Sachtler Video 20 S1, video 18 S1 User Manual

Video 20 S1

Fluid Head

Fluidkopf

Manual / Benutzerinformation

© by sachtler®. Alle Rechte vorbehalten / All rights reserved

Originalbetriebsanleitung/Original User Manual

Version: 1.6/02/12

Ausgabedatum / Issue date: 02/12

Bestellnr. / Order no.: S 2021-4980

sachtler

®

Vitec Group Videocom Division

www.vitecgroup.com

Erfurter Strasse 16 Postfach / P.O.BOX 2039

D-85386 Eching D-85380 Eching

Germany Germany

Telefon: +49/(0)89 321 58 200

Telefax: +49/(0)89 321 58 227

E-Mail: contact@sachtler.de

Internet: http://www.sachtler.com

- I -

Video 20 S1

Table of contents

1 Safety instructions / General Information.............................1

2 Operating elements..............................................................2

3 Operation..............................................................................4

3.1 Intended use ................................................................4

3.2 Moving of the pan bar ..................................................4

3.3 Levelling of the fluid head ............................................5

3.4 Mounting of the camera and / or plate.........................5

3.5 Counterbalancing of the camera..................................7

3.6 Setting of the damping.................................................8

3.7 Brakes ..........................................................................8

3.8 Change of battery ........................................................8

3.9 Transport setting of damping, counterbalance

and brakes ...................................................................9

4 Technical Data....................................................................10

5 Accessories ........................................................................11

6 Inspection & Cleaning ........................................................11

7 Warranty .............................................................................11

Inhaltsverzeichnis

1 Sicherheitshinweise / Grundlegende Hinweise..................13

2 Bedienelemente .................................................................14

3 Betrieb ................................................................................16

3.1 Bestimmungsgemäße Verwendung ...........................16

3.2 Schwenkarmverstellung .............................................16

3.3 Nivellieren des Fluidkopfes ........................................17

3.4 Entnehmen und Einsetzen der Kameraplatte ............17

3.5 Einstellen der Kamerabalance ...................................19

3.6 Einstellen der Dämpfung............................................20

3.7 Bremsen.....................................................................20

3.8 Austausch der Batterie...............................................20

3.9 Transportstellung von Dämpfung, Gewichts-

ausgleich und Bremsen .............................................21

4 Technische Daten...............................................................22

5 Zubehör ..............................................................................23

6 Inspektion & Pflege ............................................................23

7 Gewährleistung ..................................................................23

- II -

Video 20 S1

Manual

Video 20 S1

- 1 -

1 Safety instructions / General Information

Á Before using the fluid head read the manual.

Á Before mounting the fluidhead on the tripod, check if the tri-

pod has a safe standing and if the ttripod leg extensions are

clamped.

Á Before releasing the tie down on the fluid head (with a

mounted camera), the tripod must be secured against fall

over.

Á Before releasing the vertical brake (at a non balanced

camera set up) or the clamping of the camera-/balance plate

the camera must be secured against suden movement,

otherwise there may be a danger of finger trapping.

Á During camera tilt movements with extreme tilt angles there

may be a danger of finger trapping between balance plate

and housing for users and third persons.

