Page 1

Automatic Machine for Espresso Coffee and Hot Beverages

IT

UK

FR

DE

ES

NL

PT

WARNING: This instruction manual is intended exclusively for specialized personnel.

USE AND MAINTENANCE

Page 2

Automatic Machine for Espresso Coffee and Hot Beverages

UK

WARNING: This instruction manual is intended exclusively for specialized personnel.

USE AND MAINTENANCE

Page 3

English

47

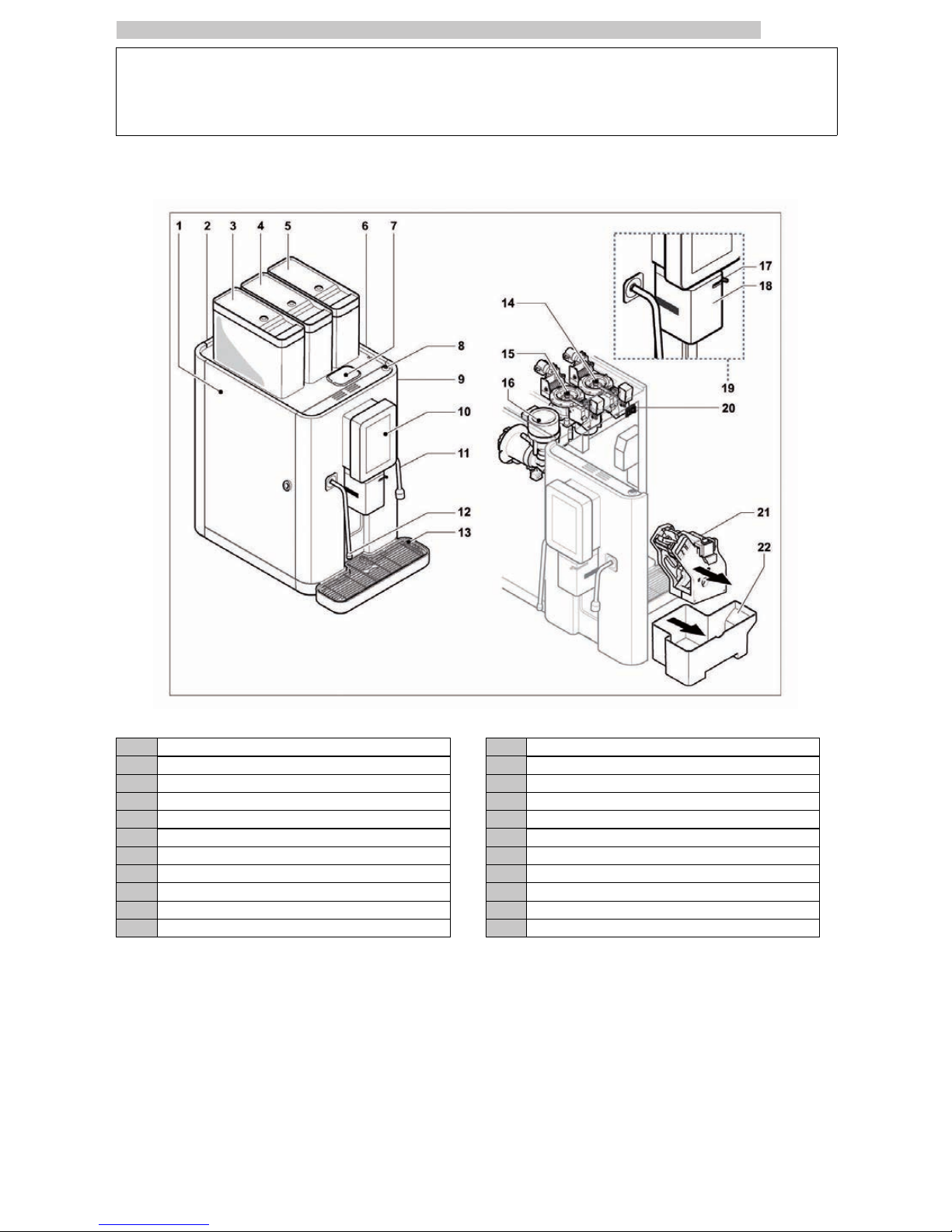

MAIN PARTS

Nextage Main Parts

1 Left hand side panel 12 Steam wand

2 Back panel 13 Drip Tray

3 Instant product container 14 Coffee grinder/right dosing unit group

4 Left coffee bean hopper 15 Coffee grinder/left dosing unit group

5 Right coffee bean hopper 16 Mixer

6 Right hand side panel 17 Milk crema adjusting device

7 Pre-ground coffee door 18 Dispenser cover

8 Door lock 19 Dispenser

9 Door 20 Power button

10 Control panel 21 Coffee Group

11 Hot water wand 22 Dump box

Page 4

English

48

CONTENTS

MAIN PARTS

47

1 INTRODUCTION TO THE MANUAL

49

1.1 INTRODUCTION

49

1.2 SYMBOLS USED

49

2 INFORMATION ABOUT THE MACHINE

50

2.1 NOTES FOR THE USER

50

2.2 INTENDED USE OF THE APPLIANCE

50

2.3 APPLIANCE IDENTIFICATION

50

2.4 TECHNICAL DATA

51

3 SAFETY

52

3.1 INTRODUCTION

52

3.2 GENERAL SAFETY REGULATIONS

52

3.3 OPERATORS' REQUIREMENTS

53

3.4 SAFETY DEVICES

53

3.5 RESIDUAL RISKS

53

4 HANDLING AND STORAGE

54

4.1 UNLOADING AND HANDLING

54

4.2 STORAGE

54

5 INSTALLATION

55

5.1 WARNING

55

5.2 UNPACKING AND POSITIONING

55

5.3 CONNECTION TO WATER MAINS

57

5.4 CONNECTION TO THE ELECTRIC NETWORK

58

5.5 MOUNTING THE SPOILERS

58

5.6 CONNECTING THE USB PORT

59

6 DESCRIPTION OF CONTROLS

61

6.1 COMMANDS

61

7 SUPPLY AND STARTING UP

62

7.1 CONTAINER CONFIGURATION

62

7.2 COFFEE BEAN SUPPLY

62

7.3 REFILLING WITH PRE-GROUND COFFEE

62

7.4 INSTANT PRODUCT SUPPLY

63

7.5 CREAM ADJUSTMENT

63

7.6 TEMPERATURE SETTING

63

7.7 COFFEE GRINDING CALIBRATION

64

7.8 FIRST START-UP OF THE MACHINE

65

7.9 CLEANING THE PARTS IN CONTACT WITH

FOODSTUFFS

67

7.10 USE OF THE MACHINE

67

8 MAINTENANCE MENU

68

8.1 MAINTENANCE MENU

68

9 OPERATION AND USE

70

9.1 SWITCH ON

70

9.2 BEVERAGE SELECTION

70

9.3 DISPLAY MESSAGES

72

9.4 MACHINE SWITCHING-OFF

73

10 CLEANING AND MAINTENANCE

74

10.1 GENERAL NOTES FOR CORRECT OPERATION

74

10.2 CLEANING AND SCHEDULED MAINTENANCE

74

10.3 NON-SCHEDULED MAINTENANCE

85

11 TROUBLESHOOTING

86

12 STORAGE DISPOSAL

87

12.1 CHANGE OF LOCATION

87

12.2 INACTIVITY AND STORAGE PERIODS

87

13 INSTRUCTIONS FOR END-OF-LIFE

DISPOSAL TREATMENT

88

Page 5

English

1

49

1 INTRODUCTION TO THE MANUAL

1.1 Introduction

This manual is an integral part of this machine and it

must be kept in a handy place, in good conditions, for

as long as the machine will be operating (including any

transfer of ownership). Il suo fine, è la trasmissione

delle informazioni necessarie all’uso competente e

sicuro della macchina stessa.

In case of lost or deterioration of this brochure, please

ask a copy to the Authorized customer Service

Center, specifying the model and the year of

construction of your machine.

The Authorized Customer Service Centers, are also

available for any technical explanation, information on

its operation, technical assistance and spare parts

supply.

The subjects mentioned aim, in an exclusive way, at

ensuring the proper use of the machine, in the safest

way for users, the very machine and the environment.

This is made through a simple diagnostics of troubles

and anomalous functioning, and by carrying out some

simple checks and maintenance operations, always

respecting the precautions explained in the following

pages and the current Safety and Health Regulations

Before any intervention read very carefully and be sure

to have completely understood the subject of this

brochure.

If several persons use (individually) this machine,

everyone must previously and very carefully study the

Instruction Manual.

The manufacturer reserves the right to modify and

improve the described models, without being bound

to give any notice.

For any particular need contact the Distributor or

your Country Importer (if any) or the Constructor.

All the rights of this brochure are reserved to SAECO

Vending S.p.A.. Any copy or even partial divulgation,

not expressively authorized in writing, are strongly

forbidden.

Always refer to this publication before carrying out any

operation.

Manufacturer: SAECO Vending S.p.A.

Località Casona, 1066 40041 Gaggio Montano

Bologna, Italy

1.2 Symbols used

This publication contains various warnings which indicate

different degrees of danger or skills required.

Alongside the graphic symbol, a message will define the procedures to be

adopted and all useful information will be detailed.

Warning

Information about the user’s safety and the machine

integrity.

Prohibition notice

It is used to highlight actions/operations not to be

performed.

Important

It draws the attention on a particularly important subject.

Machine off

Operations to be done without power supply .

User

Actions concerning the machine user.

Maintenance Technician

Operations strictly concerning personnel in charge of

unscheduled maintenance or repairs.

Page 6

English

2

50

2 INFORMATION ABOUT THE MACHINE

2.1 Notes for the user

The appliance must be installed in a properly lighted,

sheltered and dry location and on a working surface able

to withstand its weight.

To guarantee the correct operation and reliability over

time, the following is recommended:

• ambient temperature: from +1°C to +25°C;

• maximum humidity: 90% (not condensed).

For special installations not covered in this publication,

please contact the dealer or the local importer. If this is

not possible, please contact the Manufacturer directly.

For all possible requirements, always refer to the Distributor or

Importer for each Country. If a specific Country has no

Importer, recourse should be made directly to the Manufacturer.

The Manufacturer’s maintenance service is available to

clarify any doubts concerning the correct operation of the

appliance.

In case of damages to the power cable, it must be replaced

by the Manufacturer or by its Technical Assistance Service,

or alternatively, by a person with similar qualifications.

The AUTHORISED SERVICE CENTRE is available for any

type of explanation and information pertaining to appliance

operation and to satisfy requests for the supply of spares

or technical assistance.

The Manufacturer reserves the right to introduce further

improvements to the appliance without notice.

