Page 1

Automatic drink vending machine

Model

PHEDRA

Type: D.A. 5P07

WARNING: This instruction manual is intended exclusively for specialized personnel.

USE AND MAINTENANCE

Page 2

English

2

CONTENTS

CONTENTS ............................................. 2

MAIN PARTS - ESPRESSO VERSION .......... 3

MAIN PARTS - INSTANT VERSION ............ 5

MAIN PARTS - T.T.T. VERSION .................. 7

MAIN PARTS - CAPPUCCINO VERSION .... 9

1 - INTRODUCTION TO THE MANUAL ... 11

1.1 Introduction ...................................................11

1.2 Symbols used ................................................11

2 -

INFORMATION ON THE VENDING MACHINE

... 11

2.1 Information for the Maintenance Technician ..... 11

2.2 Description and intended use..........................12

2.3 Vending Machine Identification ......................12

2.4. Technical specifications .................................13

3 SAFETY ............................................ 13

3.1 Introduction ...................................................13

3.2 General safety regulations .............................. 13

3.3 Operators’ requirements ................................14

3.4 Safety devices ...............................................14

3.5 Residual risks ................................................15

4 - HANDLING AND STORAGE ............. 15

4.1 Unloading and handling ................................15

4.2 Storage ........................................................15

5 - INSTALLATION ............................... 15

5.1 Important ...................................................... 15

5.2 Unpacking and positioning ............................16

5.3 Label application ........................................... 16

5.4 Fitting the payment systems ............................17

5.5 Connection to water mains .............................18

5.6 Connection to the electric network ...................18

5.7 Coffee Grounds Discharge Setting ..................19

5.8 Liquid Drain Setting ....................................... 19

5.9 Drip Tray Locking .......................................... 20

5.10 Front Door Intermediate Locking .....................20

6 - CONTROLS DESCRIPTION ............... 21

6.1 Display .........................................................21

6.2 Keypad ......................................................... 21

6.3 Key description in standard operation mode ....21

6.4 CPU card keys ............................................... 21

7 - SUPPLY AND STARTING UP ............ 22

7.1 Container supply (Espresso) ............................ 22

7.2 Container supply (Instant) ...............................22

7.3 Container supply (T.T.T.) ................................23

7.4 Container supply

(Cappuccino) ......................... 23

7.4.1 Coffee bean supply ............................................ 24

7.4.2 Instant product supply .......................................... 24

7.5 Coffee grinding calibration ............................25

7.6 Dose calibration ............................................25

7.7 First start-up of the vending machine ............... 26

7.8 Filling the boiler manually .............................. 26

7.9 Use of the vending machine ...........................26

8 - PROGRAMMING AND MAINTENANCE

MENU ........................................... 27

8.1 Key description of programming and

maintenance phases ......................................27

8.2 Programming menu .......................................27

8.2.1 Entering the programming menu ............................27

8.2.2 Structure of the programming menu ........................28

8.2.3 Description of messages in the programming menu ... 29

8.3 Maintenance menu ........................................41

8.3.1 Entering the maintenance menu ............................. 41

8.3.2 Structure of the maintenance menu ......................... 41

8.3.3 Description of messages in the maintenance menu ....41

8.4

Machine Ready/Free Button ................................. 43

8.5 Reset ............................................................43

9 - OPERATION AND USE .................... 44

9.1 Beverage selection ........................................ 44

9.2 Cappuccino with cold milk function

(only for Cappuccino version) ......................... 44

10 - CLEANING AND MAINTENANCE ..... 44

10.1 General notes for correct operation ................. 45

10.2 Cleaning and scheduled maintenance .............45

10.2.1 Maintenance schedule ........................................45

10.2.2 Cleaning the Drip Tray and the Coffee Grounds

Drawer .............................................................45

10.2.3

Cleaning the tray and drawer - Version with extension

...45

10.2.4 Cleaning of the coffee brew group ........................ 46

10.2.5 Cleaning the dispensing arm ................................ 46

10.2.6

Cleaning the instant product dispenser and the mixer

... 47

10.2.7 Cleaning the containers ....................................... 48

10.2.8 Cleaning the coffee grinder .................................. 48

10.2.9

Semi-automatic cleaning of the Cappuccinatore

(only for Cappuccino version) ................................49

10.2.10

Manual cleaning of the Cappuccinatore

(only for Cappuccino version) ...............................50

10.3 Software Update ...........................................51

11 - DISPLAY MESSAGES ....................... 52

11.1 Messages during operation ............................52

11.2 Error messages ..............................................52

12 - STORAGE - DISPOSAL .................... 54

12.1 Change of location ........................................54

12.2 Inactivity and storage periods .........................54

13 - INSTRUCTIONS FOR END-OF-LIFE DI-

SPOSAL TREATMENT ...................... 54

Page 3

English

3

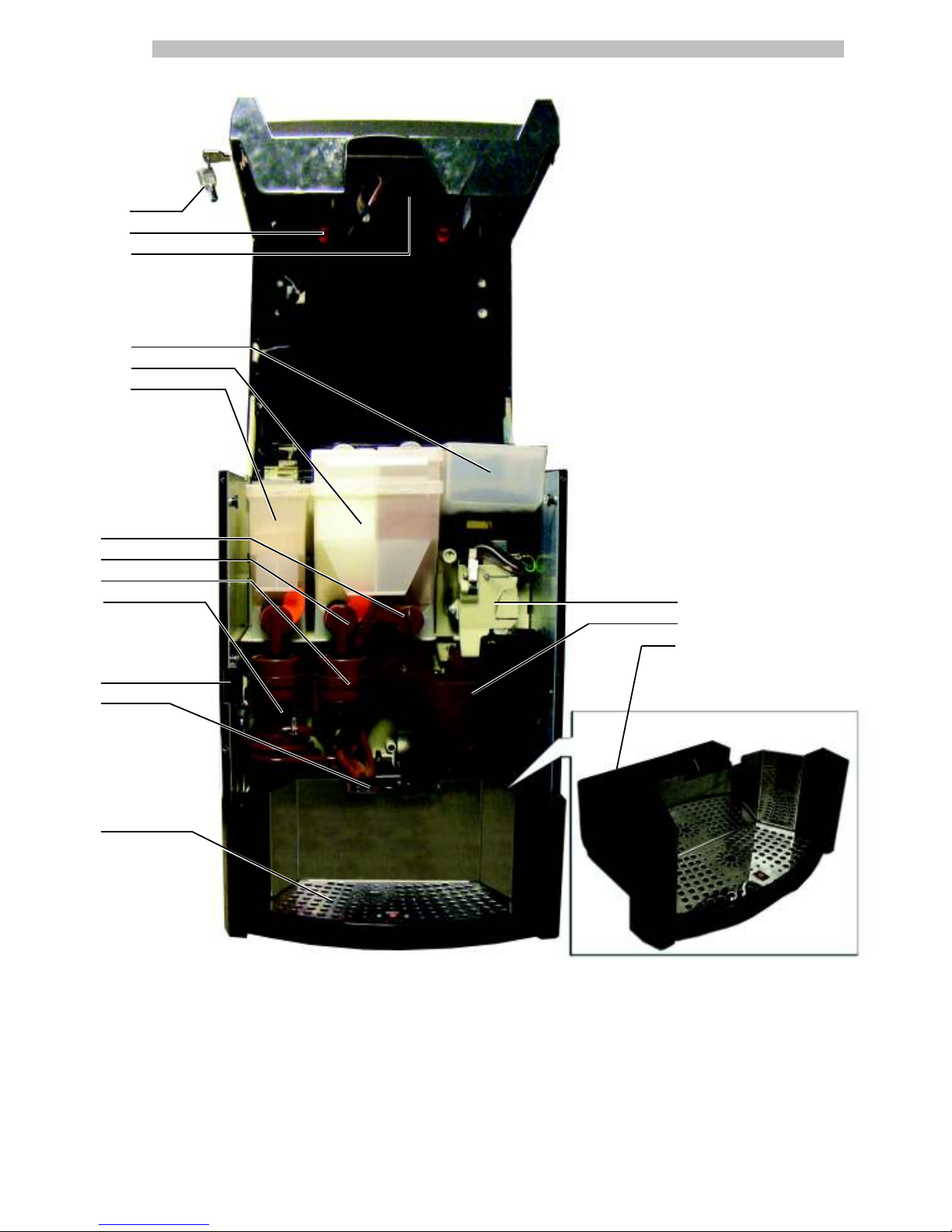

MAIN PARTS - ESPRESSO VERSION

1

2

3

4

5

6

7

Fig. 2

1 Top door

2 Display

3 Front door

4 Buttons

5 Dispensing outlet (beverage dispensing)

6 Coupling for connection to water network

7 Power cord outlet

Fig. 1

Page 4

English

4

8 Door lock

9 Front door fastener knob

10 CPU electronic board

11 Coffee bean hopper

12 Container 2/3 (instant products)

13 Container 1 (instant products)

14 Adjustable powder dispensing channel

15 Instant product dispenser

16 Mixer

17 Spiral mixer

18 Safety switch

19 Brewing arm

20 Coffee grounds drawer

21 Grill

22 Coffee grinder

23 Brew group

22

23

8

9

10

11

12

13

14

15

16

17

18

19

21

Fig. 3

20

Page 5

English

5

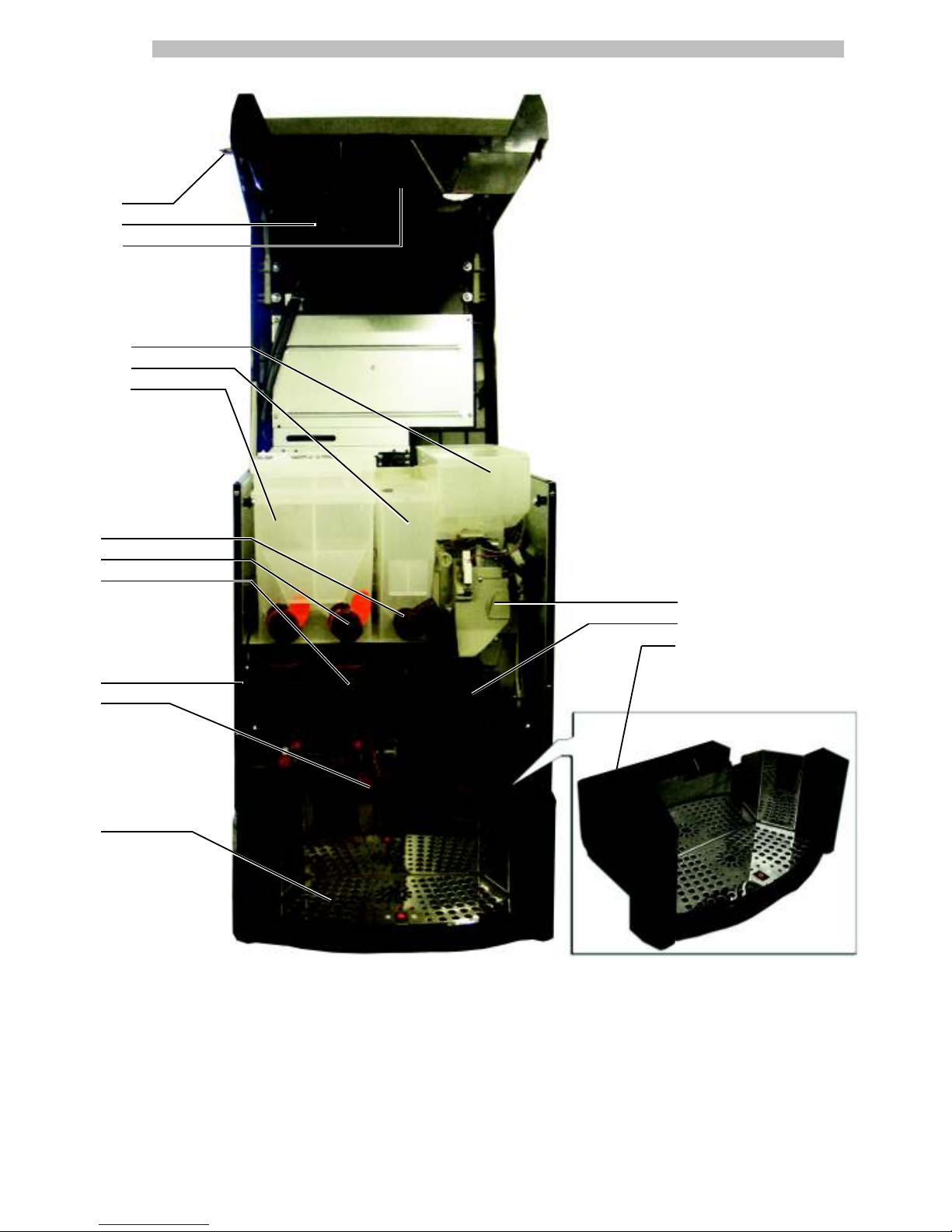

MAIN PARTS - INSTANT VERSION

6

7

Fig. 1

1 Top door

2 Display

3 Front door

4 Buttons

5

Dispensing outlet (beverage dispensing)