- 2 -

Video 20 S1Manual

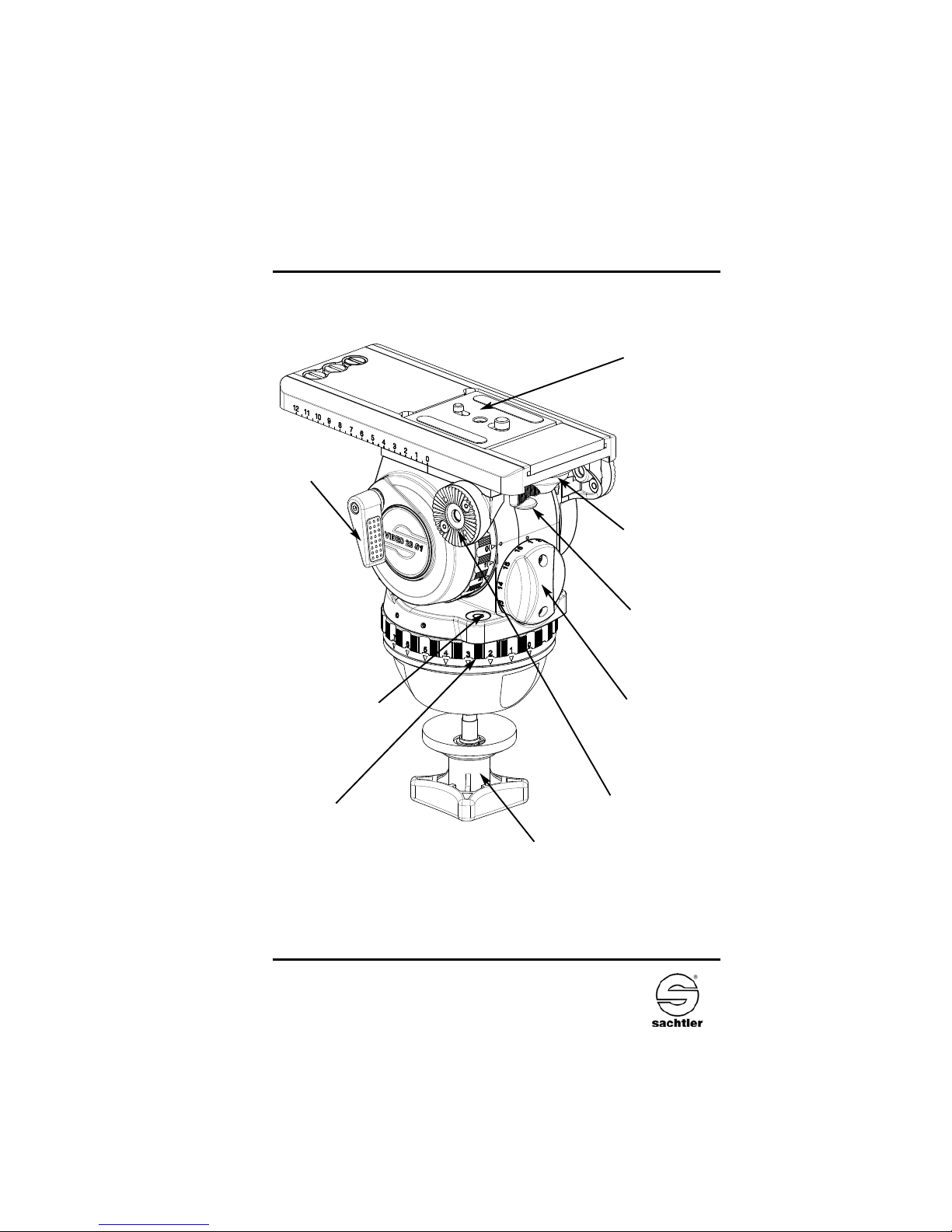

2 Operating elements

Camera plate

Safety Lock of

Touch & Go System

Counterbalance

Adjustment Knob

Vertical brake

Tie down

Pic. 1

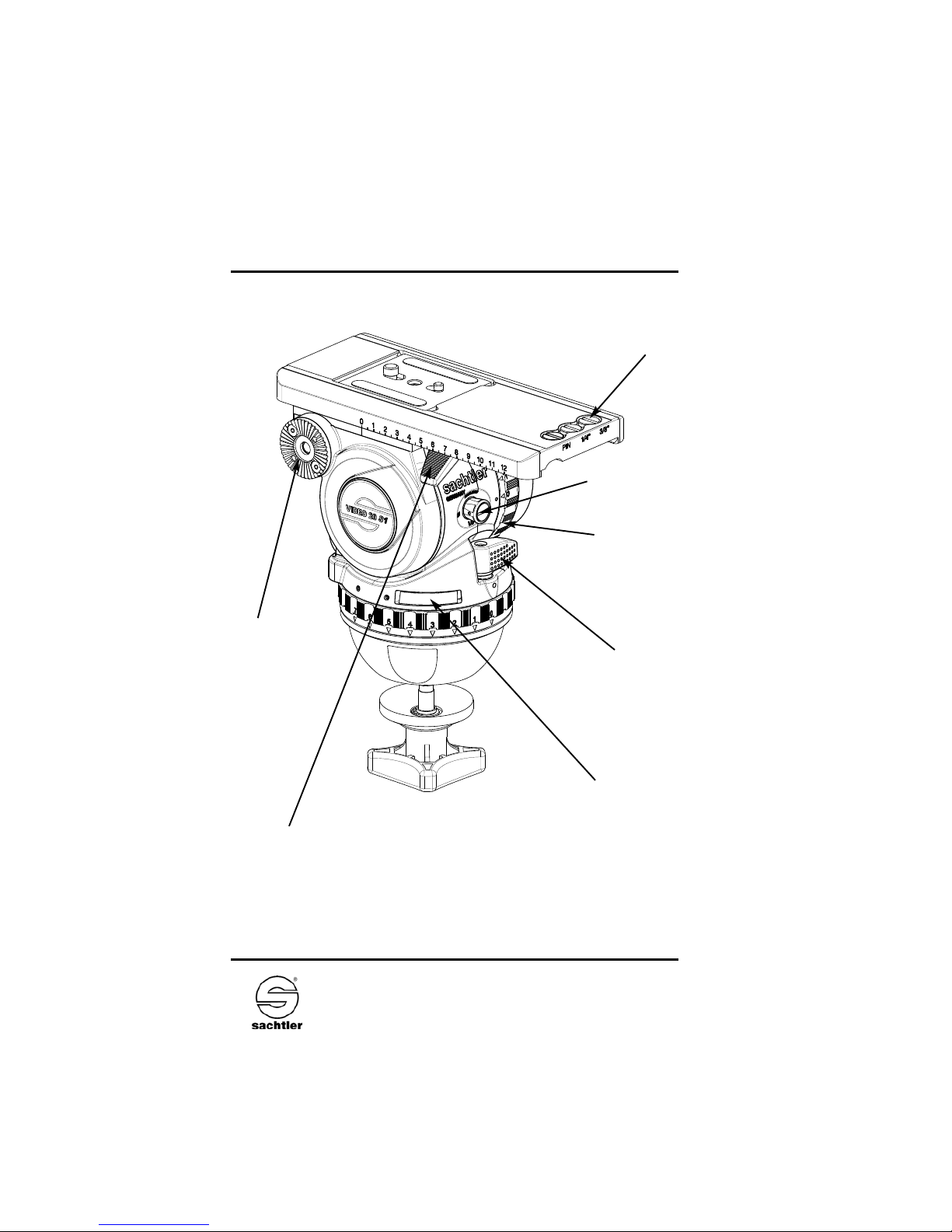

Illuminated

Touch Bubble

Rosette for left pan bar

Horizontal drag

adjustment

Lever Locking of

Touch & Go System

Rosette for right

pan bar

Clamp lever

balance plate

Battery compartment

for touch bubble

Payload range

shifter

Vertical drag

adjustment

Pic. 2

Manual

Video 20 S1

- 3 -

Horizontal brake

Spare/Camera

screws

- 4 -

Video 20 S1

Manual

3 Operation

3.1 Intended Use

This fluidhead was developed to enable pan- and tilt movements of cameras. The maximum payload is specified in

chapter 4.

3.2 Moving of the pan bar

Open the clamping lever of the pan bar and move the pan

bar into the desired position. Close the clamping screw of

the pan bar. While lifting the lever it will be disengaged and

can now be placed in a desired angular position.

During transportation the pan bar can be moved next to the

tripod legs.

Caution:

Open the clamping screw of the pan bar far

enough. The teeth of the pan bar clamp should not clatter

while moving the pan bar. Make sure that the teeth interleave with each other when closing the clamping lever of

the pan bar.

Use of the enclosed pan bar on the left side of the fluid

head is also possible. The pan bar has to be removed from

the head and the black plastic cap on its top should be

opened and removed with a coin or screw driver. The toothed clamp should be removed and relocated. The plastic

cap needs to be tightened again.

Loading...

Loading...