All rights of reproduction of this manual are reserved by

the Manufacturer.

The Maintenance Technician must carefully read and

respect the safety warnings contained in this manual so

that every intervention concerning installation, starting up,

use and maintenance will be safely carried out.

2.2 Intended use of the appliance

The machine is intended for the brewing of coffee and hot

beverages (decaffeinated coffee, cappuccino, chocolate,

etc.). The dosage of each type of brewing can be

programmed. Instant products must be consumed right

after the brewing and cannot be stored for long.

Any other use is to be considered improper and therefore

dangerous.

Do not place any product inside the machine which

may be dangerous as a result of unsuitable

temperatures.

Improper use of the vending machine invalidates all

warranties. The Manufacturer declines any liability for

damage to property or injury to persons.

Improper use also includes:

• any use of the vending machine other than the intended

use and/or according to procedures which are not

described in this publication;

• any intervention on the appliance contrasting with the

indications referred to in this manual;

• any alteration of components and/or safety devices

without prior consent of the Manufacturer or carried out

by personnel not authorized for such operations;

• any location of the vending machine not provided in this

manual.

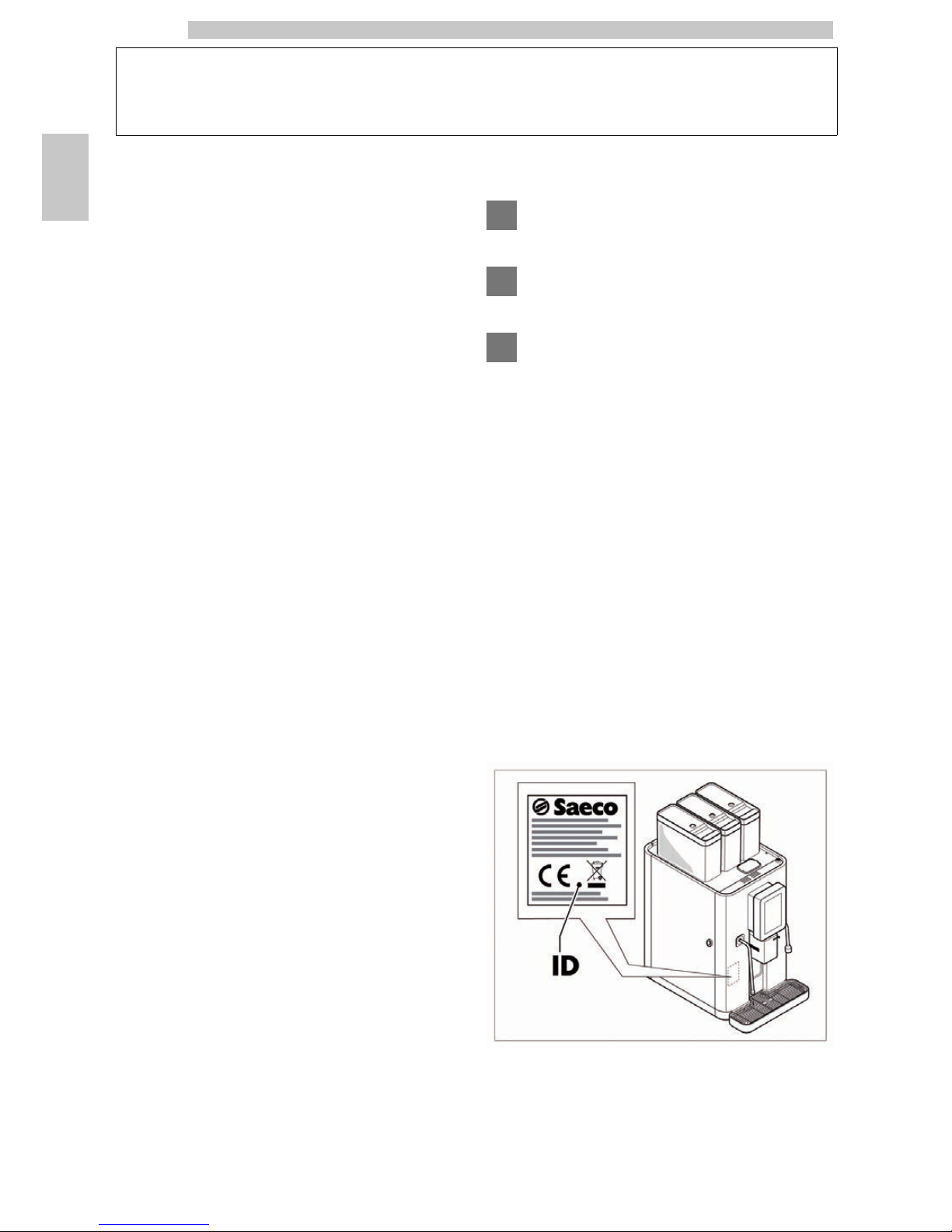

2.3 Appliance identification

The appliance is identified by the model name and serial

number shown on the special plate.

ID Data plate

Page 7

English

2

51

The following data can be found on the plate:

• name of Manufacturer;

• marks of compliance;

• model;

• serial number;

• year and month of manufacture;

• supply voltage (V);

• supply frequency (Hz);

• electrical power consumption (W).

• number of phases of the electric line (PH);

• pressure allowed in the water network (MPa);

It is strictly forbidden to tamper with or modify the

data plate.

When contacting the technical service, always refer to

this plate by indicating the technical data shown on it.

In case of any request to the Authorized Customer Service

Centers, model and serial number must be specified.

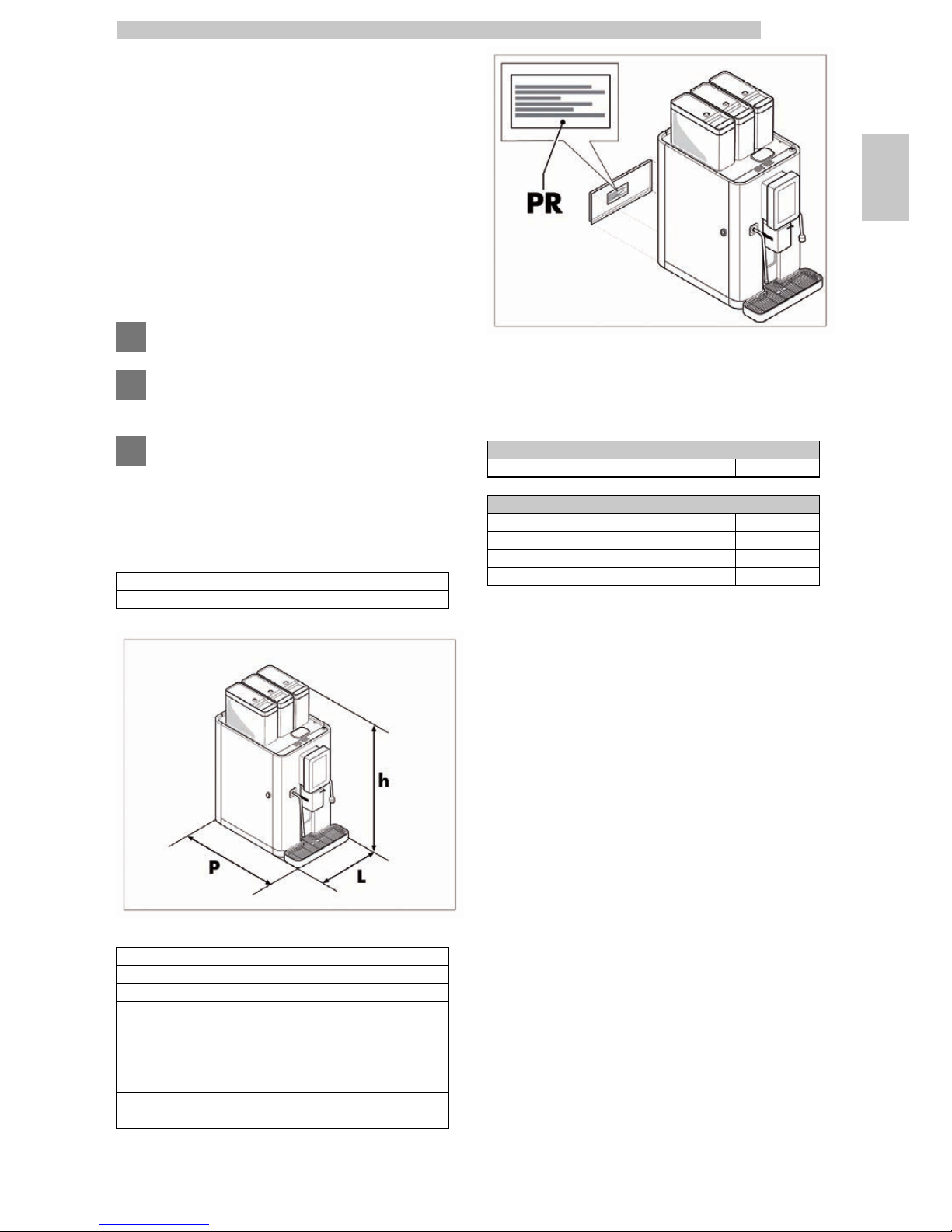

2.4 Technical data

Dimensions (w x h x d) 364 x 790 x 596 mm

Weight 60 kg

Power consumption see data plate

Supply voltage see data plate

Electric voltage frequency see data plate

Power cord length 3,000 mm

Water mains connection 3/8"

A-Weighted sound pressure

level

less than 70 dB

Water mains pressure

See the pressure data

plate

PR

Data plate showing minimum and maximum water

supply pressure

Container capacity

Bean hopper capacity

Coffee beans 1,3 kg

Instant product container capacity

Tea 1,5 kg

Hot Chocolate 1,75 kg

Barley 0,33 kg

Freeze-dried coffee 0.3 kg

Page 8

English

3

52

3 SAFETY

3.1 Introduction

According to the low voltage Directive 2006/95/EC

(substituting Directive 73/23/EEC and following

amendments) and the CE marking Directive 93/68/EEC,

SAECO VENDING has arranged for a NextAge technical

file at its premises, thus transposing the following

standards during the designing phase:

