Page 1

(SJ

SACHS

Repair Instructions No. 4072.8 E

SACHS

SA

2-440

Snowmobile Engine

Edition December

FICHTEL & SACHS

1970

AG . D-8720

SCHWEINFURT

Page 2

Page 3

CONTENTS

Introduction

In

stallation

Te

chnical

R

epoi

Di

smontling the engine

Work

Assembling

Engine with BaSCH Bendix.

In

structions

Instructions

end

Test-running

loying

lubricotion

Tightening

Trouble-s

dimensions

deta

r tools

end

ossembly

on

ind

ivi

dual

components

Replocing

Reploci

Receil

Mogneto

Replocing ignition

Replocing

Corburettor

Decorbonizing

Ignition timing

Operation,

Storter

BOSCH Bendix-pinion

up

hooting

crankshaft

ng

fan shoft

starter

. . . . . . . .

generator

the

flonged

. . . . . . . . . . . . . . . . . . . . . . . . . . .

the

the

Fa

end

ond

end

the

engine

ond

torques

engine

wiring

. . . . . . . . . . . . . _

........

mointenance

ults . . . . . . . . . . . . . . . . . . . . . . .

diegram

wiring

diogram

running-in

.. _ ...

moi

ntenonce

for bolts

chart

. . .

i

ig

beorings

beor

ceils

end

hub,

exhaust

pinion

type

period

chert

ond

...

ings

ignition

the

muffler,

type

ond

lubricotion

for

magneto

for

mogneto

electric

nuts

.

lead

s with

mogneto flyw

the

cylinders

.....

electric

starter

starter

of

generator

generator

(type DG)

spark

heel

ond

ond

.

(type DG)

the

electric

12 V 40 W ond

12 V

...

plug

the

the

storter

75

(fold-out

(fold-out page)

terminals

cam

cylinder

.

12 V 75 W

W

heads

Poge

2

poge)

4

6

10

12

12

15

16

17

18

22

23

27

32

33

35

36

38

40

41

42

43

44

Page 4

INTRODUCTION

This manual is designed to

give

dealers and

their

staff

all

guidance and information necessary

to

enable them to

pro-

vide

and efficient

repair

and maintenance service, but

it

is in

no way intended as a substitute

for

the

practical and theo-

retical training available to person ne I

at

our

Service

Training

School.

It will be found useful as a ready reference in

day-to-day

workshop

practice.

Gur

illustrated Spare Part s List, which shows the

various

components in detail, will also be found helpful when used in

conjunction with

this

booklet.

Naturally

, good maintenance and

repair

work

and

efficient

servicing call

for

good

equipment, a well-equipped

workshop

and ski lied personnel.

Dealers

are requested to make this manual and all

SACHS

Service Bulletins, which contain technical

modifications

,

available to

every

individual

responsible

for

actual

servicing

.

The

proper

place

for

this

kind

of

technical

infor-

matio

l1', is

in

the

workshop

and

not

in

the

filing

cabinet.

We hope that this manual will be

of

real practical assistance

to

all

our

dealers, agents and associates.

FICHTEL

&

SACHS

AG

0-8720

SCHWEINFURT

Service Department

Page 5

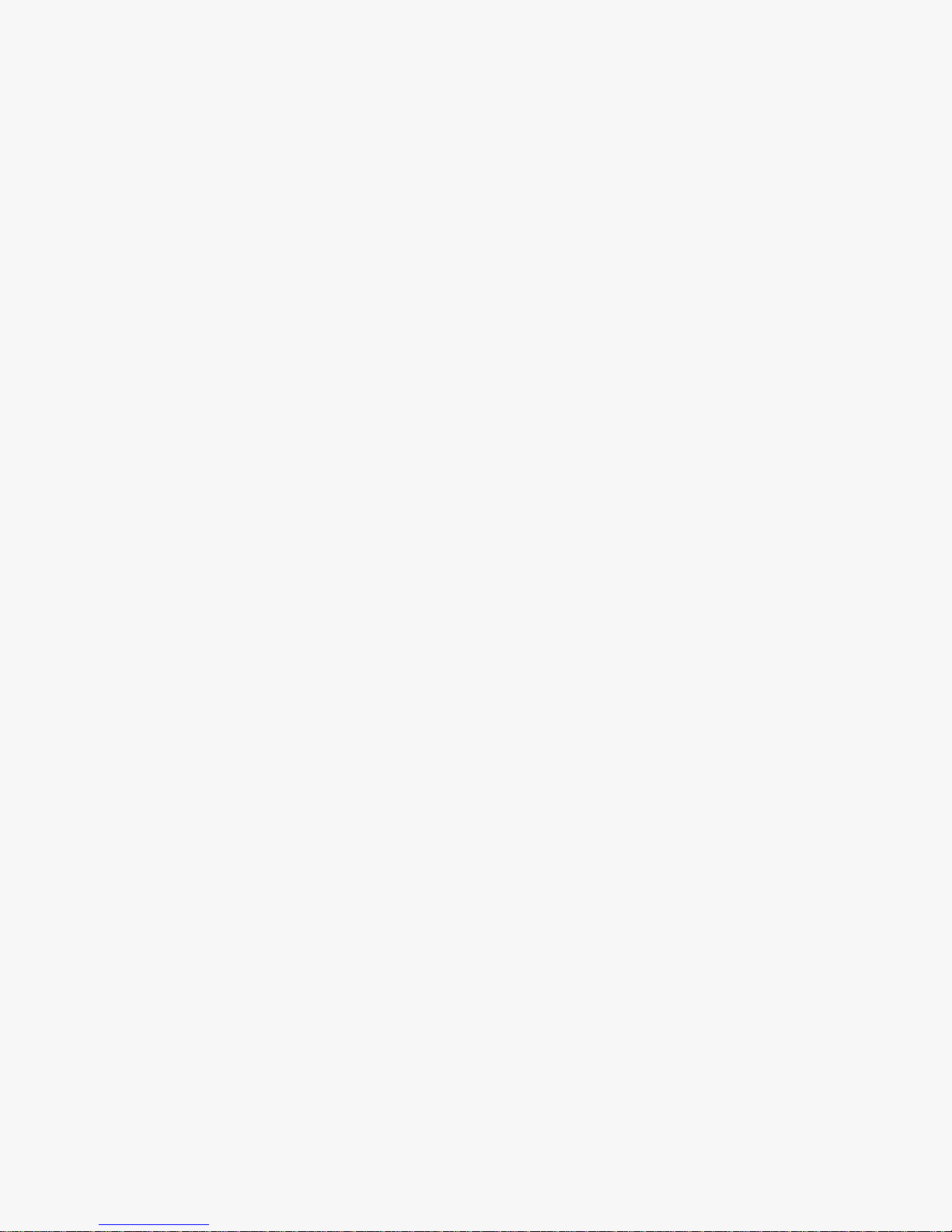

><

~

z

cn

-I

>

r

r

>

-I

0

I><

Z

c

3:

l'T1

Z

cn

0

z

cn

~F

e-

'

.

:~

, '

F'1

~~

~

, " , ,

_L(:'t:;

"

>:.l!

--

,

~l

I

f:~-

'If

~

x

~

.

.

,

ö

..

~

~

>i

------

-----

'"

''''

Page 6

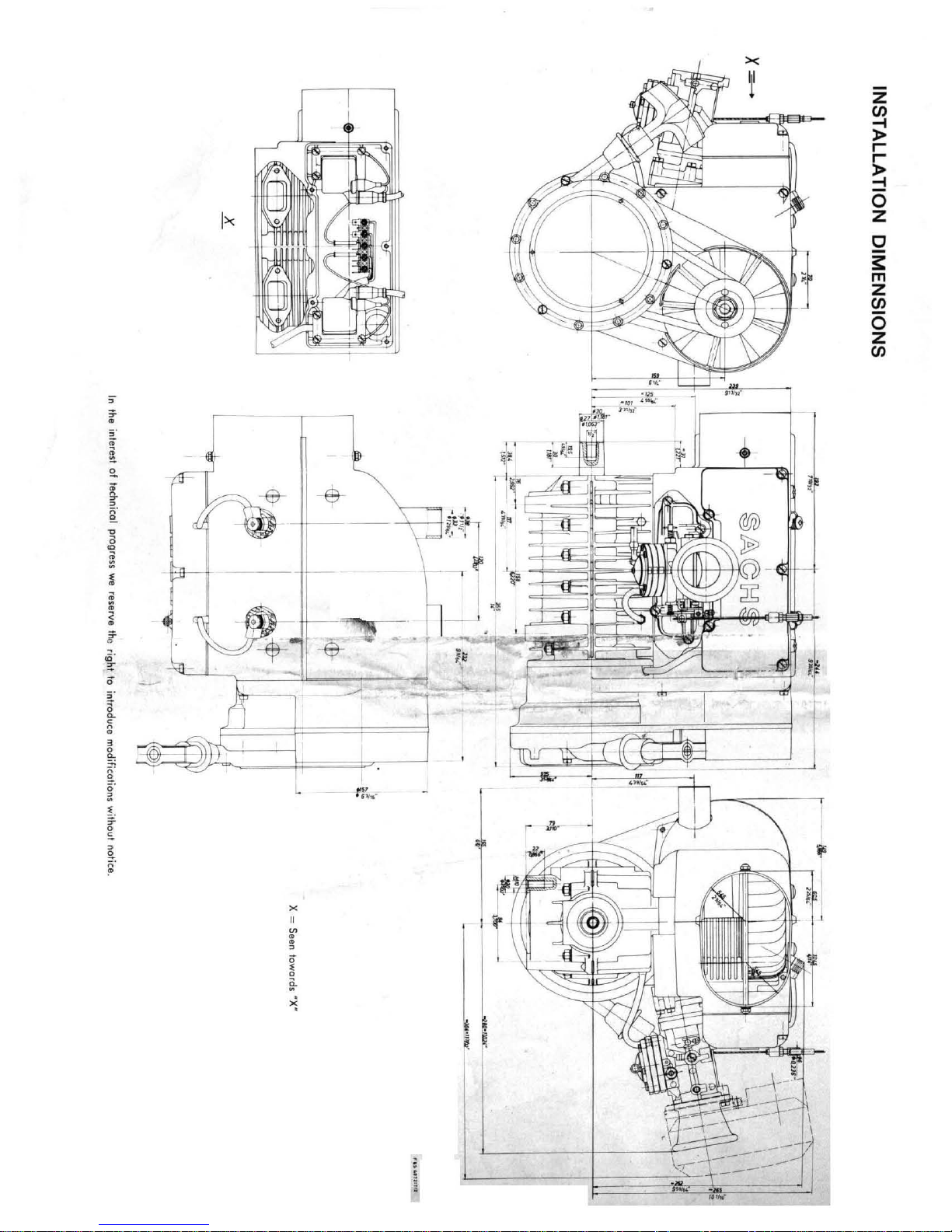

TECHNICAL

f'SiMP)

..