6

Coupling for connection to water network

7 Power cord outlet

24 Extension (option)

1

2

3

4

5

Fig. 2

24

Page 6

English

6

8 Door lock

9 Front door fastener knob

10 CPU electronic board

12 Container 2/3 (instant products)

13 Container 1 (instant products)

14 Adjustable powder dispensing channel

15 Instant product dispenser

16 Mixer

18 Safety switch

19 Brewing arm

20 Coffee grounds drawer

21 Grill

25 Container 5 (instant products)

26 Container 4 (instant products)

27 Grill for extension (option)

28 Powder diverter for small-type containers

29 Coffee grounds drawer (option)

30 Drip conveyor (option)

31 Drip tray (option)

28

8

9

10

25

26

12

13

14

15

16

18

19

21

27

20

29

30

31

Fig. 3

Page 7

English

7

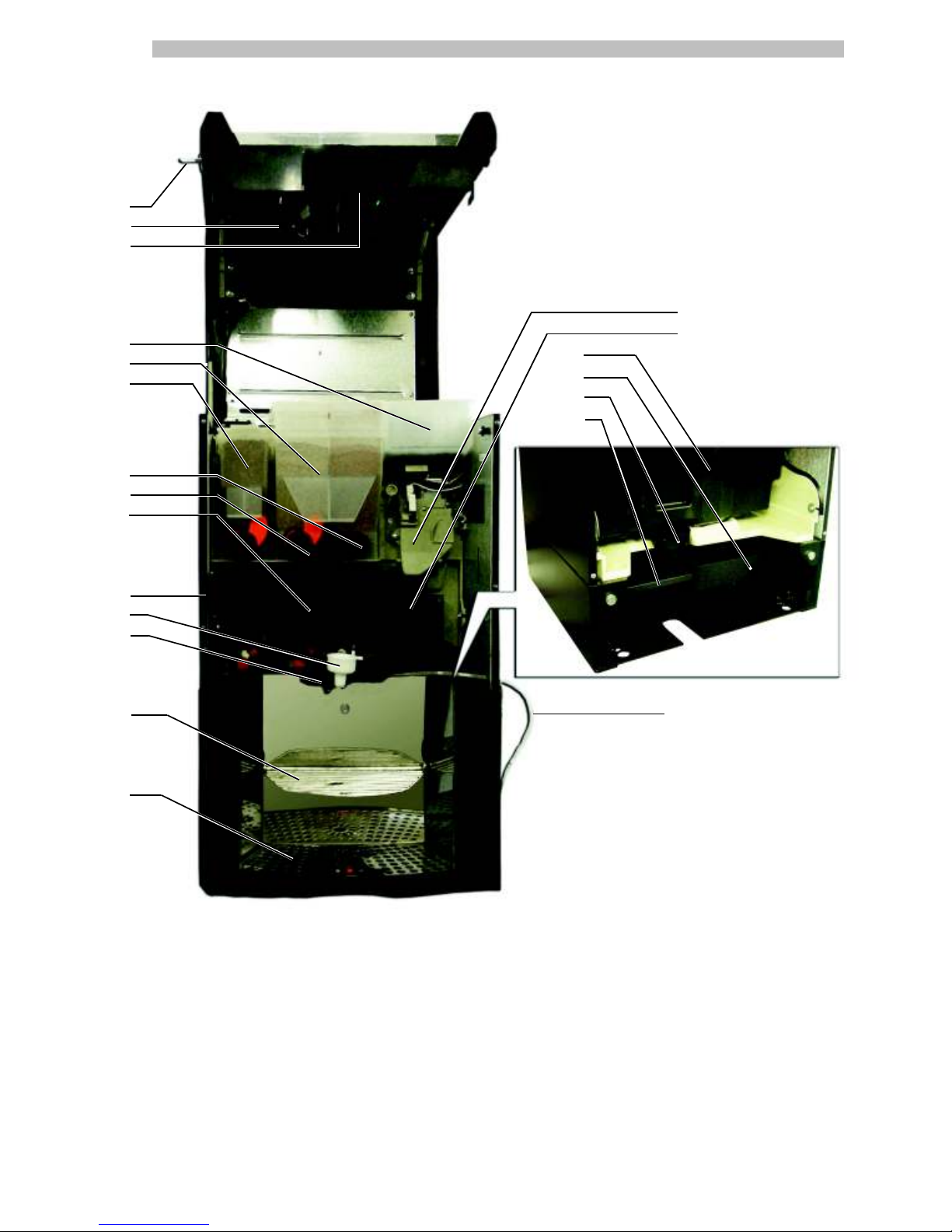

MAIN PARTS - T.T.T. VERSION

6

7

Fig. 1

Fig. 2

1 Top door

2 Display

3 Front door

4 Buttons

5

Dispensing outlet (beverage dispensing)

6

Coupling for connection to water network

7 Power cord outlet

1

2

3

4

5

Page 8

English

8

8 Door lock

9 Front door fastener knob

10 CPU electronic board

11 Coffee bean hopper

12 Container 1/2 (instant products)

14 Adjustable powder dispensing channel

15 Instant product dispenser

16 Mixer

18 Safety switch

19 Brewing arm

20 Coffee grounds drawer

21 Grill

22 Coffee grinder

32 Container 3 (“fresh brew” pre-ground coffee)

33 T.T.T. Brew group

22

33

8

9

10

11

32

12

14

15

16

18

19

21

Fig. 3

20

Page 9

English

9

MAIN PARTS - CAPPUCCINO VERSION

6

7

Fig. 1

1 Top door

2 Display

3 Front door

4 Buttons

5

Dispensing outlet (beverage dispensing)

6

Coupling for connection to water network

7 Power cord outlet

24 Extension (option)

1

2

3

4

5

Fig. 2

24

Page 10

English

10

8 Door lock

9 Front door fastener knob

10 CPU electronic board

11 Coffee bean hopper

12 Container 2/3 (instant products)

13 Container 1 (instant products)

14 Adjustable powder dispensing channel

15 Instant product dispenser

16 Mixer

18 Safety switch

19 Brewing arm

20 Coffee grounds drawer

21 Grill

22 Coffee grinder

23 Brew group

27

Grill for extension (option)

29 Coffee grounds drawer (option)

30 Drip conveyor (option)

31 Drip tray (option)

34 Cappuccinatore

35 Hose for Cappuccinatore

8

9

10

11

12

13

14

15

16

18

34

19

21

27

20

29

30

31

Fig. 3

22

23

35

Page 11

English

11

User

Indicates the user of the vending machine. This person is

not authorized to carry out any cleaning or maintenance

operation.

Supply operator

Indicates operations to be carried out only by personnel in

charge of supplying and cleaning the vending machine.

Maintenance operations requiring a Maintenance Technician

are not to be performed by the supply operator.

Maintenance Technician

Indicates operations to be carried out by qualified personnel

in charge of maintenance.

The Maintenance Technician is the only person authorized

to keep the MICROSWITCH ENABLING KEY, by which the

security systems can be disabled.

2 - INFORMATION ON THE

VENDING MACHINE

2.1 Information for the

Maintenance Technician

The vending machine must be installed in a well-lit, dry and

not dusty area, protected from exposure.

To guarantee the correct operation and reliability over time,

the following is recommended:

- ambient temperature: from +1°C to +32°C;

- maximum humidity: 90% (not condensed).

For special installations not covered in this publication,

please contact the dealer or the local importer. If this is not

possible, please contact the Manufacturer directly.

AUTHORIZED CUSTOMER SERVICE CENTRES are available

for information and explanations about the vending machine,

and to provide technical assistance or spare parts.

The Maintenance Technician must carefully read and respect

the safety warnings contained in this manual so that every

intervention concerning installation, starting up, use and

maintenance will be safely carried out.

It is the Maintenance Technician’s absolute responsibility to

give the keys to access the inside of the vending machine

to another operator (Supply Operator), provided that the

Maintenance Technician bears full responsibility for all work

carried out.

This manual is an integral part of the machine and must be

always read carefully before performing any operation.

1 - INTRODUCTION TO THE

MANUAL

1.1 Introduction

Important

This publication is an integral part of the vending machine and

must be read carefully to ensure the machine is used correctly

and in compliance with essential safety requirements.

This manual contains the technical information required for

the correct use, installation, cleaning, and maintenance of

the vending machine model PHEDRA. Always refer to this

publication before carrying out any operation.

Manufacturer: SAECO Vending S.p.A.

Località Casona, 1066 - 40041 Gaggio Montano

Bologna, Italy

This publication should be kept carefully, together with the

vending machine throughout its operational life, even in case

of changes of ownership.

Should this manual be lost or worn out, a copy can be

requested from the Manufacturer or an Authorized Customer

Service Centre by indicating all data on the identification

plate on the back of the vending machine.

1.2 Symbols used

This publication contains various warnings which indicate

different degrees of danger or skills required.

The symbol is integrated with a message suggesting use

procedures or actions and providing useful information for

the correct operation of the machine.

Warning

Indicates dangerous situations for the users, supply operators

and maintenance technicians dealing either with the vending

machine or the product to be dispensed.

Important

Indicates the operations for keeping the vending machine in

good working order.

Recommended solutions

Indicates alternative procedures that make the programming

and/or maintenance operations quicker.

Page 12

English

12

2.2 Description and intended

use

The vending machine is intended for automatic distribution of

coffee and hot beverages (decaffeinated coffee, cappuccino,

chocolate, etc.) and is programmable for every single type of

dispensing dosage. The instant products must be consumed

immediately, and cannot be preserved for a long time.

Any other use is to be considered improper and therefore

dangerous.

Do not place any product inside the distributor which may

be dangerous as a result of unsuitable temperatures.

With reference to the definition of “professional appliance” given by the

standard EN60335-2-75 for vending machines, this appliance can not be

classed as professional.

Important

Improper use of the vending machine invalidates all warranties.

The Manufacturer declines any liability for damage to property

or injury to persons.

Improper use also includes:

- any use of the vending machine other than the intended use

and/or according to procedures which are not described

in this publication;

- any intervention on the vending machine which differs from

the instructions given in this publication;

- any alteration of components and/or safety devices

without prior consent of the Manufacturer or carried out

by personnel not authorized for such operations;

- any location of the appliance which is not recommended

in this manual.

