. -',

,

",,-ryc I NSTRUCTION BOO,K

.

.,

-~. . FOR SABB MARINE DIESEL ENGINE

,

MODEL 2fi:

Engine with controllable pitch propeller :

MODEL 2HG:

Engine with reverse gear and solid propeller .

MODEL2HSP

Engine with fully feathering propeller ,c'

-

..

SABB MOTOR 1lJ.@

BOX 2728 -5010 BERGEN -NORWAY

, Telegram: Sabbmotor - Telephone: (05) 26 05 04 - Telex: 42559 sabb n

- '~!f:'

,

I:

t' ~

" ,-"

.Jo-

:~

'.

~

~ /

CONTENTS Page

Engine Specification .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

RulesforStarting 6

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 8

Running-in a new Engine 10

ElectricaIEquipment 11 1

InstrumentConnections 13 äi

MAINTENANCESCHEDULE ... 14 ~J

j,~

LubricatingOilSystem,OleckingOil 15 ~

ChangingLub. Oil, Engine, Gearbox 17 ":~

Olanging Oil Filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 19

Greasing 19

FuelOiI.OlangingFuelOiIFilter 24

Bleeding Fuel System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 2S

CleaningInjectorNozzles 26

CoolingWater.Draining 28

FreshWaterCooling 29

Adjustments (see Maintenance Schedule) . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . .' 37

Engine Olecks (see Maintenance Schedule) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 41 ,

WinterLayingUp 48 i

;~ ,

.'

co"

1

CheckingtheAlignment 49

Irregular Engine Operation. Faults Location Olart so

SA BB SERVICE

Main SABB Importers and Service Stations. . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 53

.-

2

'c

~, ~

- ..-

SPECIFICATION:

2-cyl., water cooled, 4-stroke diesel engine.

Cyl.bore/stroke 9Ox90mm3.S4x3.S4in.

, Cubiccapacity 1140cm3 69.6cu.in.

; Compressionratio 22:1

Compressionpressure 30kp/cm2 426,7p.s.i.

~~c.t Con~uousra~gat2(X)Orpm .16 HP (DIN B) (11,7 kW/33 r/s)

'"--~ Continuousratingat22S0rpm .18HP(DINB) (13,2kW/37r/s)

Brake mean effective pressure. . . . . . . . . . . . . . . . . . .. 6.3 kp/cm2 89,6 p.s.i.

Fuel consumption 210 g/hph (18 HP) . . . . . . . . . . . . . . 4.7Iiters/h

Lub.oi!. consumption 1.5-2 g/hph (18 HP) . . . . . . . . 0.035-0.045 l/h

. .

25 2 Lub.oupressure 1.5-. kp/cm

Reductionratio 2:1

Piopellertorque 11.5kpm 83ft.lb.

Rotation Left

Piopellerdiaxpitch(2HG) 16"xI4"

Weight of engine, less stern gear . . . . . . . . . . . . . . . . . . 1~ kg 419 Ibs.

Max. installation angle, under power. . . . . . . . . . . . . . 15 degrees

Valvestemclearance, exandair(cold) 0.3mm .012 in.

Pistontopclearance,incl.gasket 1.0-1.2Smm

Injectionpressure(openingpress.) l00kp/cm2

Injection commences (against atm. press.) ., 15 degrees BillC

Inj.pumpelement,dia 6.5mm

Exh. valve opens, before B.D.C. . . . . . . . . . . . . . . . . . . 50 degrees

Exh. valve closes, after T .D.C. 15 degrees

Inl. valve opens, before T .D.C. . . . . . . . . . . . . . . . . . . . 15 degrees

Inl. valve closes after B.D.C. .. . . . . . . . . . . . . . . . . . . . SO degrees

~

<

", ~

Lubricating Dil capaçities:

Crankcase sump (incl. 0.5 I in filter) ... . . . . . .. 4.5 liters

Outch housing, 2H-2HSP . . . . . . . . . . . . . . . . .. 0.5 liters

Reversegearbox,2HG 0.5liters

3

,

ii~

.-

",

Lubricating oil grade (single grade):

Wmter SAEI0

Summer SAE20

Reversegearboxorclutchhousing SAE20

Capacity of cooling water:

Fresh water (closed) cooling system

withkeeicooler , 5liters 8.8pints

Bolts and nuts torques:

Cylinderheadnuts llkpm 79ft.Ibs

Crankcase-cyl. block studs (fit in crankcase) 12 kpm 87 ft.lbs

Rockerarmbolts 8kpm 58 ft. Ibs

Big end hearing. Tensilock M12 . . . . . . . . . . . . . . 12 kpm 87 ft.Ibs

Big end hearing. Tensilock M14 (before 1972). . . 17 kpm 123 ft.lbs

F1ywheeIboIts.TensilockM14 17kpm 123ft.Ibs

Found.iron boIts(fit in crankcase)

TensiIockM12 12kpm 87ft.lbs

Propeller boss bolts. MlO hex.socket 5-5.5 kpm 38 ft.Ibs ,

'c .

PropellerbossboIts.V2"W.bronze 2-3kpm l?ft.Ibs

Freshwatertanknuts 4,5kpm 32ft.Ibs

Remaining holts and nuts:

M8(5/16 VNC) ...'.'.".".".'..' '. 2-2.4kpm 14-17ft.Ibs

MI0(3/8 VNC) 4-4.2kpm 29-30ft.Ibs

.-

4

,,~c;;",~,2 ',,~~:. . ~~,,~

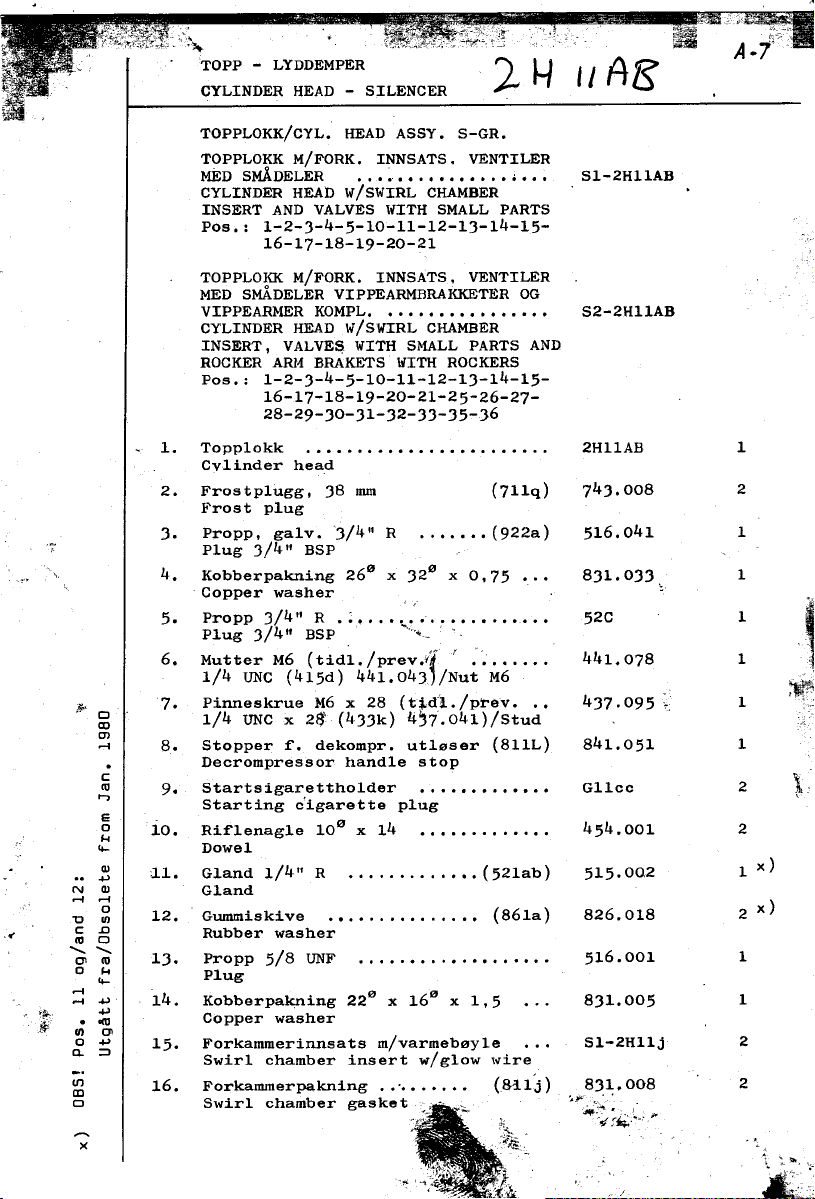

"'1~':I:.'JJ~i~' MODEL 2 H 2 3 4 5 6 7 10 11

1. Outch lever

2. Pitch controllever

3. Governor (speed) controllever

4. Dipstick ~~t

5. Lub.oil pressure gauge

"'""' 6. Fuel filter 6tdnds~o~~,I~e-r

( connection)

7. Inlet muffler In 'dO~~' \\c.r

~ 8. Rockercover I<I~p~~S(,\ .

9. Injectionpipe(fore) l...jtd;t.bllM'

10. Alternator '1)lJ""'~"

11. V-belt, alternator 'Y. ~"ót)~ , k

12. Outchhousingcover l/t.n~l'\'"1.~\\.:)

13. Adj. screw max. propeller pitch 'S\;.:\s~,..t2 13 14 15 16 17 18

14. Injectionpump J"',;;'c.h--\)O\"\'(1 .

15. Governor cover Flg.1

16. Crankcase cover CdY'be.""

17. Selfstarter s k.\rl-tIt o~'" l-

18. Foundation iron ~nI~~f d~

19. Starting cigarette socket lo'lr c;~y-~ F \1A'j

20. Decompressor clr\'\~v'e...,H(.1

21. Exhaust silencer l..i..\:-1 ~CA\-c\t-rv

22. ~austflange, 11/2" B.S.P. ~~\I.II)\-S'pY~tf~'"

23. Wetexhaustpipe n,,'t-~I-'i~\~o~,

24. Fuelleak-off pipe 1'J~~~~~cli'~9 20 21 22 23 2' 25

25. Startingbracket c;J.qrl,~,,~\

26. Startinghandle ~d",~rl-dY\;t,..

27. Prop.pitch hand screw

28. V-belt, bilge pump VS"~oO~

29 Bil I~"s DOr-. p

. ge pump ,

30. Drain cock, bilge pu.mp

31. Lub.oilfilter olief.ilkv'

32. Fuelliftpump f>ro"cI{~eorV't...yo~']

.. 34. Draincocks,

33. Watervalvehousing ~dtt.-ro""f

engine & water pump

35. Outchhousing

36. Grease nippies ~~~I rr,v;'

28 29 30 31 32 33 3' 35 36

Fig.2

~'

'",cc, , 5

c,:;

;',;ic

3r:; . "

i.f!:!'

~,7B.:

.

,"-

RUlES FOR STARTING

Before starting first time: '.

1. Fuel tank filled up, fuel tank cock open. See page. . . . . . . . . . . . . . . . . . . . .. 24

2. Fuel system bIed, a11 connections tight, see bleeding page. . . . . . . . . . . . . . .. 25

3. Lubricating oil in engine and clutch or reverse gearbox. Page. . . . . . . .. 17-18

4. Sea cock open, pump drain cocks (2 in No) closed.

Impeller pump cover tight (if fitted, page 35). . . . . . . . . . . . . . . . . . . . . . . . . .. 28

5. Fresh water cooled engines:

System filled with fresh water or water / antifreeze mixture. See page. . . . . .. 29

6. Electrlcal equipment:

Correctly connected.

Exercise particular care with alternating current installations. See page. . .. 11

jii;

"

~"

~ ~.:ii;,.,

\11'1,,;-'

Fig. 3

~

:

6

w

,- ~ ~

STARTING: 1 2 5 4

Hand Start~~".7~~ 1 r rTf /-

1. Ensure that alternator and h\~~~

regulator are connected to the ~ ~ ~S--

battery . ~ \ ï~~

2. Propeller disengaged (gearbox

or clutch in neutral). ..

3. Set governor control handle (2) ".' ,

to full speed position ( down). ') ., 1

Turn decompressor lever (3) \ \

downwards and set decom- ..\

pressor arm (4) so that it engages L\'" \J I"'" .

with the threads on the starting --IJ...< , Flg.4

spindie.

