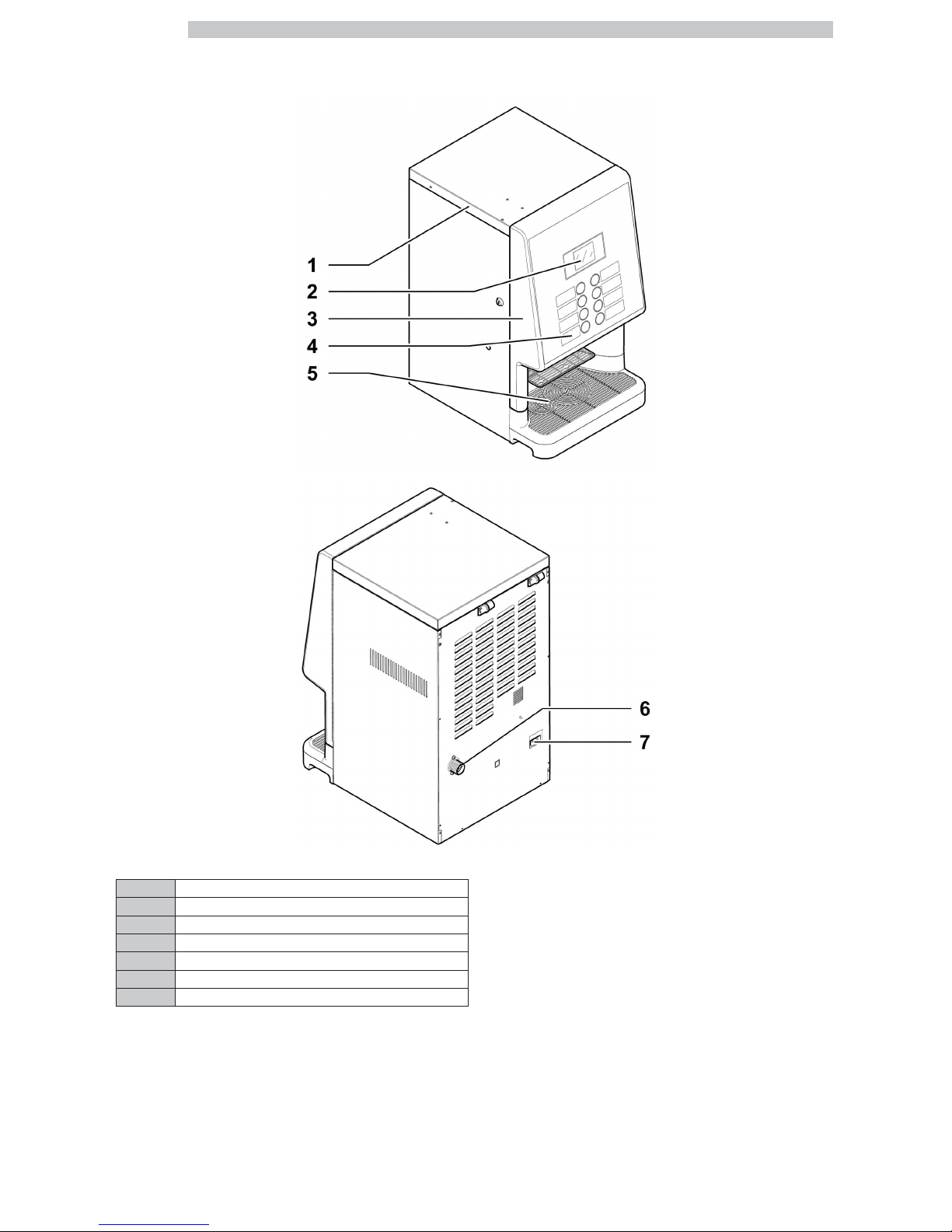

MAIN PARTS - ESPRESSO T.T.T. VERSION

1 Top door

2 Display

3 Front door

4 Keypad

5 Dispensing outlet (beverage dispensing)

6 Water connection coupling

7 Power cord socket

Page 7

English

7

8 Safety switch 17 Drain conveyor

9 Coffee bean hopper 18 Drip Tray

10 Container 2/3 (instant products) 19 Grill

11 Adjustable powder dispensing channel 20 Coffee grinder

12 Instants opening 21 CPU card

13 Mixer 23 Coffee grounds drawer

14 Door lock 24 Container 1 (instant products)

15 Dispensing arm 25 Spiral mixer

16 Coffee grounds drawer 29 T.T.T. Brew group

Page 8

English

8

MAIN PARTS - CAPPUCCINO VERSION

1 Top door

2 Display

3 Front door

4 Keypad

5 Dispensing outlet (beverage dispensing)

6 Water connection coupling

7 Power cord socket

Page 9

English

9

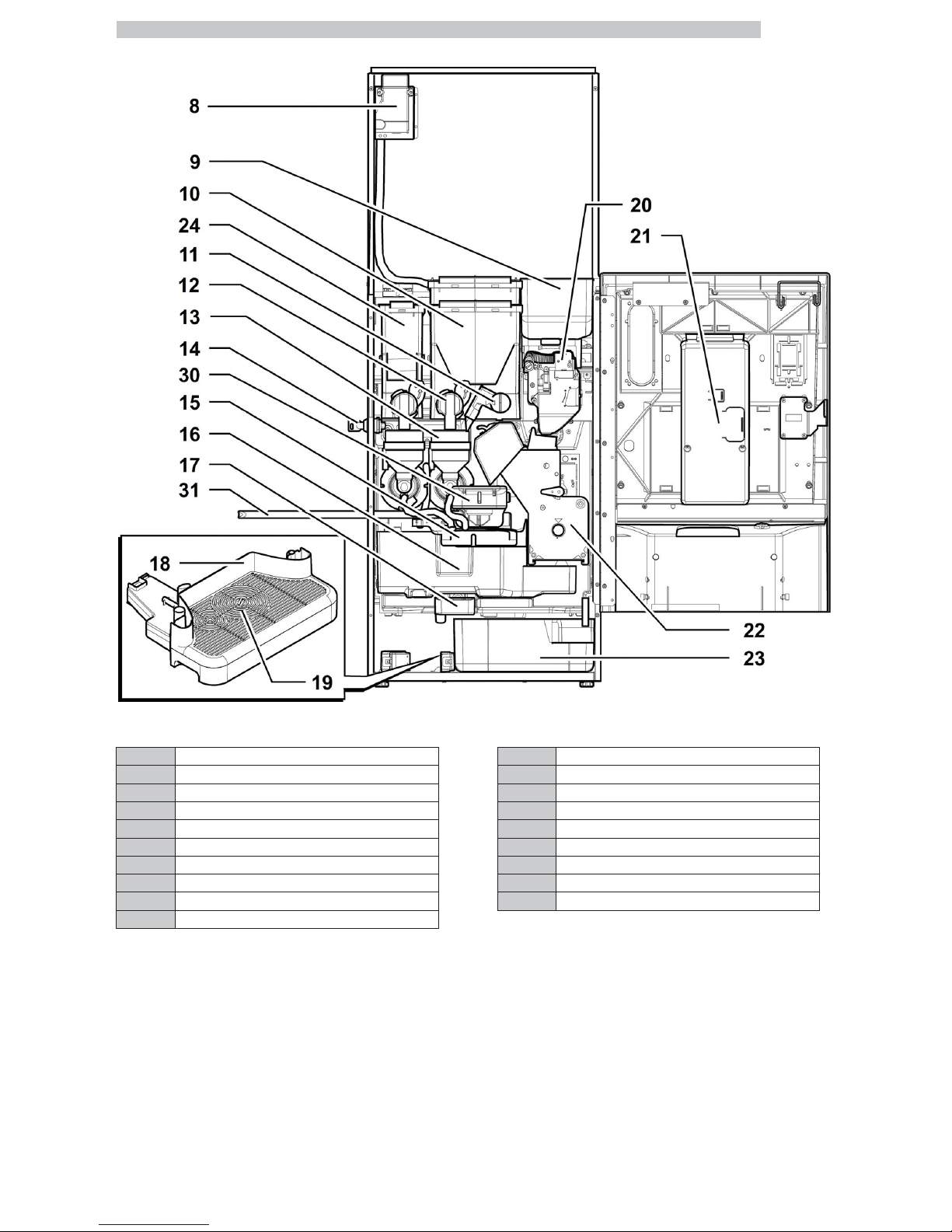

8 Safety switch 18 Drip Tray

9 Coffee bean hopper 19 Grill

10 Container 2/3 (instant products) 20 Coffee grinder

11 Adjustable powder dispensing channel 21 CPU card

12 Instants opening 22 Brew group

13 Mixer 23 Coffee grounds drawer

14 Door lock 24 Container 1 (instant products)

15 Dispensing arm 30 Cappuccinatore

16 Coffee grounds drawer 31 Hose for Cappuccinatore

17 Drain conveyor

Page 10

English

10

MAIN PARTS - CAPPUCCINO WATER TANK VERSION

1 Top door

2 Display

3 Front door

4 Keypad

5 Dispensing outlet (beverage dispensing)

7 Power cord socket

26 Tank funnel door

Page 11

English

11

8 Safety switch 18 Drip Tray

9 Coffee bean hopper 19 Grill

10 Container 2/3 (instant products) 20 Coffee grinder

11 Adjustable powder dispensing channel 21 CPU card

12 Instants opening 23 Coffee grounds drawer

13 Mixer 26 Tank funnel door

14 Door lock 27 Water tank

15 Dispensing arm 28 Brew group Gusto

16 Coffee grounds drawer 30 Cappuccinatore

17 Drain conveyor 31 Hose for Cappuccinatore

Page 12

English

12

MAIN PARTS - CAPPUCCINO T.T.T. VERSION

1 Top door

2 Display

3 Front door

4 Keypad

5 Dispensing outlet (beverage dispensing)

6 Water connection coupling

7 Power cord socket

Page 13

English

13

8 Safety switch

18

Drip Tray

9 Coffee bean hopper

19

Grill

10 Container 2/3 (instant products)

20

Coffee grinder

11 Adjustable powder dispensing channel

21

CPU card

12 Instants opening

23

Coffee grounds drawer

13 Mixer

24

Container 1 (instant products)

14 Door lock

25

Spiral mixer

15 Dispensing arm

29

T.T.T. Brew group

16 Coffee grounds drawer

30

Cappuccinatore

17 Drain conveyor

31

Hose for Cappuccinatore

Page 14

English

14

SAFETY INSTRUCTIONS

For professional use only.

The vending machine

cannot be installed

outdoors; avoid placing it

in areas where the

temperature is less than

2°C or more than 32°C

and in particularly dump or

dusty areas.

Do not install the appliance

in a location where water

jets may be used.

The vending machine must

be installed on a flat

surface.

It is forbidden to: use jets of

water for cleaning operations.

The appliance is only to be

installed in locations where its

use and maintenance is

restricted to trained

personnel.

The use by children older

than 8 years or by persons

with reduced physical, mental

or sensory abilities or with lack

of experience and skills is

allowed, provided that they

are supervised or instructed

on how to use the appliance

correctly and that they

understand the hazards

involved.

Children must not play with

the appliance.

Children must not carry out

any cleaning and maintenance

operations without being

monitored.

Do not direct water jets on

the components and/or on

the vending machine.

Page 15

English

15

Before connecting the

appliance to water network,

please read and follow the

applicable regulations in force

in your country.

If the supply cord is damaged,

it must be replaced by the

manufacturer, its service agent

or similarly qualified persons in

order to avoid a hazard.

Connect the vending machine

to drinking water mains with

pressure between 0.15 MPA

and 0.8 MPA (1.5 and 8 bar),

see data on the label.

Access to the service area is

restricted to persons having

knowledge and practical

experience of the appliance, in

particular as far as safety and

hygiene are concerned.

Before performing any

maintenance and/or cleaning

operation, unplug the power

cord.

