SAB Goblin 700 User Manual

GOBLIN 700 KYLE STACY EDITION

SAB HELI DIVISIONSAB HELI DIVISION

- Carefully check your model before

each flight to ensure it is airworthy.

- Consider flying only in areas

dedicated to the use of

model helicopters.

- Check and inspect the flying

area to ensure it is clear of

people orbstacles.

- Rotor blades can rotate at very

high speeds! Be aware of the

danger they pose.

- Always keep the model at a

safe distance from other pilots

and spectators.

- Avoid maneuvers with trajectories

towards a crowd.

- Always maintain a safe distance

from the model.

Goblin 700 Kyle Stacy Edition Manual

Release 1.0 - June 2015

WORLD DISTRIBUTION

www.goblin-helicopter.com

For sales inquiries, please email:

sales@goblin-helicopter.com

For info inquiries, please email:

support@goblin-helicopter.com

Attention: If you are a consumer and have questions or need of assistance,

please contact in a first time the Goblin retailer where you made the purchase

EUROPEAN DISTRIBUTION

www.sabitaly.it

For sales inquiries, please email:

sales@sabitaly.it

For info inquiries, please email:

info@sabitaly.it

Attention: If you are a consumer and have questions or need of assistance,

please contact in a first time the Goblin retailer where you made the purchase

375 mm

1388 mm

196 mm

7 – Assembling The Modules

8 – Installation of Swashplate Servos

9 – Installation of The Motor

10 – Installation of The ESC

11 – Installation of Flybarless Unit and RX

12 – Tail Assembly

1 – Serial Number

2 – Important Notes

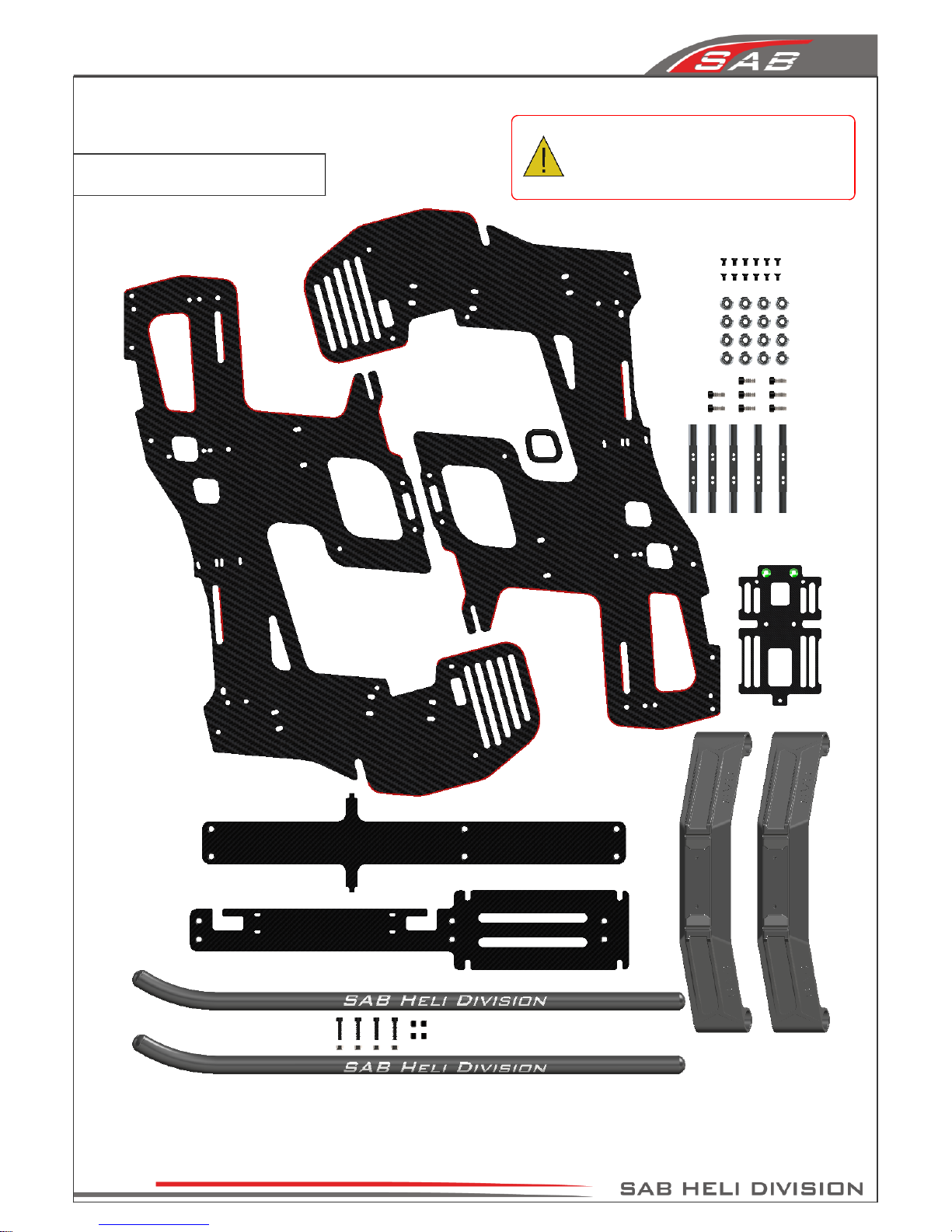

3 – Components and Box

4 – Carbon frame Assembly

5 – Trasmission Assembly

6 – Main rotor

INDEX

13 – Installation of the Boom, Canopy

14 – Battery

15 – In flight

16 – Maintenance

17 – Exploded Views

18 – Spare Parts

//www.goblin-helicopter.com

http:

Main rotor diameter: 1582mm (with 690mm blades)

Main blade length: 690mm

Tail rotor diameter: 305mm

Tail blade length: 115mm

Main shaft diameter: 12mm

Tail shaft diameter: 6mm

Spindle diameter: 10mm

Weight including standard electronics: 4175g (excluding batteries).

Motor size: Maximum 64mm diameter, maximum height 64mm

Battery compartment: 60x58x350mm (adaptable to 75x58x350mm)

SPECIFICATIONS

It is extremely important that you take a moment to register your helicopter with us. This is the only way to ensure that you are

properly informed about changes to your kit, such as upgrades, retrofits and other important developments. SAB Heli Division

cannot be held responsible for issues arising with your model and will not provide support unless you register your serial number.

