J8

Sabre Yard Tractors

1842GV and 1842HV

1848GV and 1848HV

Serial No. (020,001-)

OPERATOR’S MANUAL

John Deere

Worldwide Commercial And

Consumer Equipment Division

OMM138147 J8

North American Version

Litho in U.S.A.

English

INTRODUCTION

THANK YOU for purchasing a John Deere

product.

Read this manual and your attachment manual

thoroughly. Failure to do so could result in personal

injury or equipment damage.

WARNING:

c

This manual should be considered a permanent par t of

your machine and should remain with the machine when

you sell it.

Product warranty is provided as part of John Deere’s

support program for customers who operate and

maintain their equipment as described in this manual.

The product warranty is explained on the warranty

certificate you received from your dealer.

Measurements in this manual are metric units and their

U.S. customary equivalents. RIGHT-HAND and LEFTHAND sides are determined by facing in the direction

the machine will travel when going forward. When you

see a broken line arrow (------>), it indicates the part it is

pointing to is hidden.

product contains chemicals known to the

State of California to cause cancer, birth

defects or other reproductive harm.

CALIFORNIA Proposition 65 Warning

The Engine Exhaust from this

Record identification numbers below. Be sure to record

all the numbers to help in tracing the machine if it is

stolen. You also need to give these numbers to your

dealer when you order parts.

DATE OF PURCHASE: _______________________________

DEALER NAME: ____________________________________

DEALER PHONE: ___________________________________

Sabre® is a registered trademark of Deere & Company

Introduction

Vehicle Serial Number:

Located on Rear of Tractor

INTRODUCTION

M88555

Briggs & Stratton Engine Information

Model

Located on Engine

Type

Code

M88589

Introduction

TABLE OF CONTENTS

Assembly...............................................................................................................................................1

Safety Signs...........................................................................................................................................8

Controls ............................................................................................................................................... 11

Operating the Machine ........................................................................................................................13

Operating the Mower...........................................................................................................................30

Replacement Parts..............................................................................................................................37

Service Machine Safely.......................................................................................................................39

Service Interval Chart.......................................................................................................................... 41

Service Engine .................................................................................................................................... 43

Service Transmission........................................................................................................................... 48

Service Mower.....................................................................................................................................49

Service Electrical.................................................................................................................................56

Service Miscellaneous......................................................................................................................... 61

Removing Mower................................................................................................................................. 69

Installing Mower................................................................................................................................... 71

Troubleshooting ..................................................................................................................................72

Storing Machine................................................................................................................................... 77

Specifications.......................................................................................................................................80

Warranty..............................................................................................................................................83

Index....................................................................................................................................................89

Service Literature ................................................................................................................................ 93

All information, illustrations and

specifications in this manual are based

on the latest information at the time of

publication. The right is reserved to

make changes at any time without

notice.

COPYRIGHT© 1998

Deere & Co.

John Deere Worldwide Comme rcial and

Consumer Equipment Division

Horicon, WI

All rights reserved

Previous Editions

COPYRIGHT© 1997

OMM138147 J8

Table of Contents

ASSEMBLY

C

B

A

M88598

1842GV and 1842HV Only - Box of Parts

NOTE: If you are missing any parts see the

Replacement Parts section for additional service

part numbers.

A Sabre Operator’s Manual

Safety Video

M135884

M134321

B Steering Wheel AM121918

C Bag of Hardware

• 1 - Shoulder bolt-Steering Wheel

• 1 - Nut- Steering Wheel

• 1 - Washer- Steering Wheel

• 2 - M8x16 Bolts- Battery

• 2 - M8x16 Nut- Battery

• 2 - Keys

H63686

M87404

M63662

24H1721

19M7775

14M7303

M127340

Assembly - Page 1

ASSEMBLY

C

B

D

E

A

F

G

M88598A

1848GV and 1848HV Only - Box of Parts

NOTE: If you are missing any parts see the

Replacement Parts section for additional service

part numbers.

A Sabre Operator’s Manual

Safety Video

M135884

M134321

B Mower Gage Wheels (2) M111489

C Mower Drive Belt M110312

D Mower Discharge Chute with:

Chute Pin

Chute Spring

Chute Hinge

M123859

M112899

M83410

M83411

E Front Lift Rod Assembly:

Rod

Welded Pivot

Clevis (2)

Spacers (2)

Lock Nuts (2)

Jam Nuts (2)

M132735

AM119811

M113014

M110875

M85540

14M7275

F Steering Wheel AM121918

G Bag of Hardware

• 2 - Bolts

• 2 - Nuts

• 2 - Bushings

• 2 - Washers

• 1 - Shoulder Bolt-Steering Wheel

• 1 - Nut-Steering Wheel

• 1 - Washer-Steering Wheel

• 2 - M8x16 Bolts-Battery

• 2 - M8x16 Nut-Battery

• 2 - M8x20 Bolts-Chute

• 2 - M8x20 Nuts-Chute

• 2 - Keys

H63686

19M7274

14M7396

M111491

M110698

M87404

M63662

24H1721

19M7775

14M7303

03M7184

14M7464

M127340

Assembly - Page 2

ASSEMBLY

A

M88599

A

A

M92883

M88566

A

B

M88560

A

Remove Packaging

CAUTION: Avoid eye injury. Wear eye

c

protection when removing wire bands. Wire

bands are under tension and could snap

when removed.

Remove plastic and paper.

Remove wire bands (A) from front and rear tires.

1848GV and 1848HV Only - Remove Mower

Deck from Side of Crate

CAUTION: •Mower Deck is heavy. To avoid

c

injury, use a hoist or safe lifting device when

removing mower deck from crate.

•Mower Blades are sharp. Always wear gloves

when handling mower deck.

1. Remove two bolts (A) from crate.

2. Using a hoist or a safe lifting device, remove mower

deck from crate.

Install Steering Wheel

1. Put front wheels in the straight forward position.

2. Lubricate the steering shaft.

3. Install steering wheel with Sabre logo in the upright

position.

4. Install shoulder bolt (A). Driv e bolt in until head of bolt

contacts steering wheel.

5. Install washer and nut (B).

6. Tighten lock nut until it is snug. Do not tighten lock nut

to pull washer or head of bolt into steering wheel.

Remove Tractor from Crate

1. GEAR MODEL: Put transmission shift lever in

N (Neutral).

AUTOMATIC MODEL: Pull out free-wheeling lever (A).

2. Carefully push tractor off crate.

3. Lock park brake.

4. AUTOMATIC MODEL: Push free-wheeling lever (A)

IN before operating tractor.

Assembly - Page 3

ASSEMBLY

A

C

B

M88558

Connect and Check Battery

CAUTION: Prevent Battery Explosions:

c

- Keep sparks, lighted matches, and open

flame away from the top of battery. Battery

gas can explode.

- Never check battery charge by placing a

metal object across the posts. Use a voltmeter or hydrometer.

- Do not charge a frozen battery; it may

explode. Warm battery to 16° C (60° F)

IMPORTANT: This battery comes fully charged. If

the mower is not used by the Service Expiration

Date indicated on the battery, charge the battery.

(See Charging the Battery in the Service Electrical section.)

CAUTION: DO NOT attempt to open, add fluid

c

or service battery. Any attempt to do so will

void warranty and lead to possible injury.

NOTE: Do not remove the BLACK negative (–)

protective cap at this time.

1. Remove and discard the RED positive (+) protective

cap from the positive (+) battery terminal.

2. Connect blue harness wire (B) and RED positive (+)

cable (A) to battery. Apply petroleum jelly or silicone

spray to terminal to prevent corrosion. Make sure

connection is tight. Install the red terminal cover.

3. Remove and discard the BLACK (–) protective cap

from the negative battery terminal.

4. Connect black negative (–) cable (C) to battery. Apply

petroleum jelly or silicone spray to terminal to prevent

corrosion. Make sure connection is tight.

Assembly - Page 4

ASSEMBLY

M88571

D

A

B

C

M88577

A

M88578

D

C

B

1848GV and 1848HV Only - Assemble and

Install Mower Deck

Install Rear Gage Wheels

1. Install rear gage wheels, one on each side, using bolt

(A), bushing (B), washer (C), and tighten with nut (D).

2. Adjust gage wheels after mower deck is installed.

(See Adjust Mower Gage Wheels in Operating the

Mower section.)

Install Mower Deck

CAUTION: Avoid injury, before installing

c

mower on machine: STOP engine. Remove

key. Wait for all moving parts to STOP.

Avoid injury from loaded spring: LOCK lift

lever before installing mower.

Avoid injury from spring loaded rod: Make

sure you have a tight grip on drive belt

tension rod when installing.

1. STOP engine, LOCK park brake, push PTO switch

down to DISENGAGE, turn key to the OFF position, and

remove key.

2. Raise mower lift lever to TRANSPORT (upper)

position.

3. Slide mower under the tractor.

4. Put wood blocks under each side of mower.

5. Put mower lift lever in the MOWING (lower) position.

6. Install rear draft arms, one on each side of tractor, to

mower lift brackets with spring loaded J-pins (A).

7. Put front lift rod assembly (B) in slotted brackets (C)

on mower deck and install the front lift rod assembly to

the front of the tractor frame.