Page 16

English

16

CONTENTS

MAIN PARTS

2

1 INTRODUCTION TO THE MANUAL

17

1.1 PREAMBLE

17

1.2 ICONS USED

18

2 INFORMATION ON THE VENDING

MACHINE

19

2.1 INFORMATION FOR THE MAINTENANCE

TECHNICIAN

19

2.2 DESCRIPTION AND INTENDED USE

19

2.3 VENDING MACHINE IDENTIFICATION

20

2.4 TECHNICAL SPECIFICATIONS

21

3 SAFETY

22

3.1 PREAMBLE

22

3.2 GENERAL SAFETY INSTRUCTIONS

22

3.3 OPERATOR REQUIREMENTS

23

3.4 SAFETY DEVICES

23

3.5 RESIDUAL RISKS

24

4 HANDLING AND STORAGE

25

4.1 UNLOADING AND HANDLING

25

4.2 STORAGE

25

5 INSTALLATION

26

5.1 CAUTIONS

26

5.2 UNPACKING AND POSITIONING

26

5.3 LABEL APPLICATION

28

5.4 INSTALLATION OF PAYMENT SYSTEMS

31

5.5 CONNECTION TO WATER MAINS

32

5.6 CONNECTION TO THE ELECTRIC NETWORK

33

5.7 COFFEE GROUNDS DISCHARGE SETTING

33

5.8 LIQUID DRAIN SETTING

34

6 DESCRIPTION OF CONTROLS

35

6.1 DISPLAY

35

6.2 KEYPAD

35

6.3 BUTTON DESCRIPTION DURING NORMAL

OPERATION

35

6.4 CPU CARD KEYS

35

7 SUPPLY AND START UP

36

7.1 CONTAINER CONFIGURATION

36

7.2 INSTANT PRODUCT SUPPLY

39

7.3 COFFEE BEAN SUPPLY

39

7.4 FILLING THE WATER TANK

40

7.5 TOP DOOR INTERMEDIATE LOCKING

41

7.6 DOSE CALIBRATION

41

7.7 COFFEE GRIND ADJUSTMENT

42

7.8 FIRST START-UP OF THE VENDING MACHINE

42

7.9 WATER CIRCUIT FILLING

42

7.10 WASHING THE PARTS COMING INTO

CONTACT WITH FOOD

42

7.11 USE OF THE VENDING MACHINE

42

8 PROGRAMMING AND MAINTENANCE

MENU

43

8.1 KEY DESCRIPTION OF PROGRAMMING AND

MAINTENANCE PHASES

43

8.2 PROGRAMMING MENU

43

8.3 MAINTENANCE MENU

64

8.4 MACHINE READY / FREE BUTTON

68

9 OPERATION AND USE

69

9.1 BEVERAGE SELECTION

69

9.2 CAPPUCCINO WITH COLD MILK FUNCTION

70

9.3 WARNING SIGNALS

71

10 CLEANING AND MAINTENANCE

72

10.1 GENERAL NOTES FOR CORRECT

OPERATION

72

10.2 CLEANING AND SCHEDULED

MAINTENANCE

73

10.3 NON-SCHEDULED MAINTENANCE

83

10.4 SOFTWARE UPDATE

84

10.5 MANAGEMENT OF DEFAULT VALUES

85

11 TROUBLESHOOTING

86

12 STORAGE - DISPOSAL

88

12.1 LOCATION CHANGE

88

12.2 INACTIVITY AND STORAGE

88

13 INSTRUCTIONS FOR END OF

OPERATIONAL LIFE DISPOSAL

89

Page 17

English

1

17

1 INTRODUCTION TO THE MANUAL

1.1 Preamble

This publication is an

integral part of the vending

machine and must be read

carefully to ensure the

machine is used correctly

and in compliance with

essential safety

requirements.

This manual contains the

technical information

required for the correct

use, installation, cleaning,

and maintenance of the

vending machine.

Always refer to this manual

before carrying out any

operation.

Manufacturer: SAECO Vending S.p.A.

Località Casona, 1066 - 40041 Gaggio Montano

Bologna, Italy

This publication should be

kept carefully, together

with the vending machine

throughout its operational

life, even in case of changes

of ownership.

If this manual is damaged

or lost, a copy may be

requested from the

manufacturer or the

technical service by

indicating the data

contained on the data

plate on the rear side of

the vending machine.

Page 18

English

1

18

1.2 Icons Used

Various kinds of warnings are contained in this manual to

highlight the different hazard or competence levels.

The symbol is integrated with a message suggesting use

procedures or actions and providing useful information for

the correct operation of the machine.

Warning

Indicates dangerous situations for the users, supply

operators and maintenance technicians dealing either with

the vending machine or the product to be dispensed.

Prohibition

It is used to highlight actions/operations not to be

performed.

Important

Indicates the operations for keeping the vending machine

in good working order.

Suggested solutions

It is used to indicate alternative procedures which make

programming and/or maintenance operations quicker.

User

Indicates the user of the vending machine. Users are not

allowed to perform any cleaning or maintenance

operations.

Supply operator

Indicates operations to be carried out only by personnel in

charge of supplying and cleaning the vending machine.

Supply operators can not perform any operations

requiring a Maintenance Technician.

Maintenance technician

It is used to signal those operations that must be

performed only by the specialised maintenance technicians.

The Maintenance Technician is the only person authorized

to keep the MICROSWITCH ENABLING KEY, by which

the security systems can be disabled.

Page 19

English

2

19

2 INFORMATION ON THE VENDING MACHINE

2.1 Information for the

Maintenance Technician

The vending machine must

be installed in a well-lit, dry

area, away from bad

weather and dust, on a

floor suitable to support its

weight.

To ensure its correct operation and reliability over time,

comply with the following recommendations:

• ambient temperature: from +2°C to +32°C;

• maximum humidity allowed: 80% (non-condensed).

For special installations, not covered by this manual, please

contact the dealer or the local importer. If this is not

possible, please contact the Manufacturer.

The technical service is available for any explanation or

information regarding the correct operation of the vending

machine and to satisfy any request for spare parts supply

or technical assistance.

The Maintenance Technician must carefully read and

observe the safety warnings contained in this manual to

ensure that installation, start-up, use and maintenance

operations are performed in complete safety.

It is the Maintenance Technician’s absolute responsibility

to give the keys to access the inside of the vending

machine to another operator (Supply Operator), provided

that the Maintenance Technician bears full responsibility

for all work carried out.

This manual is an integral part of the machine and must be

always read carefully before performing any operation.

2.2 Description and Intended Use

The vending machine is intended for automatic distribution of

coffee and hot beverages (decaffeinated coffee, cappuccino,

chocolate, etc.) and is programmable for every single type of

dispensing dosage. The instant products must be consumed

immediately, and cannot be preserved for a long time.

Using the machine for any other purpose is considered

dangerous and as a misuse.

Do not place any product

inside the vending machine

which may be dangerous as

a result of unsuitable

temperatures.

With reference to the definition of “professional appliance” given

by the standard EN60335-2-75 for vending machines, this

appliance can not be classed as professional.

Misuse voids all forms of

warranty, releasing the

Manufacturer from any

responsibility for damage to

property and/or personal

injury.

The following are also

considered misuse:

• any use other than the intended use and/or employing methods

other than those described in this manual;

• any intervention on the vending machine which differs from the

instructions given in this publication;

Page 20

English

2

20

• any tampering with parts and/or safety devices not previously

authorised by the Manufacturer and performed by unauthorised

personnel;

• any location of the vending machine not provided in this manual.

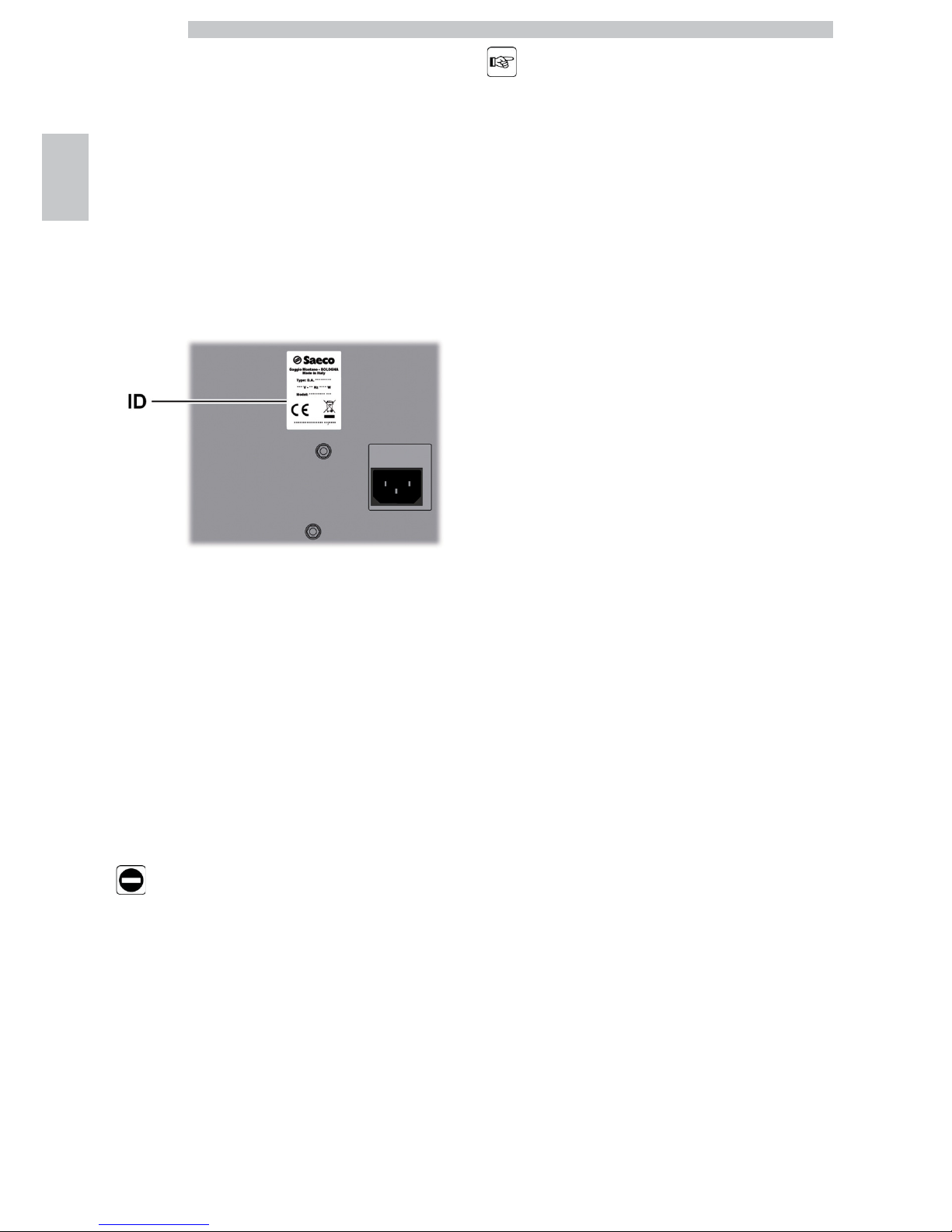

2.3 Vending Machine

Identification

The vending machine is identified by the name, model and serial

number which can be found on the relevant data plate.

ID Data plate

The plate contains the following data:

• name of the Manufacturer;

• marks of conformity;

• model;

• serial number;

• year and month of manufacture;

• supply voltage (V);

• supply frequency (Hz);

• electrical power consumption (W);

• VM Code

It is strictly forbidden to

tamper with or modify the

data plate.

When contacting the

technical service, always

refer to this plate by

indicating the technical

data shown on it.