4. For cold weather starting.

See cigarette starting, page. . .

5. Stand to starboard of the engine, not behind it. (fig. 3.) The starting handle (5) is

operated using the left hand, (except where there is a front starting handle). Turn

the engine over rapidly until the decompressor closes and the engine starts.

Remove starting handle.

6. When the engine bas started and is running evenly, return the governor control

handle to a position giving a suitable engine speed.

7. Check oil pressure (6) and coaling water temperature.

(")Q ha.""ls-\-~t .Lup tJa,"'\ 3Q",,~~.) ~~

\ ~- ..

t Qvt- '\ \ -9. ç' ~a. ~, ; . ro.t . i"

Electrical starting:

If the battery is well charged, r:- e

decompression is not necessary. / '"

In cold ~eather, or if the battery. 0 - 0 charge IS low, the starter laad

., compressor valve. - i- - ]!I - - - -

1. Propeller disengaged (gear- ! ~~ ~...

box or clutch in neutral). K

2. Set governor control handle START SWI~C!i GL0DEI GLOW ~ 1

to futl speed position. Handle ~~.~ ç(;\Q~tl<lOV STARTSWITCH GL0DESTIFT

(2) pointing downwards. Fig. 5 q~~e"" GLO~PLUG

- --~~-~ -- ~c

rtjI", ~' I "' can be reduced by using the de- >I; \ ~.4

J... JIDe.f'1~7

] ~ f1 Q

~"

Electrical Starting (Continued from page 7)

3.0 KEY: Insert (or re move) (fig. 5.)

ION: Normal operating position.

11 HEA TING: Keep in position for heating of plugs (1) for 20-40 seconds.

4. 111 START: Push key in and turn clockwise. When engine starts, release key

which returnsto position I.

S. Set engine speed by retuming govemor con trol handle to suitable position.

6. Check oil pressure, cooling water circulation and battery charging.

Starting using Cartridges (starting cigarettes)

2 In cold weather, or if the engine

" bas not been used for same time,

r <: use starting cartriges. (cigarettes.)

1. Unscrew bath cigarette holders

(2).

. 2. Insert cigarettes (1) into holders

'" (2), white end fust. Replace hol-

ders and screw firmly home.

. . : igniting provided that they are

" dry.

"

- '. " 3. As an alternative to, or in ad-

Fig. 6 CATING OIL into the cylinders

1 2 ' dition to, starting cigarettes, a

, ,"

The cigarettes (7 trim) are self-

recommended procedure is to

spray 6 full shots of LUBRI-

to facilitate starting, using squirt

can supplied in tooI box.

OPERATION

1. Let the engine idle at 400-600 rpm.

~ 2. ENGAGING CLUTCH: STOP

Type 2HG: Engage gear lever using light pressure.

Type 2H: Press clutch lever forward to full extent of

Ensure that gear lever or clutch lever does not foul on the

engine casing or other obstruction. Fig. 7

8

its travel. It moves over an indent to hold it HALF

in the engaged position. ULL

3. Use pitch control lever to select desired propeller pitch (2H).

NOTE:

The fully feathering (sailing) propeller tor model 2HSP is feathering in rearmost

position of pitch controllever. It is recommended to stop engine or disengage

clutch before the blades are set into feathering position.

4. Select desired engine speed using governor controllever. Do not use full power

until the engine bas started to warm up. The fuel supply should he gradually

increased up to maximum.

5. Oleck instruments:

0

Cooling water temperature:

Freshwater~ling: S5-75°C fl (TACHOM LAMP

~8 BBOIL '" TEMP ~

Sea water coolmg: 4O-(i)° C

Oil pressure: 1.5-2.5 kg/cmz C~W

Charging indicator lamp: Should be oH. à

Engine speed. See page 10. Fig. 8

IMPORTANT:

For controllabie pitch and fully feathering propellers the clutch must always be fully

engaged when manoeuvring. All manoeuvring should be clone using the propeller

pitch control and not with the clutch.

For both controllabie pitch and fixed propellers, use reduced engine speed when

manoeuvring. Never approach a jetty at full speed but slow down in good time.

STOPPING

1.. Reduce engine speed.

2. Gearbox or clutch in neutral.

3. Allow engine to idle tor a tew minutes to dissipate heat.

4. Stop engine. Governor controllever up.

5. Turn switch key to position "0". Remove key. Replace protective cover.

...

SETTING ADJUSTING SCREW FOR MAXIMUM PITCH

.l, C.

~~

(Not applicable to Type 2HSP with fully feathering propeller.)

A pitch control adjusting screw (2) is situated on the starboard side of the clutch

housing (1). This screw facilitates the setting of propeller pitch tor full speed.

(Normal position.)

9

-:,:,,-~~ccc'

1. Unscrew nut (3) one turn.

2. Insert pin in head of adjusting screw and

adjust position of screw, in or out, when

engine is running at maximum speed.

3. Set position of adjusting screw so that

maximum propeller pitch corresponds to

the optimum value of fu11 speed rpm from

the point of view of vibration and boat

speed. This engine speed will depend on Fig.9

the boat's size and huIl form. It win nor-

mally he in the region of 200) rpm and

must not exceed 2250.

Note that the propulsive power of the engine (propeller torque) is nearly constant

for engine speeds in the range 1800-2(XX) rpm but falls at higher engine speeds.

This means that, with a controllable pitch propeller, maximum propulsive power will

he obtained in tros engine speed range. There is therefore little point, in the case of

most boats, of running the engine at the maximum of 2250 rpm. Only if the boat is

particularly easy to propel will the use of maximum rpm result in higher boat speed.

If the boat is used for fishing, it is generally preferable to use maximum pitch when

towing lines and a slightly reduced pitch for ful1 speed.

RUNNiNG-IN A NEW ENGINE

A new engine should not he subjected to any unnecessary stress or loading. Run the

engine carefully to begin with using full speed only for short periods. Increase the

engine loading gradually during the initial2S hours running.

Remember thaI treating the engine sensibly during the running-in period will

lengthen the life of the engine appreciably.

~

After thefirst 25 hours running:

I.Changeenginesumpoil Page 17

2. Type 2HG: Change reverse gearbü:x oil Page 18

3.Type2H:Checkclutch Page 39

4.Checkenginealignment Page 49

S. Check all pipe connections

. 6.CheckV-belttightness Pages 37-38

After the first 50-] ()(} hours running:

1.Adjustvalveclearances Page 40

2. For subsequent routine maintenance, follow chart

"CAREANDMAINTENANCE" Page 14

10

"~~ - -~~~--

r

ElECTRICAl EQUIPMENT

Altemator 12V 35A (SOOW) S. E. V.

The alternator produces 3-phase altemating current. The altemating outputs of

each phase are rectified by means of 6 silicon diodes (3 positive and 3 negative

diodes). During starting, the field current is fedto the rotor trom the battery via the

regulator.

The alternator must therfore only be run ij the battery is connected. Ij a battery iso-

lating switch is fitted the engine must not be started until battery has been switched

on.

Use of an altemator ensures continuous charging of the battery even if the engine is

idling for long periods.

The SEV altemator bas an integral electronic regulator.

.

Follow the connection diagram precisely. Incorrect connection will probably

damage alternator or voltage regulator and repair will be expensive.

In addition to the above:

1. Check carefu1ly that all connections are made as shown in diagram.

2. The altemator must never be run unless both battery terminals and the

regulator are connected. Remove the altemator drive belt before discon-

necting the battery.

3. If the battery is to be charged trom an extemal source, first disconnect bath

battery terminals.

4. When welding on board (steel hu1ls), disconnect the battery negative terminal

beforehand.

Starter, BOSCH

It is very important that the starter should not be exposed to sea water. The engine

must not be started if the level of water in the bilge reaches to the flywheel. Pump

out sufficiently to avoid splashing the starter.

Battery

The battery should be contained in its own box made of wood or special plastic and

it should be positioned as near to the engine as possible. The battery box should be

0( weU ventilated and the battery firmly secured.

Check the battery regularly. Top up with distilled water to keep the electrolyte level

1/2 cm-1 cm above the plates. After topping up in cold weather, run the engine for a

while to ensure circulation of the electrolyte. Keep the battery terminals and cable

clamps clean. Remove any oxidation and coat lightly with vaseline. Make sure the

cables are tightly clamped onto the terminals.

The electrical equipment is not covered by the engine guarantee.