'"

"

"

DATA

,

I

.....

,,,ted po"'.'

/un·'" I"gine ond

....tri< pr

."u,.

on

oi.

... ilh " to leron

Fot date.minin" Ihe

1o

Ge.mon Stondord

Hg

ond

b.

multiplied by

01

temperatur.

ee

'l

= 2O'C),

01

OIItp

.. t

;.

mtO'ured

b" _ 760

of

'L _ 2O'C

± S .,..

pow"

DIN

Ihe

Ihe

<orr.er

opplie.

10

01

mm

HiI

output

o,cordin

6270

(bo ..

IlbovI outp"t

io

..

10"0.

" fully

11

boro-

on<!

(68'FI,

736

h,"lo

0

"I

g

mm

.97.

,~

"-

,

-

glP5h

,

..

'"

..

,

W,

..

,

''',

-

,~

4000

5000

~

...

,

~OOO

U/minl.pm)

M

V/m'"

'""

..

....

U/mi"

""

1000

,,,

.

It,lb

'"

~

"

•

(.pm)

(b/HPh

'.'

..,

...

U

.,

(rp",j

In

'he in'

".u

01

ledoni,ol

p.ogr

...

""1

r •

••

rv.

,h,

r'''"

' 1o

in

trod

...

ce

modilicoti

onl

wilhout

noti'

l.

Page 7

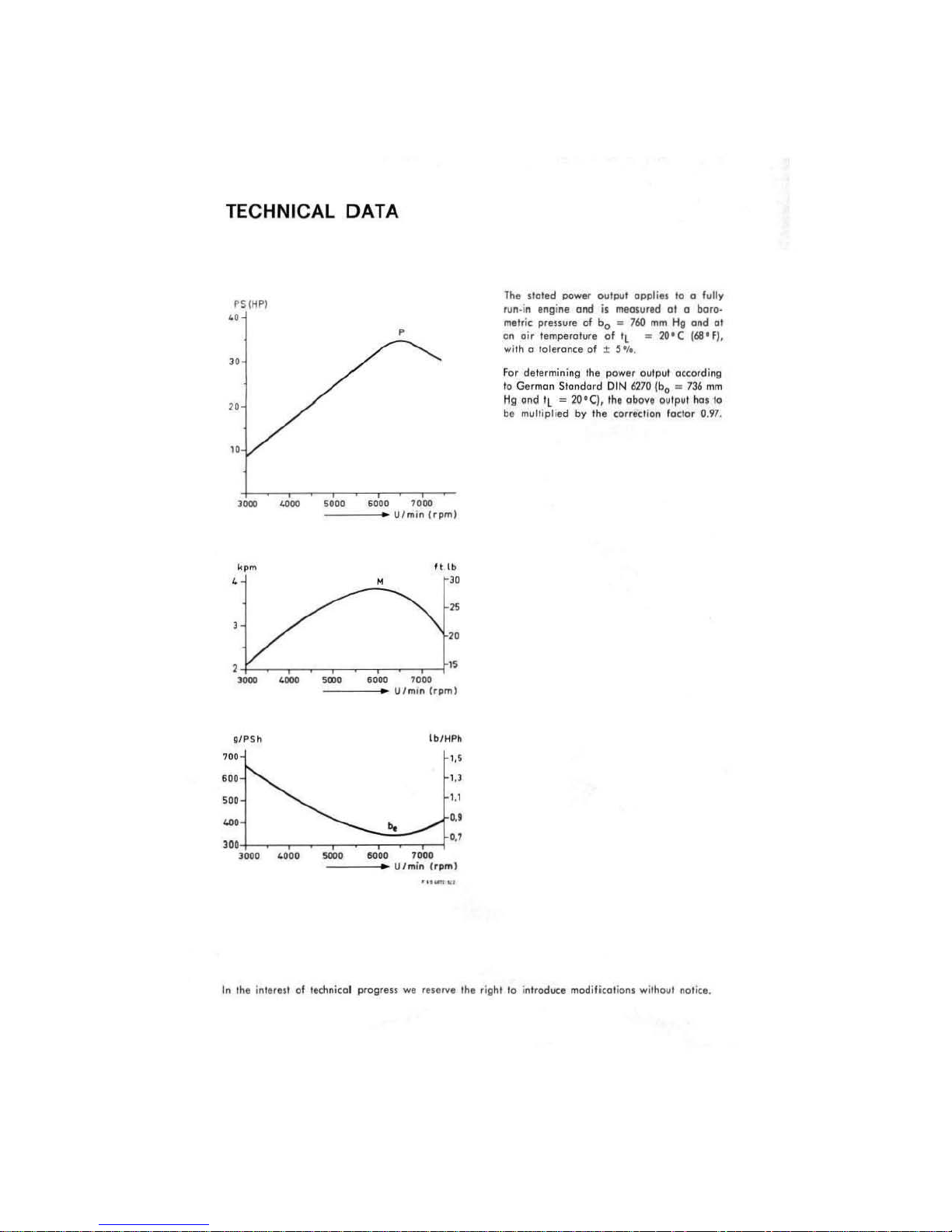

Technical

data

Type:

Cooling :

Direclion of rololion

of

engine

:

Copocily:

Bore :

Strake:

Compress ion

Oulput :

Cronkshoft beo rings : 4 on li-friclion

Eng

ine lubricot ion :

Ignition :

Ignition timi

Contocl

Pole shoe

Spork plug:

Corburetlor

Corb

Air inlok

Storling m

breoker

urellor

e:

ratio

: 9.3 10 1

ng:

gop

:

sett

elhod

gop

: 0.4 ± 0.

:

ina .

,

Siopped

Runn

Siopped

Running engin

TlllOTSON

Tw

o-cylinde r Iwo-cycle

Anliclockwise

Oil.in.gasoline

mognelo

BOSCH

engine

ing

:

engine

:

engine:

e:

BOSCH

diophrogm

Moin jel: 1'1. lurns

Idl

ing jet : 1 lurn

on

request BOSCH Bendix-pinion type

elect r

(necessory

Fon-Iype

oir coolil1g

(seen on cronkshofl p.

43

7 ce (26.

(/)

67.5 mm (2.

mm

(2.402 in

61

35

HP

(OIN)

gosoline

/oil

generolor

0.25 ... 0.

30

3.

25

mm

50

.. .4

.00

mm

05

mm

(0.0

...

29

mm

\0.

11

mm

7 ...

(see note on

0.2756 ...

W260T2

corburellor

open

open

via 1 inloke stock

Recoil slo r

ic

storler

bollery

gosoline

646

cu. in

657 in.)

.)

01

6500

beoring

lubri

cotion

ratio

25

12 V 75

bef

ore TDC

before

16

± 0

9843

... 1.1417 in'l

0.4331 in.

orW240

poge

HO

ler

12 V - 0.4

12

V 32 ...

engi ne

I. o. side)

.)

rpm

s

,

: 1

W or 40 W

!O.0098

TDC 0.1378

.002 in.)

T 1

24)

131'

/1-

HP

38 Ah)

---

... 0.0118 in'l

... 0.

(0 38.10

---

---

---

1575 in.

mm

--

---

)

--

bhoust

pipe:

Exhousl muffler :

Exhousl moni

ond inlerm

150

lenglh

fo

ld (F & S

ediole

pipe

mm

(5.906 in.) (nol

Swirl

(F & S

part no. 1473019001)

pari

42

type

mm

no.

supplie

3673

(1.654 in.)

d by F & S)

003

001)

L C.,

I

3

Page 8

REPAIR

TOOLS AND ASSEMBL Y

~

tj

5

6

~

11

,8

Ä

~

1

7,8

2

JIG

n

~17.9

3

7

4

~

~

9

8

4

21

18

12

10

~

13

~

14

r:ri

15

11

16

C1i

17

Page 9

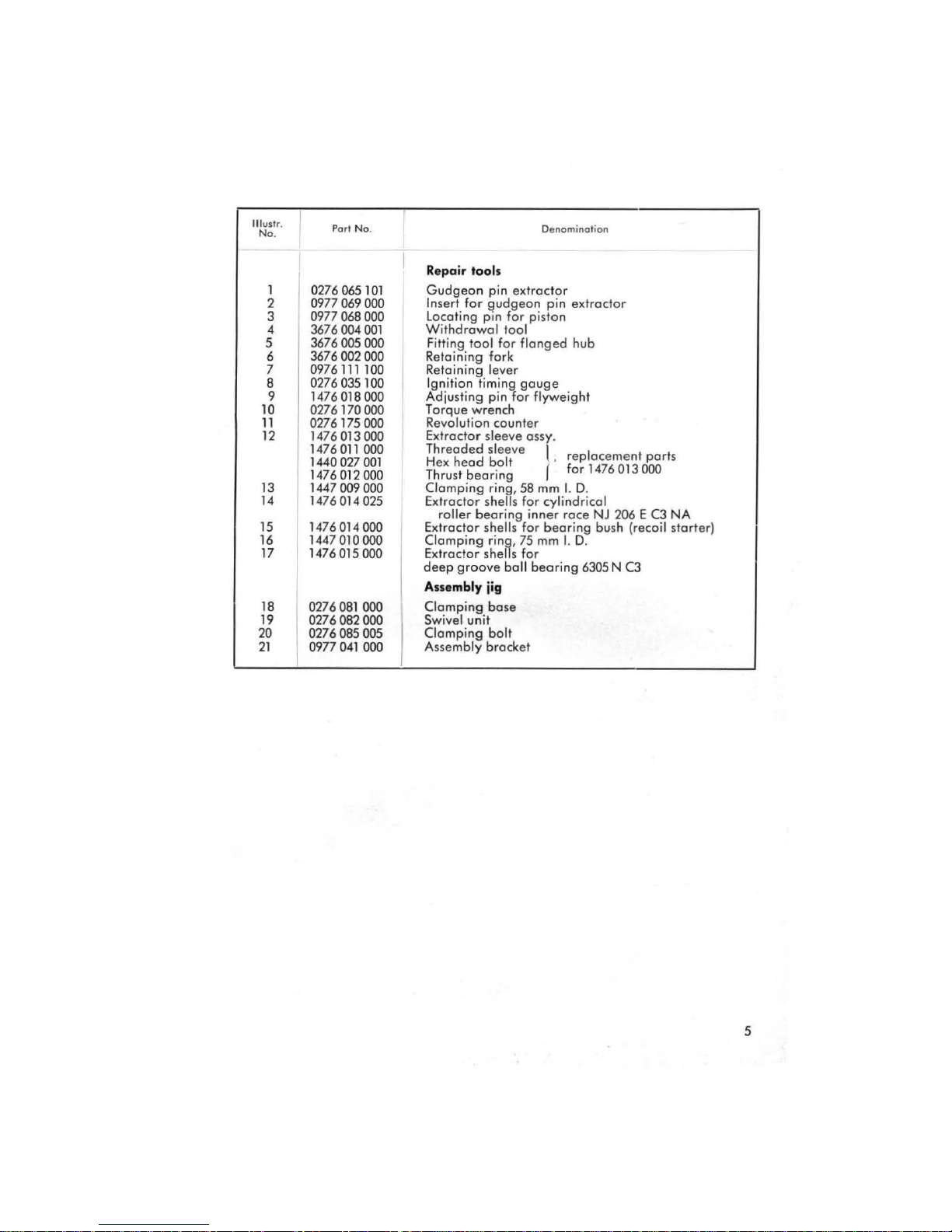

IlIuslr.