Page 21

English

2

21

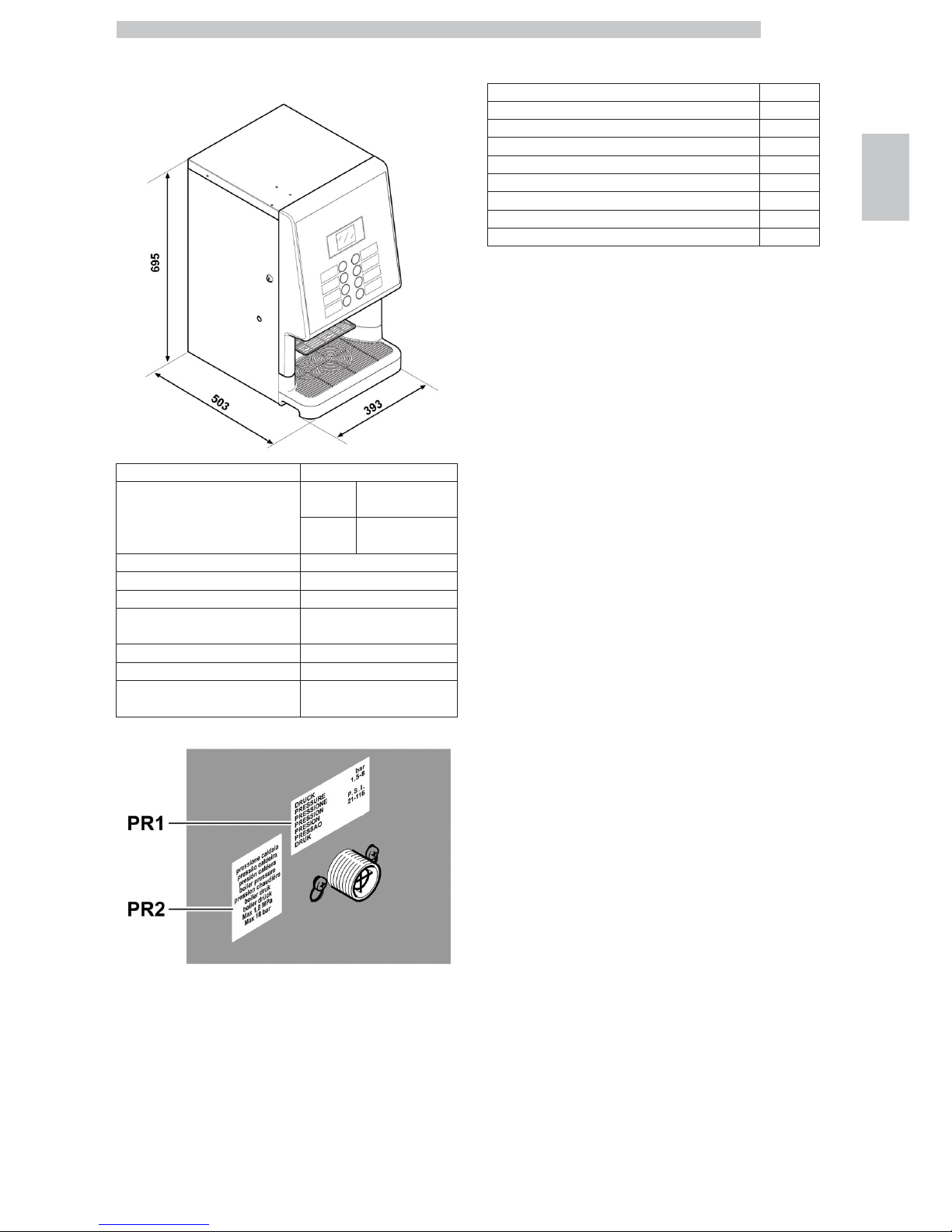

2.4 Technical Specifications

Size (w x h x d) 393 x 695 x 503 mm

Weight

36,5 kg Espresso model

37,5 kg

Cappuccino

model

Power consumption See the data plate

Supply Voltage See the data plate

Electric voltage frequency See the data plate

Power cord length 1600 mm

Water mains connection 3/4” Gas type

Water mains pressure See the data plate

A-weighted sound pressure level less than 70 dB

PR1

Data plate showing minimum and maximum water supply

pressure

PR2 Boiler pressure data plate

Container capacity

Coffee beans 1 kg

Hot Chocolate 1,75 kg

Milk 0,65 kg

Lemon tea 1,5 kg

Ground coffee 0,62 kg

Double Ginseng 1,85 kg

Standard Ginseng 1,15 kg

Standard Freeze-dried coffee 0,41 kg

Standard Barley 0,36 kg

Page 22

English

3

22

3 SAFETY

3.1 Preamble

In accordance with the applicable standards and

regulations, SAECO VENDING has prepared a technical

file relating to the PHEDRA EVO vending machine at its

premises, acknowledging the following standards in the

design stage:

- EN 55014 - EN 61000-4-4

- EN 6100-3-2 - EN 61000-4-5

- EN 61000-3-3 - EN 61000-4-11

- EN 61000-4-2 - EN 60335-2-75

- EN 61000-4-3 - EN 60335-1

3.2 General Safety Instructions

It is forbidden to:

• tamper with or disable the safety systems installed on the

vending machine;

• carry out maintenance on the vending machine without

unplugging it first;

• install the vending machine on the outside. It is advisable to place

it in a dry place where the temperature does not drop below

2°C, in order to prevent any possible freezing.

• use the vending machine for purposes other than those indicated

in the sale contract and in this publication;

• electrically connect the appliance using multi-sockets or adapters;

• use jets of water for cleaning operations.

It is mandatory to:

• check conformity of the power supply;

• use original spare parts;

• carefully read the instructions contained in this manual and in the

attached documents;

• use personal protective equipment when performing installation,

testing and maintenance operations.

• Use a new gasket kit every time you disconnect and then

connect again the machine to the water supply.

Precautionary measures to prevent human errors:

• make the operator aware of safety issues;

• handle the vending machine, either packaged or unpackaged, in

safe conditions;

• deeply know the installation procedures, its correct operation

and its limits;

• dismantle the vending machine in safe conditions, in accordance

with the environmental protection and health and safety laws in

force.

To prevent machining

residues from coming into

contact with the beverages,

dispense about 0.5 l of

water for each dispensing

path before definitely

starting the machine. The

dispensed beverages can

be drunk only after

performing this operation.

In case of failure or

malfunctioning, please refer

only to the qualified

personnel of the technical

service.

Page 23

English

3

23

The manufacturer is not

liable for damage to

persons or property

resulting from failure to

follow the safety

instructions provided in

this section.

3.3 Operator Requirements

Three operators with different skills are required in order

to guarantee the appliance’s safety:

User

Access to the internal part of the vending machine is

forbidden to the user.

Supply operator

The Maintenance Technician assigns the safekeeping of the

access key to the Supply operator who is in charge of

product supply, external cleaning, and starting up /

stopping of the vending machine.

The Supply operator is not

allowed to carry out

operations indicated in this

manual as competence of

the Maintenance

Technician.

Maintenance technician

The maintenance technician is the only person authorised to

service the machine, start the programming procedures and

perform the adjustment, set up and maintenance operations.

Access to the service area is

restricted to persons having

knowledge and practical

experience of the appliance,

in particular as far as safety

and hygiene are concerned.

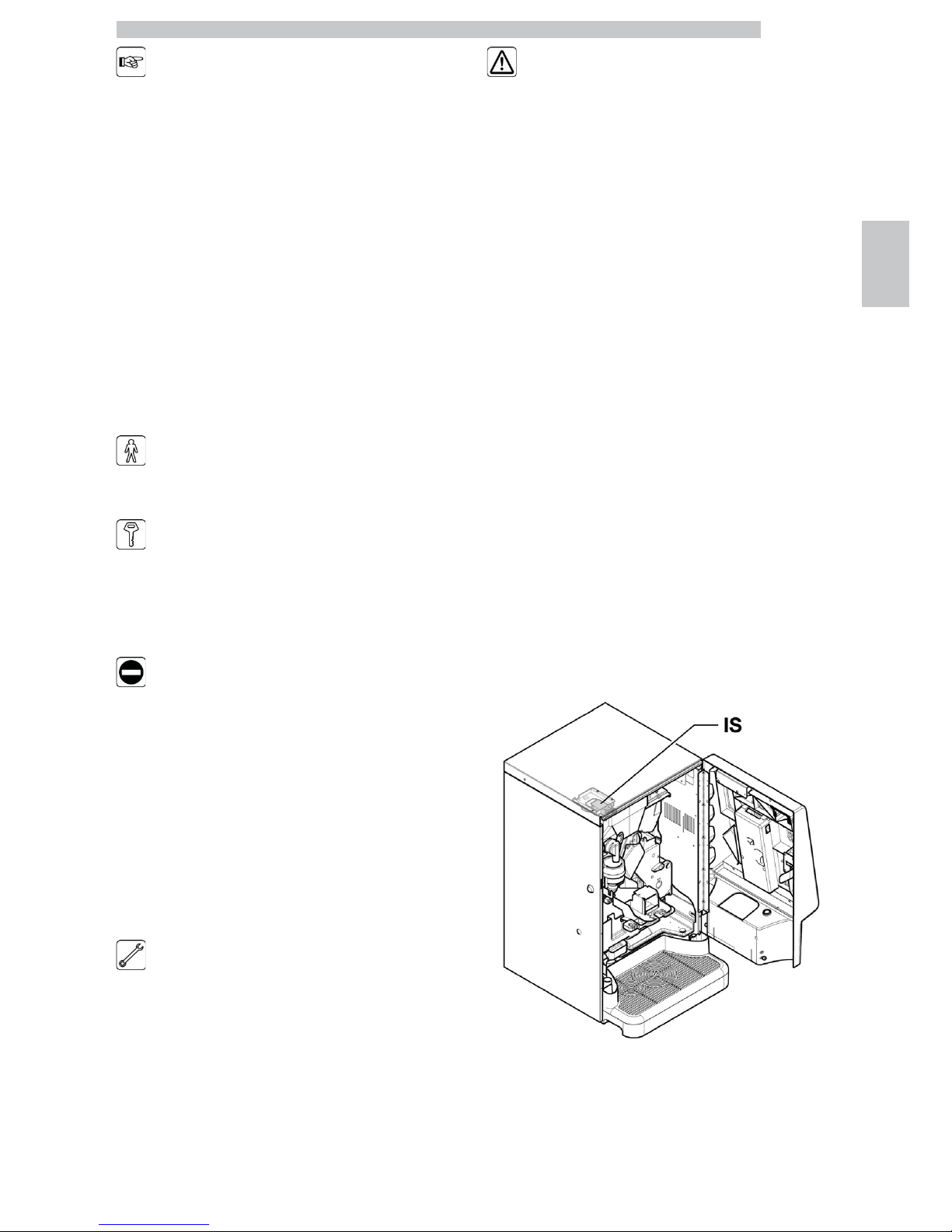

3.4 Safety devices

The vending machine is equipped with:

• a safety switch which cuts out the voltage to all the inside

components any time the front door is opened.

• A microswitch interrupts the dispensing of coffee products

when the coffee grounds tray is not correctly positioned.

A message indicating the incorrectly positioned part

appears on the display.

• A microswitch blocks vending machine operation when

the drip tray is not correctly positioned. A message

indicating the incorrectly positioned part appears on the

display.

• A sensor blocks vending machine operation when the drip

tray is full. The message "Empty water tank" is displayed.

IS Safety switch

Page 24

English

3

24

Maintenance technician

In case of programming or setting up operations only the

Maintenance Technician can intervene by inserting the

relevant key into the safety switch and resetting the

voltage even if the door is open.

This operation, necessary

for starting up the vending

machine, disables the safety

system.

It must therefore be

carried out by qualified

personnel (Maintenance

Technician) aware of the

risks resulting from the

presence of live or moving

components.

3.5 Residual Risks

Risk of burning if the hands

are placed inside the outlet

during beverage brewing.

Before removing the cup

from the outlet, please

wait for the message

“REMOVE CUP” on

display.

Before brewing a beverage

make sure that the

previous one has already

been picked up and that

the cup support is empty.

Page 25

English

4

25

4 HANDLING AND STORAGE

4.1 Unloading and Handling

Unloading and handling operations after transportation

must be carried out only by qualified personnel and using

suitable equipment.

The vending machine will be delivered in a package, so as

to ensure protection against any mechanical and

environmental agent.