11

-

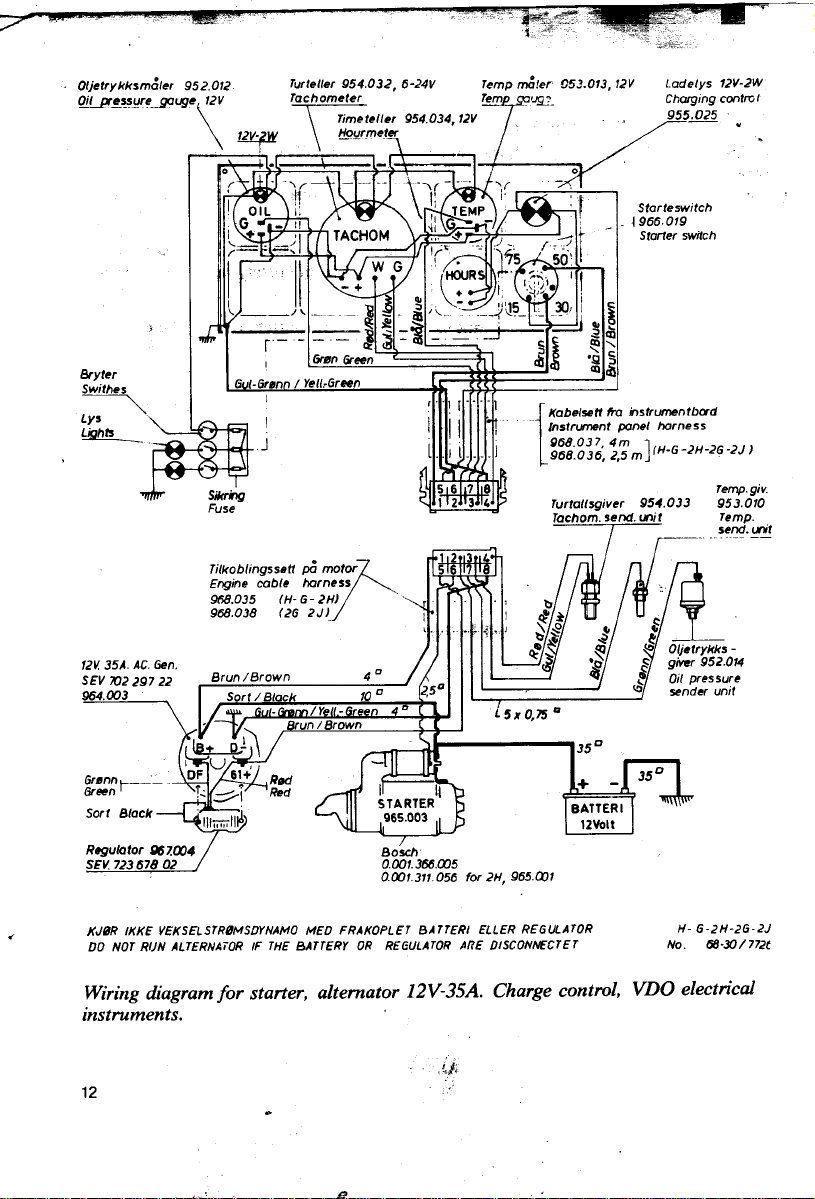

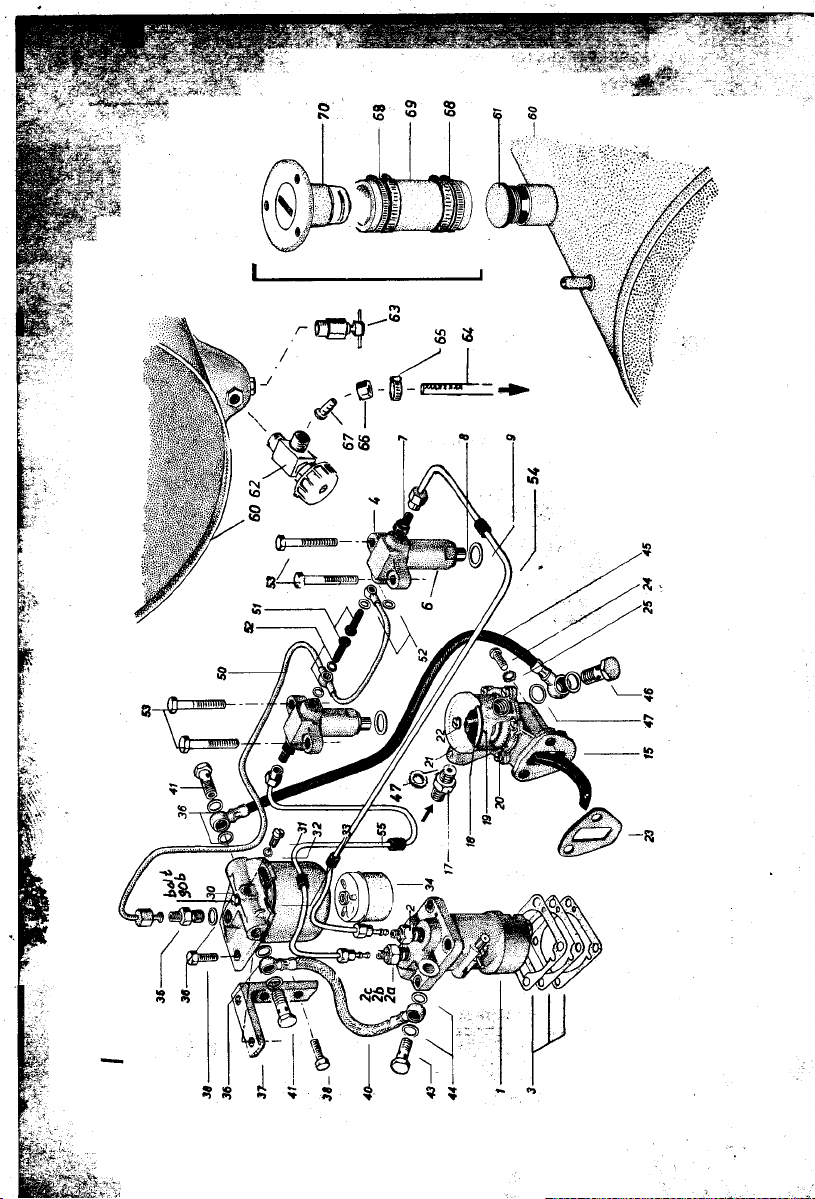

Otjetrykksmaler 952.0t2 TUf teller 954.032, 6-24V Temp má!er !J53.013,12V l.adetys 12V-2W

QiLP"~~!'!r~_~uge

Bryter

Swithes

Lys

L. Is lnstrlHnent ~nel harness

12~ 35A AC Gen. 14

SEV JO2 297 22 re

964.003 t

\t2V Tachometer Tem '~- Chargin9 controt

~ \ tf9!!rme!er . ,

J

TitkobtingssBtt pÖ m

968.035 (H-G-2HI ~

968.038 (2G 2JI

\ Timetetter 954.034, t2V 955~

Starteswitch

1966019

Star/er switch

lKabet5ett /I"a "strlHnentbad

g68037.4m

968.035,2,5 m](H-G-2H-2G-2J 1

~'OI' Engine cabte harness

Tempgiv

953.010

Temp.

send. oot

Gr.nn~

Green

50ft 8tack

Regulator ~Z004

SE~ 72357802

0( KJBR tKKE VEKSELSTRBMSDYNAMO MEO FRAKOPLET 8ATTERI ELLER REGULATOR H- G-2H-2G-2J

DO NOT RUN ALTERNAïOR IF THE BATTERY OR REGULATOR AI1E DtSCONAf:CTET No /i8.301772t

. 1 'or 2H, 965001

Wiring diagram/or starter, alternator 12V-35A. Charge contral, VDO electrical

instroments.

12 .'

.!:I;.

.

g

,

.

INSTRUMENT CONNECTIONS

Tachometer (Mechanical Drive Type).

1. Unscrew tachometer drive .~--~_. ~ end nut (1). ~--.l_,~~ I

2. Insert hexagonal part of I. 2 1

tachometer drive screw(2)

through centre of axial

hearing housing to engage F. 10

with hexagonal socket (3). Ig.

3. Couple up tbe tachometer

drive cable and tighten tbe

.. cablenut(4).

Avoid sharp bends in tbe drive cable. Minimum radius: SO cm (20 in.)

Drive cables longer than 1.5 m (5 ft.) should be secured witb clips.

Tbe water temperature gauge is connected to tbe temperature sensor fitted in tbe

port after wall of the cylinder head.

Tbe oil pressure gauge pipe is connected to tbe nipple on tbe starboard side forward

of the governor cover.

Tachometer (Electricallmpulse Type - af ter August 1977.)

. ~

1. Fitimpulse senderunit(A) ~, ~p

Fig. 11, in flywheel shield of n --=--;~ ,~. ~

main hearing housing. Adjust f'

'distancebe~eensenderpoint, C "-~~~1C" ~ 1.[Jl~.)

and starter nog 1.5 mm(1/16 ')

See wiring diagram page 12. \."". ~ ,').G, ( ') ~~

0' Water Temperature Gauge ~;:s;, "- ~~

Temperature sender unit (B) is \:;: '"

fitted info cylinder head. ':j \

Oil Pressure Gauge (Electrical or MechanicaI). Fig, 11

Sender unit (C) or gauge pipe is connected

to the nipple on starboard side of crankcase.

\ . 13

~~~- .

\ ~ ~ ;-"":. ~l!J G 2. Connect wires to tachometer. ~ ~ .

~C _~,_I~ !

~I. \ ,I

~,. -

I~t~' (Electrical) c~ I\~

-

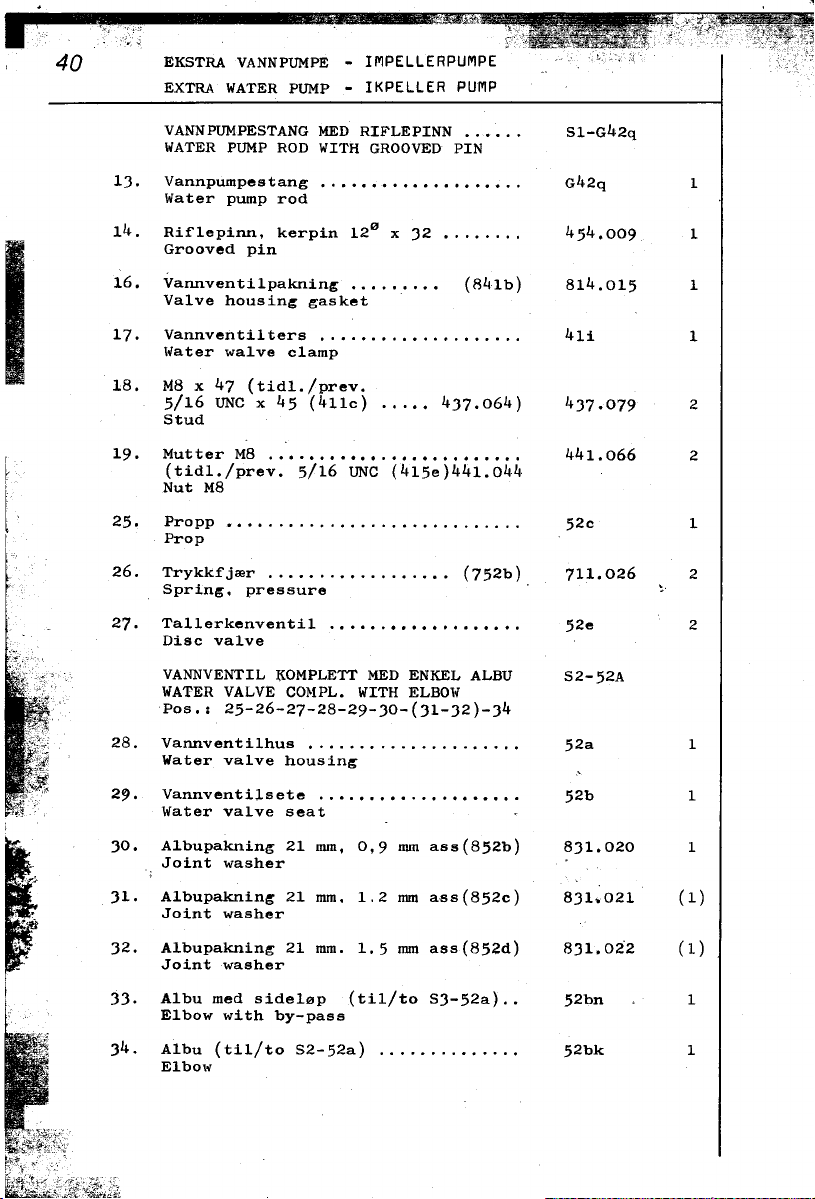

F. Checks

E. Adjultmentl

~ ;', ~

44 Check Injection pump . 44

43 Reverse gearbox . 43

42 Change propeller shall driving block . 42

41 Clean crankcase sump and strainer. 41

40 Tighten down cylinder head . 40

39 Check or change governor springs . 39

38 Adjust decompressor vaJve . 38

37 Adjustairandexhauatvalveclearances. 37

36 Adjust clutch. 36

35 Adjust idle . 30

.. 34 Adjust V.belt (impeller pump) . J4

33 Adjust V.belts . 33

32 Check heat exchanger ! . 3Z

31 Changeimpeller '. . 31

30 Checkzincanode . ~

29 Check thermostat (1974 model) . 29

28 Check thermostat and thermostat atralner . ~

27 Check diaphragms In double water pump .. ~,

26 Change water pump diaphragm . ~

25 Check water pump dlaphragm . 25

24 Checkwatervalve . 24

23 Check cooling water level. 23

22 Drain coollng water .. 22

D. Coollng woter ;

21 Check or change 1111 pump dlaphragm , . ~1

20 Clean lill pump strainer 2g.R.,. . . 2IJ

19 Clean injector nozzles I . 19

18 Bleed luel system . 10

17 Changeluelfilterelement . , 17

C. Fuel IYltem

~'

16 Grease gearwheel bllge pump . lti

15 Greaseruddercontrols . '"

14 Greaseremotecontrolcompo~nts I . 14

13 Greaseremotecontrollever ~I~~ . 1"

12 Grease starter plnion I' ... . 1~

11 Greasegearboxseal . 11

10 Grease pitch control ,. 10

9 Grease inboard stulling box. ~

6 Grease propeller. 8

8. G","lng

7 Change lubricaling olliliter .

6 Change gearbox 011 . ti

5 Change cluch 011 ."

4 Check oliln clutch . 4

3 Change engine oil . "

2 Checkgearboxoillevel. ~

1 Check engine oi! level. 1

A. Lubrtceling Dil

running hlS running hlS running hrsrunning hn running h.. running hrs equire<

Every 5 Every 25 Every 100 Every 300 Every 600 Every 1200 As

D811y Weekly At "8lt8nnu8l1y 2 V_rIy

CHECK POINTS

J.'f!r:I:.'II1.'1~' Maintenance schedule tor types 2H-2HSP-2HG

I

"; ';

'"

CARE AND MAINTENANCE

To achieve good results in operation, it is important to give the engine the attention

recommended. Tbe following section includes general guidance, descriptive notes

and sketches to assist in routine maintenance.

If the specified maintenance is carried out correctly and at the recommended

intervals, engine deterioration will be minimised and optimum performance will be

ensured.

MATERlALS '. Cc,

" ;,

A. LUBRICATING OIL SYSTEM

'" Tbe lubricating oil system is pressur-

ised, the oil being pumped from tbe .

sump oil filter (1) via tbe oil pump (2)

(gear pump fitted inside pump housing) and, under pressure, to the fu1l

flow filter (3). Oil channels in tbe

crankcase/ main hearing housing provide lubrication for crankshaft main

hearings and connecting rod hearings.

A pulsed oil flow is also fed via the

camshaft (5) and the pipe (6) to tbe

~ rocker arm hearings before being re-

turned to the sump.

. Tbe oil pressure is limited by the oil

pressure relief valve (4) fitted behind Fig. 12

tbe oil filter (see Figs 12 and 18). Tbe

oil pressure is indicated on the

pressure gauge (7).

LUBRICATING OIL

Tbe engine oil should be checked daily before starting. Tbe dip stick is located in

the governor cover and bas two level marks. Tbe upper mark indicates tbe oillevel

. when the sump is fu1l (4Iitres). Tbe level shouJ.d never be allowed to fall below the

lower mark.

To ensure effective lubrication and long lasting engine cleanliness, it is important to

use an approved oil to tbe correct specification.

API-SERVICE CO (Previous nomenclature: Service OS-Series 111):

15

-'

The manufacturer recommends the use of mono:-grade oil (SAE 10. SAE 20 or

SAE 30.) Multi-grade oil (SAE 10/30) should not be used.

LUB.OIL VISCOSI1Y AT AMBIENTTEMPERATURES SUMPCAPACITY

QUALITY Below +IO"C +10to +30" C Above +30°C 0il01ange Incl. OilFilter

. 4litres 4.5 litres

Service CD SAE 10 SAE 30 (7 pints) (8 pints)

The following makes and grades may e used (as may other makes of corresponding

quality): r-O

HP Energol DS3 Mobil Delvac 1300

Chevron Delo 300 Motor Oil Ocean Diesoline 3

Castrol Devsol RX Super Reginol CD-SD

Essolube XD-3 Shell Super Marine Oil

Fina Solna S3 Texaco Ursa S3

Gulfpride Series 3

IMPORTANT:

If the engine bas been wholly or partly immersed in

water, all oil in the crankcase and clutch housing (or

(SO°F) ( (86°F)

~O-~

Use the same oil for clutch/ gearbox.

~gearbox) must be changed immediately.

.1

1). DIPPING ENGINE OIL (Daily):

1. Withdraw dipstick (1) and wipe clean.

2. Insert dipstick fully and withdraw to read oillevel.

Repeat if necessary .

3. The oillevel must never he allowed to fall below the J

0( lower mark on the dipstick. If necessary, top up so ~o

that level is at upper mark. ""'

4. Replace dipstick and screw home.

If the engine is mounted at an angle exceeding 8

degrees the oillevel when the sump is full (4 litres)

wililie above the upper mark on the dipstick. The .

oillevel should normally lie between the two marks. Fig. 13

16

"" 2. DIPPING GEARBOX OIL (Weekly):

1. Unscrew dipstick ("QIL" cap) (1) and' I

wipe clean. 7 -r~'"

2. losert dipstick fully (to fust thread) and

withdraw to read oillevel.

3. Top up if necessary and replace "QIL"

cap and screw home.

Note that dipstick reading is dependent on

engine mounting angle.

.. Fig. 14

3. ENGINE OIL CHANGE (at least annually):

The crankcase sump holds 4 litres of oil and this

should he changed while it is still warm.

~ 1. Oean round "QIL" cap (1) and unscrew cap.

~"

~ 2. Hold oil removal syringe (2) with its flexible tube

; down in the sump. Pump oil out and into an emty

:: cao.

=- 3. Place a mnnel in the filler opening and fi11 with 4

litres of oil of the correct grade. (See page 16.)

4. Screw back the "QIL" cap and replace the dipstick.

5. Start engine and check oil pressure.

I- ~()

4. CHECKING OIL IN CLUTCH (at least annually)

... The clutch housing holds 0.5 litres of lubricating oil.

1. Unscrew clutch housing cover (Fig 16 Item 1) and

check oillevel in the clutch. Turn the engine over Fig. 15

and check that the clutch reaches into the oil. Top

up if necessary .

2. Check condition of cover gasket and replace cover. :.\