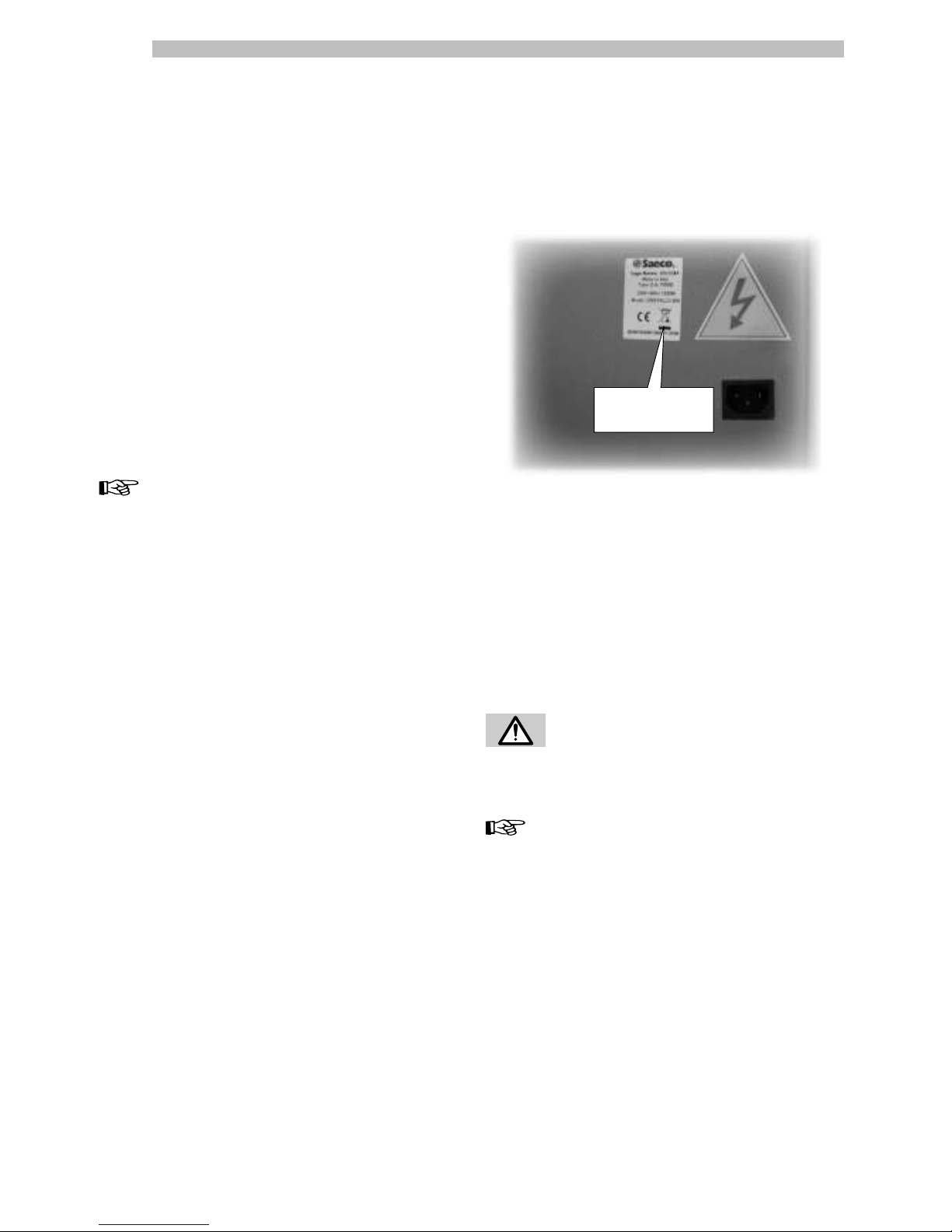

Fig. 4

Data plate

2.3 Vending Machine

Identification

The vending machine is identified by the name, model and

serial number which can be found on the relevant data

plate (Fig. 4).

The following data can be found on the plate:

- name of Manufacturer;

- marks of compliance;

- model;

- serial number;

- year and month of manufacture;

- supply voltage (V);

- supply frequency (Hz);

- electrical power consumption (W).

Warning

It is strictly forbidden to tamper with or modify the data

plate.

Important

When contacting the AUTHORIZED CUSTOMER SERVICE

CENTRES always refer to this plate and its relevant data.

Page 13

English

13

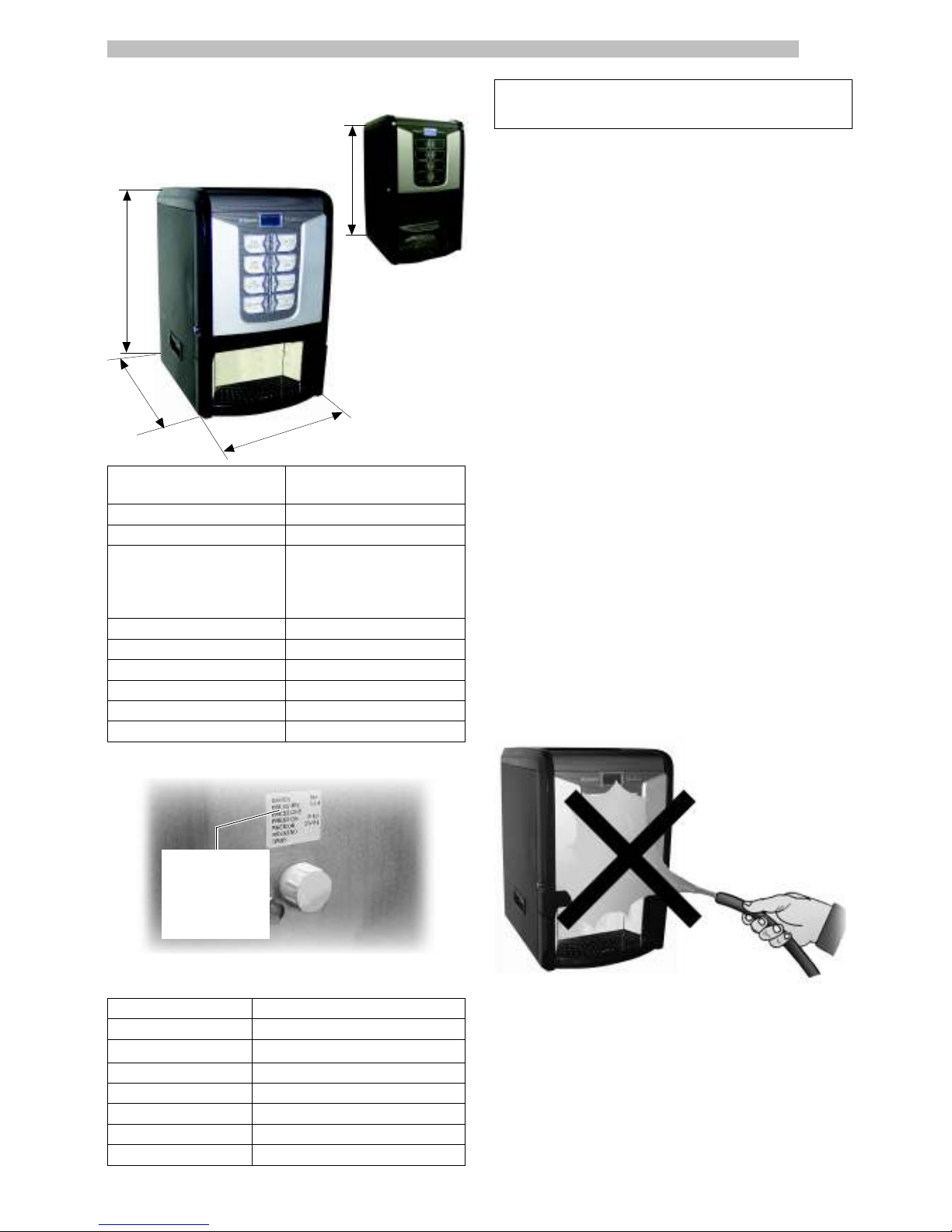

Fig. 6

2.4. Technical specifications

Data plate

showing minimum

and maximum

water supply

pressure

Container capacity

Coffee beans

: 1,00 kg

Chocolate

: 1,75 kg

Milk

: 0,65 kg

Lemon tea

: 1,50 kg

Ginseng:

double: 1,85 kg, standard: 1,15 kg

Ground coffee: 0,62 kg

Freeze-dried coffee:

standard: 0,41 kg, small: 0,23 kg

Barley:

standard: 0,36 kg, small: 0,20 kg

Height:

594 mm standard

714 mm with extension

Width: 394 mm

Depth: 430 mm

Weight:

31 kg Espresso

35 kg Instant with extension

31 kg T.T.T.

38 kg Cappuccino with extension

Power consumption: see data plate

Supply voltage: see data plate

Electric voltage frequency: see data plate

Power cord length: 1,600 mm

Water mains connection: 3/4” Gas type

Water mains pressure: see figure 6

3 SAFETY

3.1 Introduction

In compliance with the Low Tension Directive 2006/95/

EC (which replaces the directive 73/23/EEC and following

amendments) and CE Marking Directive 93/68/EEC,

SAECO VENDING has drawn up a technical file of the

PHEDRA vending machine held at its plants. The following

regulations were taken into account during the design

phase:

- EN 55014 - EN 6100-3-2

- EN 61000-3-3 - EN 61000-4-2

- EN 61000-4-3 - EN 61000-4-4

- EN 61000-4-5 - EN 61000-4-11

- EN 60335-2-75 - EN 60335-1

3.2 General safety regulations

It is forbidden to:

- tamper with or disable the safety systems installed on the

vending machine;

- carry out maintenance on the vending machine without

unplugging it first;

- install the vending machine outdoors. It should be placed in

dry areas where the temperature never falls below 1°C;

- use the vending machine for purposes other than those

indicated in the sale contract and in this publication;

- connect the appliance to the mains using multi-sockets or

adapters;

- use water jets to clean the vending machine (Fig. 6).

It is compulsory to:

- check the electrical power line for conformity;

- use original spare parts;

- read the instructions contained in this publication and in

the enclosed documents carefully;

- use personal protection devices during installation, testing

and maintenance operations.

Fig. 7

Fig. 5

594

430

394

714

Standard version

Extension version

Page 14

English

14

Precautions for preventing human errors:

- make the operators aware of safety issues;

- handle the vending machine, either packaged or

unpackaged, in safe conditions;

- have a thorough knowledge of the installation procedures,

its operation and limits;

- dismantle the vending machine in safe conditions, in

accordance with the environmental protection and health

and safety laws in force.

Warning

In case of failure or malfunctioning contact only qualified

CUSTOMER SERVICE personnel.

Important

The Manufacturer declines any liability for any damage

caused to property or injury caused to persons as a result of

failure to observe the safety regulations described here.

Important

This appliance is not intended for use by persons (including

children) with reduced physical, sensory or mental capabilities,

or lack of experience and knowledge, unless they have

been given supervision or instruction concerning use of the

appliance by a person responsible for their safety.

3.3 Operators’ requirements

Three operators with different skills are required in order to

guarantee the safety of the vending machine:

User

Access to the internal part of the vending machine is forbidden

to the user.

Supply operator

The Maintenance Technician assigns the safekeeping of the

access key to the Supply operator who is in charge of product

supply, external cleaning, and starting up / stopping of the

vending machine.

Warning

The Supply Operator is not authorized to carry out operations

which are indicated as being the duties of the Maintenance

Technician in this publication.

Maintenance Technician

The Maintenance Technician is the only person authorized

to intervene and start programming procedures, and perform

adjusting, setting up and maintenance operations on the

vending machine.