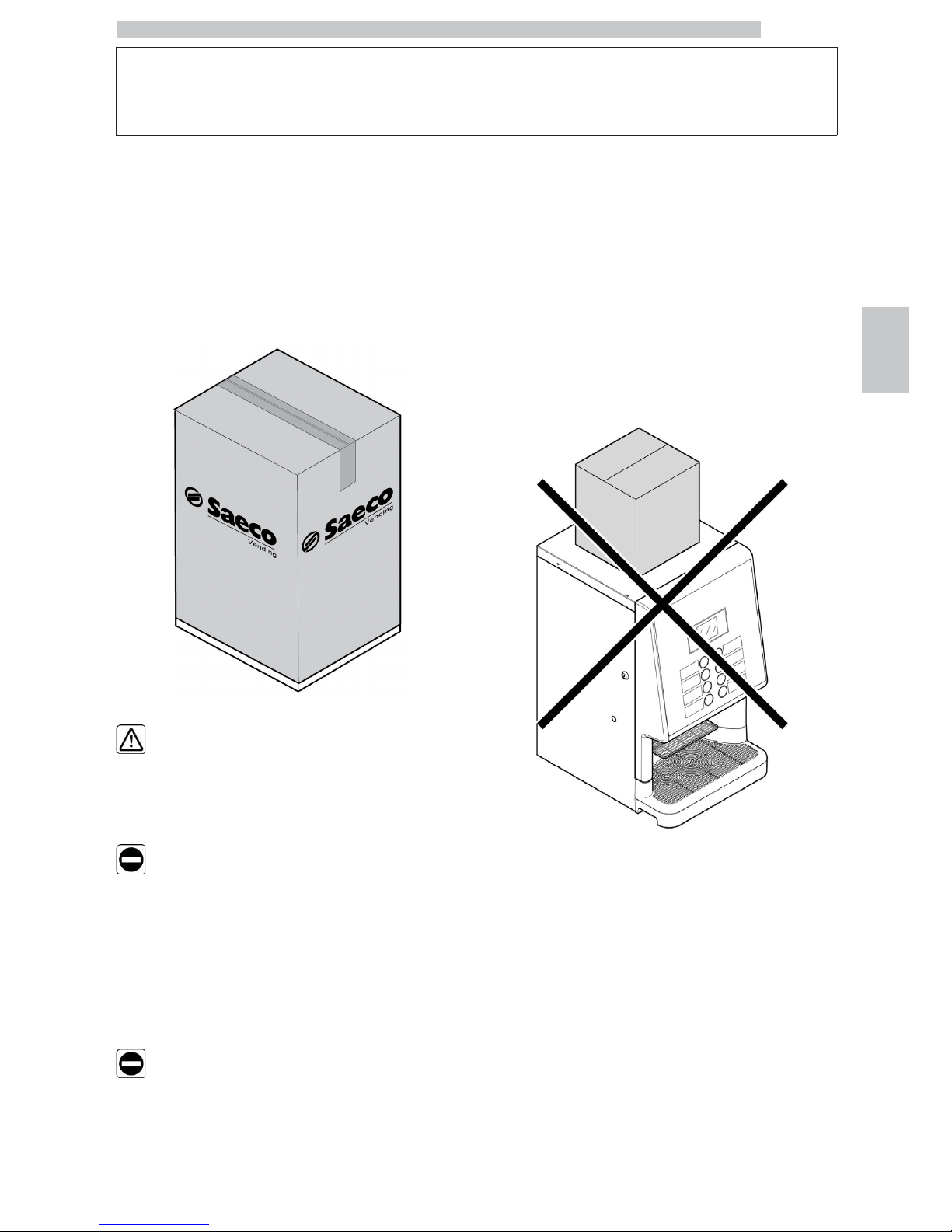

The vending machine must

always be kept in the

upright position.

Do not:

• dragging the vending machine;

• overturning or laying the vending machine flat during

transport and handling;

• shaking the vending machine;

• lifting the vending machine with ropes or cranes;

• leaving the vending machine exposed to the elements, in

humid areas or close to heat sources.

Avoid that:

• being bumped into

• being overloaded with other parcels

4.2 Storage

If the vending machine is not installed immediately, it

should be stored in a sheltered area, conforming to the

following instructions:

• the packaged vending machine must be stored in a closed,

dry area at a temperature between 1°C and 40°C;

• do not put other appliances or boxes on the vending

machine;

• it is always good practice to protect the vending machine

from any deposits of dust or other material.

Page 26

English

5

26

5 INSTALLATION

5.1 Cautions

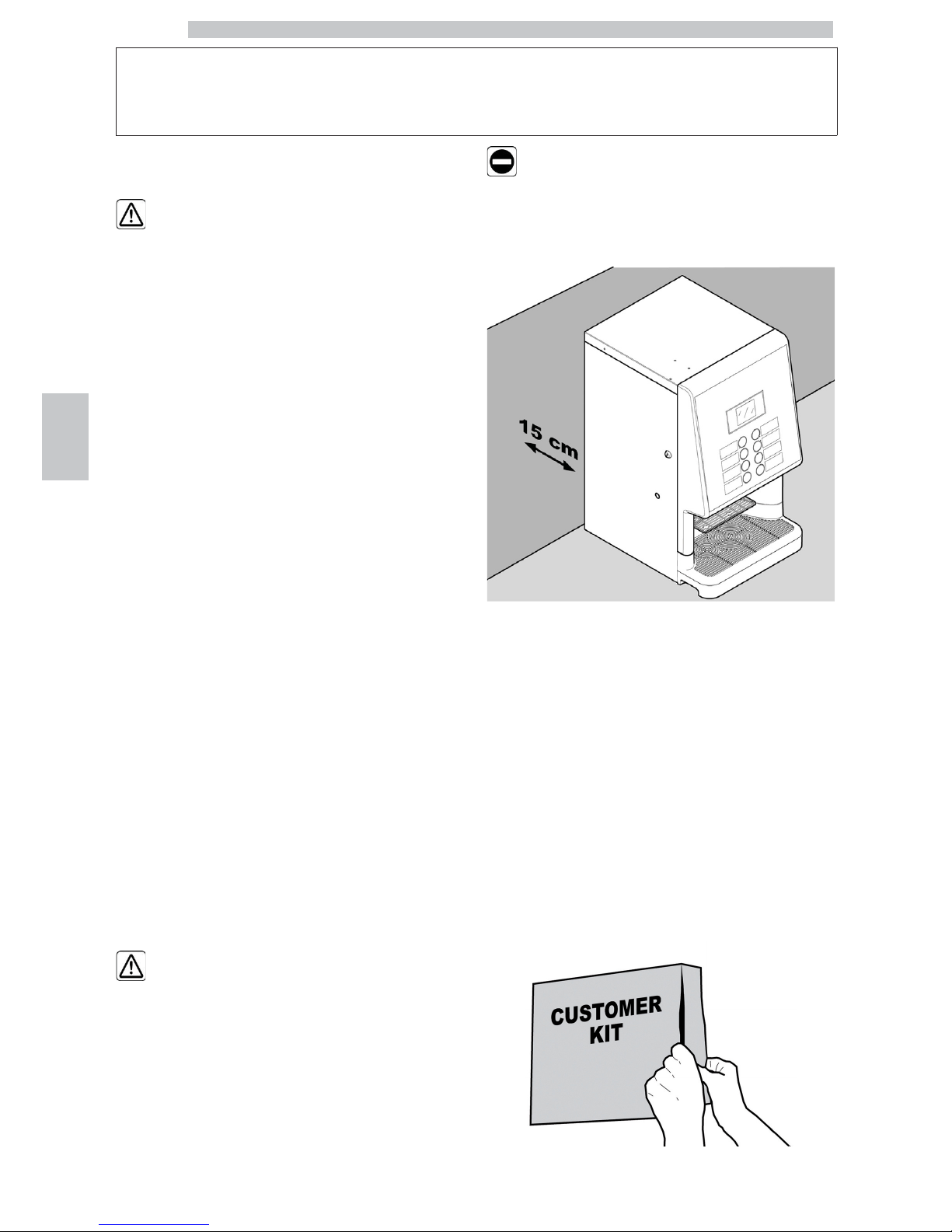

The vending machine

cannot be installed

outdoors; avoid placing it

in areas where the

temperature is less than

2°C or more than 32°C

and in particularly dump or

dusty areas. It should

neither be installed in

places where water jets are

used for cleaning

operations nor where

there is a risk of fire or

explosion.

Make sure that the installation place is compatible with the

following specifications, before unpacking the appliance:

• the power socket must be located in an easily accessible

area, not more than 1.5 meters away;

• the socket voltage must correspond to that indicated on

the appliance data plate.

• the surface or floor must NOT have a gradient of more

than 2°.

The vending machine must

be installed on a flat

surface.

If the vending machine needs to be positioned close to a

wall, it is necessary to leave a space of at least 15 cm

between the back and the wall in order to keep the air

outlet grille free.

Under no circumstances

cover the vending machine

with cloths or similar.

5.2 Unpacking and Positioning

On receipt of the vending machine make sure that it has

not been damaged during transportation and that package

has not been tampered with or that internal parts have not

been removed.

A bag, called “CUSTOMER KIT”, is supplied with the

vending machine. It contains the following items:

• Instruction booklet

• Power cord

• Door safety microswitch disabling keys (Maintenance

Technician)

• Product labels and prices

Page 27

English

5

27

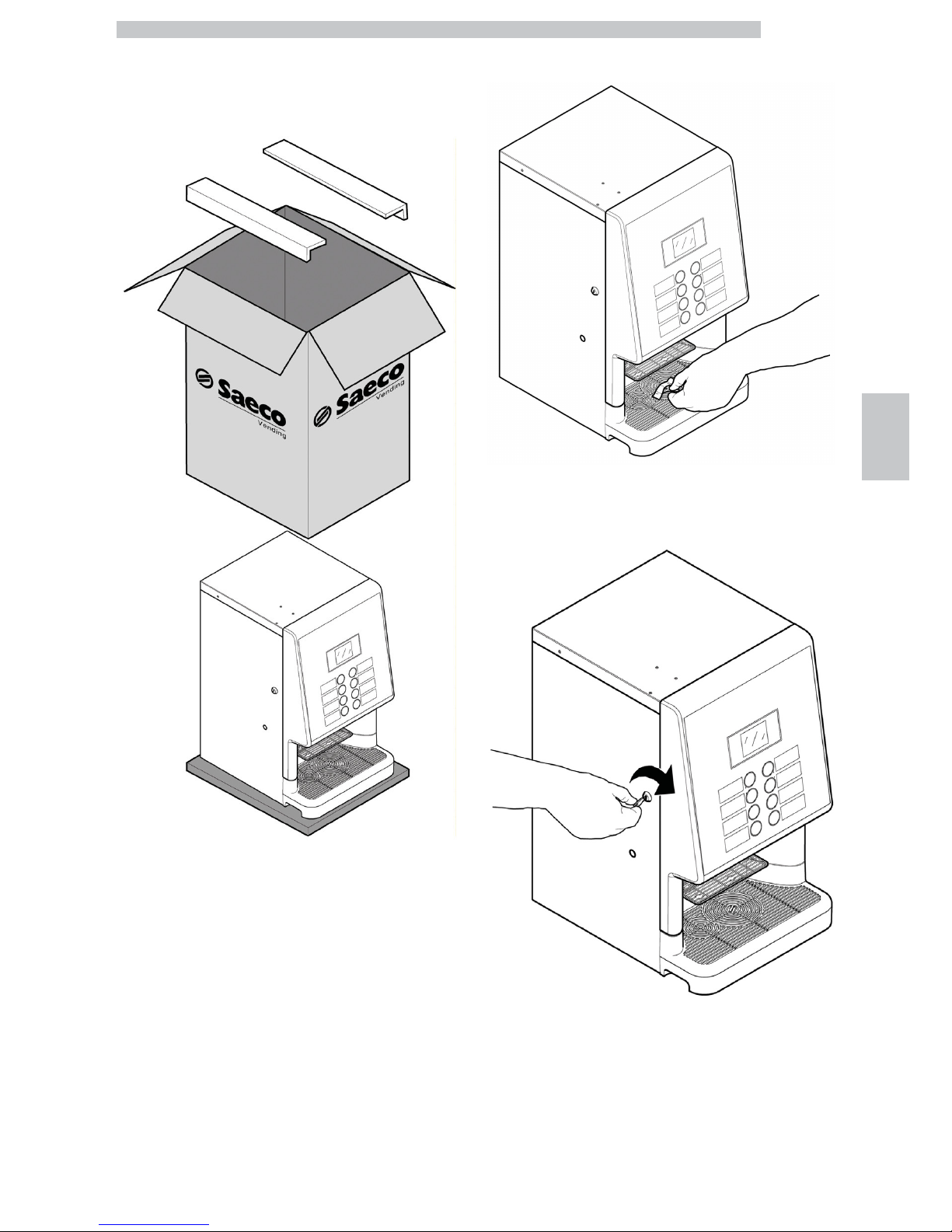

The vending machine is placed on a polystyrene base protected by two polystyrene corners, a polyethylene

foam sheet and a bag - and is delivered in a box.