8. Push up on lever (D) and lock into tractor frame.

Assembly - Page 5

M88579

E

F

G

M47397

A

B

M88557

B

A

ASSEMBLY

9. Put mower drive belt (E) on engine drive sheave.

10.Push drive belt tension rod (F) into bracket (G).

11.Raise mower lift lever to TRANSPORT (upper)

position.

12.Remove wood blocks from both sides of mower.

13.Level mower. (See Leveling Mower in Operating the

Mower section.)

Install Mower Discharge Chute

CAUTION: To avoid injury:-NEVER operate

c

mower without chute in place.

-Hold chute firmly on mower deck when

installing, mower discharge chute is spring

loaded.

-After installing chute on deck check to make

sure hinge on chute is working properly by

opening chute and releasing it. Chute MUST

spring back to the LOWERED position.

1. Install mower discharge chute to mower deck with two

M8 x 20 bolts (A) and lock nuts (B).

2. Tighten nuts to 20 N•m (15 ft-lb).

Break-In Electric PTO Clutch

1. Start engine and push throttle lever (A) up to full

throttle (

2. With no load on mower, ENGAGE PTO (B) and allow

mower to run for 10 seconds.

3. DISENGAGE PTO and wait 10 seconds.

4. Repeat Step 2 for 12-15 cycles.

r

) position.

5. PTO clutch is now properly burnished.

Assembly - Page 6

ASSEMBLY

Check Machine Safety System

Perform safety system check to make sure the

electronic safety interlock circuit is functioning properly.

Perform all six Tests. (See Testing Safety System in the

Operating section)

Checking Tire Pressure

CAUTION: Explosive separation of a tire and

c

rim parts can cause serious injury or death:

- Do not attempt to mount a tire without the

proper equipment and experience to perform

the job.

- Always maintain the correct tire pressure.

Do not inflate the tires above the

recommended pressure. Never weld or heat a

wheel and tire assembly. The heat can cause

an increase in air pressure resulting in a tire

explosion. Welding can structurall y weaken or

deform the wheel.

- When inflating tires, use a clip-on chuck and

extension hose long enough to allow you to

stand to one side and NOT in front of or over

the tire assembly.

- Check tires for low pressure, cuts, bubbles,

damaged rims or missing lug bolts and nuts.

1. Check tires for damage.

2. Check tire pressure with an accurate gauge.

3. Add or remove air, if necessary:

Tire Size Pressure-kPa (psi)

Front: 16 x 6.5 97 kPa (14 psi)

Rear: 23 x 9.5 83 kPa (12 psi)

Assembly - Page 7

SAFETY SIGNS

Safety-Alert Symbol

Read and recognize safety information. Be alert to the

potential for personal injury when you see this safetyalert symbol.

On your machine safety labels, the words DANGER,

WARNING, and CAUTION are used with this safetyalert symbol. DANGER identifies the most serious

hazards.

In this manual, the word CAUTION and this symbol call

attention to safety messages.

Machine Safety Labels

DANGER

ROTATING BLADES CUT OFF ARMS AND LEGS

• Do not mow when children or others are around

• Do not mow in reverse

• Look down and behind before and while backing

• Never carry children

WARNING

AVOID SERIOUS INJURY OR DEATH

• Drive up and down slopes, not across

• Avoid sudden turns

• If machine stops going uphill, stop blade and back

down slowly

• Keep safety devices (guards, shields, and switches)

in place and working

• Read operator’s manual

• When leaving machine:

–Stop engine

–Set park brake

–Remove key

M88552

Safety Signs - Page 8

SAFETY SIGNS

M88552

WARNING

LOADED SPRING

LOCK LIFT LEVER FORWARD BEFORE CHANGING

ATTACHMENTS

Picture Note: One decal on each side of tractor frame

DANGER/POISON

SHIELD EYES.

M88552

EXPLOSIVE GASES CAN

CAUSE BLINDNESS OR

INJURY.

NO

•SPARKS

• FLAMES

• SMOKING

SULFURIC ACID

CAN CAUSE BLINDNESS OR

SEVERE BURNS

FLUSH EYES IMMEDIATELY WITH WATER.

GET MEDICAL HELP FAST.

MAINTENANCE-FREE

KEEP OUT OF THE REACH OF CHILDREN. DO NOT

TIP. DO NOT OPEN BATTERY!

Picture Note: Located on Battery

Safety Signs - Page 9

SAFETY SIGNS

M88552

M88552

1-1996

DANGER

ROTATING BLADE

DO NOT PUT HANDS OR FEET UNDER OR INTO

MOWER WHEN ENGINE IS RUNNING

THROWN OBJECTS

BEFORE MOWING, CLEAR AREA OF OBJECTS THAT

MAY BE THROWN BY BLADE

DO NOT OPERATE MOWER WITHOUT DISCHARGE

CHUTE OR ENTIRE GRASS CATCHER IN PLACE

DANGER

ROTATING BLADE

DO NOT PUT HANDS OR FEET UNDER OR INTO

MOWER WHEN ENGINE IS RUNNING

Picture Note: Located on Left-Hand side of deck

Certification Label

This OPEI label on your mower indicates that this model

has been certified by an independent laboratory for

compliance with American National Standard B-71.11996, “Safety Specifications” for Power Lawn Mowers,

Lawn and Garden Tractors, and Lawn Tractors.

Safety Signs - Page 10

Console Controls

M88557

A

C

B

D

E

F

M88564

G

M88556

A

B

C

M88553

E

D

A - Light Switch

B - PTO Switch/RIO Switch

C-Key Switch

D - Choke Knob

E - Throttle Lever

F - Battery Discharge Light

G - Cut Height Adjustment Lever

CONTROLS

Foot and Panel Controls (Gear Models,

1842GV and 1848GV)

A - Park Brake Lever

B - Brake Pedal

C - Gear Shift Lever

D - Mower Deck Lift Lever

E - Clutch Pedal

Controls - Page 11

CONTROLS

M88563

A

B

C

D

M88561

E

Foot and Panel Controls (Automatic Models,

1842HV and 1848HV)

A - Park Brake Lever

B - Brake Pedal

C - Forward Travel Pedal

D - Reverse Travel Pedal

E - Mower Deck Lift Lever

Controls - Page 12

OPERATING MACHINE

Operate Safely

• In addition to reading your Operator’s Manual, view

your John Deere Mowing Safety Video.

• Check brake action before you operate. Adjust or

service brakes as necessary.

• Inspect machine before you operate. Be sure

hardware is tight. Repair or replace damaged, badly

worn, or missing parts. Be sure guards and shields are

in good condition and fastened in place. Make any

necessary adjustments before you operate.

• Clear work area of objects that might be thro wn. K eep

people and pets out of the work area. Stop machine if

anyone enters the area.

• If you hit an object, stop the machine and inspect it.

Make repairs before you operate. Keep machine and

attachments properly maintained and in good working

order.

• DO NOT leave machine unattended when it is

running.

• Only operate during daylight or with good artificial

light.

• Be careful of traffic when operating near or crossing

roadways.

• Do not wear radio or music headphones while

operating the machine. Safe operation requires your full

attention.

Park Safely

• Stop machine on a level surface, not on a slope.

• Disengage mower blades.

• Lower attachments to the ground.

• Engage park brake.

• STOP engine.

• Remove key.

• Before you leave the operator’s seat, wait for engine

and all moving parts to STOP.

Operating Machine - Page 13

OPERATING MACHINE

Rotating Blades are Dangerous - Protect

Children and Prevent Accidents

PROTECT CHILDREN:

• Ne ver assume that children will remain where you last

saw them. Children are attracted to mowing activity, stay

alert to the presence of children.

• Keep children in the house when you are operating

the machine.

• Turn machine off if a child enters the mowing area.

• Use extra care when you come to blind corners,

shrubs, trees, or other objects that may block your

vision.

• DO NOT let children or an untrained person operate

the machine.

• DO NOT carry or let children ride on machine or any

attachment. DO NOT tow children in a cart or trailer.

HELP PREVENT SERIOUS OR FATAL ACCIDENTS:

• Be alert at all times, drive forward carefully. People

especially children can move quickly into the mowing

area before you know it.

• Back carefully. Disengage mower blades and look

behind the machine carefully, especially for children,

before you back up.

• DO NOT mow in reverse unless it is absolutely

necessary.

• Disengage mower blades when you are not mowing.

• DO NOT operate machine if you are under the

influence of drugs or alcohol.

Operating Machine - Page 14

OPERATING MACHINE

Avoid Tipping

• DO NOT drive where machine could slip or tip.

• Stay alert for holes and other hidden hazards in the

terrain.

• Keep away from drop-offs.

• Slow down before you make a sharp turn or operate

on a slope.

• When pulling loads or using heavy equipment, use

only approved hitches, limit loads to those you can

safely control, and use counterweights or wheel

weights when required per this manual or your

attachment manual.

• Drive up and down a hill—not across. Be careful

when you change direction on a slope.

• DO NOT stop when going up hill or down hill. If

machine stops going up hill, DISENGAGE mower

blades and back down slowly.

• DO NOT mow wet grass. Reduced traction could

cause sliding.

• DO NOT try to stabilize the machine by putting your

foot on the ground.

Keep Riders Off

• Only allow the operator on the machine. Keep

riders off.

• Riders on the machine or attachment may be struck

by foreign objects or thrown off the machine causing

serious injury.