~~~

~ 17

5. CHANGING CLUTCH HOUSING OIL (at least annually):

re clutch tension adjustment.

I

6. CHANGING REVERSE GEARBOX OIL (at least annually):

, 1. Unscrew dipstick. Hold oil removal syringe

. (2) with its flexible tube passing through

1. Unscrew clutch housing cover (1). Hold oil

removal syringe (3) with its flexible tube

down in the clutch sump. Pump the oil out

and into an emty can.

2. If the oil is thick or dirty, wash out the

clutch housing with fuel oil and carefully

wipe dry before refilling with new oil.

3. Fill with 0.5 litre clean lubricating oil

through cover opening. Do not add extra

oil. If the clutch slips, see Item 36 tor

Fig. 16

Q~~.tfai

The reverse gearbox holds 0.5 litres of

lubricating oil.

the dipstick opening and down into the reverse gearbox sump. Pump the oil out and

into an emty cao.

. 2. The oil catl also be drained by unscrewing

the magnetic plug in the after end of the

reverse gearbox. Always remove the magnetic plug and clean before replacing.

.- 3. If the oil is thick or dirty, remove the gear-

e,_" box housing cover and wash out the gear-

:: box with fuel oil and carefully wipe dry

before filling with 0.5 litres of clean lubricating oil by way of either gearbox housing

cover opening or dipstick opening.

Fig. 17 4. Replace dipstick.

18

. Cc

',,';;P

..

;~)~.";

.'

7. CHANGING ENGINE OIL FILTER (at least annually): ':,,;j~"'é}-)

The oil filter is located on the

outside of t~e crankcase on the t' 2 3 ~.i'

left hand slde. It should be

changlng the engme oil. (. ~ i

1. Loosen the oil filter (1) with a ) 1

spanner or hammer a screw

driver through the filter to '~ 4~

facilitate loosening. Unscrew ~Ii

and dispose of both filter and

rubber gasket.