If damage of any kind is found, the courier must be

informed and notice must be immediately given to the

importer or to the seller.

If these are not in the purchaser’s country, please contact

the manufacturing company directly.

Take the key from the dispensing outlet.

Insert the key into the lock, turn clockwise and open the

door.

Page 28

English

5

28

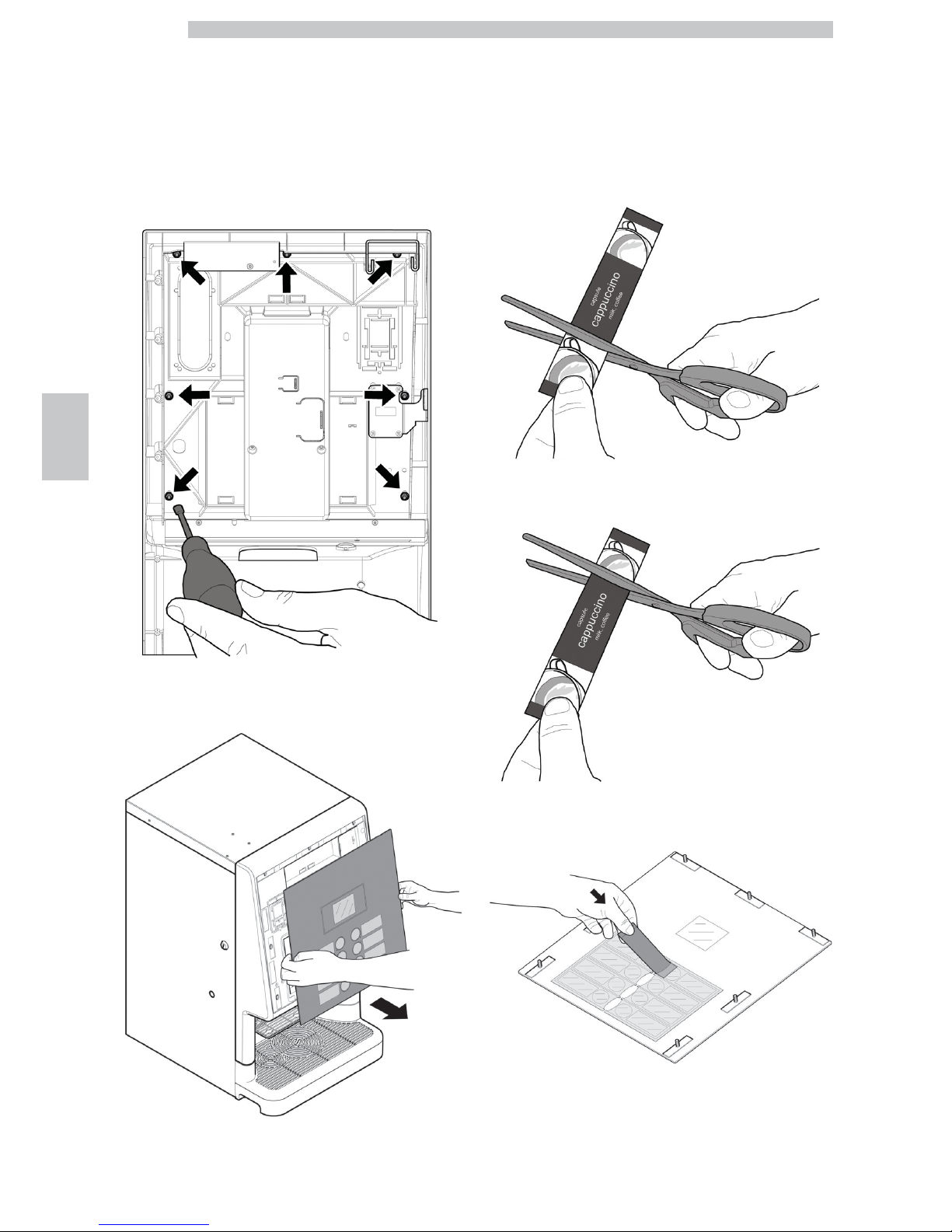

5.3 Label application

5.3.1 Product labels

Open the door. Using a box spanner, unscrew the 7

keypad panel locknuts.

Remove the keypad panel.

Take out the product label sheet included in the customer

kit.

Remove the labels from the product label sheet by

following the pre-cut line.

Cut the labels as shown in the figure to make the left ones

or the right ones.

Left labels

Right labels

Insert the product labels in the keypad panel.

Page 29

English

5

29

Check the exact position of the labels against the selection

key. Insert the keypad panel back into place. Using a box

spanner, screw the 7 keypad panel locknuts to their limit

stop.

To make different labels from the ones provided in the kit,

please use the "Labels" module available on our web portal

"Saeco Vending Online" at www.saecovending-online.com.

For printing, we suggest using paper with the following

properties: 170-g matte coated paper.

Standard product configuration

Phedra Espresso 2 instant products

Phedra Espresso 3 instant products

Phedra Espresso Water Tank

Phedra Espresso T.T.T

Page 30

English

5

30

Phedra Cappuccino

Phedra Cappuccino Water Tank

Phedra Cappuccino T.T.T.

Page 31

English

5

31

5.4 Installation of Payment

Systems

The vending machine is designed for the installation of

various payment systems, such as:

- parallel validator 24 V DC

- executive systems (also PRICE HOLDING);

- MDB systems;

- BDV systems;

- cashless reader;

A coin validators

B cashless reader

The vending machine is

not supplied with any

payment system, which

must be installed by the

person in charge of its

fitting.

After the chosen payment

system has been installed,

the corresponding

parameters can be set

through the programming

menu (see section

“Programming menu”).

The Manufacturer declines

any liability for any damage

to the vending machine, to

property and/or injury to

persons, caused by the

installation of the payment

system. The responsibility

falls to the person who

carried out the installation.

Page 32

English

5

32

5.5 Connection to water mains

The pressure reducer is

calibrated during assembly.

Should problems occur

with the calibration of the

pressure reducer, the

outlet pressure value must

absolutely be reset to 0.8 –

1 bar max. Different or

approximate calibration

may cause product quality

and quantity variations

when brewed.

It is recommended to use

a descaling device for the

water network supplying

the vending machine,

especially for water with a

high calcium and

magnesium content (hard

water).

Connect the vending

machine to drinking water

mains with pressure

between 0.15 MPA and

0.8 MPA (1.5 and 8 bar),

see data on the label.

Before connecting the

appliance to water

network, please read and

follow the applicable

regulations in force in your

country.

Connect the water network hose (supplied with the

appliance) to the vending machine 3/4" Gas coupling.

The water mains pipe

should be certified

according to the standard

IEC 61770.

Page 33

English

5

33

The new hose-sets

supplied with the appliance

are to be used and that old

hose-sets should not be

reused.

5.6 Connection to the Electric

Network

The Maintenance Technician,

who is responsible for the

installation of the vending

machine, must ensure that:

• the power supply system complies with the safety instructions in force;

• the voltage corresponds to that indicated on the appliance data plate.

In case of doubt, do not

proceed with the installation

and ask qualified and

authorised personnel to

accurately check the system.

The vending machine is equipped with a power cord which must be

plugged into the appropriate socket on the vending machine back panel.

Do not use adapters or multi-sockets.

Make sure that the power

cord plug is easily reachable

after installation.

5.7 Coffee Grounds Discharge

Setting

The appliance is setup for direct discharge of the coffee grounds

into the bag in the dedicated cabinet or into another container

located below the appliance (ex. bar counter).

For this setting, the vending machine base must be cut along the

indicated marks.

The appliance has an alarm

signal to indicate when to

empty the coffee grounds

in the standard version. For

this setting it is necessary

to exclude this counter

using the menu.

Page 34

English

5

34

A Marks

Use the coffee grounds

conveyor C (optional) as

shown in the figure.

In case of placing the appliance on the top of a working

surface, in order to discharge the coffee grounds into a

container placed below , make a 75 mm Ø hole (minimum)

on the surface as shown in the figure. Install the machine in

its final position on the supporting surface (the rings P

indicate the ideal position of the adjustable feet).

FR Machine front side

F Hole to be made

P Ideal position of the adjustable feet

5.8 Liquid Drain Setting

The appliance is setup for direct drainage of the drip tray

into container in the dedicated cabinet or into another

container located below the appliance. To use this setting,

cut (or drill a hole in) the panel in the indicated area.

A diaphragm

Page 35

English

6

35

6 DESCRIPTION OF CONTROLS

6.1 Display

The display shows the messages during normal operation

and during the programming and maintenance phase.

6.2 Keypad

Each key function changes

according to the vending

machine mode (ordinary

dispensing or programming

mode).

Each key has a double

function that varies

according to the vending

machine status (standard

operation or programming).

6.3 Button Description during

Normal Operation

6.3.1 Set 1 Pre-selection button

The function connected to the button may be chosen from

the following options:

A. Beverage 5

B. Pre-selection of beverages 9-16

C. Disabled

6.3.2 Set 2 Pre-selection button

The function connected to the button may be chosen from

the following options:

A. Beverage 6

B. Pre-selection of beverages 17-24

C. Disabled

6.3.3 Keys (1 to 8)

By pressing these keys, the programmed beverages are

dispensed.

6.4 CPU card keys

The CPU electronic board is equipped with 3 buttons

which allow the Maintenance Technician to carry out the

programming and maintenance operations.

P1 Programming menu key

P2 Maintenance menu key

P3 Machine Ready / Free Button

Page 36

English

7

36

7 SUPPLY AND START UP

7.1 Container Configuration

7.1.1 Espresso Version

The containers delivered

are designed to dispense

the following products:

2 instant products 3 instant products

Instant pr. 1 not present Tea

Instant pr. 2 Milk Milk

Instant pr. 3 Hot Chocolate Hot Chocolate

Instant pr. 4 Coffee beans Coffee beans

7.1.2 Espresso Water Tank version

The containers delivered

are designed to dispense

the following products:

Instant pr. 1 not present

Instant pr. 2 Milk

Instant pr. 3 Hot Chocolate

Instant pr. 4 Coffee beans

Page 37

English

7

37

7.1.3 Espresso T.T.T. version

The containers delivered

are designed to dispense

the following products:

Instant pr. 1 Tea

Instant pr. 2 Milk

Instant pr. 3 Ground coffee

Instant pr. 4 Coffee beans

7.1.4 Cappuccino Version

The containers delivered

are designed to dispense

the following products:

Instant pr. 1 Freeze-dried coffee

Instant pr. 2 Barley

Instant pr. 3 Hot Chocolate

Instant pr. 4 Coffee beans

Instant pr. 5 Fresh milk container

Page 38

English

7

38

7.1.5 Cappuccino Water Tank

version

The containers delivered

are designed to dispense

the following products:

Instant pr. 1 not present

Instant pr. 2 Barley

Instant pr. 3 Hot Chocolate

Instant pr. 4 Coffee beans

Instant pr. 5 Fresh milk container

7.1.6 Cappuccino T.T.T. version

The containers delivered

are designed to dispense

the following products:

Instant pr. 1 Tea

Instant pr. 2 Hot Chocolate

Instant pr. 3 Ground coffee

Instant pr. 4 Coffee beans

Instant pr. 5 Fresh milk container

Page 39

English

7

39

7.2 Instant product supply

Open the vending machine front door. Open the top door.