- EN 55014 - EN 61000-4-4

- EN 6100-3-2 - EN 61000-4-5

- EN 61000-3-3 - EN 61000-4-11

- EN 61000-4-2 - EN 60335-2-75

- EN 61000-4-3 - EN 60335-1

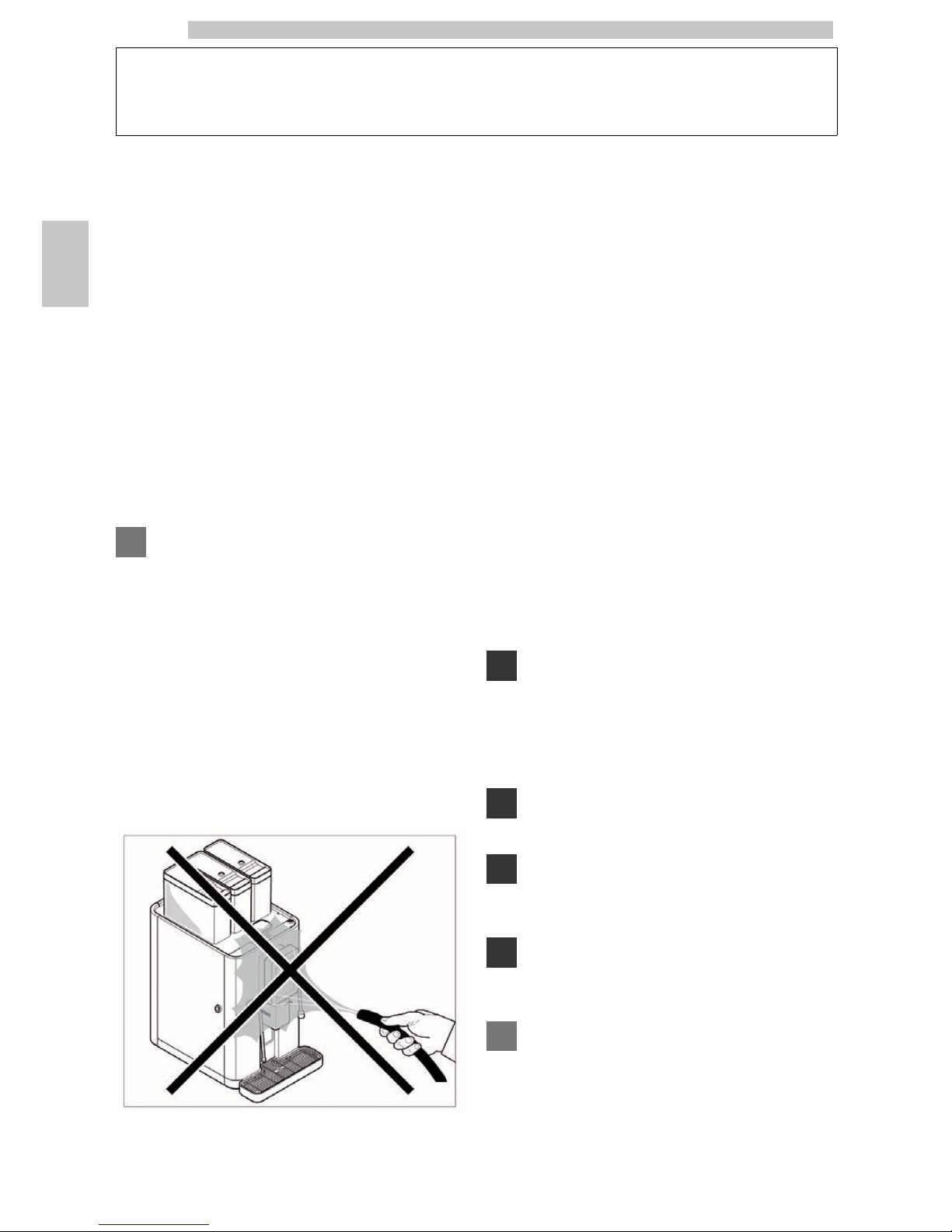

3.2 General safety regulations

It is forbidden to:

• disable the safety devices installed on the appliance;

• carry out maintenance on the machine without

unplugging it first;

• Install the appliance outdoors. It is advisable to place it in a

dry place where the temperature does not drop below

1°C, in order to prevent any possible freezing.

• use the machine for purposes other than those indicated

in the sale contract and in this publication;

• connect the appliance to the mains using multi-sockets or

adapters;

• use water jets to clean the vending machine.

It is compulsory to:

• check the electrical power line for conformity;

• use original spare parts;

• read the instructions contained in this publication and in

the enclosed documents carefully;

• use personal protection devices during installation, testing

and maintenance operations;

• Use a new water network connection set each time the

machine is disconnected and connected again to the

system.

Precautions for preventing human errors:

• make the operators aware of safety issues;

• handle the machine, either packaged or unpackaged, in

safe conditions;

• have a thorough knowledge of the installation procedures,

its operation and limits;

• dismantle the machine in safe conditions, in accordance

with the environmental protection and health and safety

laws in force.

To prevent machining residues from coming into

contact with the beverages, dispense about 0.5 l water

for each dispensing path before definitely starting the

vending machine. The dispensed beverages can be

consumed only after performing this operation.

Do not install the appliance in a location where water

jets may be used.

The appliance must only be installed in places where it

can be used and maintained only by qualified staff.

In case of failure or malfunctioning, please refer only to

the qualified personnel of the technical service.

The Manufacturer declines any liability for any damage

caused to property or injury caused to persons as a

result of failure to observe the safety regulations

described here.

Page 9

English

3

53

3.3 Operators' requirements

Two operators with different skills are required in order

to guarantee the appliance’s safety:

User

Person in charge of using and attending the machine. The

user is allowed to: Operate the appliance, adjust the

operating parameters, stop the appliance, refill the

appliance with coffee and instant products, empty the

liquid collection tray and the coffee grounds drawer, clean

the outside of the appliance. On detection of appliance

malfunctions, the User must request the assistance of the

Maintenance Technician.

The User is not allowed to carry out operations

indicated in this manual as competence of the

Maintenance Technician.

Maintenance Technician

Person in charge of installation, adjustment, set-up and, in

general, maintenance operations on the machine.

Access to the service area is restricted to persons having

knowledge and pratical experience of the appliance, in

particular as far as safety and hygiene are concerned.

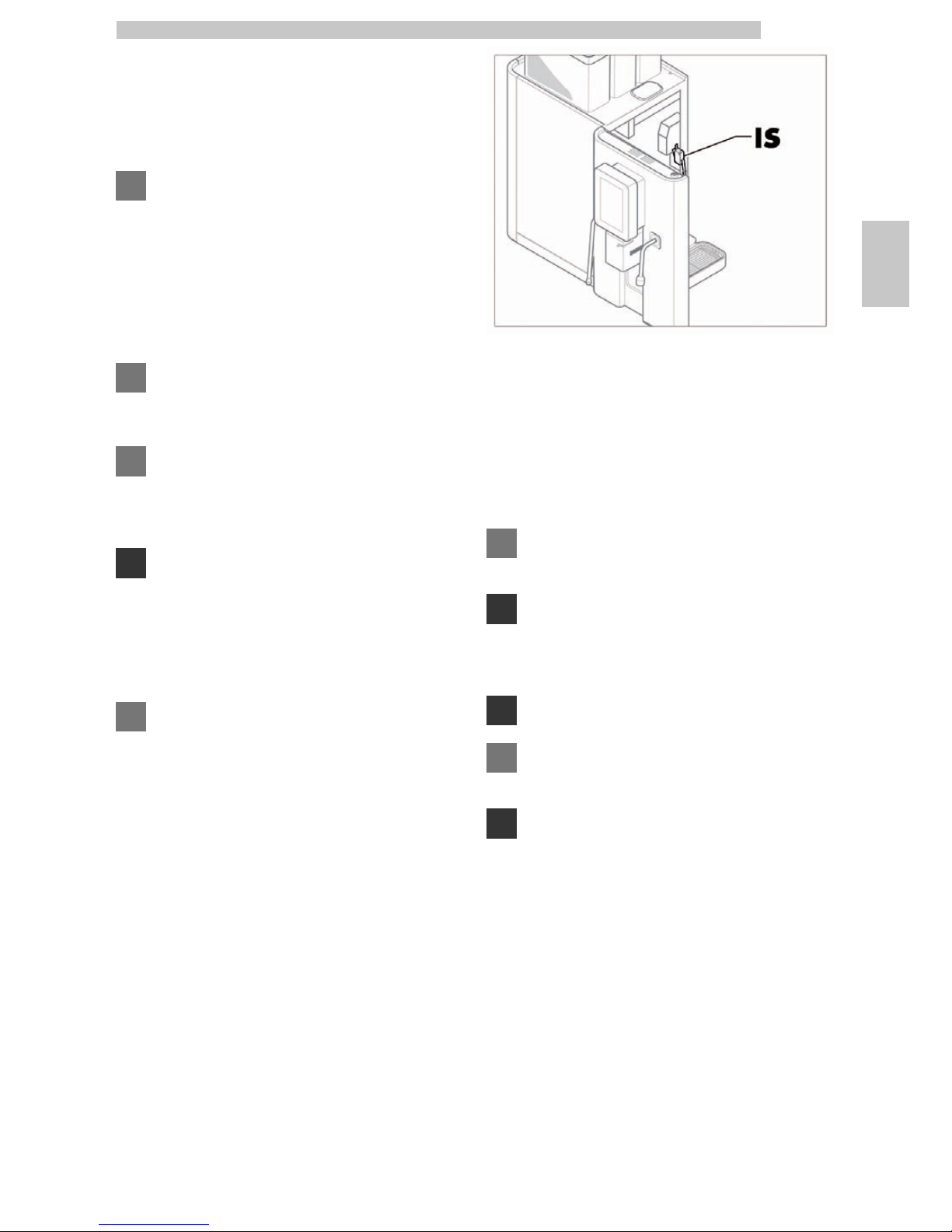

3.4 Safety devices

The machines described in this brochure are in

conformity with the specific current European

Regulations and therefore all their potentially

dangerous parts are protected.

Any overpressure in the water system that produces

steam and hot water is detected by 3 safety valves.

A thermostat avoids boilers overheating.

The door position is controlled by 1 microswitch that

stops machine operation when the component is not

placed correctly.

IS Safety switch

An electronic pulse counter stores the number of brewing

procedures performed and allows the scheduled

maintenance to be programmed.

3.5 Residual risks

Do not use containers that are not made of food

materials.

The structural characteristics of the machines

described in this brochure, do not protect the user

from the direct steam or hot water spouts.

Danger of burns.

During hot water and steam brewing do not turn the

spouts towards yourself or someone else.

Grab the spout only by the respective anti-burns

protectors.

Page 10

English

4

54

4 HANDLING AND STORAGE

4.1 Unloading and handling

Unloading from the transport vehicle and handling

operations of the appliance must be carried out by

qualified personnel only and using suitable equipment.

The appliance must always be kept in upright position.

Avoid:

• dragging the appliance;

• Overturn or lay down the appliance during transport and

handling;

• shaking the appliance;

• lifting the vending machine with ropes or cranes;

• leaving the appliance exposed to the elements, in humid

areas or close to heat sources.