• Riders obstruct the operator’s view resulting in the

machine being operated in an unsafe manner.

Operating Machine - Page 15

OPERATING MACHINE

M88554

A

Wear Appropriate Clothing

• Wear close fitting clothing and safety equipment

appropriate for the job.

• Loud noise can cause impairment or loss of hearing,

wear a suitable protective device such as earplugs.

Stay Clear of Rotating Drivelines

Entanglement in rotating driveline can cause serious

injury or death:

• Wear close fitting clothing.

• STOP the engine and be sure PTO driveline is

stopped before getting near it.

Transport Safely

• Use saf ety lights and de vices. Slo w moving machines

when driven on public roads are hard to see, especially

at night. Avoid personal injury or death resulting from a

collision with a vehicle.

• Whenever driving on public roads, use flashing

warning lights and turn signals according to local

regulations. Extra flashing warning lights may need to

be installed.

Adjusting Seat

1. Tip seat forward and loosen two knobs (A) to slide

seat assembly forward or rearward to most comfortable

OPERATOR position.

2. Tighten knobs after adjustment to keep seat in place.

Operating Machine - Page 16

M88554

A

M88556

B

C

M88557

A

M88557

A

OPERATING MACHINE

Using the Park Brake

CAUTION: To av oid i njury, always LOCK park

c

brake before getting off tractor or leaving

tractor unattended.

LOCKING PARK BRAKE:

Picture Note: Gear Model Shown

1. Gear Only: Push clutch pedal (A) all the way down.

2. Push brake pedal (B) all the way down.

3. Lift park brake lever (C) up.

4. Release pedal(s) and park brake lever. Pedal(s)

should stay down and park brake lever should stay

LOCKED in UP position.

UNLOCKING PARK BRAKE:

1. Push and hold pedal(s) down.

2. Push park brake lever (C) down to UNLOCK park

brake.

3. Release pedal(s).

Using Headlights

Push top of light switch (A) to turn headlights ON.

Push bottom of light switch to turn headlights OFF.

Check Battery Discharge Light

The Battery Discharge light (A) should go out when

throttle lever is moved to the HIGH IDLE/Mowing (

position.

a

)

The battery discharge light may remain on for several

minutes while the battery is being charged.

Operating Machine - Page 17

Starting Engine

M88556

A

B

C

M88561

E

D

F

CAUTION: Start engine ONLY outdoors or in a

c

well ventilated place. Exhaust fumes are

dangerous.

OPERATING MACHINE

IMPORTANT:

Do not operate starter more than 20

seconds at a time, or you may damage

it. If engine does not start: Wait two

minutes before you try again. See

Troubleshooting section.

NOTE: Engine will not start unless: PTO switch is

DISENGAGED, park brake is LOCKED or brake

pedal pushed down. On GEAR model: The

transmission shift lever should be in N (NEUTRAL)

position.

1. On GEAR model: Move transmission shift lever (A) to

N (NEUTRAL) position.

Picture Note: Gear Model Shown

2. Lock the park brake (B).

3. Push PTO switch (C) down to DISENGAGE.

4. Pull choke knob (D) out to the ON (k) position.

5. Move throttle lever (E) to the HALF-SPEED (R)

position.

Picture Note: Automatic Model Shown

6. Tu rn key (F) to START position.

7. When engine starts, release key to RUN position.

8. Check starting conditions:

If engine is COLD:

•

Gradually return the choke to

the OFF position after the engine starts and warms

up. (See Cold Weather Starting in this section.)

If engine is WARM:

•

Return choke to the OFF

position as soon as the engine starts.

9. Let engine run for a couple of minutes to warm-up

before operating tractor.

Operating Machine - Page 18

OPERATING MACHINE

M88576

A

M88553

B

A

M88553

A

M88556

B

Warming and Idling Engine

WARMING ENGINE:

• Run Engine at half speed for 2–3 minutes.

IDLING ENGINE:

• Engine is air-cooled and needs a large volume of air

to keep cool. K eep air intake screen (A) on top of engine

clean.

• Avoid unnecessary engine idling.

Stopping Engine

1. Move throttle lever (A) to SLOW (t) position. Let

engine run at low throttle a few seconds.

2. Tu rn key (B) to OFF position.

3. Remove key.

4. LOCK the park brake.

Using and Stopping Gear Transmission

CAUTION: TO AVOID INJURY: • Before

c

moving forward or rearward, make sure area

is clear of bystanders, especially children.

• Disengage mower or attachment before

backing up.

IMPORTANT:You do not have to STOP tractor to

shift on the go, but do not shift on

the go when tractor is under extreme

load. To shift on the go, follow steps

below under TRAVEL FORWARD.

TO TRAVEL FORWARD:

1. Push down on clutch pedal (A).

2. Move shift lever (B) to desired forward gear.

3. Release clutch pedal slowly.

Operating Machine - Page 19

TO TRAVEL IN REVERSE:

M88556

CB

M88563

A

B

OPERATING MACHINE

NOTE:

The engine and any operating attachment

will stop as the gear shift lever is moved to R

(REVERSE) position with attachment engaged.

1. Push clutch pedal and brake (C) all the way down to

STOP tractor.

2. Push PTO knob down to the OFF position to

disengage attachment.

3. Look behind the vehicle to be sure there are no

bystanders nearby.

4. Move shift lever (B) to R (REVERSE) position.

5. Release clutch pedal slowly.

FOR EMERGENCY STOPPING

1. Push down on clutch pedal and brake at the same

time.

NOTE: This tractor is equipped with a Brake/Clutch

Interlock. Pressing the brake pedal will also depress

the clutch pedal for emergency stops.

Using and Stopping Automatic Transmission

CAUTION: TO AVOID INJURY: • Before

c

moving forward or rearward, make sure area

is clear of bystanders, especially children.

• Disengage mower or attachment before

backing up.

1. UNLOCK park brake. (See Using the Park Brake in

this section.)

TO TRAVEL FORWARD:

1. Push down pedal (A).

TO TRAVEL IN REVERSE:

NOTE: The engine and any operating attachment

will stop as the REVERSE pedal is depressed with

attachment engaged.

1. Bring the vehicle to a stop.

2. Push PTO knob down to the OFF position to

disengage attachment.

3. Look behind the vehicle to be sure there are no

bystanders nearby.

4. Push down pedal (B).

Operating Machine - Page 20

OPERATING MACHINE

g

p

p

g

M88563

A

B

C

M88557

A

FOR EMERGENCY STOPPING:

1. Push down on brake pedal (C). Travel pedals (A and

B) will return to NEUTRAL position.

Using Reverse Implement Option

CAUTION: TO AVOID INJURY: Before moving

c

forward or rearward, make sure area is clear

of bystanders, especially children.

NOTE: Operating the mower while backing up is

strongly discouraged. The Reverse Implement

Option should be used ONLY when operating

another attachment or when the operator deems it

necessary to reposition the machine with the mower

engaged.

1. Stop the machine FORWARD travel with the

attachment still engaged.

2. Look behind the vehicle to be sure there are

bystanders

.

no

3. Lift and hold the PTO knob (A) up past the PTO

engagement position to activate the reverse implement

position while:

• depressing REVERSE foot pedal slightly

(Automatic Transmission)

OR

• moving the gear shift lever to the R (REVERSE)

position (Gear Transmission).

NOTE:

re

OFF

The En

If the en

ine and attachment stop while

ositioning the machine, return PTO knob to the

osition and restart the machine. (See Starting

ine in this section.) Begin again with Step 2.

4. As the machine begins to move backward, release

the PTO knob and reposition the machine.

5. Resume FORWARD travel. The attachment should

continue operating.

6. Repeat Steps 1 through 5 to reposition the machine

again.

Operating Machine - Page 21

OPERATING MACHINE

M88556

B

A

M88560

C

Pushing Machine

IMPORTANT: Avoid transmission damage, DO

NOT tow machine.

To move machine when engine is STOPPED:

• Unlock the park brake (A).

Picture Note: Gear Model Shown

• GEAR MODEL: Put transmission shift lever (B) in N

(Neutral).

• AUTOMATIC MODEL: Pull out on free-wheeling lev er

(C).

• Push machine to desired location.

NOTE: AUTOMATIC MODEL: Push free-wheeling

lever (C) IN before operating tractor.

Daily Operating Checklist

• Test safety systems.

• Check tire pressure.

• Check fuel level.

• Check engine oil level.

• Remove grass and debris from machine.

Operating Machine - Page 22

OPERATING MACHINE

M88557

A

B

M88557

A

Testing Safety Systems

CAUTION: Engine exhaust fumes can cause

c

sickness or death.

If it is necessary to run an engine in an

enclosed area, remove the exhaust fumes

from the area with an exhaust pipe extension.

If you do not have an exhaust pipe extension,

open the doors and get outside air into the

area.

NOTE: Your Yard Tractor is equipped with a

ELECTRONIC SAFETY INTERLOCK. Engine will not

start unless: • Operator is on seat; • PTO switch is

DISENGAGED; • Brake pedal is depressed OR

parking brake is set.

Use the following checkout procedure to check for

normal operation of tractor.

If there is a malfunction during one of these procedures,

DO NOT operate tractor. (See your Sabre Service

Center for service.)

Perform these tests in a clear open area. Keep

bystanders away

.