To mount the serial number tag on your helicopter, please refer to page 29.

Thank you for your purchase, we hope you enjoy your new Goblin helicopter!

SAB Heli Division

VERY IMPORTANT

Inside Box 5, you will find Bag 21. This bag contains your serial number tag. Please take a moment to register your kit online via our

web site at:

Please read this user manual carefully, it contains instructions for the correct assembly of the model.

Please refer to the web site www.goblin-helicopter.com for updates and other important information.

Page 1

Chapter 1, Serial Number

IMPORTANT NOTES

*This radio controlled helicopter is not a toy.

*This radio controlled helicopter can be very dangerous.

*This radio controlled helicopter is a technically complex device which has to be built and handled very carefully.

*This radio controlled helicopter must be built following these instructions. This manual provides the necessary information

to correctly assemble the model. It is necessary to carefully follow all the instructions.

*Inexperienced pilots must be monitored by expert pilots.

*All operators must wear safety glasses and take appropriate safety precautions.

*A radio controlled helicopter must only be used in open spaces without obstacles, and far enough from people to minimize

the possibility of accidents or of injury to property or persons.

*A radio controlled helicopter can behave in an unexpected manner, causing loss of control of the model, making it very

dangerous.

*Lack of care with assembly or maintenance can result in an unreliable and dangerous model.

*

Neither SAB Heli Division nor its agents have any control over the assembly, maintenance and use of this product.

Therefore, no responsibility can be traced back to the manufacturer. You hereby agree to release SAB Heli Division from

any responsibility or liability arising from the use of this product.

SAFETY GUIDELINES

*Fly only in areas dedicated to the use of model helicopters.

*Follow all control procedures for the radio frequency system.

*It is necessary that you know your radio system well. Check all functions of the transmitter before every flight.

*The blades of the model rotate at a very high speed; be aware of the danger they pose and the damage they may cause.

*Never fly in the vicinity of other people.

NOTES FOR ASSEMBLY

Please refer to this manual for assembly instructions for this model.

Follow the order of assembly indicated. The instructions are divided into chapters, which are structured in a way that

each step is based on the work done in the previous step. Changing the order of assembly may result in additional or

unnecessary steps.

Use thread lockers and retaining compounds as indicated. In general, each bolt or screw that engages with a metal part

requires thread lock.

It is necessary to pay attention to the symbols listed below:

Important

Use retaining

compound

(eg Loctite 648)

Use retaining

compound

(eg Loctite 243)

Use CA Glue

Use Proper

Lubricant

Indicates that for this

assembly phase you need

materials that are in bag xx.

Bag xx

Page 2

Chapter 2, Important Notes

ADDITIONAL COMPONENTS REQUIRED

*Electric Motor: 12S – 480/520Kv

Maximum diameter 64mm,

Maximum height 64mm,

Pinion shaft diameter 6/8mm

*Speed controller: minimum 160A to be safe

*Batteries: 12S - 5000mAh

*1 flybarless 3 axis control unit

*Radio power system, if not integrated with the ESC

*3 cyclic servos

*1 tail rotor servo

*6 channel radio control system on 2.4 GHz

(See configuration examples on page 17)

The assembly process is described in the following chapters.

Each chapter provides you with the box, bag and/or foam

tray numbers you will need for that chapter. The information

is printed in a green box in the upper right hand corner of the

page at the beginning of every chapter.

TOOLS, LUBRICANTS, ADHESIVES

*Generic pliers

*Hexagonal driver, size 1.5,2,2.5,3,4mm

*4mm T-Wrench

*5.5mm Socket wrench (for M3 nuts)

*8mm Hex fork wrench (for M5 nuts)

*Medium threadlocker (eg. Loctite 243)

*Strong retaining compound (eg. Loctite 648)

*Spray lubricant (eg. Try-Flow Oil)

*Synthetic grease (eg. Tri-Flow Synthetic Grease)

*Grease ( eg. Vaseline grease )

*Cyanoacrylate adhesive

*Pitch Gauge (for set-up)

*Soldering equipment (for motor wiring)