4.2 Storage

If the appliance is not installed within a short time, but is

to be stored for a long time, it shall be kept in a sheltered

place according to the following instructions:

• the packaged appliance shall be stored in a closed, dry

area at a temperature between 1°C and 40°C;

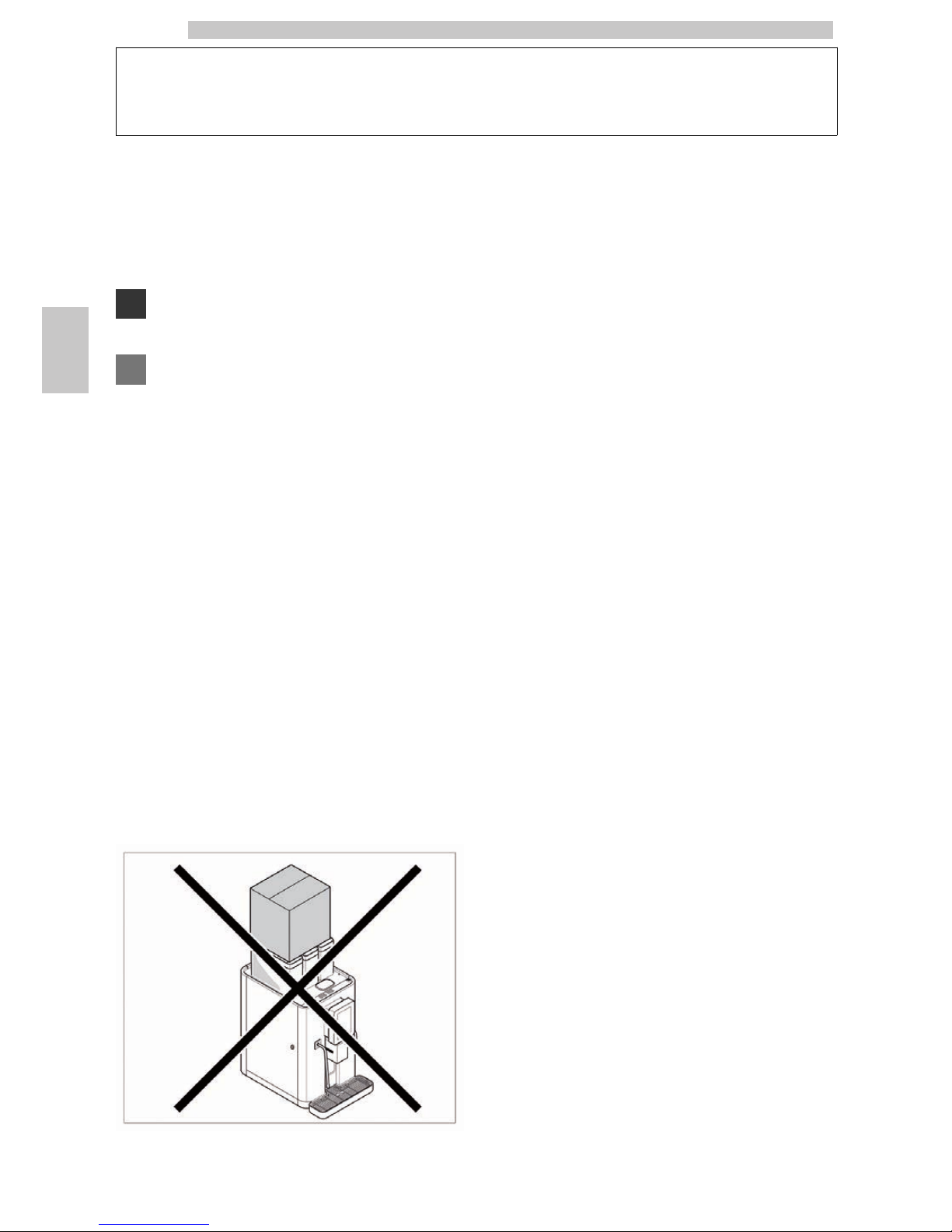

• do not put other appliances or boxes on the appliance;

• in any case, it is good practice to protect the appliance

from possible deposits of dust or other substances.

Page 11

English

5

55

5 INSTALLATION

5.1 Warning

The appliance cannot be installed in external areas.

Avoid installing it in areas where the temperature is

lower than +1°C or higher than 25°C and in

particularly humid or dusty places and it should not be

installed in places subject to explosion or fire hazards,

or where cleaning is done with water jets.

Before unpacking, check that the installation area complies

with the following specifications:

• the electric socket which the appliance is connected to

must be easily accessible for the user, so that the user will

easily disconnect the appliance from the electric mains

when necessary;

• the socket voltage must comply with that on the

identification plate;

• the maximum angle of inclination of the supporting

surface must NOT exceed 2°.

Check if the surface where the machine is installed has

the adequate dimension and solidity to support the

machine safely.

For a correct and ergonomic use of the machine, it is

recommended to install it onto a surface which is at

least 1 m high.

The appliance must be installed on a horizontal

surface.

The appliance must only be installed in places where it can

be used and maintained only by qualified staff.

If the appliance needs to be positioned close to a wall, it is

necessary to leave a space of at least 8 cm between the

appliance’s back and the wall in order to make sure that

the air outlet grill at the back of the appliance is

unobstructed.

5.2 Unpacking and positioning

On receipt of the appliance, make sure that it has not

suffered any damage during transport or that the packaging

has not been unduly opened with consequent stealing of

the components contained in it.

If damage of any kind is found, the courier must be

informed and notice must be given to the importer or the

seller immediately.

If these are not in the purchaser’s country, please contact

the manufacturing company directly.

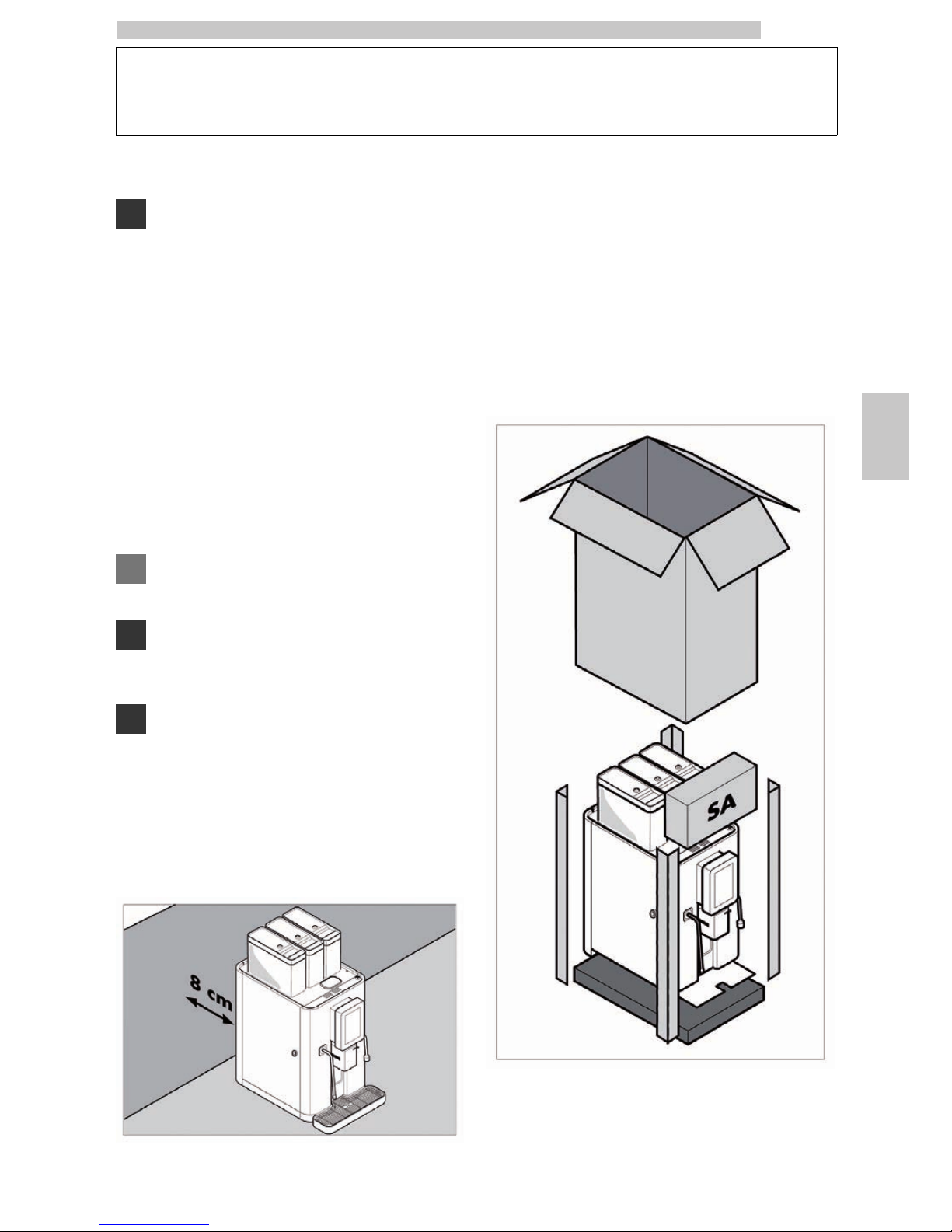

The appliance is protected by 4 angle bars and a plastic bag

and is delivered in a box.

Page 12

English

5

56

The appliance is supplied with an “ACCESSORY BOX”

that contains the following items:

• Instruction booklet

• Drip tray

• Rear spoiler

• No. 2 side spoilers

• Filling tube

• Drain tube

• Metal clamp

• Silicone hose

• Scraper

• No. 2 small brushes

• Measuring scoop

• Cleaning brush

• Detergent

• Grease tube

• Door key

SA Accessory box

Check that the surface where the appliance shall be

positioned is steady.