Test 1

Check operation of indicator lights:

• Turn key to RUN position.

• Pull PTO switch (B) up to ENGAGE.

• LOOK: Indicator light (A) must light.

• If indicator does not light, see Replacing Indicator

Light Bulb in Service – Electrical section.

• If new indicator bulb does not light or no indicators

work, see your Sabre Service Center for service.

Test 2

1. Operator on seat.

2. UNLOCK the park brake.

3. Push PTO switch (A) down to DISENGAGE.

4. Try to start engine.

5. Engine MUST NOT start. If engine starts, there is a

problem with your safety interlock circuit.

Operating Machine - Page 23

OPERATING MACHINE

M88557

A

M88557

A

B

M88556

A

C

B

Test 3

1. Operator on seat.

2. LOCK the park brake.

3. Pull PTO switch (A) up to ENGAGE.

4. Try to start engine.

5. Engine MUST NOT start. If engine starts, there is a

problem with your safety interlock circuit.

Test 4

1. Operator on seat.

2. Lock the park brake.

3. Push PTO switch (A) down to DISENGAGE.

4. Start engine and move throttle lever (B) to HALFSPEED (R) position.

5. Pull PTO switch (A) up to ENGAGE.

6. Move throttle lever to FAST (r) speed position.

7. Raise up off of seat. DO NOT get off tractor.

8. Engine MUST stop. If engine does not stop, there is a

problem with your safety interlock circuit.

Test 5

1. Operator on seat.

2. Push brake pedal down.

3. Push PTO switch (A) down to DISENGAGE.

4. Put transmission shift lever (B) in N (NEUTRAL)

position.

5. Start engine and move throttle lever (C) to FAST (r)

speed position.

6. Release brake slowly.

7. Raise up off of seat. DO NOT get off tractor.

8. Engine MUST stop. If engine does not stop, there is a

problem with your safety interlock circuit.

Operating Machine - Page 24

OPERATING MACHINE

M88557

A

B

M88556

A

B

M88560

C

Test 6

1. Operator on seat.

2. Lock the park brake.

3. Push PTO switch (A) down to DISENGAGE.

4. Start engine and move throttle lever (B) to FAST (r)

speed position.

5. Raise up off of seat. DO NOT get off tractor.

6. Engine MUST remain running. If engine does stop,

there is a problem with your safety interlock circuit.

Test 7

1. Lock the park brake (A).

2. GEAR MODEL: Put transmission shift lever (B) in N

(Neutral).

AUTOMATIC MODEL: Pull out free-wheeling lever (C).

3. Try to push machine manually.

4. Park brake MUST prevent machine from moving. If

machine moves, parking brake needs to be adjusted.

Operating Machine - Page 25

OPERATING MACHINE

Test 8

CAUTION: TO AVOID INJURY: Before moving

c

rearward, make sure area is clear of

bystanders, especially children.

Test Reverse Implement Option:

1. Start engine.

2. Engage PTO to start attachment.

3. Look behind the vehicle to be sure there are no

bystanders.

4. Begin REVERSE travel by depressing REVERSE foot

pedal (Automatic transmission) or moving gear shift

lever to R (REVERSE) position (Gear transmission).

5. Attachment and engine should stop operation. If

attachment or engine continues to operate while tractor

travels in REVERSE, do not continue to operate

attachment. See your John Deere dealer for service.

Avoid Damage to Plastic and Painted

Surfaces

• DO NOT wipe plastic parts unless rinsed first. (See

Correct Cleaning Care in Service-Miscellaneous

section.)

• Insect repellent spray may damage plastic and

painted surfaces. Do not spray insect repellent near

machine.

• Be careful not to spill fuel on machine. Fuel may

damage surface. Wipe up spilled fuel immediately.

Operating Machine - Page 26

OPERATING MACHINE

Avoid Using Ground Engaging Equipment

IMPORTANT: This tractor is NOT intended for use

with ground engaging equipment. Use of such

equipment could result in damage to

transmission components.

This tractor is not intended for use with ground engaging

equipment such as a rear tiller, disk, blade or plow.

Using Front Weights

CAUTION: Tractor front wheel weights

c

improve stability in most slope operation. To

avoid injury, add front wheel weights for

better front-end stability and steering when

using a rear mounted attachment or pulling a

cart.

NOTE: Before installing wheel weights on your

machine, MAKE SURE that the tire valve stems are

facing the inside.

Install front wheel weights for better stability and

steering control when you use equipment such as the

rear-mounted grass bagger or dumpcart.

Remove front wheel weights when not required.

Using Rear Wheel Weights

IMPORTANT: When adding weight to rear of

tractor, use wheel weights only.

75 lbs. (34 kg) MAX. each wheel.

Use of rear wheel weights is recommended when an

attachment, such as snowthrower or blade is used.

Operating Machine - Page 27

OPERATING MACHINE

M73743

A

M73744

D

B

C

M73745

F

E

Using Tire Chains

Tire chains are recommended for use with snowthro w er

and, under certain conditions; the front blade.

Preparing Tractor for Installing Chains on

Tires

• Park the tractor on a level surface.

• Lock the park brake.

• STOP the engine.

• Remove the key.

Installing the Chains

1. Remove chains from bag and lay out flat with the

cross chain hook ends facing upward. Remove any

twists and tangles from cross chain and rim chain.

2. Drive machine onto chains.

3. Drape chain over tire with the lever fastener on

outside of tire and cross link hooks (A) facing upward

and away from tire.

4. Adjust chain for straightness and an even amount of

cross chain links on each side of tire.

5. Place the first cross chain (opposite the end with

fastener and inside hook) under tire.

6. Pull the inside rim chain tight and hook the inside

hook. Pull the outside rim chain tight and hook the

outside lever fastener (B) by running the end through a

free link (C). Close the fastener by rotating it back 180

degrees and engaging the hook (D) on the end of the

fastener into a rim chain link (E). Make sure the chain is

centered on the tire with approximately the same

number of free rim links (F) on the inside and outside.

Operating Machine - Page 28

OPERATING MACHINE

M73746

G

7. Tie excess rim chain links (G) back to the rim chain.

8. The chain should be as tight as possible by hand.

Unhook the fastener and repeat Step 5 if the chain is

loose.

9. Drive forward on chains 30’-40’ and recheck for

tightness. Adjust as necessary.

IMPORTANT: Periodically check chains for

looseness and adjust when necessary.

Maintain proper air pressure in tires.

Transporting

Do not tow machine.

Use a heavy-duty trailer to transport your machine.

Drive forward onto trailer.

Lower mower or any attachment to trailer deck.

LOCK park brake.

Be sure trailer has all the necessary lights and signs

required by law.

Fasten machine to tr ailer with heavy-duty straps , chains,

or cables. Both front and rear straps m ust be directed

down and outward from tractor.

Operating Machine - Page 29

OPERATING MOWER

Operate Mower Safely

• In addition to reading your Operator’s Manual, view

your John Deere Mowing Safety Video.

Check Ground Conditions

• Clear mowing area of objects that might be thrown.

Keep people and pets out of mowing area.

• Study mowing area. Set up safe mowing pattern. Do

not mow under conditions where traction or stability is

doubtful.

• First, test drive area with PTO switch DISENGAGED

and mower lowered. Slow down when you travel over

rough ground.

Avoid Injury From Contacting Blades

Before you dismount to unplug or adjust mower:

• DISENGAGE PTO switch to stop mower blades.

• STOP the engine.

• LOCK the park brake.

• Remove key.

• Wait for mower blades to STOP.

• K eep hands , f eet and clothing a way from mower deck

when engine is running.

• DISENGA GE PT O s witch to stop mower b lades when

you are not using mower.

Operating Mower - Page 30

OPERATING MOWER

M88553

A

B

M88564

A

Using Lift Lever to Raise and Lower Mower

Check out the two different lift lever positions before

operation:

• TRANSPORT (UPPER) POSITION: Raises mower

for transport.

• MOWING (LOWER) POSITION: Maintains cutting

height set by mower height control yet allows deck to

float over uneven terrain.

To put mower in MOWING (lower) position:

• Pull lift lever (A) back slightly.

• Push in button (B).

• Push lever forward until it latches down.

To put mower in TRANSPORT (upper) position:

• Push down on lift lever (A) slightly.

• Push in button (B).

• Pull lever back towards you until it latches.

Adjusting Cutting Height

IMPORTANT: Lift lever must be in TRANSPORT

(upper) position before turning cutting height

knob.

NOTE: Adjust cutting height after you change

cutting height. (See Adjusting Mower Gage Wheels

in this section.)

Cutting height can be adjusted from approximately

25–100 mm (1–4 in).

When lift lever is in TRANSPORT (upper) position (lift

lever all the way back), cutting height is approximately

100 mm (4 in).

Knob (A) has cutting height identification numbers

embossed in it. To change or attain cutting height

desired:

• Pull lift lev er all the w a y back to TRANSPOR T (upper)

position.

• Turn cutting height knob (A) to desired cutting height

position. Mower will be at this cutting height each time

you lower it.

Operating Mower - Page 31

OPERATING MOWER

M88571

D

A

B

C

Adjusting Mower Gage Wheels

CAUTION: To avoid injury, before you adjust

c

gage wheels: STOP engine, remove key, and

wait for blades to STOP.