~ ' - .-#

~~~~ chang~d in co~junc~on with ~

. 2. Before fitting a new filter -

(FRAM PH9A or MANN

W9.20/7), dry the sealing Fig. 18

face of the filter holder using

a clean rag.

3. The new filter gasket (2) is lightly coated with oil and fitted into the filter seating.

Screw on the filter by hand until the gasket is touching the sealing face.

Tighten by hand ODe further hal/turn. Do not tighten using tools. (Item (3) is the

~ oil pressure relief valve.)

~ 4. After filling with oil (4.5 litres including filter), start the engine and check that

I~ there is nó leakage at the filter seal.

B. GREASE

The engine, and remote control equipment if fitted, have greasing points that

require regular attention.

The following types of universal grease cao be used for all greasing points (engine

, propeller): .

. Castrol Spheerol AP2 Gulfpride SF " ~

BP Energrease LS-EP Fina Marson EPL ._~

... . - "

Chevron Dura-Lith Grease No 2 Mobilux 2 or Mobilplex 47

Esso MP Grease Beacon EP2 Shell Alvania Grease En "',

Texaco Multifak EP2

19

8. GREASING OF PROPELLER (Daily):

WPropeller and stern hearings are lubncated by screwing

. up one turn on the grease cup (1) after every 5 hours run-

ning or daily.

Lf-lfljl. When operating in sandy waters it is important that the

I '/~ 1 controllable pitch propeller should be greased regularly

1 and liberally.

I

~/' IMPORTANT:

11 1 2 If the controllabie pitch propeller controls are noticeably

,;1 / heavier when the boat bas been out of use for rome time,

ïtt= : .. 3 the reason may be that the propeller grease bas been

\ I. I washed out by contarninated sea water or strong current

. - I. etc. In such cases the propeller should be greased with

I special stern grease.

.oR. Fig. 19 should only be used for propellers and stern hearings.

9. GREASING OF INBOARD STUFFING BOX (Daily).

~ .,'/ . '.. The stuffing box bas a gland (6) packed with

(i . ~ .~allow. The gland should only be tightened just

. There are many good quality stern greases but they

.:'~.::::: 5 running or daily.

.'.'::".~

~.- ~ufficiently to prev~nt leakage. Excessive tighten-

- 0

~' The tallow packing should be changed when the

oe mg causes overheating and wear on the shaft.

Fig. 20 does not seal properly.

Note:

One turn of the grease cup (5) after every 5 hours

gland movement is fully taken up or if the gland

20

i --~ - "- ,-'- --~

10. GREASING OF PROPELLER CONTROL (Weekly):

The engine, including clutch/

grease ~n lubrication (see lig) I

2H-2HSP. -""

1. Sliding bolts: t 2

2 shots with grease gun.

2 shots with grease gun.

3. Propellercontrol hearing: -

2 shots with grease gun.

!;: 4. Propeller controllever:

2 shots every 50-100 hours running.

S. Qutch lever:

2 shots every 50-100 hours running. Fig. 21

11. GREASING OF GEARBOX SEALS (Weekly): :

The rear sealing rings (6) should be I ti

lubricated weekly, 2 shots with a ~

grease ~n or until grease emerges c

round the wear ring. '

~propeller control, bas 5 niples lor "

\\2. Oil Seals: t:

IMPORTANT:

If there is so much water in the boat

that it covers the sealing rings, the

boat should be pumped out before

operating the gearbox.

Fig. 22

21

""CC,ccc, .

GREASING OF AUXILIARY EOUIPMENT .'

12. Greasing of Starter Pinion (as required):

The starter must not be subjected to

water spray off the starter ring.

(See page 11.)

If the bendix pinion becomes rusted,

~ the starter should be removed (or

I sprayed with oil) and the starter pinion

~ r greased.

'f4;C-L-~ 1. Disconnect the electricalleads and

.1 Q rr:" unscrew the starter hom the engine.

. . 2: Insert a screwdriver (1) behind the

3 2 1 pinion (2). Lever the starter pinion

out while turning it clockwise.

Fig. 23 . 3. Apply grease (or lubricating oil) to

the shaft (3) and the starter pinion.

Turn the pinion to and from until it

moves freely in its track.

4. Assembie and fit the starter. Reconnect electricalleads and battery.

13. Lubrication of Remote Control

Lever (as required):

Apply oil or grease reguiarly to the rack

drive as shown in the figure.

Fig. 24

14. Greasing of Remote Control

(as required):

! The drive block on the end of the telescope

tube is free to move on its securing bolt

and this nipple (1) should he greased regu~arly to ensure the easiest possible manoeuvr-

fig.

Cables for propeller pitch, clutch or reverse

gearbox control, redder control cables and

cable guides should he coated with grease

during installation.

Fig. 25 J. Suitable grease: Esso Beacon ]00 EP.

22

15. Greasing of Rudder Controls (as required):

SABB rudder controls incorporate 2 grease

nip'ples. ~e is on the un?erside of th~ Ope- b ~ ~

ratIng Umt and one (2) IS on the umversal 0"",- "'

joint. Both points should be greased regu- -

larly.

Gearwheel Bilge Pump

The pump is driven by a V -belt (L T 28) on the outermost track of the flywheel

drive pulley. The V -belt is tightened by slaékening screw (1) and tuming the whole

pump. Re-tighten the screw securely.

Engaging anddisengaging (handle 5) must onIy be performed at low engine speeds

to avoid wear on the driving pulley or damage to the drive key.

Ensure that the pump is engaged or disengaged fully.

The drive key (2) can be replaced by unscrewing the set screw (3) with a 3/8" socket

spanner. Anew drive keycanbe made from 1/4" x 1/4" x34 mm mild steel.

If the pump is not working properly or if it needs excessive priming, tros may be a:n

indication of intemal wear causing leakage between suction and pressure sides of

~ the pump. In tros case the end clearances of the gearwheels must be reduced by

~ filing the pump housing flangeuntil flush with the gearwheels.

.:~~~~~~~~ ~ )

Fig. 26

i Useathingasket(O.15-0.20mm)

5 &'

16. Greasing (as required):

Remember to lubricate regularly using the

grease cup ( 6). The coupling sleeve and

coupling bolt also need greasing occasio-~; -

nally. "',

The ~arings are sealed and do not require

greasmg.

Use the drain cock (4) to drain oft the water" 4

in cold weather.

Keep the strainer clean. 1 2 3 Fig. 27

~j;;;'

23

r.' . ,,-, C. FUELOIL

"; Use only gas oil (auto diesel).

I The oil must be absolutely clean and should contain as little water as possible. This

is a good insurance against fuel pump or injector nozzle problems.

; Drain of! water and sediment trom the fuel tank regularly, at least once tor each

cî time the tank is ftlled. Use a straining cloth, cotton cloth or nylon stocking over the

tunnel when filling.

Make sure that the tank is never run dry. If this does happen, the fuel system must

be bleed. It is not necessary to close the fuel tank cock because leakage is not

possible provided that the fuel plpes are intact.

If the engine is started with the cock closed it will stop after a few minutes and

bleeding will be necessary .

.

2 " 5 3 (At least annually):

17. CHANGING FUEL OIL FILTER

1. Oase the fuel tank cock.

2. Unscrew the fuelleak-off pipe (1), fuel

bases (2 and 3) from the filter cover.

Loosen screws (4) and lift off the filter.

3. Unscrew the central bolt (5) and lower

filter bowl (6) and element (7).

Remove and dispose of used element

(7). Oean filter bowl and insect new

element.

(BOSCH FJ/SJ 27511 457431324)

4. Ensure that the rubber gasket (8) is

28 correctly located in the filter bowl

seating and tighten the central bolt (5).

Fit the filter to its bracket and secure

the fuel hoses and fuelleak-off pipe.

5. Open the fuel tank cock and bleed the

fuel system. See Bleeding page 25. -

Tighten central bolt.

24

..

18. BLEEDING THE FUEL SYSTEM (as required).

1. Check level of fuel in tank and see

that fuel tank cock is open.

2. Bleed filter by looserJng nut on fuel

leak-oH pipe (1) three turns.

Operate hand pumping lever (Fig

32, item 6) on fuellift pump until oil

escaping trom filter is tree of bub- \ - I.

les. ~, --~-

pump by slackening banjo nipple -~\ C~

hand pumping lever until the \

escaping oil is free of bubbles. Fig. 29

4. Retighten banjo nipple plug securely, making sure that the base is not kinked

during tightening.

NOTE: Never unscrew the injection pump delivery valves (3).

S. Open decompressor valve and set govemor control lever to fun speed position.

Turn the engine over (either by hand or using the starter) until noticeable

'"

"knocking" can he feIt in the injector pipes coincident with each injection.

- ,

~~1 3. Bleed fuel hose (2) to injection' "

)plug (4) three furns and operating ,

t The knocking indicates that the system is free of air and that the nozzIes are

t~ working.

I

,

~~

"f ..

,

~r',! " .

. u~" ,

; ",

! .. i

; i:"-..

~~c-~c:;.

25

"~~"'."

19. CLEANING THE INJECTOR NOZZLES

(As required):

Impurities in the fuel, or fuel containing

6 5 water, can lead to poor atomisation in the

\~ . , .! nozzIes, spray distortion or post-injection

'" --3 black smoke in the exhaust and be

leakage. The engine may knock, make

~ difficult to start.

i .~~ If this is the case, the nozzle must be

~-,:,:; ~...1 2 cleanedorrenewed.

7" \ \\ \ cf. / 1. ~~screw inj~tor pipes (1 and 2) fr°t;n

\ ' , IV"~!~--~ mjector bodies (6). Unscrew banjo

\ \ \ \ !~~ ///1 nipp~e plugs (4) and remove fuelleak-

~/ f offplpe(3).

'\ \6'\,

\ ,,\~&\~ ~ T 2, 2. Remo~e.injector h?dy balts and wit.h-

1 ~p // " '/ draw .injector bodies tor further dis-

~~ \... _/ mantlmg.

~ -.. -' ff7J;:;:' The injector body is best held upside

Fig. 30 upside down on the cylinder head and

3. The nozzIe sleeve (7) is unscrewed and the nozzle removed. The needle (11) should move freely in the

nozzIe. Never touch the needle itself but hold it by the

~~- - 6 cylindrical spigot. Wash all components in clean ~el

U- oil. Any particles adhering to the nozzIe end or to the

needie should be removed using a small piece of wood

i . or matchstick.

~ 4. Re-assemble the injector body exactly as shown in Fig

~ 10 towards the spring.

f\ Remember to insert the nozzIe joint washer (13) before

\J I I positioning and securing the injector body.

9 31, ensuring that item 9 is fitted with its shorter spigot

down in a vice but it may also be placed

secured by means of its balts (5).

~ 5. Fit the fuelleak-off pipe. The injection pipe Duts should

0--12 be screwed up lightly. Turn the engine over with gover-

~ nor control lever set to fuIl speed (decompressor lever

'j.:~;, ~"""';

: Fig. 31

26

,,--~

7 open) untiloil sprays out.

0 13 "%,- Ti ghten Duts securel

,

c'. ;-~~- ...

"--.

y.

20. CLEANING OF LIFT PUMP STRAINER

(When renewing fuel oil filter element):

<"

.c hand side of the crankcase and sup- 1- ~

The lift pump is positioned on the left \!I

plies fuel to the filter . ~

1. Oose fUel tank cock. 8

2. Unscrew central bolt (1). Remove

9