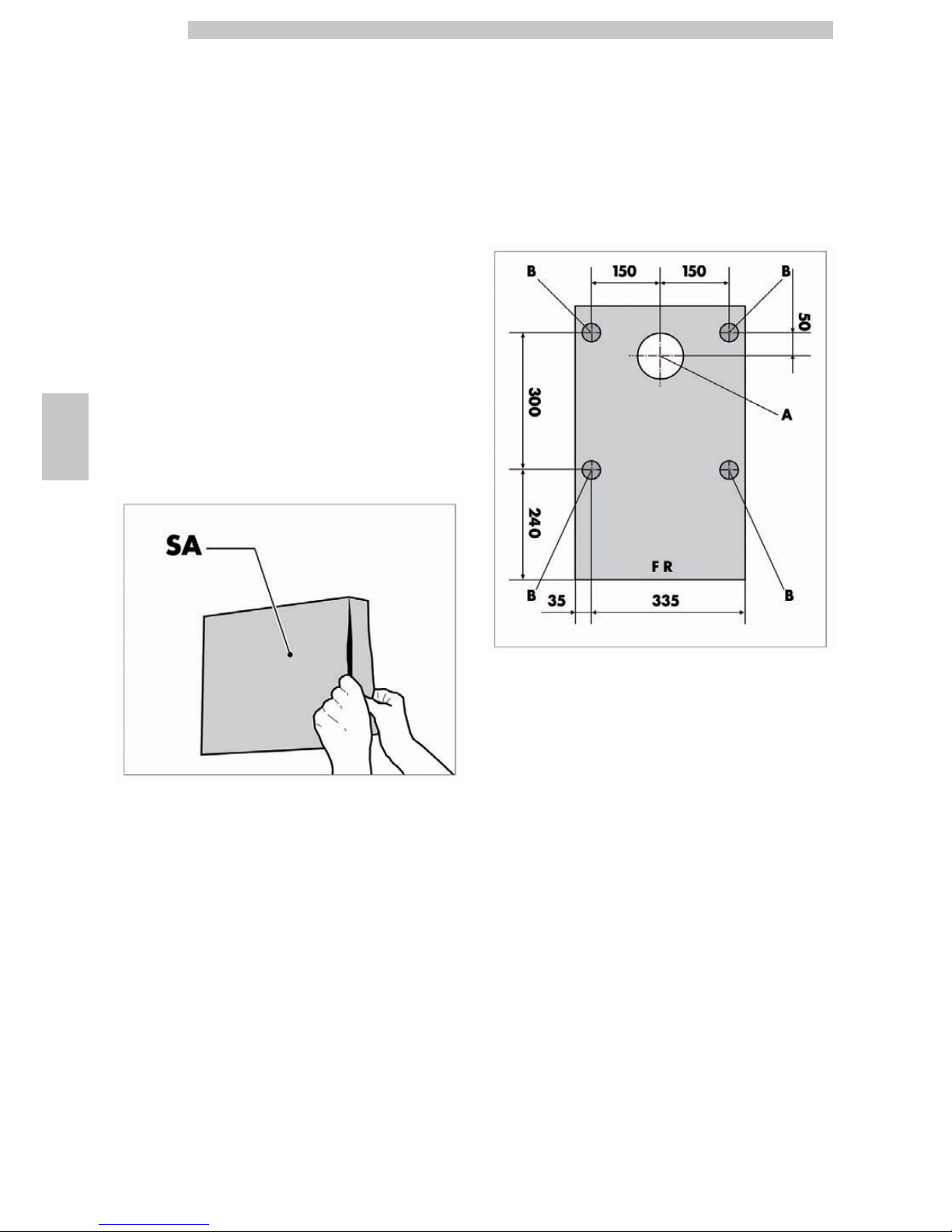

Make a 100 mm Ø hole on the surface (hole A in the figure).

Install the machine in its final position on the supporting

surface (the rings B indicate the ideal position of the

adjustable feet).

Level the machine by setting the adjustable feet.

FR Machine front side

A Hole to be made

B Ideal position of the adjustable feet

Page 13

English

5

57

5.3 Connection to water mains

Before connecting the appliance to water network,

please read and follow the applicable regulations in

force in your country.

Make sure the water network provides drinkable

water, with pressure ranging between 0,15MPA =,8MPA (1,5 and 8 bars).

Water hardness should not be less than 8°F.

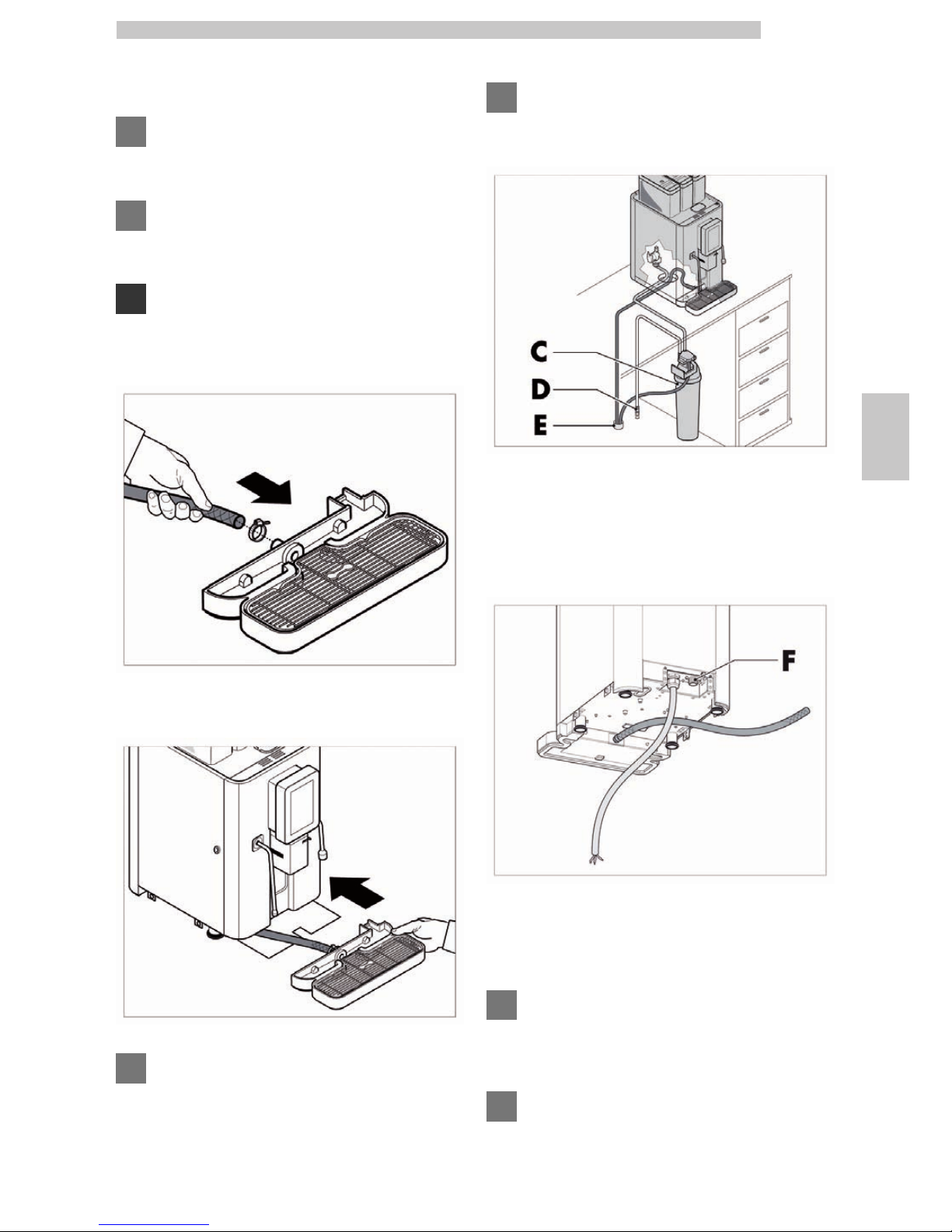

Use the metal clamp to connect the drain tube to the drip

tray.

Insert the drip tray into the machine front.

We recommend that the machine be supplied with

water treated by a descaling device, particularly for

water with high content of calcium and magnesium

(hard water).

Connect the water filter (C) to the water network (D).

Before connecting the water softener to the machine,

wash the machine until the water is clear.

C Water Filter

D Water network

E Drain channel

Connect the machine to the drinking water network by

means of the coupling (F). Only a tube and couplings

suitable "for food" must be used for the connection.

F Water inlet coupling

Insert the filling tube and the drain tube into the hole A.

Connect the drain tubes to the drain pipe (E).

Should the machine be moved to a different place, the

fitting unit must be replaced with a new one (water

network connecting pipe).

The water mains pipe should be certified according to

the standard IEC 61770.

Page 14

English

5

58

5.4 Connection to the electric

network

The Maintenance Technician, who is responsible for

the installation of the machine, must ensure that:

• the electric system complies with current safety

regulations;

• the supply voltage corresponds to that indicated on the

data plate.

If in doubt, do not proceed with the installation and

ask qualified and authorized personnel to check the

system accurately.

Also make sure that the electrical system the appliance

is connected to has the maximum load capacity

required, as indicated on the data plate.

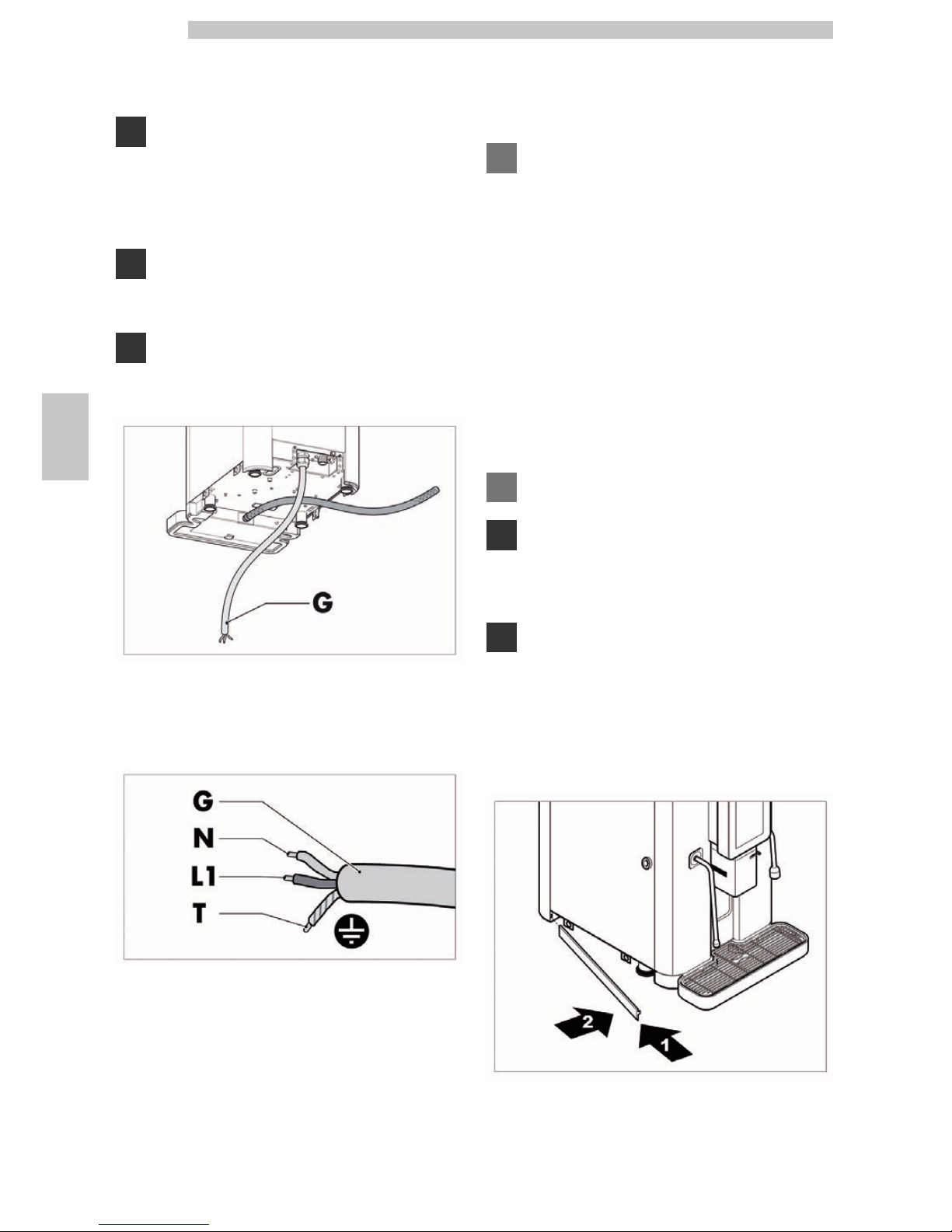

G Power cord type H07RNF sec. 3x2.5 mm²

Insert the power cord (G) into the hole A.