IMPORTANT: Mower gage wheels must not ride

on ground to support mower weight. Adjust gage

wheels each time you change cutting height.

1. Check tractor tire pressure. Inflate tires to the correct

pressure. (See Checking Tire Pressure in Service Miscellaneous section.)

2. Raise mower lift lever to TRANSPORT (upper)

position and adjust cutting height. (See Adjusting

Cutting Height in this section.)

3. Remove bolt (A), bushing (B), washer (C), and nut

(D).

4. Move mower gage wheels, one on each side, to one

of four holes for desired position.

5. Install bolt and tighten with nut.

6. Move lift lever forward to MOWING (lower) position.

7. Bottom of gage wheels should be approximately 6-13

mm (1/4-1/2 in) from the ground when properly

adjusted.

Adjusting Mower Level (Side-to-Side)

CAUTION: To avoid injury, before you adjust

c

mower: STOP engine, remove key, and wait

for blades to STOP.

Be careful, sharp edges on mower blades.

Always wear gloves when handling mower

blades.

NOTE: A deck leveling gauge (Part Number

TY15272) to aid in deck leveling may be obtained

through your local SABRE Service Center at a

nominal cost.

1. Park tractor on a hard, level surface.

2. Stop engine and remove key.

Operating Mower - Page 32

OPERATING MOWER

M40434

M88585

B

M40161

A

3. CHECK: Tire pressures must be correct. (See

Checking Tire Pressure in Service – Miscellaneous

section.)

4. Adjust cutting height to 50 mm (2 in). (See Adjusting

Cutting Height in this section.)

5. Put mower lift lever in MOWING (lower) position.

NOTE: Mower gage wheels should not contact the

ground.

6. Turn left blade parallel to tractor axle. Hold drive belt

and turn right blade parallel to axle.

7. Measure from each outside blade tip (A) to the level

surface. The difference between measurements must

not be more than 3 mm (1/8 in).

NOTE: Adjustable lift links are on both sides of

mower. Cutting height can closely match knob

setting by using adjustment on both sides. DO NOT

adjust deck too high or it will not lock in transport

(upper) position.

8. Tu rn nut (B), (right side shown): Clockwise to RAISE

right side of mower and counterclockwise to LOWER

right side of mower.

9. Check side-to-side measurements and readjust if

necessary.

Operating Mower - Page 33

OPERATING MOWER

M88564

A

M88581

C B

B

Adjusting Mower Level (Front-to-Rear)

CAUTION: To avoid injury, before you adjust

c

mower: STOP engine, remove key, and wait

for blades to STOP.

Be careful, sharp edges on mower blades.

Always wear gloves when handling mower

blades.

NOTE: Mower gage wheels should not contact the

ground during leveling.

1. Park tractor on a hard, level surface.

2. Stop engine and remove key.

3. CHECK: Tire pressure must be correct. (See

Checking Tire Pressure in Service – Miscellaneous

section.)

4. Pull lift lever all the way bac k to TRANSPOR T (upper)

position.

5. Turn mower depth control knob (A) to adjust cutting

height to 50 mm (2 in).

6. Move lift lever forward to MOWING (lower) position.

7. Turn left blade so blade tip points straight forward.

8. Hold drive belt and turn right blade straight forward.

9. Measure from the front of each blade tip to the level

surface. The front blade tips must be 6–9 mm

(1/4–3/8 in.) lower than rear blade tips or blades will cut

grass twice and tips will turn brown.

10.Loosen two rear nuts (B) on front lift rod assembly

and turn two front nuts (C) clockwise to RAISE front of

mower deck or counterclockwise to LOWER front of

mower deck.

11.Tighten rear nuts (B) after adjustment is completed.

12.Check front-to-rear deck measurements and readjust

if necessary.

Operating Mower - Page 34

M88557

A

B

M88557

A

OPERATING MOWER

Engaging Mower

IMPORTANT: Operate mower at HIGH IDLE/

Mowing (

blades are engaged.

Machine may require 2-3 minutes warm-up period

before engaging the mower deck.

1. START engine.

2. Move throttle lever (A) to the FAST (r) position.

3. Lower mower to cutting height.

4. Pull PTO switch (B) up to ENGAGE mower.

NOTE: Any operating attachment and the engine

will stop as the gear shift lever is moved to the R

(REVERSE) position (Gear transmission) or the

REVERSE foot pedal is depressed (Automatic

transmission) with attachment engaged.

) position when mowing or after mower

a

5. Disengage PTO before shifting to REVERSE.

Disengaging Mower

1. Push PTO switch (A) down to DISENGAGE mower.

2. If you hit an object with mower while mowing, STOP

mower and engine immediately. Inspect mower for

damage.

Operating Mower - Page 35

OPERATING MOWER

Dismounting to Inspect or Unplug Mower or

Optional Bagger

CAUTION: To help prevent personal injury, do

c

the following steps before you dismount to

inspect or unplug mower or bagger.

1. STOP machine.

2. Push PTO switch down to DISENGAGE mower.

t

3. Move throttle lever to SLOW (

4. Lower mower to the ground.

5. LOCK park brake.

6. STOP engine.

7. Remove key.

) position.

8. Wait for all moving parts to STOP.

Operating Mower - Page 36

REPLACEMENT PARTS

WE RECOMMEND JOHN DEERE

Service Center.

PART NUMBERS MAY CHANGE

changes, your dealer will have the latest number.

WHEN YOU ORDER PARTS,

number and engine serial number. These are the numbers that you have recorded on the inside front

cover of this manual.

quality parts and lubricants, available at your Authorized SABRE

, use part numbers listed below when you order. If a number

your Authorized SABRE Service Center needs your machine serial

Parts for Tractor and Mower Deck

ITEM PART NUMBER

Air Cleaner Elements:

Foam

Paper

Battery AM121593

Fuel Filter LG493629

Oil Filter AM125424

Spark Plug TY6129

LG272490

LG394018

Fuse-15 amp 99M7065

Leveling Gauge TY15272

Mower Deck Belt (42-Inch Mower):

Primary (PTO clutch to upper deck sheave)

Secondary (lower deck sheave to blade spindles)

Mower Deck Belt (48-Inch Mower):

Primary (PTO clutch to upper deck sheave)

Secondary (lower deck sheave to blade spindles)

Blade:

• 42-Inch Mower

• 48-Inch Mower

Steering Wheel Assembly AM121918

Seat AM124425

Headlight Bulb (2 required) AD2062R (#1156)

Fuel Cap AM115497

Shift Knob M132841

M131152

M131151

M110312

M110313

M127179

M115495

Ignition Key M127340

Replacement Parts - Page 37

REPLACEMENT PARTS

ITEM PART NUMBER

Gage Wheel Assembly:

Gage Wheels (2 required)

Bolts

Nuts

Bushings

Washers

Throttle Cable AM124424

Choke Cable AM125849

Seat Spring M110439

Front Wheel & Tire Assembly:

Wheel

Tire

Stem

Rear Wheel & Tire Assembly:

Wheel

Tire

Stem

M111489

19M7274

14M7396

M111491

M110698

AM124324

M131036

AM130795

AM124326

M131038

AM130795

Muffler AM125998

(Part numbers are subject to change without notice. Part Numbers

may be different outside the U.S.A.)

If you would like a copy of the Parts Catalog for this

machine, please use the

Order Form

in the John Deere

SERVICE LITERATURE section.

Replacement Parts - Page 38

SERVICE MACHINE SAFELY

Practice Safe Maintenance

• Understand service procedure before doing work.

Keep area clean and dry.

• Never lubricate, service, or adjust machine while it is

moving. Keep safety devices in place and in working

condition. Keep hardware tight.

• To prevent them from getting caught, keep hands,

feet, clothing, jewelry, and long hair away from any

moving parts.

• Before servicing machine, disengage all power and

stop the engine. Lock park brake and remove the key.

Let engine cool.

• Securely support any machine elements that must be

raised for service work.

• Keep all parts in good condition and properly

installed. Fix damage immediately. Replace worn or

broken parts. Remove any buildup of grease, oil, or

debris.

• Disconnect battery ground cable (-) before making

adjustments on electrical systems or welding on

machine.

• Unauthorized modifications to the machine may

impair its function and safety.

Wear Appropriate Clothing

• Wear close fitting clothing and safety equipment

appropriate for the job.

• Loud noise can cause impairment or loss of hearing,

wear a suitable protective device such as earplugs.

• Do not wear radio or music headphones while

servicing the machine. Safe service requires your full

attention.

Service Machine Safely - Page 39

SERVICE MACHINE SAFELY

Avoid Injury From Contacting Blades

Before you unplug or adjust machine:

• STOP the engine.

• Remove key.

• Wait for blades to STOP.

• K eep hands, f eet and clothing aw ay from b lades when

engine is running.

Handling Waste Product and Chemicals

• Waste products such as used oil, fuel, coolant, brake

fluid, and batteries, can harm the environment and

people.

• DO NOT use beverage containers for waste fluids someone may drink from them.

• See your local Recycling Center or John Deere

dealer to learn how to recycle or get rid of waste

products.

• A Material Safety Data Sheet (MSDS) provides

specific details on chemical products: physical and

health hazards, safety procedures, and emergency

response techniques. See your John Deere dealer for

the MSDS on chemical products used with your

machine.