Open the cover of the container to be supplied.

Pour the instant product into the container.

Close the container cover.

7.3 Coffee Bean Supply

Open the vending machine front door. Open the top door.

Remove the container cover.

Pour the coffee beans into the hopper.

Replace the cover on the container.

Page 40

English

7

40

If the message “NO MORE

COFFEE” is displayed, refill

the vending machine, turn

it off and then on again.

7.4 Filling the Water Tank

(For Water Tank version only)

Open the vending machine front door. Open the top door.

Remove the tank and place it under a water tap.

Fill the tank with tap water.

Put the water tank back in place.

An optional kit allowing to fill the water tank without

removing it from the vending machine is available.

Page 41

English

7

41

7.5 Top door intermediate

locking

The vending machine is provided with an intermediate

locking position for the top door in case, due to its

location, it cannot be completely opened.

Proceed as follows to lock the top door in the

intermediate position:

- Open the vending machine front door.

- Lift the door and press bracket A.

Slightly lift the door, pull bracket A and lower the door to

unlock the door.

7.6 Dose calibration

The vending machine is delivered with standard calibration

values set by the manufacturer.

Dose calibration can be performed by means of two

calibration levels:

• remove the cover;

• free the adjusting lever from the rack and put the internal

divider pulling peg into one of the 4 possible positions in

the basic coffee quantity area (7 gr - 8 gr - 9 gr - 10 gr);

• move the adjusting lever into the rack and select the slot

corresponding to the dose required.

Page 42

English

7

42

7.7 Coffee Grind Adjustment

Turn the ring until the required results are obtained.

After any calibration three selections are necessary before

the new setting becomes effective.

7.8 First start-up of the vending

machine

Supply the vending machine (following the instructions

given previously) and plug it into the power supply (see

section "Power Grid Connection").

At this point the message “PHEDRA EVO” will appear on

the display and the self-diagnosis phase is activated to

check the correct positioning of the machine devices.

Any faults detected during the self-configuration cycle are

stored so that the vending machine can display them at the

end of the self diagnostic phase.

Carry out the grinder adjustment as indicated in the

instructions at section "Coffee Grinder Adjustment" after

refilling the water circuit.

7.9 Water circuit filling

At first VM start-up, the boiler is filled automatically.

7.9.1 Filling the boiler manually

After switching the vending machine on it is possible to fill

the boiler by activating the following procedure:

Procedure A

• press the P2 key to enter the maintenance menu;

• Enter the Maintenance/Washes menu and start the

automatic washing cycle;

Procedure B

• press the P2 key to enter the maintenance menu;

• Enter the Maintenance/ Boiler Refill menu and start the

automatic refill cycle;

The rinsing operation must

be repeated until water

flows out of the brewing

nozzles regularly.

7.10 Washing the Parts coming

into Contact with Food

Clean all the parts of the VM which are in contact with

foodstuffs.

• Thoroughly wash your hands.

• Prepare a chlorine-based, antibacterial disinfecting solution

(the products can be purchased at the chemist's) following

the concentrations indicated on the product.

• Remove all the product containers from the vending machine.

• Remove the container lids and product chutes. Immerse

all these parts in the previously prepared solution.

7.11 Use of the vending machine

The beverage selection modes are indicated in chapter

"Operation and Use".

Page 43

English

8

43

8 PROGRAMMING AND MAINTENANCE MENU

This section illustrates how

to set up or modify the

vending machine

programming and

maintenance settings.

Therefore it is necessary to

carefully read it and to

understand the exact

sequence of operations

before performing them.

8.1 Key description of programming

and maintenance phases

To scroll through the vending machine menu, the keys

described below are used.

“e” Key: ENTER

By pressing this key it is possible to enter the following

programming or maintenance level. It is also possible to

modify or confirm the values set in the entries of the

programming or maintenance menus.

“c” Key: CANCEL

By pressing this key it is possible to go back to the

previous level of the programming or maintenance menu.

It is also possible to avoid storing the previously modified

values.

“v” Key: DOWN

Pressing this key it is possible to access the previous entry

inside the same level. If used after a setting modification

request, the value of this setting decreases.

“^” Key: UP

By pressing this key it is possible to access the next entry

inside the same level. If used after requesting the change of

a setting, the value of this setting increases.

8.2 Programming Menu

The structure of the programming menu is indicated in

section "Structure of the Programming Menu".

The section "Description of Messages in the Programming

Menu" describes all the items in the programming menu.

8.2.1 Access to the Programming

Menu

Open the door, disable the safety device (see section

“Safety Devices”) and press the P1 key to enter the

programming menu.

If no password has been assigned, the programming menu

is entered directly.

Page 44

English

8

44

If a password was assigned

to the vending machine to

enable the programming

menu, the message

"PASSWORD 000000" will

appear on the display with

a flashing cursor on the

first digit.

Now the password should

be entered using the UP

and DOWN keys. Confirm

the digit entered by

pressing the ENTER key.

Proceed as follows to exit the programming menu and

return to standard operation of the vending machine:

• Press the CANCEL button repeatedly until "EXIT ?"

appears. Select YES and press ENTER;

• remove the key from the safety switch in order to turn off

the vending machine;

• close the door and wait for the self-configuration process

to end.

Page 45

English

8

45

8.2.2 Structure of the

Programming Menu

ITEM NO. MENU ITEM

1. SYSTEM MANAGEMENT

1.1. VM Code

1.2. Stops *

1.2.1. Stop coffee C

1.2.2. Stop Pre-ground *

1.2.3. Stop beverages

1.2.4. CofGrounds contr. *

1.2.5. Stop CofGrounds *

1.2.6. Reset

1.3. Water Filter *

1.3.1. Last filter change

1.3.2. Remaining qty

1.3.3. Filter limit

1.3.4. Filter reset

1.3.5. Filter enabled

1.4. Temp. Boilers

1.4.1. Boiler 1 temp.

1.4.1.1. Min. Temperature

1.4.1.2. Max. Temperature

1.4.2. Boiler 2 temp.

1.4.2.1. Temperature

1.5. Energy save

1.5.1. Stand-by timeout

1.5.2. Eco timeout

1.5.3. Delta temp. Eco

1.6. Rinsing cycle *

1.6.1. Automatic

1.6.2. Programmable

1.7. Steam Cleaning

1.7.1. Steam Cleaning Time

1.7.2. Enable Capp. Clean.

1.8. Preheating

1.8.1. Coffee Preheat.

1.8.1.1. Operation after(min)

1.8.1.2. Extra Coffee Dose

1.8.2. Cappuccino Preheat.

1.8.2.1. Extra Time

1.8.2.2. Warm-Up T-Out

1.9. EV Water Assign *

1.10. Clock *

1.10.1. Time *

1.10.2. Date *

1.10.3. Date/time format *

1.11. On/Off time *

1.11.1. On 1

1.11.2. Off 1

1.11.3. On 2

1.11.4. Off 2

1.12. Audit Msg. Enable *

1.13. Water compensation

1.13.1. Beans

1.14. Lighting Type

1.15. Grouping Powders

1.15.1. Enable

1.15.2. Grouping Powders

1.16. Pre-grinding

1.17. Display settings

1.17.1. Brightness

1.18. Pulse counter *

1.19. Multiple beverage *

1.19.1. Multiple beverage

1.19.2. Enable Mult. bev.

1.19.3. Free *

1.20. Enable reset *

1.21. Buttons *

1.21.1. Button P3 *

1.21.1.1. Free vend key *

1.21.1.2. Free or Test *

1.22. Set 1 Pre-Selection

1.23. Set 2 Pre-Selection

1.24. Programmable texts *

1.24.1. Dispensing

1.24.2. Out of service

1.24.3. Set1 Pre-selection

1.24.4. Set2 Pre-selection

1.24.5. Default messages

1.25. Audit Device

1.25.1. Protocol

1.25.2. EA1..2 (Events)

1.25.3. EA3..5 (Readouts)

1.25.4. LA1-Prices Lists

1.25.4.1. LA1 Normal Prices

1.25.4.2. LA1 Diff1 Prices

1.25.4.3. LA1 Diff2 Prices

1.25.4.4. LA1 Card Prices

1.25.4.5. LA1 Free

1.25.4.6. LA1 Test

1.25.5. PA - Products

1.25.5.1. PA2

1.25.5.2. PA7

1.25.6. VA1..3 Sales

1.25.7. BA1-CA15-Cash

1.25.8. DA1..7-CashLess

1.25.9. Quick Reading

1.25.10. Extended Time-outs

1.26.-5 Tube emptying time *

1.27. Change Password *

1.27.1. Password prog.

1.27.2. Service Password

1.28. Complete menus

1.29. Drip Tray warning

1.30. Default Menu *

1.30.1. Factory default

1.30.2. Custom Default

1.30.2.1. Read Custom Default

1.30.2.2. Write Custom Default

1.31. VM Model *

1.32. Language

1.33. System Info

2. PAYMENT SYSTEMS

2.1. Protocol

2.2. Coin validator

2.2.1. Enable

2.2.2.-9 Coin Values

2.3. Banknote validator

2.3.1. Enable

2.3.2. INHIBITION LEVEL

Page 46

English

8

46

ITEM NO. MENU ITEM

2.3.3.-6 Banknote Value

2.3.3.4. Banknote

2.4. MDB settings *

2.4.1. Recharge enabled

2.4.2. Max Card Recharge

2.4.3. Max Card Value

2.4.4.-8 Coins Enabling

2.4.5. Alt. payout

2.4.6. Max change

2.4.7. Exact change policy

2.4.8. Min Tube Level

2.4.9. Manual Tube Filling

2.4.10. Manual Tube Empty

2.4.11. Commit to vend

2.4.12.-2 Bill Enabling

2.4.13. Bill Escrow

2.4.14. MDB Slave Address

2.4.15. no change =no bills

2.5. Max credit

2.6. Multivend

2.7. Overpay Time

2.8. Fixed Zeroes *

2.9. Decimal Digits *

2.10. Credit Wdog *

2.11. Preselection

2.11.1. Pre-selection Time

2.12. Cash sale cmd sending

2.13. (EXE/PHD) safe mode

3. PRODUCT SETUP

3.1.-2 Product Before *

3.2. Beverage Enabling *

3.3. Beverage Preparation

3.3. Sequence

3.3. H2O / Coffee

3.3. Steam Duration

3.3. Freshbrew Water

3.3. Pre-ground Water

3.3. Fresh inst. time

3.3. Pre-gr.inst.time

3.3. Just water

3.3. % instant product #:

3.3. % pump #:

3.3. Instant prod. dose #:

3.3. Inst. prod. water #:

3.3. Beverage test

3.4. Prebrewing

3.4.1. Prebrewing [ml]

3.4.2. Pre-brew. pause[s/10]

3.5. Beverage interruption

3.6. Ingredient management

3.6.1. Enable

3.6.2. Read from USB KEY

3.6.3. Display

3.6.4. Write on USB KEY

4. SALE MANAGEMENT

4.1.-8 Price table

4.2. Beverage price

4.2.1. Normal

4.2.1.1. Global price

4.2.1.2. Single Prices

4.2.2. Differentiated 1 *

4.2.2.1. Global price

4.2.2.2. Single Prices

4.2.3. Differentiated 2 *

4.2.3.1. Global price

4.2.3.2. Single Prices

4.2.4. Card *

4.2.4.1. Card Prices

4.2.4.2. Global price

4.2.4.3. Single Prices

4.3. Free

4.4. Free On

4.5. Free Off

4.6. Diff Prices 1-On

4.7. Diff Prices 1-Off

4.8. Diff Prices 2-On

4.9. Diff Prices 2-Off

(*) = Visible only if complete menus are enabled.