cover. Remove and wash out the

strainer (2).

3. Replace strainer and fit cover, en- 3

suring that the gasket is properly in

position. Tighten central bolt se- I. /'

I curely.

4. Open fuel tank cock and bleed the

system. 5 .

i

6

7

~

Fig. 32

' 21. CHECKING OR RENEWING LIFT PUMP DIAPHRAGM (as required:)

1. Oose fuel tank cock.

2. Unscrew fuel pipe (9) and fuel hose (8) from lift pump. Remove securing screws (7) and withdraw lift pump from engine. Oean strainer as in item 2

. above.

3. Loosen and remove upper body (3) or lift pump. Check that the two valves and

the diaphragm are in good order. If the diaphragm needs renewing, hold the lift

~ pump arm and press down on the diaphragm while at the same time turning it a

quarter of a turn to free it for removal.

Ensure toot the spring underneath the diaphragm is properly in place before

'" fitting a new diaphragm.

4. Check that the air vent (5) on the underside of the lift pump body is open.

(Prevents fuel being pumped into the engine if the diaphragm is damaged.)

"" 5. Re-assemble lift pump, fit to engine (check that gasket is in good condition) and

J

~. secure.

;

, Refit fuel hose and pipe and bleed the system.

27

,

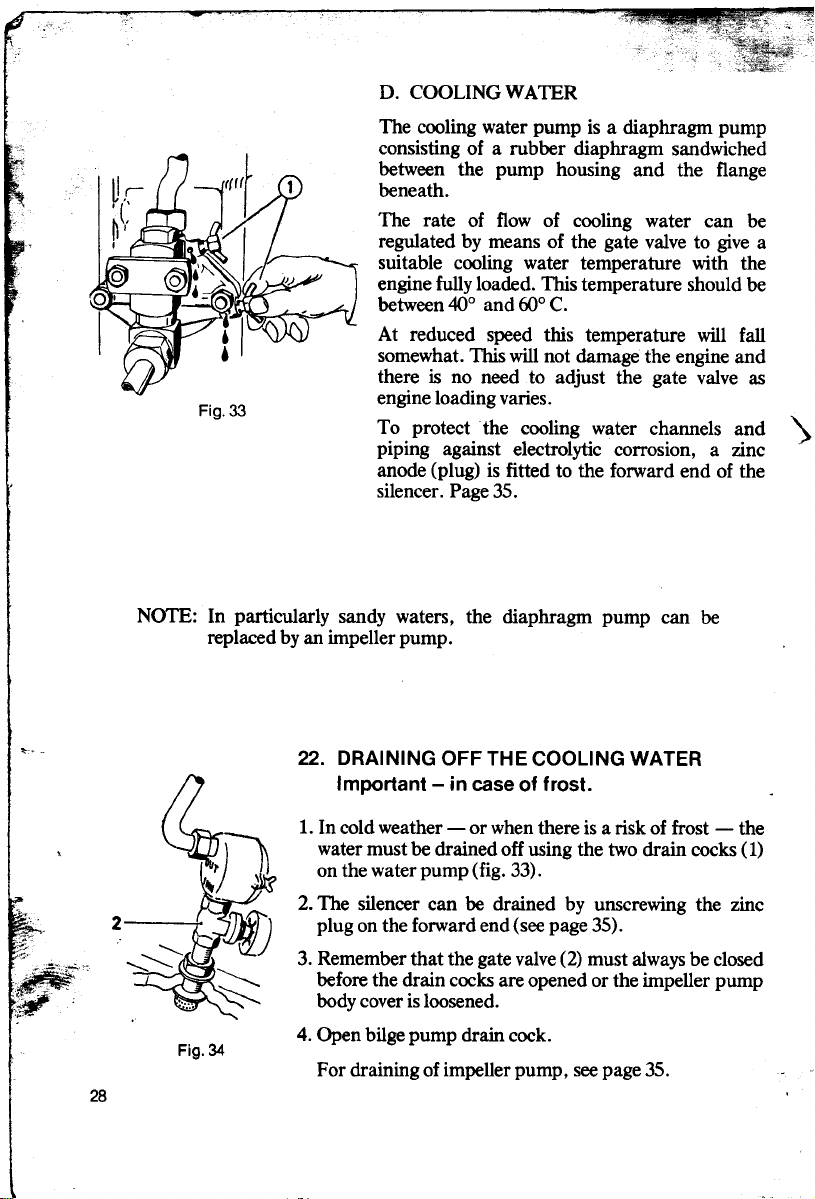

D. COOLINGWA1ER

The cooling water pump is a diaphragm pump

consisting of a rubber diaphragm sandwiched

between the pump housing and the flange

beneath.

The rate of flow of cooling water can be

regulated by means of the gate valve to give a

suitable cooling water temperature with the

engine fully loaded. This temperature should be

between 40° and roo C.

At reduced speed this temperature will fal!

somewhat. This wi1l not damage the engine and

there is no need to adjust the gate valve as

Fig. 33

engine loading varies.

T.o. protect. the cooling .water c~annels a.nd ')

plpmg agamst electrolytic corrOSlon, a Zlnc

anode (plug) is fitted to the forward end of the

silencer. Page 35.

NOTE: In particularly sandy waters, the diaphragm pump can he

replaced by an impeller pump.

". 22. DRAINING OFF THE COOLING WATER

Important - in case ot trost.

1. In cold weather - or when there is a risk of trost - the

, water must he drained off using the two drain cocks (1)

on the water pump (fig. 33).

2. The silencer can be drained by unscrewing the zinc

'-~ 2 plug on the forward end (see page 35).

-,

:;: ""f"""~"

;~ ~ before the drain cocks are opened or the lmpeller pump

~.~ ".'.' '- "- body cover is loosened.

':-,'~ .

~ 3. Remember th~t the gate valve (2) must ~ways be closed

. 4. Open bilge pump drain cock.

Fig. 34

For draining of impeller pump, see page 35.

28

FRESH WATER COOLING (Closed System)

The fresh water tank (2) (1974 1

model) is separate from the ---7 - - I

silencer and is mounted on top 2 - - . I

of it.

The thermostat (3) is located in

the silencer where it adjoins the

fresh water tank.

The keel cooler (4) is mounted

on the underside of the huIl.

If preferred, it is possible to fit

an intemal heat exchanger in

place of en extemal cooler.

). This requires a separate pump.

...

"' . through the system until the

. ~ tank is full. Check that there -~::

~

~ \ are no leaks in the system. Fig. 35

See page 30.

When first starting, fill the tank

with clean fresh water, or a

water / antifreeze mixture, via

the filler with pressure cap (1).

Top up as the water disperses

~

.~-

Operation

Until the cooling water bas warmed up the water flow is through the silencer cooling

jacket channels, out of the rear of the silencer and via the by-pass pipe back to the

water pump.

When the engine bas warmed the cooling water up to 55° C, the thermostat begins

to open and divert part of the water via the fresh. water tank to the extemal cooler

(or intemal heat exchanger where it is cooled before once more entering the water

pump).

- When in operation, the termostat will automatically distribute the cooling water

between extema! cooler and by-pass pipe, thus maintaining the cooling water

'" temperaturebetween55° and 75° C. (130-170° F.)

In case onncorrect operation (water temperature too high or too low) check:

.*' .

~ 1. Waterpumpdlaphragm Page 32

~ 2. Watervalves Page 31

~ 3. Termostat Page 34

4. Too little water in the tank Page 31

,\

1"'c

29

5. Keelcoolerdefectiveorpainted "",,"""""""""""'" Page 29

6. Heat exchanger. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ., Page 36

7. Cracked cylinder head causing compression leak into cooling

jacket. Symptom will be heavy bubbling in water tank. Most

easily confirmed by letting the motor cool and then letting it idle.

Winter Use

For use in winter the system should be filled with an approved make of glycol antifreeze. With standard piping the system holds approximately 5 litres. The

addition of 1 litre antifreeze (4 litres water) affords protection down to -80 C

while 1.5 litres of antifreeze will protect down to -150 C. Flush the whole

system with water before filling with antifreeze solution. After filling, run the engine

for 3 minutes to ensure thorough mixing. When using glycol antifreeze it is not

necessary to drain the system before or after winter use (or laying up) provided thai

the coolant remains clean and tree of rust flakes. If this is not the case the system

must be flushed through.

SEA . Fresh Water Cooling

WATE .

PUM

5 water may be discharged

CG wlth Heat Exchanger

6 .

\ The lmpeller pump (4)

\ pumps sea water through

the heat exchanger (2)

where the engine fresh

water is cooled. The sea

overboard via the exhaust

,,\ hose (wet exhaust).

NOTE:

".--

2 drained trom heat

3 '

-G:.~ ~",,:~~ Fig. 36 ~:~~d ~; ~~~n;~~ be

When there is a risk of trost

the sea water must be

exchanger and im peller

.. FRESH WATER the pump housing cover

slightly. The heat exchanger

~ SEA WATER may be drained by slacking

off the drain plug (3). Oose

the gate valve (1).

30

,

"-'"

,-" y"

23. CHECKING COOLING WATER LEVEL (Weekly):

A weekly .-;:heck is generallyadequate but if the engine is being run continuously in

warm weather, a daily check may be necessary. 1

1. The engine cooling water must have cooled

down sufficiently for the fresh water tank to

be touched without discomfort.

2. Open the pressure cap carefully. Beware of

any water spraying out since this can scald.

3. Check the level and top up if necessary to

bring the water level up to the lover edge of

the filler neck.

.. If the system contains anti-freeze, it should be

. topped either with a solution of the same _n

strength or with neat anti-freeze. (See page 30.) ~

Fig. 37

J,. 24. CHECKING THE WATER VALVE (as required):

i The wa~er valve housing (4). is mou!1ted on the cooling water pump ?n the left of

, the engIne. If pump effectlveness IS reduced, the cause may be dirt under the

'\ valves(3).

vi ~

; 1. Oose the gate valve. 1 ~

Open the drain cocks (9). 2-8

2. Undo the suction pipe connection 3 ~

to valve seat (5) and unscrew the

valvehousing(4). 1.'-

3. Holding the valve housing in a vice,

unscrew the plug (1) and the valve 2---e'

~ the valves. Renew valves and springs 3 =Ij

~ if necessary ..

* moval of plug and valve seato

'" If the valve seat is scored it can be 6 7 8 9

c;.

,~i 4. Before securing the valve housing in position between clamp (7) and water pump

'~ housing, check that the gasket (8) is in good condition.

seat (5). Check for any dirt under ~

secured to the water pump for re- ~

rubbed carefully over a fine file, Fig. 38

rotating the seat while doing SQ.

~The housing may alternatively be 5 c,

~ 5, Fit the suction pipe. Oose drain cocks and open gate valve.

i 31

-- 25. CHECKING WATER PUMP DIAPHRAGM

(At least once annually):

1. If the cooling water level (fresh water cooled

ff~ engines) falls abnormally, or if the pump cir-

I f culation is irregular(sea watercooledengines),

V the cause may be a detective diaphragm.

i 2 2. In the case of both sea water cooled and fresh

I water cooled engines, this may easily be

t:1 checked by slipping a piece of paper (3)

. ~ underneath the pump housing and flange

"\ while the engine is running.

' , "'" 3. The pump flange (1) bas drain holes (2)

1 &~ // underneath and, if diaphragm is detective,

3 ~ ..~ water will drain out and wet the paper.

Fig. 39

26. RENEWING WATER DIAPRAGM

(as required). 1. Oose gate valve. Open drain cocks (7)

and undo the pipe connections. In the

. drain oH the anti-freeze into an emty

.., against the diaphragm.

. .. / :?" Screw firmly home.

" / r- 5. Fit the pump housing and close the

.. drain cocks. Fit the pipe connections

2 7 3 5 1 and open the gate valve. In the case of

Fig. 40 system adding anti-freeze as required.

32

case of fresh water cooled engines,

can.

2. Unscrew the nuts (3) and withdraw

pump housing (2) and valve housing to-

gether.

3. Undo the diaphragm screw (4) using a

good screwdriver, remove diaphragm

washer(6), andrepiace detective diaphragm (5) with a new one.

4. The new diaphragm is fitted with its

marked side facing inwards. The diaph-

ragm washer is fitted on the inner side

of the diaphragm with its convex side

fresh water cooled engines, fill cooling

/ ,.:\"

, '

27. CHECKING DIAPHRAGMS IN DOUBLE WATER PUMP

(Ay least once annually):

~ Fresh water cooled engines are usually fitted with a double water pump (wet

" exhaust). The stand;trd pump (outermost) circulates the fresh water and the extra

pump (nearestengine) cools the rubber exhaust base.

. .

- 1. Remove pressurecap, open dram cocks (6)

f ,.rr'r2. Oose gate valve tor extra pump /'

/(

~:) ~~ ~~~p~ pipe connections 8 9 ,10 ,'1 -I Il ~

~off anti-freeze into an emty can. "',f..-"

3. Undo securing ~lts(7) and with-

draw pump housmg(8). e ( v ~ :::---9

~ r~ ,'I ~ ./' "'-

"" diaphragm washer (11). Undo ::->

.'" washer (2).

"" 5. Check bath diaphragms and renew if necessary .

.\

~ 7. The large diaphragm (3) is positioned in the pump housing seating and the

~ bly is positioned against the pump flange (1), centred and secured using

~ thefixingbolts(5).

4. Unscrew the diaphragm screw %k ~

(9) using a good screwdriver, re- ; -< '\ ,~

the securing balts (5) and with- ~~

draw pump housing (4). Remove 7 6 5 I. 3 2 1

large diaphragm (3) and inner Fig. 41

Assembly:

6. Diaphragm (10), with its marked side facing inwards, is fitted onto the diaph-

ragm screw (9). Then fit the diaphragm washer (11) with its convex side against

the diaphragm.

diaphragm screw, with diaphragm and washer, is insérted trom the outside. The

diaphragm washer (2) is fitted onto the end of the screw (9) and the whole assem-

8. Tighten the diaphragm screw (9) securely, fit the water pump and re-make all

pipe connections. Oose the drain cocks and open the gate valve on the extra