Service Machine Safely - Page 40

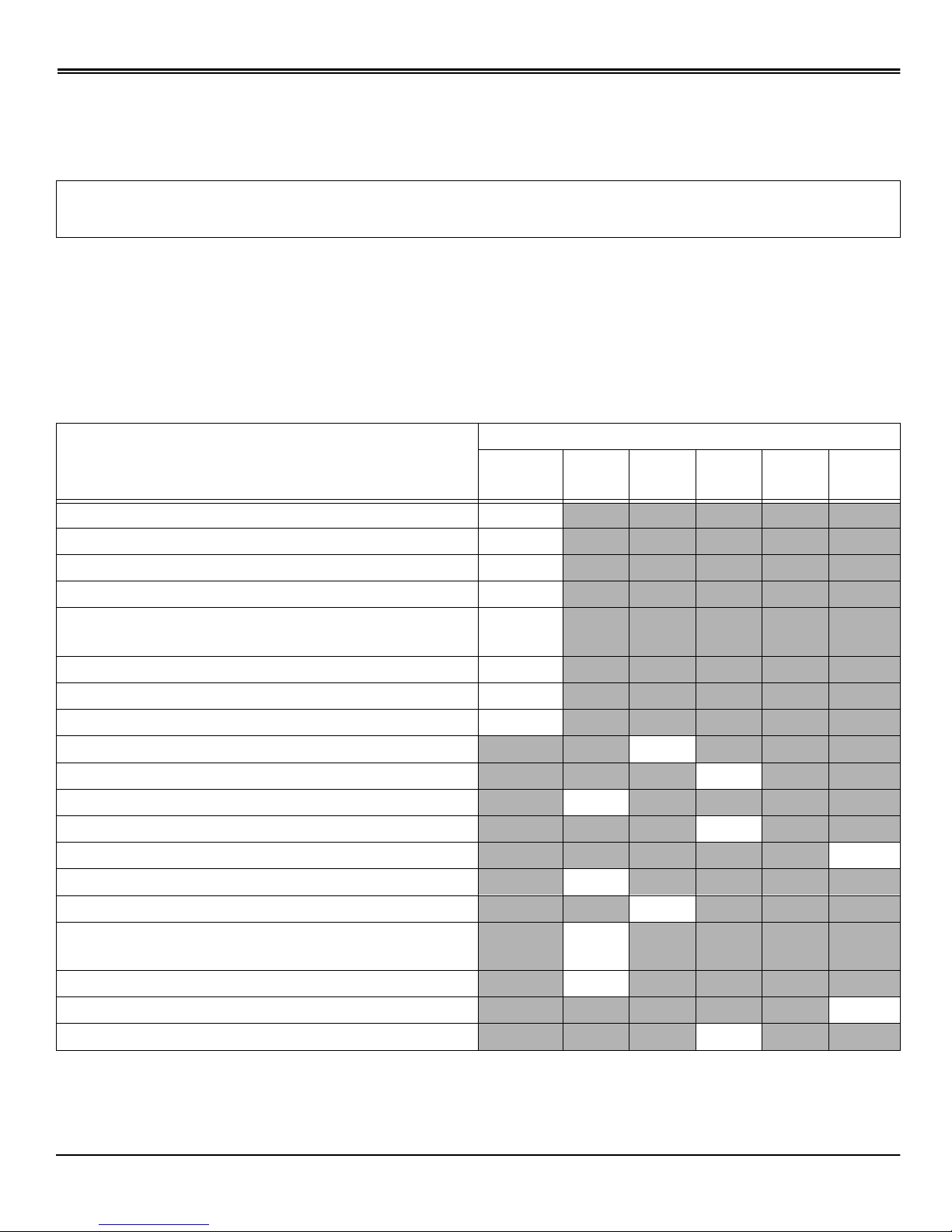

SERVICE INTERVAL CHART

Servicing Your Machine

Please use the following timetables to perform routine maintenance on your machine. Service

procedures included in this manual but not on this chart are to be performed on an as needed basis.

IMPORTANT: If you operate mower in extreme heat, dust or other severe conditions, service

more often than shown below.

After the first 5 hours of operation (break-in period):

• Check/tighten all hardware

• Check wheel bolt torque (also check again at 50 hours for break-in, then every 200 hours)

• Change engine oil (also change oil again at 50 hours for break-in, then every 50 hours)

• Lubricate front steering spindles, wheel bearings and axle pivot

Intervals in Hours

Service to be Performed

Test safety systems

Check fuel level

Check engine oil level

In severe conditions lubricate all mower spindles

In severe conditions check and clean

engine air cleaner

Check tire pressure

Check cutting height

Check/tighten hardware

Change engine oil

Change engine oil filter

Change/clean engine air cleaner pre-cleaner

Change/clean engine air cleaner cartridge

Replace fuel filter

Lubricate mower spindles

Clean battery

Before

Each Use

X

X

X

X

X

X

X

X

Every25Every50Every

100

X

X

X

X

X

X

Every

200

Yearly

X

Lubricate front steering spindles, wheel bearings

and axle pivot

Check automatic transmission oil level

Replace spark plugs

Clean cooling shrouds and cooling areas

X

X

X

X

Service Interval Chart - Page 41

SERVICE INTERVAL CHART

After Each Use

• Clean debris from engine, especially air intake screen.

• Remove belt shields, clean belt area, check belts. Be sure shields are secure.

• Clean under deck. Inspect blades.

• Check for loose, missing, or damaged parts.

Service Interval Chart - Page 42

SERVICE ENGINE

Engine Warranty Maintenance Statement

Maintenance, repair, or replacement of the emission

control devices and systems on this engine, which are

being done at the customers expense, may be

performed by any nonroad engine repair establishment

or individual. Warranty repairs m ust be performed by an

authorized John Deere dealer.

Adjusting Carburetor

NOTE: Carburetor is calibrated by the engine

manufacturer and should not require any

adjustments.

If engine is operated at altitudes above 1829 m

(6,000 ft), some carburetors may require a special

high altitude main jet. See your John Deere dealer.

Possible engine surging will occur at high rpm with

no load (with transmission in “N” neutral and

mower blade engagement lever disenga ged). This is

a normal condition due to the emission control

system.

If engine is hard to start or runs rough, check the

Troubleshooting section of this manual.

After performing the checks in the troubleshooting

section and your engine is still not performing correctly,

contact your John Deere dealer.

Service Engine - Page 43

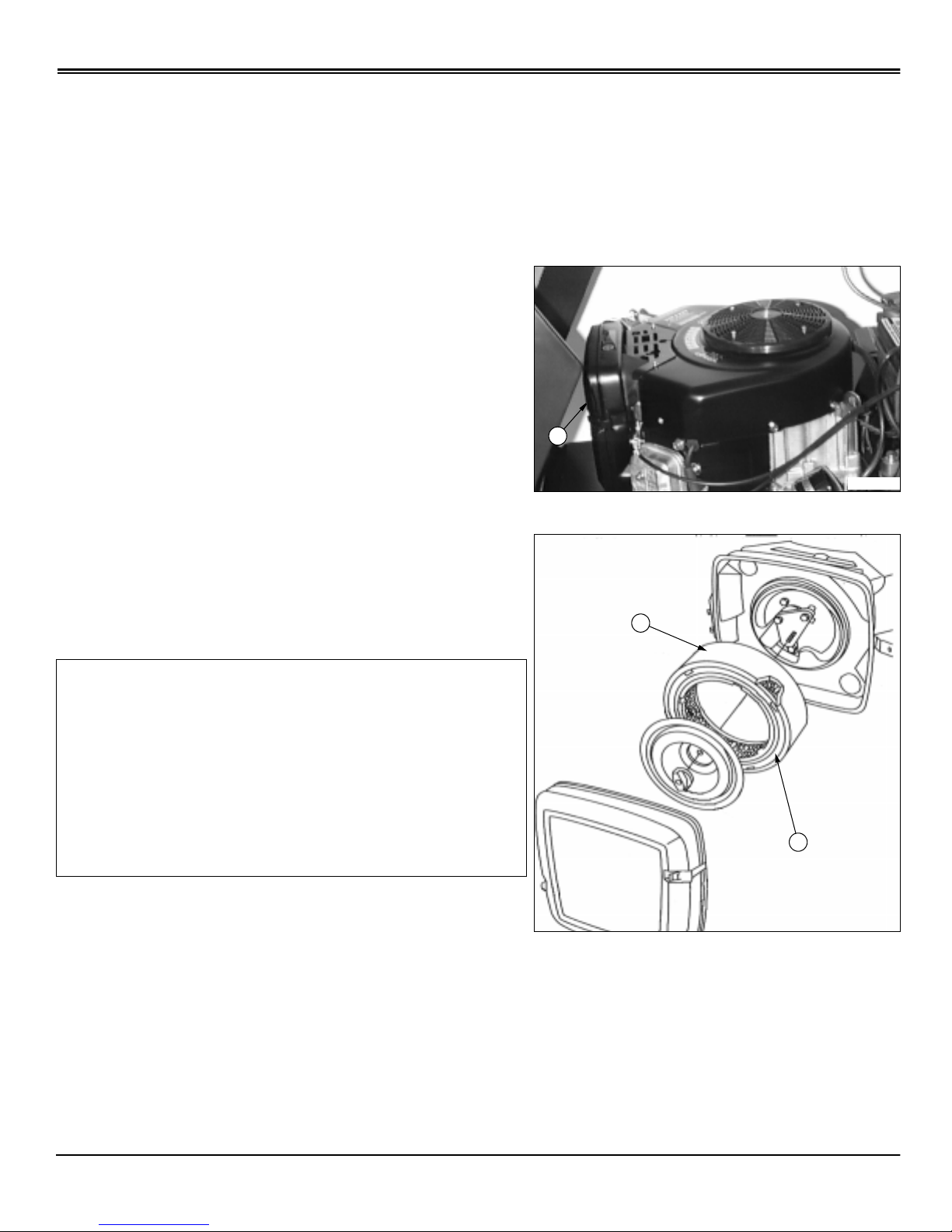

Avoid Fumes

M88589

A

CAUTION: Engine exhaust fumes can cause

c

sickness or death:

- If it is necessary to run an engine in an

enclosed area, use an exhaust pipe extension

to remove the fumes.