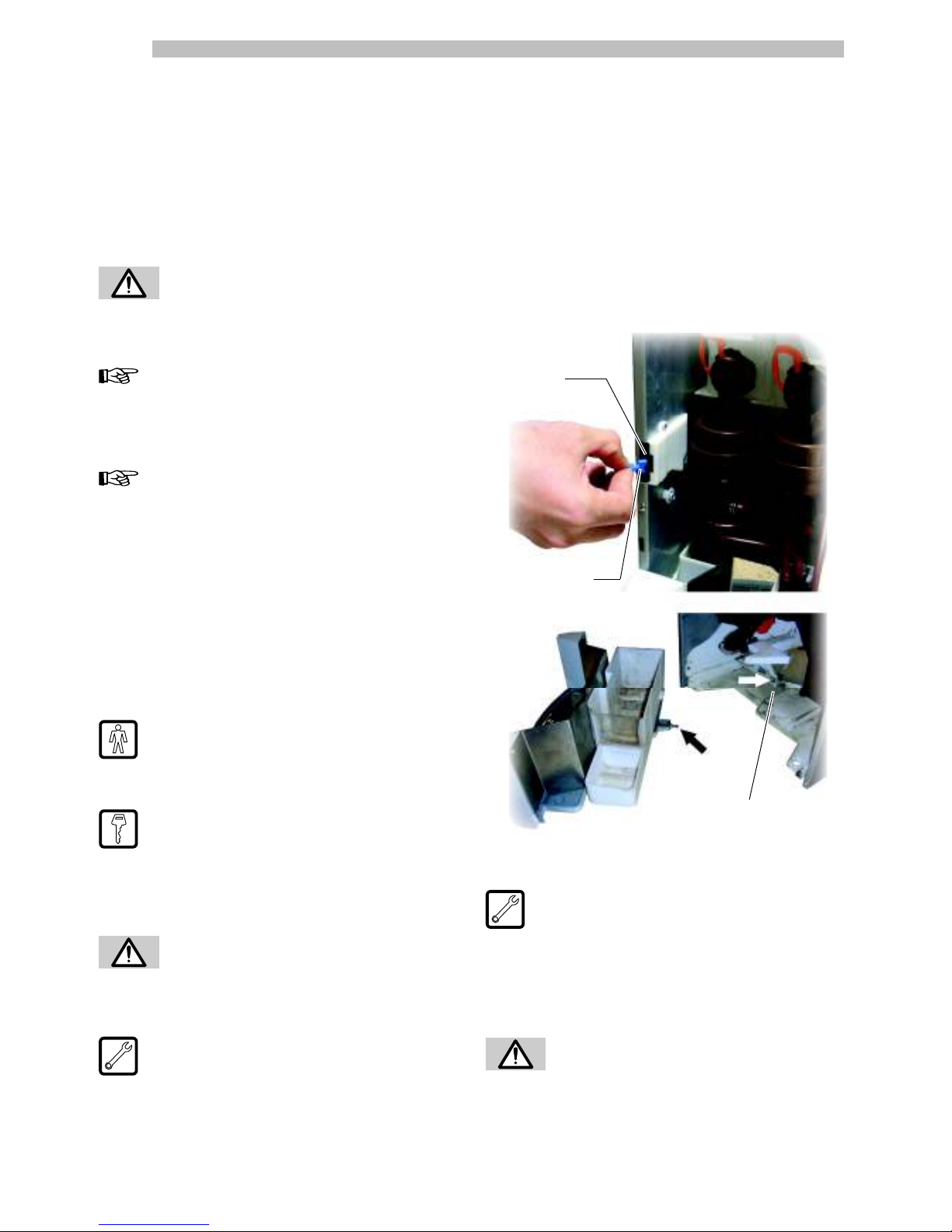

Fig. 8

3.4 Safety devices

The vending machine is equipped with:

- A microswitch (Ref. 18, Fig. 8) automatically cuts out the

power supply when the front panel is opened.

The microswitch can be disabled by inserting the key (Ref.

24, Fig. 8).

- A microswitch (Ref. 25, Fig. 8) blocks vending machine

operation when the drip tray and/or coffee grounds

drawer are not correctly positioned. A message indicating

the incorrectly positioned part appears on the display.

Maintenance Technician

In case of programming or setting up operations only the

Maintenance Technician can intervene by inserting the

relevant key into the safety switch (rif. 24, fig. 8) and resetting

the voltage even if the door is open.

Warning

This operation, necessary for starting up the vending machine,

disables the safety system.

It must therefore be carried out by qualified personnel

(Maintenance Technician) aware of the risks resulting from

the presence of live or moving components.

25

18

24

Page 15

English

15

3.5 Residual risks

Warning

Risk of scalding if hands are placed inside the outlet during

brewing.

Do not remove the cup or put your hands inside the

compartment during beverage brewing before the brewing

cycle has finished.

Before removing the cup from the outlet, please wait for the

message “REMOVE CUP” on display.

Important

Before brewing another beverage, check that the previous

one has been taken out and that the cup support is empty.

4 - HANDLING AND

STORAGE

4.1 Unloading and handling

Unloading and handling operations after transportation

must be carried out only by qualified personnel and using

suitable equipment.

Warning

The vending machine must always be kept in the upright

position. Avoid:

- dragging the vending machine;

- overturning or laying the vending machine flat during

transport and handling;

- shaking the vending machine;

- leaving the vending machine exposed to the elements, in

humid areas or close to heat sources.

4.2 Storage

If the vending machine is not installed immediately, it should

be stored in a sheltered area, conforming to the following

instructions:

- the packaged vending machine must be stored in a closed,

dry area at a temperature between 1°C and 40°C;

- do not put other appliances or boxes on the vending

machine;

- it is always good practice to protect the vending machine

from any deposits of dust or other material.

Fig. 9

5 - INSTALLATION

5.1 Important

Warning

The vending machine cannot be installed outdoors; avoid

placing it in areas where the temperature is less than 1°C or

more than 32°C and in particularly dump or dusty areas.

Before unpacking, check that the installation area complies

with the following specifications:

- the power socket must be located in an easily accessible

area, not more than 1.5 meters away;

- the socket voltage must comply with that on the identification

plate;

- the surface or floor must NOT have a gradient of more

than 2°.

If the vending machine needs to be positioned close to a wall,

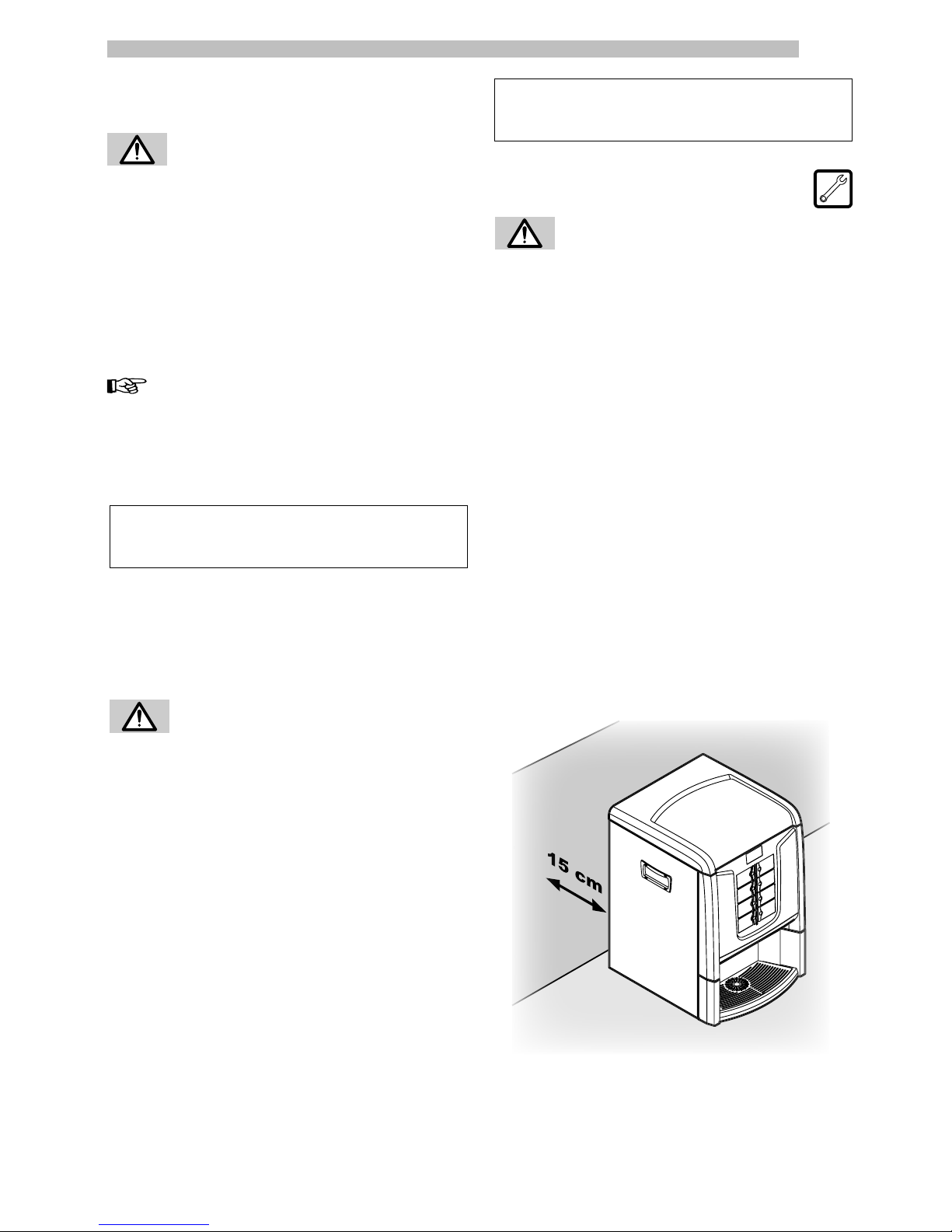

it is necessary to leave a space of at least 15 cm between

the back and the wall in order to keep the air outlet grille

free (Fig. 9).

Page 16

English

16

Fig. 10

- Instruction booklet

- Power cord

- Product labels and prices

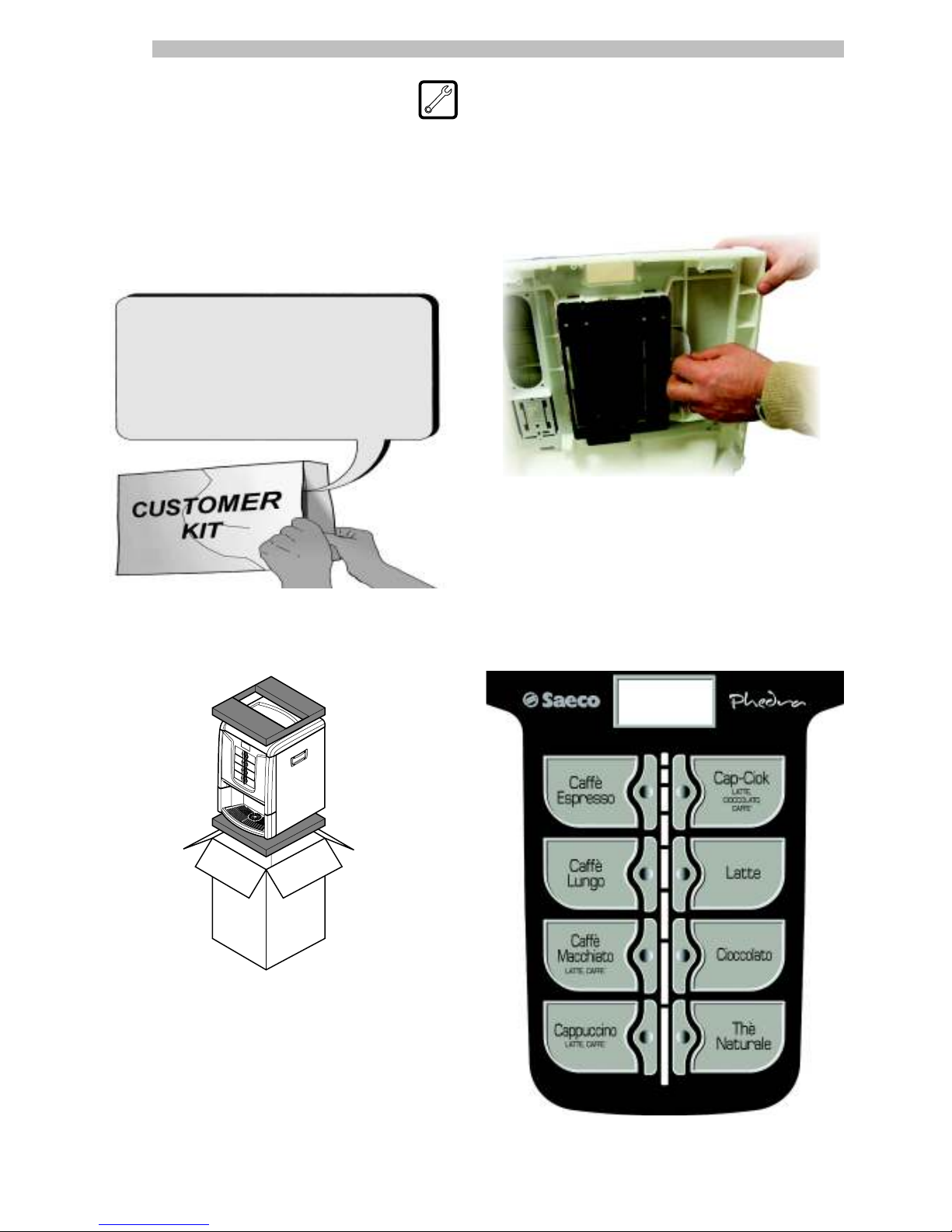

The vending machine is protected by an expanded

polyethylene foam sheet and a plastic bag inside a box

(Fig. 11).