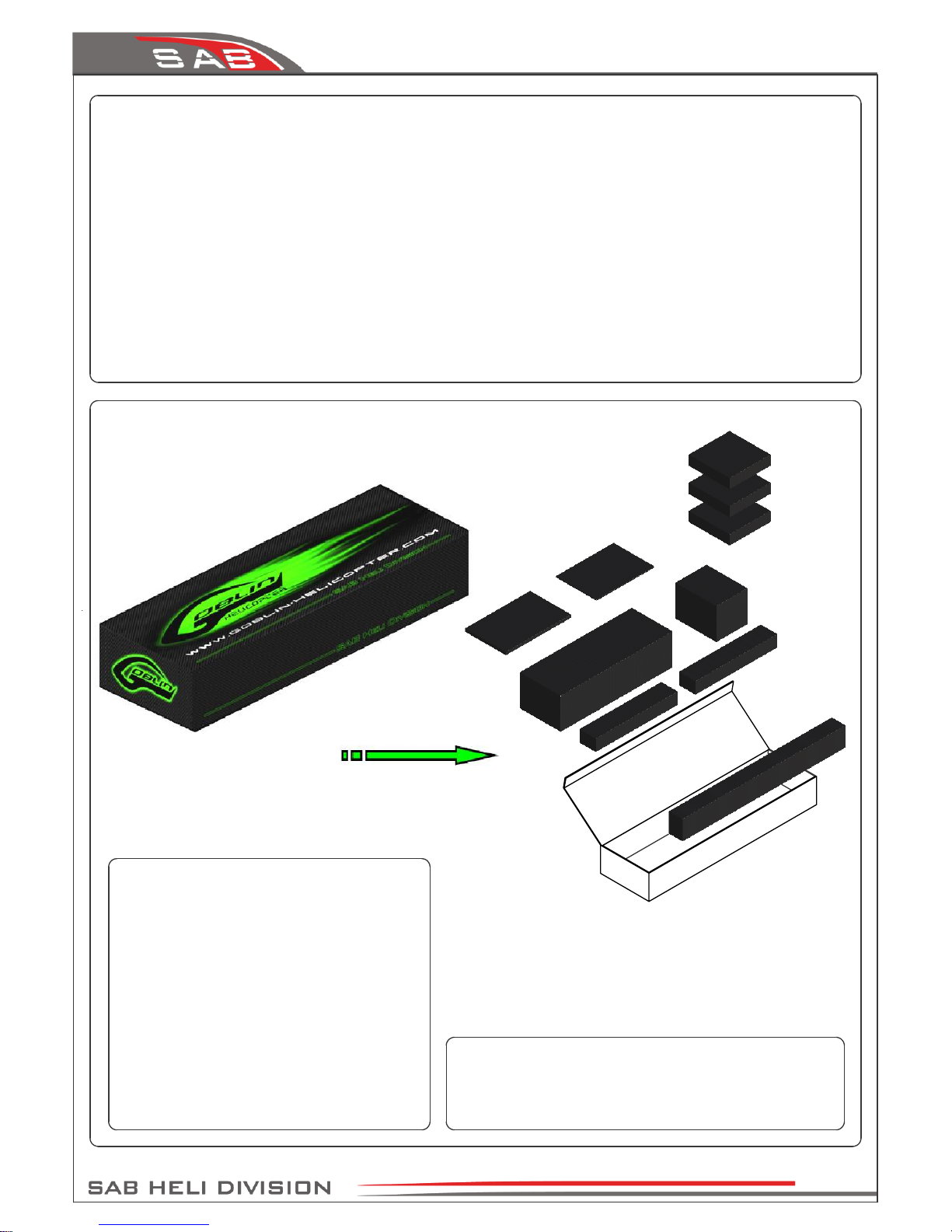

Inside the main box:

Box 2: Canopy, Blade Holder.

Box 3: Boom, Blades, Tail blades, Carbon rod.

Box 4: Mechanical parts in 4 trays:

Tray 1: Main rotor

Tray 2: Carbon frame and tail rotor

Tray 3: Transmission

Tray 4: Main structure

Box 5: Bags

Box 6: Carbon parts

Box 7: Landing Gear

Inside the main box there are:

Tray 1

Tray 2

Tray 3

Manual

BOX 6

BOX 7

BOX 2

BOX 4

BOX 5

BOX 3

Page 3

Chapter 3, Components and Box

4-Carbon Frame

The manufacturing process of the carbon parts

often leaves micro-burrs and sharp edges. We

recommend de-burring the edges to minimize

the risks of electrical wire cuts, etc. Very

important in red line zone.

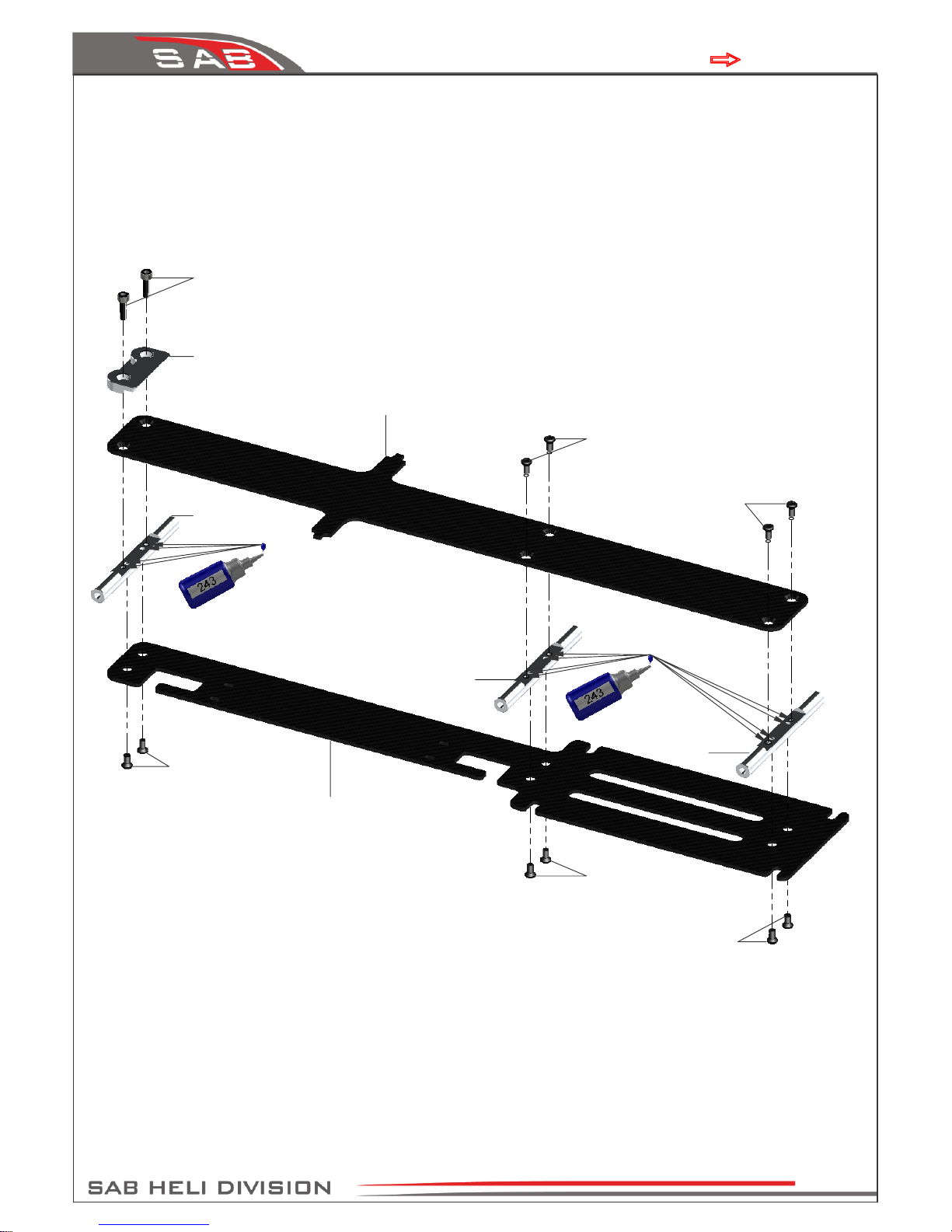

Page 4

Chapter 4, Carbon Frame

Flat Head Cap

Screw M2.5x5mm

(HC128-S)