~~~d\'~~ (~~~?'-

~~' '""'

1move the diaphragm (10) and

:. pump. Top up the fresh water system.

~

. .

j '"""

~ .cc~'-

.

-~~.,,~""~"""~"'c"cc~-~""

33

'.

:

,

i

, 28. CHECKING THERMOSTAT, 1. Remove pressure cap (1) and open

CLEANING THERMOSTAT drain cocks on water pump.

STRAINER 2. Drain oH anti-freeze into an emty

(At least once annually): caD.

1 6 "J 3. Remove thermostat housing (2) and

, "" ~ 60° C. The thermostat should now

~ """ i 3 open and close again when placed in

, ~ cold water.

~ j' 4. Remove thermostat cover (5) and

~.. ~ . wash out strainer in gasket ( 6) .

, I , Thermostat and strainer caD be

I !I~ 5 washed in white spirit if necessary.

~I ~ Ifc ~ If the thermostat does not function,

~ the installation can be run witbout a

~ lt' 2 hot water at a temperature above

! withdraw thermostat (3). Place it in

",Cc

" / thermostat provided the by-pass

v' pipe in blanked oH.

/î 5. Re-assemble. Ensure that the cor-

Fig. 42 during topping up. Oase the drain

rect amount of anti-freeze is added

cocks.

8--,--9 10 7

29. CHECKING THERMOSTAT 8 '~

11 1. Disconnect the return hose (11) trom the after ~"',.~ -

end of the fresh water header tank. I . .-;--

2. Remove pressure cap (7) to allow air into the ~ i; I

tank and drain oH the anti-freeze into an ~

empty caD via the nipple at the after end of

thetank.

Undo the Duts (9), lift oH the fresh water

tank (10) and remove the thermostat (8).

Place it in hot water at a temperature above

60° C. It should now open, then close again

when placed in cold water. If necessary, wash

the thermostat in white spirit.

If the thermostate does not function, the I

jJ(1974 Model): ~~~:::~J-?> - ~

~installation can be run without a termostat

provided that the by-pass pipe is blaked oH.

4. Re-assemble. See item 5 above. Fig. 43

34

'~:l~?~(c

':~

,i"t' '

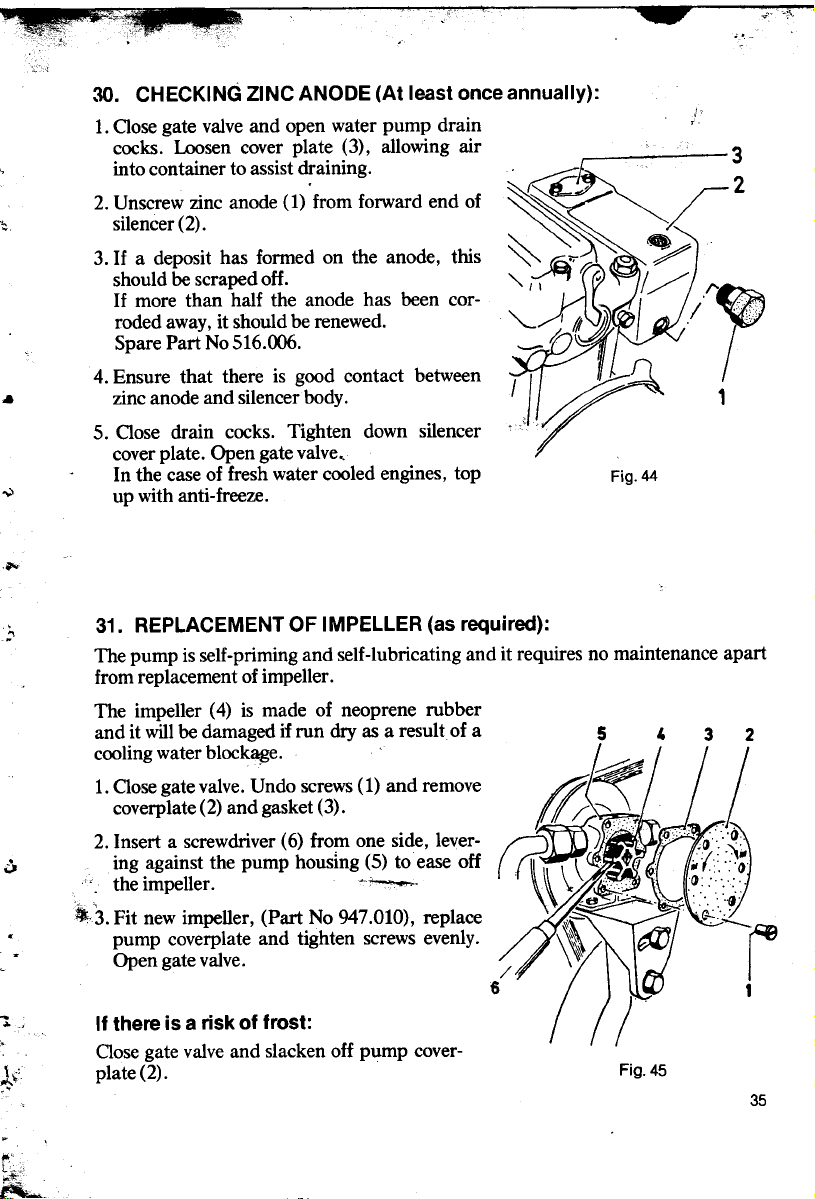

30. CHECKING ZINC ANODE (At least once annually):

1. Oose gate valve and open water pump drain :

cocks. Loosen cover plate (3), allowing air ' 3

into container to assist draining., ~~~

" 2. t!nscrew zinc anode (1) from forward end of ~~

;: sllencer(2). ~"~~ ~

3. If a deposit bas formed on the anode, this ~ ~ ~

shouldbescrapedoH. ",~

If more than half the anode bas been cor- . cC

roded away, it should be renewed. "'- I III~» I ,/ '~;

Spare Part No 516.006. '-""" d ~

.. zmc anode and sllencerbody. 1

5. Oase drain cocks. Tighten down silencer "

cover plate. Open gate valve,

~ up with anti-freeze.

,..

,:, 31. REPLACEMENT OF IMPELLER (as required):

In the case of fresh water cooled engines, top Fig. 44

The pump is self-priming and self-lubricating and it requires no maintenance apart

from replacement of impeller.

The impeller (4) is made of neoprene rubber

and it will be damaged if run dry as a resultof a 5' 2

cooling water block~e.