5.2 Unpacking and

positioning

On receipt of the vending machine make sure that it has

not been damaged during transportation and that package

has not been tampered with or that internal parts have not

been removed.

An envelope, called “CUSTOMER KIT” is supplied with the

vending machine; it contains the objects shown in Fig. 10.

Fig. 11

If damage of any kind is found, the courier must be informed

and notice must be given to the importer or the seller

immediately. If these are not in the purchaser’s country,

please contact the manufacturing company directly.

The accessory bag contains:

- 1 key for the brew group;

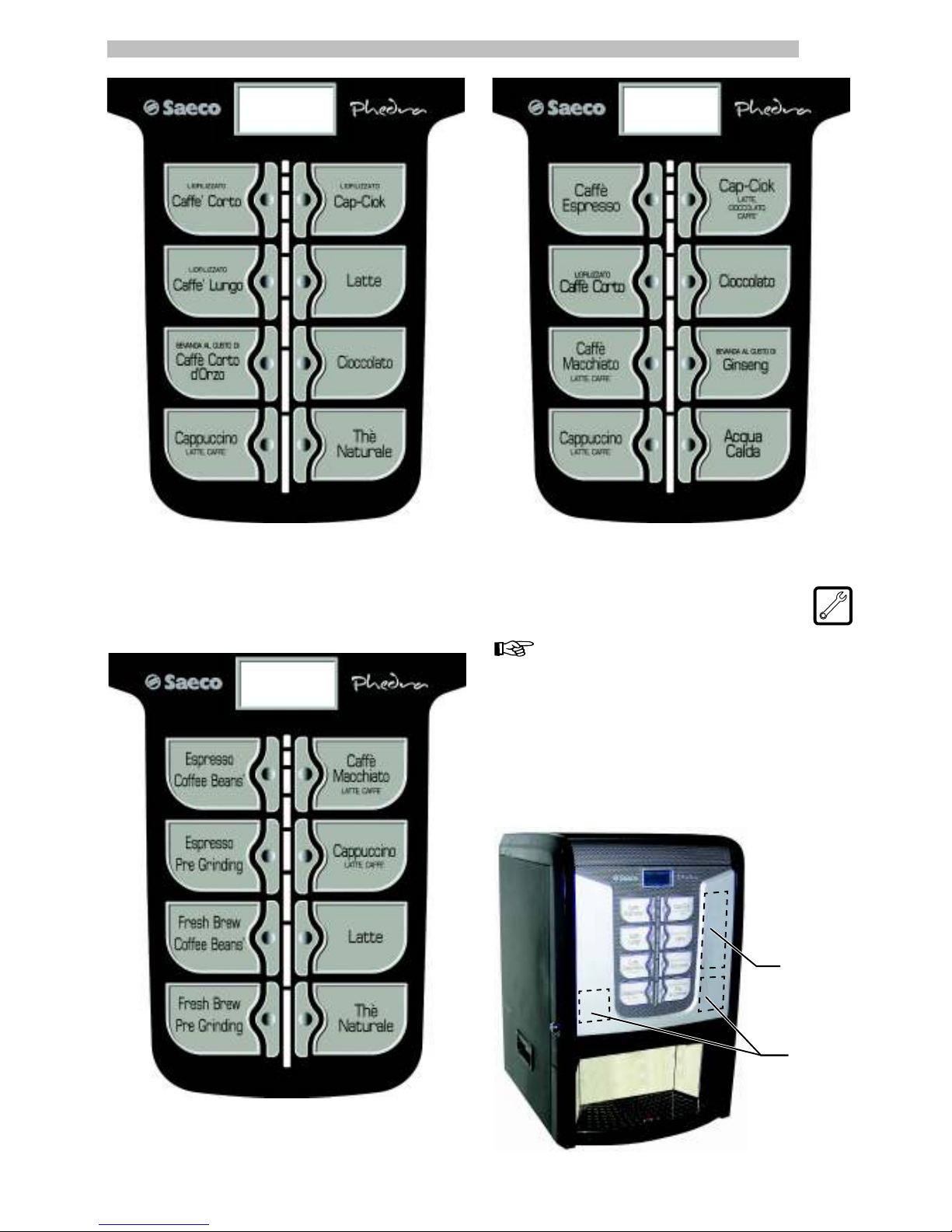

5.3 Label application

Product labels

Open the vending machine. Insert the product labels (Fig.

12).

Check the exact position of the labels against the selection

key (Fig. 13a,13b, 13c, 13d).

Fig. 12

Fig. 13a

Espresso version

Page 17

English

17

5.4 Fitting the payment

systems

Important

The vending machine is not supplied with any payment

system, which must be installed by the person in charge of

its fitting.

The vending machine is designed for the installation of

various payment systems, such as:

- Parallel coin validator, 24 V DC

- Cashless reader (EXECUTIVE, PRICE HOLDING, MDB, and

BDV systems)

Coin

validator

Cashless

reader

Fig. 13b

Fig. 13c

Instant version

T.T.T. version

Fig. 13d

Cappuccino version

Fig. 14

Page 18

English

18

Fig. 15

5.5 Connection to water

mains

Important

The pressure reducer is calibrated during assembly. Should

problems occur with the calibration of the pressure reducer,

the outlet pressure value must absolutely be reset to 0.8 – 1

bar max. Different or approximate calibration may cause

product quality and quantity variations when brewed.

Important

It is recommended to use a descaling device for the water

network supplying the vending machine, especially for water

with a high calcium and magnesium content (hard water).

Connect the vending machine to a drinking water supply

pipe with a pressure ranging between 1.5 and 8 bars (see

data plate).

Important

Before connecting the appliance to water network, please

read and follow the applicable regulations in force in your

country.

Remove the cap from the coupling placed on the vending

machine back panel (Fig. 15). Connect the water supply

pipe to the 3/4” Gas coupling of the vending machine

(Fig. 15).

5.6 Connection to the

electric network

Warning

The Maintenance Technician, who is responsible for the

installation of the vending machine, must ensure that:

- the electr ic system c ompli es with current safety

regulations;

- the supply voltage corresponds to that indicated on the

data plate.

If in doubt, do not proceed with the installation and ask

qualified and authorized personnel to check the system

accurately.

The vending machine is equipped with a power cord which

must be plugged into the appropriate socket on the vending

machine back panel (Fig. 16).

Important

After the chosen payment system has been installed,

the corresponding parameters can be set through the

programming menu (see 8.2).

Warning

The Manufacturer declines any liability for any damage to the

vending machine, to property and/or injury to persons, caused

by the installation of the payment system. The responsibility

falls to the person who carried out the installation.

Page 19

English

19

5.7 Coffee Grounds Discharge

Setting

The appliance is setup for direct discharge of the coffee

grounds into the bag in the dedicated cabinet or into another

container located below the appliance (ex. bar counter).

For this setting, the plate (Ref. A, Fig. 18) and coffee grounds

drawer (Ref. A, Fig. 19) must be cut along the indicated

marks.

Remove the tab the coffee grounds drawer hooks to (Ref. B,

Fig. 19) using a cutter or a jigsaw.

Fig. 18

Fig. 19

Fig. 20

A

A

B

A

Important

The appliance has an alarm signal to indicate when to empty

the coffee grounds in the standard version. For this setting it

is necessary to exclude this counter using the menu.

5.8 Liquid Drain Setting

The appliance is setup for direct drainage of the drip tray into

container in the dedicated cabinet or into another container

located below the appliance.

To use this setting, cut (or drill a hole in) the panel in the

indicated area (Ref. A, Fig. 20).

Do not use adapters or multi-sockets (Fig. 17).

Fig. 17

Fig. 16

Page 20

English

20

5.9 Drip Tray Locking

Important

This option can be used to guarantee the appliance additional

safety.

It is possible to block the removal of the drip tray without

opening the door.

To use this option, remove the two locking pins integrated

on the drip tray (Ref. A, Fig. 21).

Divide them and, after trimming them with a cutter, glue them

on the two studs (Ref. A, Fig. 22) located on the lower front

part of the drip tray (thus lengthening the centring pieces).

In this manner, it will no longer be possible to remove the

drip tray without first opening the door.

Fig. 21

Fig. 22

A

A

5.10 Front Door Intermediate

Locking

In order to perform an unscheduled maintenance lock the

front door as shown in Fig. 23.

Fig. 23

Fig. 24

This is possible after opening the vending machine, by

turning the key clockwise and fitting the slots (Ref. A, Fig.

24) on the pins (Ref. B, Fig. 24).

B

A

Page 21

English

21

Fig. 26

6.4 CPU card keys

The CPU electronic card has 4 keys enabling the Maintenance

Technician to carry out programming or maintenance

operations (Fig. 26).

6 - CONTROLS

DESCRIPTION

6.1 Display

The display (2 - Fig. 1) shows the messages during standard

operation, programming and maintenance modes.

6.2 Keypad

Important

Each key function changes according to the vending machine

mode (ordinary dispensing or programming mode).

Each key has a double function that varies according

to the vending machine status (standard operation or

programming).

6.3 Key description in

standard operation mode

Keys (1 to 8 - Fig. 25)

By pressing these keys, the programmed beverages are

dispensed.

1

2

3

4

5

6

7

8

Fig. 25

Page 22

English

22

7 - SUPPLY AND STARTING

UP

7.1 Container supply

(Espresso)

Important

The containers delivered are designed to dispense the

following products (Fig. 27a):

Instant product 1 = Tea

Instant product 2 = Milk

Instant product 3 = Chocolate

Fig. 27a

Instant

product 1

Coffee bean

Instant

product 2

Instant

product 3

7.2 Container supply

(Instant)

Important

The containers delivered are designed to dispense the

following products (Fig. 27b):

Instant product 1 = Tea

Instant product 2 = Milk

Instant product 3 = Chocolate

Instant product 4 = Barley

Instant product 5 = Freeze-dried coffee

Fig. 27b

Instant

product 1

Instant

product 2

Instant

product 3

Instant

product 4

Instant

product 5

Page 23

English

23

Fig. 27d

7.3 Container supply

(T.T.T.)

Important

The containers delivered are designed to dispense the

following products (Fig. 27c):

Instant product 1 = Tea

Instant product 2 = Milk

Instant product 3 = Ground coffee

Fig. 27c

Instant

product 1

Coffee bean

Instant

product 2

Instant

product 3

7.4 Container supply

(Cappuccino)

Important

The containers delivered are designed to dispense the

following products (Fig. 27d):

Instant product 1 = Freeze-dried coffee

Instant product 2 = Ginseng

Instant product 3 = Chocolate

Instant

product 1

Instant

product 2

Instant

product 3

Coffee bean

Fresh milk

container

Page 24

English

24

7.4.2 Instant product supply

Open the cover of the container to be supplied (Fig. 30).

Fig. 30

Pour the instant product into the container (Fig. 31).

Fig. 31

7.4.1 Coffee bean supply

Remove the container cover (Fig. 28).

Fig. 28

Fig. 29

Replace the cover on the container.

Important

If the message “COFFEE NOT AVAILABLE” is displayed after

the supply, the following operations should be carried out:

- press the “P2” key (Fig. 26) to enter the maintenance

menu;

- press the key “e” twice (Fig. 36) to eliminate the error (see

sect. 8.3.3 Description of messages in the maintenance

menu).