- Always try to work in a well ventilated area.

Engine Oil

CAUTION: To prevent injury from accidental

c

starting, always remove wire fr om spark plugs

and disconnect battery at negative terminal

before servicing engine.

SERVICE ENGINE

Use oil viscosity based on the expected air temperature

range during the period between oil changes.

The following John Deere oils are preferred:

• John Deere PLUS-4®

Other oils may be used if they meet one of the following

specifications:

• API Service Classification SG

• API Service Classification SF

• CCMC Specification G4

Oils meeting Military Specification MIL-L-46167B may

be used as arctic oils.

Checking Engine Oil

1. Park tractor on a level surface.

2. STOP engine.

3. Lift hood.

4. Remove dipstick (A). Wipe with clean cloth.

5. Install dipstick in tube, tighten dipstick, remove

dipstick, and check oil level.

6. Oil must be between ADD and FULL marks.

7. Add oil to FULL mark if necessary. DO NOT overfill.

8. Install and tighten dipstick. Lower hood.

Service Engine - Page 44

SERVICE ENGINE

M88589

A

B

M88590

A

Changing Engine Oil

1. Run engine to warm oil.

2. Park tractor on level surface.

3. STOP engine and remove key.

4. Remove drain plug (A) and drain oil into oil drain pan.

5. Replace drain plug.

6. Remove dipstick (B) and refill with new oil of

recommended grade.

7. Install dipstick and then remove to check oil level. Oil

level must be between ADD and FULL marks. Do not

overfill.

8. Install and tighten dipstick.

9. Start engine and check f or oil leaks. Correct any leaks

before operating.

Changing Engine Oil Filter

1. STOP engine and remove key.

2. Drain engine oil and replace with fresh oil. (See

Changing Engine Oil in this section.)

3. Wipe debris and dirt from around oil filter.

4. Remove old filter (A) and wipe off filter tray with a

clean cloth.

5. Lightly oil filter gasket with fresh, clean oil.

6. Install replacement oil filter. Turn oil filter to the right

(clockwise) until rubber gasket contacts filter adapter.

Tighten filter an additional on-half turn.

7. Start and run engine at idle to check for leaks. Stop

engine.

8. Check oil level. (See Checking Engine Oil Le vel in this

section.)

9. Add oil if required. (See Engine Oil in this section.)

Service Engine - Page 45

SERVICE ENGINE

M88590

A

C

B

Checking and Cleaning Air Cleaner

Elements

NOTE: It may be necessary to check the air filter

more frequently if operating vehicle in dusty

conditions.

1. Lift hood.

2. Clean any dirt and debris from the air cleaner before

removing cover.

3. Remove cover (A).

4. Inspect foam precleaner (B) and element (C) without

removing.

5. If precleaner (B) is dirty, carefully remove from filter,

leaving element (C) in the air cleaner housing.

NOTE: DO NOT wash paper element.

6. Wash precleaner (B) in a solution of warm water and

liquid detergent.

7. Rinse precleaner thoroughly. Squeeze out excess

water in a dry cloth until precleaner is completely dry.

8. Put approximately 30 ml. (1 oz.) of clean engine oil

onto precleaner. Squeeze precleaner to distribute oil

evenly. Squeeze out excess oil with a clean cloth.

IMPORTANT: A damaged paper element (C) can

allow dirt into the carburetor and can cause poor

engine performance, engine damage or failure:

• DO NOT attempt to clean paper element by

tapping against another object.

• Replace element ONLY if very dirty.

• DO NOT use pressurized air to clean element.

• If element is damaged or the seal is cracked,

replace.

9. Remove and replace filter element (C) ONLY if

damaged or very dirty.

10.Carefully remove element (C) from air cleaner

housing. Replace with a NEW element.

11.Carefully clean air cleaner housing. Prevent any dirt

from falling into carburetor.

12.Install precleaner onto new filter element and install

into air cleaner housing.

13.Install cover. Lower hood.

Service Engine - Page 46

SERVICE ENGINE

M88590

A

M88589

B

A

Checking Spark Plugs

CAUTION: To av oid injury: Before y ou remove

c

spark plugs, STOP engine and wait until

engine is cool.

1. Stop engine. Remove key. Lift hood.

2. Disconnect spark plug wires (A), one on each side,

and remove spark plugs.

3. Clean spark plugs carefully with a wire brush.

4. Check plug gap with a wire feeler gauge.

• Gap should be 0.76 mm (0.030 in.)

5. To change gap, move the outer electrode.

6. Install and tighten spark plug(s).

• If you ha ve a torque wrench, tighten plug(s) to:

20 N•m (15 lb-ft).

7. Connect the spark plug wires.

8. Lower hood.

Replacing Fuel Filter

CAUTION: Avoid injury: Keep cigarettes,

c

sparks, and flames away from the fuel system.

Make sure engine is cool to the touch.

IMPORTANT: When disconnecting fuel tank hose

from filter, be sure to hold hose above fuel tank

level so fuel does not run out.

NOTE: Change filter when fuel is low in fuel tank.

1. Park tractor on a level surface.

2. STOP engine. Remove key. Let engine COOL.

3. Lift hood.

4. Using pliers, slide hose clamps (A) away from fuel

filter (B).

5. Disconnect hoses from filter.

6. Connect hoses to new filter.

7. Install clamps and check for leaks.

8. Lower hood.

Service Engine - Page 47

SERVICE TRANSMISSION

M63559

A

M63557a

B

C

B

C

A

Transmission Oil (Models 1842HV and

1848HV Only)

NOTE: Your SABRE Yard Tractor is filled with 5W30

at the factory

Use 5W30 or 10W30 when adding transmission fluid.

Check Automatic Transmission Fluid Level

(Models 1842HV and 1848HV Only)

1. Park machine on level surface.

2. Allow oil in transmission to cool before checking.

3. On the rear of the tractor, there is a sight hole (A)

through the left rear side of the fuel tank. The automatic

transmission reservoir can be seen through the sight

hole.

4. Check FULL (B) and ADD (C) marks on the reservoir

bottle which will indicate if fluid needs to be added.

5. Add transmission fluid if necessary. (See Adding

Automatic Transmission Fluid below.)

Adding Automatic Transmission Fluid

(Models 1842HV and 1848HV Only

1. Tip seat forward and slide seat suspension all the way

forward.

2. Remove cap (A) from automatic transmission

reservoir. Cap is located under seat and left of fuel cap.

3. Fill to correct level using 5W30 or 10W30 motor oil.

DO NOT OVERFILL.

Service Transmission - Page 48

SERVICE MOWER

TS1417

122°F

104°F

86°F

68°F

50°F

32°F

14°F

- 4°F

- 22°F

- 40°F

- 67°F

40°C

30°C

50°C

20°C

10°C

0°C

- 10°C

- 20°C

- 30°C

- 40°C

- 55°C

JD Moly High Temp

JD High Temp EP

GREASE-GARD

BIO-GREASE-GARD

Arctic Grease

NGLI Number 0

NGLI Number 1

NGLI Number 2

Avoid Injury From Contacting Blades

CAUTION: To avoid injury, before you unplug,

c

adjust or service mower:

- DISENGAGE PTO switch to stop mower

blades.

- Wait for mower blades to STOP.

- LOCK the park brake.

- STOP the engine.

- Remove the key.

Clean unit by removing all grass clippings

and dirt from mower deck.

Disconnect spark plug wire from spark plug.

Grease

Use grease based on the expected air temperature

range during the service interval.

The following greases are preferred:

• John Deere Moly High Temperature EP Grease.

• John Deere High Temperature EP Grease.

• John Deere GREASE-GARD.

Other greases may be used are:

• SAE Multipurpose EP Grease with 3 to 5 percent

molybdenum disulfide.

• SAE Multipurpose EP Grease.

• Greases meeting Military Specification

MIL-G-10924C may be used as arctic grease.

Service Mower - Page 49

SERVICE MOWER

M88569

A

A

M88572

A

A

Lubricating Mower Spindles

42-Inch Mower Deck

Lubricate both mower spindles grease fittings (A) with

Multipurpose EP Grease or an equivalent.

48-Inch Mower Deck

Lubricate three mower spindles grease fittings (A) with

Multipurpose EP Grease or an equivalent.