No

.

1

2

3 0977

Porl

0276065

0977

069

068

No.

4 3676004001

5 3676005000

3676002000

6

0976

7

111

8 0276035100

9 1476018000

10

11

12

0276170000

0276175000

14

76013000

1476011000

1440027001

14

760

13

14

15

16

120

1447009000

1476014025

1476014000

144701 0

17 1476015000

18

19

20

21

0276081000

0276082000

0276085005

0977

041

101

000

000

100

00

000

000

I

Repair

.oolt

Gudgeon pin extroclor

In

ser

t for gudgeon pin extroctor

locoti

ng

WithdrowoJ

Fitting tool for flonged hub

Retaining fork

Retoining lever

Ignition timi ng gauge

Adju

T orque wrench

Revolution counter

Extroctor sleeve

Threoded sleeve

H

ex

Thrust

Clomping

Extroctor

Extroctor

Clompi

Extractor

deep

pin for piston

1001

sting

pin for flyweight

ossy.

head bolt . replocement ports

beorin g for

ring,

58

roller beoring inner roce NJ

shells for cylindricol

shells

ring,

sh

ells

for bearing

75

for

ng

groove ball beari ng

Ass.mbly jig

Clomping ba

Swivel unit

se

Clamping ball

Assemb

ly brocket

Denomination

f

1476

mm

I.

D.

mm

I.

D.

6305 N C3

013 000

206 E C3

bush

(recoil starter)

NA

5

Page 10

DISMANTLING

THE ENGINE

Detach

all

contral

cables

between

engine

ond

frame

.

$crew

off

cover

(wit

h inscription SACHS) .

Pul1

ignition

leads

with

rubber

boots

out

of

the

recesses

ond

remove

cover.

Disconnect

electrical

wir

ing

bet

ween engi

ne

end

frame

cf

the

terminals

(2

end

3,

F

ig.42).

Remove

exhaust

muffler,

exhoust

tube

end

manifold

.

Remove

the

engine

end

clean

it

thoroughly

be

fore

toking

it

aport.

When

giving

the

engine 0 general

overhaul,

components

should

be

dismounted

in

the

seque

nce

ind

icated

.

f ig. l

Fig. 2

6

I"take stack, carburettor

and recoil starter

Fig. l

Mount engine

on

asse

mbly

i

i~

(repair tools

no. 18, 19, 20 ond 21)

with 2 hex

head

bolts M

'0 x 30

,

os

shown

in

the ill

ustration

.

Sc

rew

off intoke

stack

(5)

wit h

rei

nforcement

ring

(4)

.

Pull

off

impulse pipe

(2)

.

Remove

carburettor

(3)

(ta king

co

re

of

insulati ng sl

eeves

a nd

go,ket).

Unscrew

rec

oi l

starte

r

(1)

to-

gether

with inser

ted laby

rinth

ring.

V-pulle

ys

and V-belt

Fig. 2

Use retoining

fork

\3,

repoir

too

l

no

. 6)

to hold

the

id

er

pulley half

(l),

os

shown

in

the

illust

ratio

n.

Unscrew

nut

and

remove

idle

r

pulley

half

(taking

ca

re

of

wosh-

ers).

Unscrew

pulley

(4)

and

remo

ve

it

together

with

V-belt

(5).

Remo

ve

secand

idler

pulley half

together

with

washers.

Remove

Woodruff

key from

fan

shaft

(2).

Page 11

Magneto

Fig. 3

Use

no

os

unscrew

Remove

Fig. 4

Repos itio n

shown

retaining

.

7)

10

hold

shown

nut

washer

in

the illustration,

flywheel

lever

magneto

in

Ihe

(2).

(1)

retaining

(3,

repo;r

illustration,

.

lever,

move mogneto Ilywheel

means

cf

pair

tao

Remo

ve

crankpin

withdrowol

I no. 4

).

Woodruff

.

tao

key

tao

flywheel ,

end

os

end

re·

(2)

by

I (1, re-

from

I

Fan housing, fan

plote

Fig. 5

Unscrew

out

Detoch

plote

uns

Ion

(3)

crew

fan

housing

(1)

(sliding lit).

leads

ot

the

ormature

end

(2)

fram

terminals

plote

armature

end

take

ormoture

ond

.

Fig. 4

Fig

. S

7

Page 12

Fig. 6

Fi

g.7

Fi

g.8

8

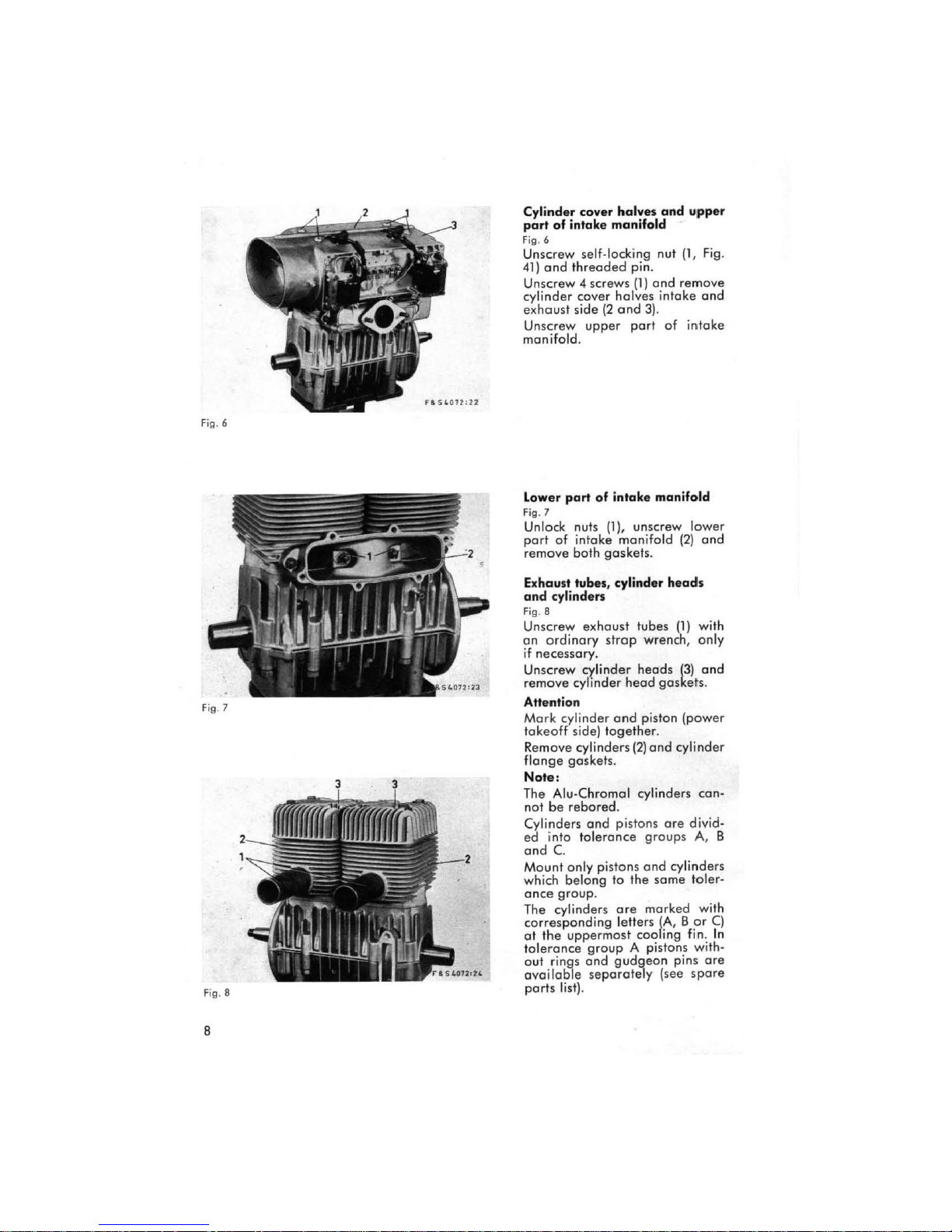

Cylinder cover halves

and

upper

part

of

intake manifold

Fig

. 6

Unscrew self-Iocking nut (1,

Fig

.

41)

end

threoded

pin.

Unscrew 4 serews

(1)

ond

remove

eylinder cover hclves intoke ond

exhaust

side

(2

ond 3).

Unscrew

upper

port

of

inloke

monifold.

Lower

part

of

intake

manifold

F

ig.7

Unloek nuts (1), unscrew lower

port of intoke monifold

(2)

and

remove both gaskets.

Exhaust tubes, cylinder

heads

and

cylinders

Fi

g.8

Unscrew exhoust tubes

(1)

with

on

ordinory

strap

wrench, only

if

neeessory.

Un

serew eylinder

heeds

(3)

end

remove eylinder heod ge skets.

AHention

Mark

ey

linder

ond

piston (power

lakeoff

side)

tagether.

Remove eylinder s

(2)

end

eylinder

flonge

gasket

s.

Note

:

The

Alu-Chromel cylinders eon-

not

be

rebored

.

eylinders

end

pistons

are

divid-

ed

info to l

erance

groups A, B

and

C.

M

ount

only pistons

and

eylinders

which belong

10 the

same

toler

-

enee

group.