Put coffee beans into the container (Fig. 29).

Close the container cover.

Page 25

English

25

7.6 Dose calibration

The vending machine is delivered with standard

calibration values set by the manufacturer. The quantity of

coffee powder is set to 7.0 gr.

Dose calibration can be performed by means of two

calibration levels:

- remove the cover (Fig. 33);

Fig. 33

- move the adjusting lever into the rack and select the slot

corresponding to the dose required (Fig. 35).

- release the adjusting lever from the rack and place

- the dragging tooth of the inner panel on one of the 4

positions available, which indicate the basic quantity area

(6 gr. – 7 gr. – 8 gr. – 9 gr.) (Fig. 34);

Fig. 34

Fig. 35

Fig. 32

7.5 Coffee grinding

calibration

Turn the ring (Fig. 32) until the required results are obtained.

After any calibration three selections are necessary before

the new setting becomes effective.

Page 26

English

26

7.8 Filling the boiler

manually

Manual filling of the boiler is required during the first startup of the vending machine.

After switching on the vending machine, it is possible to fill

the boiler by means of the following procedure:

- press the “P2‰ key (Fig. 26) to enter the maintenance

menu;

- press the “e” key (Fig. 36) followed by the “UP” key

(Fig. 36) to access the RINSING entry;

- press the “e” key (Fig. 36) to carry out the automatic

complete rinsing cycle.

- repeat the washing operation until water comes out of

the beverage dispensing nozzles.

Important

The rinsing operation must be repeated until water flows out

of the brewing nozzles regularly.

7.9 Use of the vending

machine

The beverage selection procedures are shown in section 9.

7.7 First start-up of the

vending machine

Supply the vending machine (following the instructions given

previously) and plug it into the power supply (see 5.6).

At this point, the message “PHEDRA” appears on the display

and the self-configuration is turned on.

Any faults detected during the self-configuration cycle are

stored so that the vending machine can display them at the

end of the self diagnostic phase.

Adjust grinding as instructed in 7.2; the boiler must be

necessarily filled.

Page 27

English

27

8.2 Programming menu

The structure of the programming menu is shown in 8.2.2.

8.2.3 describes all the entries in the programming menu.

8.2.1 Entering the programming

menu

Open the door, disable the safety device (see 3.4) and press

the “P1” key (Fig. 26) to enter the programming menu.

If no password has been assigned, the programming menu

is entered directly.

Important

If a password was assigned to the vending machine to

enable the programming menu, the message “PASSWORD

000000” will appear on the display with a flashing cursor

on the first digit.

Now the password should be entered using the UP and

DOWN keys. Confirm the digit entered by pressing the

ENTER key.

Proceed as follows to exit the programming menu and return

to standard operation of the vending machine:

- Press the ESC button repeatedly until “EXIT ?” appears.

Select YES and press ENTER.

- remove the key from the safety switch in order to turn off

the vending machine;

- close the door and wait for the self-configuration process

to end.

8 - PROGRAMMING AND

MAINTENANCE MENU

Important

This section illustrates how to set up or modify the vending

machine programming and maintenance settings.

It is therefore necessary to read it carefully, and intervene only

when the correct sequence of operations to be performed is

fully understood.

8.1 Key description of

programming and

maintenance phases

To scroll through the vending machine menu, the keys

described below are used.

„e‰ Key: ENTER (Fig. 36)

By pressing this key it is possible to enter the following

programming or maintenance level. It is also possible

to modify or confirm the values set in the entries of the

programming or maintenance menus.

„c‰ Key: CANCEL (Fig. 36)

By pressing this key it is possible to go back to the previous

level of the programming or maintenance menu. It is also

possible to avoid storing the previously modified values.

„V‰ Key: DOWN (Fig. 36)

Pressing this key it is possible to access the previous entry

inside the same level.

If used after a setting modification request, the value of this

setting decreases.

„^„ Key: UP (Fig. 36)

By pressing this key it is possible to access the next entry

inside the same level.

If used after requesting the change of a setting, the value of

this setting increases.

e

c

Fig. 36

^

^

Page 28

English

28

8.2.2 Structure of the programming menu

1. System manag.

1.1. VMC code

1.2. Stop

1.2.1. Stop coffee

1.2.2. Stop Preground

1.2.3. Stop beverages

1.2.4. CofGrounds contr

1.2.5. Stop CofGrounds

1.2.6. Reset

1.3. Water filter

1.3.1.

Last filter change

1.3.2. Remaining qty

1.3.3. Filter limit

1.3.4. Filter reset

1.3.5. Filter enabled

1.4. Boiler 1 Temp.

1.4.1. Min temperature

1.4.2. Max temperature

1.5. Boiler 2 Temp.

1.6. EnergySave

1.6.1. Stand-By Timeout

1.6.2. Eco Timeout

1.6.3. Delta Temp. ECO

1.7. PreHeat

1.7.1. Coffee preheat.

1.7.2. InstProd preheat

1.7.3. Capp. PreHeat

1.8. Steam Cleaning

1.8.1. Steam clean time

1.8.2. EnableSteamWash

1.9. Rinse cycle

1.10. Pre-grinding

1.11. Program messages

1.11.1. Stand-by

1.11.2. Preselection

1.11.3. Brewing

1.11.4. Out of service

1.12. Contrast

1.13. Pulse counter

1.14. Clock

1.14.1. Time

1.14.2. Date

1.15. Multiple bever.

1.15.1. Multiple bever.

1.15.2. Enable MultBev

1.16. Enable reset

1.17. Free prod button

1.18. Presel. button

1.19. Language

1.20. Change password

1.20.1. Prog. password

1.20.2. Service password

1.21. On/Off time

1.21.1. On 1

1.21.2. Off 1

1.21.3. On 2

1.21.4. Off 2

1.22. EVA-DTS

1.22.1. EA1..2 (Events)

1.22.2. EA3..5 (Readout)

1.22.3. LA1-Prices Lists

1.22.4. PA1..4 Products

1.22.5. VA1..3 Sales

1.22.6. BA1-CA15-Cash

1.22.7. DA1..7-CashLess

1.23. Audit Msg.Enable

1.24. Ev Water Assign.

1.25. Complete Menus

1.26. VM Model

1.27. Factory Default

1.28. System Info

2. Payment system

2.1. Protocol

2.2. Parallel coiner

2.2.1. Enable

2.2.2. Coin values

2.3. Banknote reader

2.3.1. Enable

2.3.2. Inhibition level

2.3.3. Banknote values

2.4. MDB settings

2.4.1. Recharge enabled

2.4.2. Max CardRecharge

2.4.3. Max card charge

2.4.4. Coins enabling

2.4.5. Alt. payout

2.4.6. Max change

2.4.7. Exact change

2.4.8. Min tube level

2.4.9. Tube filling

2.4.10.

Tube emptying

2.4.11.

Commit to vend

2.4.12.

Banknote enabl.

2.4.13.

Banknote escrow

2.4.14.

Slave address

2.5. Max credit

2.6. Multivend

2.7. Overpay time

2.8. Fixed zeros

2.9. Decimal digits

3. Product setup

3.1. Prod. before

3.1.1. Instant Product

3.1.2. Instant Product

3.1.3. Instant Product

3.1.4. Instant Product

3.1.5. Instant Product

3.2.

Beverage enabled

3.3.

Beverage brewing

4.

Sales management

4.1. Price table

4.1.1. Price (1-100)

4.2. Beverage prices

4.2.1. Normal

4.2.2. Diff 1

4.2.3. Diff 2

4.2.4. Card

4.3. Free

4.4. Free on

4.5. Free off

4.6.

Diff Prices 1-On

4.7.

DiffPrices 1-Off

4.8.

Diff Prices 2-On

4.9.

DiffPrices 2-Off

Page 29

English

29

8.2.3 Description of messages in the

programming menu

SYSTEM MANAGEMENT

The SYSTEM MANAGEMENT

items are:

VM Code

Enables an identification code

to be assigned to the vending

machine.

Stops

Enables setting of the maximum

amount of beverage or coffee.

Once the maximum amount is

reached, the vending machine stops dispensing the relevant

beverages.

STOP COFFEE

Enables setting of the maximum

number of coffee cups to be

dispensed before the stop.

BLOCCO PREGOUND

It allows setting the maximum

number of beverages with pre-

ground coffee to be brewed

before stopping the pre-ground products.

STOP BEVERAGES

Enables setting of the maximum

number of beverages to be

dispensed before the stop.

COFGROUNDS CONTR

Enables or disables control

of the number of grounds

discharged into the coffee

grounds drawer.

When set to “YES” the machine will allow a certain number

of cups of coffee to be brewed before requiring the drawer

to be emptied (see “STOP COFGROUNDS”).

When set to “NO” the machine will not control the number

of grounds discharged into the drawer.

STOP GROUNDS

It allows you to set the maximum

number of coffee cups to be

brewed, corresponding to

maximum dump box capacity. Once reached the set

quantity, coffee-based beverages dispensing is stopped.

Five cups of coffee before the lock is engaged, a

blinking message appears on the display, “EMPTY

COFGROUNDS”.

Important

This lock can be reset by removing the coffee grounds drawer

for at least 10 seconds.

Recommended solutions

It is advisable to set a max. of 30 coffees when using the

dump box supplied with the machine

Important

Do not set any stop value if you are using the machine together

with the supporting cabinet, which is equipped with its own

dump box which is not controlled electronically

RESET

Enables resetting of all partial

counters relative to product

quantity stop functions.

Water Filter

(Only if Complete Menus are

enabled) Allows the use of the

water filter to be checked.

LAST FILTER CHANGE

Date of the last filter reset.

REMAINING QTY

Number of litres of water

that can still be dispensed

before the filter needs to be

regenerated. When this value is less than 1, a Warning

(W83) is recorded in the Error LOG.

FILTER LIMIT

Number of litres of water that

can still be dispensed from the

filter.

FILTER RESET

Select YES to indicate a new

filter has been installed. This

operation returns “Remaining

Qty” to the same value as “Filter Limit” and the date in the

“Last Filter Change” is changed to today’s date.

FILTER ENABLED

Enables management of the

“Remaining Qty” countdown.

Important

From the maintenance menu (button P2 on the CPU), you

can access “Water Filter”, “Last Filter Change”, “Remaining

Qty” and “Filter Reset”.

1.2.

Stop

...

1.1.

VMC code

531000

Th

it

em

1.

System manag.

...

1.2.1.

Stop coffee

0

1.2.6.

Reset

...

1.2.5.

Stop CofGrounds

00

1.2.4.

CofGrounds contr

Yes

1.2.3.

Stop beverages

1.3.1.

Last filter change

31 gen 08

1.3.

Water filter

...

1.3.2.

Remaining qty

95

1.3.3.

Filter limit

100

1.3.4.

Filter reset

1.3.5.

Filter enabled

si

1.2.2.

Stop preground

Page 30

English

30

ECO TIMEOUT

The “ECO” mode is activated

after some minutes of inactivity

which can be set by means

of this menu option. By setting it to zero the function is

disabled.

When the “ECO” mode is activated, the target temperature

of boiler 2 (steam boiler for the “Cappuccino” version and

auxiliary boiler for the “Instant” version) is reduced by a

preset value (see the following menu option).

The vending machine remains in its “Ready” status and no

message is shown to the user.

To exit the ECO mode, press any button or insert some credit.

When ECO mode is deactivated, the target temperature for

boiler 2 is restored and the machine starts the warm-up

phase.

DELTA TEMP. ECO

It allows setting the °C reduction

to be applied to the temperature

of boiler 2 in “ECO” mode.

Preheating

This menu allows setting the

parameters related to the the

preheating operations for the

brew group, the brewing circuits for instant products or the steam

dispensing circuit.

COFFEE PRE-HEATING

It allows enabling a pre-heating

cycle of the Brew Group if it

remains inactive for a period

of time.