Page 47

English

8

47

8.2.3 Description of Messages in the Programming Menu

DISPLAY Description

1. The SYSTEM MANAGEMENT items are:

SYSTEM MANAGEMENT

…

1.1. Enables an identification code to be assigned to the vending machine.

VM Code

531000

1.2.

Enables setting of the maximum amount of beverage or coffee.

Once the maximum amount is reached, the vending machine stops dispensing the relevant beverages.

The first digit on the left (“00000”) refers to the quantity of product dispensed since the last “RESET” (partial

counters).

The right hand digit, preceded by “LIM”, shows the maximum dispensable quantity (value may be modified).

Stops

…

1.2.1. Enables setting of the maximum number of coffee cups to be dispensed before the stop.

Stop coffee C

1.2.2.

It allows setting the maximum number of pre-ground product servings to be brewed before

stopping the pre-grinding.

Stop Pre-ground

1.2.3. Enables setting of the maximum number of beverages to be dispensed before the stop.

Stop beverages

1.2.4.

Enables or disables control of the number of grounds discharged into the coffee grounds drawer.

When set to “YES” the machine will allow a certain number of cups of coffee to be brewed before

requiring the drawer to be emptied (see “STOP COFGROUNDS”).

When set to “NO” the machine will not control the number of grounds discharged into the drawer.

CofGrounds contr.

1.2.5.

It allows you to set the maximum number of coffee cups to be brewed, corresponding to

maximum dump box capacity.

Once reached the set quantity, coffee-based beverages dispensing is stopped.

Five cups of coffee before the lock is engaged, a blinking message appears on the display,

“EMPTY COFGROUNDS”.

Important

This lock can be reset by removing the coffee grounds drawer for at least 10 seconds.

Suggested solutions

It is advisable to set a max. of 30 coffees when using the dump box supplied with the

machine.

Important

Do not set any stop value if you are using the machine together with the supporting cabinet,

which is equipped with its own dump box which is not controlled electronically.

Stop CofGrounds

1.2.6. Enables resetting of all partial counters relative to product quantity stop functions.

Reset

1.3. Allows the use of the water filter to be checked.

Water Filter

…

1.3.1. Date of the last filter reset.

Last filter change

31.01.2008

1.3.2.

Number of litres of water that can still be dispensed before the filter needs to be

regenerated.

When this value is less than 1, a Warning (W83) is recorded in the Error LOG.

Remaining qty

95

1.3.3. Number of litres of water that can still be dispensed from the filter.

Filter limit

100

Page 48

English

8

48

DISPLAY Description

1.3.4.

Select YES to indicate a new filter has been installed

This operation returns “Remaining Qty” to the same value as “Filter Limit” and the date in

the “Last Filter Change” is changed to today’s date.

Filter reset

1.3.5.

Enables management of the "Remaining Qty" countdown.

Important

From the maintenance menu (button P2 on the CPU), you can access "Water Filter", "Last

Filter Change", "Remaining Qty" and "Filter Reset".

Filter enabled

yes

1.4.

According to the model, the Phedra vending machine may be equipped with 1 or 2 boilers.

The following "BOILERS TABLE" matches the boilers with the vending machine models.

Temp. Boilers

1.4.1. This menu option allows setting the operating temperature of boiler 1.

Boiler 1 temp.

1.4.1.1.

It allows you to set the temperature that the vending machine keeps for a few minutes after

a beverage has been brewed.

The set value is expressed in centigrade.

Min. Temperature

00

1.4.1.2.

It allows you to assign the temperature to which the vending machine is brought after a

certain time from the last dispensing, so that the natural lowering of the temperature of the

hydraulic circuits can be compensated.

The set value is expressed in centigrade.

Max. Temperature

000

1.4.2. This menu option allows setting the operating temperature of boiler 2.

Boiler 2 temp.

1.4.2.1.

It allows you to set the temperature that the vending machine keeps for a few minutes after

a beverage has been brewed.

The set value is expressed in centigrade.

Temperature

00

1.5.

The “Stand-by” and “ECO” modes allow reducing the energy consumption of the machine.

It is possible to select one or both modes.

Energy save

…

1.5.1.

The “Stand-by” mode is activated after some minutes of inactivity which can be set by

means of this menu option. By setting it to zero the function is disabled.

When the "Stand-by" mode is activated the coffee and steam boilers are off and the display

shows the message "Stand by".

To exit the “Stand-by” mode, press any button or insert some credit.

When normal operation is restored, the boilers are turned on and the vending machine

starts the warm-up phase.

Stand-by timeout

1.5.2.

The “ECO” mode is activated after some minutes of inactivity which can be set by means of

this menu option. By setting it to zero the function is disabled.

In “ECO” mode, the target temperature of the boiler is reduced by a preset value (see the

following menu option).

The vending machine remains in its “Ready” status and no message is shown to the user.

To exit the "ECO" mode, press any button or insert some credit.

When "ECO" mode is deactivated, the target temperature for boiler 2 is restored and the

machine starts the warm-up phase.

Eco timeout

1.5.3.

Allows to set by how many °C the steam boiler temperature must be reduced during the

“ECO mode” phase.

Delta temp. Eco

1.6. It allows enabling of the automatic rinsing of the mixing bowls.

Rinsing cycle

yes

1.6.1.

The automatic rinsing is performed as follows: the first rinsing takes place 10 minutes after

the “machine ready” status; if necessary, other rinses occur 7 hours after the last dispensing.

Automatic

Page 49

English

8

49

DISPLAY Description

1.6.2.

Programmable

1.7.

In case the steam circuit remains inactive for some hours (to be set under the option

“Steam Cleaning Time”) the vending machine will not allow brewing any beverages with

steam (under the letter “S” in the product list) unless a cleaning cycle is activated.

The message “NO Cappuccino” will be displayed (by setting the number of hours to zero

the cleaning message and the stop status will be disabled).

The cycle can be activated in the “Maintenance” menu as well as during normal operation of

the machine through the user cycle.

Activation using the menu:

Select the option “Steam Cleaning“ in the “Maintenance” menu.

Activation during normal operation:

The machine must comply with the following:

1 - Vending machine in its “Ready” status.

2 - No brewing in progress.

3 - Option “Enable Steam Wash” in the “System Management” menu enabled.

To activate the cycle simply press the buttons corresponding to beverages 4 and 8

simultaneously.

Cycle description:

The cycle operation is independent from the activation mode (no matter if started or not

from the “Maintenance” menu) and it consists of two phases: the “Wash Cycle” and “Rinse

Cycle”.

During the first phase, a display message will request to pour the mix of water and cleaning

solution (about 400 gr of water and Saeco compound).

Simultaneously press the buttons corresponding to beverages 4 and 8 to start the “Wash

Cycle”.

This phase will last 75 seconds, then the machine will pass to the following one.

During the second phase, a display message will request to insert only the water container

(about 400 gr of water).

Simultaneously press the buttons corresponding to beverages 4 and 8 to start the “Rinse

Cycle”.

This cycle will last 75 seconds.

At the end of this procedure, the cleaning cycle will be considered as completed and the

Cappuccinatore as cleaned, thus enabling brewing beverages with milk.

Steam Cleaning

1.7.1.

It refers to the circuit of the Cappuccinatore: it allows setting the interval (in hours) after

which a cleaning cycle of the circuit is requested.

Steam Cleaning Time

1.7.2.

If set on YES, it allows starting the cleaning cycle by simultaneously pressing the two

beverage buttons 4 and 8.

This allows executing a cleaning cycle on the circuit of the Cappuccinatore without the need

to open the machine.

Enable Capp. Clean.

1.8.

Allows setting timing and amounts for preheating and precooling for instant product circuits

and for the coffee brew group.

Preheating

00

1.8.1. Settings for the preheating cycle of the brew group.

Coffee Preheat.

1.8.1.1.

Time (expressed in minutes) of brew group inactivity after which the group starts

preheating.

By setting it to 0, the preheating is disabled.

Operation after(min)

1.8.1.2.

Increase in the water dose (in ml) for the first coffee (by first coffee we understand the

coffee for which the preheating of the brew group is activated).

Extra Coffee Dose

1.8.2.

It refers to the circuit of the Cappuccinatore: it allows setting the minutes of inactivity after

which a preheating cycle is requested before dispensing steam (by setting this value to zero

the preheating cycle is disabled).

This cycle improves the operation of the Cappuccinatore after a long period of inactivity.

Cappuccino Preheat.

00

Page 50

English

8

50

DISPLAY Description

1.8.2.1.

Extra time (in tenths of seconds) for steam dispensing applied in case the circuit is cold, since

a reduced quantity of milk is dispensed in this case.

Extra Time

00

1.8.2.2.

It determines the delay time (in minutes) after which the preheating of the Cappuccinatore

is enabled.

Warm-Up T-Out

00

1.9.

By setting the “W” value in the product list, hot water will be dispensed.

This menu allows choosing the solenoid valve to be used for dispensing

If the “hot water solenoid valve” kit is installed, set the value to 0 (zero) or select the

solenoid valve operating on the desired circuit among the available ones.

EV Water Assign

…

1.10. Enables setting of the hour, minute, day of the week, day of the month, month and year.

Clock

…

1.10.1.

Time

08:00

1.10.2.

Date

1.10.3. Enables date and time display in US format - enables temperature display in °F

Date/time format

1.11.

Allows setting the vending machine’s automatic on and off time ranges over the course of a

week.

On/Off time

…

1.11.1.

On 1

00:00

1.11.2.

Off 1

00:00

1.11.3.

On 2

00:00

1.11.4.

Off 2

00:00

1.12.

It allows displaying for a few seconds the selection counters (total and since last reset)

during the machine start-up phase.

Audit Msg. Enable

Page 51

English

8

51

DISPLAY Description

1.13.

Water compensation for coffee beverages.

The exact quantity of water dispensed by each machine depends on the construction

tolerances of each water circuit component (pump, flowmeter, tubes, etc.).

This menu allows you to set a correction "evening out" these differences so that the end

result in the cup is always the same even if the machine is different.

During manufacturing, the optimum value is calculated and stored for each vending machine.

If a FACTORY DEFAULT is carried out or the CPU board is replaced, you need to reset

the correct value by following the simple instructions here below:

• Set the water for the COFFEE beverage = 30

• Dispense 3 beverages, checking their weight and calculating the rounded-up mean value

• If the result obtained is higher or lower than 30, the excess/default value must be

subtracted/added from/to the value set by default

EXAMPLE:

BEVERAGE 1 SEQUENCE 000C

COFFEE WATER = 30

Coffee 1 = 32 g

Coffee 2 = 35 g

Coffee 3 = 28 g

Work out the mean:

32 + 35 +28 = 95 -> 95/3 = 31.6

In this case, 31.6 being the obtained value, the machine is dispensing more water than the

set amount, so you will need to subtract 2 from the value set in the BEANS

COMPENSATION menu

If the mean value obtained were 28, you should add 2 to the value set in the BEANS

COMPENSATION menu

Water compensation

1.13.1. Allows you to select the water compensation for products made from coffee beans

Beans

1.14.

It allows selecting the lighting mode of the dispensing outlet.

The options are:

Never, Always, beverage dispensing, beverage end.

Lighting Type

1.15.

It enables creating a group of 2 instant product containers.

The groups of containers can be used when a higher capacity of instant powder is required for a particular product

(e.g. when chocolate is largely used in a certain location, 2 chocolate powder containers can be dedicated

accordingly).

The machine software will be responsible for alternatively starting the two powder motors, to guarantee equal

product consumption in the 2 containers.

To use the instant product groups proceed as follows:

enter the System Management through the Groups option

enable groups management

select the pair of containers you would like to group together

programme the beverage recipe by introducing one of the 2 instant products that have been grouped.