Service Mower - Page 50

SERVICE MOWER

C

M88569

B

M88569

A

Replacing Mower (Secondary) Belt

CAUTION: To avoid injury: Before replacing

c

mower drive belt: STOP engine, remove key,

wait for all moving parts to STOP, and wear

gloves when replacing belt.

1. STOP engine, LOCK park brake, push PTO switch

down to DISENGAGE, turn key to the OFF position, and

remove key.

2. Remove mower deck. (See Removing Mower in

Removing Mower section.)

42-Inch Mower Deck

1. Remove three carriage bolts, washers, and nuts (A)

and belt shield if necessary.

2. Disconnect idler spring (B).

3. Remove mower belt (C).

4. Clean upper mower deck and sheaves.

5. Inspect belt for wear or damage; replace as

necessary.

6. Install belt (C) on mower deck as shown.

7. Connect idler spring (B).

8. Install belt shield and fasten with three carriage bolts,

washers, and nuts.

9. Install mower deck. (See Installing Mower in Installing

Mower section.)

Service Mower - Page 51

SERVICE MOWER

M88572

A

A

B

M88595

C

D

48-Inch Mower Deck

1. Remove three cap screws and belt shields (A).

2. Put drive belt tension rod (B) in the released position

as shown and disconnect idler spring (C).

3. Remove mower belt (D).

4. Clean upper mower deck and sheaves.

5. Inspect belt for wear or damage; replace as

necessary.

6. Install belt (D) on mower deck as shown.

7. Connect idler spring (C).

8. Install two belt shields and fasten with three cap

screws.

9. Install mower deck. (See Installing Mower in Installing

Mower section.)

Service Mower - Page 52

SERVICE MOWER

M88119a

A

C

D

B

M88112g

C

D

A

B

Servicing Mower Blades

42-Inch Mower Deck

CAUTION: Be careful, sharp edges on mower

c

blades. Always wear gloves when handling

mower blades.

REMOVING MOWER BLADES

1. Raise mower deck to gain access to mower blades. If

necessary, remove mower deck.

2. Using a wooden block, prevent mower blades from

spinning.

NOTE: Before removing hardware, note the

orientation of the cupped blade washer (B) to

ensure proper installation.

3. Loosen and remove cap screw (A), cupped blade

washer (B), blade (C) and deflector cup (D).

4. Inspect blades; sharpen/balance or replace as

necessary.

INSTALLING MOWER BLADES

1. Lightly lubricate cap screw threads with a general

purpose grease or oil. This lubrication is to prevent

rusting and seizing.

2. Install deflector cup (D) on spindle.

3. Position mower blade (C) with the cutting edge

towards the ground onto the mower spindle.

4. Install cupped blade washer (B) with CUPPED SIDE

toward the blade.

5. Install and tighten cap screw (A) by hand until mower

blade is in full contact (fully seated) with spindle.

6. With mower blade blocked, to prevent spinning,

tighten bolt to 67.8 N•m (50 lb-ft).

Service Mower - Page 53

SERVICE MOWER

M88116

A

B

C

D

M88112C

D

C

M88127A

E

B

C

A

48-Inch Mower Deck

CAUTION: Be careful, sharp edges on mower

c

blades. Always wear gloves when handling

mower blades.

REMOVING MOWER BLADES

1. Raise mower deck to gain access to mower blades. If

necessary, remove mower deck.

2. Using a wooden block, prevent mower blades from

spinning.

3. Loosen cap screw (A).

4. Remove cap screw (A), round blade washer (B),

blade (C) and deflector cup (D).

5. Inspect blades; sharpen/balance or replace as

necessary.

INSTALLING MOWER BLADES

1. Lightly lubricate cap screw threads with a general

purpose grease or oil. This lubrication is to prevent

rusting and seizing.

2. Install deflector cup (D) on spindle.

3. Position mower blade (C) with the cutting edge

towards the ground onto the mower spindle.

IMPORTANT: Some blade washers (B) have 2

index marks (E). When these blade washers are

installed, the index marks must be visible. This

will indicate that the cup side of the washer is

toward the blade (C).

4. Install blade washers (B) and make sure 2 index

marks (E) are visible when installed.

5. Install and tighten cap screw (A) by hand until mower

blade is in full contact (fully seated) with spindle.

6. With mower blade blocked, to prevent spinning,

tighten cap screw (A) to 84 N•m (62 lb-ft).

Service Mower - Page 54

SERVICE MOWER

A

B

Sharpening Blades

CAUTION: To avoid injury, wear goggles and

c

gloves when you handle blades.

1. Sharpen blades with grinder, hand file or electric

blade sharpener.

2. Keep original bevel (A) when you grind.

3. Blade should have 0.40 mm (1/64 in.) cutting edge

(B).

Balancing Blades

CAUTION: To avoid injury, wear goggles and

c

gloves when you handle blades.

1. Clean blade.

2. Put blade on nail in vise or on vertical wall stud. Turn

blade to horizontal position.

3. If blade is not balanced, heavy end of blade will drop.

4. Grind bevel of heavy end. Do not change bevel.

Service Mower - Page 55

Checking the Battery

M88558

A

B

C

D

CAUTION: Sulfuric acid in battery electrolyte

c

is poisonous. It is strong enough to burn skin,

eat holes in clothing, and cause blindness if

splashed into eyes. Wear eye protection and

avoid spilling or dripping electrolyte.

Flush eyes with water for 15-30 minutes if acid

is splashed into eyes.

If acid is swallowed, get medical attention

immediately.

DO NOT attempt to open, add fluid or service

battery. Any attempt to do so will void

warranty and lead to possible injury.

•Keep battery and terminals clean.

•Keep battery bolts tight.

SERVICE ELECTRICAL

•Keep small vent holes open.

•Recharge, if necessary, at 6–10 amperes for 1 hour.

(See Charging the Battery in this section.)

Removing and Installing the Battery

CAUTION: Always remove negative (–)

c

battery cable first, and install it last, to

prevent electrical short circuit to chasis.

1. Turn ignition key off and raise seat.

2. Remove rubber hold-down strap (A).

3. Disconnect negative (–) battery cable (B).

4. Remove red cover (C) from positive (+) battery

terminal. Remove positive (+) cable and blue harness

wire (D) from battery.

5. Remove battery.

6. Install the battery following these steps in reverse

order. (See Connect the Battery in the Assembly

section.)

Service Electrical - Page 56

SERVICE ELECTRICAL

M88558

B

A

C

D

Clean Battery and Terminals

CAUTION: Battery gas can explode, to avoid

c

injury:

- Keep sparks and flames away fr om batteries.

Use a flashlight to check battery electrolyte

level.

- Never check battery charge by placing a

metal object across the posts. Use a vo ltmeter

or hydrometer.

- Always remove grounded (-) battery clamp

first and replace it last.

1. Turn ignition key off and lift hood.

2. Remove rubber hold-down strap (A).

3. Disconnect BLACK (–) battery cable (B) first.

4. Disconnect RED (+) battery cable (C) and blue

harness wire (D) and remove battery from mower.

5. Wash battery with solution of four tablespoons of

baking soda to one gallon of water . Be careful not to get

the soda solution into the cells.

6. Rinse the battery with clean water. Let dry.

7. Clean terminals and battery cable ends with wire

brush until bright.

8. Apply petroleum jelly or silicone spray to terminal to

prevent corrosion.

9. Reinstall battery. (See Removing and Installing the

Battery in this section and Connect the Battery in the

Assembly section.)

Service Electrical - Page 57

Charging the Battery

CAUTION: BE VERY CAREFUL: Battery fluid

c

(electrolyte), is a solution of water and

sulfuric acid. It is very harmful to eyes, skin,

or clothing.

- Wear goggles or an eye shield when you

work with a battery.

- If the acid contacts your eyes, skin, or

clothing, flush the area immediately with

water. Get medical help, if necessary.

A battery gives off gas which can explode. An

exploding battery will spray sulfuric acid in all

directions.

- Keep cigarettes, sparks, and flames away

from the battery.

- Charge the battery in an area with good

ventilation.

SERVICE ELECTRICAL

- DO NOT charge a frozen battery.

IMPORTANT: This battery comes fully charged. If

the mower is not used by the Service Expiration

Date indicated on the battery, charge the battery

using the following instructions.

Before you charge a battery:

• Wait until the battery has warmed to room

temperature. Do not charge a frozen battery.

Turn OFF and unplug the charger before you connect cables to the battery or disconnect cables from the battery.

If the battery becomes warm to touch during charging:

• Reduce the charging rate OR

• Stop charging the battery until it cools.

NOTE: Your charger may have an AUTOMATIC

STOP to prevent charging the battery:

• When the battery is fully charged OR

• When the battery is not in condition to take a charge.

Service Electrical - Page 58

SERVICE ELECTRICAL

BOOSTER

BATTERY

VEHICLE

BATTERY

TO ENGINE

GROUND

A

C

B

D

CAUTION: DO NOT attempt to open, add fluid

c

or service battery. Any attempt to do so will

void warranty and lead to possible injury.

Battery gas is explosive:

- DO NOT smoke while you charge battery.

- Keep all flames and sparks away.

- DO NOT charge frozen battery.

- DO NOT connect booster battery negative (-)

cable to starting vehicle negative (-) terminal.