The eylinders

are

morked wit h

eorresponding letters

(A, B or

Cl

01

Ih

e uppermosl eooling fin. In

toleronee

group

A pistons with-

out rings

end

gudgeon

pins

are

ovailable

separately

(see

spore

parts list)

,

Page 13

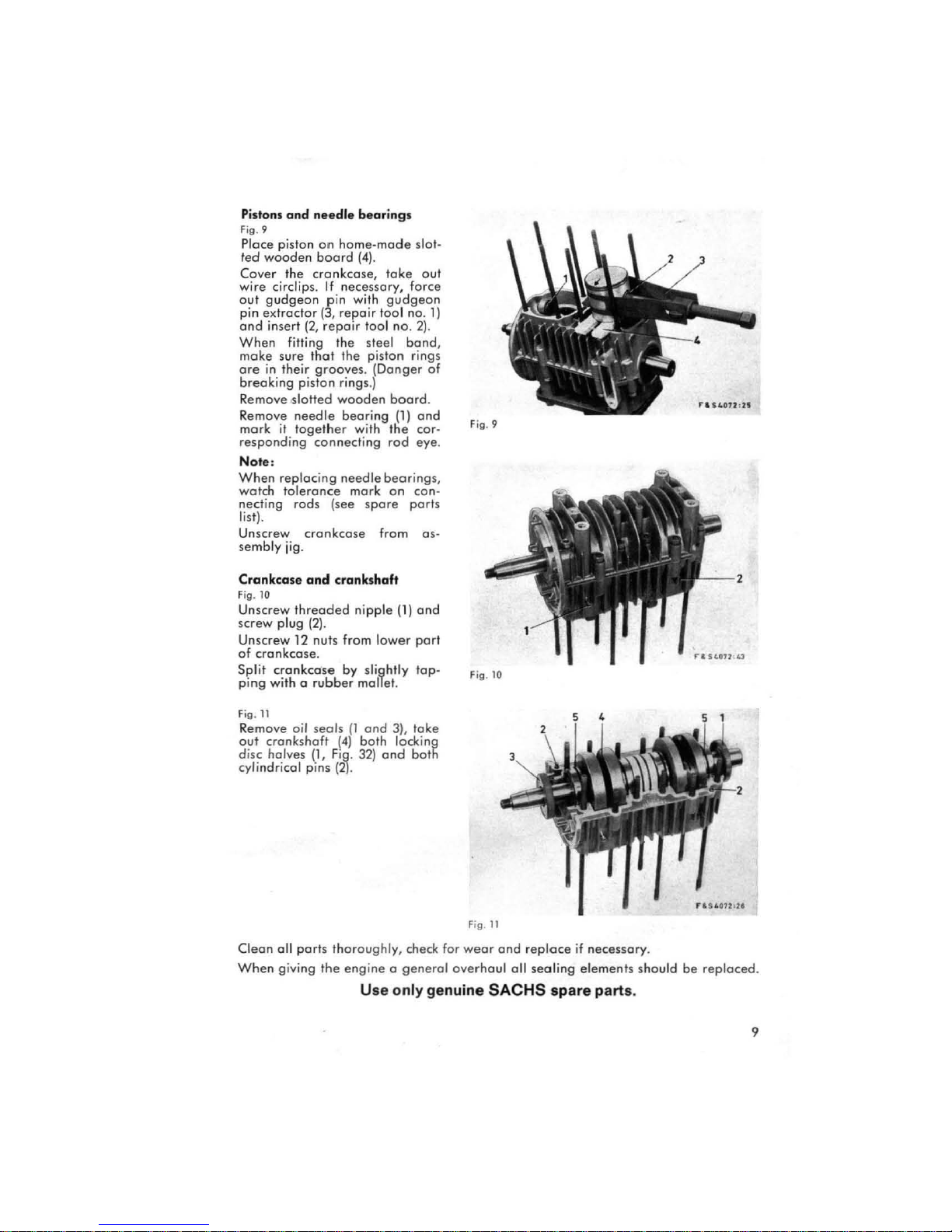

Pistons

and

ne

edle

Fig. 9

Piece piston

led

wooden

on

home-mode

board

(41.

Cover the cronkcose,

bearing

wire circlips.

out

gudgeon

pin extroctor

ond

insert

When

make sure

ore

in

If

necessory, force

pin with

(3,

repair

(2,

repOlr

fitting the steel bond,

thot

their

the piston rings

grooves

s

slol-

toke

out

gudgeon

tao

I no. 1)

tao I no. 2).

. (Donger of

breoking piston rings.)

Remove

Remave

mark

it

,slotted

needle

taget

wooden

bearing

her

with

board

(1)

the

.

and

cor- F

responding connecting rod eye.

Note

:

When

replocing

wolch toleronce mark

necting rads (see

needle

spore

bearings,

on

con-

pari

lisll·

Unscrew crankcose from as-

sembly

jig.

ig

. 9

s

Crankcase

Fig. 10

Unscrew

screw plug

Unscrew 12 nuts from lower

and

crankshaft

Ihreaded

(21.

nipple

(11

ond

part

of crankcose.

Split crank.case by slightly top- Fig.

ping with 0

F

ig.1

Remove ail seals

out

disc halves (

cylindricol pins

Clean

When

rubber

mallet.

1

(1

and

3), take

cronkshaft (4) both locking

1,

Fi~

.

321

ond

bolh

(2).

oll ports thorough

giving the

ly,

check for

engine a general

Use

only

genuine

Fig.

weor

overhoul oll sealing elements should be reploced.

10

11

and

reploce

SACHS

if

necessory.

spare parts.

F&

S40U'1I

9

Page 14

WORK

ON

INDIVIDUAL

COMPONENTS

Replacing

Of

Ihe cronkshoft

end

Ihe cylindrical roller

Removal

Fig.

12

Remove

(

1)

01

Remove

(7)

by

sleeve (3,

cf

outer race

beoring

inner

meons

repoir

crankshaft

inner roc

.

of

Remove shims

bearings

beorings

(4)

race

(1)

suitabl e

tools no . 12, 13, 14, 15, 16

{Bl

.

only Ihe

bearing

es

cf

cf

cylindricol roller bearing end roller eoge from inner

of

cylindricol roll

edrector

on the

cylindricol roller

shells (5

deep

er

groo

power

bearings

bearing

end

ond 17)

ve ball

tokeoff s

end

--4

ond

6),

clamping

.

beoring

ide

can

deep groove

the

deep

rings

on Ihe

be

replaced

groove

(2)

mogneto

.

ball

bearing

Fe S 4072:

ball

bear

ond

extroctor

side

s.

27

roc::e

ing

A"ention

If

shims

have

cylindricol roller

10

been

domoged

bearing, reploce

dur

ing the

Ihem by

operation

new

ones

cf

removing Ihe inner

.

race

of

Ihe

Page 15

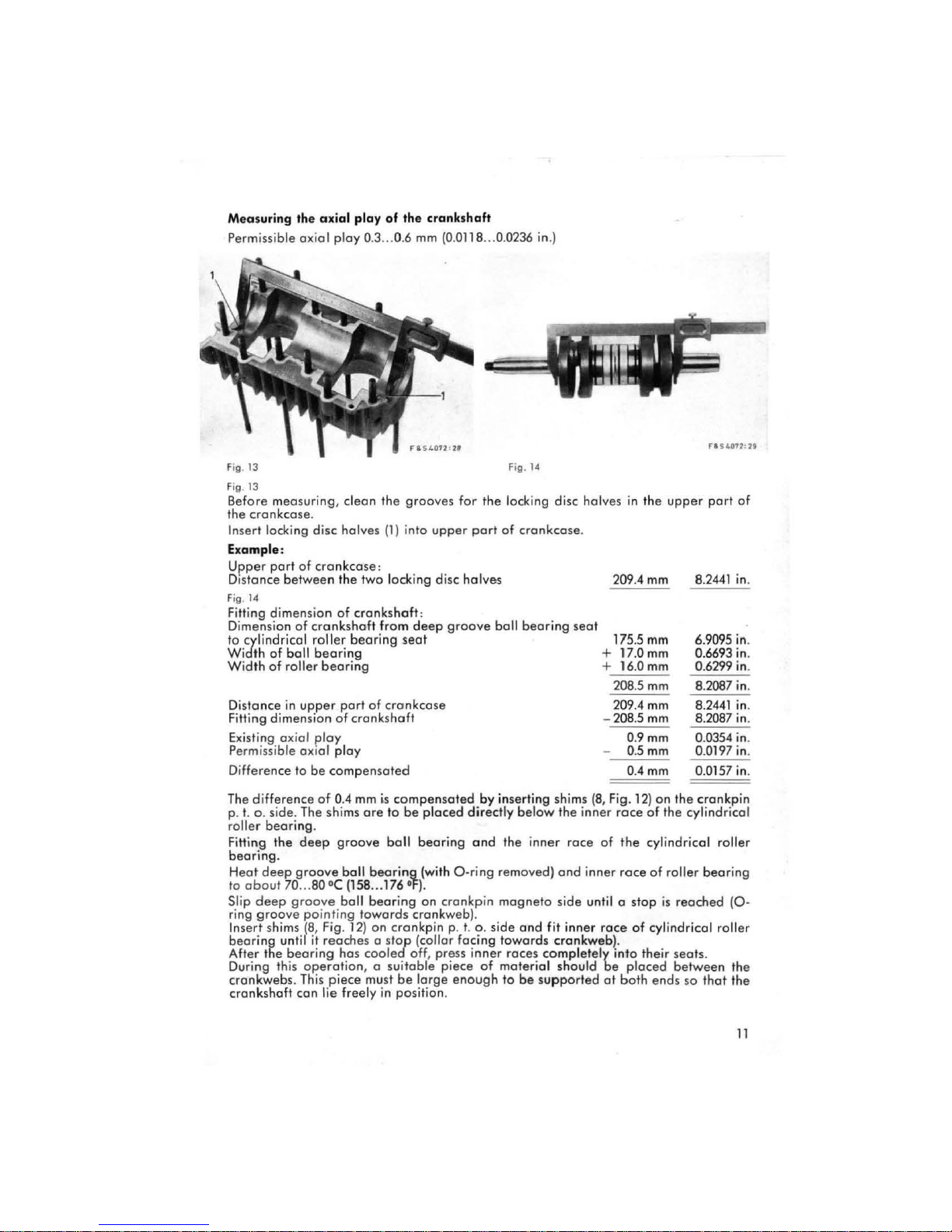

Measurin9

Perm issib

.he

le axi

axial

play

al

ploy 0.3 ... 0.6

of

.he

cra

nks

haf.

mm

(0.0118 ... 0.0236 in.)

Fig. 13 Fig.

Fig. 13

Before meosuri ng,

the

crankcose

In

sert

locking disc halves

clean

the grooves for

the

locking disc halves

.

(1)

into

upper

port

of

Example:

Upper

port

of

Distonce

Fig.

14

Fitting dimensio n

Dimension

to cylindrical

Widlh

Width

Distance

Fitting dimension

Existing axial

Perm

issi

Difference

The

difference

p. t. o.

roller

bearing.

Fitting

beari

ng.

H

eot

deep

10

aboul

Slip d

eep

ring

9roo

In

sert

shims (8, Fig. 12) on

beoring

After the

During this

cronkwebs. This

crcnkshaft

cronkcose:

between

01

ball

of

roller

in

the two locking disc halves

of

of

cronkshaft

crankshaft

roller

bearing

fram

bearing

bearing

upper

port

of

of

cronkcose

cronkshoft

ploy

ble aXial

side

the

70 ... 80 'e (158 ... 176 'F) .

ve pointing

unlil

bearing

play

to

be

compensoted

of

0.4

. The shims

deep

9roove

9roove

9roove

it

reache

ball

ball

has

operation

piece

mm

is

are

bearing

bearing

towards

s 0 s

cooled

, a suitable pie

must

con lie freely in position.