1. Oose gate valve. Undo screws (1) and remove

coverplate (2) and gasket (3).

2. Insert a screwdriver (6) from one side, lever- ~

.

~~~~~)""'" r 2

~Il" // /'1

i,

~'; ó ing .against the pump housing (5) to ease oH :';

. thelmpeller. "'~. ':"

" , -ti

.,3. Fit new impeller, (Part No 947.010), replace '

. pump coverplate and tighten screws evenly. ~

. Open gate valve. I

6 1

"l If there is a risk ot trost:

, Oase gate valve and slacken oH pump cover-

l'" plate(2). Fig. 45

c'

t~,.'

~

c~

35

...' ,,:t(~

32, CHECKING HEAT EXCHANGER

An apparent failure in the cooling water supply (rising engine temperature) that

, piping, may be due to an end aperture blockage in the tube cooler.

I Checking tube cooler: Fig. 46

i If the level falls abnormally, the tube cooler

cao not be attributed either to a faulty impeller or to air in the pump or associated

Checking:

1. Oose the gate valve. Open drain cock (1)

to drain sea water from the tube cooler.

2. Remove suction hose and end cover (3).

Remove any waste material (grass etc) that 2

may he blocking the cooler end aperatures

and preventing effective flow through the

cooler.

3. Re-assemble in reverse order.

6 5 4 3 1

should be checked. Remove the entire heat

l exchanger.

i 4. Remove the covers (3) and gaskets (4) from both ends of the heat exchanger.

5. Place a piece of wood over ODe end of the tube cooler (5) and tap carefully to

remove cooler from its housing ( 6).

6. Insert replacement cooler, fit end covers and re-connect hoses. Top up engine

fresh water cooting system.

.. . ~"'V-;J1. dj" ~"i',~

,-,,' 1 ~:~ ~\'"' ;~f?

"'.

'é:

I'" 36 ,:;!";

f

I. c

.",. """',~c

E. ADJUSTMENTS

r'

;t" Every 100 running hours: 1'" ~~À~

33. ADJUSTMENT OF V-BEL TS (Alternator)

~. drive the altemator and maintain the battery 2 ~ ~,~

charge. ~'. '-

Therefore check the V-belt tension regularly

(initially after 2S running hours), and parti- 3

cularly if charging is not satisfactory. 4

1. Slightly loosen the securing bolts (2 and 3) 5

and slacken oH the tensioning bolt (5).

.j-'- 2. Tension the belt (6) by moving the alter- 6

nator (1) upwards. Tighten the tensioning

bolt (5).

.; 3. Check the tension. When the tension is Fig. 47

cÇ>rrect, it should be possible to deflect the

belt about 3 mm using thumb pressure at

.., pulley.

a point midway between flywheel and drive 2 1

~ . 4. Tighten bolts 2 and 3, check that tension- :---

-" ing bolt (5) is tight. (V-belt: Rofan 3915.)

Direct Current Generator ~~

1. Slightly loosen securing nut (1). &

wheel (2) clockwise until the desired tens- 3

ion is achieved (see item 3 above). ..)

3. Re-tighten securing nut.

~ (V-belt: Rofan 3915.)

.al1=~-~; ~..:\ ~~\\

. I~/'::!J)J;.II "

9==- : The important function of the V -belt is to ~~~:. / -c:-

I ~

w.1 2. Tension the belt (3) by tuming the hand- ,

." Fig. 48

. .

~l'

V

. 37

-*

~:

34. ADJUSMENT OF V-BELT

(Impeiier pump):

Q ' \ "\.:=~ ~' ~ ~ pump and alternator, V-belt (3) tension-

~ ~ ~ In the case of engines fitted with impeller

~~ --:. / = ing is carried out as described foT engines

'" '_~? I - with, altenators (.see Fig 47), but with the

. '" 1 tensIon tested mldway between pump and

~ alternator.

~' ~ For engines fitted only with an impeller

: ~.,; //

~ ..). ~(/~ ~ ing oft t~e securing and tensioning balts (~)

~ 1)

""'cc.

, ()

'".: ,Re-tighten balts securely.

l

, 35. ADJUSTMENT OF ENGINE IDLING

:

(~~~;;~~~~::~;~~ ~ omng screw IS shown as Item 5 m FIg 36.

~ 2 pump, the V-belt (4) is tensioning by slack-

) 3 aD? movmg.the pump <?utwar?s. !De tensl-

Fig. 49

t j

i ~~"""!;f';::= means of the set screw on the TeaT of the

I

\ ~ ~ Idling speed may be adjustet externally by

h1'~ ~ --- governor cover.

3 '\ ~

~ 1.R~movethedomenut(1).

U \\-'---:-- \ 2. Insert key (2) into hexegonal socket of idle

% -'~ setscrew(3).

--' ~ 3. Adjust idling speed by turning set screw.

' --,' \ '@ ---::::::::: Screwing set screw (3) out ~111 tighten

~. ,; ! I, 0 ;; spring and increase engine idling speed.

J J ~ Minimum idling speed should be set at

~Jl about 350-400 rpm and it should remain

I

~ ) constant foT 100 -150 movement of the

.. ~ -..p(/ governor controllever.

: 4. Setting "extent" of idling range (not

".~, Fig. 50 usually necessary to adjust).

Unscrew plug (4) using 5/16 Allen key. Insert screwdriver in opening and engage

with governor arm adjusting screw. Screwing in the adjusting screw will"ipcrease

'" the idling range givenby the governor but it win at the same time reduce the

maximum engine speed available.

38 :j,.

.'

,

"

~ :~;; ".., .

"'1; ".\

;,,~,'

...

~'

~"

36. ADJUSTING OF CLUTCH (as required):

The clutch may be adjusted when necessary (e.g. if slipping occurs), preferably in

conjunction with a clutch oil change.

1. Remove clutch housing cover.

2. First check ihat the clutch

lever (1) is pushed right forward. The clutch arms (2)

must pass the indent if the

clutch is to remain in position.

3. The engagement pressure CaD

be regulated by means of the "

Duts (3) on the two clutch \(;

\' \

3 1

f- clamps(4).

; After tightening all these Duts r"

by 1/6 turn, check engage-

., cl;utch lever. If the clutch is /}v

. two Duts are diamentrically 't "

ment pressure by operating ~

then toa tight it may be suf- V

ficient to slack back 1/6 turn

on ODe nut on each clamp, ie

opposed to oDe another. Fig. 51

- the other two DutS. In this way an even adjustment is assured. The DutS are locked

On the neKt occasion of clutch adj ustment , tighten up correspondingly on

by means of the springs positioned against the flats.

.. .., c-

.,~'t'

. 1;~;";+ '"

.- .

"

. ~

'" ~".;

;. ,

.~ ::l'~:C' ,Y 39

;\";:2;,

{c~? .:J

~: -

,a.,

ê",

37. ADJUSTMENT OF INlET AND EXHAUST VALVE ClEARANCES

(0.3 mm with engine cold): ;'!;:~~.y?~~~'~:

Adjust initially after 50-100 running hours and stib~.t1y af.ter every 600

running hours or if starting difficulties are experienced. '"

1. Unscrew both 'startiirg'cigarette plugs

2 3 (1). Free the spnng at the rear end of

I ' EX IN

- ~ v .

~ ~ ;:: -- . 2. Tü.rn the' flywheel until the pi.ston in

~ ~~v '" cylmderN01(nearestflywheel)lsatthe

i . ~ '

@ the cylinder head, unscrew the rocker

cover bolts and lift the cover (2) off.

~ to~ of its travel and both valves lor

" ~ cylloder No 1 are closed. (Push rods

~ ~ // 1 free to move.

4 '" - '., 'r, I f See top dead centre mark (ruC) on the

I . IJ !~r~~~~ flywheel guard and on the flywheel

.. ,," ~-~::~~::: (single mark),

l"i/,~A / 3, Insert valve clearance feeIer gauge (3)

""

# / /1 -(0.3 mm) between rocker arm and

(',/ ' valvestem. Slackenoffnut(4). Usinga

,,~ screwdriver, set the adjusting screw so

Fi t~at the ~eeler can be móved with only

g,52 sllght reslstance.

Re-tighten nut (4) and check clearance again. Transfer feeier gauge to exhaust

valve (EX) and set the same clearance as lor the inlet valve.

4. Similarly lor cylinder No. 2: Turn the flywheel until the piston in cylinder No 2 is

at the top of its travel and both valves are closed. (Both push rods tree to move.)

See TDC mark on the flywheel guard and twin marks on flywheel. Continue as in

item 3 above.

. , 38. ADJUST.NG DECOMRESSOR VAlVE

~. ,

, g,-

With decompressor handle (C) in lower (open) position the engine should be easy to .

0 A B 8 A C.~ A

.. i u

~ ~ ;é';"

'" E ;:

-

C

al

E

~.

~"

Fig, 53

40 IN E

\~~~:' ,- -' ~~

crank by hand. The decompressor shaft acts on both inlet valves and keep them in

open position. If not, the decompressor is adjusted by means of the eccentric

hearing (A) both ends of rocker cover. Pointmark (E) on hearing shows position of

eccentric. With point down the decompressor bas max. opening.

F. CHECKS

39. CHECK OR RENEWAL OF GOVERNOR SPRINGS (as required).

In the case of any ~parent irregular~ govemor con trol, the govemor com-

ponents shoulç1 becnecked to see th""at;,~-ermove freely and without fouling. Gover-

- nor con trol irregularities may &:t~'be due to stretch in the govemor springs, in

f which ca:se these should be renefled.

1. Remove dipstick and detach govemor 6 ,3

cover (4). lmm.t 1

2. Check that the govemor components

cao be moved freely. If necessary, wash

them in fuel oil.

If it is nècessary to renew the govemor

springs, this cao now be dolle without

removing the govemor itself.

tc 3. Assembie govemor cover. Check mea-

-, sure 21 mm of arm position. The :::--arm cao be slightly bent to get correct. ~fe: '

measure. Ensure that the fuel pump '~

spigot (6) engages in the slot in th~ ~\~ ".

govemor arm (5). This cao be feIt as a ~ 7 9

f slight "click" or dead movem~nt when F'

. the govemor controllever (8) is tumed Ig.54

é in the "stop" position. :..

. 4.lf the govemor bas to be removed,

. unscrew theset screw (7). Then release

the cap nut in the af ter end of the

govemor cover and the idling adjusting ';.

" screw cao be screwed in through the.

hole (without dismantling the spring)

in the cover and the whole arm cao

then be removed. The centrifugal

govemor (9) cao be detached using a

'"

cj NOTE: Right hand thread,

è

'::::I : 41

, ;J ",;;;..;'

. ~ :,.",::é.,

'- . )ft. c:it,

22mm spanner.

# :-~cc, ~,

"c , ;,-

r -"...'"

- . ~

r 40. TIGHTENING CYLINDER HEAD BOL T5

i If the cylinder head bas been removed, the

I cylinder head bolts should he tightened after

about 10 hours further running.

1. Run engine until it reaches normal working temperature then stop.

2. Unfasten the decompressor spring at the

TeaT end of the cylinder head.

Re1!1°ve rocker cover (9).

3. Slacken both bolts (10). Carefully lift off

the rocker arm brackets and branch pipes

without further dismantling.

4. Tighten the cylinder head bolts in the correct sequenëe. Use a torque wrench (11).

Start with bolt ~o 1 on the port (silencer)

side and then tighten No 2 and No 3 on the

starboard side etc.

(Torque setting 11 kgm, 79 ft.lbs.)

5. Fit rocker arm brackets (torque setting 8

kgm, 58 ft.lbs.) , adjust valve clearances

and fit rocker cover.

: 41. CLEANING CRANKCASE SUMP AND OIL STRAINER

(Once every 2 or 3 years) The strainer only needs to be removed foT

cleaning if the oil pressure is low on starting (when the oil is thickest) when the oil

level is normal. Otherwise it is sufficient

I ; to wash out only the crankcase sump itself

~ i (see item 3 on the next page).

r j' 1. Withdraw dipstick (1). Undo the secur-

, ; ing screws (2), bend the fixing clip (3)

I to one side and remove the governor

cover (4).

/" 2. The strainer pipe (5) is visible through

! the opening in the gear housing. Undo

: nut on L-piece (6) and carefu1ly ease

the pipe out.

i _\ :;;.? Sj:':., , Wash.out the pipe (strainer) in fuel oil

\c '. ~ Fig. 56 6.iJf '.'~, and Wlpe or blow dry.

, " 42 J. ::;"i\':

"

_._~ - ' -

, ~~.~:,:' .,

.

3. Remove crankcase cover (7) and wash out crankcase internally using fuel oil.

Remove oil with oil syringe inserted through the cover opening. Dry thoroughly

with paper wipes or lint-free rag.

Assembly:

4. Insert strainer pipe throUgh cover opening, down towards the forward corner of

the gear housing and with the strainer in the crankcase. Ease the pipe çarefully

into position and secure firmly.

IMPORTANT:

Ensure that the pump spigot (see Fig 54, item 6) engages with the slot in the

governor arm (Fig 54 item 5). This caD be feIt as a slight "click" or dead movement when the governor controllever (8) is turned in the "stop" position.

42. CONTROLLABLE PITCH PROPELLER

The propeller blade pitch is altered by means of the drive block (4), the whole shaft

being moved in and out. The drive block thus both transmits the engine power and

controls the pitch of the propeller blades.

The thrust hearing is located in the forward end of the propeller boss and consists

of three nylon rings, two (2 and 3) to take the ahead thrust and ODe (the centre oDe,

not shown) to take the astern thrust.

Pitch Control Stiff:

A. If the pitch control is stift to operate, it

may be due to lack of grease in the 7

propeller boss, poor alignment between .

engine and propeller shaft, or to stiff- 1

ness of the drive block within the pro-

" peller boss.

I B. Check shaft alignment by inserting a 2

feeier gauge between the coupling flange

and the engine drive flange, and then try

; with the two flanges disconnected.

If pitch control then works freely and the

shaft alignment is correct, the boat must

be slipped for examination of the pro-

I C. In the case of new engines, stiffness in

0' Therefore check that the marks on the

, drive block, the propeller boss and ODe

". . become fouled by rope etc. Fig. 57

peller.

propeller control may be due to incorrect

assembley of the propeller components.

bladeall point the same way.

D. If the stiffness continues after a period of

use, it may be due to the propeller 8

having struck some obstruction or having

... 43

., "co' è,~

t;-

Dismantlil1g Propeller.

1. Outch in neutral.

2. Undo boss screws using 8 mIn (5/16") Allen key.

3. Remove the boss and propeller blades. Check whether the drive block (4) is

cracked. If not, the stiffness can possibly be cured by careful filing of the drive

block faces.

If the drive block is cracked or loose on its threads, it must be replaced.

4. If the propeller blades are damaged, they must be repaired so that they are again

identical. Any blade differences will cause vibration leading quickly to wear on

the shaft.

Assembly.

1. Fit the blade tap blocks (5) to the blade taps (6).

2. The marked blade (7) is positioned with its tap block (5) engaged in the

recess on the marked side of the drive block. One half of the propeller boss (8) is

then fitted itl position from the port side in such a way that all the marks point in

the same direction.

3. The other blade is then fitted with its tap block (5) engaged in the remaining

recess in the drive block.

4. Fit the thrust rings, ensuring that the raised beaded side of each rings runs in

contact with the corresponding stern bearing surfaces. Fill stern propeller boss

with grease.

5. Fit the remaining half of the propeller boss and screw home the boss screws

which are locked with lork washers (1).

Torque setting, stainless steel bolts MlO. . . . . . . . . . . . . . . .5-5.5 kgm (38 ft.lbs.)

Torque setting, brass bolts (old type)V2"W. . . . . . . . . . . . . . 2-3 kgm (16ft.lbs.)

.. ('\

.

.-

~-

...

c',,"

44

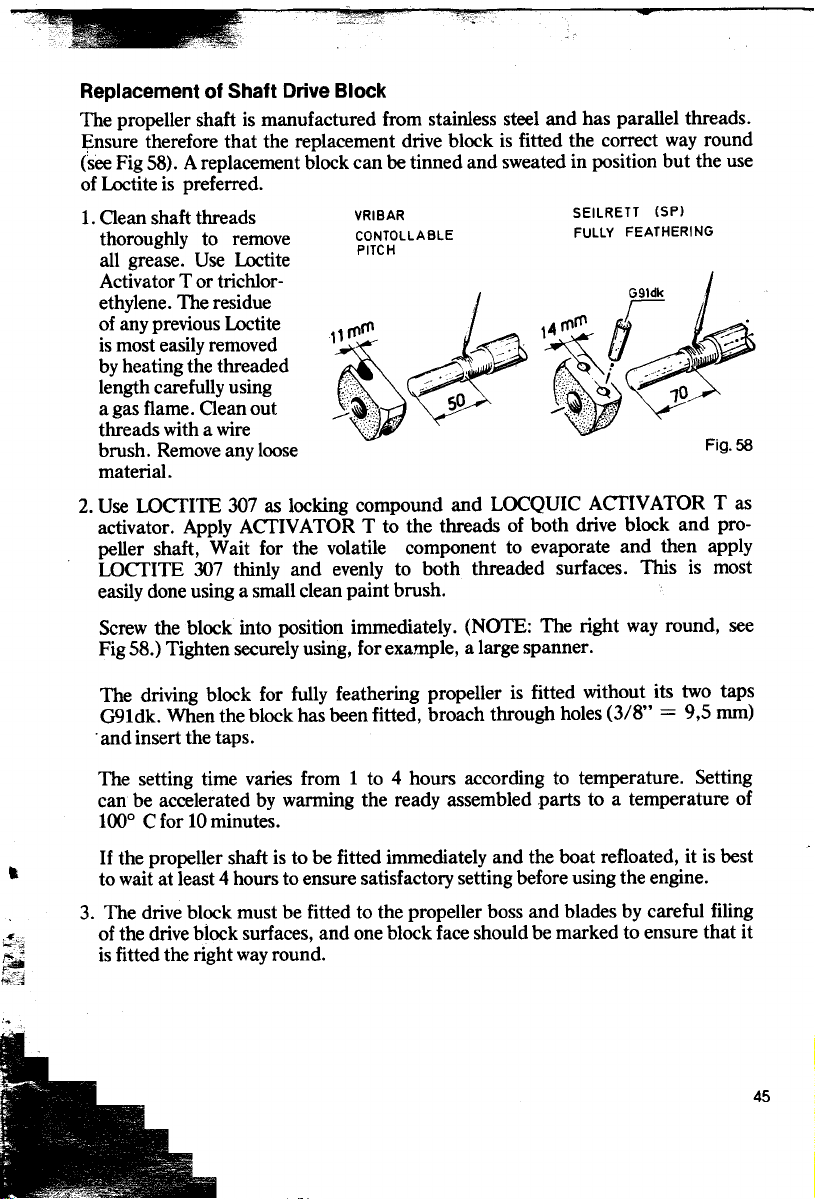

Replacement of Shaft Drive Block

The propeller shaft is manufactured trom stainless steel and bas parallel threads.

I;:nsure therefore that the replacement drive block is fitted the correct way round

(see Fig 58). Areplacement block can be tinned and sweated in position but the use

of Loctite is preferred.

1. Oean shaft threads VRIBAR SEILRETT (SP)

thoroughly to remove CONTOLLABLE FULLY FEATHERING

all grease. Use Loctlte

Activator T or trichlor-

.of any pre~ous Loctite rn \4 rnrn ,/ :.- .

lsmost.easllyremoved

length carefully using ,c . ' 10

a gas flame. Oean out 50

threads with a wire

brush. Remove any loose Fig. 58

material.

2. Use LOCfITE 307 as locking compound and LOCQUIC ACfIVATOR T as

activator. Apply ACfIVATOR T to the threads of both drive block and propeller shaft, Wait tor the volatile component to evaporate and then apply

LOCfITE 307 thinly and evenly to both threaded surfaces. This is most

easily done using a small clean paint brush.

Screw the block into position immediately. (NOTE: The right way round, see

Fig 58.) Tighten securely using, tor example, a large spanner.

. PITCH

~j. ~-: ~ tI

iethylene. The residue G91dk

~""'. by heatlng the threaded ,~ Á~ ! .:~. 1

The driving block tor fully feathering propeller is fitted without its two taps

G91dk. When the block bas been fitted, broach through holes (3/8" = 9,5 mm)

. and insect the taps.

The setting time varies trom 1 to 4 hours according to temperature. Setting

can be accelerated by warming the readyassembied parts to a temperature of

100° C tor 10 minutes.

If the propeller shaft is to be fitted immediately and the boat refloated, it is best

.. to wait at least 4 hours to ensure satisfactory setting before using the engine.

3. The drive block must be fitted to the propeller boss and blades by careful filing

r!"'i of the drive block surfaces, and one block face should be marked to ensure that it

~ is fitted the right way round.

~f!~

45

0 ~WfJ-""" viJSt..I!.o:.d l

--~ I

z.el? tlfrklle...~ ~Î.s~ 1c1..JIo,)',e-!("

43. REVERSE GEARBOX ~o..

The reverse gearbox works on the principle of self-adjusting CODe clutches for ahead

and astern drive. When the gear lever is moved, the gear shaft (4), together with

flange coupling (7) and propeller shaft, is moved forward for ahead drive and back-

ward for reverse.

The clutch is held engaged by the propeller thrust. To avoid a degree of clutch slip

during engagement, the clutch lever should be engaged with a light pressure. As

soon as the propeller bas begun to generate thrust, the clutch will hold in. The lever

must not touch engine casing etc.

1 The nature of this method of clutch operation makes it important that exact align-

ment between engine and propeller shaft is maintained. Any misalignment fuld

g;ive rise to clutch slip. -';..,die~ c\t. "-"o\.." e.. ~~ sc.~voe~J "ie~ tJ"~"" ~~

\0\ e'e"" ,C)"" 5"\ "',~", t.l-t. \It~y!eli"'5 Q~j"'I/&o"~).~ QIl.~ ~dd s)'~e..

If the water level in the boat is such that water may reach the oil seals in the rear

face of the gearbox, operation of the gearbox should be avoided until the boat bas

j been pumped out. This will prevent damage to the hall race on the far side of the

seals.

Replacement of Oil Seals (Gearbox Engines)

(as required):

1 --7:-'[ 1. Re~ove. dip~tick (2) and pump out the

", Fig. 59 lubncatlng 011.

,I. 2 3 .

)1 2. Remove the flange couplmg bolts and ease

"""-' I, I 4 5 6 7 8 9 the propeller shaft and after coupling

,~ I

- ~~-j I I I

~ 1 [, "

1 1 flange approx9cm tothe rear.

=1i 7?'b / ~ ) 'i,flij;:;~: ~~:~~~~y ~~h~:~t ~~~~~h~:e~~~~~:nt-

~~I--J~ rDfî;î!j

~ 10 !;' -

4. Set gear lever in the fully back position. Position two wooden blocks, about 1"

truck, between coupling flange (7) and gearbox flange (3). Press the coupling

flange off by pushing the gear lever carefully forward. If this is not effective, an

extractor must be used. Take care of the key (10).

!.', S. Tip the oil seals (S and 6) out of the gearbox flange (3) and clean the sealing face.

.;;

6. Insert newoil seals, both with their open ends inwards. The outer seal bas the dust

lip turned outwards. Place a flat piece of wood over the oil seals and knock them

in, ODe at a time. Apply a little grease. See that the grease nipple hole is open into

the space between the oil seals.

7. Position the key and ease the coupling flange (7) carefully onto the gear shaft (4).

Fit the lock washer, knock the nut tight and lock with locking tabs. Fill with

fresh oil. Fit propeller shaft.

46

~~ ~ ,J 3. S.traighten the locking tabs and knock the

~ ~~~-[,-- nng nut (9) loose. Remove lock washer (8).

~tk _.:i!i~-

Gear Lever Movement

If the ahead clutch CODe lining becomes wam Ca 100

af ter a long time in use, the lever must be

pushed further forward to engage the clutch. 1

This cao be adjustèd using shims between the

clutch CODe forward face and the ballrace on the

shaft spigot in the gear housing (2).

Similarly, if the astem clutch CODe line becomes

wam, the clutch lever backward movement cao

be reduced by removing the shims from the 3

forward end of the ballrace in the operating

sleeve (3). This is a major repair and should be

carried out by a SABB Workshop or other

approved agency. Oetailed instructions will be ~

supplied on request. ~

Check: Fig. 60