ESC Support

(H0153-S)

Flat Head Cap

Screw M2.5x5mm

(HC128-S)

Flat Head Cap

Screw M2.5x5mm

(HC128-S)

Flat Head Cap Screw

M2.5x5mm

(HC128-S)

Frame Spacer

(H0003-S)

Frame Spacer

(H0003-S)

Frame Spacer

(H0003-S)

Flat Head Cap

Screw M2.5x5mm

(HC128-S)

Battery Tray

(H0002-S)

Stop Battery Plate

(H0150-S)

Socket Head Cap

Screw M2.5x8mm

(HC020-S)

BAG 1.1, FOAM 3, BOX 6

Page 5

Chapter 4, Carbon Frame

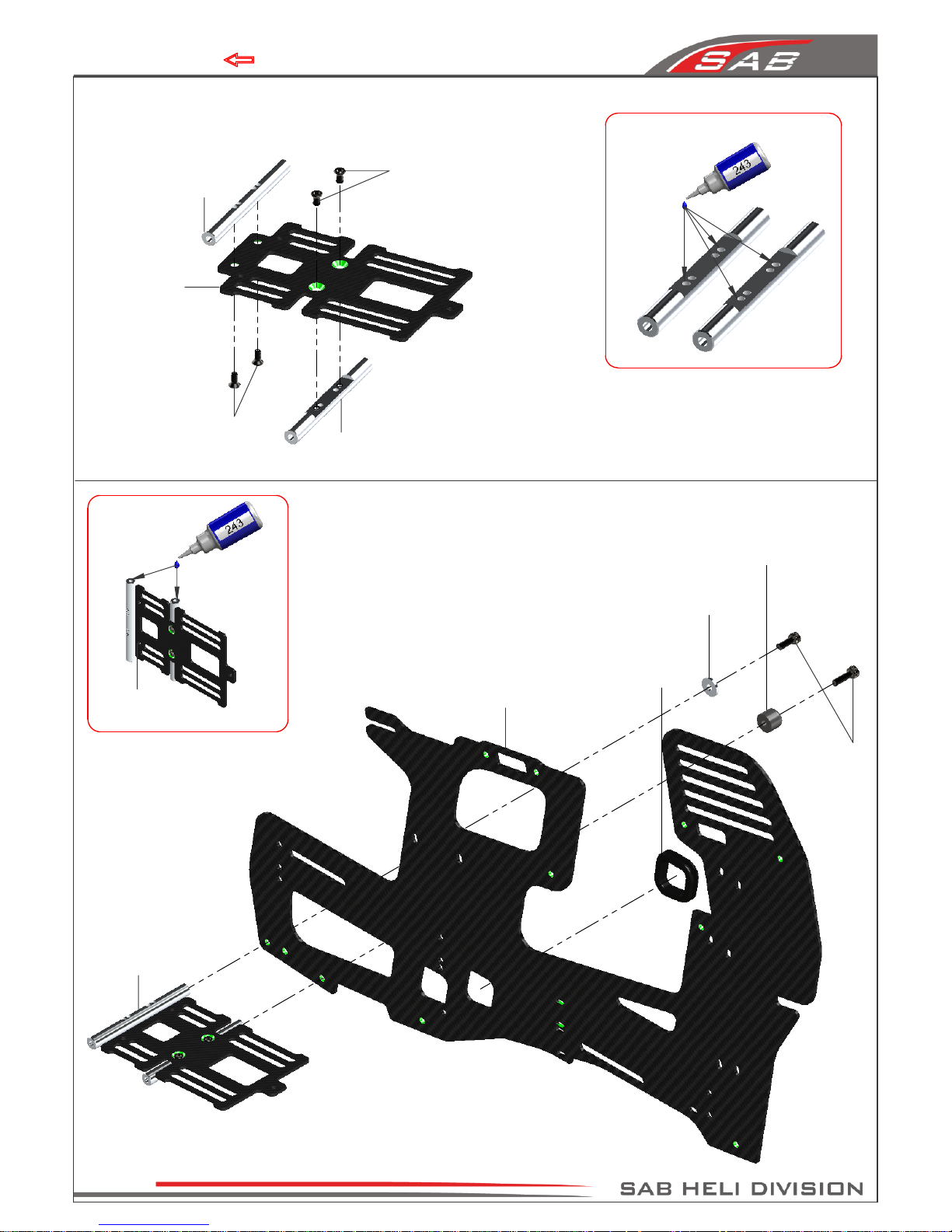

Flat Head Cap Screw

M2.5x5mm

(HC128-S)

Frame Spacer

(H0003-S)

Socket Head Cap

Screw M3x10mm

(HC056-S)

Finishing Washer M3

(H0007-S)

ESC Support

Assembly

Main Frame 1

(H0354-S)

Flat Head Cap

Screw M2.5x5mm

(HC128-S)

Frame Spacer

(H0003-S)

ESC Support

(H0088-S)

Cable Pass

(HA010-S)

Canopy Positioners

(H0159-S)

ESC Support

Assembly

Note:

Note:

BAG 1.2, BAG 1.3, FOAM 3

Page 6

Chapter 4, Carbon Frame

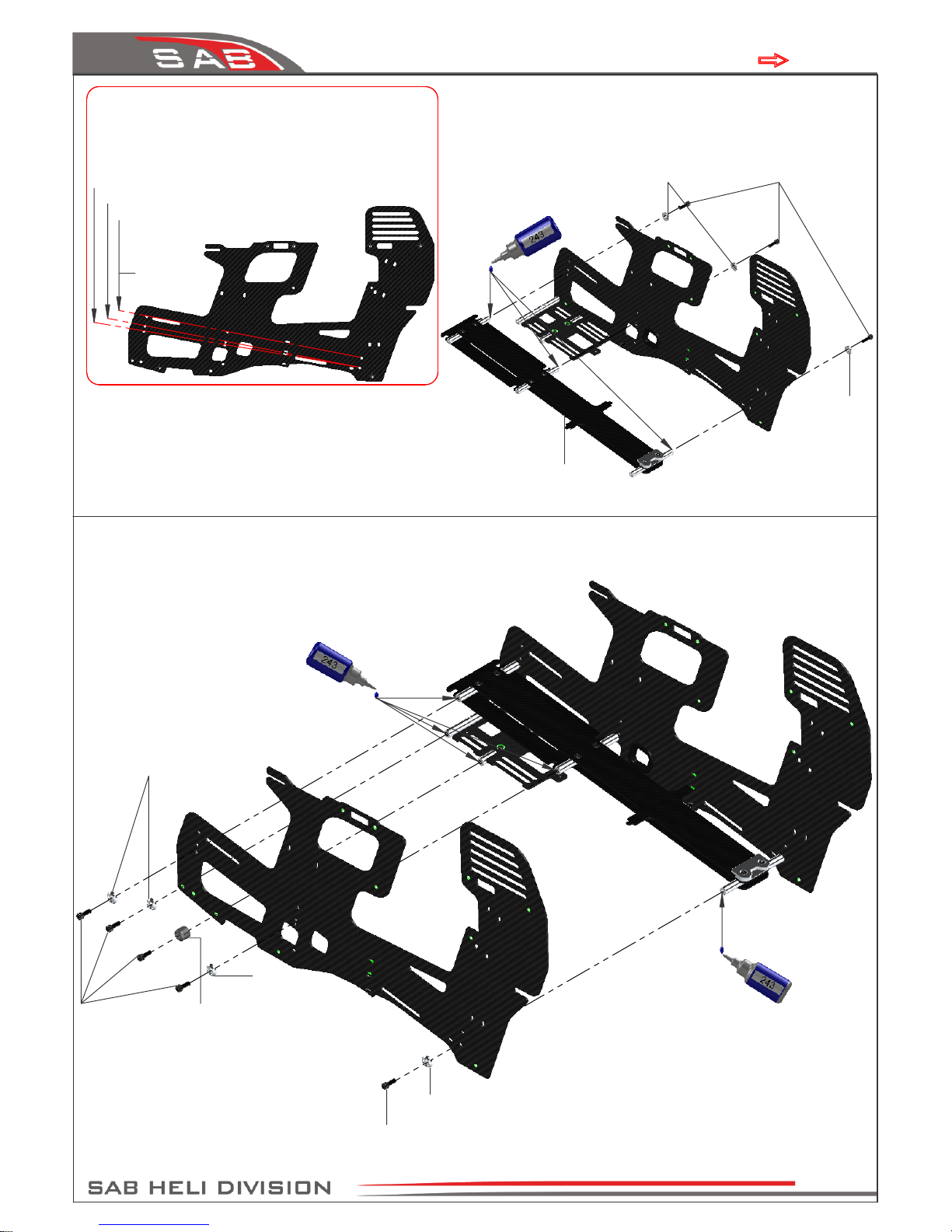

Socket Head Cap

Screw M3x10mm

(HC056-S)

Finishing

Washer M3

(H0007-S)

Finishing Washer M3

(H0007-S)

Battery Support

Assembly

Finishing Washer M3

(H0007-S)

Finishing

Washer M3

(H0007-S)

Finishing

Washer M3

(H0007-S)

Main Frame Assembly

Socket Head Cap

Screw M3x10mm

(HC056-S)

Socket Head Cap

Screw M3x10mm

(HC056-S)

Bottom holes: 75mm max height batteries.

Middle holes: 70mm max height batteries.

Canopy

Positioners

(H0159-S)

Top holes: 60mm max height batteries.

Note:

Choose the position for the batteries

For the best 3D performance (with 12S-5000 batteries)

we recommend position 1

Pos 1

BAG 1.2, BOX 6

Page 7

Chapter 4, Carbon Frame

Note:

You can use Super Glue to lock

the nuts in correct position

Metric Hex

Nylon Nut M3

(HC206-S)

Plastic landing gear F3C

(H0449-S)

[HC152-S]

Set Screws M4x4mm

(HC152-S)

Oring

(HC453-S)

Landing Gear Plug

(H0432-S)

Landing Gear ROD

(H0431-S)

Finishing

Washer M3

(H0007-S)

Socket Head Cap

Screws M3x16mm

(HC068-S)

Socket Head Cap

Screws M3x16mm

(HC068-S)

Finishing Washer M3

(H0007-S)