This menu allows setting the seconds of inactivity after which

the pre-heating cycle has to take place. The settable values

are:

- 0 (zero) pre-heating cycle disabled,

- from 60 seconds to 900 seconds at intervals of 60.

The default value is 300.

PREHEAT. SOLUBLES

Enables selection of th e

instant products for which the

preheating function will be

enabled.

By enabling this function, the vending machine performs

a preliminary dispensing of water through the circuit

corresponding to the instant product selected. The user can

choose for which instant product prerinsing can be enabled,

by setting cu cm of water to be used.

Example: the settings shown in the figure enable preheating

for instant product 1 with 10 units of water and do not enable

preheating for instant product 2.

Boiler 1 temperature

According to the model, the

Phedr a vending machine

may be equipped with 1 or

2 boilers. The following table matches the boilers with the

vending machine models.

Model Boiler 1 Boiler 2

Espresso

Beverage and coffee boiler

Not present

Instant Beverage boiler

Beverage boiler

T.T.T.

Beverage and coffee boiler

Not present

Cappuccino

Beverage and coffee boiler

Steam boiler

This menu option allows setting the operating temperature

of boiler 1.

MIN. TEMPERATURE

En a b l e s set ti ng of th e

temperature to be maintained

for a few minutes by the

vending machine after a beverage has been dispensed.

The set value is expressed in centigrade.

MAX. TEMPERATURE

En ab l e s se t t i n g of the

temperature to which the

vending machine is brought

after a certain time from the last dispensing, in order to

compensate for the natural decrease of the temperature of the

hydraulic circuits. The set value is expressed in centigrade.

Boiler 2 temperature

This menu allows setting the

operating temperature for

boiler 2.

This setting is not used for the boiler of the Instant version

and in case the boiler 2 is not installed.

Energy Save

The “Stand-by” and “ECO”

modes allow reducing the

energy consumption of the

machine. It is possible to select one or both modes.

STAND-BY TIMEOUT

The “Stand-by” mod e i s

activated after some minutes

of inactivity which can be

set by means of this menu option. By setting it to zero the

function is disabled.

When the stand-by mode is activated the boilers are turned

off and the display shows the message “Stand-by”.

To exit the stand-by mode, press any button or insert some

credit. When normal operation is restored, the boilers are

turned on and the vending machine starts the warm-up

phase.

1.4.

Boiler 1 temp.

00

1.5.

Boiler 2 temp.

000

1.4.1.

Temperatura min.

00

1.4.2.

Temperatura max.

000

1.6.

Energy Save

1.6.1.

Stand-by Timeout

1.6.2.

Eco Timeout

1.6.3.

Delta Temp. Eco

1.7.

PreHeat

1.7.1.

Coffee preheat.

00

1.7.2.

InstProd preheat.

00

INST.PROD.PREHEAT.

INSTANT PRODUCT 01

10

INSTANT PRODUCT 02

0

Page 31

English

31

the machine will pass to the following one.

2. During the second phase, a display message will request

to insert only the water container (about 400 gr of

water). Simultaneously press the buttons corresponding

to beverages 4 and 8 to start the “Rinse Cycle”. This

cycle will last 75 seconds. At the end of this procedure,

the cleaning cycle will be considered as completed and

the Cappuccinatore as cleaned, thus enabling brewing

beverages with milk.

Steam Cleaning Time

It refers to the circuit of the

Capp u cinatore: it all o ws

setting the interval (in hours)

after which a cleaning cycle of the circuit is requested.

Enable Steam Wash

If set on YES , it al l o ws

starting the cleaning cycle by

simultaneously pressing the

two beverage buttons 4 and 8.

This allows executing a cleaning cycle on the circuit of the

Cappuccinatore without the need to open the machine.

Rinsing Cycle

It allo ws enabling of the

automatic rinsing of the mixing

bowls. The automatic rinsing is

performed as follows: the first rinsing takes place 10 minutes

after the “machine ready” status; if necessary, other rinses

occur 7 hours after the last dispensing.

Pre-grinding

Enables instant pre-grinding of

the coffee dose.

Programmable texts

STAND-BY TEXT

It enables setting the message

appearing on the display when

the vending machine is in

standard operating mode.

PRESELECTION TEXT

It allows setting the message

appearing on the display when

the preselection mode of the

preselection key is active.

DISPENSING TEXT

It allows setting the message

appearing on the display

when the vending machine is

dispensing a product.

Instant product preheating takes place if:

- at least 3 minutes have passed since the mixing bowl

was last used;

- the quantity of water for the instant product is < 50

units.

CAPP. PREHEAT

It refers to the circuit of the

Cappuccinatore: it allows

setting the minutes of inactivity

after which a preheating cycle is requested before dispensing

steam (by setting this value to zero the preheating cycle

is disabled). This cycle improves the operation of the

Cappuccinatore after a long period of inactivity.

WARM-UP T-OUT

It det e rmi n es th e d e lay

ti m e ( in mi nu t e s ) a ft er

which the preheating of the

Cappuccinatore is enabled.

EXTRA TIME

Extra time (in tenths of seconds)

for steam dispensing applied in

case the circuit is cold, since a

reduced quantity of milk is dispensed in this case.

Steam Cleaning

In case the steam circuit remains

inactive for some hours (to be

set under the option “Steam

Cleaning Time”) the vending machine will not allow brewing

any beverages with steam (under the letter “S” in the product

list) unless a cleaning cycle is activated. The message “NO

Cappuccino” will be displayed (by setting the number of

hours to zero the cleaning message and the stop status will be

disabled). The cycle can be activated in the “Maintenance”

menu as well as during normal operation of the machine

through the user cycle.

ACTIVATION USING THE MENU:

Select the option 1.8 in the “Maintenance” menu.

ACTIVATION DURING NORMAL OPERATION:

The machine must comply with the following:

1.Vending machine in its “Ready” status.

2. No brewing in progress.

3.Option “Enable Steam Wash” in the “System Management”

menu enabled.

To activate the cycle simply press the buttons corresponding

to beverages 4 and 8 simultaneously.

CYCLE DESCRIPTION:

The cycle operation is independent from the activation mode

(no matter if started or not from the “Maintenance” menu)

and it consists of two phases: the “Wash Cycle” and “Rinse

Cycle”.

1. During the first phase, a display message will request to

pour the mix of water and cleaning solution (about 400

gr of water and Saeco compound). Simultaneously press

the buttons corresponding to beverages 4 and 8 to start

the “Wash Cycle”. This phase will last 75 seconds, then

1.11.2.

Preselection

Bevande con orzo

1.11.3.

Brewing

Attendere

1.11.

Program messages

...

1.11.1.

Stand-by

** DA5P MY07 **

1.10.

Pre-grinding

Si

1.9.

Rinse cycle

Si

1.7.3.

Capp. PreHeat

00

1.8.1.

Steam Cleaning Time

1.8.2.

Enable Steam Wash

1.8.

Steam Cleaning

1.7.3.1.

Warm-Up T-Out

00

1.7.3.2.

Extra Time

00

Page 32

English

32

- PRESELECTION: by pressing this key the vending machine

displays the preselection message (“PRESELECTION

by default) and makes another group of beverages

available.

Important

With this configuration it is necessary to set the new

beverage/recipe group available (see the BEVERAGE

BREWING menu).

- Beverage: in this case, pressing the button will dispense

beverage / recipe number 5.

- DISABLED

pressing the key has no effect.

Language

Enables selection of th e

language to be used by the

vending machine. Languages

available: Italian, English, French, German, Spanish,

Portuguese and Dutch.

Password change

Enables setting of a password

or modification of the current

one.

The password consists of a number between 000001 and

999999. The 000000 value (default value) means no

password. To set the password, press UP and DOWN keys

and confirm with the ENTER key.

PROG.PASSWORD

Allows a password to be set for

the programming menu.

SERVICE PASSWORD

Allows a password to be set for

the maintenance menu.

On/Off Time

Allows you to set the vending

machine’s automatic on and

off time ranges over the course

of a week.

OUT OF SERVICE TEXT

It enables setting the text on

the display when the vending

machine stops due to a fault.

Contrast

Adjusts the contrast of the

display.

Coffee / beverage pulse

counter

Enables selection of whether

the 24V dc electromechanical

pulse counter (optional - to be connected to the CPU card)

has to count the coffees or all dispensed beverages.

Clock

Enables setting of the hour,

minute, day of the week, day of

the month, month and year.

Multiple beverage

Enab l es s e lect i on o f th e

beverages to be enabled for

multiple dispensing and the

maximum number of beverages

dispensed. The upper line

will remain the same for all

following operations, while the

lower line will display the number of consecutive beverages.

It is possible to set a value between 2 and 8.

BEVERAGES ENABLING

It allows enabling or disabling

of the beverage keys.

During standard operation the

message “NOT AVAILABLE” will

be displayed when a disabled

key is pressed.

Reset enabling

It allows enabling of the

“RESET” for data in the statistics

maintenance menu.

Free vend key

It enables the “P3” key (Fig.

26) of the CPU card for free

dispensing of a product during

standard operation.

Preselection key

The functions associated with

the preselection key can be

selected from the following:

1.21.

On/Off time

...

1.21.1.

On 1

lmmgvsd 00:00

1.21.2.

Off 1

lmmgvsd 00:00

1.21.3.

On 2

lmmgvsd 00:00

1.21.4.

Off 2

lmmgvsd 00:00

1.17.

Free prod button

No

1.18.

Presel. button

Beverage

1.15.

Multiple bever.

...

1.15.1.

Multiple bever.

000

1.15.2.

Enable MultBev

1.15.2.

Beverage 1

Yes

1.16.

Enable reset

No

1.19.

Language

1.20.

Change password

1.20.1.

Prog. password

1.20.2.

Service password

1.13.

Pulse counter

Coffee

1.14.

Clock

...

1.14.1.

Time

08:00

1.14.2.

Date

01 Gen 08

1.11.4.

Out of service

Chiama assist.

1.12.

Contrast

Page 33

English

33

Fig. 37

Factory default

I t a l l o w s re v e r t i n g t h e

programmable parameters to

factory preset values.

System Info

This option allows accessing

a page showing the overall

machine configuration.

The display shows the following information:

FIRST ROW: Sw version (“x.yy.zz” format) / Program CRC

(“abcd” format)

Example: “SW v1.02.12/087c”

SECOND ROW: Boot loader version (“xx” format) and name

of the file searched for by the boot loader on the USB key

(“.s19” extension not displayed)

Example: “Boot 08SAE_DA5P”

THIRD ROW: Memory version (“xxx.yyy.” format) / Content

CRC (“zzz” format)

Example: “Mem 123.456.789”

Audit Msg. Enable

It allows displaying for a few

seconds the selection counters

(total and since last reset)

during the machine start-up phase.

EV Water Assign

By setting the “W” value in the

product list, hot water will be

dispensed. This menu allows

choosing the solenoid valve to be used for dispensing. If the

“hot water solenoid valve” kit is installed, set the value to 0

(zero) or select the solenoid valve operating on the desired

circuit among the available ones.

Complete menu

Enables selection of whether

the entries of the programming

menu should be shown fully or

only partially.

VM Model

It allows selecting the current

m o d e l o f t h e v e n d ing

machine.

The possible options are:

Espresso

Cappuccino

TTT

Instant

The vending machine model is specified on the label located

in the inside of the right-hand side panel (Fig.37).

1.25.

Complete Menus

1.22.

EVA-DTS

1.22.1.

EA1..2 (Events)

1.22.2.

EA3..5 (Readout)

1.22.3.

LA1-Prices Lists

1.22.3.1.

LA1 Normal Prices

1.22.3.2.

LA1 Diff1 Prices

1.22.3.3.

LA1 Diff2 Prices

1.22.3.4.

LA1 Card Prices

1.22.3.5.

LA1 Free

1.22.3.6.

LA1 Test

1.23.

Audit Msg. Enable

1.22.4.

PA1..4 -Products

1.22.5.

VA1..3 Sales

1.22.6.

BA1-CA15-Cash

1.22.7.

DA1..7-CashLess

1.24.