:

deep

groove

seat

compensated

to

be

placed

ball

bearing

(wilh

on

cronkp

cronkweb).

crankpin

fop

be

(collor

off

, press

lorge e

p. t.

by

directly

and

0-rin9

o.

facing

inner

ce

of

nough

in

ball

inserting shims

the

removed)

mogneto

side

towards

roces

material

10

14

cronkcose

bearing

below

the

inner

ond inner

side

and

fit

cronkweb).

completely

should

be

supported

.

seat

inner

race

unlil a

inner

209.4

175

+ 17.0

+ 16.0

- 208.5

(8,

Fig. 12)

of

ro

be

ct

in

the

upper port

mm

.5

mm

mm

mm

208.5

mm

209.4

mm

mm

0.

9mm

0.

5mm

OAmm

on

roce

the

roce

ce

into

ploced

.he

of

the cylindrical

cylindrical roller

of

roller

stop

is

of

cylindrical roller

the

ir seafs.

between

bolh ends

8.2441

6.9095

0.6693

0.6299

8.2087

8.

2441

8.2087

0.0354 in.

0.0197

0.0157

crankp

bearing

reached

so

thot

of

in

in

in

in

in

in

in

in

in.

(0 -

the

the

.

.

.

.

.

.

.

.

in

11

Page 16

Never

clamp

the

the

crankshoft

inner

roces

by

unserviceoble

Piece

auter

(groove

Wel

bearings

for

O-rings (5, Fig. 11) slightly with oil

.

hommering

. •

race

cf

O-rin~

facing

in

cylindricol

towords

0 vise

ol:a

cronkpin

. This will crush

roller

bearing

cronkweb)

end

the

with

.

insert

or

of

the

webs

roller

them into

webs,

end

cage

ond

render

onlo

the

auter

never

Iry

the

cronkshoft

the inner

roces

of

10

ra

fit

ce

the

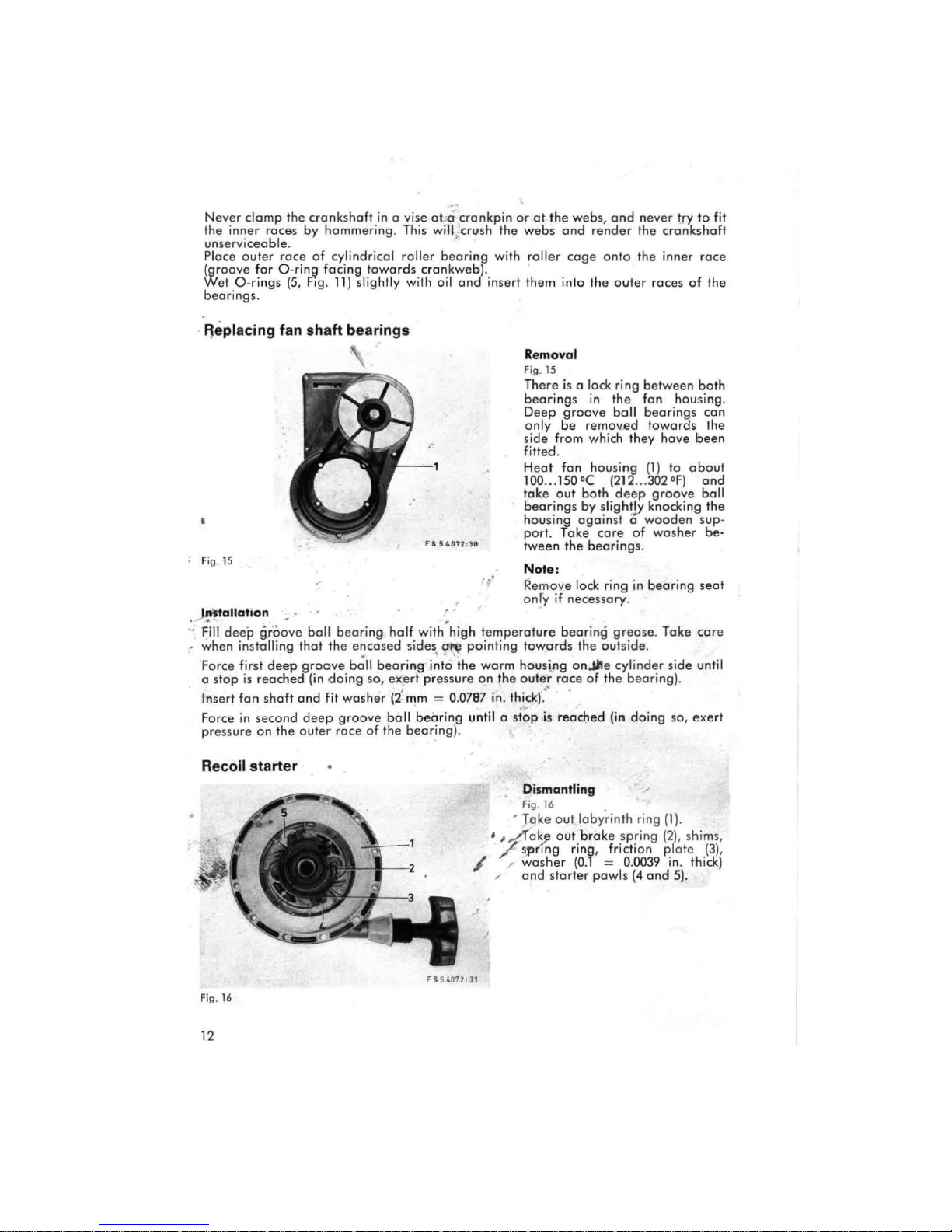

~eplacing

. Fig.

15

fan

shaft

bearings

) Mtallation . .

:. F-

i11

deep

.

when

Force first

a

stop

Insert

F

orce

pressure

Recoil

gtöove

instolling thot

is

reoched

fan

in second

on

starter

deep

shaft

the

ball

groove

(in

and

fit

deep

outer

bearing

the

encosed

ball

doing

washer

groove

roce

half

with"hi

sides

~

so,

of

bearin

ball

the

\ \

.g into

exert

press

(2

~

mm = 0.0787 in. thick)

beoring

beoring

\Ji!P

"'"

ure

).

gh

the

Removal

Fig.

1S

There

is

bearings

Deep

groove

only

be

side

from which they nove

fitted .

Heat

fon housing (

100

...

150'( (212 ...

take

out

beerings

housing

port. Take

tween

the

Note :

't

' Remove lock ring

only if

necessary

temperature

pointing

warm

on

the

until 0

stop

towords

houslng

outer

race

:-

.,

•• s

reac~ed

bearing

onJite

Dismantling

Fig.

16

,

Take

out

•

,~e~

7

/ /

",

out

s'p

flng ring, fricti

wosher (0.1 ~ 0.0039 in. thick)

and

starter

0 lock

ri

n9

the

boll

between

fon

housing.

bearings

towords

1)

10

in

remov.ed

302'F)

balh

deep

groove

by slightlY knocking

ogoinst 0 wooden

core

of wosher

beorings

.

in

bearing

.

grease

cylinder

bearing).

(in

doing

. Take

.

side

so, exerl

the

of

outside

the

...

laby~inth

brake spr

pawls

ring

ing

on

(4

and 5).

(1)

.

(2). shim,

plate

baln

can

the

been

cbaut

end

ball

the

sup·

be·

seat

car

until

(3),

e

.

Fig.

16

12

""s

«171

: J1

Page 17

Fig. 17

Pull

out

cm

(19

horne-mode

os

show"

clamping

{51

.

clomping

.

clomping

handle

(4)

from

rope

retoining

rope

ro

sterter

in.1

taper

pe

50

with

(2)

,

Take

clomping

hondle

Withdraw

from

rope

Remove

ter

(SI, ,top

(9)

Remove

starter

Remove

necessory.

Carefully

coil

coil

Toke

Remave

Fig. 18

Reise

toke

spring, toking

spring

jump

core

of

rope

spring

spring.

Hold

coil

thumbs

roising

o~

Note

Replece

necessary

shells,

spring

(see

eoch

oltl!ro.0te sides .

;

bush (1, Fig .

, using the

clampin~

tractor slee ve

15

, 13

ond

121

Take

ca

re

bush {I, Fig .

of

ro

ond

hold

retaining

in

the

illustration.

ring

out

clomping

ring

ring

with

Hanged

ond

f10nged

.

clip

run

back

guide

out

care

out

.

disc

{3,

from

pulley

end

10

toke

firmly

illustrotion)

thumb,

let

ring

(repair

.

toleronce

201

.

pe

opprox

pulley

clip

(6)

with

of

starter

taper

end

detoch

end

star-

sleeve

sleeve

ond

completely.

(3) only

pulley

with

not

10

Fig. 19

1.

.

out

coil

with

both

end,

out

spring

201

only

extroctor

and

ex-

tools no.

ring

(11

(7)

let

if

let

by

if

in

.

FI541111

' 32

Fi

g.

17

Assembly

Fig

. 19

B

efore

assembling,

with

Aero-SHEll-Grease

fi

l/

the

4 lubricating

the pul/ey with

cont

.

Insert coil spring, os shown in

illustration, with

in

stud

(1)

anti-clockwi

Ensure

flat

, fitting coil by co.!

se

direction .

that

ond

the ccil spring lies

even.

grease

grooves

~he

.same lubri-

end

of

spring

14

and

in

sprin~

(2)

in

Fig.

19

f 1 !o4071;

lI

Page 18

Fig.

20

r&5""012,)",,

Fig.

21

F

'~40

72'

JI

F

ig.22

Fig. 20

Before inserting pulley, stick

wasller

(3,

Fig

. 19, 0.8

mm

thick

= 0.032

in.)

with 0 little

grease

into recess

of

pulley.

Fit

pulley

onto

bearing

pin

ond

insert

end

of

spring

(4,

Fig

.

19

)

ot

stud (2).

Tension pulley/ coil sp ring

in

storting direction until 0 s

top

is

encountered.

Release coil s

pring

appr

ox.

112

•.•

1 turn until tlle recess for the sol·

dered

nipple

in

the pulley rests

near

the

rope

passage

of the

housing.

Hold pulley with

home-made

retoining

clIP

(2,

Fig.

21)

.

Pull

the

starter rope

through

a

rag

moistened with

SAE

1 0 oil be-

fore

assemb

ling.

Fig.