Grouping Powders

1.15.1. Enables the instant product containers groups

Enable

1.15.2. Choosing the powder motor pair to be grouped together

Grouping Powders

1.16. Enables instant pre-grinding of the coffee dose.

Pre-grinding

yes

1.17. Display settings

Display settings

Page 52

English

8

52

DISPLAY Description

1.17.1. It allows adjusting the display brightness.

Brightness

1.18.

Enables selection of whether the 24 V dc electromechanical pulse counter (optional - to be

connected to the CPU card) has to count the coffees or all dispensed beverages.

Pulse counter

Coffee

1.19.

Allows selecting which beverages will be enabled for multiple brewing and the number of

brewings.

Multiple beverage

…

1.19.1. number of brewing procedures for multiple brewing

Multiple beverage

000

1.19.2. Allows selecting which beverages will be enabled for multiple brewing

Enable Mult. bev.

1.19.3. enables the free-of-charge dispensing of the multi beverage

Free

1.20. It allows enabling of the “RESET” for data in the statistics maintenance menu.

Enable reset

no

1.21. button settings

Buttons

…

1.21.1. Menu for setting the function of the P3 button

Button P3

no

1.21.1.1. Allows you to enable the P3 button on the CPU board during normal operation.

Free vend key

no

1.21.1.2.

Allows you to choose whether to associate the P3 button on the CPU board to free

product dispensing or to test product dispensing

Free or Test

1.22.

The function connected to the button may be chosen from the following options:

A. Beverage 5

B. Set 1 Pre-selection

C. Disabled

A - Beverage button 5:

this is the default function.

Button 9 functions as a regular button.

B - Set 1 pre-selection: by choosing this function, the button becomes a pre-selection button for the 9-16 beverage

set.

When pressed, the vending machine shows the pre-selection message on the display (“ DECAFF ” as default) and

makes the new beverage group available.

C Disabled: pressing the key has no effect.

Set 1 Pre-Selection

…

1.23.

The function connected to the button may be chosen from the following options:

A. Beverage 6

B. Set 2 Pre-selection

A - Beverage button 10:

this is the default function.

Button 6 functions as a regular button.

B - Set 2 pre-selection: by choosing this function, the button becomes a pre-selection button

for the 17-24 beverage set.

When pressed, the vending machine shows the pre-selection message on the display (“

BARLEY ” as default) and makes the new beverage group available.

Set 2 Pre-Selection

…

1.24.

Programmable texts

…

Page 53

English

8

53

DISPLAY Description

1.24.1.

it allows setting the message appearing on the display when the vending machine is

dispensing a product.

Dispensing

1.24.2. It enables setting the text on the display when the vending machine stops due to a fault.

Out of service

1.24.3.

Allows you to set the message appearing on the display when the pre-selection mode of

button 5 is activated for beverages 9-16.

Set1 Pre-selection

1.24.4.

Allows you to set the message appearing on the display when the pre-selection mode of

button 6 is activated for beverages 17-24.

Set2 Pre-selection

1.24.5.

It allows bringing the programmable messages back to their pre-set default value (this is

useful when changing the language is required).

Default messages

1.25.

It allows selecting the protocol to be used for transferring data from the VMC (DDCMP o

DEX) and which data category has to be transferred during an audit session.

Audit Device

…

1.25.1.

Protocol

1.25.2.

EA1..2 (Events)

1.25.3.

EA3..5 (Readouts)

1.25.4.

LA1-Prices Lists

1.25.4.1.

LA1 Normal Prices

1.25.4.2.

LA1 Diff1 Prices

1.25.4.3.

LA1 Diff2 Prices

1.25.4.4.

LA1 Card Prices

1.25.4.5.

LA1 Free

1.25.4.6.

LA1 Test

1.25.5.

PA - Products

1.25.5.1.

PA2

1.25.5.2.

PA7

Page 54

English

8

54

DISPLAY Description

1.25.6.

VA1..3 Sales

1.25.7.

BA1-CA15-Cash

1.25.8.

DA1..7-CashLess

1.25.9. Delete value = 0 data from EVA-DTS report

Quick Reading

1.25.10. Prolongation of response waiting time from EVA-DTS data players

Extended Time-outs

1.26.-5

Allows setting a delay between the end of beverage preparation and the display of the

"Remove cup" message to the user.

Such delay is necessary to allow a complete drainage of the liquid in the dispensing tubes.

Tube emptying time

1/5

1.27.

Enables setting of a password or modification of the current one.

The password consists of a number between 000001 and 999999.

The 0000 value (default value) means no password.

To set the password, press the UP and DOWN keys and confirm using the ENTER key.

Change Password

1.27.1. Allows setting a password to access the programming menu.

Password prog.

1.27.2.

Allows setting a password to access the maintenance menu.

Important

If the password is lost, you will have to contact the Saeco Vending Technical Assistance

Service to regain access to the Programming Menus.

Service Password

1.28.

Enables selection of whether the entries of the programming menu should be shown fully or

only partially.

Complete menus

1.29.

It allows to select the VM's operation in case the sensor detects that the maximum level in

the drip tray has been exceeded.

Machine block:

the VM does not allow to dispense beverages if the tray is full;

Message Only:

a display message is shown but it is possible to dispense beverages (WARNING failure to

empty the tray can lead to water coming out from the machine);

DISABLED: the sensor is not being used (WARNING failure to empty the tray can lead to

water coming out from the machine);

Drip Tray warning

1.30.

Management of default values for machine configurations.

The user can create and recall his own configuration.

Default Menu

1.30.1.

It allows reverting the programmable parameters to factory preset values.

This operation does not reset the product counter.

Factory default

1.30.2. Management of the configuration which has been created by the user

Custom Default

1.30.2.1. Restoring the configuration which has been saved by the user on the machine

Read Custom Default

1.30.2.2. Saving the user machine configuration

Write Custom Default

Page 55

English

8

55

DISPLAY Description

1.31.

It allows selecting the current model of the vending machine.

The vending machine model is specified on the label located inside the right side panel.

VM Model

1.32.

It allows to select the language to be used by the machine.

The available languages are:

Italian, English, French, German, Spanish, Portuguese, Dutch, Turkish, Russian, Polish,

Norwegian, Swedish, Finnish and Danish.

The machine texts can be modified according to the user’s needs to add new languages not

included in the default list.

(Contact the Customer Service for any information).

Language

1.33.

"This option allows you to access a page showing the overall machine configuration.

The display shows the following information:

First line: sw version (""x.yy.zz"" format) / program CRC (""abcd"" format)

Example: ""'SW v1.02.12/087c""

Second line: Boot loader version (""xx"" format) and name of the file searched for by the

boot loader on the USB key ("".s19"" extension not displayed)

Example: ""Boot 08SAE_DA5P""

Third line: memory version (""xxx.yyy."" format) and content CRC (""zzz"" format)

Example: ""Mem 123.456.789"""

System Info

2. The entries of the PAYMENT SYSTEMS are:

PAYMENT SYSTEMS

…

2.1.

Protocol

2.2.

Allows enabling of the parameters of the parallel coiner, the mechanical coiner, the

cancelling machine and the choice of values to be assigned to the single money channels.

Coin validator

…

2.2.1.

By setting "Y", the parallel coiner, the mechanical coiner and the cancelling machine control

are enabled.

If set on "N", the parallel coiner (if any) connected to the vending machine will be excluded.

Enable

no

2.2.2.-9

It allows you to set the value of the coins forwarded to the vending machine by the parallel

coiner, the mechanical coiner and the punching machine.

The following "PAIRING TABLE" indicates how channels and related payment systems are

connected to each other.

Coin Values

0.00

2.3.

It enables the parameters of the parallel banknote validator and the choice of values to be

assigned to single banknote channels.

Banknote validator

…

2.3.1.

By setting “Y”, the management of the parallel reader is enabled.

By setting “N”, a parallel reader which may be connected to the vending machine is always

disabled.

Enable

no

2.3.2. Enables setting of the active level of the banknote reader inhibition signal.

INHIBITION LEVEL

255

2.3.3.-6

Enables setting of the value of banknotes transferred to the vending machine from the

parallel reader.

Banknote Value

…

2.3.3.4.

Banknote

2.4. Enables access to particular functions of the MDB protocol.

MDB settings

…

2.4.1.

It allows disabling or enabling the possibility of performing any Saeco Card recharge operation

By setting RECHARGE = NO the vending machine will only deduct the cost from MDB cards.

Recharge enabled

no

Page 56

English

8

56

DISPLAY Description

2.4.2.

Enables setting of the maximum credit level, beyond which all recharge operations (if

enabled) are ineffective.

By setting MAX RECHARGE = 20.00, the credit on the vending machine will be transferred

to the card if the sum does not exceed 20.00.

Max Card Recharge

10.00

2.4.3.

It enables to set the maximum credit level, beyond which the card is rejected by the system.

By setting MAX CARD VALUE = 25.00, the vending machine will reject all cards with a credit which

exceeds this amount.

If this card is detected, the display will not show the credit but a “ ——” message will be displayed

and no sale will be carried out.

Max Card Value

10.00

2.4.4.-8

Coins Enabling

…

2.4.5.

It enables / disables the use of Alternative Payout for the level 3 MDB change-giving coiner.

By setting "Yes" the change-giver is called on to dispense change.

Change is limited to 255 times the scaling factor (typically € 12.75 for the Euro area - with scaling factor of 5).

By setting “No” change is given by exploiting the machine’s algorithm.

Max. change is 60000 units (typically € 600 for the Euro area).

Alt. payout

no

2.4.6.

Enables setting of the maximum amount of change which can be dispensed by the

change-giving coiner.

Default = 10.00.

Max change

0.00

2.4.7.

With MDB coin return, the "no change available" status can be selected through the "CHANGE TABLE".

Note

Even if the no change available message is displayed, the vending machine continues to give change as long as

coins are present in the channels.

The minimum level (the same for all channels) can be set on a special menu item.

Exact change policy

0

2.4.8.

Enables setting of the minimum number of coins in the channels.

Default = 4.

Min Tube Level

0

2.4.9.

Allows the coin return tubes to be filled by hand.

Press Esc to exit the channel loading mode.

Manual Tube Filling

…

2.4.10.

Allows the change-giving coiner channels to be emptied by pressing the beverage selection

keys.

Manual Tube Empty

…

2.4.11.

By setting “N”, the credit inserted can be returned even if no sale has been made.

This function may be useful, for example, for changing banknotes into coins.

By setting “Y”, the credit inserted can be returned as change only after the sale has been

completed.

Default = YES.

Commit to vend

no

2.4.12.-2

Bill Enabling

…

2.4.13.

By setting “Y”, an inserted banknote is stored in the escrow position by the banknote reader

(if supported); this function is supported by the banknote reader.

In this way, if the sale fails or the card system fails to charge, the banknote will be returned.

By setting “N”, any inserted banknote goes to the banknote reader’s stacker, so that the

banknotes cannot be returned.

Default = No.

Bill Escrow

no

2.4.14.

When the vending machine is in Master mode, this menu enables setting of the address of any slave connected

vending machine.

If the vending machine is in Slave mode, it enables setting of its address.

Possible addresses are 0x40, 0x48 and 0x50.

Default = 0x40.

MDB Slave Address

0x40

Page 57

English

8

57

DISPLAY Description

2.4.15. Allows you to disable the bill reader if there is no change.

no change =no bills

…

2.5.

It allows the user to set the maximum credit which can be accepted by the vending machine.

Once this limit has been reached, the payment systems are disabled so that no more credit can be

accepted.

Default = 20.00.

Max credit

255

2.6. Enables the user to use any residual credit to purchase other beverages.

Multivend

no

2.7.

By setting “N” (no), the residual credit will be collected by the vending machine.

It establishes the maximum time (expressed in seconds) beyond which the vending machine collects the displayed

residual credit.

The time is adjustable at intervals of 10 seconds.

Setting “000” the function is disabled.

Overpay Time

180

2.8. Enables setting of the number of fixed zeros of the credit.

Fixed Zeroes

0

2.9. Enables setting of the position of the decimal point of the credit.

Decimal Digits

0

2.10.