Ev Water Assign.

1.26.

VM Model

1.27.

Factory Default

1.28.

System Info

EVA-DTS

Allows selecting the category

of data that will be transferred

by the VM during an Audit Eva

Dts session.

Page 34

English

34

COIN VALUE: Enables setting

of the value of the coins

transferred to the vending

machine from the parallel

coiner, the mechanical coiner

and the cancelling machine.

The following table shows

the channel/payment system

combinations.

Channel Payment system

1 Parallel coiner

2 Parallel coiner

3 Parallel coiner

4 Parallel coiner

5 Parallel coiner

6 Parallel coiner

7 Cancelling machine

Banknote Reader

It enables the parameters of

the parallel banknote validator

and the choice of values to be

assigned to single banknote channels.

Entry description:

ENABLE: By setting “Y”, the

management of the parallel

reader is enabled. By setting

“N”, a parallel reader which

may be connected to the vending machine is always

disabled.

INHIBITION LEVEL: Enables

setting of the active level of

the banknote reader inhibition

signal.

BANKNOTE VALUE: Enables

setting of the value of banknotes

transferred to the vending

machine from the parallel

reader.

PAYMENT SYSTEMS

The entries of the PAYMENT

SYSTEMS are:

Protocol

Enables selection of the protocol

used by the vending machine

to dialogue with the payment

system installed on it:

- EXECUTIVE protocol;

- PRICE HOLDING/DISP Protocol;

- BDV Protocol;

- MBD Protocol;

- NO PROTOCOL (no serial protocol);

- Master/Slave executive (the vending machine operates

as master for another vending machine);

- PHD Master /Slave (the vending machine operates as

master for another vending machine that works with the

PRICE HOLDING/DISP protocol);

- MDB SLAVE (the vending machine operates as slave to

another machine);

The “NO PROTOCOL” setting will be used when a payment

system operating with one of the protocols provided by the

other settings “EXECUTIVE”, “PRICE HOLDING”, “BDV”,

“MDB” “MDB SLAVE” or “EXEC MASTER/SLAVE” is not

installed on the VM.

This setting is necessary since the VM continuously checks

for dialogue with the provided payment system. If the VM

detects no dialogue, it signals this fault on the display through

the message “NO LINK”.

This signal cannot be considered an error condition.

Parallel coiner

All ows e na b lin g of t he

parameters of the parallel

coiner, the mechanical coiner,

the cancelling machine and the choice of values to be

assigned to the single money channels.

Entry description:

ENABLE: By setting “Y”, the

parallel coiner, the mechanical

coiner and the cancelling

machine control are enabled.

By setting “N”, a parallel coiner which may be connected

to the vending machine is always disabled.

Th

SY

2.

Payment system

...

2.2.

Parallel coiner

...

2.2.1.

Enable

No

2.2.2.

Coin values

...

2.2.2.1.

Moneta 1/6

0.00

2.3.

Banknote reader

...

2.3.1.

Enable

No

2.3.2.

Inhibition level

255

2.1.

Protocol

...

2.3.3.

Banknote values

...

2.3.3.1.

Banconota 1/4

0.00

Page 35

English

35

EXACT CHANGE POLICY: In

MDB change-giving coiners,

the condition of no change

available can be selected

within the following table:

Key:

L = channel with the lowest coin value below the minimum

level

M = channel with the medium-low coin value below the

minimum level

HL = channel with the medium-high coin value below the

minimum level

HH = channel with the highest coin value below the minimum

level

No. Description

0 L or M or HL or HH

1 L or M

2 HL or HH

3 L or HH

4 L

5 M

6 HL

7 L and HH

8 HL and HH

9 L and M

10 L and M and HL and HH

11 L and HL or L and HH

12 L or HL and HH

13 HH

14 L and M and HL

15 Never (change always available)

Note

Even if the no change available message is displayed, the

vending machine continues to give change as long as coins

are present in the channels. The minimum level (same for all

channels) can be set on a special menu item.

CH A NN E L LE VE L L OW :

Enables setting of the minimum

number of coins in the channels.

Default = 4.

MANUAL CHANNEL LOAD:

Allows the change-giving

coiner channels to be filled

manually. Press Esc to exit the

channel loading mode.

MANUAL CHANNEL EMPT.:

Allows the change-giving

coiner channels to be emptied

by pressing the beverage

selection keys.

2.4.5.

Alt. payout

No

2.4.6.

Max change

0.00

2.4.7.

Exact change

0

2.4.8.

Min tube level

0

2.4.

MDB settings

...

2.4.1

Recharge enabled

No

2.4.2.

Max CardRecharge

10.00

2.4.3.

Max card charge

10.00

2.4.4.

Coins enabling

...

2.4.4.1.

Moneta 1/16

No

2.4.9.

Tube filling

...

2.4.10.

Tube emptying

...

MDB settings

Enables access to particular

f u nc t i o n s o f t h e M D B

protocol.

RECHARGE: Allows disabling

or enabling of any Saeco card

recharge operation.

By setting RECHARGE = NO

the vending machine will only deduct the cost from MDB

cards.

MAX CA R D RECHAR G E :

Enables setting of the maximum

credit level, beyond which

all recharge operations (if

enabled) are ineffective.

By setting MAX RECHARGE = 20.00, the credit on the

vending machine will be transferred to the card if the sum

does not exceed 20.00.

MAX CARD VALUE: Enables

setting of the maximum credit

level, beyond which the card is

rejected by the system.

By setting Max card value =

25.00, the vending machine will reject all cards with a

credit which exceeds this amount. If this card is detected,

the display will not show the credit but a “ ——” message

will be displayed and no sale will be carried out.

COINS ENABLING: Enables

selection of which coins will

be accepted by the change-

giving coiner. By setting “Y” a

specific coin will be accepted.

On the contrary, the “N”

setting prevents the change-

giving coiner from accepting

a particular coin. Coins beneath the vending machine scale

factor are always disabled and display the “N” setting.

ALT. PAYOUT: It enables/

disables use of Alternative

Payout for the level 3 MDB

change-giver. By setting “Yes”

the change-giver is called on to dispense change.

Change is limited to 255 times the scaling factor (typically

Euro12.75 for the Euro area - with scaling factor of 5). By

setting “No” change is given by exploiting the machine’s

algorithm. Max. change is 60000 units (typically Euro 600

for the Euro area).

MAX CHANGE: Enables setting

of the maximum amount of

change which can be dispensed

by the change-giving coiner.

Default = 10.00.

Page 36

English

36

COMMITTED TO VEND: By

setting “N”, the credit inserted

can be returned even if no sale

has been made. This function

may be useful, for example, for changing banknotes into

coins. By setting “Y”, the credit inserted can be returned as

change only after the sale has been completed. Default =

YES.

BANKNOTES ENABLIN G:

Enables selection of which

banknotes will be accepted by

the MDB banknote reader.

A specific banknote is enabled

for acceptance by setting “Y”.

On the contrary, the “N” setting

prevents the banknote reader

from accepting a specific banknote. Default = All enabled.

B A NK N OT E E S C R O W:

By setting “Y”, an inserted

banknote is stored in the escrow

position by the banknote reader

(if supported); this function is supported by the banknote

reader. In this way, if the sale fails or the card system fails

to charge, the banknote will be returned. By setting “N”, any

inserted banknote goes to the banknote reader’s stacker, so

that the banknotes cannot be returned. Default = No.

SLAVE ADDRESS: When the

vending machine is in Master

mode, this menu ena bles

setting of the address of any

slave connected vending machine. If the vending machine

is in Slave mode, it enables setting of its address. Possible

addresses are 0x40, 0x48 and 0x50. Default = 0x40.

2.6.

Multivend

No

2.7.

Overpay time

180

2.8.

Fixed zeros

0

2.9.

Decimal digits

0

2.4.12

Banknote enabl.

...

2.4.12.1

Banknote 1/16

No

2.4.13.

Banknote escrow

No

2.4.14.

Slave address

0x40

2.5.

Max credit

2.55

2.4.11

Commit to vend

No

Max credit

This allows the user to set the

maximum credit which can

be accepted by the vending

machine. Once this limit has been reached, the payment

systems are disabled so that no more credit can be accepted.

Default = 20.00.

Multivend

Enables the user to use any

residual credit to purchase

other beverages. By setting

“N” (no), the residual credit will be collected by the vending

machine.

Overpay Time

It establishes the maximum time

(expressed in seconds) beyond

which the vending machine

collects the displayed residual credit. The time is adjustable

at intervals of 10 seconds. By setting “000” the function is

disabled.

Fixed Zeros

Allows setting of the number of

fixed zeros for credit.

Decimal point posit.

Enables setting of the position

of the decimal point of the

credit.

Page 37

English

37

IMPOSTAZIONE

PRODOTTI

Product before

It allows selecting the instant

product for which you wish

to enable powder dispensing

befor water dispensing. This

brewing cycle will be carried

out only when the quantity of

powder to be brewed does not

exceed 34.

Beverage validation

It allows to enable or disable

the beverage keys.

By pressing a disabled key

during operation, the message

“NOT AVAILABLE” will be

displayed.

The combination BUTTON –

BEVERAGE NUMBER changes if button “5” is used as the

“PRESELECTION” button.

IM

PR

3.

Product setup

...

3.1.

Prod. before

...

3.1.1.

Instant Product1/5

No

3.2.

Beverage enabled

...

3.2.

Beverage 1

Yes

KEY Press KEY

1

Beverage 1

2

Beverage 2

3

Beverage 3

4

Beverage 4

5

Beverage 5

6

Beverage 6

7

Beverage 7

8

Beverage 8

KEY Press KEY

Press

PRESELECTION+KEY

1

Beverage 1 Beverage 9

2

Beverage 2 Beverage 10

3

Beverage 3 Beverage 11

4

Beverage 4 Beverage 12

5

Preselection Preselection

6

Beverage 6 Beverage 14

7

Beverage 7 Beverage 15

8

Beverage 8 Beverage 16

BEVERAGE BREWING

The vending machine is able to

dispense 14 beverages. Each

beverage can be prepared

using coffee beans and/or instant products. The technician

can select the desired products for the recipe (max 4) and

order of use. Each component is identified by a number or

a digit (Fig. 39).

3.3.

Beverage brewing

Fig. 39

Instant pr. 3

Coffee beans C

Instant pr. 1

Instant pr. 2

KEY 5 = BEVERAGE 5

KEY 5 = PRESELECTION

1

2

3

4

5

6

7

8

Fig. 38

Page 38

English

38

% PUMP

It determines the water delivery

rate.

The value can be set between

20 and 100. The lower the value the smaller the water

delivery rate.

SEQUENCE

This is the order in which

the products making up the

beverage are brewed. The

possible choices are:

0 =

does not dispense any product

1 = dispenses product 1

2 = dispenses product 2

3 = dispenses product 3

4 = dispenses product 4

5 = dispenses product 5

C = brews coffee using instantly ground coffee

F = brews “fresh brew” coffee using pre-ground coffee

P = brews espresso coffee using pre-ground coffee

B = brews “fresh brew” coffee using instantly ground coffee

W = dispenses hot water

S = dispenses steam in the Cappuccinatore

Consequently, the combination of “3C00” or “30C0” or

“03C0” will always dispense product 3 and coffee beans.

The settings of products making up the beverage will be

requested according to the sequence.

C O F F E E WA T ER , PR E GROUND WATER, FRESHBR E W W A TE R , B E AN S

WATER

It allows setting the quantity of water to be dispensed for the

programmed coffee type (C, P, F, or B). The quantity can be

set from “1” to “999”.

STEAM DURATION

It determines the activation

time (in tenths of seconds) for

dispensing steam through the

Cappuccinatore.

JUST WATER

Defines the amount of hot

water to be dispensed.

The amount of coffee that can

be brewed can be adjusted from “1” to “999”.

% INSTANT PRODUCT

It determines the instant powder

delivery rate.

The value can be set between

10 and 100. The lower the value the smaller the powder

delivery rate.

3.3.

Beverage 1

...

3.3.

Beverage 1