G Power cord type H07RNF sec. 3x2.5 mm²

N Neutral

L1 Phase

T Ground

Depending on the current regulations of the Country

where the machine operates, the cable connecting the

electric line has to be pre-set or equipped with an

all-pole switch (with a minimum contact opening of 3

mm), (or with a plug in accordance with the same

regulations).

• The all-pole switch must suit to machine input and be able

to detect all voltage polarities.

• Check that the electrical cables of the system are

proportioned to machine input.

Connect the appliance to the mains by means of the

power cord (G).

Make sure that the electrical plug is easily accessible

even after installing the machine.

The electric socket which the appliance is connected

to must be easily accessible for the user, so that the

user will easily disconnect the appliance from the

electric mains when necessary.

If damaged, the power cable must be replaced by the

Maintenance Technician only.

5.5 Mounting the Spoilers

Insert the left side spoiler as shown in the figure.

Do the same for the right side spoiler.

Page 15

English

5

59

Insert the rear spoiler as shown in the figure.

5.6 Connecting the USB Port

The USB port can be used to connect the machine to the

AUTHORISED SERVICE CENTRES' appliances in order to

carry out checks and programming operations.

To access the USB port perform the following operations.

Each operation via USB port must be carried out with

the door closed.

Loosen the socket head screw that is placed on the back

of the control panel.

Slide the control panel upwards.

Now the control panel is not attached to the machine any

more and should be removed as shown in the figure.

Attach the pins I to the suitable guides M as shown in the figure.

I Control panel pin

M Control panel guide

Page 16

English

5

60

Turn the control panel as shown in the figure.

Remove the cap from the inner side of the control panel

and connect to the USB port Q.

Q USB port

Page 17

English

6

61

6 DESCRIPTION OF CONTROLS

6.1 Commands

The appliance has the following controls:

• Power button

• Control panel

6.1.1 Power button

When the machine is connected to the mains and the

all-pole switch is set to "I", the following happens when

operating the power button:

• Power button set to "0", the control panel is off.

• Power button set to "I", the control panel is on.

The fact that the power button is set to "0" does not

represent a guarantee that the machine is not powered.

When performing any kind of cleaning or maintenance

intervention involving the inside of the machine,

disconnect the machine from the mains and set the

all-pole switch to "0".

6.1.2 Control panel

The control panel is sensitive to the touch, i.e. it combines

the functions of a display with those of a keypad.

The display areas which are sensitive to the touch change

according to the current machine phase, e.g. standard

operation or maintenance.

Page 18

English

7

62

7 SUPPLY AND STARTING UP

7.1 Container Configuration

The containers delivered are designed to dispense the

following products:

Instant product NextAge

1 Coffee beans

2 Coffee beans

3 Hot Chocolate

4 Pre-ground Coffee

7.2 Coffee bean supply

Be sure the coffee does not contain foreign bodies

which could be dangerous for grinders.

Remove the container cover.

Put coffee beans into the container.

Replace the cover on the container.

The appliance has two coffee bean hoppers, which

means that two different types of coffee can be used.

7.3 Refilling with Pre-ground Coffee

This operation can only be performed with the

machine switched on.

Open the pre-ground coffee door.

The machine will detect that the door is open and will

disable the coffee grinders/dosing units under the coffee

bean hoppers.

A "heart" icon will be displayed on the pictures of the

coffee-based beverages; this means that pre-ground coffee

is currently being used.

Pour the pre-ground coffee (max 2 measuring scoops) into

the duct.

Select the desired pre-ground coffee-based product

and leave the pre-ground coffee door open.

If the coffee-based beverage is selected with the door

closed, the machine will enable the coffee

grinders/dosing units' operation and a double dose of

coffee will be used (pre-ground coffee dose + fresh

ground coffee dose). As a result, nothing will be

brewed.

When the operations involving the use of pre-ground coffee are

complete, close the door. The coffee grinders/dosing units will be

enabled again and the "heart" icons will disappear from the

pictures of the coffee-based beverages.

Page 19

English

7

63

7.4 Instant product supply

Open the door.

Press the retainer FC in order to unlock the external

cover.

Remove the external cover from the instant product container.

Open the cover of the instant products container.

Pour the instant product into the container.

Close the container cover.

Refit the external cover.

Close the door.

7.5 Cream adjustment

Cream quantity is adjusted through lever.

By turning the lever clockwise, there will be a greater

quantity of cream.

By turning the lever anti-clockwise, there will be a smaller

quantity of cream.

7.6 Temperature setting

The milk to be used for the Cappuccinatore must be

put in a fridge at a temperature not over 4° C; do not

leave it outside the fridge for more than 30 minutes.

To change the milk temperature remove the dispenser

cover and operate the temperature adjusting lever.

Page 20

English

7

64

• By turning the lever upward, the temperature will grow.

• By turning the lever downward, the temperature will

lower.

7.7 Coffee grinding calibration

Whatever the coffee blend is, a very fine grinding

(notch on low values) increases the density, the cream

quantity and the brewing time of the beverage. On the

contrary a coarse grinding (notch on high values)

decreases the density, the cream, as well as the

brewing time.

Should a blockage of the grinders occur because

foreign bodies contaminated the coffee blend thus

blocking the machine, please contact an Authorised

Service Centre. When such blockage occurs, the "no

coffee" icon is displayed on the beverage pictures.

If either coffee grinder blocks, the operational one can

be selected from the control panel, so as to avoid

machine downtime. This operation is allowed only if

the product recipe does not specify which coffee

grinder should be used.

The grinding is pre-set to standard values, which anyway

can be modified with the following procedure.

Switch on the machine as instructed in the "First Appliance

Start Up" section.

Press the "Customer menu" button.

Press the "Maintenance" writing.

Page 21

English

7

65

Press the "Coffee grinder" writing.

From this screen you can select which one of the two

coffee grinders you want to set.

After selecting the coffee grinder, press "Finer" to set a

finer grind (the value becomes lower), or "Coarser" to set

a coarser grind (the value becomes higher).

Press "Back" to return to the previous menu.

To exit the maintenance menu and return to the beverage

selection screen, press the bottom left arrow and wait for

a few seconds.

The effects of the grind adjustment will become

noticeable after brewing 2-3 cups of coffee.

7.8 First start-up of the machine

Check if the removable components are in the right

position and if the door is closed.

If this is not the case, an indication of the component that is in

the wrong position will be displayed upon beverage selection.

Refill the machine (follow the instructions above) and

connect the appliance to the water network (see section

"Connection to the Water Network") and to the mains

(see section"Connection to the Electric Network").

Turn the all-pole switch on “I”.

Page 22

English

7

66

Open the door and switch on the machine by means of

the power button.

Close the door.

The following screen is displayed on the control panel.

Wait for a few seconds without touching the control

panel.

When the switch-on phase is complete, the following beverage

selection screen is displayed on the control panel.

No beverage will be brewed and no icon will be

enabled until the boilers reach the operating

temperature.

At the end of the warm-up phase the machine carries out

the "Machine ready" cycle.

At this point the icons of the beverages will be enabled.

Page 23

English

7

67

During the "Machine ready" cycle the machine will

dispense hot water and steam, so make sure you do

not put your hands under the jets.

7.9 Cleaning the parts in contact

with foodstuffs

Clean all the parts of the VM which are in contact with

foodstuffs.

• Wash your hands carefully.

• prepare a chlorine-based anti-bacterial cleaning solution

(these products can be purchased at the chemist’s)

following the concentrations indicated by the product

instructions.

• remove all the product containers from the machine.

• Remove the container lids and the product channels.

Plunge all items into the previously prepared solution.

7.10 Use of the machine

The beverage selection mode is indicated in chapter

"Operation and Use".

Page 24

English

8

68

8 MAINTENANCE MENU

This section contains instructions on how to set and

change the maintenance parameters of the appliance.

It is therefore necessary to read it carefully, and

intervene only when the correct sequence of

operations to be performed is fully understood.

8.1 Maintenance menu

The structure of the maintenance menu is indicated in

section “Structure of the Maintenance Menu”.

The section “Description of Messages in the Maintenance

Menu” describes all the entries in the maintenance menu.

8.1.1 Access to the maintenance menu

Follow the instructions listed below in order to enter the

maintenance menu.

Switch on the machine as instructed in the "First Appliance

Start Up" section, wait for the start-up screen to appear

and then press the "Customer menu" button.

Press the "Maintenance" writing.

To exit the maintenance menu and return to the beverage

selection screen:

• Press the bottom left arrow and wait for a few seconds.

• Close the door.

Page 25

English

8

69

8.1.2 Structure of the maintenance menu

ITEM NO. MENU ITEM

1 MAINTENANCE

1.1. Cleaning

1.1.1. Coffee Group

01:01:02 Dispensing spout/mixer

01:01:03 Milk circuit

1.2. Coffee grinder

1.2.1. Coffee grinder 1/2

1.2.1.1. Finer

1.2.1.2. Coarser

8.1.3 Description of messages in the maintenance menu

DISPLAY Description

1

MAINTENANCE

This menu allows some maintenance and cleaning operations to be performed on some

internal machine parts.

1.1.

Cleaning

This option allows the brew group, dispensing spout, mixer and milk circuit to be washed.

1.1.1.

Coffee Group

This option allows a brew group wash cycle to be performed (see section "Brew Group

Cleaning").