Plastic Landing Gear Assembly

Plastic Landing Gear

Assembly

BAG 2, BOX 7

Page 8

Chapter 4, Carbon Frame

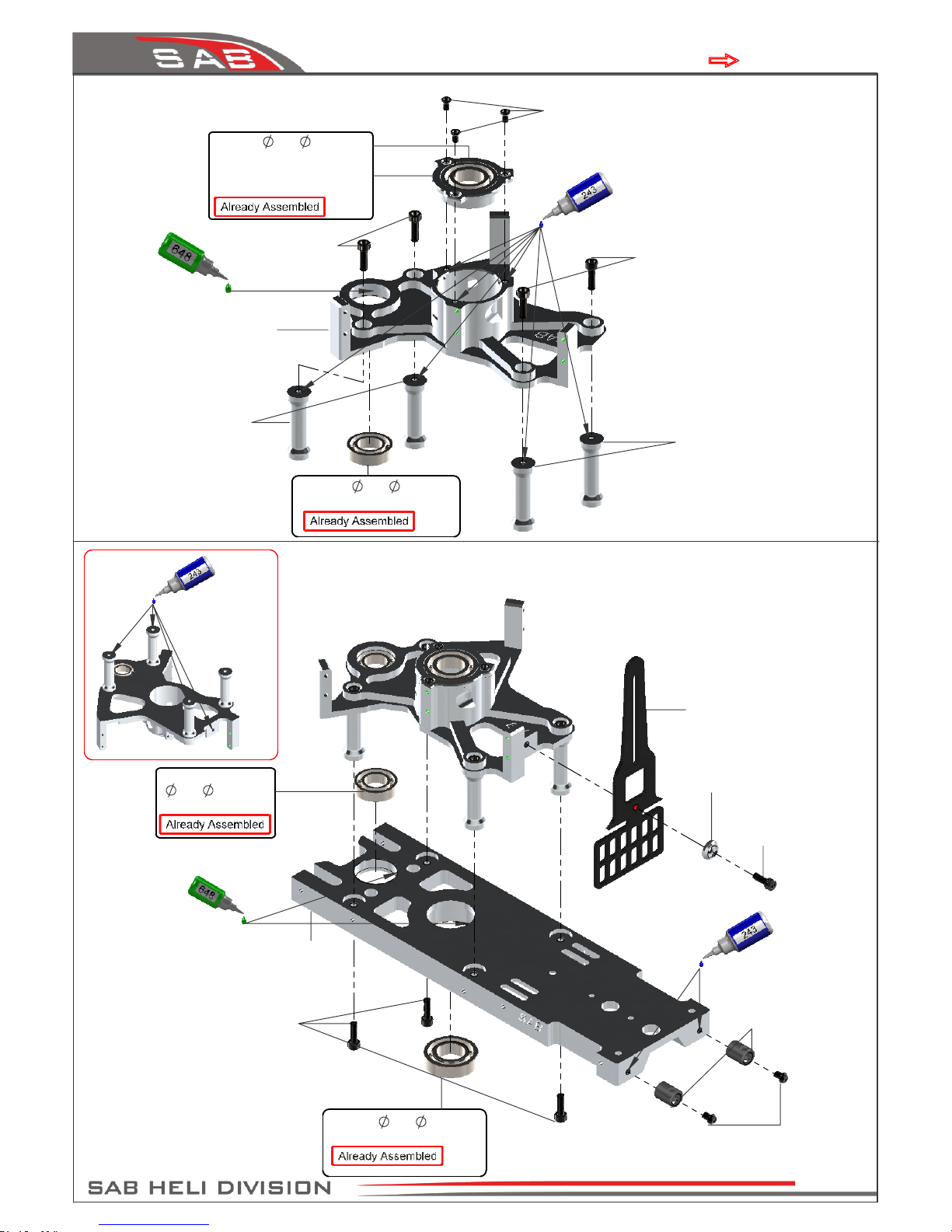

Bearing Support Assembly

(H0024-S)

Bearing

12x

24x6mm

(HC426-S)

Flat Head Cap Screw

M2.5x5mm

(HC128-S)

Socket Head Cap

Screw M3x8mm

(HC050-S)

Socket Head Cap

Screw M3x10mm

(HC056-S)

Column

(H0018-S)

Bearing

10x

19x5mm

(HC422-S)

Note:

Socket Head Cap

Screw M3x10mm

(HC056-S)

Main Structure

(H0009-S)

Antenna Guide

(H0050-S)

Button Head Cap

Screw M3x4mm

(HC038-S)

Swash plate

Anti-Rotation Guide

(H0017-S)

Bearing

12x

24x6mm

(HC426-S)

Finishing Washer M3

(H0007-S)

Column

(H0018-S)

Socket Head Cap

Screw M3x10mm

(HC056-S)

Servo Support

(H0010-S)

Bearing

10x

19x5mm

(HC422-S)

BAG 3, FOAM 1, FOAM 2

Page 9

Chapter 5, Transmission Assembly

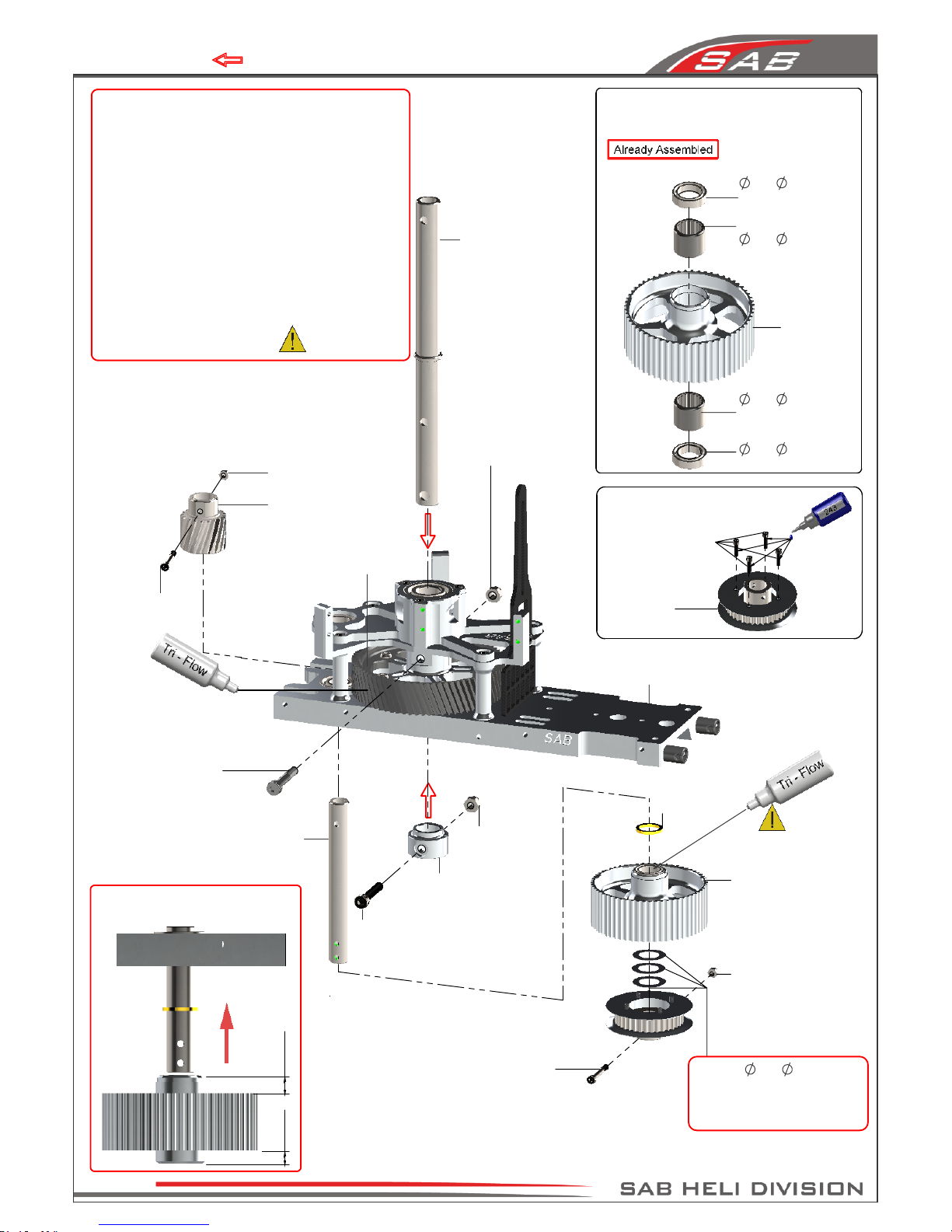

One Way Bearing

10x

14x12mm

(HC442-S)

60T Pulley Assembly

(H0171-S)

Bearing

10x

15x4mm

(HC420-S)

Socket Head Cap Screw

Shouldered M2.5x19mm

(HC033-S)

Note 1:

When you tighten the collar (

H0121-S

) on the main

shaft, ensure there is no axial play.