21

Fit

rope

guide

(3,

if

removed),

lIonged

sleeve (B),stop (4),lIonged

sleeve

(7),

starter

handle

(5)

ond

clamping

ring

(6

)

onto

Ihe

rope

.

(Iamp

rope

guide

with

filI

ister

heod

cop

screw

(9)

M 4 x

10

.

lay

starter

rope

around

clomp-

ing

taper

and

pull

it

into

clamp

-

ing ring .

Pull

clamping ring into s

tarter

handle

and

let

sta

rter

rope

run

back.

Fig. 22

lubricate

starter

pawl

bed

and

starter powls ligMly with

SAE

10

oil.

~

Fit

star

ter

powls

(4

ond

5)

.

The open

side

of

the

starter

pawl

seati ng

and

the long side

of

the

s

tarter

pawl face

in

storting di-

rection.

F

it

was

her 0.1

mm

(0

.0039

in

.)

thick, friction

plote

(3),

spring

ring and shims os required .

Insert

broke

ring

(2)

.

Insert labyrinth ring

(1)

.

After

"'ounting

the

bra

ke

spr

ing, the friction

plate

should have

an

<llöillElil,

ay

of

0.1 ... 0.2

mm

(0.0039

... 0.0079

in

.).

CQ,rrect this play by inserting shims

under

the

broke

spring .

Page 19

Magneto

generator

The cyli

Fig.

1 = Sei

2 =

3 =

4 = Ign

S = Sei

6 =

7 = Armolure

8 = l ubricoling wiek

9 =

nder

23

of

conlocl

(apacito

tgnition

ilion

of

conlocl points

(apacitor

Generator

on

points

r

armolure

arme/ure

plole

ormalure

the

p. t. o. si

I

10'

cylinder

I

'0'

cylinder

de

of

the

cronkshaft

2

1

Fig.

23

is referred

Replacing the ignit ion or generator armatur.

Open

up

the

strop

ormoture

Generator

are lothe-turned ond con be mounted 10 the armeture plote

Ploce new

(toke

After

t

ween armoture

is

oblained

ond

ormature

core

cf

installation

ground

only

.

ignition

it

p,0les

1I

Ine

Screw

holding

off

armeture

in

position

wire

is

necessary

and

gap

the

armoture

, os

on

generator

flywheel,

is

0.

25

ore

shown

under

... 0.

35

which

is

to

avoiloble

armature

all circum s

becau

mm

os

in

the

illustration,

J.

tance

se maximum ignition

(0.0098

... 0.

be reploc

spore

s 10

0138

Note:

Far

corr

ect

meo

rectly on ils

sureme nt

bearings

ond

adjustment

it

is

necessary

that

.

10 os cylinder 1.

ed

ond

unsold

ports

. The

without

ond

mea

in

.).

the

armoture

special equipment.

screw it

sure

the

and

lighting

crankshaft

air

er

on

gap

rests

leads

poles

Iightly

be·

power

cor·

.

Fig.24

Air

gap

0

.25

in

... 0.35

.).

is mea

0.

0138

The

gap

places, through

flywheel.

If

the

gap

is

slightly

the

armeture

ened

adjustment

the

apertures

odjusted

the

fastening

can

not

mm

(0.

sured

in several

the sials

correct,

it

by repositioning

ofter

having sleck-

sc rews. The

be

made

in

the flywhee

through

0098

in

can

l.

...

the

be

Fig.

24

15

Page 20

Replacing

In

order

ploce both sets

The

are

are

1.

2. Remove r

3. Unscrew

4. Unscrew pivot

New

Coulk

Use only the set s

When fitted

Apply

Smeer

slider. (BOSCH

Da

Replacing the

1. Unsolder

2.

3. Remave th e

4.

5. Sold

the

sets

10

cchieve

contoet

badly worn, if

damoged

Screw

not

off

parts

the

BaSCH

BOSCH

allow

breoker

.

primory

eloiner

filiister

should

piv

ot

in position,

Ft 1 v 8

greose

any

capacitor

sh

the

t new

er

bot

leads

capacitor

copacitor

h l

Pu

In

ser

of

shoft

greose

caulked

01

eontad

0 uniform i9nition setting

contoet points

should

the

ond

head

shoft

be

fitted

after

of

contact

grease

.

eads

points

together

be

beoring

lead

from

greo

Ft

is a v

out

spots

to their terminals.

reploced

bush

end

copacitor lead

contoet

cop screw

the

1 v 4

or

ond

brecker

armeture

in

reverse

screwing

points spec

contact bre

se 10

bear

on

ailable in

oil

to

of

the

armature

from the

carefully caulk

is

end

il in.

the lubricating

reach

.

if

the

worn

cr

arm

remo

plote.

ord

er,

ified

for

aker

ing bush

tubes at

the

contacts

plote

hole

with a sc

agoin

for

both

contocts,

if

the contoet

.

from pivot

ve

contoct carrier.

proceeding

th.s

engine

points must

before

fitting .

pad

ond

all

BaSCH

.

with a

rape

.

cylinder

round

.s

the

slider

brecker

shaft

(take

os fellows :

.

not

be

on

the

suppliers.)

piece

r.

il

is

necessory

or

the pivot

arm

care

displaced

greose

of

wood

cr

the

of

shims) .

or

wedge

.

10

re·

shoft

spring

tilted.

in

the

Replacing ignition coils and ignition leads with

Removal

F

Unscrew ignition coil

linder

2).

Remove

cab

ni

Installation

~crew

Ilon cods.

Pl

wi

cabl.

(

tion coils.

Scr

ground

cap

w

tion .

Attention

When

replac

ing

spark

the

spring

tagether

16

in

cantael

plug termina ls,

gels

with the ignition

with the

lead

into the

hang

core

of the ignitio.n

spark

spring into ignition

plug terminal.

spark

plug terminals

ig.

2S

1)

end

coble

le

shoes

tian

leads

!gnition l

ac.

cabl. ,ho.,

re

(brown)

,hae,

blue) on

asher

terminal 1

ew

on

wire using 3 filIister

screws M 5 x

s, as shown

lead

),

(5

,

coil

(4

shaes

(2)

and unscrew

(1)

.

eads

on

terminal

(3) far

ignition coils with

lead

(make s

and

insert the

for

, for cylinder

(3

)

(11

to igni·

(2)

far

graund

15

pri

mary le

of

the igni.

and

the

head

spring

illustr

ure

spr

25

in

cy·

and

ig·

and

ad

a·

thot

ing

Page 21

Replacing

the

flanged

hub

, the

magneto

flywheel

and

the cam

fig.26

Slocken

4 Phillips

screws

(l)

in

mogneto

flywheel

(5)

by

light

iorring

blows,

screw

them

out

ond

rem

ave

the

flanged

hub.

Unscrew

retaining

ring

(3)

end

take

out

cam

(4).

Fill

onnular

groove

(8)

with

BOSCH

greose

Ft

1 v 26

ond

slightly

greose

cam

support

in

flywheel.

(BOSCH

greose

is

ovailable

in

tubes

01

oll BOSCH

suppliers.)

Insert cam (4).

fit

retaining

ring

{3} ond

fasten

with 3 filiister

heod

cop

screws M 4 x 5

ond

woshers. Fig. 26

Toke

lock

ring

(7),

flyweight (6)

ond

thrust

washer

below

off

from

bearing

pin.

Greose

bearing

pin

ond

bearing

surface

of

flyweight

in

flywheel

slightly

with BOSCH

greose

Ft

1

v 26.

Fit

thrust

washer

(0.3

mm

=

0.0118

in

. thick)

on

bearing

pin,

insert spring

(2)

in

flyweight.

Fit

flyweight

on

bearing

pin

(must

engage

with cam)

end

se·

eure

with

lock

ring

(7).

Cam

end

flyweight

must

olwoys

be

freemoving.

Position

flonged

hub

on

the

mogneto

flywheel

(5) in sueh 0

woy

thot

the

bores

coin

-

eide.

Degr

ease

4 eonvex

-heod

Phillips

screws

M 6 x 10

with 0 suitoble

solvent

(we

re-

co

mmend

Tri),

lute

with LOCTITE AA-89-790

ond

screw

them

in.

Tightening

torque

0.9

...

1.1

kpm

(6.5 ... 8.0 ft. Ib.).

17

Page 22

Ca

rburettor

The type

of

therefore

No

av

the

gine

rich. Repeated

carburettor

When

thermal

or

lure

Special

os when

parts

be

Only

mum

Adjusti

Wnen

carburettor

mounta

open

of

ccrburettor,

tests in the

not

alteration

er

quietly

throttle

is

pounds

end

the

carburettor

volue

w~t

plugs

IS

too

lean.

ca

re

the

fuel

of

the

sufficient 10

0 correctly

of

economicol

ng

the car

using

setting will

inous

ing.

foctory

. T

advisoble

of

the

ond

or

carburettor

smoothly

opened,

end

runs unevenly,

spitting

or

difficult storting

is

is

used,

indicote

should

the insulotor

rich mixture,

be

taken

feed

is

restricted insufficient lubricont will

engine. With

provide

odjusted

operation.

bureHo

the

engine

oreas)

, the supply

the

iet sizes

he

setting ochieved in this

10

alter

ond

it.

setting

01

lew ,speed

gives

ifs

full

or

caugh

if

ing, bockfiring with 0 blue flame

are

correctly

odjusted

of

wnereas

to

ensure

a two-stroke

odequote

lubricotion .

corburettor

r for spe ci

at

be

oltitudes

required.

of

al

above

fuel should

Starting

On

Tillotson

diophragm

corburettors

itself .

The choke serves to facilitate storting.

cold

engine.

When

o rieher fuelloir mixlure

be

slowly

Tillotson

The

phrogms

2

pump diophragms

On 0 warm

the

choke is

opened

diaphro~m

: a

contral dlophragm

closed

.

engine

, 0

is

obtoined. Once

corburettor

for

drawing

it shou ld

higher

for

the

vocuum

the

iet

odjustment

way

should

be

(i. e.

when

output

01

the

exhaust

indications

full revs without

fumes

that

ond 0 suitable

the

spark

plug

a wnite

that

the

carburettor

engine

wil l

climatic

the

ensure low

condition

1000 metres (3280 ft.

In

places

where

be

restri

the

choke

is

II

should

be

be

c!osed only partiolly,

is

coused

the

engine

can

function

proFo

rtioning the fuel feed

fue from

the

tank

are

is

mode

idling),

are

determined

an

opimum

os

lang

occelerates

black,

the mixture

spark

snould

be

insulator

brown

indicates

setting

be

carburettor

conveyed

setting should olwoys

fue l consumption

s

density

by

changi

),

air

cted

incorporoted

fully

closed

in

the

mixing

hos

started

in

ony

position a nd hos 3

.

by

volue,

ond

os

the

engine

steodily

caughing. If

the

mixture is

stobbing

is

tao

lean

from the

.

plug with a

in

color. Sooty

thai

the

is never

0

correc

to

and

too

the

on opti·

tion

is reduced (i. e .

ng

the

main jet

in

the

corburettor

only

for

storting

if

ever.

chamber,

, Ihe choke

to

the

engine ond

m

eons

it

turns

when

the en·

tao

correct

mix·

low,

moving

of

the

in

the

so

thot

should

dia·

is

18

Page 23

TILLOTSON-Diaphragm Carburettor (Schematic view)

FiR.27

Hose nipple

10A

Idling oullel possoge

2.