01:01:02

Dispensing spout/mixer

This option allows a wash cycle of the dispensing spout and of the instant product mixer to

be performed (see section "Cleaning the Dispensing Spout and the Instant Product Mixer").

01:01:03

Milk circuit

This option allows a milk circuit wash cycle to be performed (see section "Milk Circuit

Cleaning").

1.2.

Coffee grinder

This option allows the coffee grinders' grind to be adjusted (see section "Coffee Grind

Adjustment").

1.2.1.

Coffee grinder 1/2

This option allows the user to select the coffee grinder to which the coffee grind adjustment

should be applied.

1.2.1.1.

Finer

This option allows for a finer grind.

1.2.1.2.

Coarser

This option allows for a coarser grind.

Page 26

English

9

70

9 OPERATION AND USE

Read carefully this brochure until you get a good

understanding of the machine, before starting to

operate it.

After a long time of machine inactivity, read the

paragraph “First switching-on” before re-operating the

machine.

This appliance is not intended for use by persons

(including children) with reduced physical, sensory or

mental capabilities, or lack of experience and

knowledge, unless they have been given supervision or

instruction concerning use of the appliance by a

person responsible for their safety.

Children must be supervised to ensure they do not

play with the appliance.

This appliance is to be used for household applications

or in similar areas like:

• For staff only cooking areas in shops, offices and other

professional environments;

• Farms;

• For clients use in hotels, motels and other residential type

areas;

• Environments like bed and breakfasts.

9.1 Switch On

Proceed as explained in paragraph "First switching-on".

9.2 Beverage selection

The following are the conditions necessary to select a

beverage:

• After the switch-on procedure the machine has reached

the set temperature. If not, the beverage icons will be

disabled and the message "'Beverage name' not ready" will

be displayed when touching the corresponding icon.

• There is no error condition that prevents the brewing of

beverages. If this is not the case, the icons corresponding

to the beverages in error will be disabled, and the error

message will be displayed when touching these icons.

• The selected beverage is enabled. If not, the beverage icon

will be disabled, and a message describing the cause of

beverage unavailability will be displayed when touching the

icon.

• The selected beverage is not locked. If this is not the case,

the beverage icon will be disabled and a message

displaying the locking condition will be displayed when

touching the corresponding icon.

Beverage selection

If the necessary conditions for beverage selection are met

the following screen will be displayed on the machine. If

not, some icons might be disabled.

The first 4 lines contain the selectable beverages.

The last line contains the icon for the selection of the

coffee bean hopper to use, the icon to adjust the height of

the dispensing spout and the icon of the beverage

multiplier.

Page 27

English

9

71

Selecting the Coffee Bean Hopper

This control allows the user to select which coffee bean

hopper he/she would like to use to brew the coffee

bean-based beverage.

This selection is available only if the machine is

equipped with 2 coffee bean hoppers.

This selection is available only if the recipe of the

selected beverage does not specify the coffee bean

hopper to use.

The following picture shows the two available options: The

one on the left indicates that the left coffee bean hopper is

being used, the one on the right indicates that the right

coffee bean hopper is being used.

Adjusting the Height of the Dispensing Spout

If the machine is programmed to allow the dispensing

spout height to be adjusted, the icon shown in the

following picture will be visible on the display.

This control allows the dispensing spout to be adjusted at various

heights so that glasses of different sizes can be used.

The picture below shows the minimum and maximum

heights possible.

h1 70 mm

h2 200 mm

Beverage Multiplier

This control allows the user to multiply the number of

beverages to be brewed.

Every time the icon shown in the figure is pressed, the

counter increases by 1 unit from a minimum of 1 to a

maximum of 8 beverages.

After pressing the multiplier icon, only the beverages

programmed for being multiplied will still be enabled.

If no beverage icon is pressed within 5 seconds after

pressing the multiplier icon, the counter is reset to 1.

During the beverage brewing, the number of the

current brewing process and the total number of the

required beverages is displayed.

Beverage Brewing

To brew a beverage press the icon corresponding to the

required beverage.

During the beverage brewing, a screen with the following

layout is displayed:

• On top, the product brewing bar.

• In the middle, the picture of the beverage being brewed in

that moment.

Page 28

English

9

72

• On the left bottom side, a button to stop the beverage

brewing.

• On the right bottom side, a button to stop the current

phase and go on with the subsequent phases.

The figure shows the "Cappuccino" brewing screen.

If an anomalous condition occurs during the brewing

phase, e.g. a fault or a product shortage, a message

with the causes of the block is displayed.

Special messages and signals are indicated in chapter

"Troubleshooting".

9.3 Display messages

When one or more alarms occur, the relevant beverages

are disabled and cannot be selected for the brewing.

If a disabled beverage is pressed a timed pop-up window

appears for 3 seconds, indicating which current alarm has

disabled the beverage.

Here below the list of the alarms displayed is reported,

along with the machine conditions that release them.

Temperature sensor alarm

Consequence: All the beverages for which the coffee

phase is required are disabled.

Message upon touching: "Temperature sensor alarm".

Pressure sensor alarm

Consequence: All the beverages for which the water phase, the

milk phase or the steam phase is required are disabled.

Message upon touching: "Pressure sensor alarm".

Coffee grinder 1(2) blocked

Consequence: If the selected coffee grinder is blocked all

the beverages for which the coffee phase is required are

disabled; if the blocked coffee grinder is not the selected

one, the error has no consequences.

Note: In machine models which allow for the coffee bean

hoppers to be used alternatively, the blocked coffee

grinder is just not used.

Message upon touching: "Coffee grinder blocked".

Coffee alarm

Meaning: The latest grinding cycle exceeded the timeout.

Possible causes: There is no coffee; the dosing unit sensor

is out of order or disconnected (after 5 attempts).

Consequence: The "no coffee" icon is shown over the beverages

for which the coffee phase is required with either the coffee

beans from the empty hopper or the not operational dosing unit.

Message upon touching: No message.

Water alarm

Meaning: No water pressure detected.

Consequence: All beverages are disabled.

Message upon touching: "No water".

Water level alarm

Consequence: All the beverages for which the steam phase, the

milk phase or the hot water phase is required, are disabled.

Message upon touching: "Water level error".

Brew group error

Consequence: All the beverages for which the coffee

phase is required are disabled.

Message upon touching: "Brew group error".

Coffee grounds drawer present

Consequence: When it is not detected (value = 0), all the

beverages for which the coffee phase is required are disabled.

Message upon touching: "Insert coffee grounds drawer".

Front door closing

Consequence: When it is not detected (value = 0), all

beverages are disabled.

Message upon touching: "Close front door".

Pre-ground coffee door closed

Consequence: No consequence causing the disabling of

beverages. If open (value = 0), all the beverages for which

the coffee phase is required are brewed without fresh

pre-ground coffee beans (coffee quantity = 0) - see section

"Refilling with Pre-ground Coffee".

Page 29

English

9

73

Message upon touching: No message.

Brew group present

Consequence: If the brew group is not present (value = 0), all the

beverages for which the coffee phase is required are disabled.

Message upon touching: "Insert brew group".

Coffee grounds drawer full alarm

Consequence: When this alarm is released, all the beverages for

which the coffee phase is required are disabled.

9.4 Machine switching-off

It can be obtained by switching both the main switch and

the all-pole switch on the “0” position or by disconnecting

the plug.

Page 30

English

10

74

10 CLEANING AND MAINTENANCE

Before performing any maintenance and/or cleaning

operations, turn off the appliance by switching the switches

to the “OFF” position. Disconnect the appliance from the

power supply by removing the plug from the socket and

wait for the appliance to cool down.

The Manufacturer declines any liability for any damage

or malfunctioning caused by incorrect or poor

maintenance.

Do not use direct water jets.

In case of anomalies, immediately turn off the

appliance, disconnect it from the power supply by

removing the plug from the socket and contact the

nearest service centre.

10.1 General notes for correct

operation

Non-removable components and the machine itself must

be cleaned, when not differently specified, only by using

cold or lukewarm water, with a non-abrasive sponge and a

damp cloth.

Never use direct water jets. Wring the damp cloth or the

sponge before using it to clean the appliance.

All the parts requiring cleaning are easily accessible, so no

tools are needed.

Periodic maintenance and cleaning will keep the machine in

good working conditions for a longer time and ensure

compliance with basic hygiene standards.

To guarantee the correct operation of the machine it is

recommended to conform to the instructions and times

indicated in the "MAINTENANCE SCHEDULE".

10.2 Cleaning and scheduled

maintenance

All components must be rinsed with warm water only,

without using any detergent or solvent that could

modify their form and operation.

Removable components cannot be rinsed in the

dishwasher.

Page 31

English

10

75

10.2.1 Maintenance schedule

COMPONENT TO BE

CLEANED

MAINTENANCE A B C D

Control panel See section "Control Panel Cleaning". x - - Steam wand See section "Steam Wand Cleaning". x - - Dispenser

See sections "Dispenser/Mixer Automatic Cleaning" and "Dispenser

Manual Cleaning".

x - - -

Coffee Group See section "Cleaning the Coffee Brew Group". x - - Milk circuit See section "Milk Circuit Cleaning". x - - Drip tray and relative grill See section "Drip tray and relative grill cleaning". x - - -

Dump box See section "Dump box cleaning". x - - Mixer

See sections "Dispenser/Mixer Automatic Cleaning" and "Instant

Product Mixer Cleaning".

- x - -

Instant products container See section "Cleaning the Containers". - x - -

Coffee bean container See section "Cleaning the Containers". - x - Hot water wand See section "Hot Water Wand Cleaning". - - - x

A Daily

B Weekly

C At each supply

D Monthly

Page 32

English

10

76

10.2.2 Control Panel Cleaning

The control panel cleaning must only be performed

with the power button set to "0" or the door open.

Clean the control panel only with a damp cloth or with

detergents that are suitable for food contact.

10.2.3 Steam Wand Cleaning

Perform this cleaning operation each time after using

the steam wand.

Clean the wand with a non-abrasive damp cloth.

If the wand is clogged, its end can be unscrewed and a pin

can be used to free the nozzles.

10.2.4 Dispenser/Mixer Automatic

Cleaning

Switch on the machine as instructed in the "First Appliance

Start Up" section.

Press the "Customer menu" button.

Press the "Maintenance" writing.

Press on the "Cleaning" writing.

If the machine has not reached the operating

temperature, the cleaning buttons are not active.

If the machine does not detect any pressure in the

water circuit, the cleaning buttons are not active.

Page 33

English

10

77

Press on the "Dispenser/Mixer" writing.

Now the machine starts the automatic cleaning cycle of

the dispenser and of the mixer.

Under the button corresponding to the selected cleaning

type, a progress bar indicates the cleaning cycle progress

status.

Some hot water will be dispensed through the

dispenser during the automatic cleaning cycle.