Push down the main shaft while pulling up the

locking collar. Tighten the screw

M4x22

at this time.

Note 2:

The pinion and gear are designed to have zero

backlash. This leads to initial “rough” rotation.

After some run in flights (

3-5 flights

) it will begin to

rotate freely, ensuring perfect contact and the

ability to transmit maximum power.

It is very important to lubricate these two

elements with a lubricant

( Dry Fluids Gear or similar).

One Way Bearing

10x

14x12mm

(HC442-S)

Bearing

10x

15x4mm

(HC420-S)

6.25

4.8

Main Shaft

(H0122-S)

Main Structure

Assembly 1

Socket Head Cap Screw

Shouldered M4x24mm

(HC111-S)

Metric Hex

Nylon Nut M4

(HC212-S)

Metric Hex

Nylon Nut M4

(HC212-S)

Socket Head Cap

Screw M4x22mm

(HC104-S)

Socket Head Cap

Screw Shouldered

M3x18mm

(HC079-S)

60T Pulley

(H0171-S)

60T Pulley Assembly

(H0171-S)

Socket Head Cap

Screw M2x12mm

(HC014-S)

Front Tail Pulley Assembly

(H0172-S)

Bush One Way

(H0110-S)

Note 2

The perfect play is 0.5mm

add or remove shim for this

Note:

Correct insertion of

the one-way pulley

37T Pulley

(H0172-S)

Metric Hex

Nylon Nut M3

(HC206-S)

19T Drive Pinion

(H0156-S)

Secondary Shaft

(H0157-S)

M4 Locking Collar

(H0121-S)

Washer

10x

16x0.2mm

(HC232-S)

Metric Hex Nylon

Nut M2.5

(HC200-S)

BAG 4, FOAM 2, FOAM 3

Main Gear

(H0405-S)

Page 10

Chapter 5, Transmission Assembly

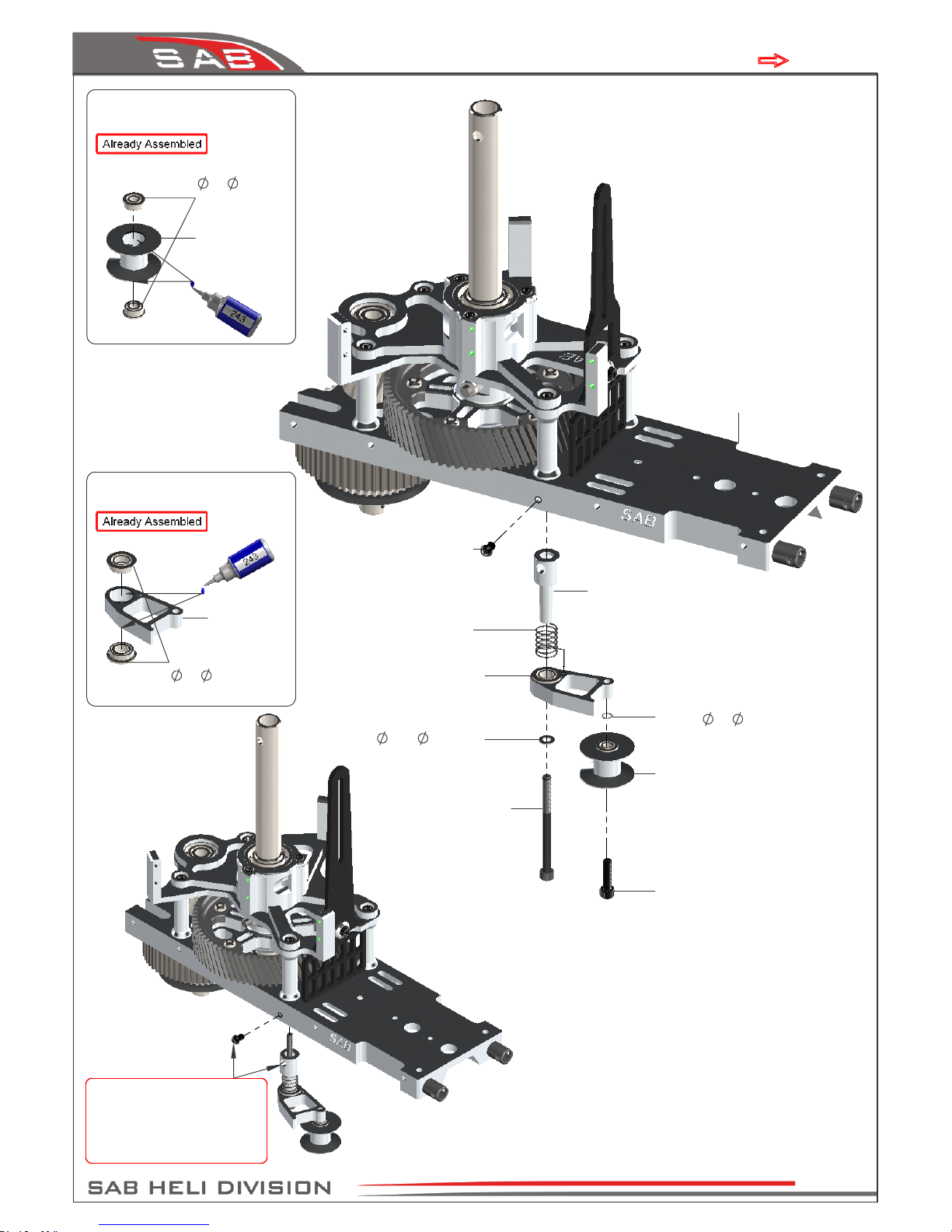

Belt Tensioner

Arm

Washer

3x

4x0.5mm

(HC176-S)

Belt Tensioner Support

(H0174-S)

Socket Head Cap

Screw M3x12mm

(HC062-S)

Tail Belt Idler Assembly

(H0174-S)

Belt Tensioner Arm

Assembly

Washer

3.2x

6x0.5mm

(HC180-S)

Socket Head Cap Screw

Shoulder M3x40mm

(HC091-S)

Main Structure

Assembly

Tail Belt Idler

Assembly

Button Head Cap

Screw M3x4mm

(HC038-S)

Belt Tensioner Arm Assembly

(H0174-S)

Note:

Position without preload.