Inlel

compression

spring

2 Fuel

pump

body

lOB

By-poss

possoge

21

In1el conlrol l

eve

r

3

Fuel

pump

diophrogm

11

Butterfly volve

22

Pi

vot pin

3A

Inlel vorve

on

pump

12

Moin jet orifice

23

Venl hole

diophrogm

13

Corburetlar

hausing

24

Diophrogm housing

38

Oullel

valve

on

pump

14

Throol of

carburellor

(venturi!

25

D

iaphrogm

diaph

ragm

IS

Moin fueJ

autlel

2.

Air

chambar

,

Fuel

pump

gaskel

16

Choke

27 Filter

gosket

5 Di

ophragm

housing

gasket

17

FueJ

passage

!rom

pump

28

Fuel

strainer

6 Conlrol

chamber

10 conlrol chomber

29

Filter housing sc re w

7

Ad

justing screw for idJing jet

J8

Inlet

needle

ond

seol

3.

Fuel

chamber

8

Impulse

possoge

18A

(opper

seal

31

Pulsation

chamber

9 Idling jet orifice

19

Adjusli

ng

screw for moin iet

32

Fuel

'iller

ho using

19

Page 24

Carburettor

The Tillol50n

odjustoble

ing

points

1.

Ta

odjust

should

2.

With

odiustoble iet

leon (see also

3. The

odjusting

closedl, 0,5 th

Initi

al

adjustment

Fig.

28

adjustment

ccrburettor

jets. If

engine

should

be

the

be

thoroughly

screws

is

is

troubles

borne

corbureltor

warmed up.

s,

care

poge 18).

for

will

deform

the

first

carburettor

occur

in

mind:

correctly

should

be

the jets must

the

seato

F&SL072;31

ond

used

the

jets

for maxi mum

token

not

never

be

screwed

have

10

on

SACHS

10

output

render

tao

be

readiu

(full

the

fight

engines

load),

fuel/oir mixt

sted ,

into

which

the

the

the seat

has

follow-

engine

ure

tao

(i.

e.

Fig.

29

Far ini

tial

ediu

.29)

the

.

odiustment,

screw

). Then

sting

screw

so

fer

bock

sc r

ew

for

in

ogein

adjusting

is

encauntered

the

Fig

turn

open

F

inel adjustment: see

20

close the

the

turn

af

thet

sectio

idling

the

t~e

.

1I

IS

ebout

n HTe

odjusting

iet

(3, Fig . 29) (turn in

odiusting

idling

jet

langer

one

o~e

who

no

st.running

screw

turn

In

contect

le

screw

far

.

Tur~

turn, so

the

engine"

for

the

clockwise

the

mein

the

wlth

the

thel

main

idling

Ihe

on

iet

(1,

Filii'

direction

iet

bock

egoin

odjustment screw

butterfly

butterfly

pege

velve leve

velve

40.

28)

end

Idl 0 light

1'

/.

r;

is slightly

the

stap

turns

then

,

(1,

Page 25

Mointenance

0'

the

carburettor

At

certoin

intervals every

corburettor

must be disassembled,

cleoned

ond

overhouled.

All

exterio

r dirt should

be

cleon

ed

off with

gaso

line

before

disossembly. The bores,

ducts, possoges

end

jets must not

be

cleoned wifh hord object.s

(e.

g. wire

or

drill),

but should only

be rinsed with

gasoline

end

cleoned

with compressed

air

(remave

diophragms

before

blowing through). Before ossembly, check thaI oll

carburettor

components (especia

lly jet

seals

ond

diophragms)

are

in

proper

working

order.

Cnecking

ond

c1eaning

the

fuel

filter

in

good

time

he lps 10

ochieve 0 sotisfoctory

per-

formance of

the

carburettor

ond langer

engine service life.

Special

maintenance

instructions

1.

If

the pump feil

s,

alwoys check (before removing the

pump

diophrogm) the

im-

pulse

pipe

for

leokage

or

blockoge.

2.

When

fitting the inlet control lever

and the

comp

ression spri ng (see illustration

),

make sure

that

both

ends

of the spring

are

embedded

in

the

spring seats.

Fig. 30

3. The compression spring

mus!

not

be

stretched,

os

the spring

tension

is

accurately

adiusted

to the carburettor.

4.

The inlel control lever

is

cor-

rectly

inserted when

it

is

at

'he

same

level os the bottom

of !he

diaphragm

chamber

(see

arrows

on illustration).

5. The inlet needle should close

iu

s!

when

the inlel control le-

ver

is

flush with the bottom of

the chomber. If

this

is

not the

case, odiust the

lever by

bending

it

0 little (on the

in

-

let ne

edle

side

).

6.

When assembling the corburettor, moke sure thot

dia-

phragms, gasket

and

cast-

ira n

part

s of the housing

are

carefully inser

ted

into !he

cast-on centering pinsi

simi-

larly,

the gaskets, the pump

diaphragms end

the fuel

pump

body

are

eligned

by

means of the

same

kind of

centering pin

s.

The

diophragm

gaskets

are

always positioned on that

side

of

the

diaphragm

wh

ich

foces

towards

the

carburettor

housing.

21

Page 26

Decarbonizing

In

every

two-strake.engine

the

200

with

Fig,

engine 0 portion

eylinders

hours

of

correct

31

corburettor

end

operation,

the

exhaust

is

deposited

in

the exhoust system. T

01 the lotest when engine performance

setting, the engine lends

of

muffle

the

lubricoting

chiefly

ra,s,4

r,

the

cylinders

oil

on

is

the

piston crowns,

he

carbon should be removed

10

011:

40

burnt

and the

ond

cylinder_heads

farms

carben

in

the exhoust ports of

drops

four-strake.

Exhoust system

Fig.

31

Detach

tube end monifold.

Clean the inside of the

with

The

exhoust

on

ordinory

exhoust

muffler,

wire

muffler

dismontled for cleaning.

Carben

by

h

cr

eot

in 0

heoting

deposits

by meons

farge

the

fire

cf

.

con

muffler 10

0 we lding

which

after

cr

when, even

•

manifold

brush.

cannot

be

burnt off

every

ex

in 0

haust

be

red

forch

The exhaust system sho uld not be modified, as

mental to

Any modifications of the

punishable offen

I

:..

Cylinder

Unscrew the cylinder heods

combustion chambers with a

performance

head.

and fuel consumption

exhaust

ce

.

and

remove t

scre

wdrive r. Take

comb ustion chambers.

Cylinder ports

Place piston

Rem

ove

Clean exhoust tubes with on

Corefully

ot

carbon

place

and

exhaust

bottom

deposits

piston

dead

in

01

top

tubes

center

exhaust

ordinary

dead

.

center

Pistons

Corefully remove only the thicker

not try 10

scrope

the piston crowns

carbon

10

any

such a lterations will

and

will increase the exhoust noise.

moreover

illegal

deposits from the inside

care

not to

damage

ports with a screwdriver.

and

system

he

transfer

are

carbon

wire brush.

and

remove loose

carbon

.

deposits (flakes) from the piston crown.

a bright metallic condition .

be

and

constitute a

the surface

detri·

of

of

s.

the

the

Do

22

Page 27

ASSEMBLING

THE

ENGINE

Crankcase and crankshaft

Fig.

32

Screw

threoded

nipple

(4)

end

convex·head filiister

heod

cop

screw

(3)

M 6 x 6

with

gasket

into

upper

part

of

crankcose.

Note:

Before

inserting

the

locking disc

ha

lves,

cleon

both

grooves

in

the

upper

part

of

the

cronkcase.

Insert both

loo.in9

disc

holve

s

(1)

and

bath

eylindrieal

pins

12)

.

Fig.

33

Insert

preossembled

crankshoft

into

upper

port

of

cronkcose,

deep

groove

ball bearing

(2)

fac -

ing towords

magneto

side.

Fill

the grooves of the oil

sea

ls

with

hii:lh

temperoture

bearing

grease

Alvenie

3)

befere

fitting

Ihern. A

so

smeor

the

seoling

lips

slightly

with tllis

grease.

Fit oil

seal

13,23.6

x 62 x 10)

on

crankpin

magneto

side,

end

oil

seal (1, 28.4 x 62 x 10)

on

eronk-

pin p. t. o.

side,

flush with Ihe

outer

edge

of

Ihe cronkcose.

(

Sealing

lips focing

towords

cronkweb.)

Smear

sealing

surfaces

in

cronk·

case

with

sealing

compound

(we

recommend

sealing

compound

No.

1073

supplied

by

Mssr·s.

Ernst

Sonderhoff,

D-50oo

Köln-Biek-

dorf

, Postfach 22).

F

ig.3

4

Put

on

lower

part

of

crankco

se

~).

Screw

cronkcase

holves

together

with 12 nuts M 8

and

spring

was

her

s.

The

nuts

have

to

be

tiQhtened

diogonolly

(beginning

wlth

the

nuts in

the

middle).

Tightening

torque

2.3 ... 2.8 kpm

116.6

... 20.211. Ib.

).

Mount

cronkcose

on o5lsembly

Fig.

32

Fig.

33

jig, os

shown

in Fig. 9. Fig.

34

"S40U

,"1

23

Page 28

Fig.

35

Fig.

36

Attention

When

.screwing

Spork plug W 2

' po

rk

plug W 260 T 2 for eylin

in

the

spark

40

T 1 for eylind

Needle

Fig.

Insert

the

needle

sponding

bearings and pistons

35

both needle

illustrotion sho

beor

eonneeting rod eyes,

oilin9 them slightly

tion

~see

ing

der

GINE"

morking of needle beor-

ond eonn

"DISMANTLING T

on

poge

Put pistons on Ihe conneeting

rads with

tao

I no. 3

),

poi nt ing t

arro

owords

side.

Attention

Fit

morked piston on connecting

rod p.

t. o.

eylinder

under

GINE" on

and piston p. t. o. side

"DISMANTLING

poge 8).

Use a slotted

F

it Ihe

gudgeon

If

neeessary, heot piston to

70

...

80'(

by

troctor

in

sert

emave

R

Cov

4 wire

Cyl

exhaust tub

Fi

g.36

(158

meen

s of the

(3, repoir

(2,

repair

the loeating pin.

er

the cronkcose

ci

rcl

ips.

inders, "ylinder heads and

es

Fit cylinder

cording

to Ihe s

fer ports .