No other operations will be allowed until the selected

wash cycle is in progress.

When the selected cleaning cycle is complete, the automatic

cleaning screen with the active buttons is displayed again.

Press "Back" to return to the previous menu.

To exit the maintenance menu and return to the beverage

selection screen, press the bottom left arrow and wait for

a few seconds.

10.2.5 Dispenser Manual Cleaning

Every time the CAPPUCCINATORE is used, it must

be cleaned in order to avoid the solidification of

residues.

All the removable parts must be washed and rinsed in

running water.

In order to clean the dispenser manually, its various parts

must be removed and washed separately.

The parts are listed in the following picture.

D1 Dispenser unit

D2 Milk suction tube

D3 Milk suction hose/Cappuccinatore coupling

D4 Temperature setting lever

D5 Dispenser cover

D6 Cappuccinatore fork

D7 Cream adjustment lever

D8 Cappuccinatore body cover

D9 Cappuccinatore body

D10

Cappuccinatore unit

D11

Dispensing spout body cover

D12

Dispensing spout body

D13

Dispensing spout unit

The operations describing how to disassemble the

dispenser unit are listed here below:

• Remove the dispenser cover D5 by pulling it towards you.

• Disconnect the coupling D3 from the Cappuccinatore unit

D10 (only for versions with Cappuccinatore).

• Use both your hands to remove the dispenser unit D1 by

pulling it towards you.

• Slide the Cappuccinatore unit D10 upwards (only for

versions with Cappuccinatore).

• Remove the Cappuccinatore fork D6 from the

Cappuccinatore unit D10 by turning it upwards (only for

versions with Cappuccinatore).

• Slide the crema adjusting lever D7 upwards (only for

versions with Cappuccinatore).

Page 34

English

10

78

• Slide the temperature adjusting lever D4 on the left (only

for versions with Cappuccinatore).

• Slide the Cappuccinatore body cover D8 upwards (only

for versions with Cappuccinatore).

• Slide the dispensing spout body cover D12 upwards.

Wash all the components with lukewarm water.

Assemble the components in reverse order.

10.2.6 Cleaning of the coffee brew

group

The brew group must be cleaned at regular intervals by

using the suitable tablets. A specific function is provided in

the machine maintenance menu in order to carry out this

operation, as explained below.

Switch on the machine as instructed in the "First Appliance

Start Up" section.

Press the "Customer menu" button.

Press the "Maintenance" writing.

Press on the "Cleaning" writing.

If the machine has not reached the operating

temperature, the cleaning buttons are not active.

If the machine does not detect any pressure in the

water circuit, the cleaning buttons are not active.

Page 35

English

10

79

Press on the "Brew group" writing.

A pop-up window is displayed indicating that the tablet

must be put into the pre-ground coffee duct.

Open the pre-ground coffee door.

Insert the tablet into the duct and press on the "Start"

writing.

The machine starts the brew group automatic cleaning

cycle.

Under the button corresponding to the selected cleaning

type, a progress bar indicates the cleaning cycle progress

status.

Some hot water will be dispensed through the

dispenser during the automatic cleaning cycle.

No other operations will be allowed until the selected

wash cycle is in progress.

When the selected cleaning cycle is complete, the automatic

cleaning screen with the active buttons is displayed again.

Now, to stop the brew group cleaning, the following

operations must be performed:

• Open the door.

• Disconnect the coffee pipe.

Page 36

English

10

80

• Remove the brew group by holding it from the special

handle.

• Wash abundantly with warm water.

Do not use detergents.

• Refit the brew group, connect the coffee pipe and close

the door.

When inserting the brew group make sure that the

rubber joint is in vertical position, with the silicone

hose going downwards.

Press "Back" to return to the previous menu.

To exit the maintenance menu and return to the beverage

selection screen, press the bottom left arrow and wait for

a few seconds.

10.2.7 Milk Circuit Cleaning

Switch on the machine as instructed in the "First Appliance

Start Up" section.

Press the "Customer menu" button.

Page 37

English

10

81

Press the "Maintenance" writing.

Press on the "Cleaning" writing.

If the machine has not reached the operating

temperature, the cleaning buttons are not active.

If the machine does not detect any pressure in the

water circuit, the cleaning buttons are not active.

Press on the "Milk circuit" writing.

A pop-up window is displayed, indicating that the milk

suction hose must be immersed in the detergent solution.

Page 38

English

10

82

Immerse the milk suction hose in the detergent solution

and then press Start.

The machine starts the milk circuit automatic cleaning

cycle.

Under the button corresponding to the selected cleaning

type, a progress bar indicates the cleaning cycle progress

status.

Some hot water will be dispensed through the

dispenser during the automatic cleaning cycle.

No other operations will be allowed until the selected

wash cycle is in progress.

When the selected cleaning cycle is complete, the automatic

cleaning screen with the active buttons is displayed again.

Press "Back" to return to the previous menu.

To exit the maintenance menu and return to the beverage

selection screen, press the bottom left arrow and wait for

a few seconds.

10.2.8 Drip tray and relative grill

cleaning

Open the door. Remove the grill. Clean the drip tray's

inside. Refit the grill. Close the door.

10.2.9 Dump box cleaning

Open the door.

Remove the coffee grounds drawer.

Empty out the coffee grounds.

Wash the coffee grounds drawer under running water.

Refit the coffee grounds drawer in its seat and close the

door.

Each time the coffee grounds drawer is removed the

coffee grounds counter is reset to zero.

10.2.10 Instant Product Mixer Cleaning

Open the door.

Disconnect the wand from the mixer body.

Remove the cap and the powders chute.

Page 39

English

10

83

Turn the ring nut clockwise and remove the mixer body.

Remove the fan by levering carefully with a flat

screwdriver.

Turn the flange housing cover clockwise and then remove it.

Wash all components with lukewarm water and pay

particular attention not to damage the fan.

Assemble the components in reverse order and connect

the dispensing hose correctly.

10.2.11 Cleaning the containers

To clean the instant product container proceed as follows:

• Open the door.

• Press the retainer FC in order to unlock the external

cover.

Page 40

English

10

84

• Remove the external cover from the instant product container.

• Remove the container by pushing it inwards in a way to

disengage the retainer A, then lift it up:

• wash the canister interior and dry it well before replacing;

• follow the above procedure in the reverse order to refit

the canister, ensuring that the catch A slots into place.

To clean the coffee bean hopper the following operations are necessary:

• Remove the coffee bean hopper lid.

• Lift the retainer FE and pull the rear level LP in a way to

close the coffee bean hopper partition, then disengage the

hopper from the upper surface of the machine.

• dispense a few test coffee cups in order to empty the

coffee grinder from coffee beans;

• Slide the hopper upwards.

• wash the inside of the container and dry it carefully before

reassembling it.

• To reinstall the hopper proceed in reverse order and

make sure that the two pins are inserted into the special

slots.

Page 41

English

10

85

10.2.12 Hot Water Wand Cleaning

Clean the wand with a non-abrasive damp cloth.

If the wand is clogged, its end can be unscrewed and the

aerator can be immersed in a solution containing a

descaling agent.

10.3 Non-scheduled maintenance

Unscheduled maintenance includes every repairing or part

replacing.

The Maintenance Technician is the only person authorized

to perform these operations.

Page 42

English

11

86

11 TROUBLESHOOTING

Here is a list of the possible machine troubles.

When the symbol "*" appears in the "Solution" box, it means that the operation must be performed by a Maintenance Technician.

Trouble Cause SOLUTION

The machine does not start No voltage Check:

- that the plug is connected

- that the all-pole switch (if

any) is on

- the fuses of the electrical

system

*

- the electrical connections

*

The display shows:

coffee grounds drawer full

Dump box full

Empty the dump box and

reintroduce it properly

Grinder error Coffee grinder unit blocked Clean the coffee grinder

*

Instead of coffee only water is brewed

The button selecting pre-ground coffee has been

pressed but the relative container has not been filled

with instant coffee.

Place the coffee dose in the

relative hopper and restart the

cycle

No water or steam supply The steam/hot water spout’s hole is clogged

Clean it as explained in

sections "Steam Wand

Cleaning" and "Hot Water

Wand Cleaning".

Coffee flows too rapidly Grinding is too coarse Set a finer grinding

Coffee flows too slowly Grinding is too fine Set a coarser grinding

Coffee is not hot enough The cup has not been preheated Preheat the cup

The machine has not yet reached the

suitable temperature

Wait for the machine to reach

the suitable temperature

Coffee has not enough cream

The coffee blend is not appropriate, coffee is

not fresh off the roasting, the coffee powder

has been ground too finely or too coarsely

Change the coffee blend or

check its grinding (if

pre-ground)

The machine requires too much time to

warm up, the water quantity is reduced

The machine circuit is clogged by scale Descale the machine *

The brew group cannot be removed.

The brew group is not in its neutral position

(N)

Switch the machine on and

off through the main switch

The brew group cannot be inserted.

The brew group is not in its neutral position

(N)

Turn the brew group by

hand until it reaches the

neutral position (N). The

reference on the shaft must

match the arrow N

The cappuccinatore does not dispense milk

The milk used is not cold enough (see

warnings)

Move the temperature

adjusting lever downward

No more milk in the container Fill milk container

Page 43

English

12

87

12 STORAGE DISPOSAL

12.1 Change of location

Should the machine be positioned in another site it is

necessary to carry out the following operations:

• unplug the machine;

• carry out the general cleaning of the machine as indicated

in chapter “Cleaning and Maintenance";

• put the components back in place and close the doors;

• lift and place the machine in the assigned location

following the instructions given in section “Vending

Machine Unpacking and Positioning”.

12.2 Inactivity and storage periods

If the machine needs to be stored or remains inactive for a

long period, carry out the same operations as described in

section “Change Location", therefore:

• wrap the machine in a tarpaulin to protect it from dust

and damp;

• check that the machine is in a suitable place (the

temperature should not be less than 1°C) taking care not

to place any boxes or appliances over it.

Page 44

English

13

88

13

INSTRUCTIONS FOR END-OF-LIFE DISPOSAL

TREATMENT

INFORMATION FOR THE USER

This product complies with EU Directive 2002/96/EC.

The symbol on the product or on its packaging indicates

that this product may not be treated as household waste.

Instead it shall be handed over to the applicable collection

point for the recycling of electrical and electronic

equipment.

By ensuring this product is disposed of correctly, you will help prevent

potential negative consequences for the environment and human health,

which could otherwise be caused by inappropriate waste handling of this

product. For more detailed information about recycling of this product,

please contact your local city office, your household waste disposal

service or the shop where you purchased the product.

The diposal of the vending machine or of a part of it must

be carried out with full respect of the environment and

according to local laws in force.

Loading...

Loading...