Insert the screw in the

hole through the aluminum

support as in the picture.

Flanged Bearing

3x

7x3mm

(HC402-S)

Tail Belt Idler

[H0069]

Flanged Bearing

5x

9x3mm

(HC410-S)

Spring

de 8 / df0.5 / LL8

(HC315-S)

BAG 5, FOAM 2

Page 11

Chapter 5, Transmission Assembly

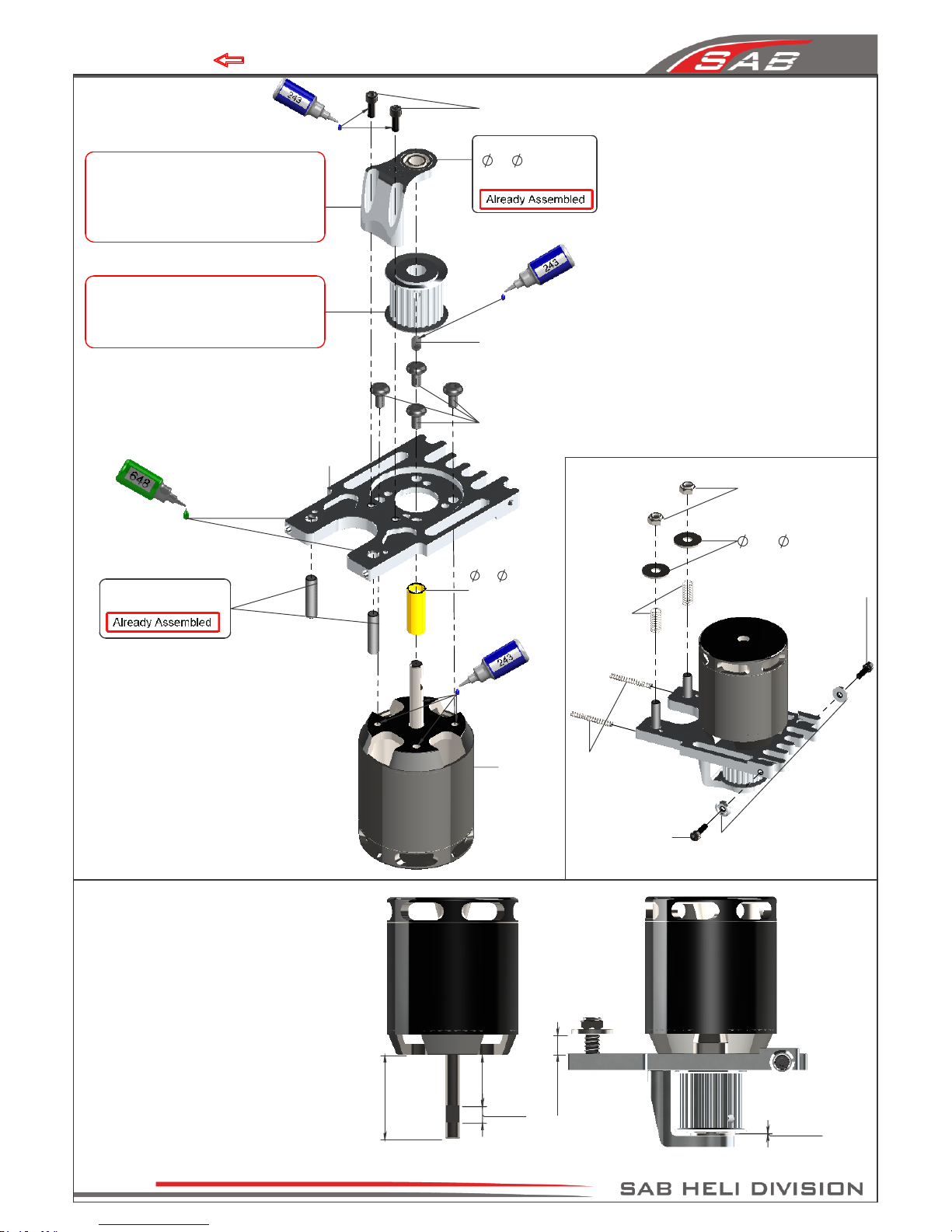

Motor Mount

(H0142-S)

Socket Head Cap

Screw M3x10mm

(HC056-S)

Finishing Washer M3

(H0007-S)

Spring

[HC310]

(HC315-S)

Washer

5.3x

15x1mm

(HC188-S)

Metric Hex Nylon

Nut M5

(HC218-S)

34mm

21mm

6mm

0.2mm

7mm

Set Screw

M4x6mm

(HC153-S)

Button Head Cap

Screw M4x8mm

(HC098-S)

20T Pulley

(H0175-20-S)

Lock motor pulley after locking H0142

(see page 17 for optional pulley selection)

Spring

HC314

(HC315-S)

Note for 6mm motor shaft

To maximize space for the batteries, it

is advisable to shorten the motor shaft.

Follow the dimensions given in this

drawing. For the cut, you can use an

electric tool like a “Dremel” with a cutoff disc.

Additionally, ensure the motor shaft

has an appropriate 'flat' for one of the

set screws.

Socket Head Cap

Screw M3x8mm

(HC050-S)

Bearing Support (H0143-S)

Lock H0142 after have locked

the motor.Motor shaft is requires

to optimize the centering. H0142

can't be used with motor shaft 8mm.

Bushing

6x

8x18mm

(H0176-S)

Use with 6mm

motor shaft.

Flanged Bearing

6x

13x5mm

(HC414-S)

Socket Head Cap

Screw M3x10mm

(HC056-S)

Set Screw M5x20mm

(HC158-S)

Motor

BAG 6, FOAM 1, FOAM 2

Page 12

Chapter 5, Transmission Assembly

Loading...

Loading...