Ploce piston s

boord

(4,

Fig

linders which should be slightly

oiled

before Ihis

morked cylinder

the p.

I. o. ,ide).

Re

mave

Fit

sheet

eyl

F

passages

slotted

cylinder head gaskets (small

meta I

inder

heod

it

cylinder heods (spark plug

focing towards miet

,ide).

plugs walch the length of the threcds .

er

heod

with

oppro

x.

13

mm

(D.

der

heod with opprox. 17

mm

(0.

51

67 in.)

-

bearings (1

ws

ing) into the

ee ting rod

only

before

eorre

inser·

eye

HE

9).

loeoling pin (

repoir

ws on piston tops

the exnoust

si

de (see merking of

THE

wooden

board

pin (sliding fit).

..

.176'F) ond

gudgeon

pin ex·

tool no. 1)

1001 no . 2).

ond

insert

flange

.

hope

on

35

goskets

of the trans-

slott

ed

)

ond

fit

woo

the

operation

is

to

be

filted on

wooden

rim

focing t

board.

owords

).

in.) threod length,

threod length.

one

un-

EN-

EN-

(4)

fit

end

ce·

den

ey-

(the

,

·

.

it

24

Page 29

for

aligning

the cylinder, sc

rew

in

exhoust

tubes (4)

provisianally,

fit

exhaust

mani

-.

fo

ld

(3)

temporori

ly

ond move

the pistons

up

end

down

severol

times

:"

F

asten cyl

inders

end

cylinder

head

s with 4 nuts

(l)

M 8

and

4 nuts

(2)

M 8 x

27

and

weshers

(3.5

mm

:;:;;

0.134 in. thick

).

Tighten

the

nuts

diag

onally.

T;ghten;ng

torque

2.8 ... 3.0 kpm (20.2 ... 22.011. Ib.).

Remove exh

aust

manifold

.

Tighten

exhaust

tube

s with

an

ordinory

strop

wrench.

Lower

and

upper

part

of

intake

manifold

Fig.

37

Fit

both

gaskets

on

the cylinders

end

fasten lower

part

of

intoke

mon;fold

(2)

w;th 4 nuts M

6,

2 spring

woshers

ond

the

two

lock;ng

plotes (1).

Send

the

locking

plotes

over

.

F

asten

upper

part

of

intake

ma-

nifold with

sea

ling ring

inserted

,

with 6

filIister

heod

cop

screws

M 6 x

30

and

spring

woshers.

Carburettor

and

intake stack

F

ig.37

Fit

gaskets

end

both

insul

ating

sleeves

on

upper

part

of

intake

manifold

and

fasten

carburettor

with

two

self-Iocking nuts M

8.

T;ghten; ng

torque

0.8 ...

1.1

kpm (5.8 ... 8.0

ft.

Ib.

).

Fit impulse

pipe

to

nipple

(4,

Fig. 32)

and

carburettor

connection

(2, Fig. 29).

Fasten

intake

stock

(5,

Fig.

1)

and

reinforcement

ring

(4,

Fig. 1) with 3 filIister

heod

cop

screws

'I, "

ond

spring

woshers.

Armature

plote

,

Fig.

38

Insert

armoture

plate

(3)

tagether

with

leads.

Watch

the

morkings

(2). A new

ormature

plote

hos

no

morking

and

can

be al

igned

by

meons

of

the

longitudinal

slots.

Sme

or

both

filiister

head

cop

s

crew

s

(1

) M 5 x

15

with wa.shers

with

sealing

compa

und (we re-

commend

the liquid

sea

lin

,9.

com-

pound "Diamant" type

OW

H,

supplied

by

Messrs .

Glöckne

r

KG,

D-8756 Kohl/Mo;n, Postfach

80)

and

tighten

them.

Ti

ghtening

torque

0.4 ... 0.5 kpm fig.

38

(2.9

... 3.611. Ib.).

25

Page 30

F

ig.39

Fig.

40

Fig.

41

26

Fan houf ing

Fig.

3'9

.. p

Pl

ace

insu

loting sheolh

(5,

Fig.38)

with wires into

Ihe

passage

(4,

Fig.38).

Ploce fan housing

(1)

into cen-

tering

device

on

cronkcase and

fasten

it

with 4 hex

heod

screws

(2)

M 8 x 25.

Tightening torque 1

.5

. . 2.0 kpm

(10

.8

... 14.411. lb.)

Cylinder covers

F

ig.40

Fasten cylinder cover exhaust

and intoke side

(l

and

5)

10

the

fon housing

(3)

wilh 2 fillisler

head

cap

screws

(4)

M 6 x 30 ond

1

filIister head

cop

screw

(2)

M 6

x

75

with spring

was

hers (moke

sure that the covers are

propedy

seoled).

Tightening

lorque

for filIister

heod

screw

M 6 x 30 0.5 ... 0.6 kpm

(3.6 .. .4.3

11. Ib

.)

Tightening torque for filIister

head

cap

screw M 6 x

75

1

.5

..

2.0 kpm (10.8 ... 14.4 11. Ib.)

Fig.

41

Screw both cylinder cover ho lves

logelher

wilh

Ihreoded

ball

(2)

M 6 x 182 (Iocked

wi

lh 2 nuls M

6)

end 1 se

lf-Iocking nul

(1)

M 6

ond

washers.

Fasten both

cylinder cover halves

to the cylinder

heads

with 4 con-

vex-heod

filIister head

cap

screws

(3)

M 8 x 15 and spring

washers.

Page 31

Fig.42

lead

insulating

wires

towards

connect

Terminal

lighting

10

Terminal

Primory

10 terminal 1

Primory

10

Ground

10 termi"

Magne

Insert

Attention

If

terminal

leod

terminal

nal

to

Woodruff

new

contaet

os

block

leods

block

leod

wire

flywhe

~(lth-

the:

folIows:

2:

(yellow)

1

end

3:

(blue

(blue)

2

(brown)

3

el

key

breokers

(11

termine 5 ond

with

2

/yellow)

into

crankpin

hove

been

0.4 ± 0.05 mm (0.01575 ± 0.00196

neto

flywheel

grealest

Degreose

Fit

mogneto

occurately

retaining

Use

washer

with

erankpin

Tightening

in

distonce

the

taper

flywheel

with

lever to

end

toper).

torque

such Q

from

the

cf

.he

with

the

groove

hold

nut M 14 x 1

11.0

... 12.0 kpm (79.6

way

thot

cronkpin

crankshaft

flonged

in

the

the

.

fitted

in.)

,

the sliders

.

hub,

flanged

mogneto

.5

(the

Fig.

42

or

odiust

end

cf

ma

king

hub.

flywheel , os

ehamfered

...

86.8 ft. Ib.).

if

'he

contoet

cf

the

the

mogneto

sure

side

contoe'

breokers

contaet

that

shown

of

breoker

before

breoker

flywheel.

the

Woodruff

in

Fig. 4,

the

wosher

gap

fitting

arms

faeing

is

key

and

not

within

'he

hove

engages

fasten

towards

mag·

'he

it

Ignition

Fig.

Firing

Stopped

0.25

before

Running

3.5

before

Contaet

timing

43

point

:

engine

...

0.30 mm (0.0098

TDC

engine

...

4.0 mm (0.1378

TDC

breaker

gap

0.4 ± 0.05 mm

(0.01575 ± 0.00196

Pole

shoe

Stopped

gop'

engine

25 ... 29 mm (0.9843

Running

7

...

Measuring

Ignitian

Feeler

The

"

O-l-M"

·0"

top

"M" indieates

engine

11

mm (0.2756

instruments:

timing

gouge

flanged

0.4 mm (0.016 in.)

hub

is

for

eoineides with

dead

center

the

gouge

is

piston 1 (p. t. o. side), "

.

firing

...

0.0118 in.)

...

0.1575 in.)

:

in

...

1.1417 in.)

...

0.4331 in.) ' ;9.

(repair

tool no . 8),

provided

the

with two

morking

position

.)

(1,

.

punched

O-M" is

Fig.

43

adjusting

mark

for

43)

on

the

pin for

s.

pisto

n

fon

housing

flyweight

2.

when

(repair

the

tool no.

piston

9)

.

is

ot

27

Page 32

It

is

advisable

since

engine

also

be

performance

coused

Also check the

Measurin9 out

If there

10 be meosured

gouge

Fig.

Fig. 45

are

no timing marks

ond

the

44

10 check

the

depends

byon

incorrect

electrode

and

out

adjusting

gap

determining timing

ond

determined

pin,

ignition setting

on

it

. Vorious

ignition setting .

01

the

spark

marks

on

the

flanged

in

occording

operating

10

5.

6. Determine TDC

every

time

when

the

in

the

lighting system

020

in

fan

by

meons cf

45

(1,

engine

.).

housing,

:

fon

Fig.

plug

hub

the

troubles

(0.5

mm

ond

position

following

Fig. «

, . Provide the

= 0.

on

the

description

end

o

mark

2. Move piston 1 (p. t. o. sideJ

with timing

10

top

position

10

that

In

this

Ilywheel,

hub

with

os

shown

Tiahten

44)

until 0 light

gauge

dead

center, ond

cf

mogneto

piston position.

position

provide

the

in

Fi~

adiustmg

countered.

3.

When

adiusting

vonce,

mi

soges

of

bearing

nd

300

it

that

are

towards

surfaces

has

Ihe

inclined

Therefore 0 correspondingly

value

has

to

be

Fig.

45,

300

ample

Ex

II

the

liring

0.1575

...

value

to

(0.1575

... 0.

rurn

odiusting

clockwise

va

lue 10

iusting nut = 1

Pul flyweighl in

4.

position, using

weight

Fig.

Turn

recti o n

nut

(3)

In

pro

mark

shawn

piston 2

Ilanged

7. Take

retai

46)

.

mogneto

(2,

Fig.

and

piston

thi,s

position

vide the

"M"

in Fi

out

ning pin.

or

of

in

hub

:

in

be

odopted, os

scole

(A)

.

point

is

belore

adopted

in

.) (scoie A).

3.5

TDC

.)

be

1811

nut (2, Fig.

direction, according

adiusted

mm)

(1 turn

.

campletely

adiustlng

retoining pin (os shown

flywheel

rotatio

n, until the

44)

rests

on

the

of

the

magneto

hub

with

the

ond

firing position

way,

pin

the

meosuring pin

and

1 hits

flonged

end

g.

43.

the

same

with "0 "

adjusting

is

serviced,

moy

they

hove

the

timing

housing

43)

.

(3

with

, Fig.

olign

flywheel

cf

the

mogneto

the

to

.

the

43.

stap

be

mark

nut

spark

borne

plug

01

an